Patents

Literature

40results about How to "Change spray direction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

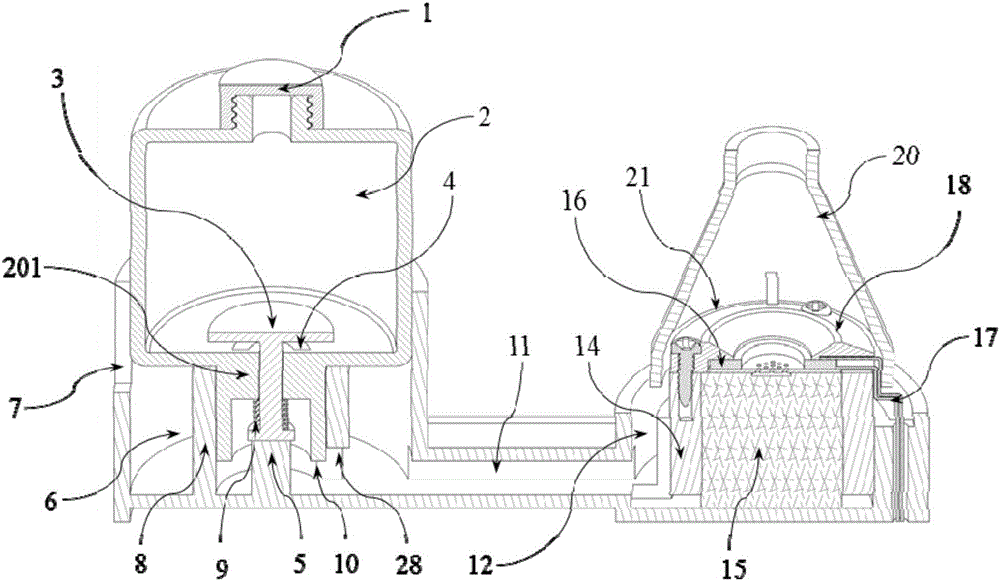

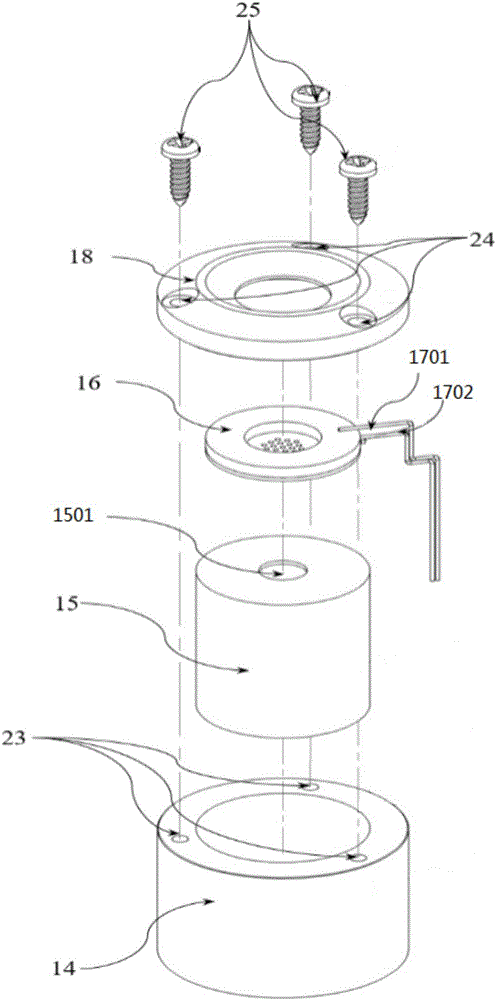

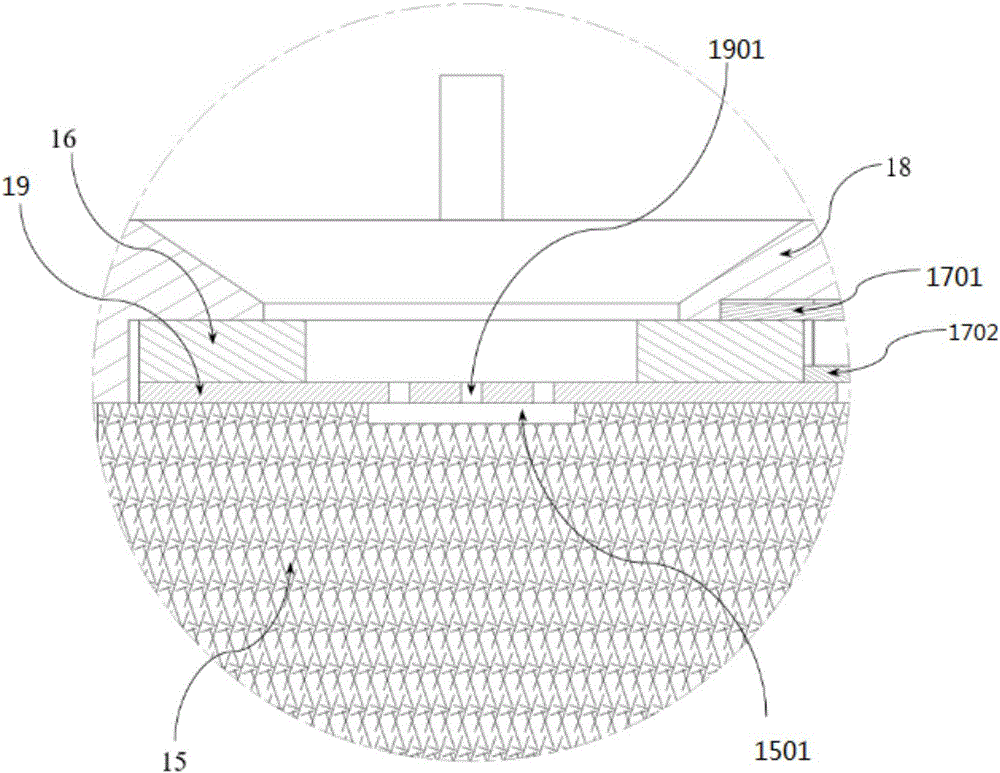

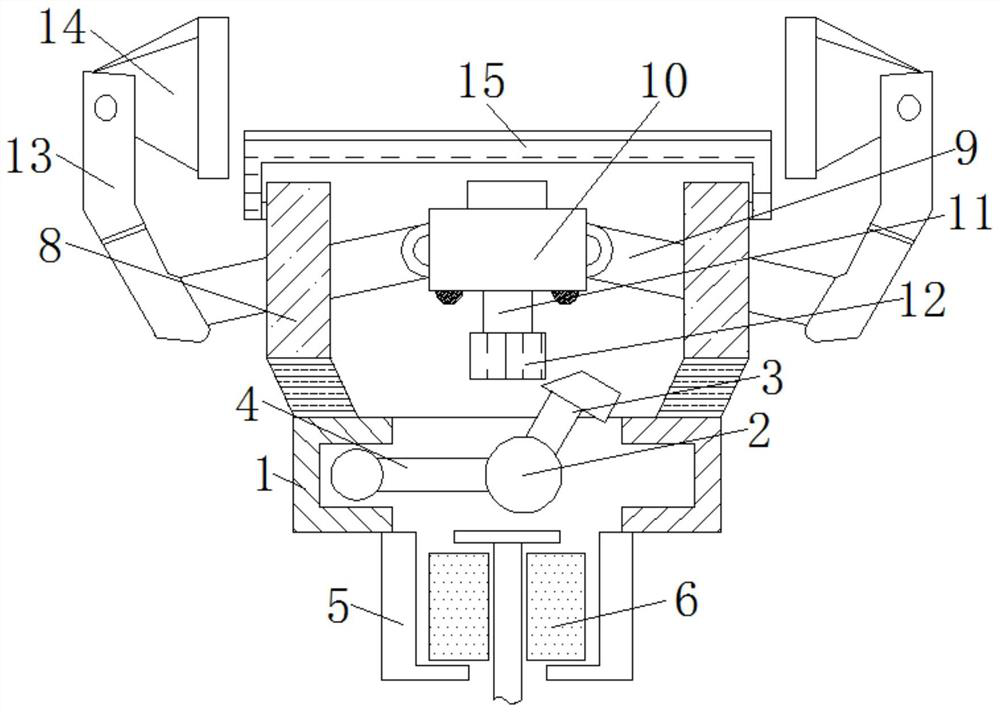

Ultrasonic atomization structure and ultrasonic atomization device using the same

ActiveCN106422005AAvoid overheating problemsChange spray directionEfficient regulation technologiesMedical atomisersEngineeringUltrasonic atomization

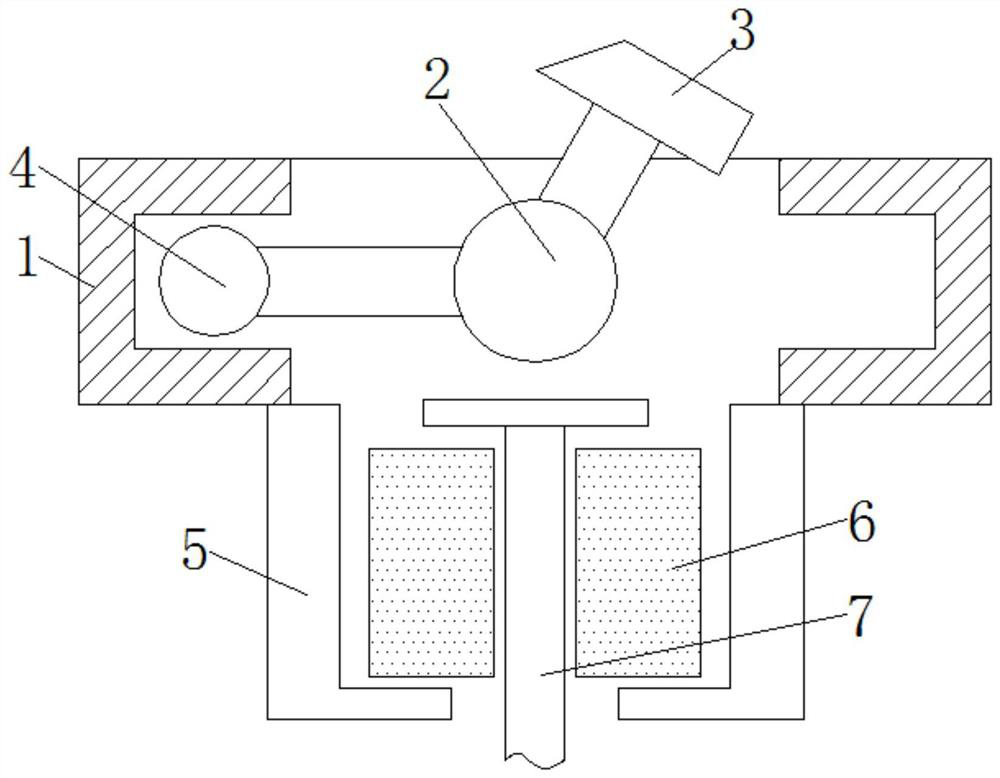

The invention discloses an ultrasonic atomization structure and an ultrasonic atomization device using the same. The ultrasonic atomization structure comprises a liquid receiving tank 12, a liquid absorption medium 15 and an atomization unit, wherein the liquid absorption medium 15 is arranged in the liquid receiving tank 12, and the bottom surface of the liquid absorption medium 15 is immersed in liquid in the liquid receiving tank 12. When the ultrasonic atomization structure is used, the liquid absorption medium 15 absorbs the liquid in the liquid receiving tank 12 and conveys the liquid to one end of the liquid imbibition medium 15, far from the bottom surface of the liquid absorption medium 15, the atomization unit is attached to the end of the liquid absorption medium 15, far from the bottom surface of the liquid absorption medium 15, and the end of the liquid absorption medium 15, far from the bottom surface of the liquid absorption medium 15, is provided with a groove 1501. The ultrasonic atomization structure and the ultrasonic atomization device using the same can atomize the high viscosity liquid into fine drops, and can not cause a superheating phenomenon to the atomization unit.

