Efficient anti-sticking UV release paint applied to pressure-sensitive adhesive as well as preparation and application of efficient anti-sticking UV release paint

A technology of pressure-sensitive adhesives and coatings, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of slow curing and achieve low adhesion strength, low critical surface tension, and high sensitization effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

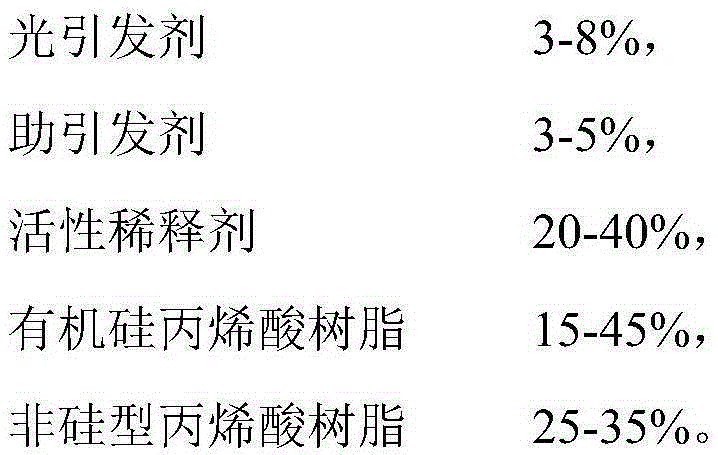

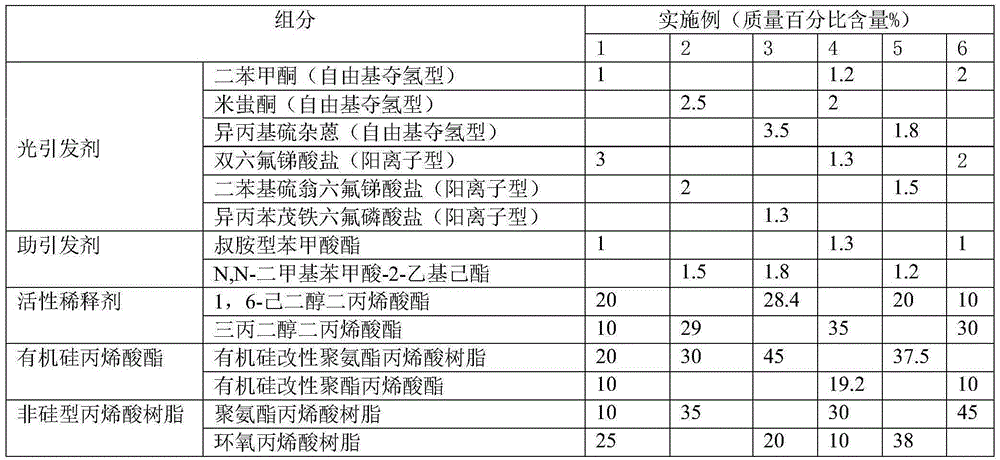

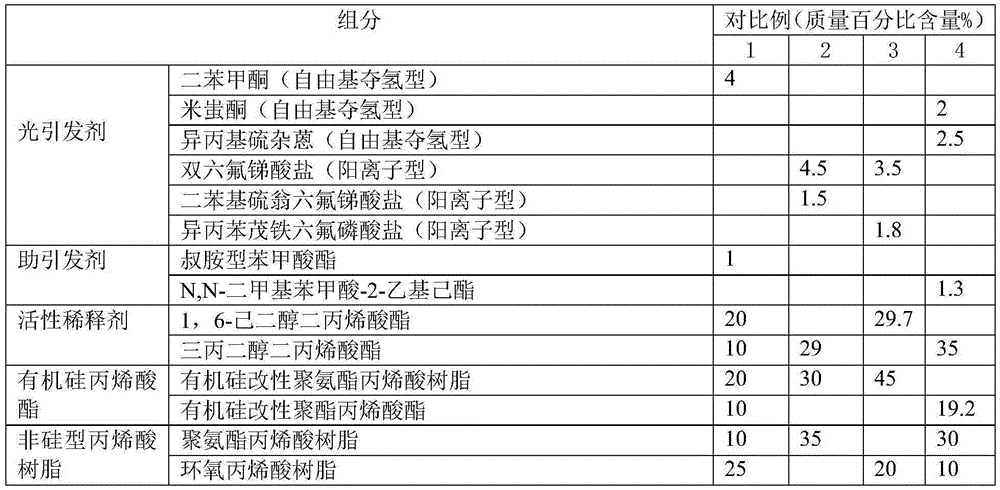

[0031] Embodiments 1 to 6 provide a high-efficiency anti-sticking UV release coating applied to pressure-sensitive adhesives and its preparation and application. The components and contents of the coating are as shown in Table 1:

[0032] Table 1 Embodiment 1~6 components and mass percent

[0033]

[0034] Described preparation and application comprise the following steps:

[0035] Step 1, adding the non-silicon type acrylic resin and silicone acrylic resin into the active diluent, mixing evenly and fully dissolving;

[0036] Step 2, adding a photoinitiator and a co-initiator to the mixed solution obtained in step 2, stirring and mixing at 1000 to 2000 rpm;

[0037] Step 3: Cool the mixture obtained in Step 2, and filter at 250 mesh at normal temperature and pressure to obtain the high-efficiency anti-sticking UV release coating.

[0038] Preferably, in step 1, the adding is sequentially adding; the uniform mixing is achieved by stirring.

[0039] Preferably, in step 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com