Ink composition, packaging structure and semiconductor device

A composition and ink technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, etc., can solve the problems of low curing shrinkage rate and inability to take into account high light curing rate and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

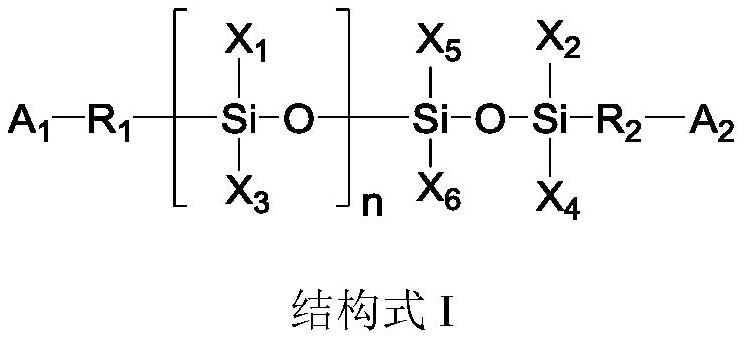

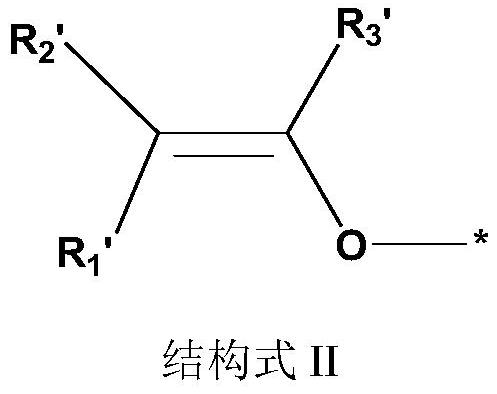

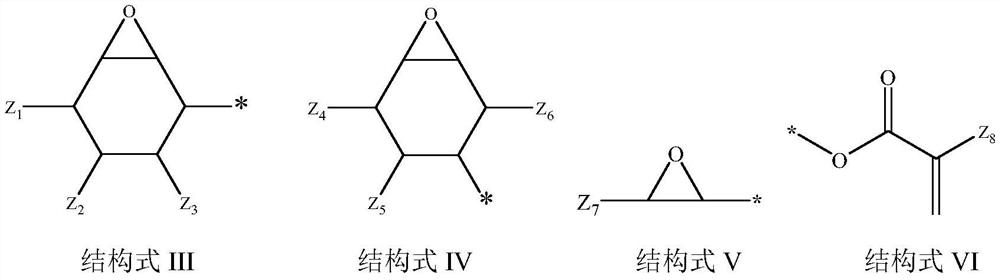

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] In a 1000 mL flask with a cooling tube and a stirrer, put 800 mL of toluene, 60 g of 1,1,5,5-tetramethyl-3,3-diphenyltrisiloxane, and 100 g of allyl alcohol, followed by nitrogen Purge for 60 minutes. After that, 0.0063 g of platinum(0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane was put into the flask, and the temperature of the flask was increased to 70° C., followed by stirring 5h. Residual solvent was removed by distillation. Further, 79 g of the obtained compound was introduced into a high-pressure reaction vessel, and after adding 400 mL of dichloromethane, 39.64 g of triethylamine was added thereto, followed by slowly introducing 90 g of vinyl chloride while stirring at 0°C. The residual solvent was removed by distillation, and 40 g of the product was obtained by column chromatography with a yield of 51%. Thus, a compound represented by Formula 1 was prepared, denoted as A1, and its purity was 98% as determined by HPLC. m / e:500.22; 1 HNMR (400MHz, Chloroform...

Embodiment 2

[0072] In a 1000mL flask with a cooling tube and a stirrer, put 800mL of toluene, 40g of 1,1,5,5-tetramethyl-3,3-diphenyltrisiloxane and 80g of allyl alcohol, followed by nitrogen blowing Sweep for 60 minutes. After that, 0.013 g of platinum(0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane was put into the flask, and the temperature of the flask was increased to 70° C., followed by stirring 5 hours. Residual solvent was removed by distillation. After introducing 71.2 g of the obtained compound into 300 mL of dichloromethane, 15 g of triethylamine was added thereto, followed by slowly introducing 40 g of methacryloyl chloride while stirring at 0°C. The residual solvent was removed by distillation, and the unilateral compound terminated by methacrylate group was obtained by column chromatography separation. The unilateral compound was introduced into a high-pressure reactor, 40 g of vinyl chloride was added, and 10 g of potassium carbonate was added. After reacting for 3 hours,...

Embodiment 3

[0076] In a 1000 mL flask with cooling tube and stirrer, put 800 mL of toluene, 54.11 g of 1,1,3,5,5-pentamethyl-3-phenyltrisiloxane and 100 g of allyl alcohol, followed by nitrogen Purge for 60 minutes. After that, 0.0063 g of platinum(0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane was put into the flask, and the temperature of the flask was increased to 70° C., followed by stirring 5h. Residual solvent was removed by distillation. Further, 79 g of the obtained compound was introduced into a high-pressure reaction vessel, and after adding 400 mL of dichloromethane, 39.64 g of triethylamine was added thereto, followed by slowly introducing 90 g of vinyl chloride while stirring at 0°C. Residual solvent was removed by distillation, and 40 g of the product was obtained by column chromatography with a yield of 51%, thus preparing a compound represented by formula 3, denoted as A3, with a purity of 97% as determined by HPLC, m / e: 588.24; 1 H NMR (400MHz, Chloroform-d)δ7.54(m,1H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com