Owner:アコースティックアークインターナショナルリミテッド

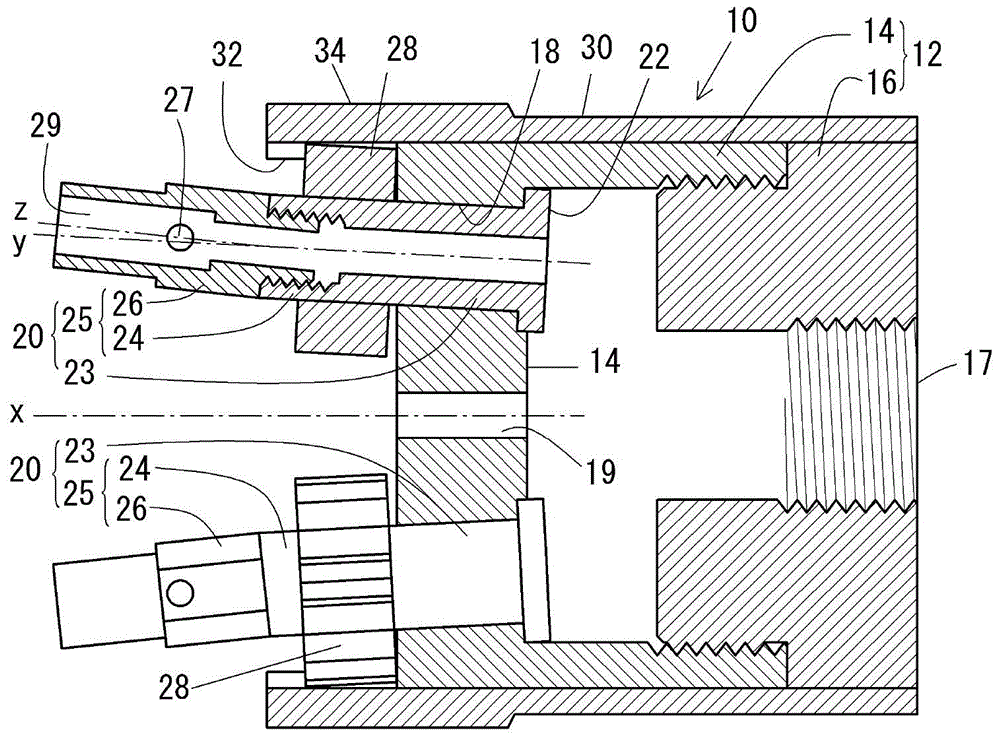

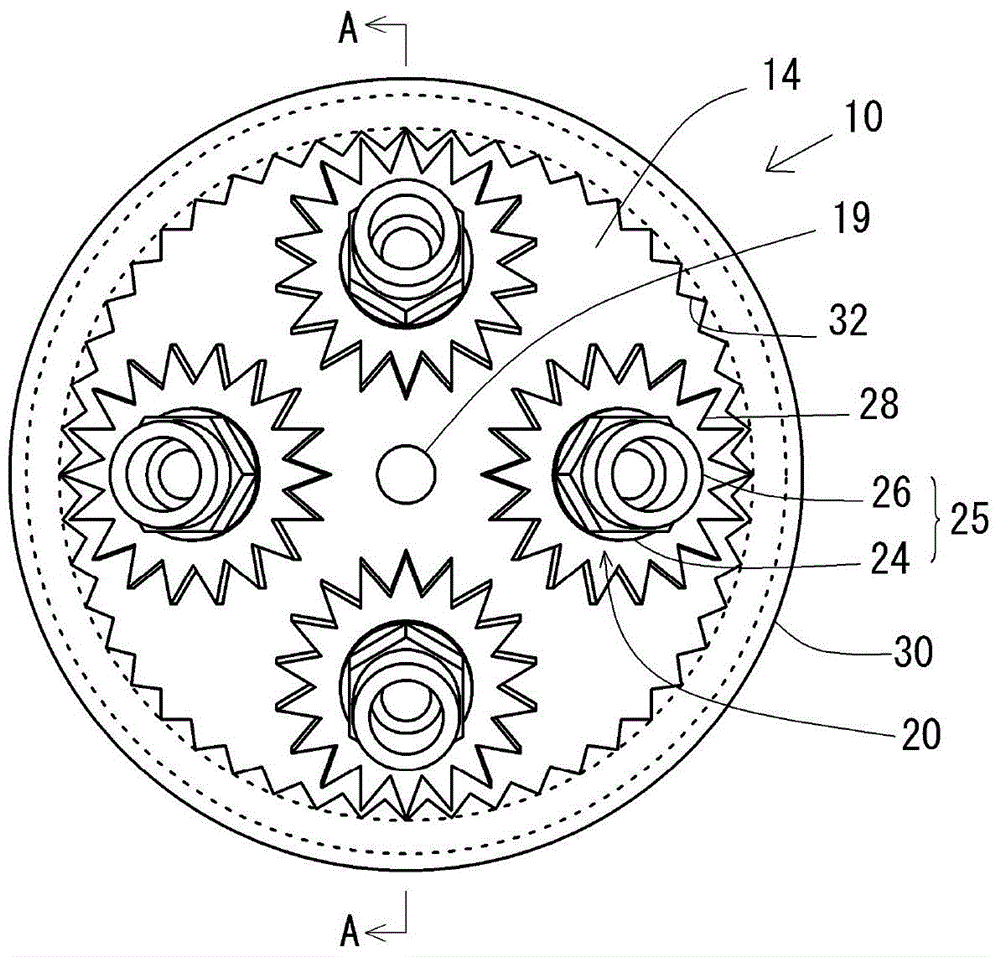

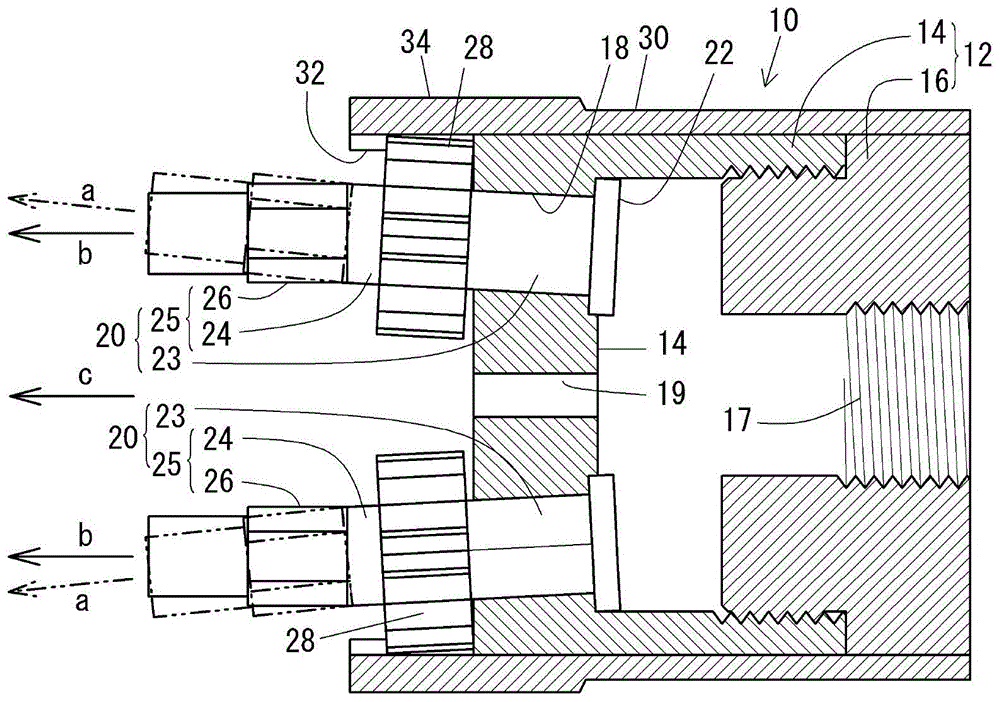

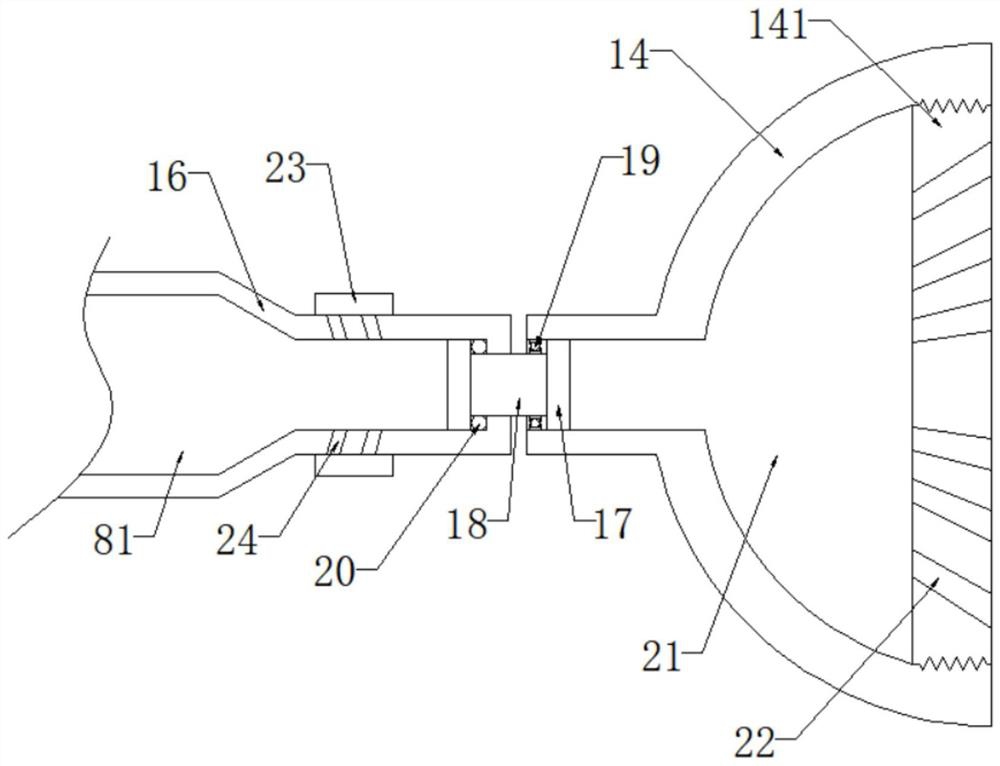

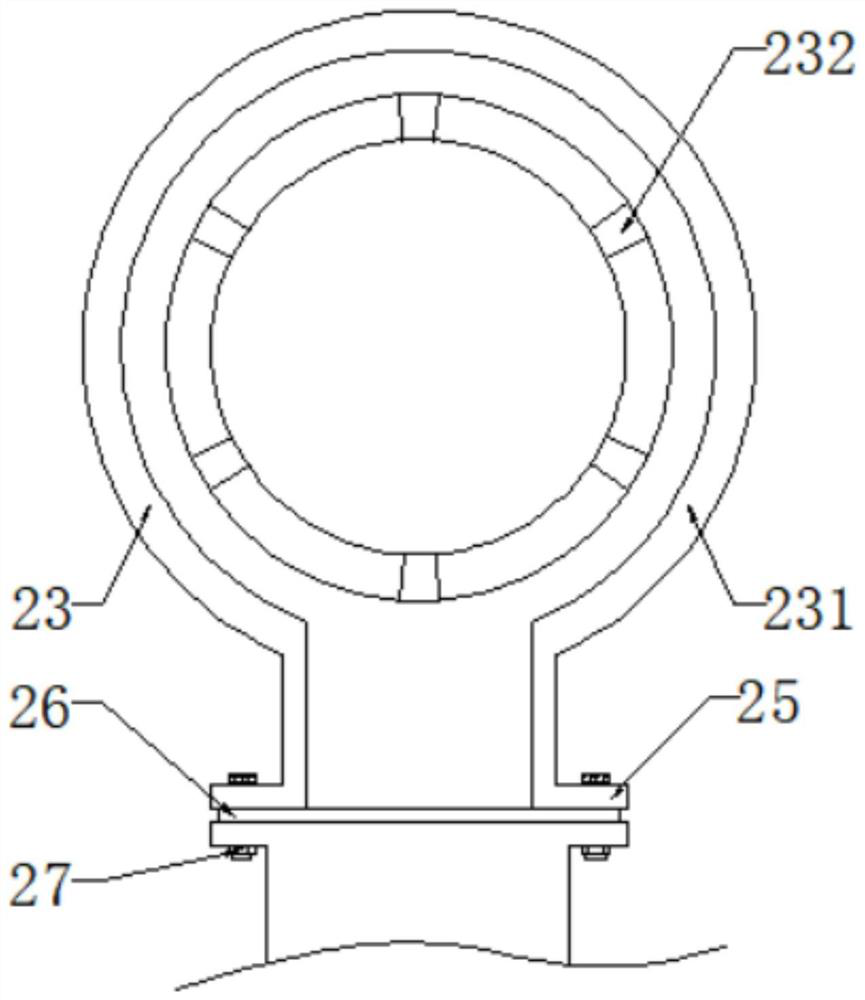

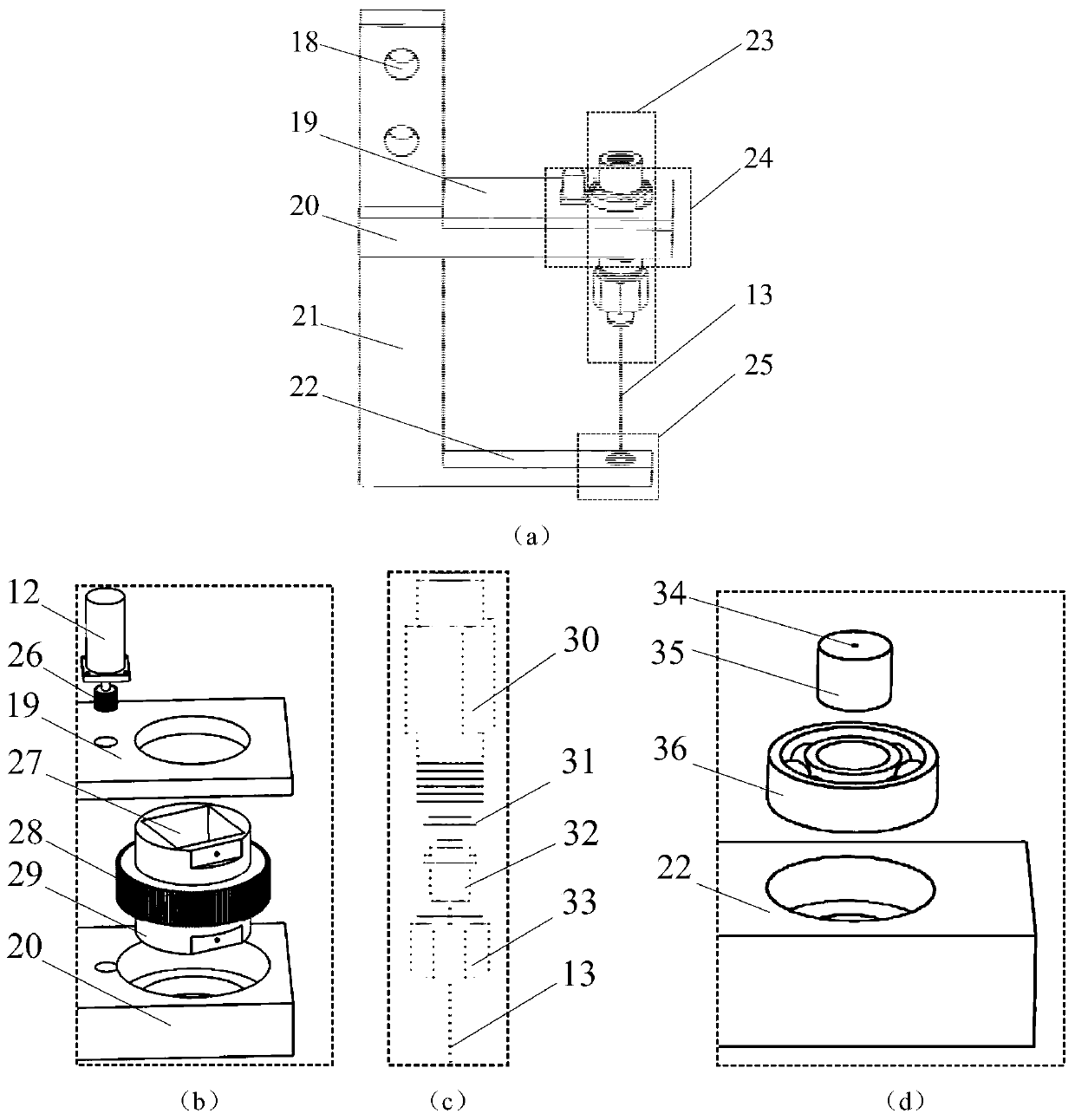

Nozzle device

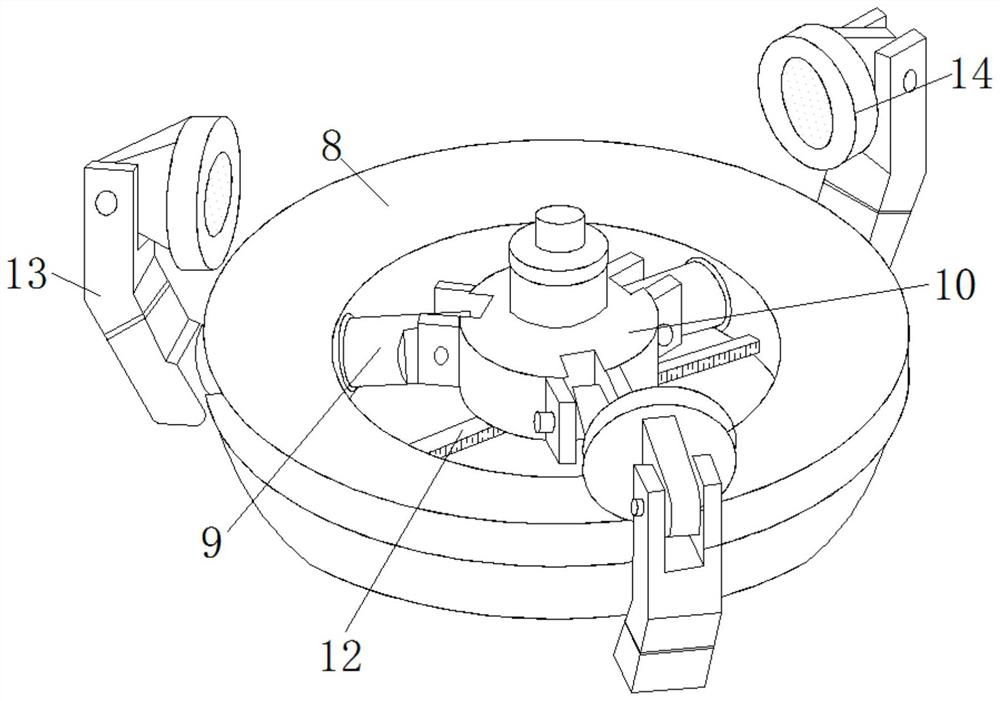

ActiveCN104014438ASimple structureChange spray directionMovable spraying apparatusSpray nozzlesRotational axisEngineering

The present invention provides a nozzle device (10) comprising: a solid cylindrical body member (12) in which a supply opening (17) and nozzle insertion holes (18) are formed; hollow rotatable nozzles (20) which are rotatably inserted through the nozzle insertion holes (18) and which protrude to the discharge side; and a hollow cylindrical rotatable ring (30) which is rotatably fitted over the outside of the body member (12). The axis (z) of a hole in the front end of the protrusion (25) of each of the rotatable nozzles (20) is tilted relative to the axis (y) of the base section (23) of the rotatable nozzle (20), the base section (23) being internally in contact with the nozzle insertion hole (18). Rotation transmission mechanisms (28, 32) which transmit the rotation of the rotatable ring (30) to the rotatable nozzles (20) are provided to the base sections (24) of the rotatable nozzles (20) and to the inner peripheral surface of the rotatable ring (30). As a result of this configuration, rotating the rotatable ring (30) enables a change in the angle of discharge of liquid which is discharged from the nozzle device.

Owner:KSK

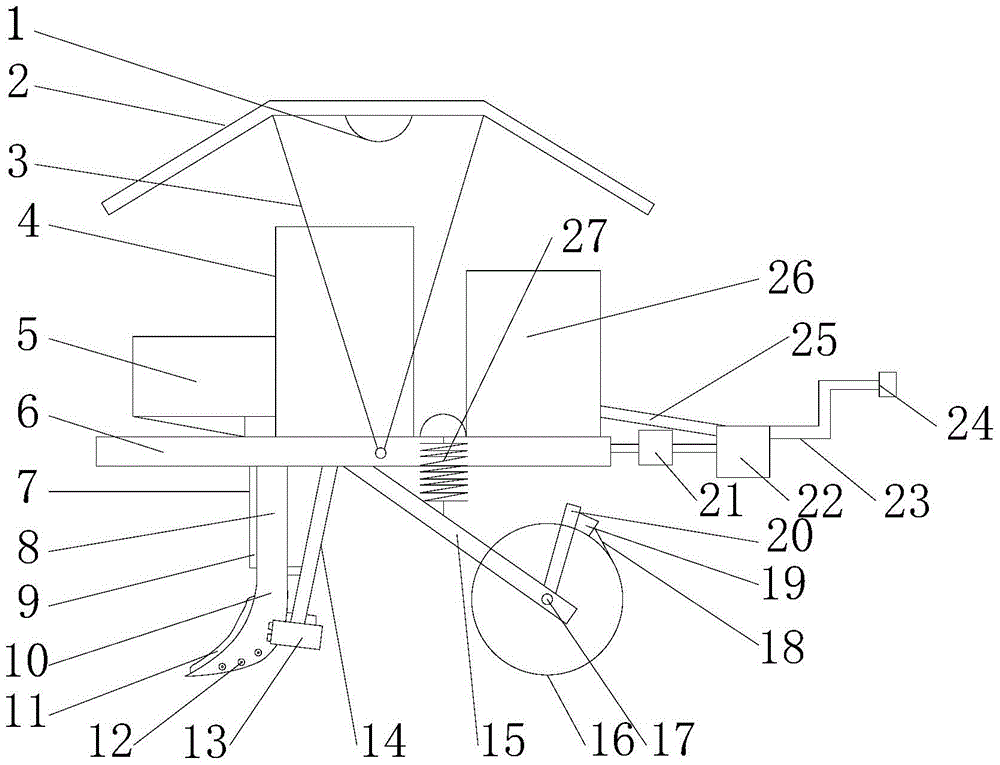

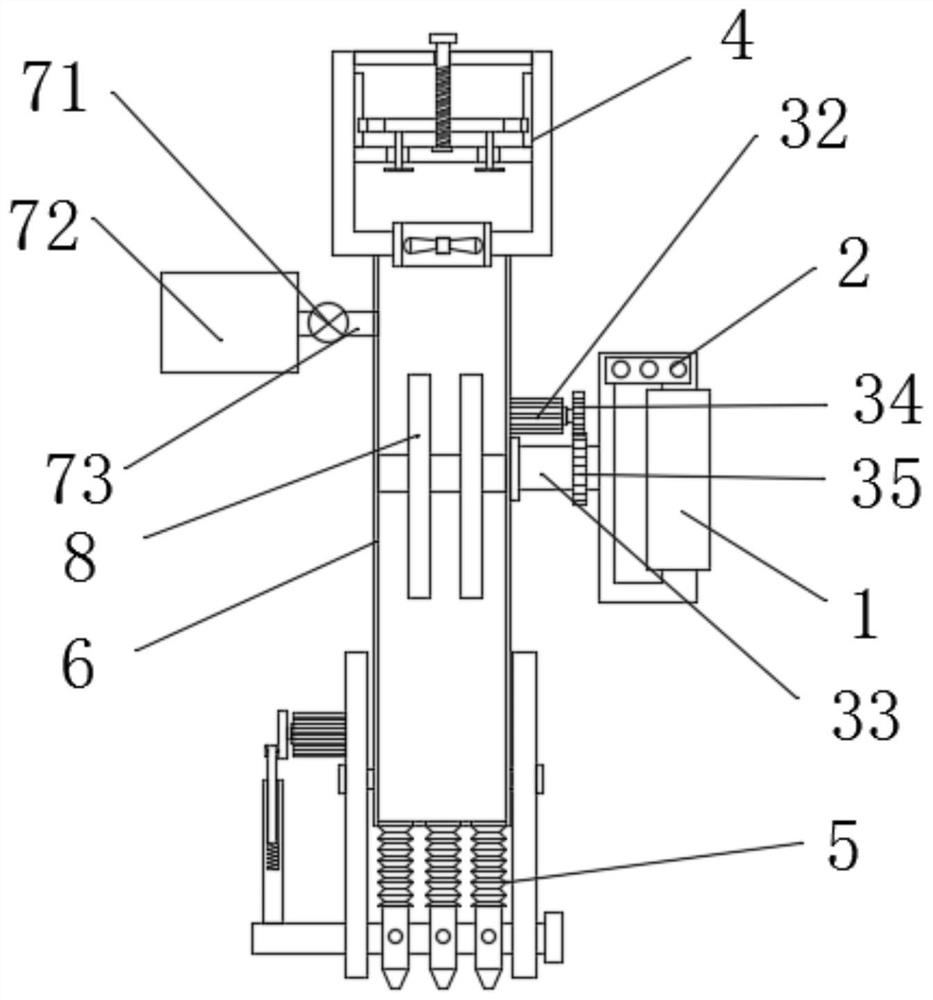

Multifunctional agricultural machine

The invention discloses a multifunctional agricultural machine comprising solar panels, a fertilizer tank, a storage battery, a frame, a fertilization shovel, a press wheel, a spraying device and a water storage tank. The solar panels are electrically connected with the storage battery. A fertilization pipe is arranged on the bottom of the fertilizer tank. The fertilization shovel is arranged below the frame. The press wheel is arranged below the frame and positioned on the back side of the fertilization shovel. A soil scraping shovel is arranged on the press wheel, and is arranged on the upper end of the press wheel through a crossbeam. A pressure spring is arranged at the place where the soil scraping shovel is connected with the crossbeam. The soil scraping shovel is pressed against the press wheel through the pressure spring. A spring is arranged between the frame and a support. The spraying device is arranged on the back part of the frame. The spraying device comprises a clutch device, a high-pressure power sprayer, a nozzle, a connection pipe, the water storage tank and a high-pressure water delivery pipe. The nozzle comprises a hollow housing. The machine is energy-saving, highly efficient, and multifunctional. The machine is convenient to mount. With the machine, deep loosening, fertilization, water or pesticide spraying and other works can be completed once, and the working efficiency is high.

Owner:李秋芬

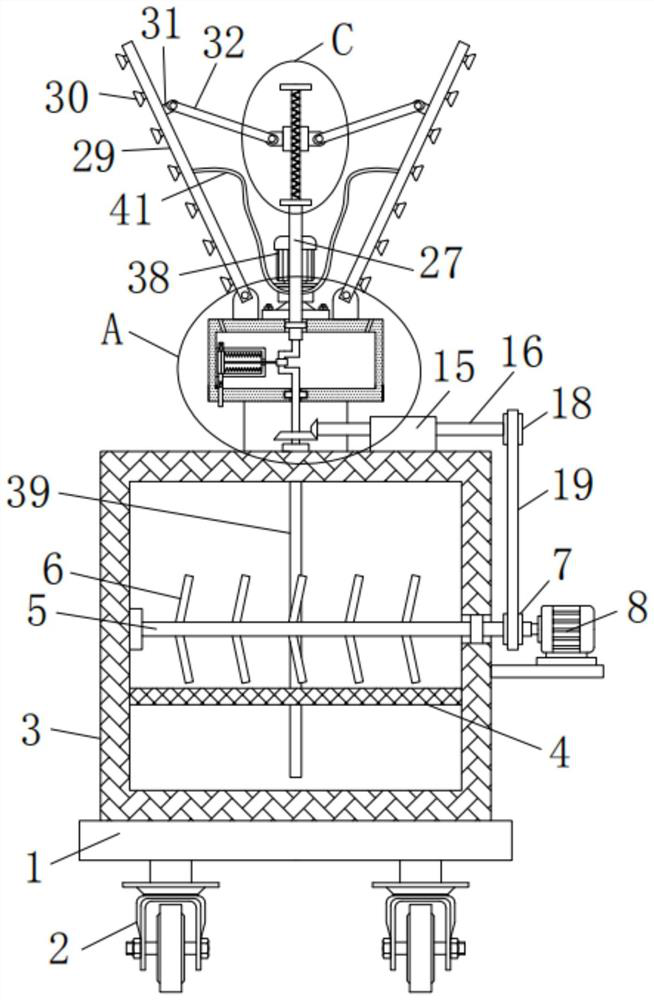

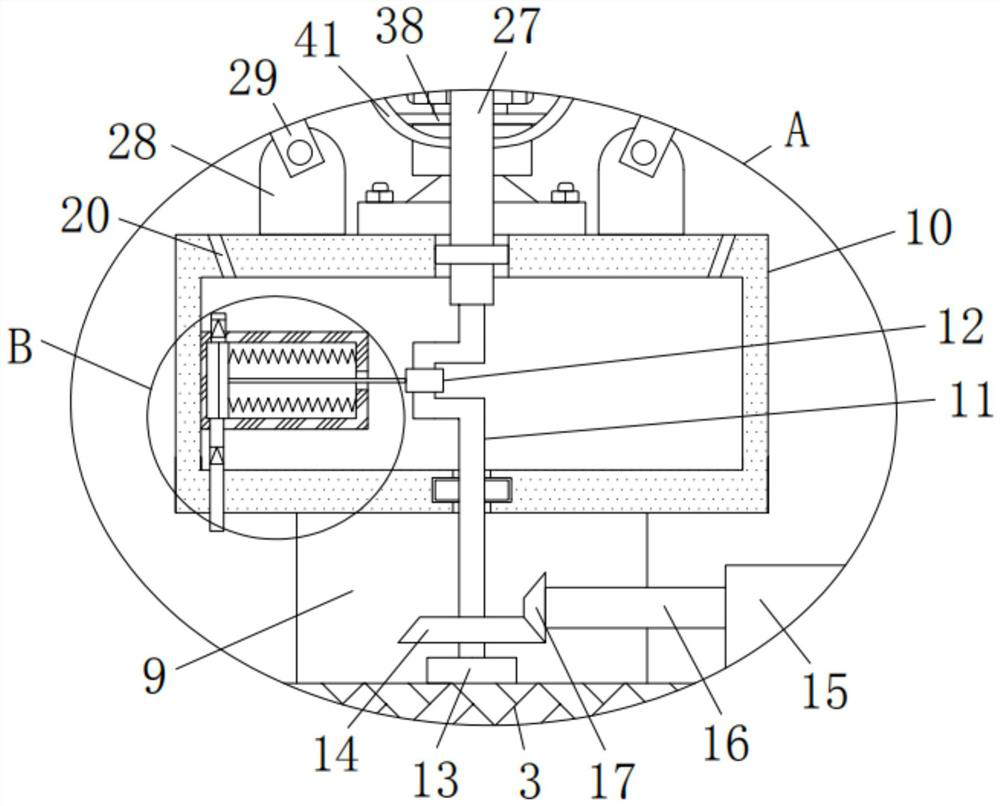

Adjustable agricultural water conservancy irrigation device and use method thereof

PendingCN112772379AImprove irrigation effectDoes not affect inhalationWatering devicesCultivating equipmentsAgricultural scienceAgricultural engineering

The invention discloses an adjustable agricultural water conservancy irrigation device and a use method thereof. The adjustable agricultural water conservancy irrigation device comprises a base, four universal wheels are fixedly installed at the bottom of the base and symmetrically arranged in pairs, a water tank is fixedly installed at the top of the base, and a filter screen is fixedly installed in the water tank; and a stirring shaft positioned above the filter screen is arranged in the water tank. The adjustable agricultural water conservancy irrigation device is reasonable in design and good in practicability, by means of reciprocating swing of two drainage pipes, the spraying directions of multiple nozzles can be changed, water mist can be evenly sprayed to crops, the irrigation effect on the crops is better, the sprayed water mist can be blown to be diffused by means of air sprayed out of multiple air holes, by means of reciprocating swing of the two drainage pipes, the irrigation area of the crops is increased, the range of sprayed water mist is enlarged, and the irrigation quality and irrigation efficiency of the crops are improved.

Owner:时冠军

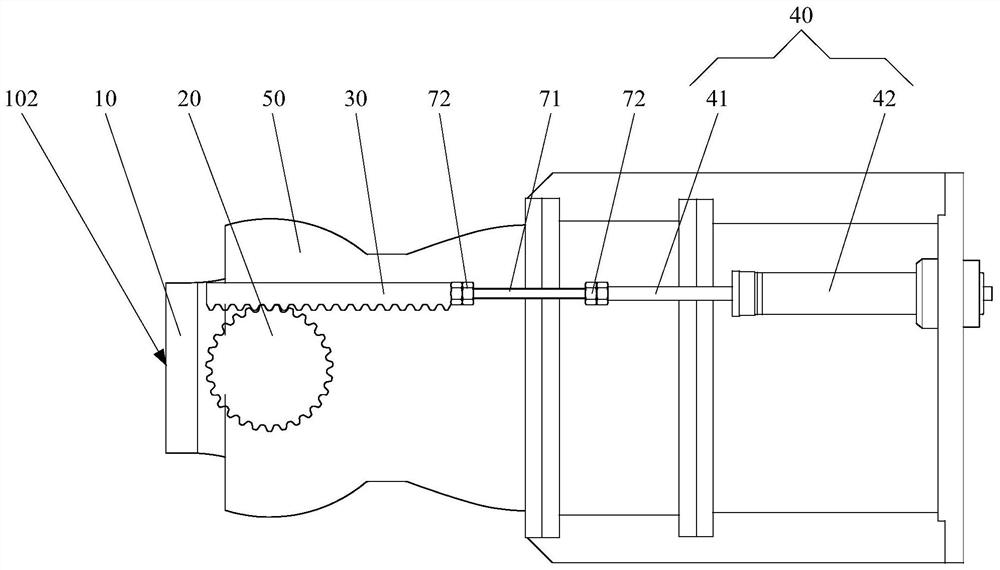

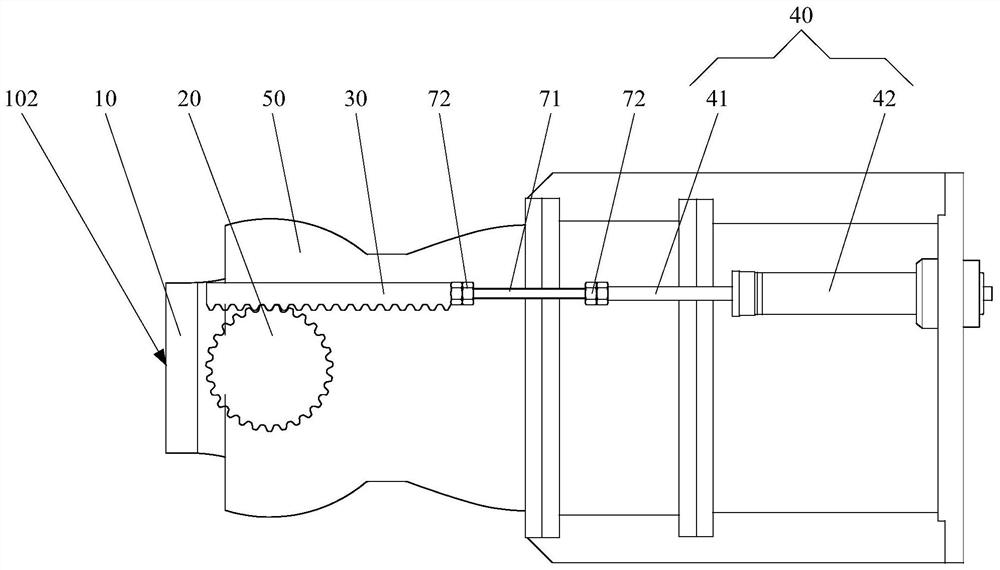

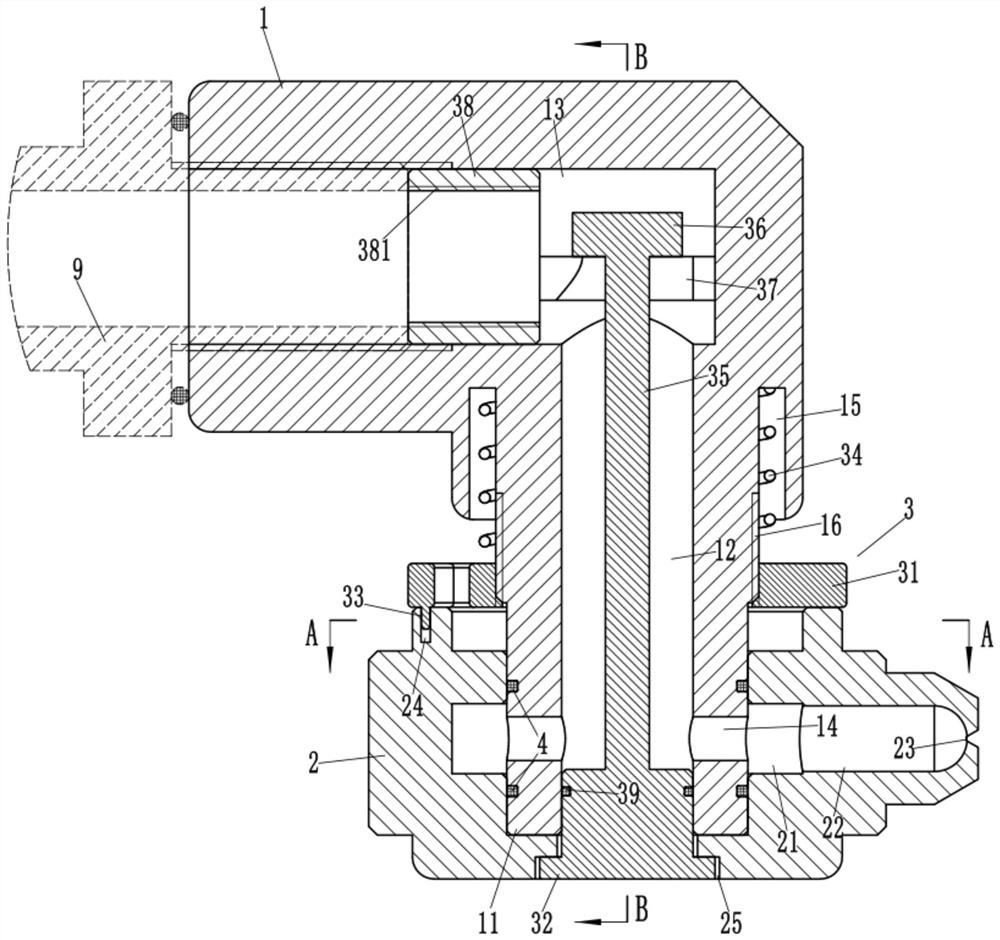

Steering device of water jet propeller

ActiveCN111661304AChange spray directionDoes not involve coordinationSteering by jetsPump-jetMarine propulsion

The invention provides a steering device of a water jet propeller, and belongs to the field of ship propelling devices. The steering device comprises a steering nozzle, a fluted disc, a rack and a hydraulic oil cylinder; the steering nozzle is provided with a nozzle water inlet installed on the water outlet of the water jet propeller and a nozzle water outlet communicated with the nozzle water inlet; the fluted disc is fixedly connected with the steering nozzle; the axis of the fluted disc is perpendicular to and intersects with the axis of the nozzle water outlet; the rack is meshed with thefluted disc; the hydraulic oil cylinder comprises a piston rod and a cylinder body used for being fixed to the water jet propeller; the first end of the piston rod is arranged in the cylinder body ina sliding mode; and the second end of the piston rod is coaxially connected with the first end of the rack. A whole process is completed through driving of one hydraulic oil cylinder, cooperation of the two hydraulic oil cylinders is not involved, and therefore, reliability is high, implementation cost is low. The device is particularly suitable for ships sailing at a high speed.

