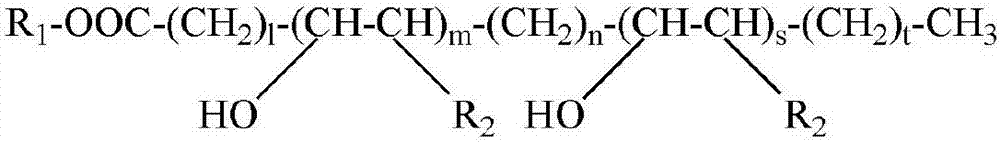

Multifunctional UV cured polyurethane vegetable oleate prepolymer, and preparation method and application thereof

A technology of vegetable oleate and vegetable oleate alcohol, applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, applications, etc., can solve the problem that UV-cured polyurethane acrylate materials do not have biodegradability, etc., and achieve Good mechanical properties and mechanical properties, reduced use, and the effect of solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

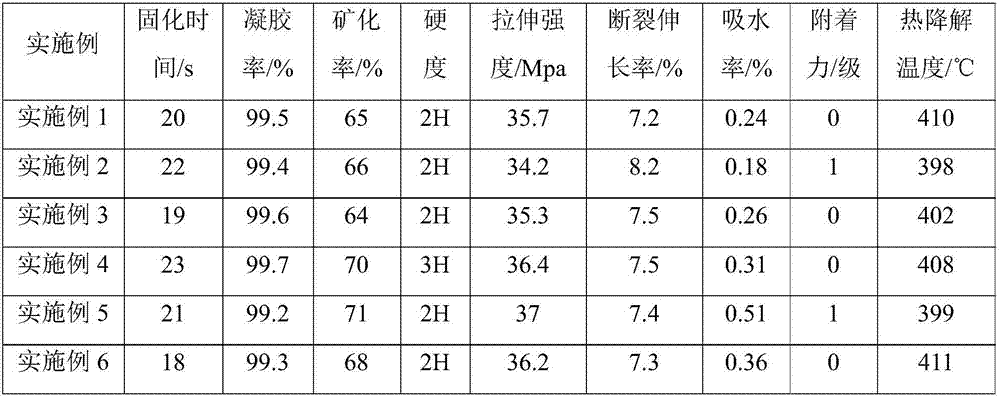

Examples

Embodiment 1

[0032] (1) Synthesis and separation and purification of tung oil ester alcohol: after heating 9mol tung oil to 60°C, add an alkaline solution of 1mol ethylene glycol, wherein the quality of the alkali is 1% of the tung oil quality, and under stirring conditions, reflux React for 80 minutes, then add an appropriate amount of acid to neutralize, let the reaction solution stand still, separate layers, and separate the lower glycerol layer; then wash the upper liquid with water, remove the lower water phase, and distill under reduced pressure to remove ethylene glycol and most of it. water, etc., and finally dry to obtain oleic acid ester alcohol;

[0033](2) Synthesis of castor oil-based PU prepolymer: Add 1 mol of polyethylene glycol (molecular weight: 1000) and 0.1 mol of castor oil to the reaction kettle in sequence, stir and heat up to 120°C, and dehydrate under reduced pressure for 2.5 hours Cool down to 65°C, then add a mixture of 1 mol of hexamethylene diisocyanate and an ...

Embodiment 2

[0036] (1) Synthesis and separation and purification of soybean oil ester alcohol: after the soybean oil of 6mol is heated to 80 ℃, add the alkaline solution of the ethylene glycol of 1mol, wherein the quality of alkali is 2% of tung oil quality, in stirring Under the conditions, reflux for 50 minutes, then add an appropriate amount of acid to neutralize, let the reaction solution stand still, separate layers, and separate the lower glycerol layer; then wash the upper liquid with water, remove the lower aqueous phase, and distill under reduced pressure to remove ethylene glycol. Alcohol and most of the water, etc., and finally dried to obtain soybean oleic acid ester alcohol;

[0037] (2) Synthesis of castor oil-based PU prepolymer: Add 1.1 mol polypropylene glycol (molecular weight: 3000) and 0.011 mol castor oil to the reaction kettle in sequence, stir and heat up to 125°C, dehydrate under reduced pressure for 2 hours, then cool down to 65°C , then add a mixture of 1mol hexa...

Embodiment 3

[0040] (1) Synthesis and separation and purification of sesame oil ester alcohol: after 8mol sesame oil is heated to 70 ℃, add the alkaline solution of the ethylene glycol of 1mol, wherein the quality of alkali is 1.5% of tung oil quality, under the condition of stirring, Reflux for 70 minutes, then add an appropriate amount of acid to neutralize, let the reaction solution stand still, separate layers, and separate the lower glycerin layer; then wash the upper liquid with water, remove the lower water phase, and distill under reduced pressure to remove ethylene glycol and large amounts. Part of the water, etc., and finally dried to obtain the sesame oil ester alcohol;

[0041] (2) Synthesis of castor oil-based PU prepolymer: Add 1 mol of polyethylene glycol (molecular weight: 2000) and 0.05 mol of castor oil to the reactor, stir and heat up to 125°C, and dehydrate under reduced pressure After 2 hours, cool down to 65°C, then add 1 mol of toluene diisocyanate and an appropriate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com