Frame sealing adhesive composition, to-be-cure display panel, curing device and display panel

A display panel and curing device technology, which is applied to the surface coating liquid device, pretreatment surface, optics, etc., can solve the problems of reducing the conductivity of metal traces and affecting the response speed of display devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An embodiment of the present invention provides a frame sealing glue composition, including: colloid and X-ray phosphor doped in the colloid; the X-ray phosphor can generate light after being irradiated with X-rays to make the colloid solidify.

[0033] Here, there is no limitation on the material of the X-ray phosphor and the specific light generated after X-ray irradiation, which can be selected according to the curing type of the colloid. For example, if the above-mentioned colloid can be cured after being irradiated with ultraviolet rays, then you can choose an X-ray phosphor that can generate ultraviolet rays after X-ray irradiation (which can be called X-ray ultraviolet phosphor); Curing can be achieved after irradiation, so X-ray phosphors that can generate visible light after X-ray irradiation can be selected. Of course, other types of X-ray phosphors can also be selected, which is not limited here.

[0034] In order to achieve a better curing effect, for examp...

Embodiment 2

[0039] An embodiment of the present invention provides a display panel to be cured, including: any one of the sealant compositions provided in Embodiment 1.

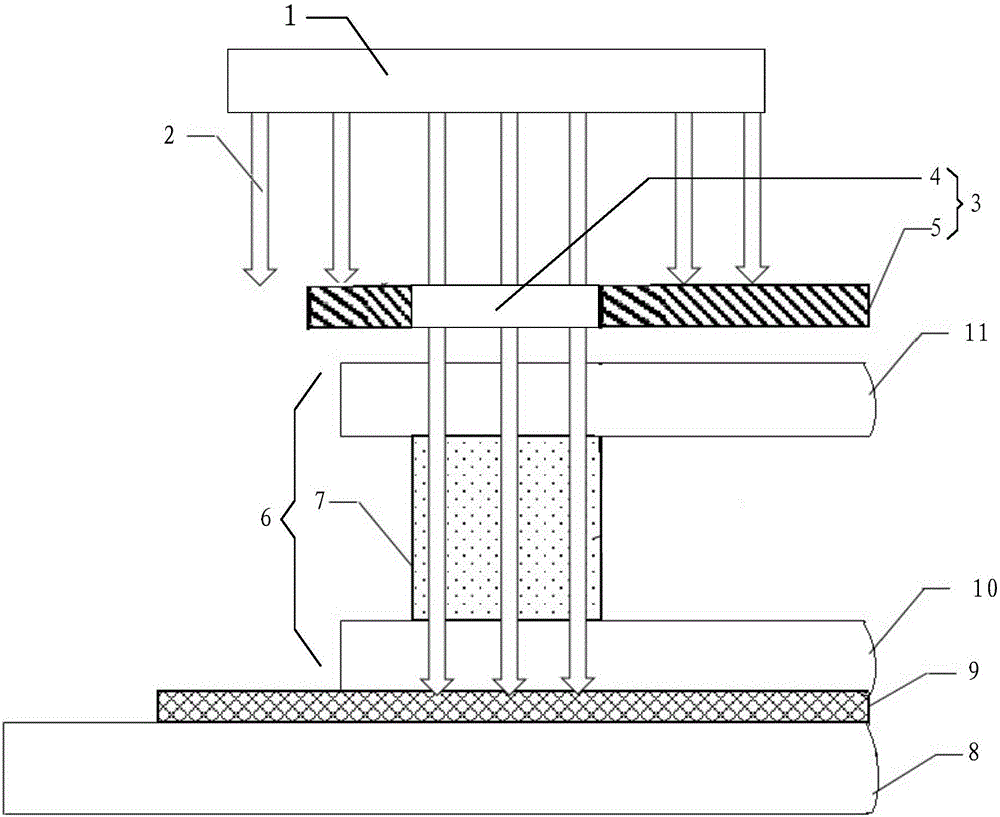

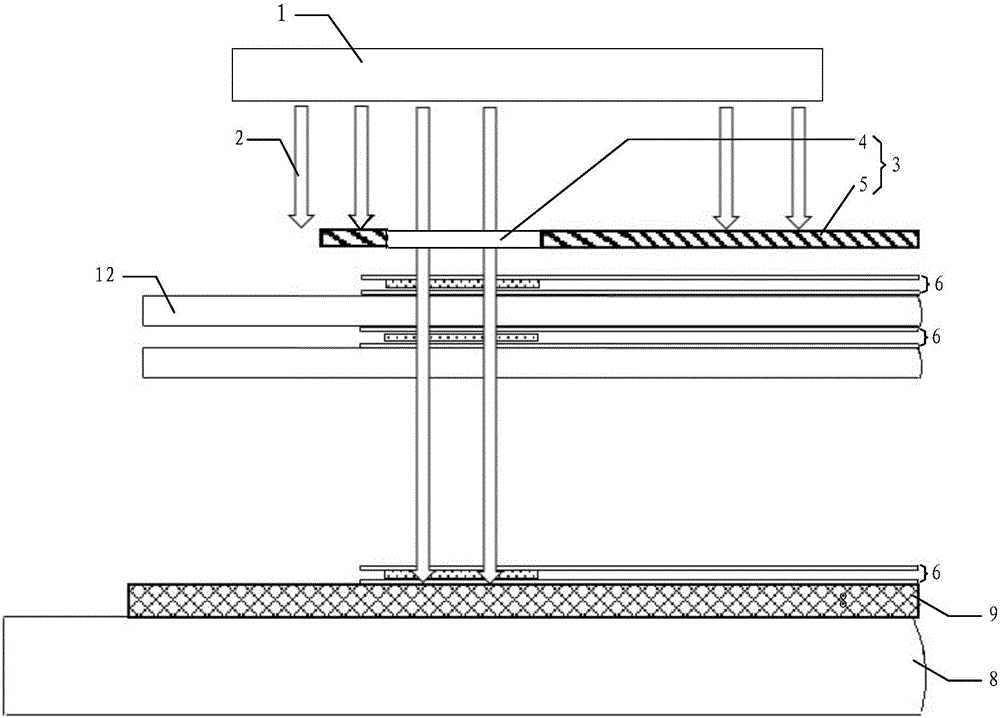