Owner:WUHAN MARINE MACHINERY PLANT

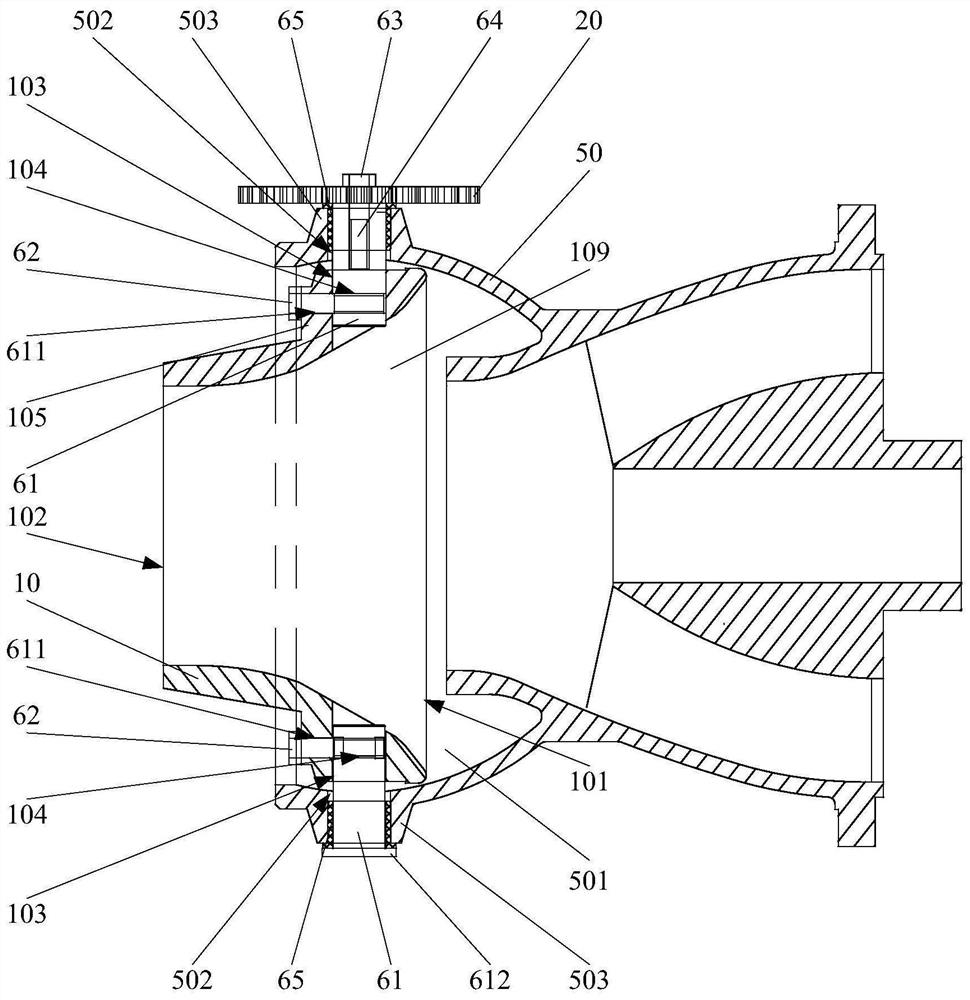

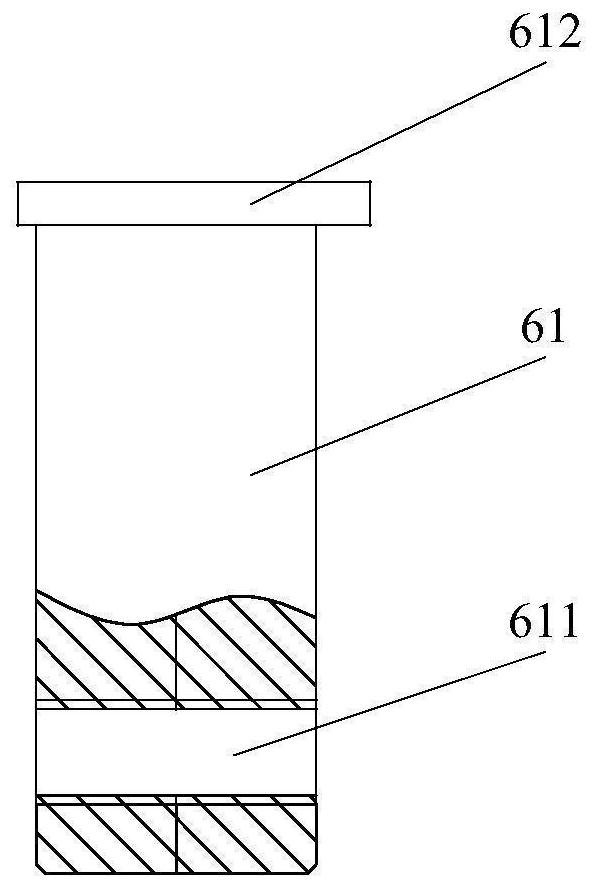

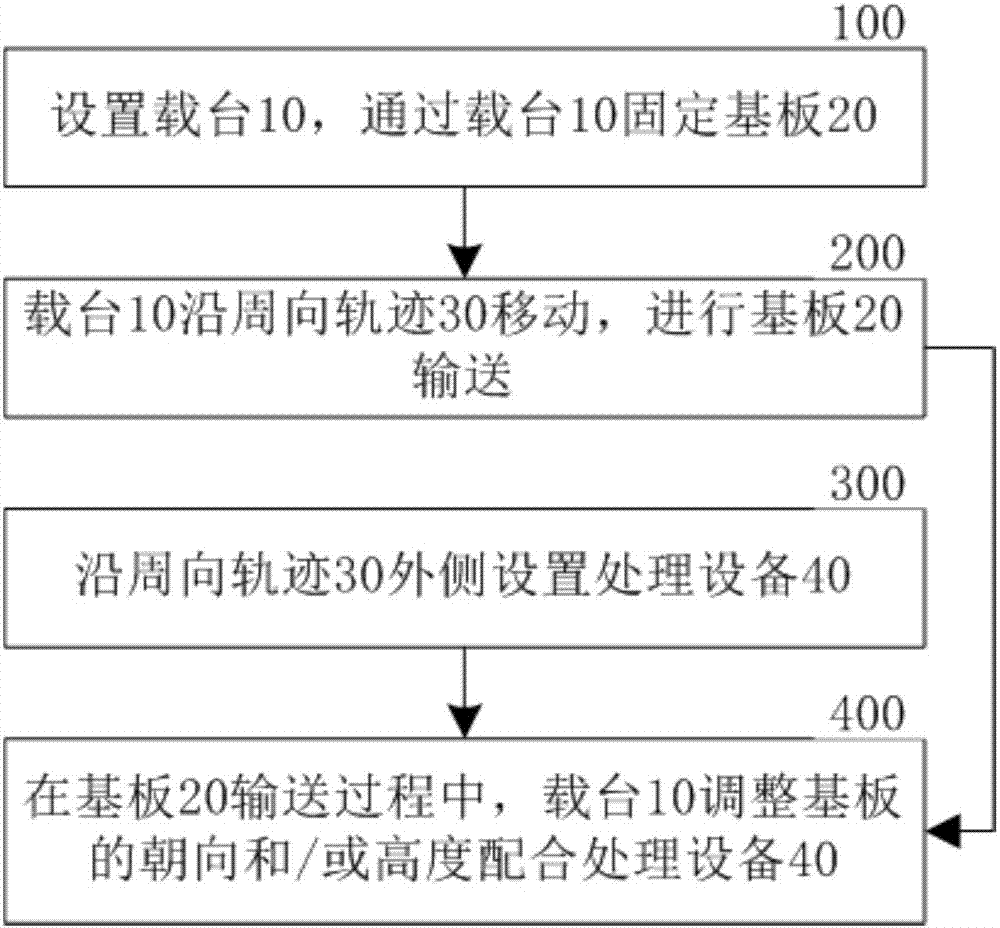

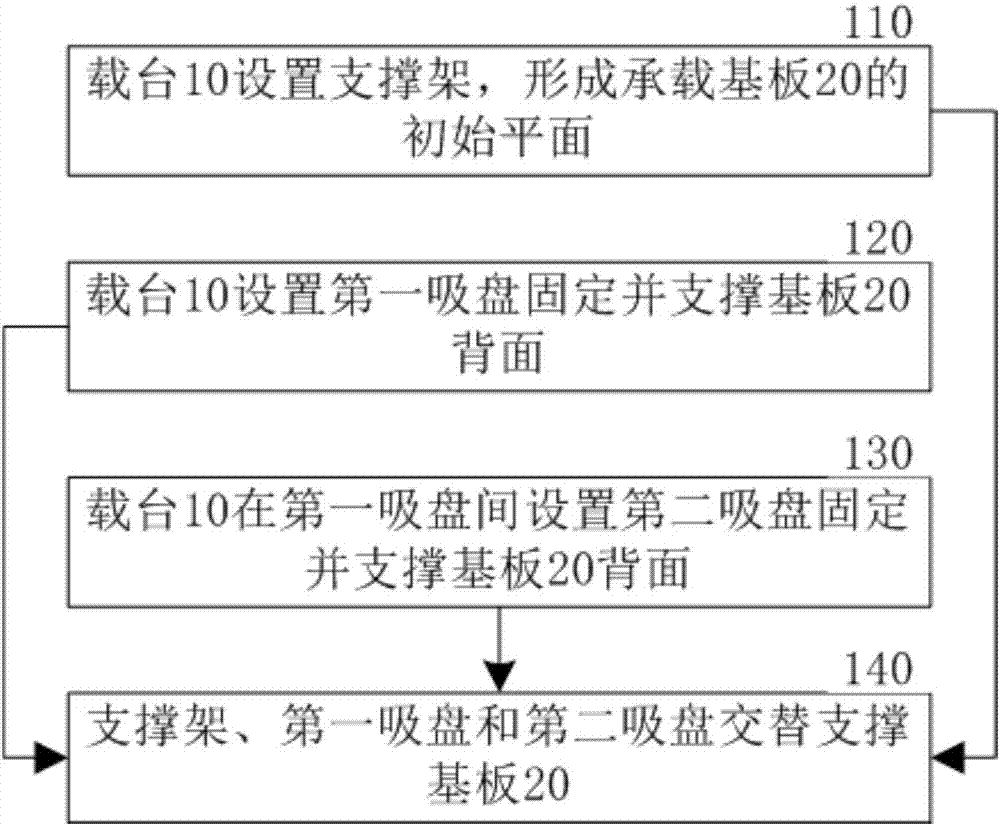

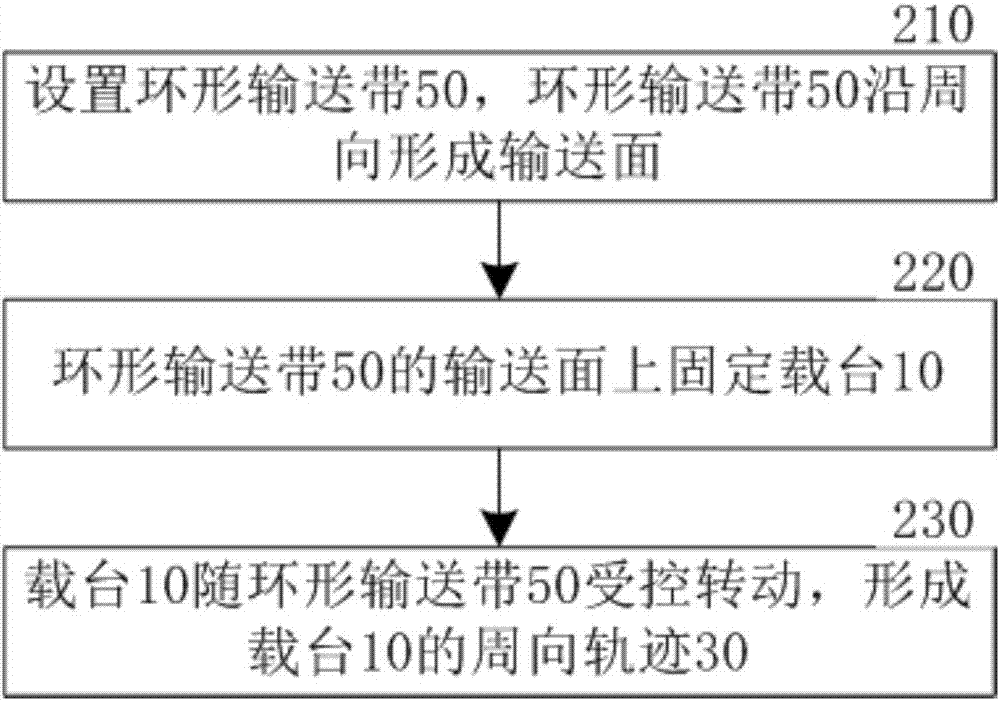

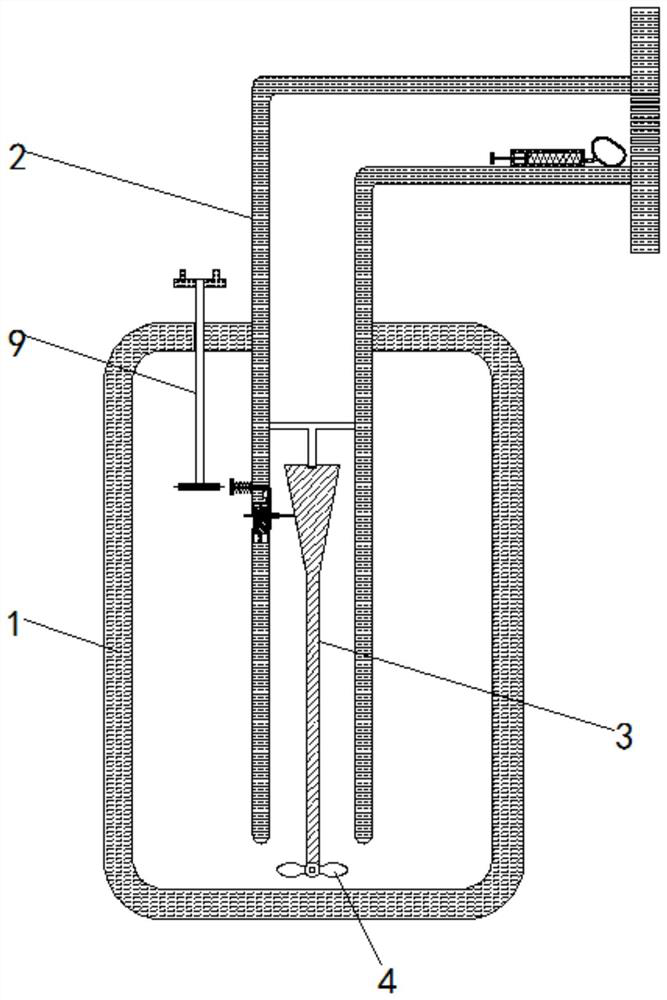

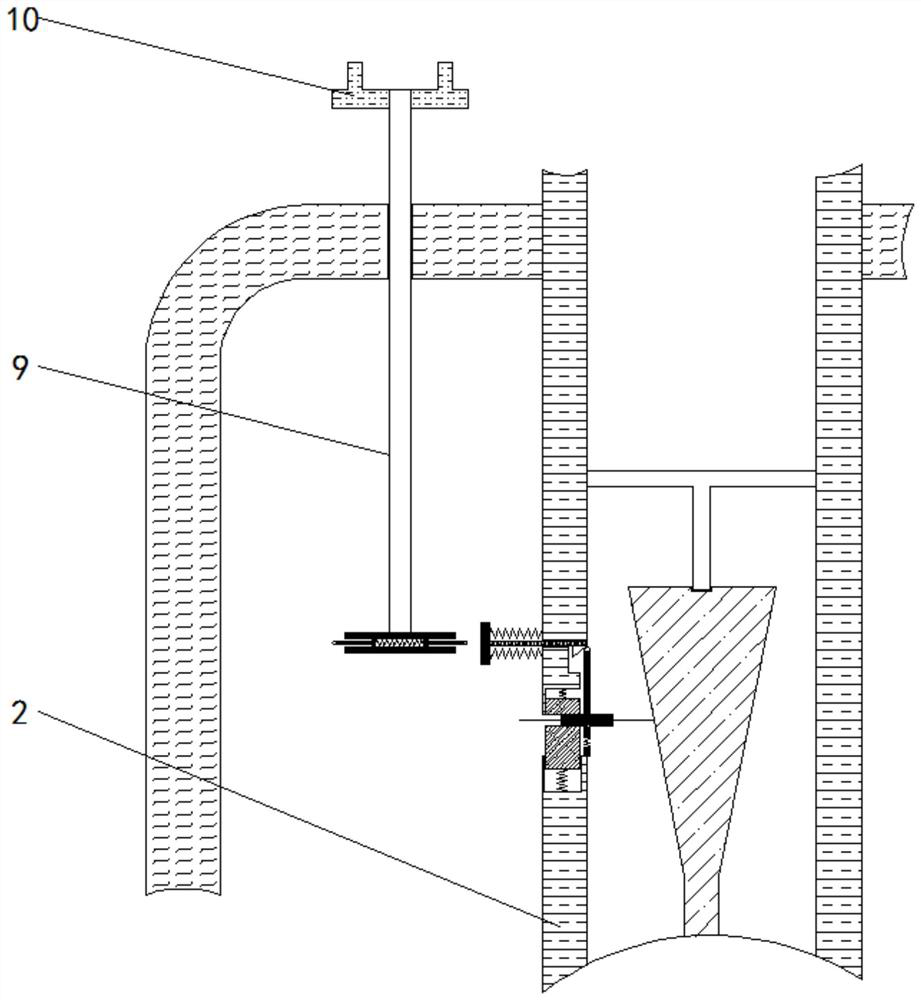

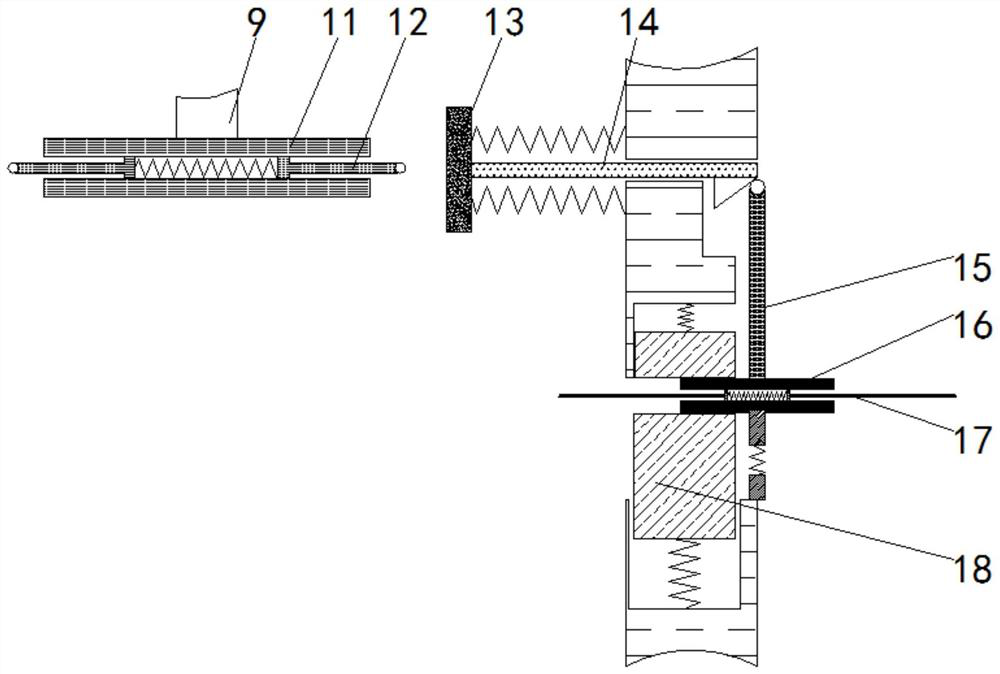

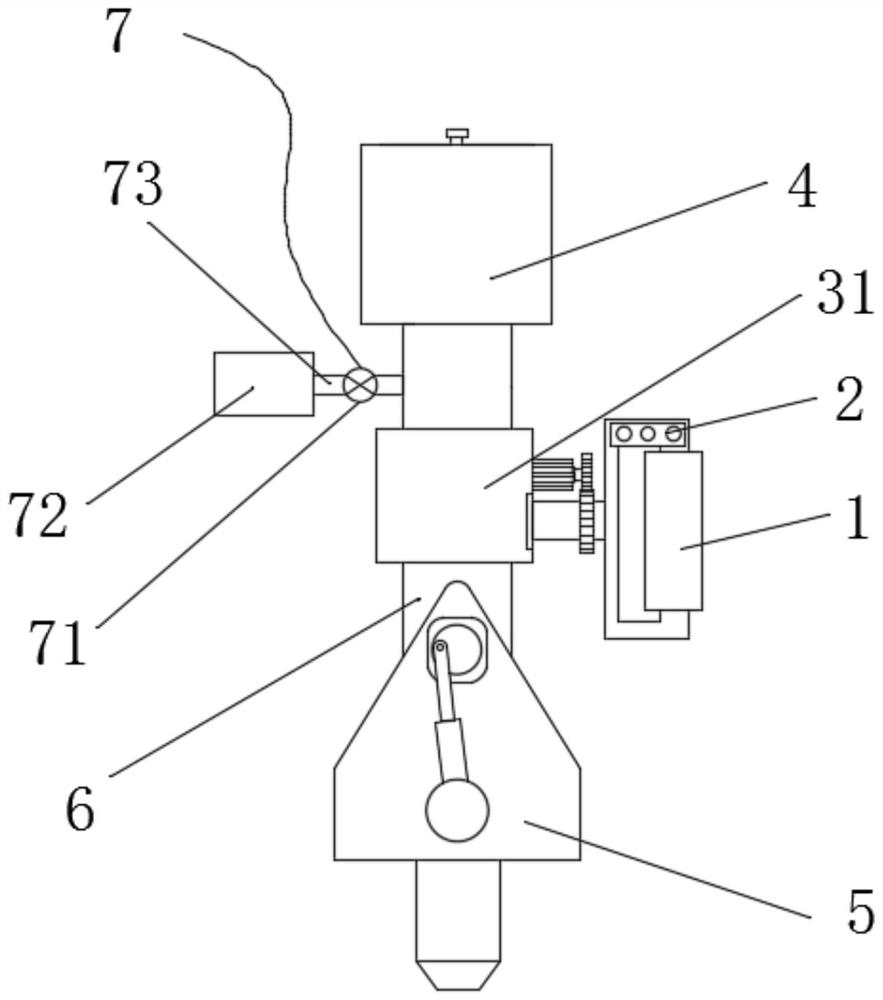

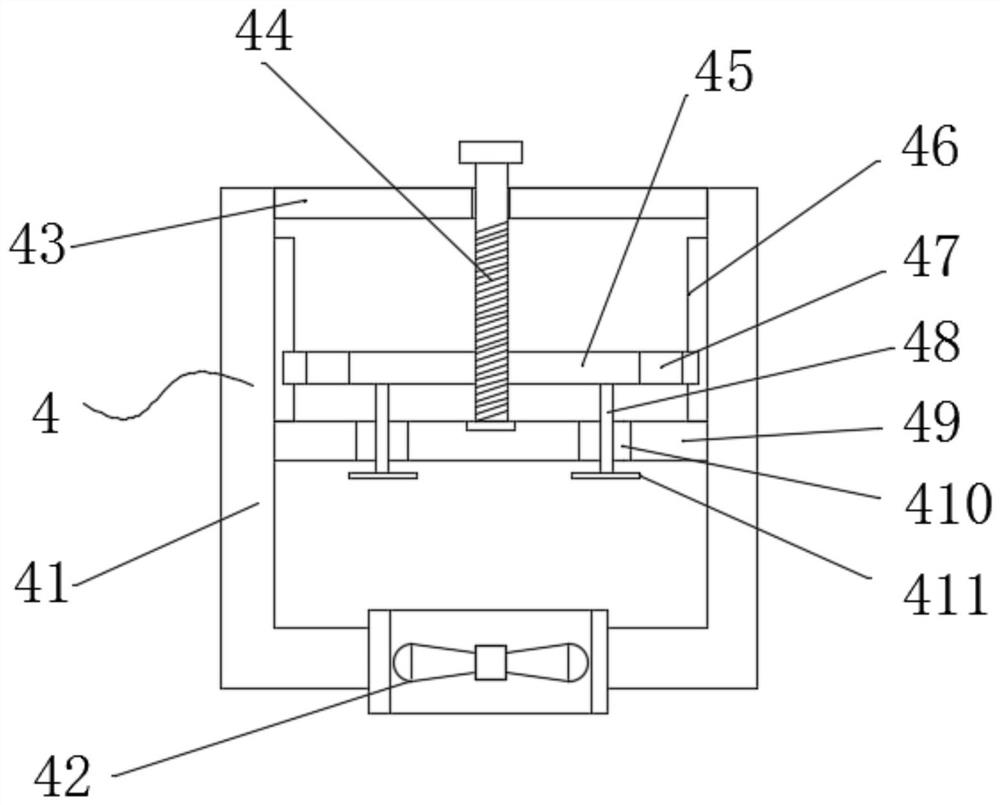

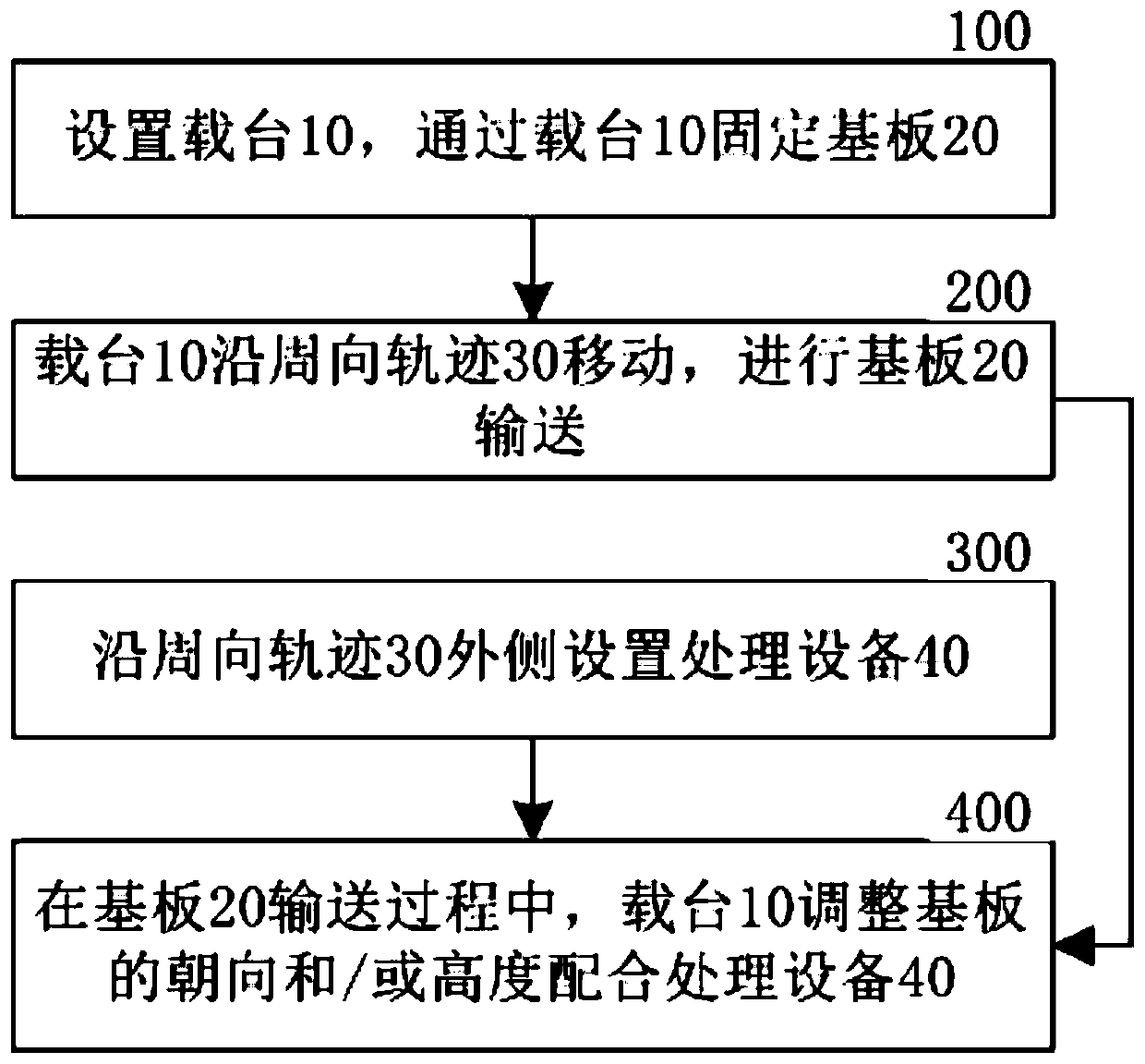

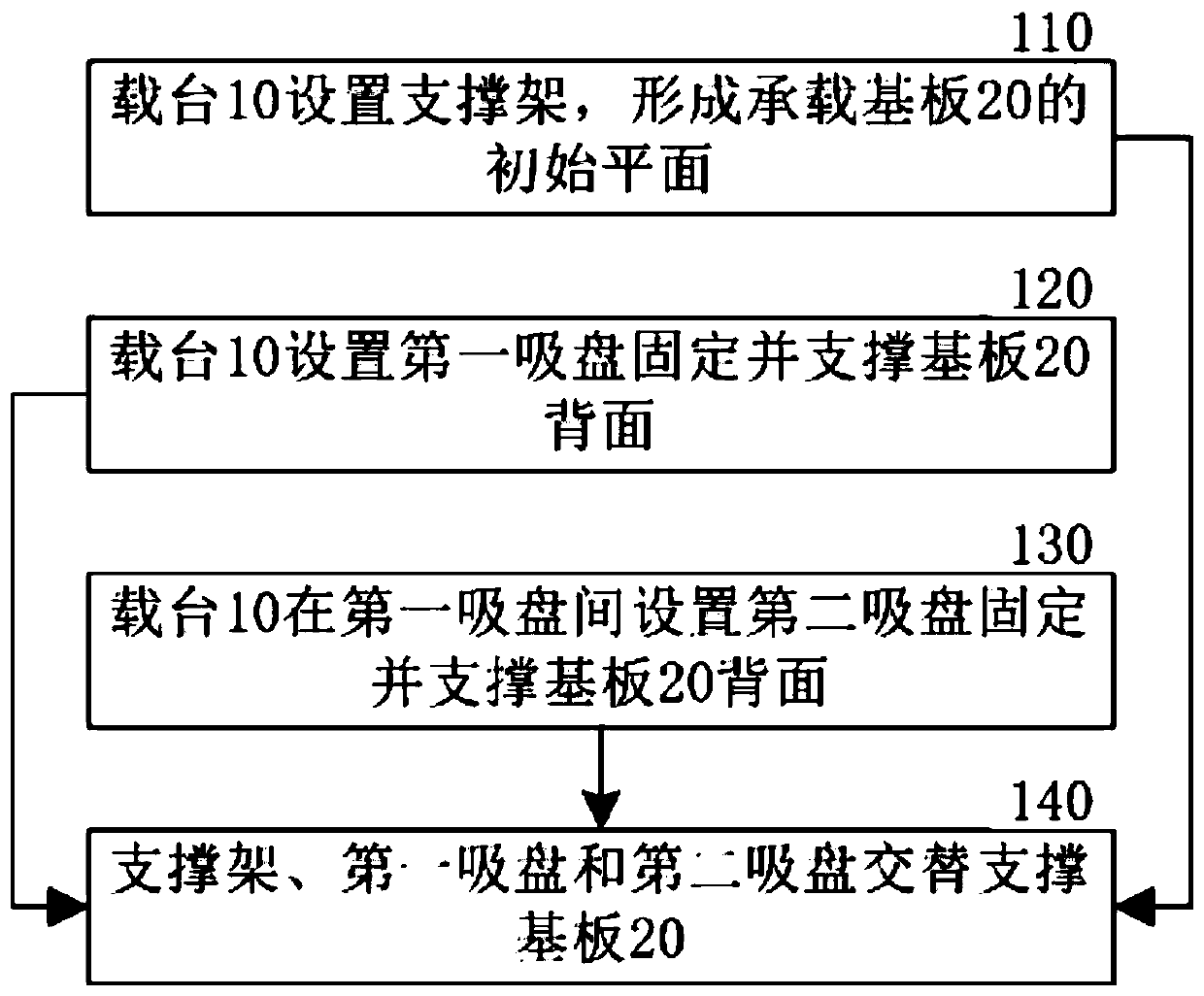

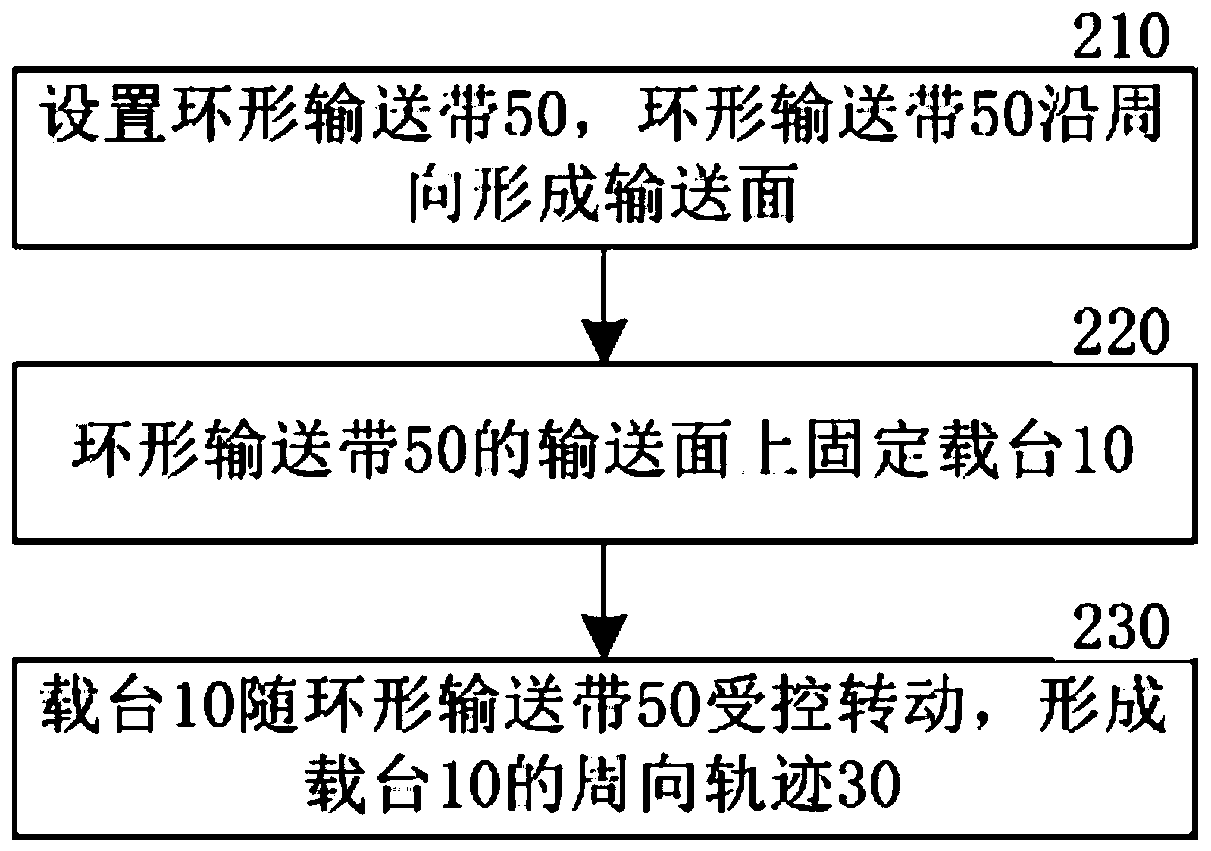

Substrate wet process technological method and substrate wet process technological apparatus

ActiveCN107170667AChange spray directionControl etch rateSolid-state devicesSemiconductor/solid-state device manufacturingEtching rateConveyor belt

The invention discloses a substrate wet process technological method, and aims to solve the technical problem of potential damage in the substrate processing process in the existing wet etching process. The technological method comprises the steps of setting a bearing platform and fixing a substrate through the bearing platform; moving the bearing platform along a circumferential track to convey the substrate; setting processing equipment along the outer side of the circumferential track; and in the substrate conveying process, adjusting the orientation and / or height of the substrate by the bearing platform to be matched with the processing equipment. The moving technological beat of the bearing platform along the circumferential track is controlled by an annular conveyor belt, so that consumed resource, manpower, time and other maintenance cost in replacing a huge number of rolling wheels periodically can be saved; the etching process and cleaning technological method are further improved; the jetting direction of the medicinal liquid and net water flow is changed; etching rate and medicinal liquid take-out amount are controlled effectively; and the cost is lowered while the etching quality can be effectively ensured. The invention also provides a substrate wet process technological apparatus.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Multifunctional pesticide spraying equipment capable of preventing wind

InactiveCN111742911ASpray evenlyLittle wind effectInsect catchers and killersAgricultural engineeringStructural engineering

