Radiation-cured water-based coating resin, and preparation method thereof

A water-based coating, radiation curing technology, used in polyurea/polyurethane coatings, coatings, etc., can solve problems such as strong volatility, strong irritating odor, and damage to coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

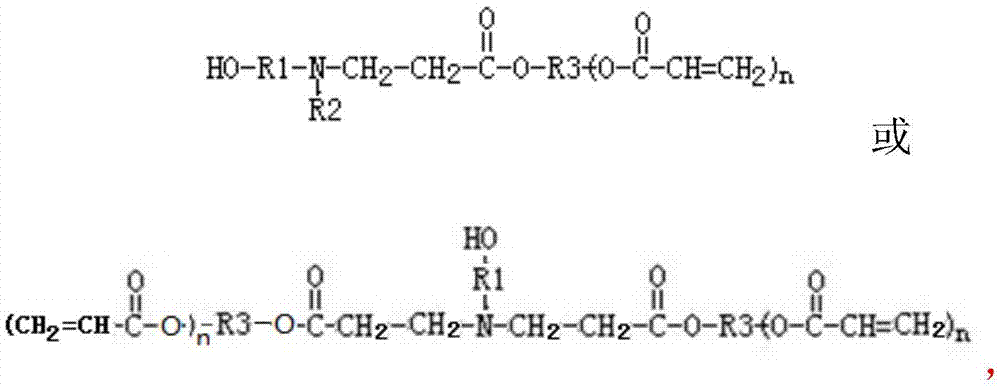

Method used

Image

Examples

Embodiment 1

[0083] Preparation of D-I

[0084] Add 320 parts (parts by weight, the same below) of trimethylolpropane triacrylate into the flask, control the reaction to stir at 30-40 degrees, and gradually add 105 parts of diethanolamine to it, and react until no detection in the system -NH- When the reaction is over, the structure compound DI containing hydroxyl, acrylate and tertiary amine is obtained, the structural formula is

Embodiment 2

[0086] Preparation of D-II

[0087] Add 254 parts of glycerol triacrylate to the flask, control the reaction to stir at 30-40 degrees, and gradually add 75 parts of N-methylethanolamine to it, and react until the reaction ends when no NH is detected in the system. Compound D-II containing hydroxyl, acrylate group and tertiary amine structure at the same time

Embodiment 3

[0089] Preparation of D-III

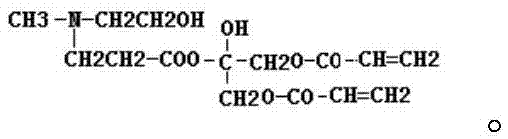

[0090] Add 300 parts of pentaerythritol triacrylate to the flask, control the reaction to stir at 30-40 degrees, and gradually add 75 parts of N-methylethanolamine to it. The reaction is completed until no NH is detected in the system, and the reaction is obtained. Hydroxyl, acrylate and tertiary amine structure compound D-III, structural formula

[0091]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com