Preparation method of high-wear-resistance UV matte paint and preparation method of high-wear-resistance UV matte coating

A highly wear-resistant and matte technology, applied in the coating and other directions, can solve the problems of easy-to-return powder particle size distribution, poor stability, poor dispersion, etc., to solve the impact of coating scratch resistance, Ensure adequate dispersion and wetting and reduce curing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Preparation of high wear-resistant matte coating

[0059] Add 6.68g of photoinitiator 1-hydroxy-cyclohexyl-phenyl ketone to 22.12g of pentaerythritol triacrylate and 8.44g of 1,6-hexanediol diacrylate and stir at low speed until completely dissolved, add 2.61g of disperse Agent Tegodispers628, 0.39g defoamer BYK-067A continue to stir at low speed, then add 5.35g C803 matting agent (produced by Grace Company), 3.48g polyethylene wax PEW-0851 (produced by Nanjing Tianshi Wax Powder) and continue to stir at low speed 1h, then add 0.19g of leveling agent BYK-310, 29.52g of B-619W (manufactured by Guangdong Boxing) and 21.22g of 230SH-T70 (manufactured by DSM) and stir for 30min at high speed, and use it after the powder is completely wetted Grind and disperse twice with a three-roll machine, and finally stir and disperse the mixed solution at high speed for 30 minutes to obtain a high wear-resistant matte coating.

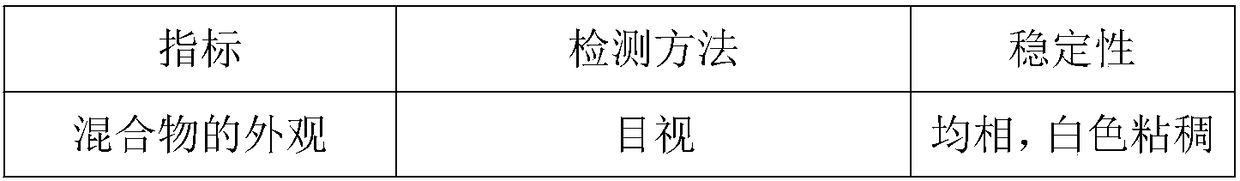

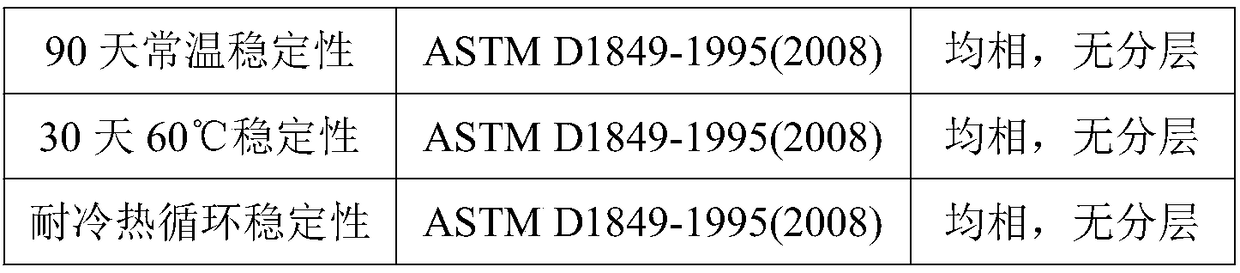

[0060] 2. Performance of high wear-resistant matte coa...

Embodiment 2

[0071] 1. Preparation of high wear-resistant matte coating

[0072] Add 4.24 g of 1-hydroxy-cyclohexyl-phenyl ketone and 1.41 g of 2,4,6-trimethylbenzoyldiphenylphosphine oxide to 12.66 g of ethoxylated modified tris Methylolpropane triacrylate EM2380TF and 8.47g of 1,6-hexanediol diacrylate were stirred at medium and low speed until completely dissolved, then 2.9g of dispersant Tegodispersers670 and 0.48g of defoamer TegoAirex96 were added and 8.47g was added after stirring evenly at low speed M7 matting agent (produced by Perguang Company), 3.38g polytetrafluoroethylene wax PTFE-0101 (produced by Nanjing Tianshi Wax Powder) were stirred at a low speed for 1h, and then 38.61g B-912 and 19.31g B-375 (produced by Guangdong Boxing Production) Stir at low speed until uniform, finally add 0.10g of leveling agent Flow370 and stir at high speed for 30min, after the powder is completely wetted, use a three-roll machine to grind and disperse twice, and finally stir and disperse the gr...

Embodiment 3

[0084] 1. Preparation of high wear-resistant matte coating

[0085] Add 6g of photoinitiator 1-hydroxy-cyclohexyl-phenyl ketone to 22g of dipentaerythritol hexaacrylate and stir at low speed until completely dissolved, add 2.9g of dispersant BYK-2013, 0.25g of defoamer BYK-065, low speed Stir evenly, then add 11g M7 matting agent (produced by Poguang Company), 3.6g YN-L001s matting agent (produced by Xiangyang Yinuoxing Chemical Industry), 3.6g polytetrafluoroethylene wax PTFE-0101 (produced by Nanjing Tianshi wax powder) and continue Stir and disperse at low speed for 1 hour, then add 51g of B-919B (manufactured by Guangdong Boxing) and stir at low speed until uniform, and finally add 0.15g of leveling agent BYK-333 and stir at high speed for 30 minutes, and grind with a three-roller machine after the powder is completely wet Disperse twice, and finally stir and disperse the ground and dispersed mixture for another 30 minutes to obtain a high wear-resistant matte coating.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com