The invention discloses multifunctional pesticide spraying equipment capable of preventing wind. The multifunctional pesticide spraying equipment capable of preventing wind comprises a pesticide box,wherein a liquid suction pipe is inserted into the top of the pesticide box; a liquid suction pump is arranged on the bottom of the liquid suction pipe; the top of the liquid suction pump is fixedly connected with a middle shaft; the side face of the middle shaft is engaged with an engaging rod; the side face of the engaging rod is in sliding connection with a power wheel; a centrifugal wheel is arranged on the left side of a baffle plate; a centrifugal rod is inserted into the side face of the centrifugal wheel; the top of the centrifugal wheel is fixedly connected with a linkage shaft; the top of the linkage shaft is fixedly connected with a wind measuring fan; the inner wall of the liquid suction pipe is fixedly connected with an air pressure box; and the inside of the air pressure boxis in sliding connection with an air pushing plate. According to the multifunctional pesticide spraying equipment capable of preventing wind, the middle shaft and the linkage shaft are used cooperatively, so that the effects of automatically adjusting pesticide spraying strength according to wind power and reducing the influences, caused by the wind power, on pesticide spraying are achieved when pesticides are sprayed.

Owner:侨远生态农业(广州)有限公司

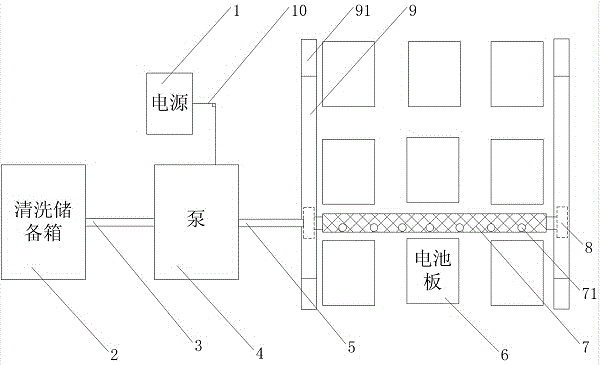

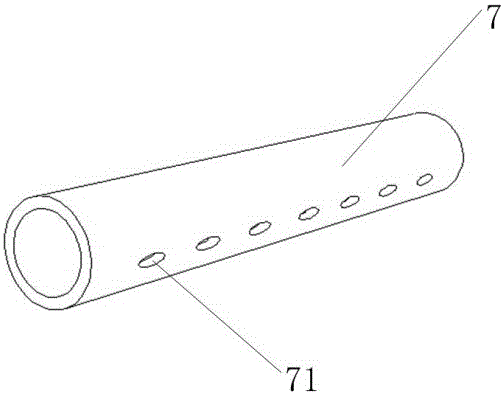

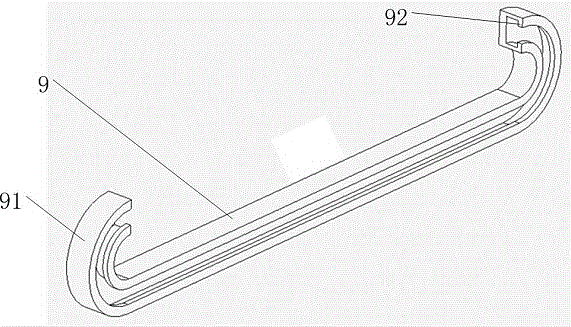

Method for cleaning solar panels

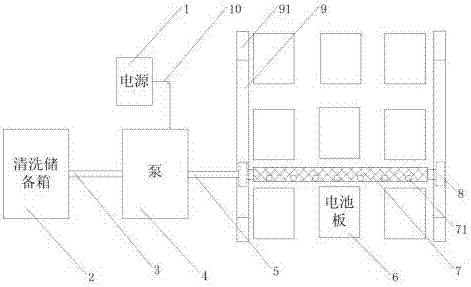

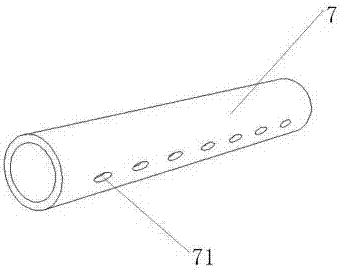

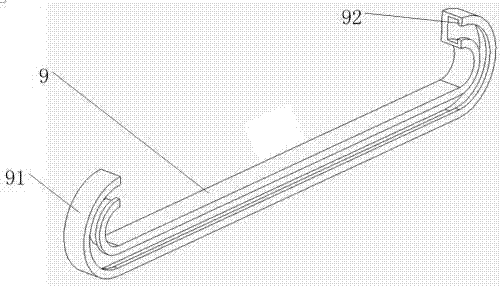

ActiveCN105880244BPrevent agingAchieve large area cleaning effectPhotovoltaicsFlexible article cleaningCells panelSolar power

The invention discloses a cleaning device and a cleaning method for a solar cell panel. The cleaning device comprises a power supply, a pump, a pump tube, a cleaning storage box, a plastic hose, a cleaning barrel and a cleaning rail, wherein the power of the pump is provided by a power supply; a cleaning liquid is held in the cleaning storage box; the pump sucks the cleaning liquid form the cleaning storage box through the pump tube, pressurizes the cleaning liquid, and then conveys the cleaning liquid to the cleaning barrel through the plastic hose; the main body portion of the cleaning barrel is a holed hollow structure, one end of the main body portion is connected with the pump through the plastic hose, the other end of the main body portion is closed, and the outer surface of the main body portion is a detachable brush sleeve; the high-pressure cleaning liquid is ejected from the hole of the cleaning barrel to clean the surface of the cell panel, meanwhile, the reaction of ejecting for the cleaning liquid pushes the cleaning barrel to move along a cleaning rail. The device is capable of automatically cleaning the surface of the solar cell panel, avoiding use of a complex rail transmission mechanism, increasing the power generation efficiency of a solar power station, saving labour, improving cleaning effect, and obviously reducing operation cost.

