Coupling anti-oxidation special color master batch for barrier bottle and preparation method of coupling anti-oxidation special color master batch

A color masterbatch, anti-oxidation technology, applied in the field of color masterbatch, to achieve the effect of good dispersion and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, the color masterbatch carrier includes the following raw material components and parts by weight:

[0025] High-density polyethylene 50 parts

[0026] Low-density polyethylene 10 parts

[0027] Low-density linear polyethylene 10 parts

[0028] Firstly, the above raw material components are mixed and put into a screw extruder for melting reaction. Preferably, the extrusion temperature is 150-230° C., the diameter of the twin-screw extruder is greater than 25 mm, and the L / D is greater than 32 / 1. The color masterbatch carrier is obtained by water-cooled grinding surface cutting or cold drawing strip cutting.

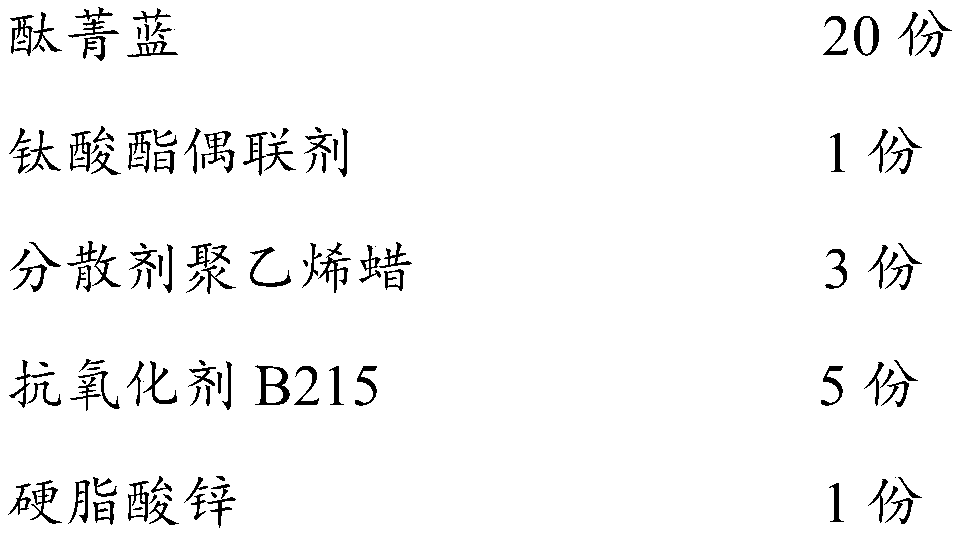

[0029] Then, the color masterbatch carrier made from the above weight parts raw materials and the following

[0030]

[0031] After mixing, it is added to a screw extruder for melting reaction. The extrusion temperature is 200°C, the diameter of the twin-screw extruder is greater than 25mm, and the L / D is greater than 32 / 1. The color mas...

Embodiment 2

[0034] In this embodiment, the color masterbatch carrier includes the following raw material components and parts by weight:

[0035] High-density polyethylene 40 parts

[0036] Low-density polyethylene 5 parts

[0037] Low-density linear polyethylene 5 parts

[0038] Firstly, the above raw material components are mixed and put into a screw extruder for melting reaction. Preferably, the extrusion temperature is 150-230° C., the diameter of the twin-screw extruder is greater than 25 mm, and the L / D is greater than 32 / 1. The color masterbatch carrier is obtained by water-cooled grinding surface cutting or cold drawing strip cutting.

