Glue for pouring conductive sliding ring body, conductive sliding ring body and pouring method thereof

A technology of conductive slip ring and pouring method, which is applied in the direction of application, household components, household appliances, etc., can solve the problems of low insulation resistance and withstand voltage strength, and cannot improve the insulation resistance and withstand voltage strength of conductive slip ring body, so as to achieve improvement Effects of Insulation Resistance and Dielectric Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention has no special requirements on the preparation method of the casting glue for the conductive slip ring body, and the method of directly mixing the compositions well known to those skilled in the art can be used. In the present invention, there is no particular limitation on the mixing method, and a mixing method well known to those skilled in the art can be used.

[0035] The invention provides a casting method of a conductive slip ring body, comprising the following steps:

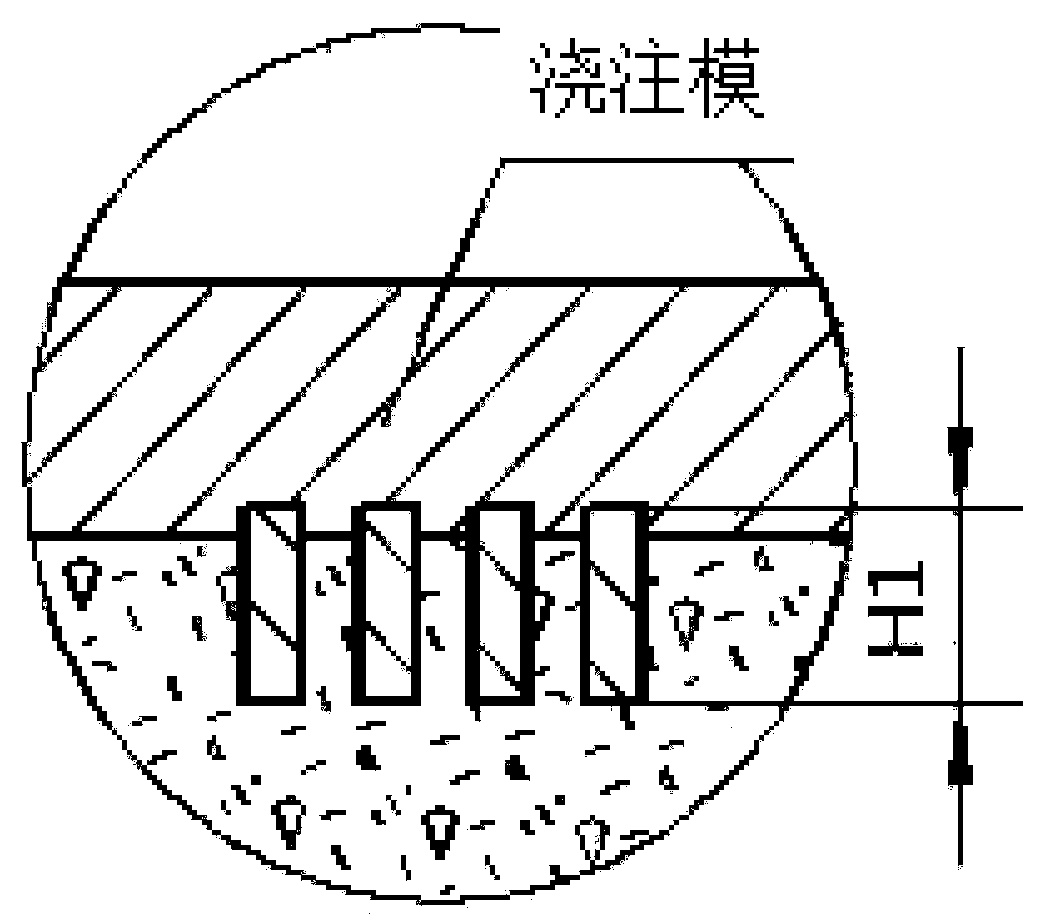

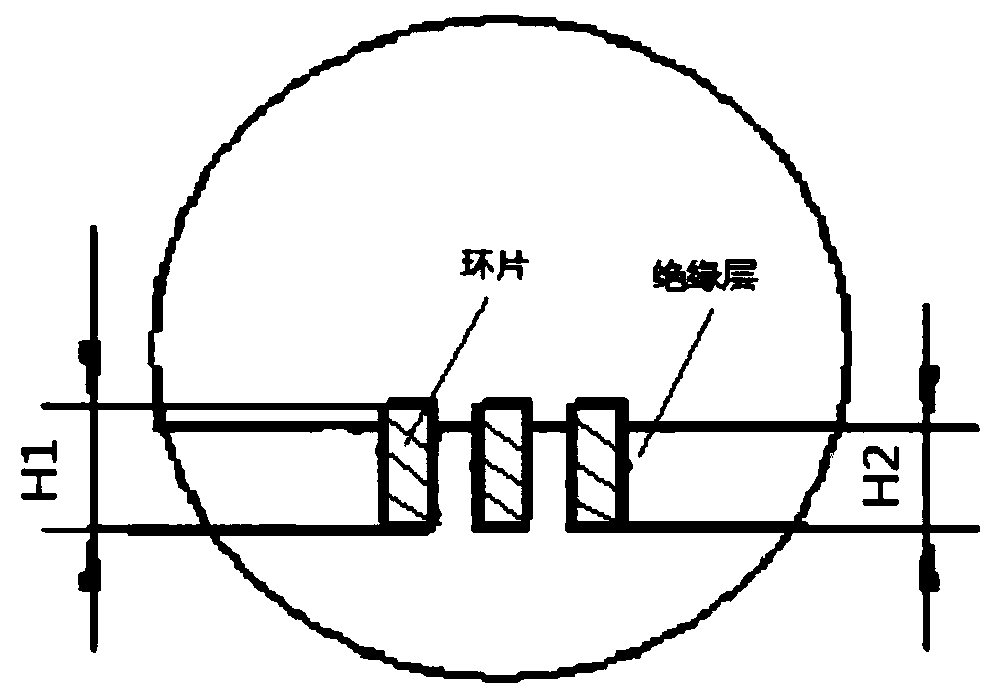

[0036] (1) Place the conductive slip ring assembly in the casting mold;

[0037] Preheat the conductive slip ring body casting glue described in the above technical solution and the casting mold with the conductive slip ring body assembly inside; fill the preheated glue into the preheated casting mold, and the The liquid level of the glue used for pouring the conductive slip ring body is controlled between 5 and 20 mm below the upper end surface of the lead port in the castin...

Embodiment 1

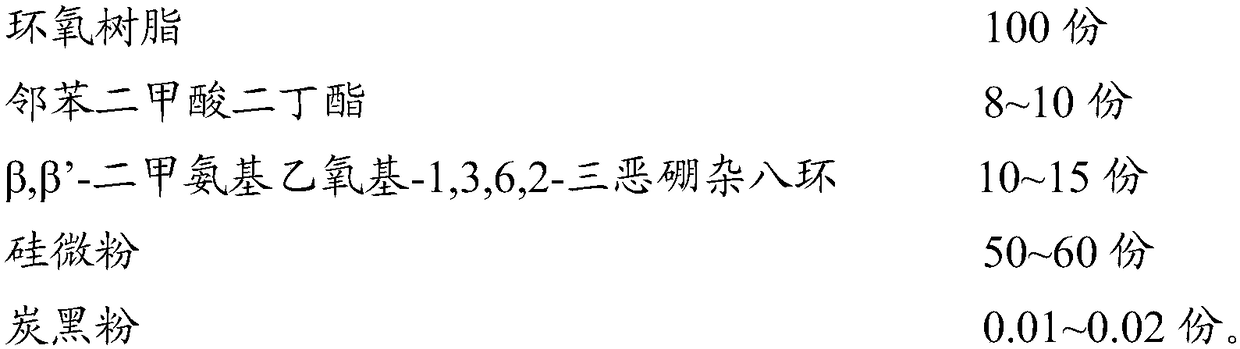