Owner:PINGYI JINGFA TECH SERVICE CO LTD

Micro turbojet atomizing device for ground

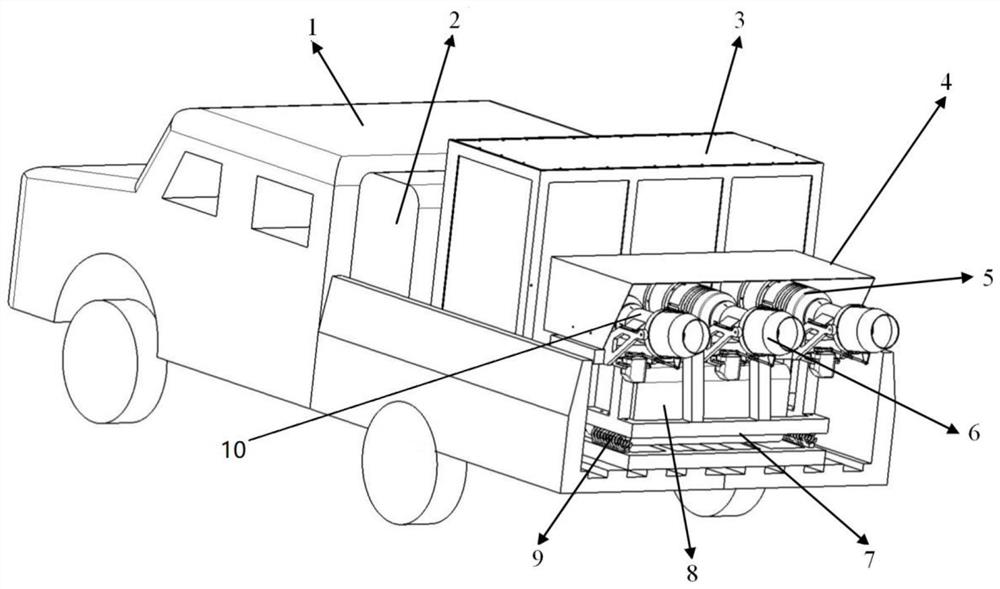

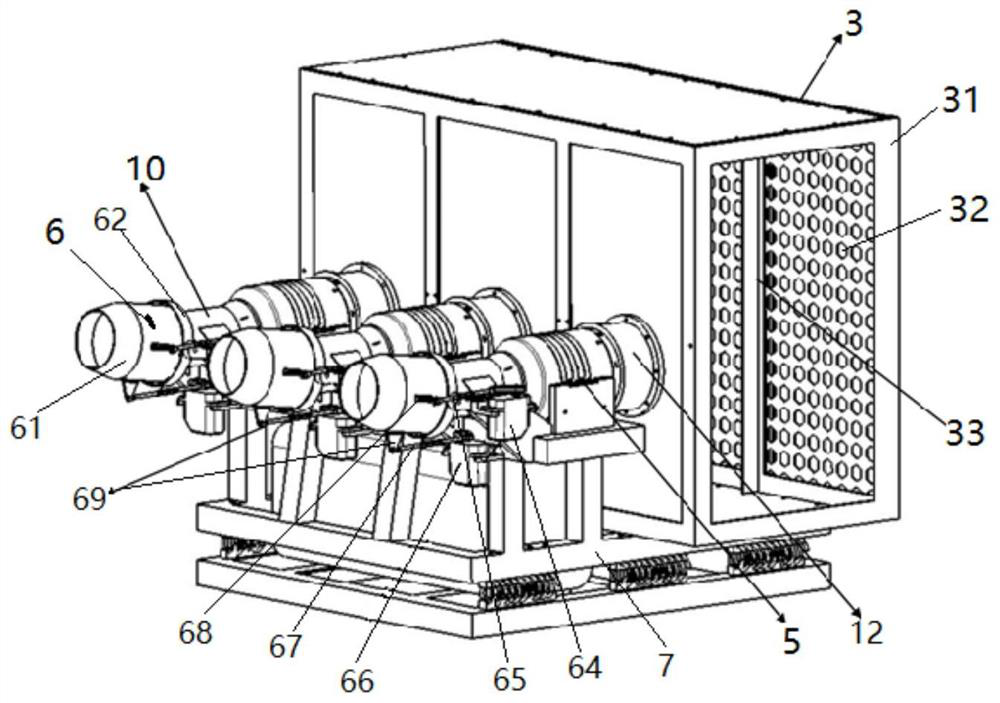

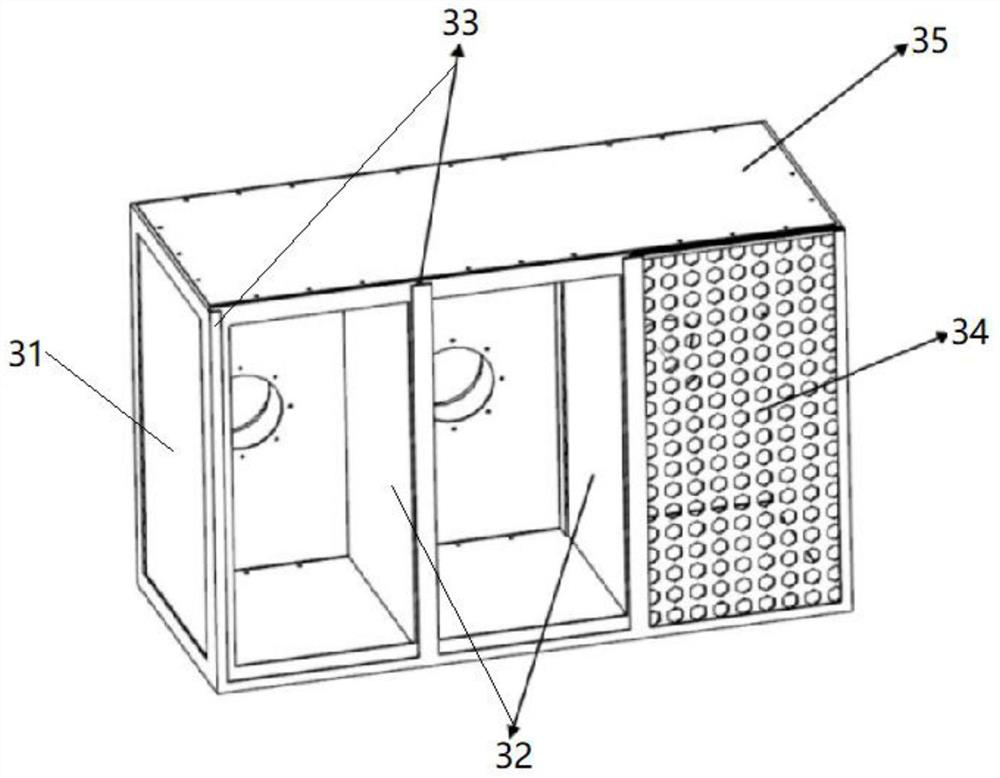

PendingCN113882950ASolve the problem of combined fog makingImprove efficiencyGas turbine plantsTurbine/propulsion air intakesEngineeringTurbojet engine

The invention relates to a micro turbojet atomizing device for ground. The device comprises an atomizing agent box and at least two micro turbojet engines, and the air inlet ends of the micro turbojet engines are communicated with an air inlet dustproof device through air inlet adapter pipes. An atomizing agent spraying pipe, an atomizing agent mixing cavity and a vector spraying pipe are sequentially arranged at the outlet end of a tail spraying pipe of each micro turbojet engine, high-temperature and high-pressure gas of the tail spraying pipes of the micro turbojet engines is sprayed into the atomizing agent mixing cavities, the temperature in the atomizing agent mixing cavities is increased, and high-temperature and high-pressure spraying flow is formed in the atomizing agent mixing cavities. An atomizing agent in the atomizing agent box enters the atomizing agent spraying pipes through a pump and a guide pipe, the atomizing agent spraying pipes spray the atomizing agent into the atomizing agent mixing cavities, the atomizing agent is heated in the atomizing agent mixing cavities to form mist, and then the mist is sprayed out of the vector spraying pipe at different spraying angles through the spraying flow. According to the device, the problem of combined atomization of multiple micro turbojet engines is solved for the first time, and the combined atomization of multiple micro turbojet engines can be carried out, so that the atomization efficiency is greatly improved.

Owner:西安觉天动力科技有限责任公司

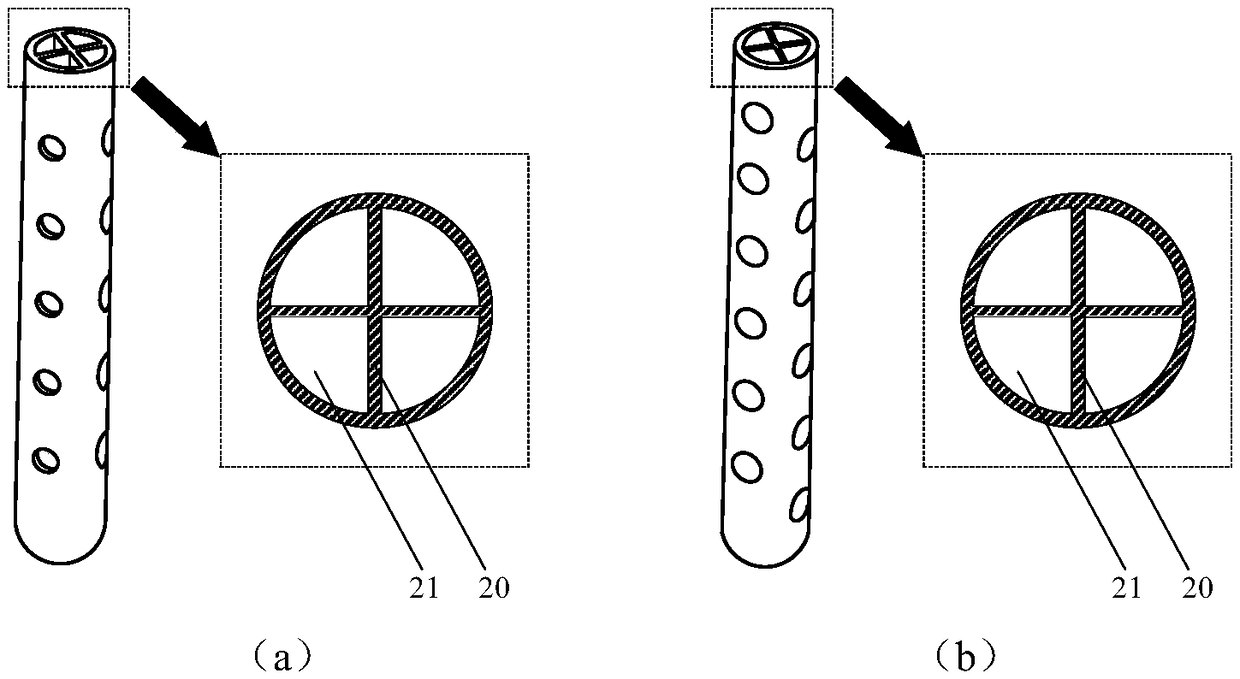

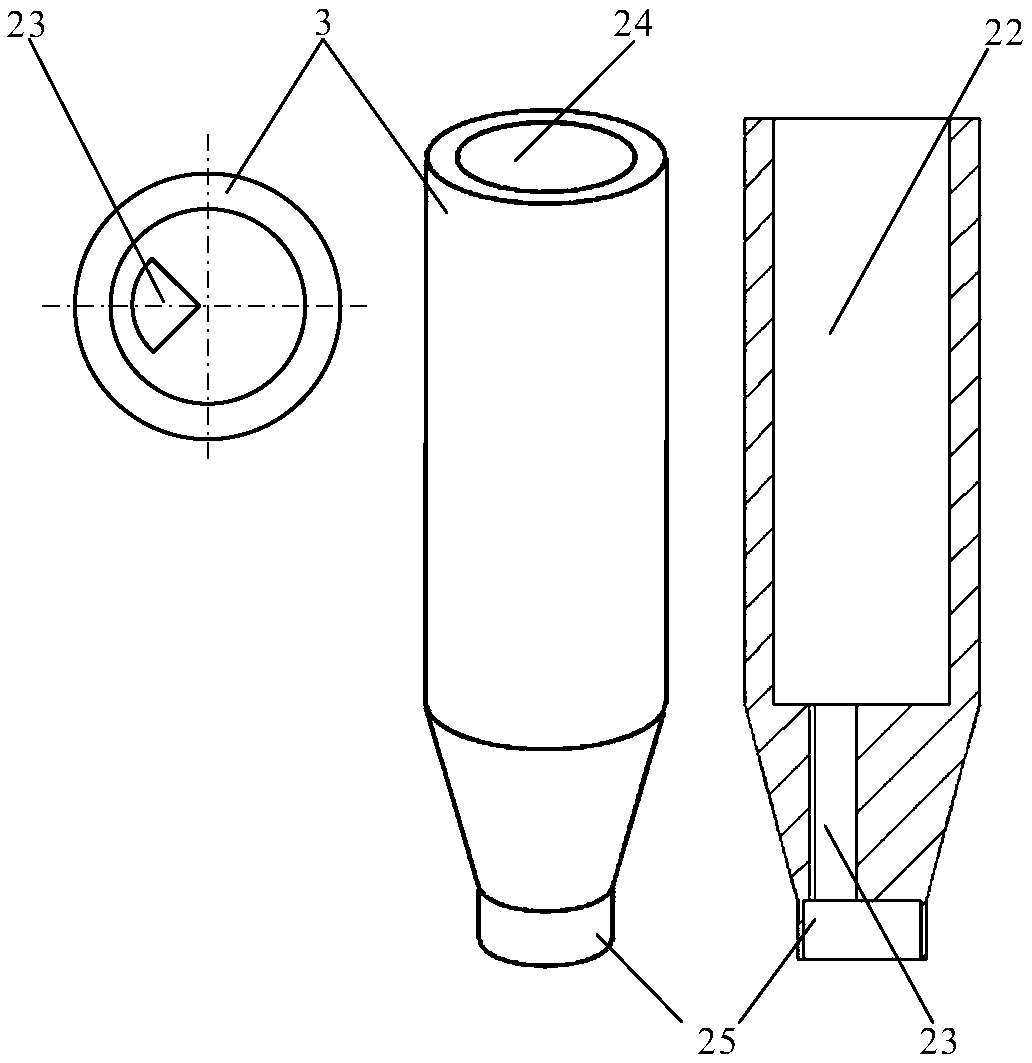

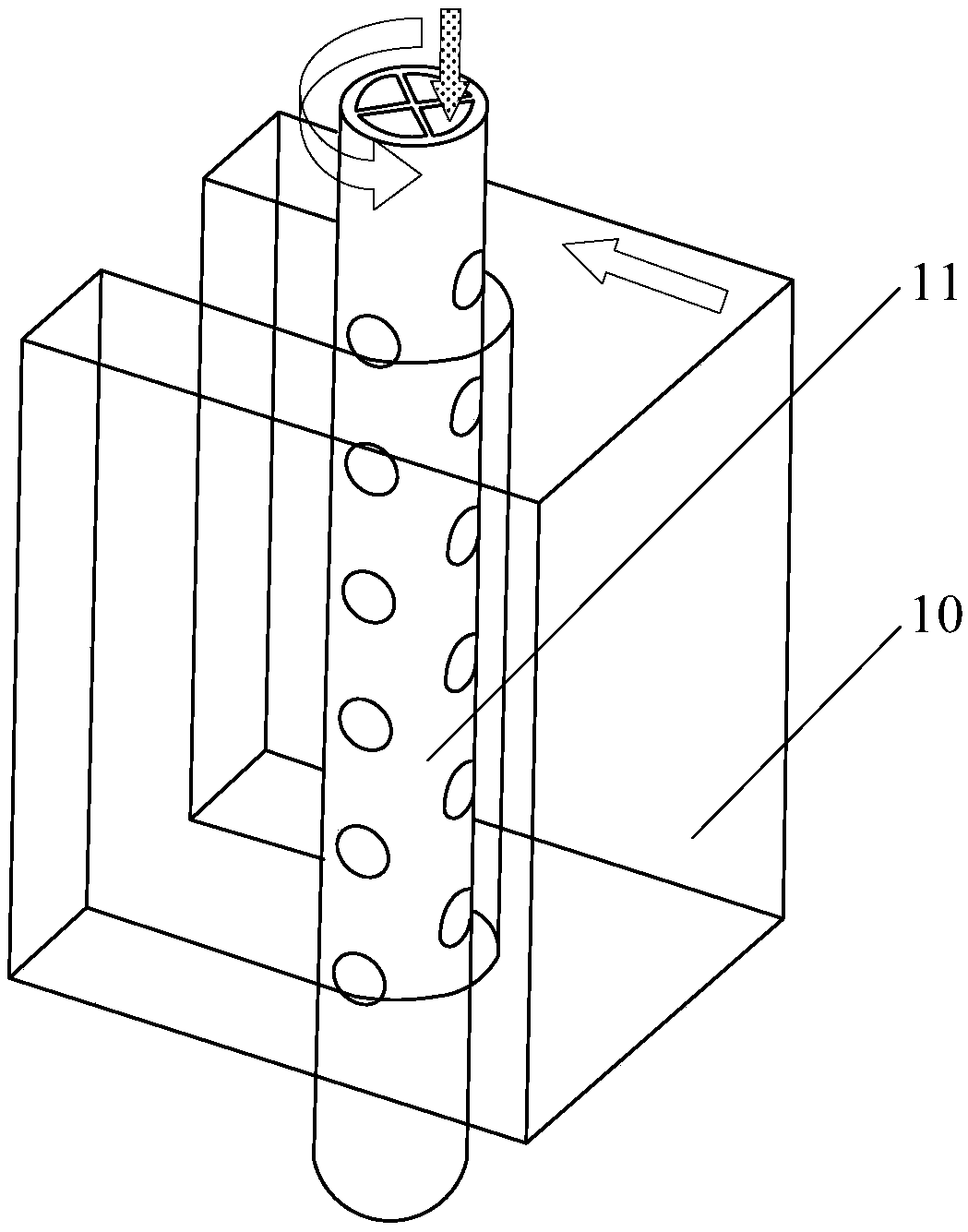

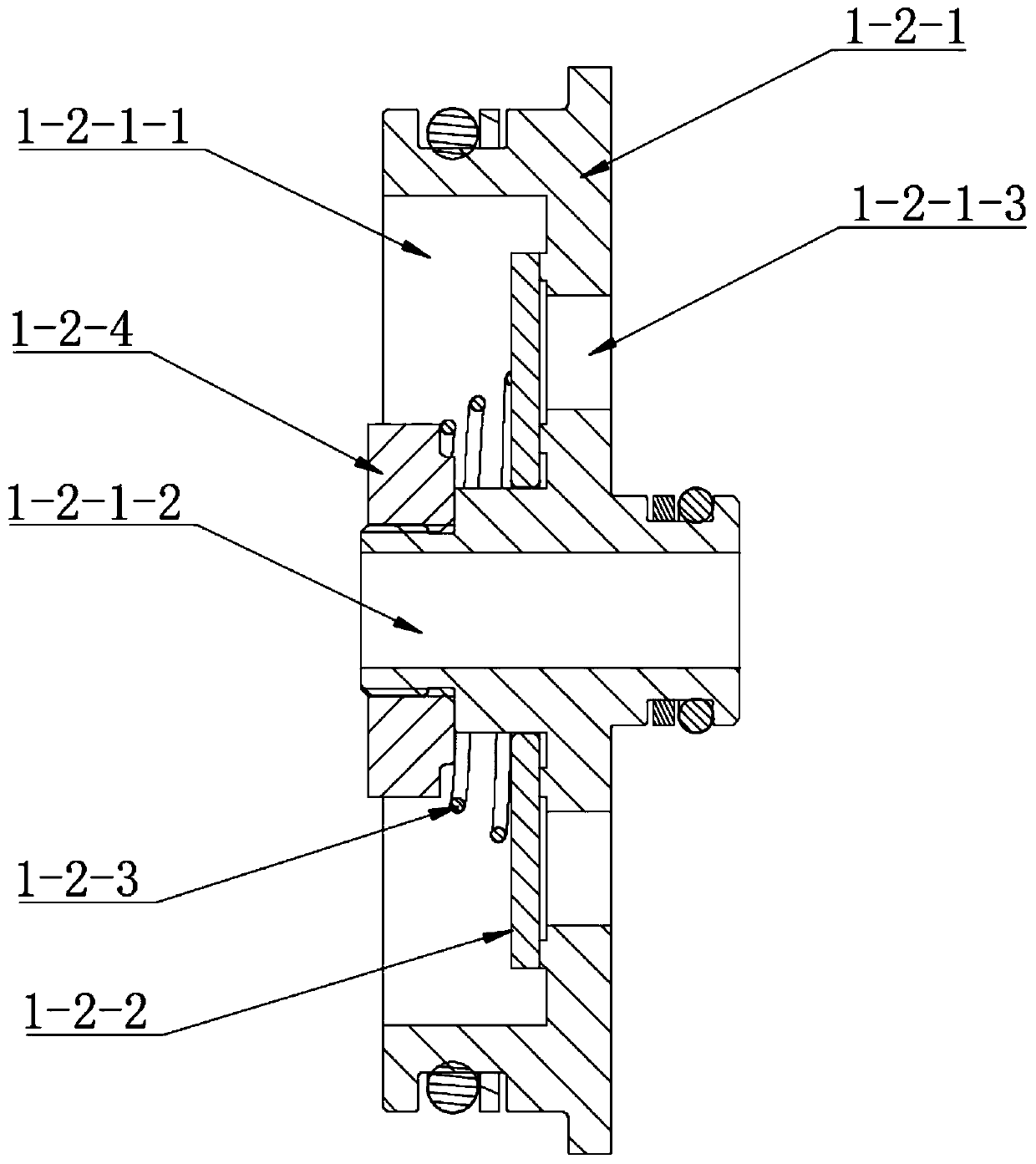

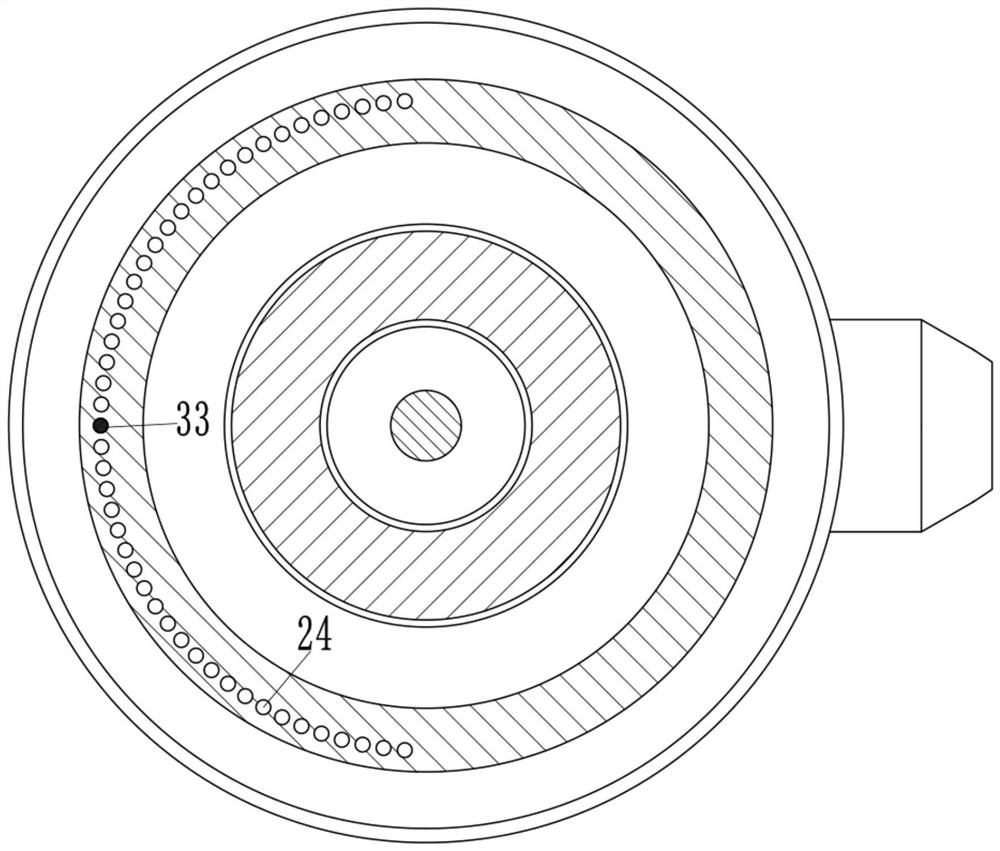

Multi-runner pipe electrode and system and single circulation electrolysis cutting method

ActiveCN108746893ARealize the switch to electrolytic cuttingEasy dischargeMachining electrodesMachining working media supply/regenerationElectricityElectrolysis

The invention relates to a multi-runner pipe electrode and a system and a single circulation electrolysis cutting method, and belongs to the technical field of electrochemical machining. A multi-runner metal circular pipe with one end closed is selected as a tool cathode during electrolysis cutting; and corresponding to various runners, the outer wall faces of the multi-runner pipe electrode are provided with small hole arrays correspondingly, and the small hole arrays corresponding to the adjacent runners are different. During electrolysis cutting, the multi-runner pipe electrode does the rotation movement, under the action of a distribution adapter, an electrolyte only enters from one runner at the multi-runner pipe electrode feeding face position and is ejected from the corresponding small hole arrays, and a workpiece is subjected to electrolysis cutting. Since the small hole arrays corresponding to the adjacent runners are different, along with rotation of the multi-runner pipe electrode (11), a flow field in a machining gap does the up-down reciprocated motion, the flow field is more uniform, and electrolysis products are easier to discharge. Various runners (21) are sequentially switched to be used, the electrolyte (15) in the machining gap is in a pulsating flow state, and the electrolysis cutting efficiency and machining precision are further improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

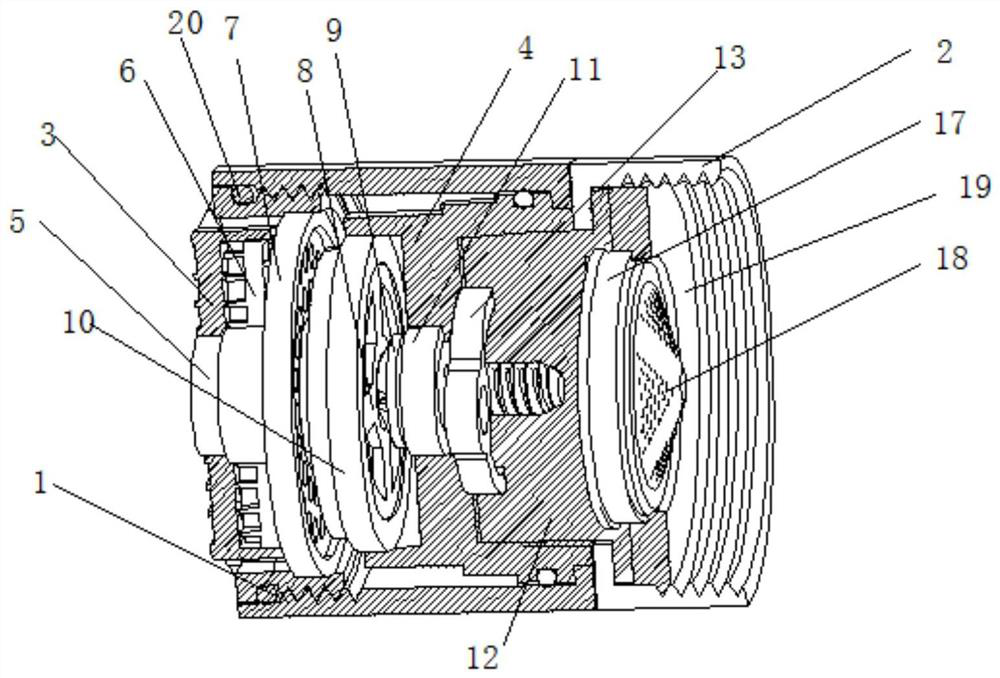

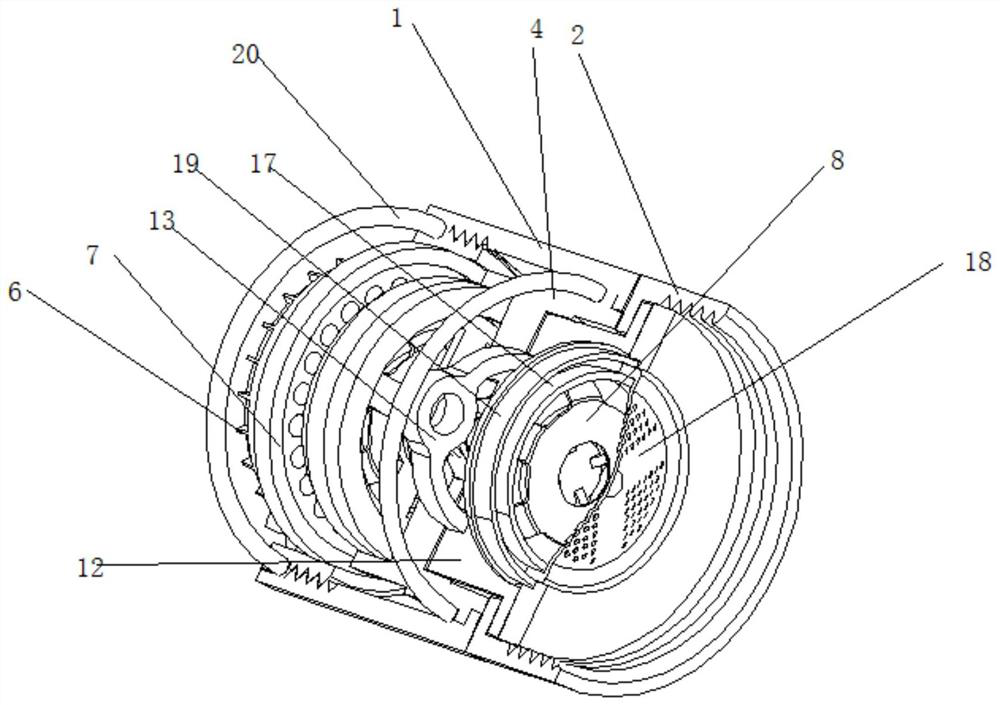

Spray type multifunctional water outlet device

The invention relates to the technical field of bubblers, in particular to a spray type multifunctional water outlet device. The device comprises a front spraying shell, the rear portion of the frontspraying shell is rotationally connected with a rear spraying shell, the inner wall of the front spraying shell is in threaded connection with a spraying base, a fixed column table is welded to the inner wall of the front spraying shell, and a rotary table is rotationally connected to the inner wall of the spraying base; and a large water dividing base is clamped to the inner wall of the rotary table, a screw is welded to the rear portion of the large water dividing base, the surface of the screw is sleeved with a connecting column, a fixing base is welded to the surface of the screw, and a valve disc is clamped into the fixing base. According to the spray type multifunctional water outlet device, the front spraying shell is twisted, the fixed column table welded to the inner wall of the front spraying shell and the spraying base in threaded connection with the inner wall of the front spraying shell are driven to rotate synchronously, and the spraying base makes sliding contact with the rotary table, a flow dividing net and a flow dividing disc in the rotating process and is subjected to certain position change, so that the effect of changing the water flow spraying direction is achieved through rotation of the spraying base.

