Ultraviolet curing adhesive capable of being quickly cured at low energy and preparation method of ultraviolet curing adhesive

A fast-curing, ultraviolet light technology, applied in the direction of adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor curing effect and reducing the energy absorbed by ultraviolet light-curing adhesives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

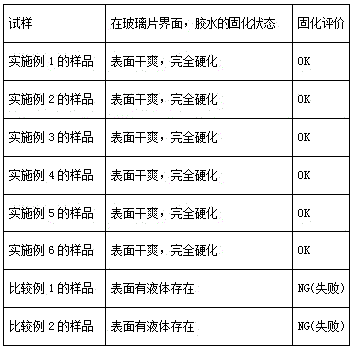

Examples

Embodiment 1

[0016] Accurately take each raw material by weight, CN120NS of Sartomer Company, 25g; CN996NS, 20g; 4312, 10g of RAHN Company; 20g of hydroxyethyl acrylate; 10g of N-vinylpyrrolidone; 7g of neopentyl glycol diacrylate; The oligoamine 5142 of RAHN company, 3g; Photoinitiator 184, 2.5g; Photoinitiator TPO, 1g; Silane coupling agent KH560, 1.5g. Put the above components into the double planetary power mixing mixer in turn, evacuate to -0.08MPa, stir at 500 rpm for 2 hours, stir evenly, and let it cool down to room temperature to obtain UV-curable adhesive, sealed and packaged That's it.

Embodiment 2

[0018] Accurately take each raw material by weight, DR-U025 of Changxing Company, 10g; CN104NS of Sartomer Company, 15g; CN996NS, 20g; 4312 of RAHN Company, 10g; Isobornyl acrylate 20g; N-vinylpyrrolidone 10g; Neopentyl glycol diacrylate 7g; Oligoamine 5275, 3g of RAHN company; Photoinitiator 184, 2.5g; Photoinitiator TPO, 1g; Silane coupling agent KH560, 1.5g. Put the above components into the double planetary power mixing mixer in turn, evacuate to -0.08MPa, stir at 500 rpm for 2 hours, stir evenly, and let it cool down to room temperature to obtain UV-curable adhesive, sealed and packaged That's it.

Embodiment 3

[0020] Accurately weigh each raw material by weight, DR-U026 of Changxing Company, 15g; CN975NS of Sartomer Company, 15g; CN8007NS, 20g; 4312, 10g of RAHN Company; 20g of isobornyl acrylate; 10g of N-vinylpyrrolidone; Neopentyl glycol diacrylate 7g; Oligoamine 5275, 3g of RAHN company; Photoinitiator 184, 2.5g; Photoinitiator TPO, 1g; Silane coupling agent KH560, 1.5g. Put the above components into the double planetary power mixing mixer in turn, evacuate to -0.08MPa, stir at 500 rpm for 2 hours, stir evenly, and let it cool down to room temperature to obtain UV-curable adhesive, sealed and packaged That's it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com