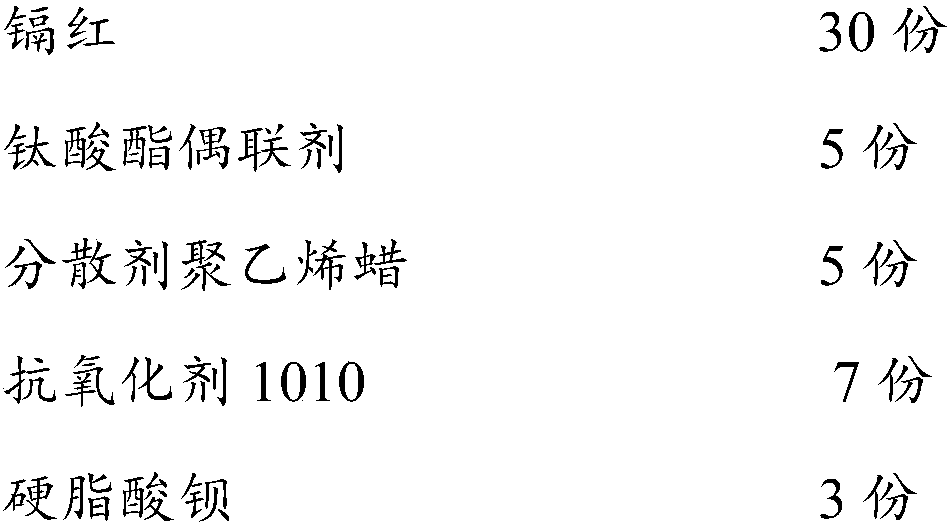

[0039] Then, the color masterbatch carrier made from the above weight parts raw materials and the following

[0040]

[0041] After mixing, it is added to a screw extruder for melting reaction. The extrusion temperature is 200°C, the diameter of the twin-screw extruder is greater than 25mm, and the L / D is greater than 32 / 1. The color maste...

Embodiment 3

[0044] In this embodiment, the color masterbatch carrier includes the following raw material components and parts by weight:

[0045] 30 parts of high-density polyethylene

[0046] Low-density polyethylene 10 parts

[0047] Low-density linear polyethylene 10 parts

[0048] Firstly, the above raw material components are mixed and put into a screw extruder for melting reaction. Preferably, the extrusion temperature is 150-230° C., the diameter of the twin-screw extruder is greater than 25 mm, and the L / D is greater than 32 / 1. The color masterbatch carrier is obtained by water-cooled grinding surface cutting or cold drawing strip cutting.

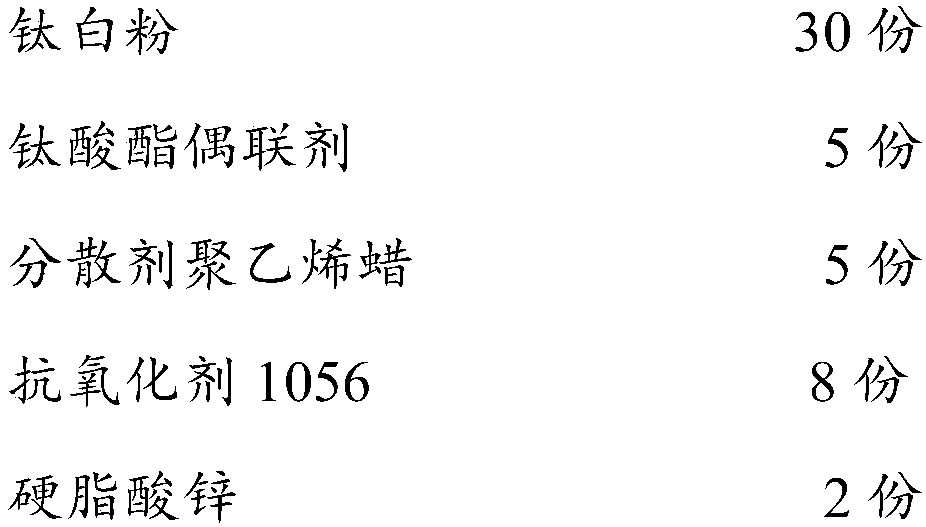

[0049] Then, the color masterbatch carrier made from the above weight parts raw materials and the following

[0050]

[0051] After mixing, it is added to a screw extruder for melting reaction. The extrusion temperature is 200°C, the diameter of the twin-screw extruder is greater than 25mm, and the L / D is greater than 32 / 1. The color ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com