Owner:开平市玛格纳卫浴有限公司

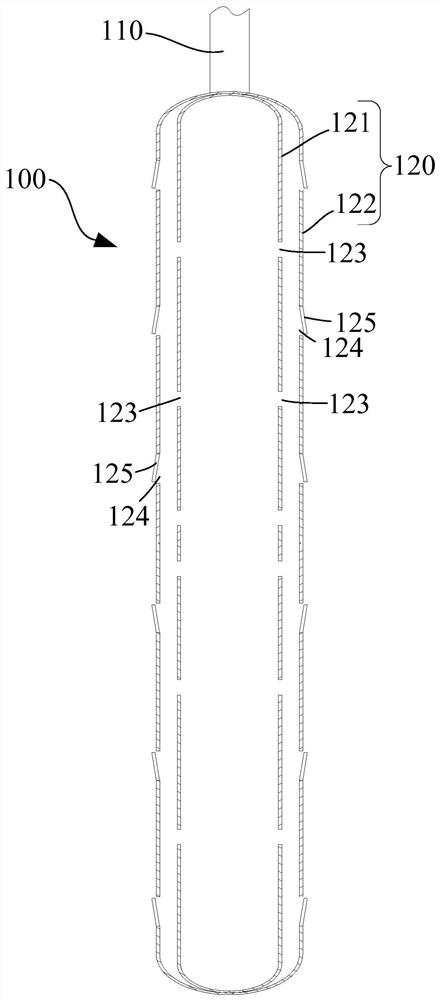

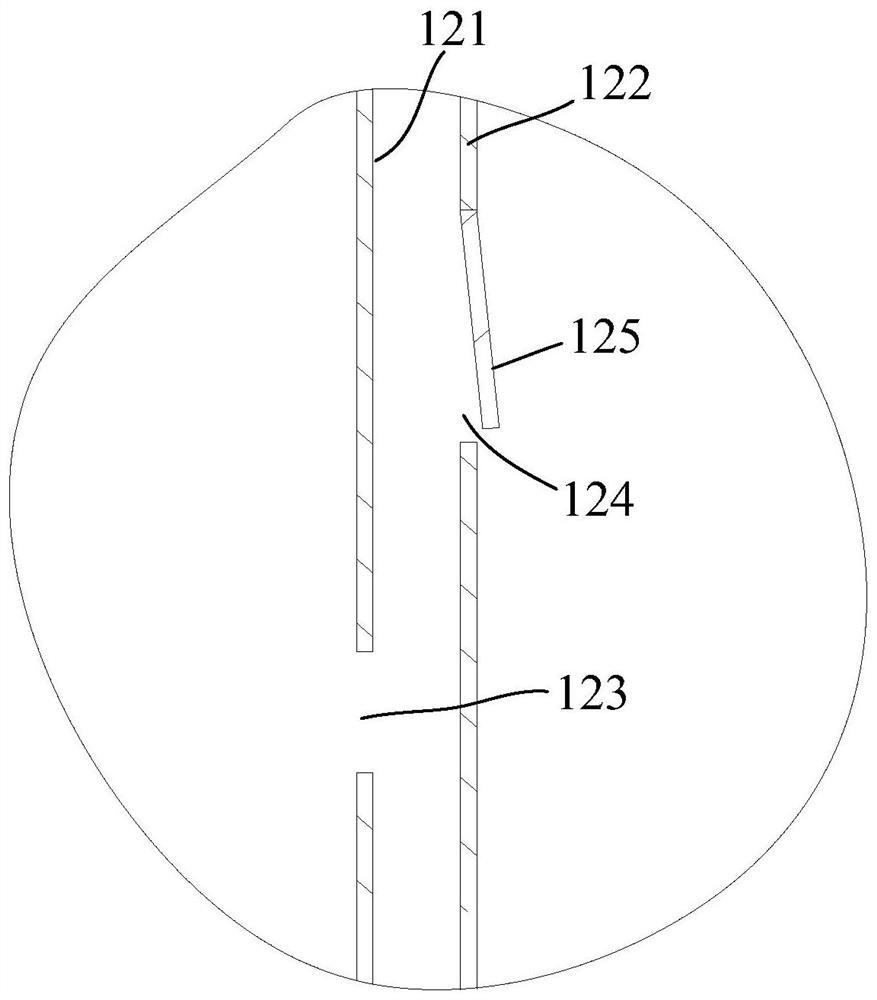

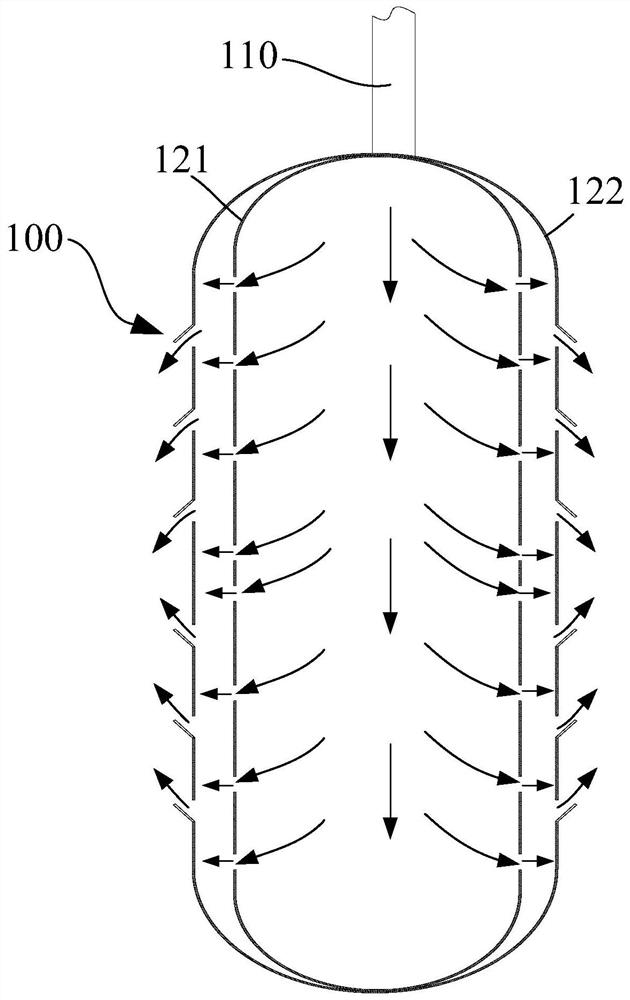

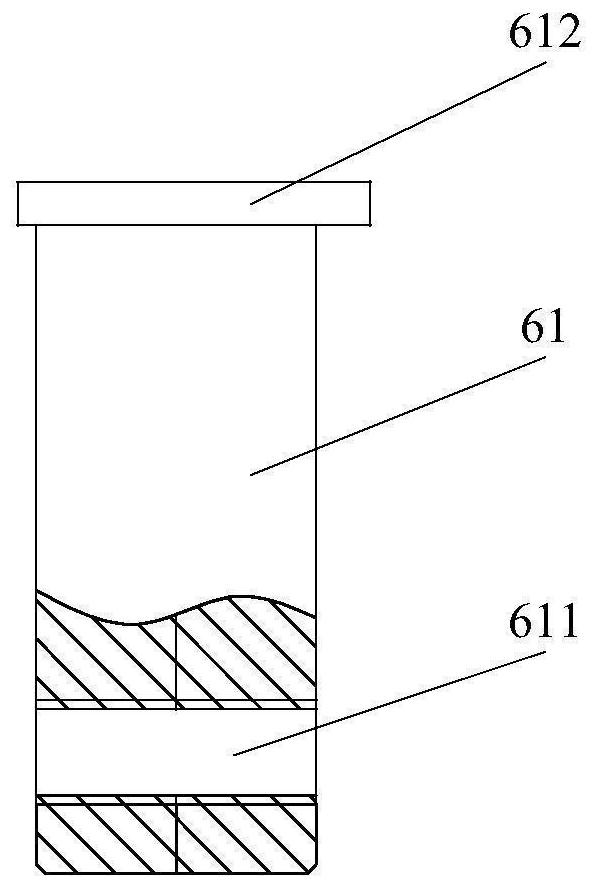

Balloon catheter and preparation method thereof

PendingCN113521505AReduce jet velocityChange spray directionBalloon catheterMedical devicesBlood vessel spasmBalloon dilations

The invention relates to a balloon catheter and a preparation method thereof. The balloon catheter comprises a catheter body and a balloon, the catheter body is sleeved with the balloon, the balloon comprises at least one first balloon, a plurality of first micropores are formed in the first balloon, and retaining walls are arranged at the first micropores; after the balloon is expanded, the retaining walls incline towards the corresponding first micropores so as to at least partially cover the first micropores, liquid medicine channels are reserved between the retaining walls and the first micropores, and the extending direction of the liquid medicine channels is not perpendicular to the longitudinal axis of the balloon catheter. The retaining walls are used for buffering liquid medicine, the spraying speed of the liquid medicine is reduced, the spraying direction of the liquid medicine is changed, and thus the stimulation effect of the liquid medicine on blood vessels is reduced, and vasospasm is reduced.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

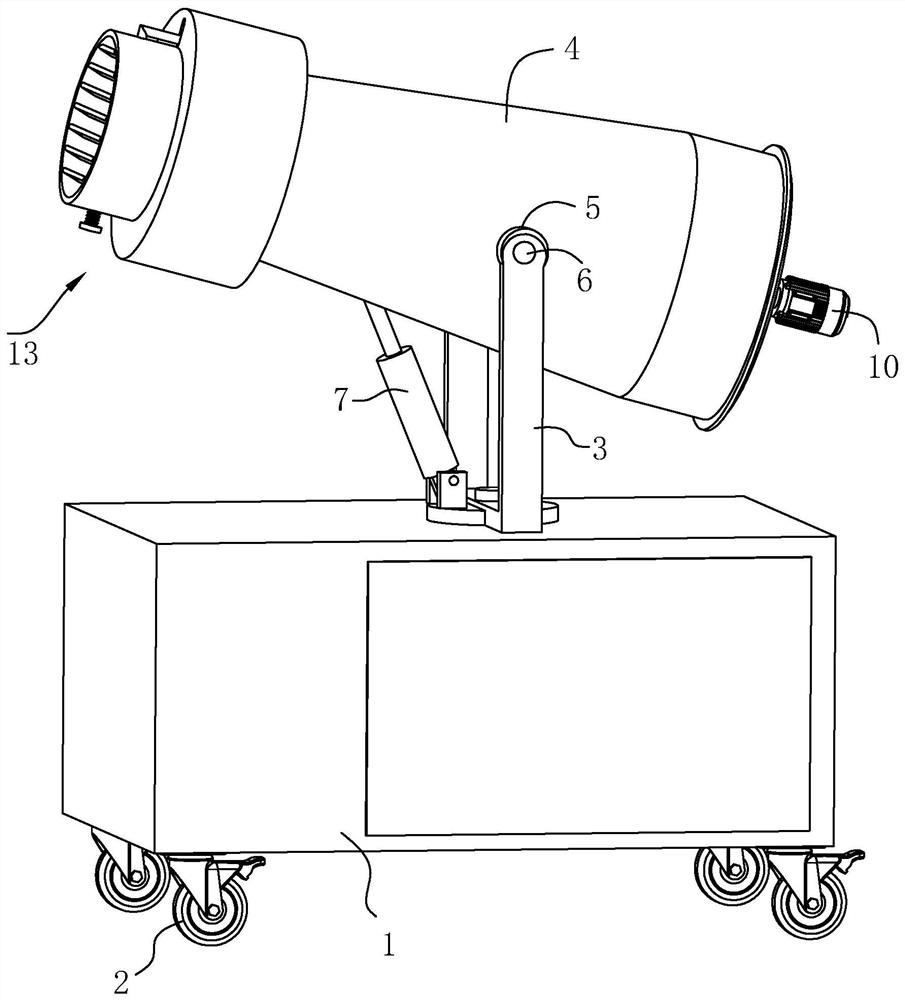

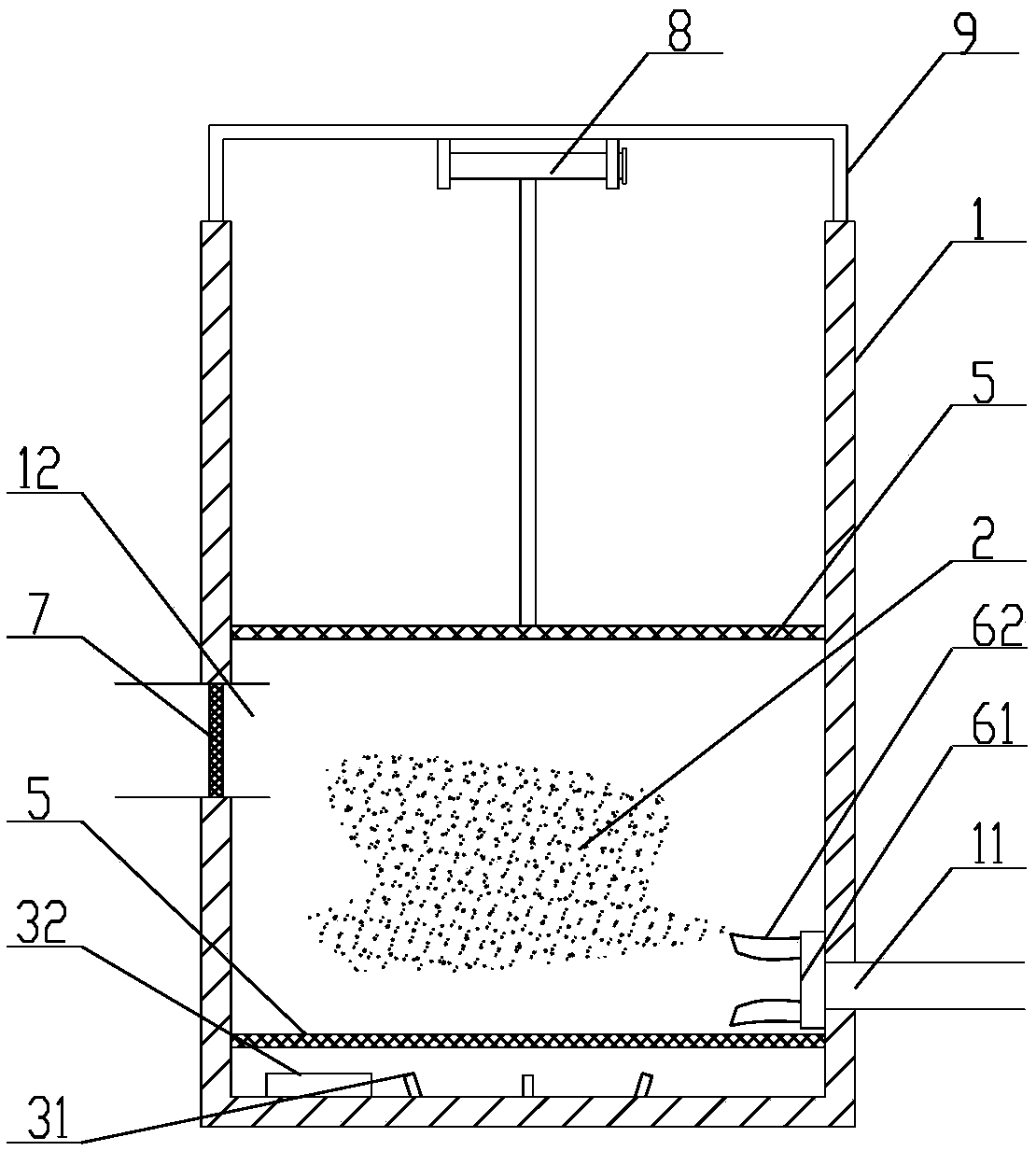

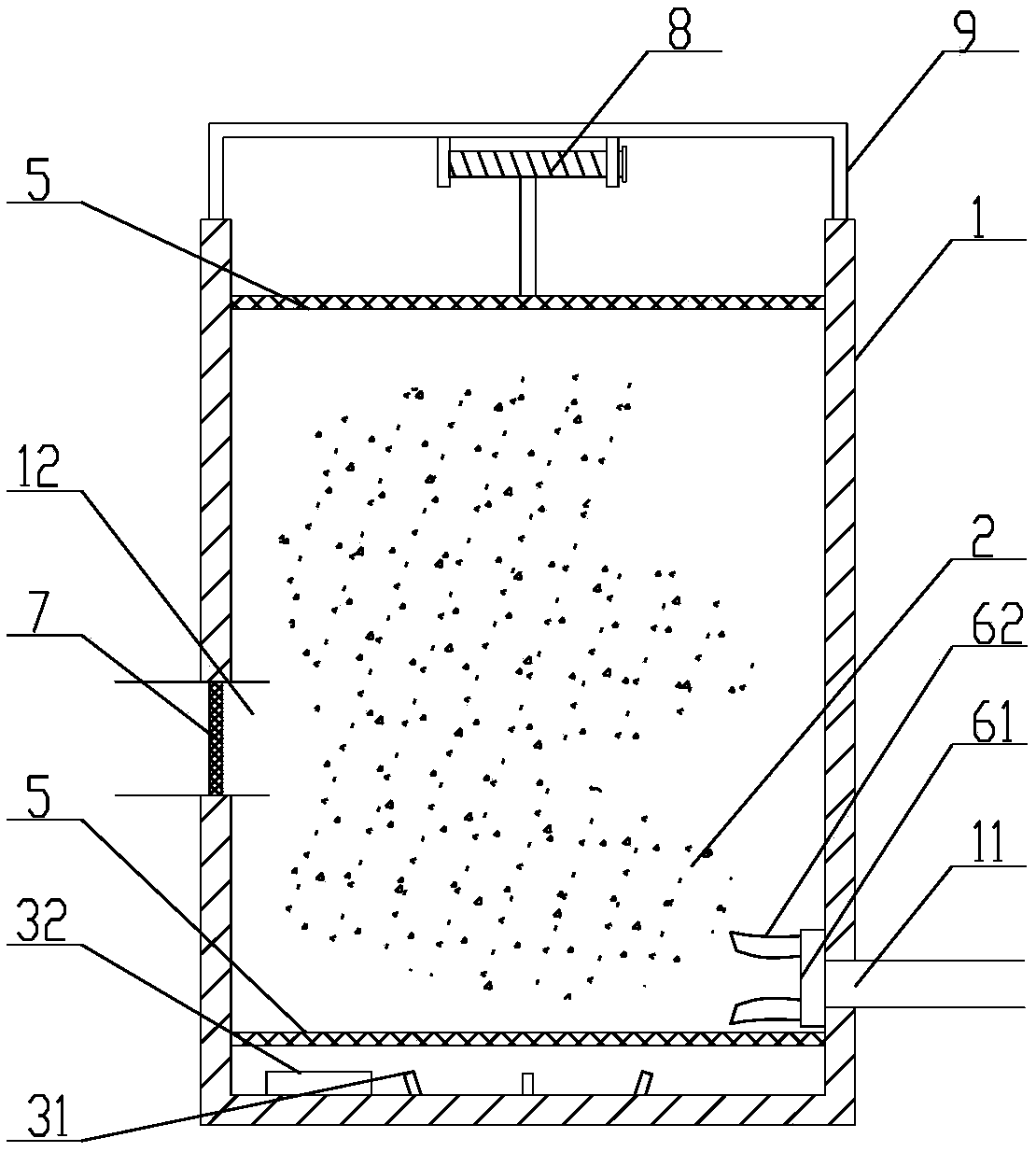

Dust falling system for cast-in-place integral reinforced concrete construction

PendingCN111749184AExpand the spraying rangeWide range of sprayingUsing liquid separation agentRoad cleaningReinforced concreteRebar

The invention discloses a dust falling system for cast-in-place integral reinforced concrete construction. According to the key points of the technical scheme, the dust falling system comprises a bottom support and a spraying device arranged on the bottom support; the spraying device comprises a hollow spraying cylinder; the spraying cylinder comprises an air inlet and a spraying opening; a mist reversing cylinder is arranged at the spraying opening of the spraying cylinder; one end of a mist reversing cylinder is rotatably connected with the spraying cylinder; a driving device used for driving the mist reversing cylinder to rotate is arranged on the spraying cylinder; a shutter is arranged at the end, away from the spraying cylinder, of the mist reversing cylinder; and a linkage mechanismused for driving the shutter to swing is arranged on the mist reversing cylinder. According to the technology, in the spraying process, the shutter swings and rotates along with the mist reversing cylinder, so that the spraying direction of mist is changed, the spraying range of the mist is enlarged by continuously changing the spraying direction of the mist, and the spraying range is wider.