[0074] According to the formula ingredients, prepare 100 parts of epoxy resin E51, 8 parts of dibutyl phthalate, 10 parts of β,β'-dimethylaminoethoxy-1,3,6,2-trioxaboraoctacycline, Particle diameter is 50 parts of silicon micropowder of 5 microns, and particle diameter is 0.01 part of carbon black powder of 16 nanometers, obtains the conductive slip ring body pouring glue;

[0075] Apply D04 glue on the 10mm surface of the wire surface of the outlet slot of the ring body component to protect the wire, and cure the D04 glue at 25°C for 6 hours;

[0076] Clean the pouring mold assembly and assemble it. When assembling, ensure that the parallelism of the upper and lower pressure plates is ≤±0.2mm. After assembly, apply 704 silicone rubber to seal the gap of the pouring mold assembly to obtain the pouring mold;

[0077] Pour the glue for casting the conductive slip ring body into the beaker, stir at a constant speed with a glass rod, and heat to 80°C;

[0078] Preheat the conduct...

Embodiment 2

[0084] According to the recipe ingredients, prepare 100 parts of epoxy resin E51, 10 parts of dibutyl phthalate, 15 parts of β,β'-dimethylaminoethoxy-1,3,6,2-trioxaboroletacycline, Particle diameter is 60 parts of silicon micropowder of 5 microns, and particle diameter is 0.02 part of carbon black powder of 16 nanometers, obtains the conductive slip ring body casting glue;

[0085] Apply D04 glue on the 15mm surface of the wire surface of the outlet slot of the ring body component to protect the wire, and cure the D04 glue at 23°C for 7 hours;

[0086] Clean the pouring mold assembly and assemble it. When assembling, ensure that the parallelism of the upper and lower pressure plates is ≤±0.2mm. After assembly, apply 704 silicone rubber to seal the gap of the pouring mold assembly to obtain the pouring mold;

[0087] Pour the glue for casting the conductive slip ring body into the beaker, stir at a constant speed with a glass rod, and heat to 110°C;

[0088] Preheat the conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com