[0040] The above-mentioned display panel to be cured may also include: figure 1 As shown in the array substrate 10 and the color filter substrate 11 , the sealant composition 7 is located between the array substrate 10 and the color filter substrate 11 . It should be noted, figure 1 The color filter substrate is located above the array substrate. At this time, the X-rays emitted by the X-ray source enter from the side of the color filter substrate of the display panel to be cured; of course, the array substrate can also be located above the color filter substrate. At this time, the X-ray source The emitted X-rays enter from the array substrate side of the display panel to be cured. The embodiments of the present invention do not limit this, and only take the color filter substrate above the array substrate as an exampl...

Embodiment 3

[0045] An embodiment of the present invention provides a curing device for curing the sealant composition of the display panel to be cured provided in Embodiment 2. Refer to figure 1 As shown, the curing device includes:

[0046] X-ray source 1, X-ray source 1 is used to provide X-ray 2; X-ray mask plate 3, X-ray mask plate 3 comprises: light-transmitting portion 4 and light-shielding portion 5; X-ray mask plate is used for making X-ray The X-rays 2 emitted by the source 1 irradiate at least the sealant composition 7 of the display panel 6 to be cured through the light-transmitting portion 4 .

[0047]X-rays are electromagnetic waves with wavelengths between ultraviolet and gamma rays. Because of its short wavelength and high energy, when it shines on a substance, only part of it is absorbed by the substance, and most of it passes through the atomic gap, showing strong penetrating ability, and can penetrate ink paper, wood, metal, etc. Substances that are opaque to visible l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com