Owner:SHENZHEN DONGSHEN ENG CO LTD

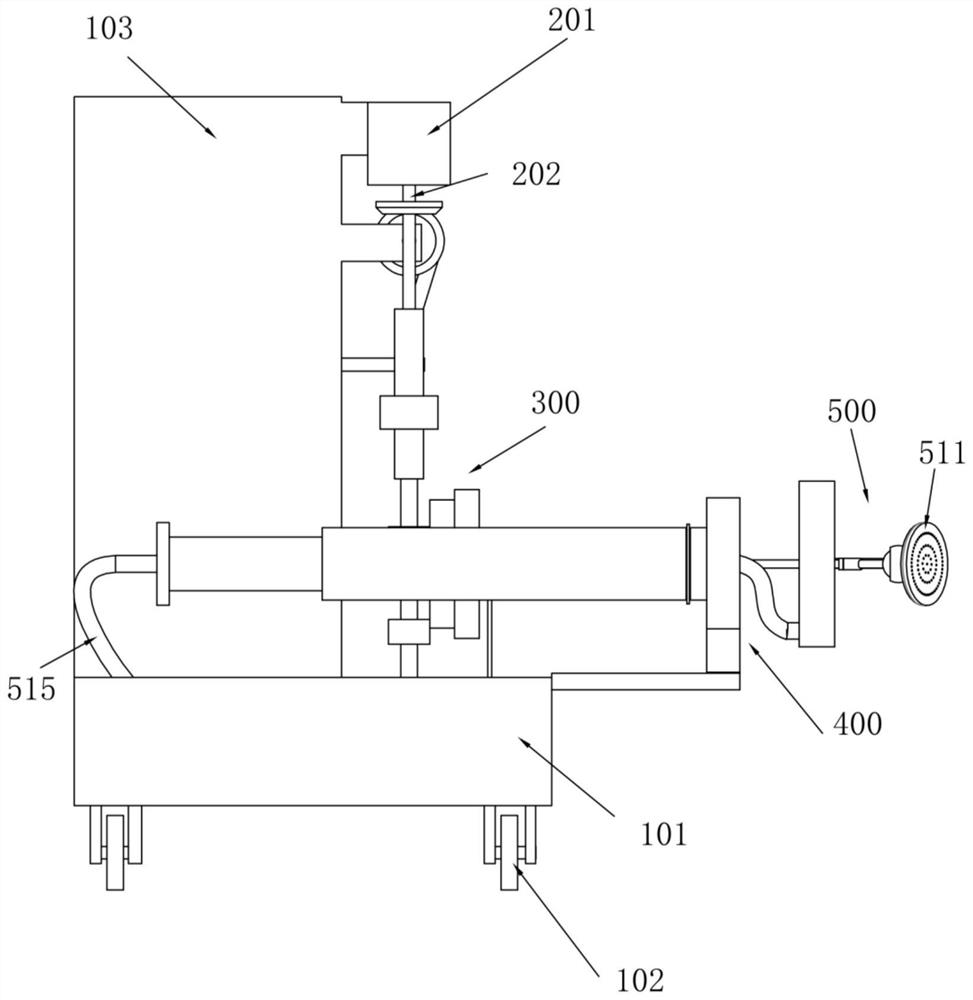

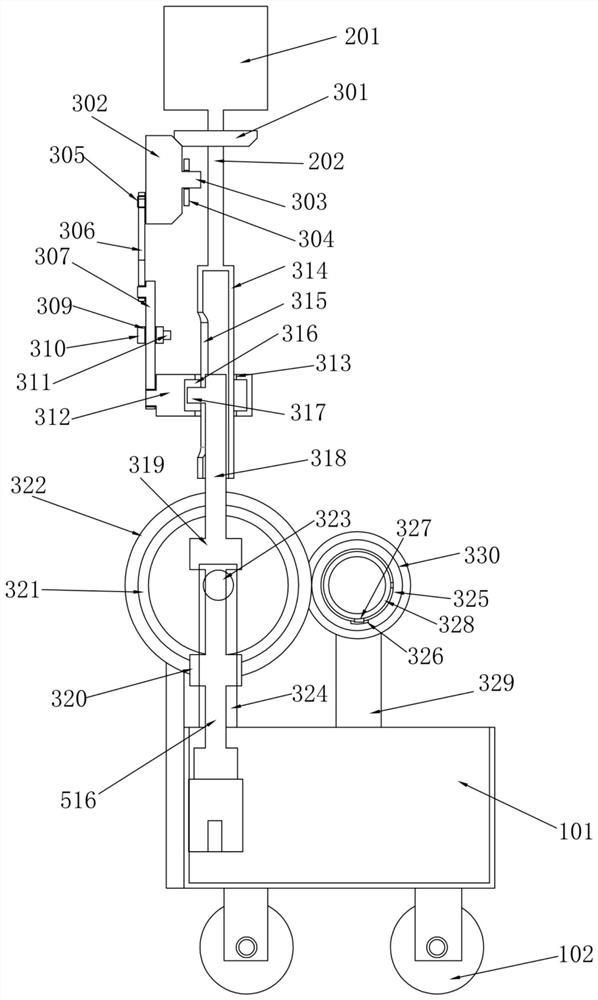

Medical spraying device

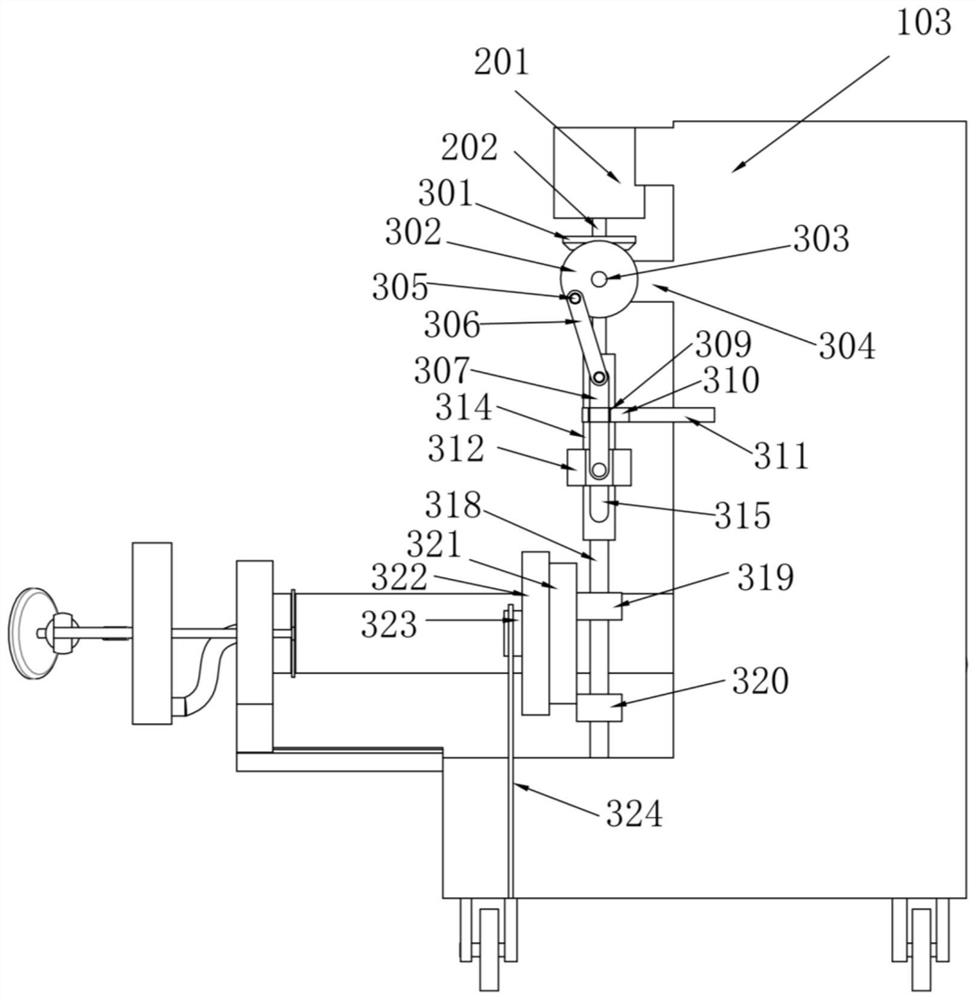

InactiveCN113069581AChange spray directionExpand the spraying areaMovable spraying apparatusLavatory sanitoryElectric machineryEngineering

The invention discloses a medical spraying device. The medical spraying device comprises a water tank (101), a water pump (513), a telescopic mechanism (300) and a rotating mechanism (400); the water pump (513) is driven by a motor (201), so that liquid in the water tank (101) is sprayed through a nozzle; the telescopic mechanism (300) is driven by the motor (201), so that left-right movement of the nozzle (511) is achieved; the rotating mechanism (400) is driven by the motor (201), rotation of the nozzle (511) is achieved, and the spraying direction is changed; and therefore, left-right movement, rotation and spraying orientation of the nozzle (511) are synchronously achieved, the spraying range is larger, the atomization effect is more obvious, spraying is more uniform, and the better disinfection and sterilization effect is achieved.

Owner:江善华

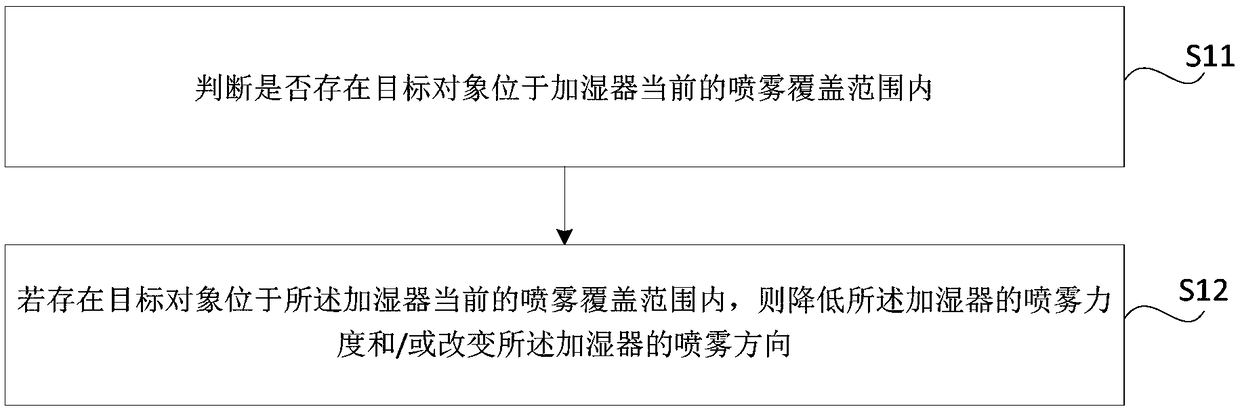

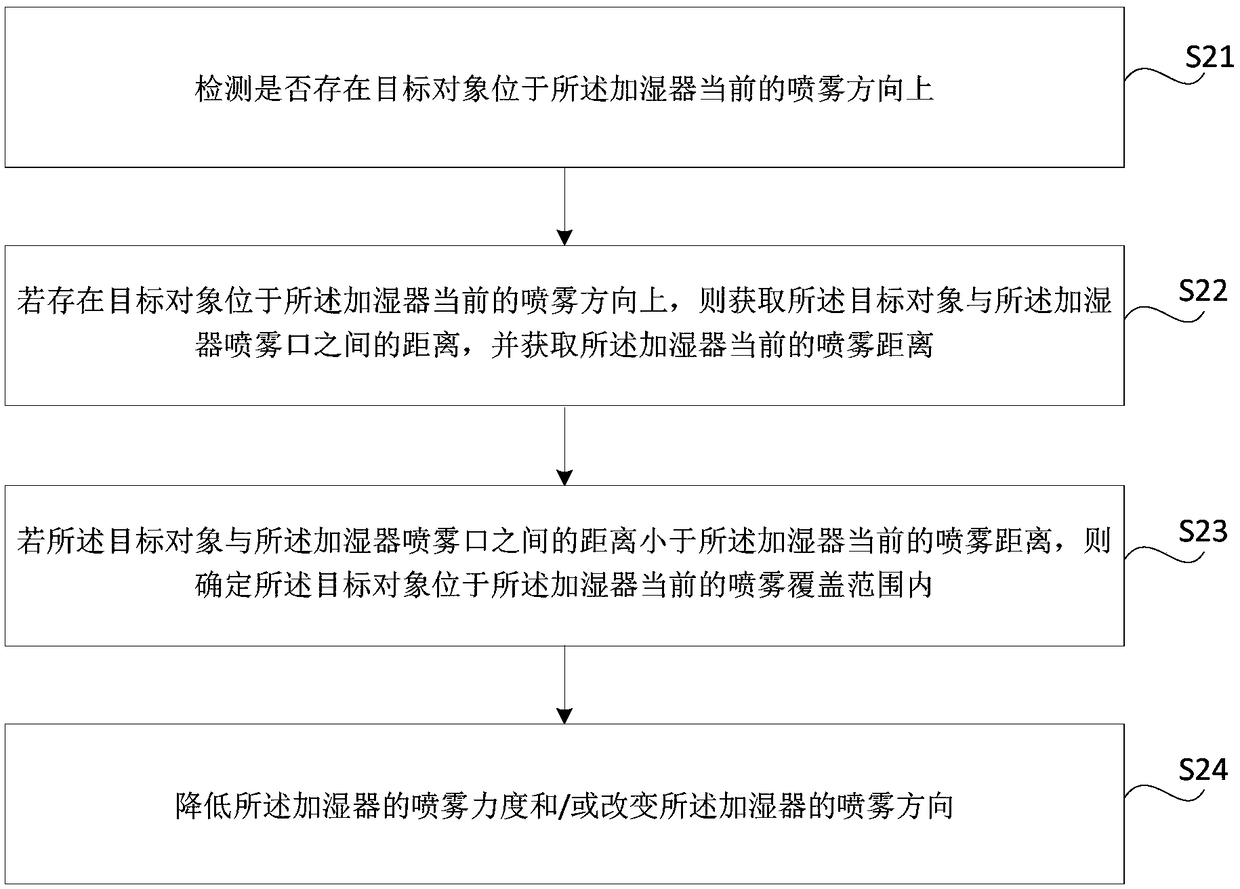

Method and device for controlling humidifier as well as storage medium

PendingCN108870675AReduce spray intensityChange spray directionMechanical apparatusEfficient regulation technologiesComputer scienceHumidifiers

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

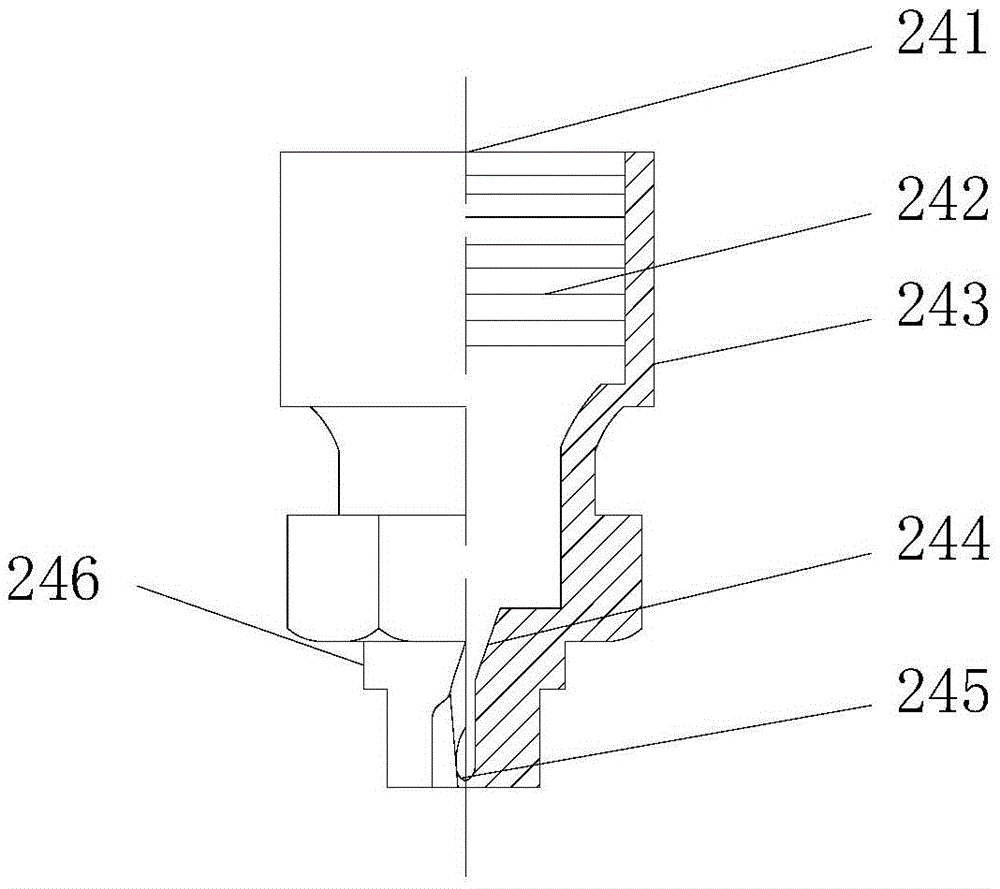

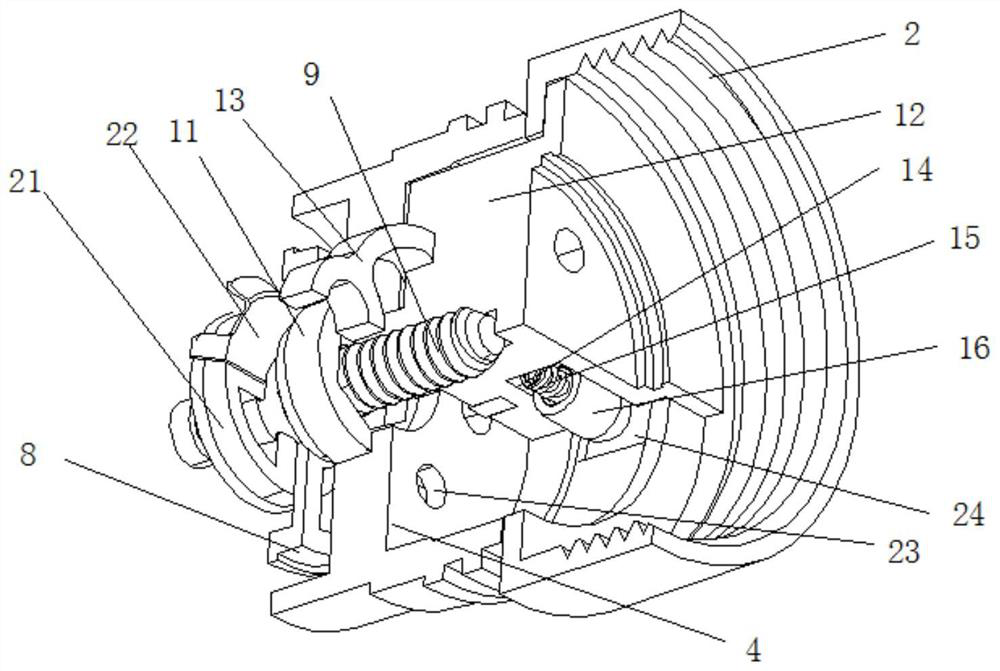

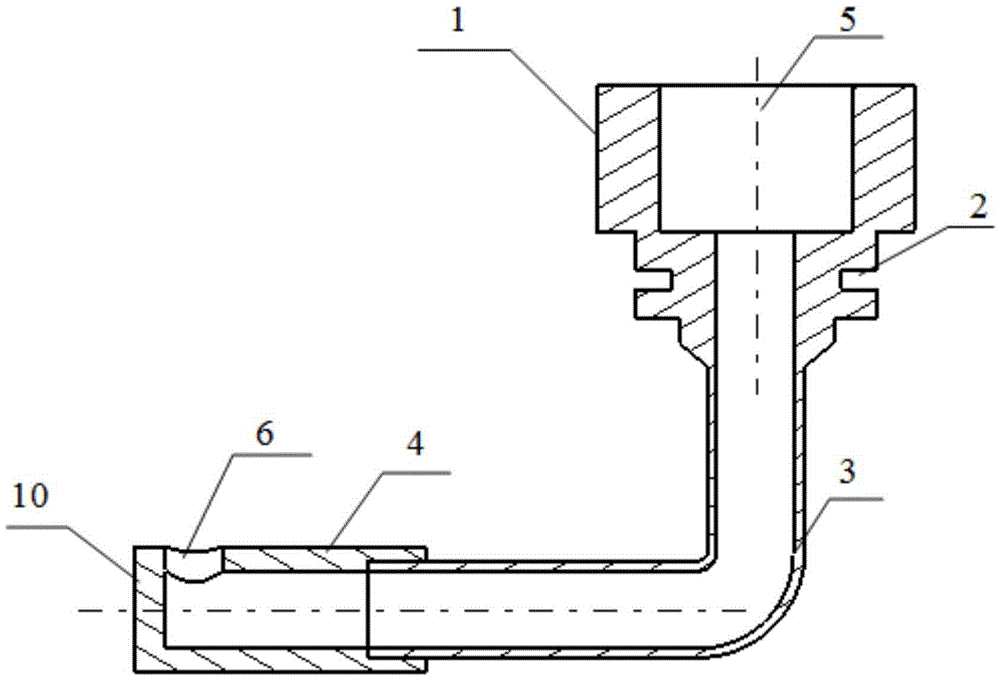

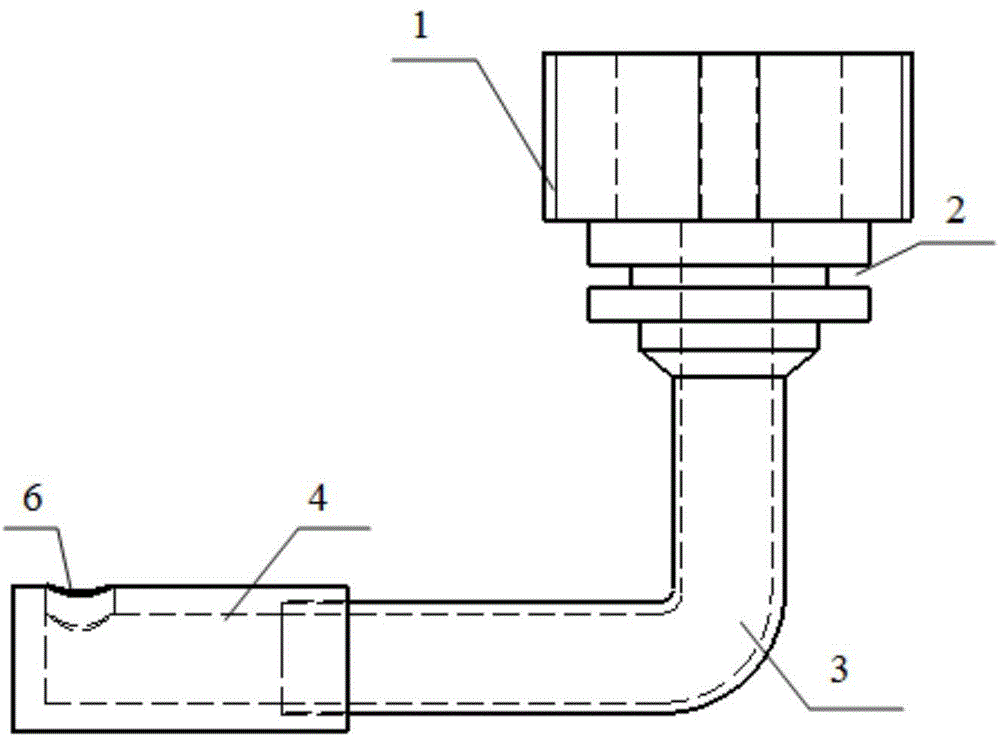

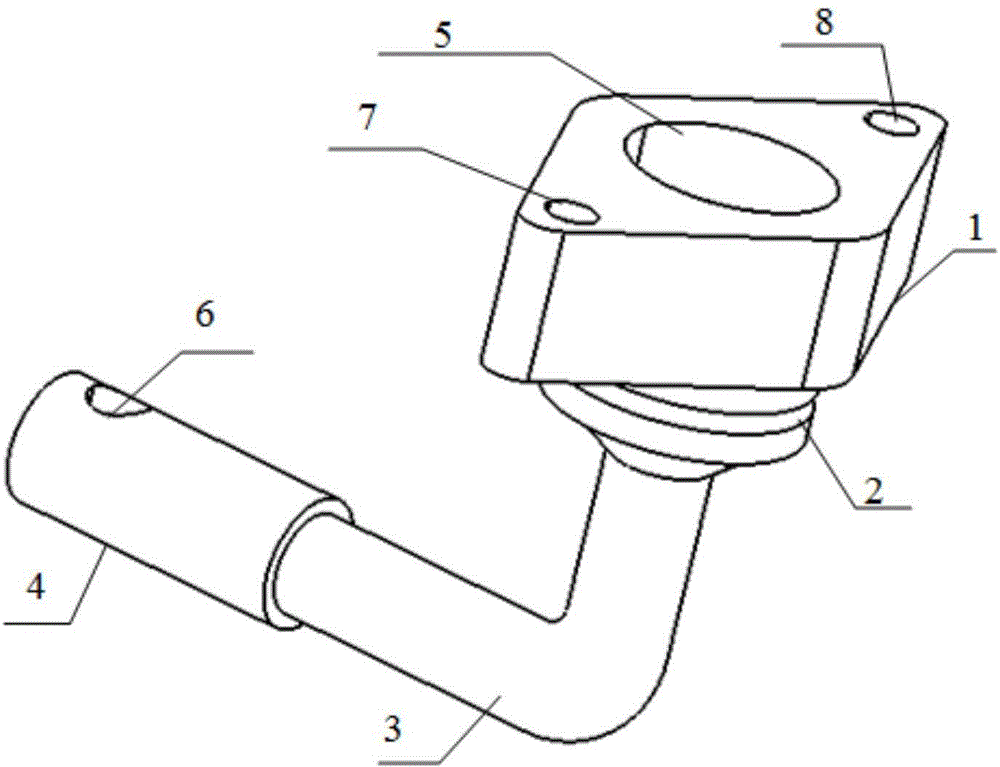

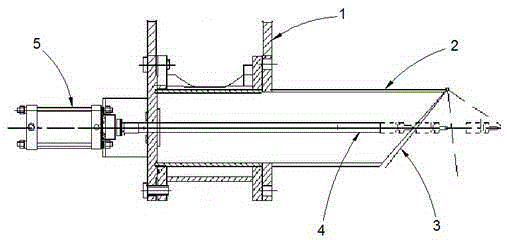

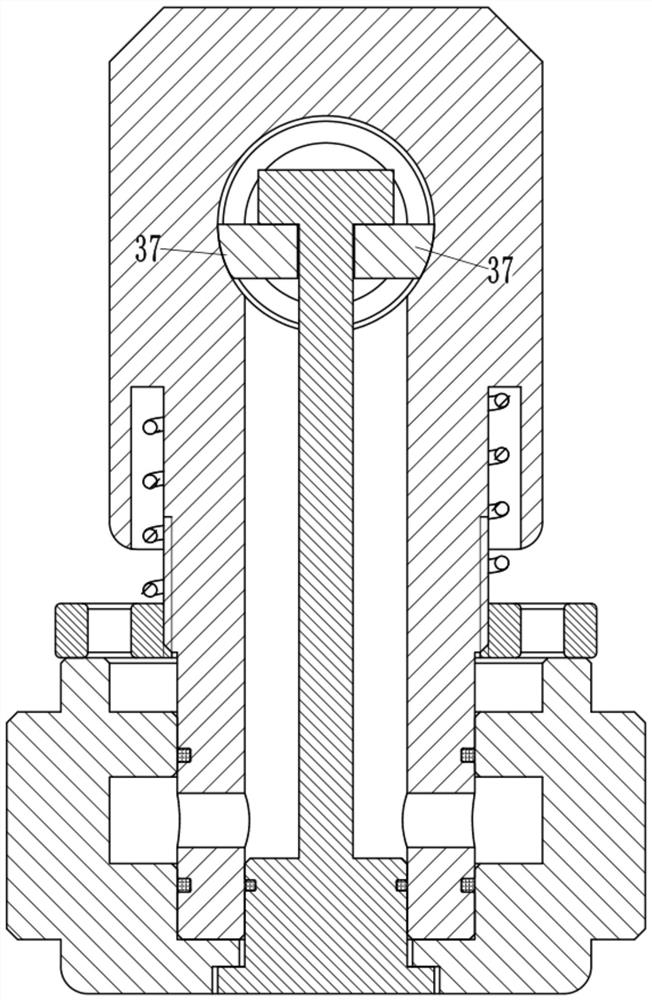

Direction-changing spray pipe for air inlet passage multi-point injection of dual-fuel engine

