Micro turbojet atomizing device for ground

A miniature and turbojet technology, which is applied in the directions of jet propulsion devices, air inlets of turbine/propulsion devices, and gas turbine devices. Achieve the effect of improving reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

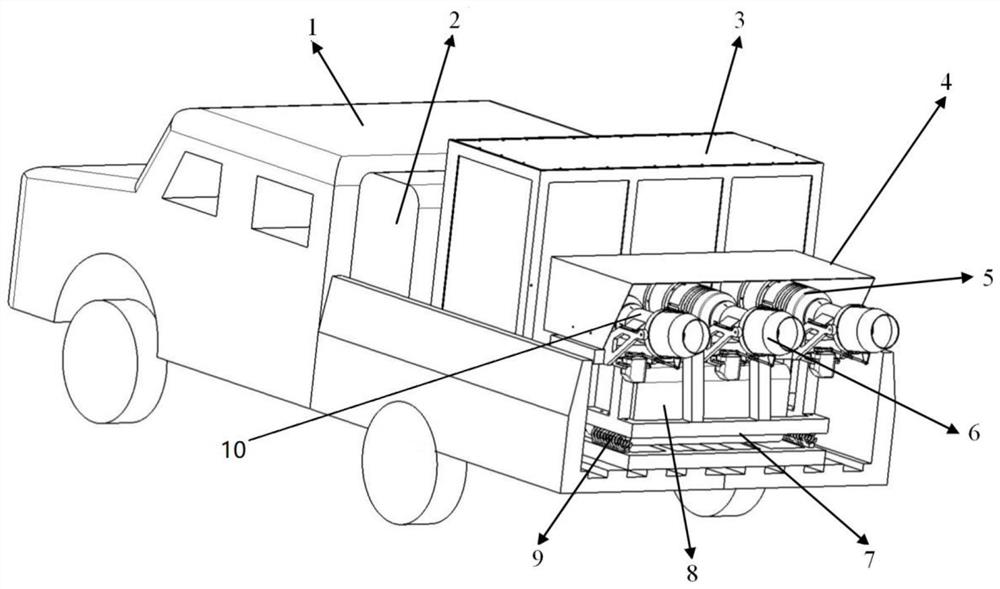

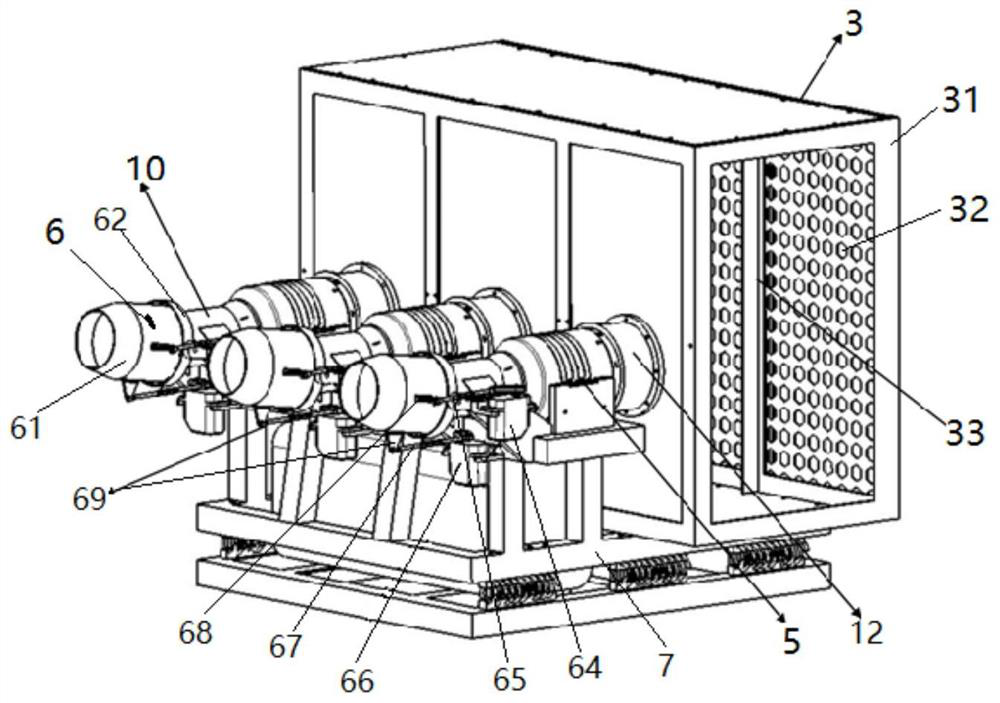

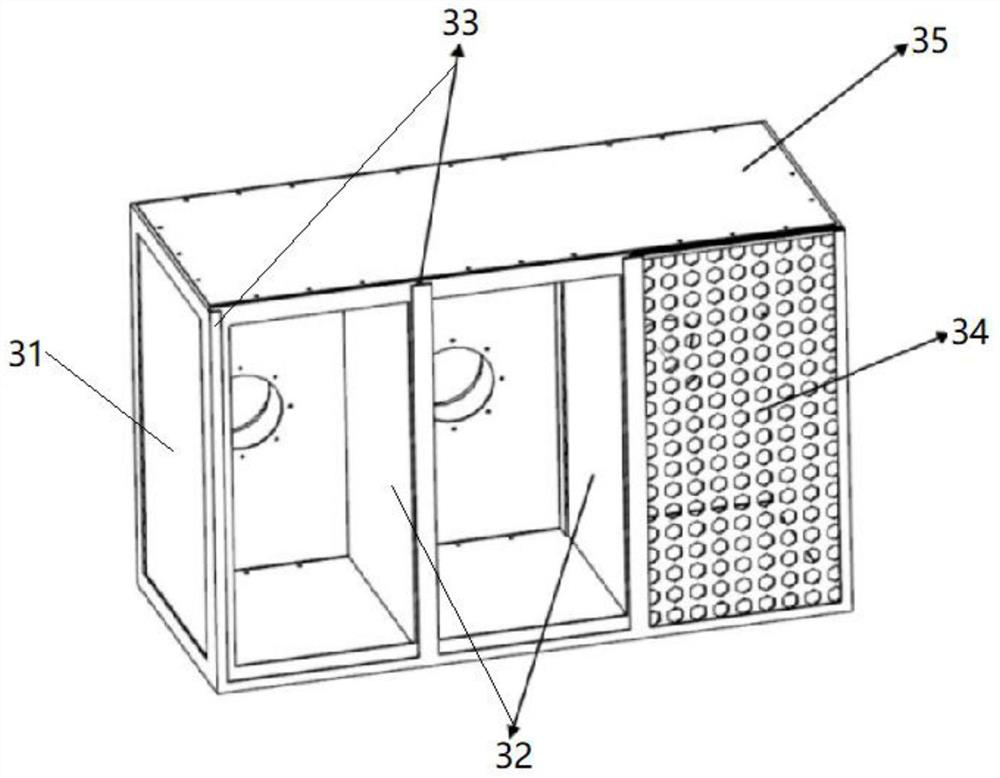

[0035] Embodiment 1: as Figure 1 to Figure 6 Shown, a kind of miniature turbojet atomizing device for ground use comprises aerosol box 2 and at least two miniature turbojet engines 5, and the intake end of microturbine jet engines 5 is connected to the air intake dust-proof unit by an air intake adapter pipe 12. The device 3 is connected, and the micro-turbojet engine 5 and the intake dust-proof device 3 are all arranged on the support stand 7; the outlet end of the micro-turbojet engine 5 tail nozzle is successively provided with a spraying agent nozzle 11, a fogging Agent mixing chamber 10 and vector nozzle 6, the high-temperature and high-pressure gas of the micro-turbojet engine 5 tail nozzle sprays into the mist-making agent mixing chamber 10, which improves the temperature in the mist-making mixing chamber 10, and in the mist-making mixing chamber 10 Form a high-temperature and high-pressure jet flow; the aerosol in the aerosol box 2 enters the aerosol nozzle 11 from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com