Light resistance composition as well as preparation method and display device thereof

A composition and photoresist technology, applied in optomechanical equipment, photosensitive materials for optomechanical equipment, optics, etc., can solve problems such as increased production cost, complicated polymerization process, etc., to improve adhesion, reduce production cost, Fast aggregation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

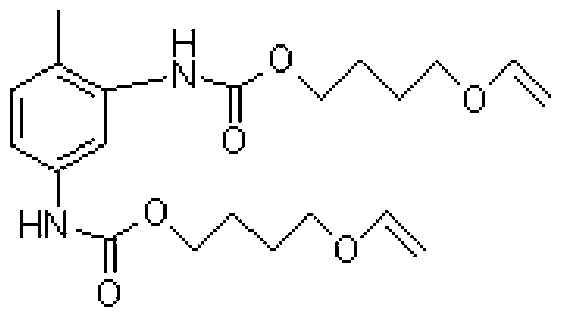

Method used

Image

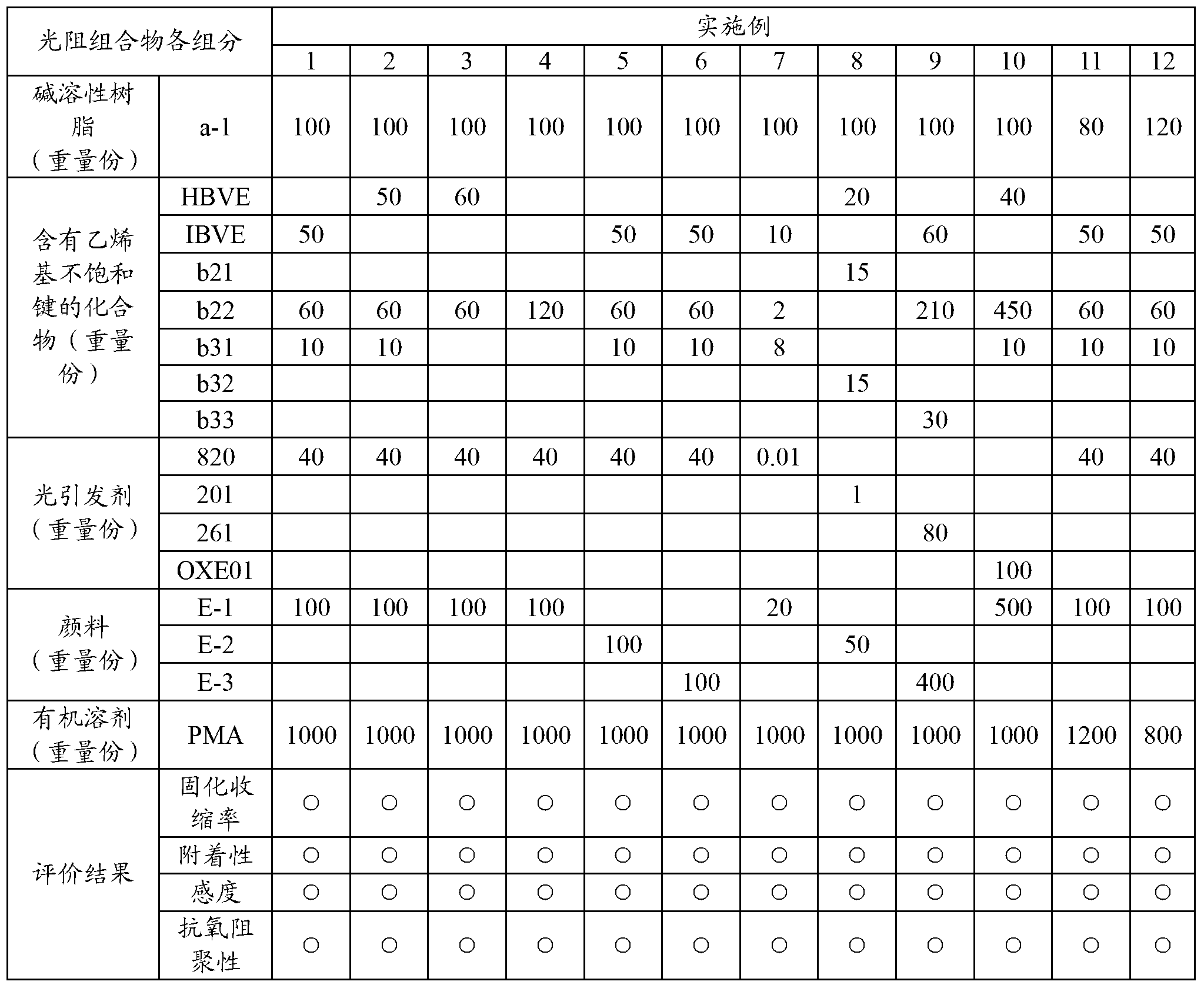

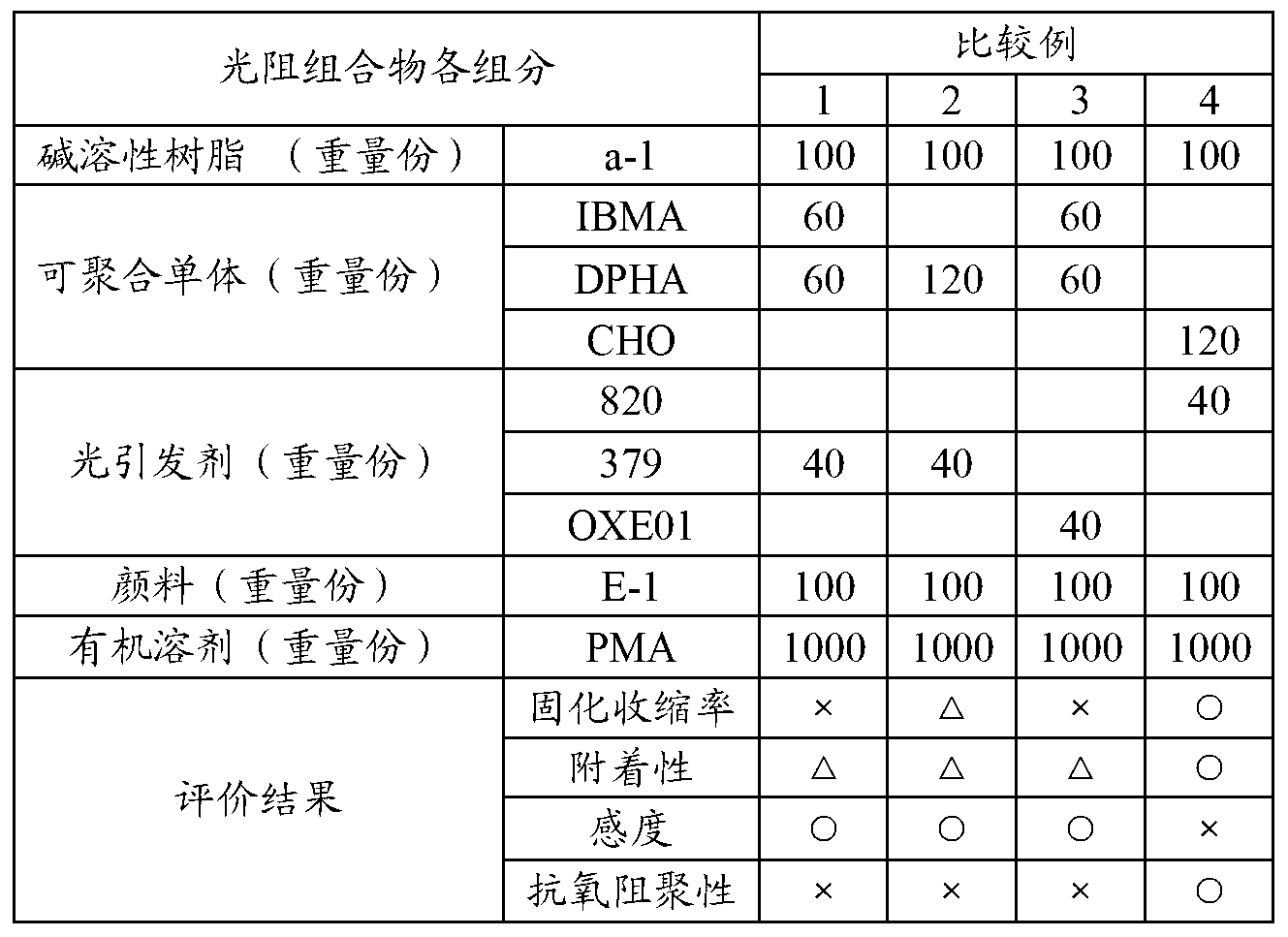

Examples

preparation example Construction

[0042] The present invention also relates to a preparation method of the above-mentioned photoresist composition, comprising:

[0043] Alkali-soluble resin, compound containing ethylenic unsaturated bond, photoinitiator, pigment and organic solvent are taken in parts by weight, dissolved and mixed.

[0044] The present invention also relates to a display device, which includes a color filter layer, and the color filter layer includes any one of the above photoresist compositions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com