ActiveCN104696101AChange spray directionSimple structureJet propulsion plantsSpray nozzleInjection device

The invention discloses a direction-changing spray pipe for air inlet passage multi-point injection of a dual-fuel engine and aims to overcome the defect that the natural gas injection direction of a conventional dual-fuel engine is non-changeable in the vertical direction of an axis of an air passage. The direction-changing spray pipe consists of a natural gas spray pipe seat (1), a sealing seat (2), a flow guide pipe (3) and a spray nozzle (4), wherein the bottom end surface of the natural gas spray pipe seat (1) is connected with the top end surface of the sealing seat (2) by adopting a welding mode; the bottom end surface of the sealing seat (2) is connected with the inlet end surface of the flow guide pipe (3) adopting a welding mode; the flow guide pipe outlet end of the flow guide pipe (3) is in threaded connection with a spray pipe inlet (9) of the spray nozzle (4). An injection device inlet (5) in the natural gas spray pipe seat (1) and a rotation axis of a central through hole in the sealing seat (2) are collinear; the central through hole in the sealing seat (2) and a rotation axis on the internal diameter at the inlet end of the flow guide pipe (3) are collinear; the flow guide pipe outlet end of the flow guide pipe (3) and a rotation axis of a spray pipe inlet (9) of the spray nozzle (4) are collinear.

Owner:JILIN UNIV

Whole body disinfection device for pediatric operating room

InactiveCN110538337BSpray evenlyTo achieve the purpose of comprehensive disinfectionLavatory sanitoryChemicalsWhole bodyOperating theatres

The invention discloses a whole-body disinfection device for pediatric operating room, comprising: a limit frame, a rotating shaft is movable installed inside the limit frame, and a movable frame is fixedly installed on the outer surface of the rotating shaft, and the outer surface of the rotating shaft is fixedly installed with limited Position rod, the lower surface of the limit frame is fixedly installed with a fixed frame, the interior of the fixed frame is fixedly connected with a corrugated column, the interior of the corrugated column is interspersed with a fixed rod, the upper surface of the limit frame is fixedly connected with a fixed frame, fixed A connecting rod is movably installed in the middle part of the frame, and an end of the connecting rod close to the movable frame is hinged with a movable shaft. The whole-body disinfection device for pediatric operating rooms can effectively spray disinfectant on the body of medical staff from top to bottom through the joint use of connecting strips, nozzles and connecting rods, ensuring that the outer surface of medical staff is sprayed evenly to achieve all-round purpose of disinfection.

Owner:JILIN UNIV

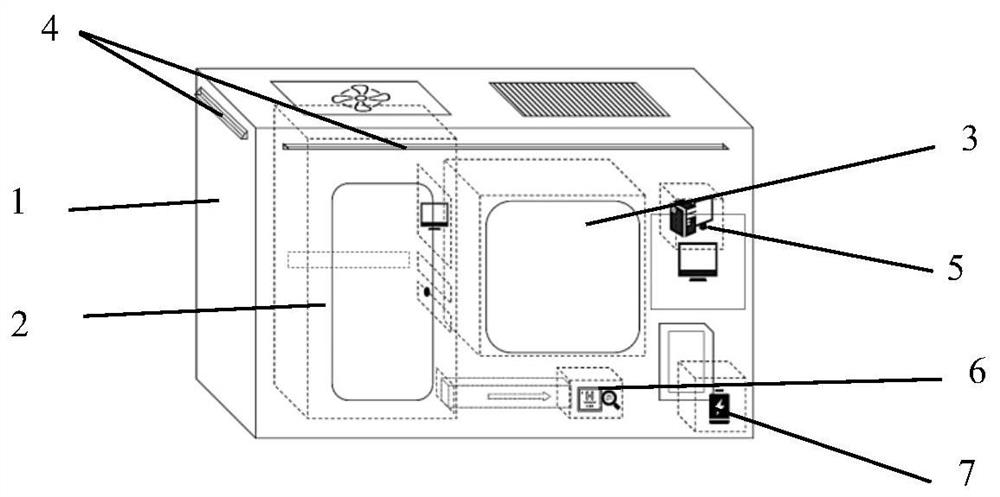

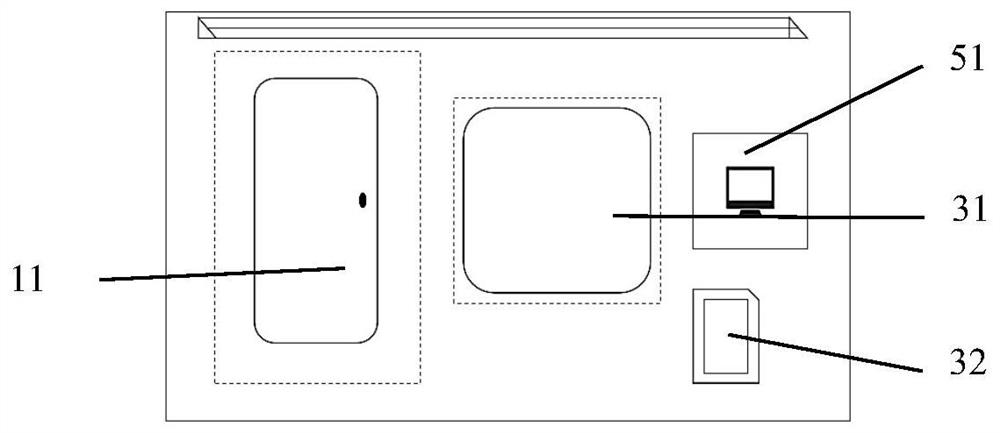

Self-service outpatient service machine

InactiveCN112116753AEnsure safetyImprove friendlinessBatteries circuit arrangementsCoin-freed apparatus detailsPhysical medicine and rehabilitationElement analysis

The invention relates to a self-service outpatient service machine. The machine comprises a shell, and a diagnosis area, a sample analysis area, a selling area, a controller and a power supply which are located in the shell; the diagnosis area is provided with an information acquisition instrument group, and the information acquisition instrument group acquires information of a to-be-diagnosed object; the sample analysis area is provided with an element analyzer, the element analyzer analyzes the detection result of a kit, and the diagnosis area is connected with the element analyzer through akit conveying device; the selling area is provided with a mechanical arm, and the mechanical arm grabs sold medical articles; the controller is in signal connection with the mechanical arm, the information acquisition instrument group and the element analyzer; and the power supply supplies power to the information acquisition instrument group, the element analyzer, the mechanical arm and the controller. Compared with the prior art, the whole self-service outpatient service machine has comprehensiveness and universality.

Owner:TONGJI UNIV

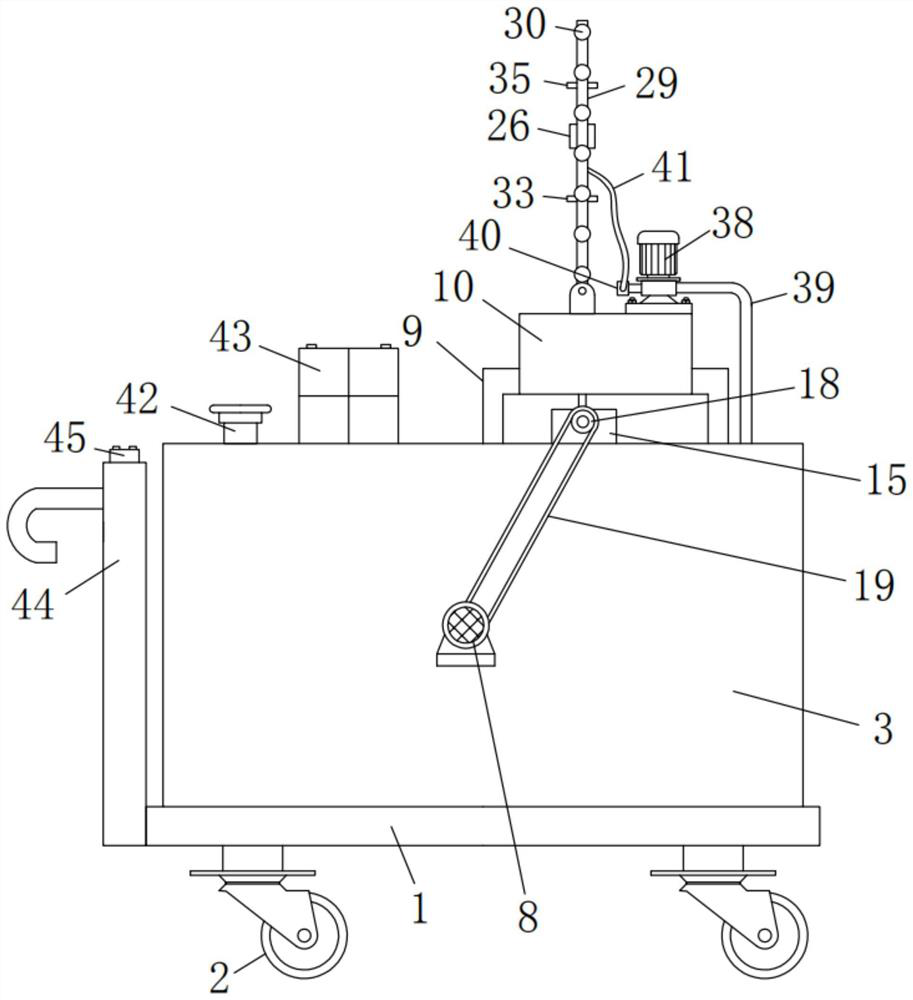

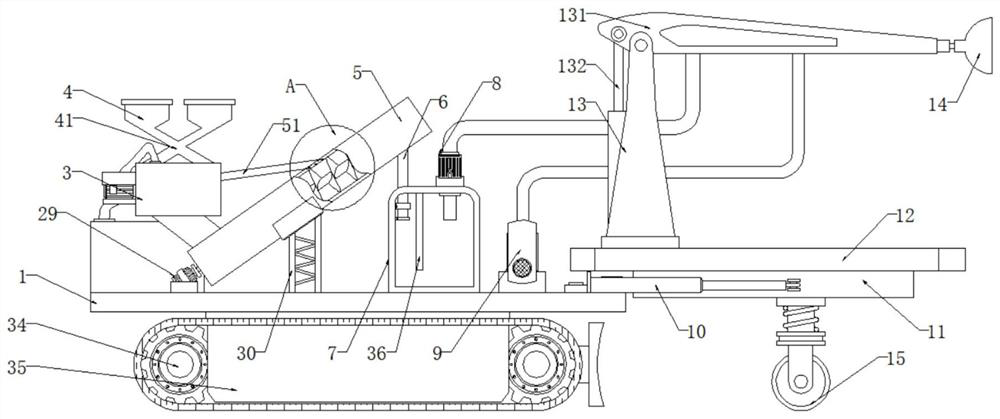

Auxiliary device of concrete spraying machine and using method of auxiliary device

ActiveCN112065450AIncrease jet speedExpand the spray rangeUnderground chambersTunnel liningSlurry pumpStructural engineering

The invention discloses an auxiliary device of a concrete spraying machine and a using method of the auxiliary device, and belongs to the technical field of engineering machinery. The auxiliary devicecomprises a vehicle plate, a water tank is arranged on the vehicle plate, a stirring box is arranged on the water tank, a feeding hopper is arranged at the top of the stirring box, a conveying cage is arranged at the bottom of the stirring box, a discharging pipe is arranged on the right side of the conveying cage, a storage box is arranged at the bottom of the discharging pipe, a slurry pump isarranged at the bottom of the storage box, an air compressor is arranged on the right side of the storage box, two hydraulic rods are arranged on the right side of the upper surface of the vehicle plate, supporting beams are arranged on the right sides of the two hydraulic rods, a moving plate is arranged at the tops of the two supporting beams, a mechanical arm is arranged on the moving plate, and a rotating spraying head is arranged on the right side of the mechanical arm. According to the auxiliary device, the moving plate is movably connected to the right side of the vehicle plate, the rotating direction of the moving plate is controlled through the hydraulic rods, and the spraying direction of the mechanical arm and the spraying head on the top of the moving plate can be changed so that the concrete spraying machine can go deep into a narrow building or wall surface to conduct spraying work.

Owner:湖南三耳重工科技发展有限公司

Spray head for gas pulse soot blower

InactiveCN106885249AIncreased flexibility of useChange spray directionGaseous fuel burnerCombustion chamberMaterial resources

The invention discloses a nozzle for a gas pulse soot blower, which includes an output pipe, a nozzle, a deflector, a push rod and a control motor, one end of the output pipe communicates with the combustion chamber of the gas pulse soot blower, and the nozzle is arranged on the The other end of the output pipe is connected with the output pipe, the deflector is movably connected to the end face of the nozzle, one end of the push rod is movably connected to the deflector, and the other end of the push rod is set on the output shaft of the control motor. The rotation drives the push rod to expand and contract, so as to control the opening and closing angle of the deflector at the nozzle, and realize multi-angle and large-scale dust removal. Compared with the prior art, the present invention realizes the opening and closing of the deflector in the range of 0°-135° by rationally designing and optimizing the structure of the nozzle, changes the direction of the airflow injection, solves the problem of a single injection direction, and increases the The range of dust removal improves the flexibility of the nozzle, greatly reduces the input of manpower and material resources, and is economical; therefore, it has a very broad application prospect.

Owner:天津春辉兴科技有限责任公司

Steering gear for water jet propulsion

ActiveCN111661304BChange spray directionDoes not involve coordinationSteering by jetsPump-jetHydraulic cylinder

Owner:WUHAN MARINE MACHINERY PLANT

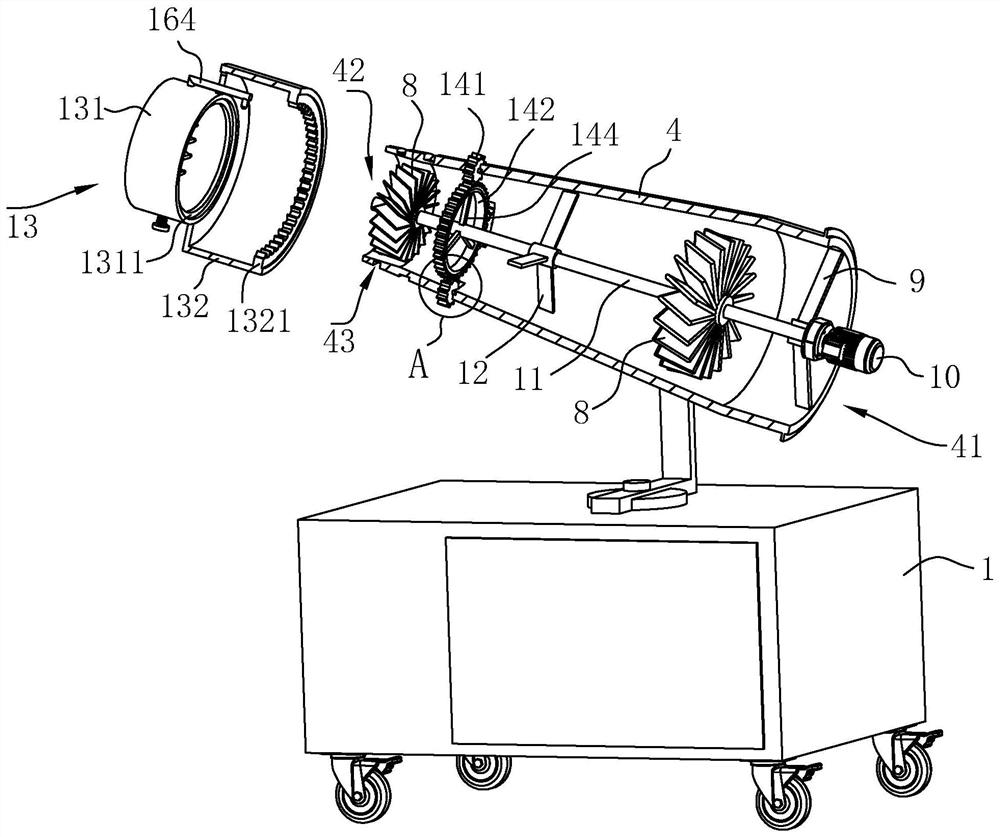

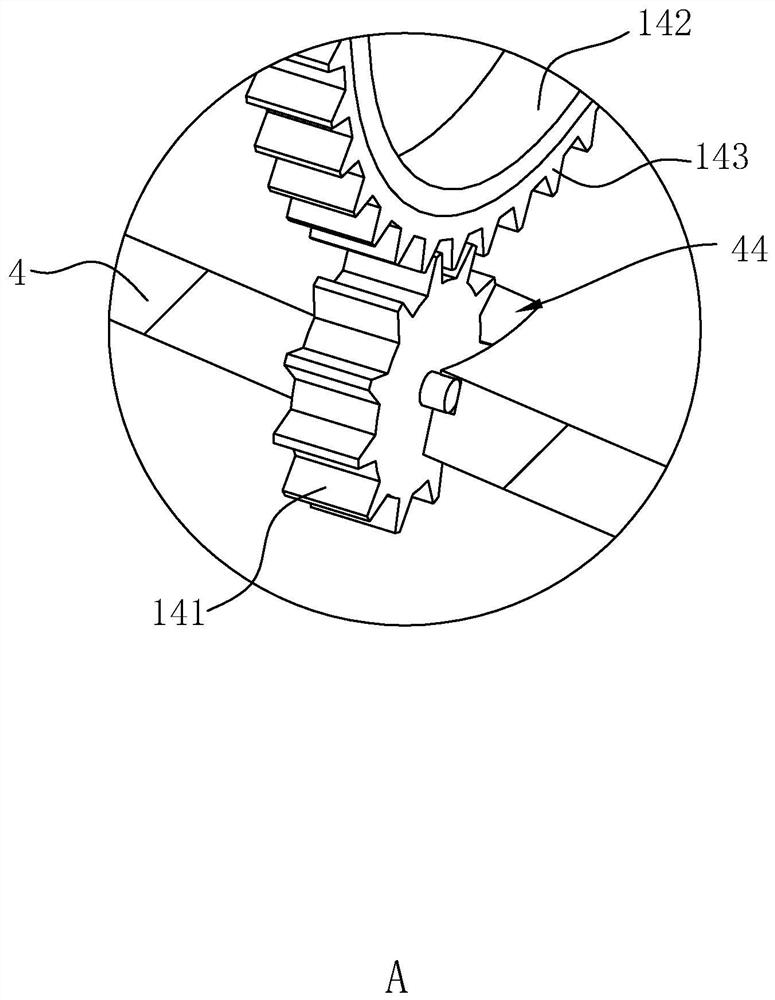

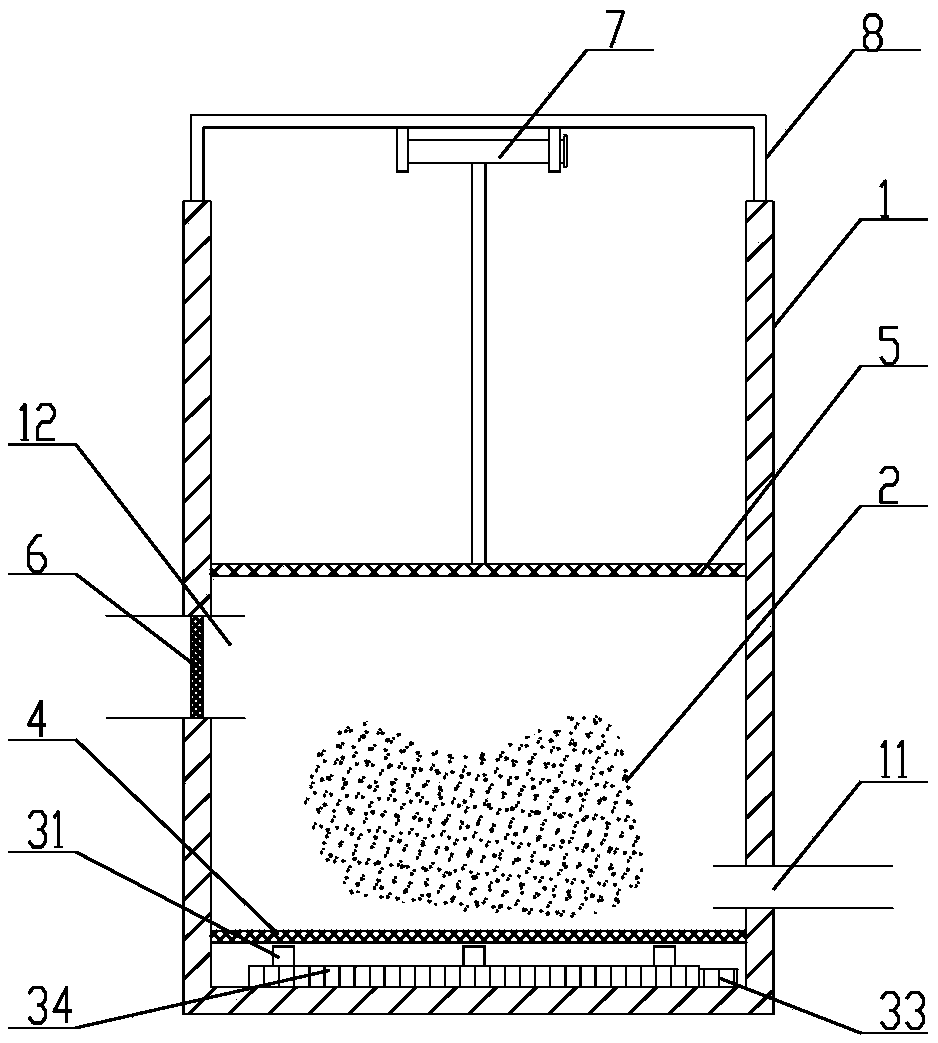

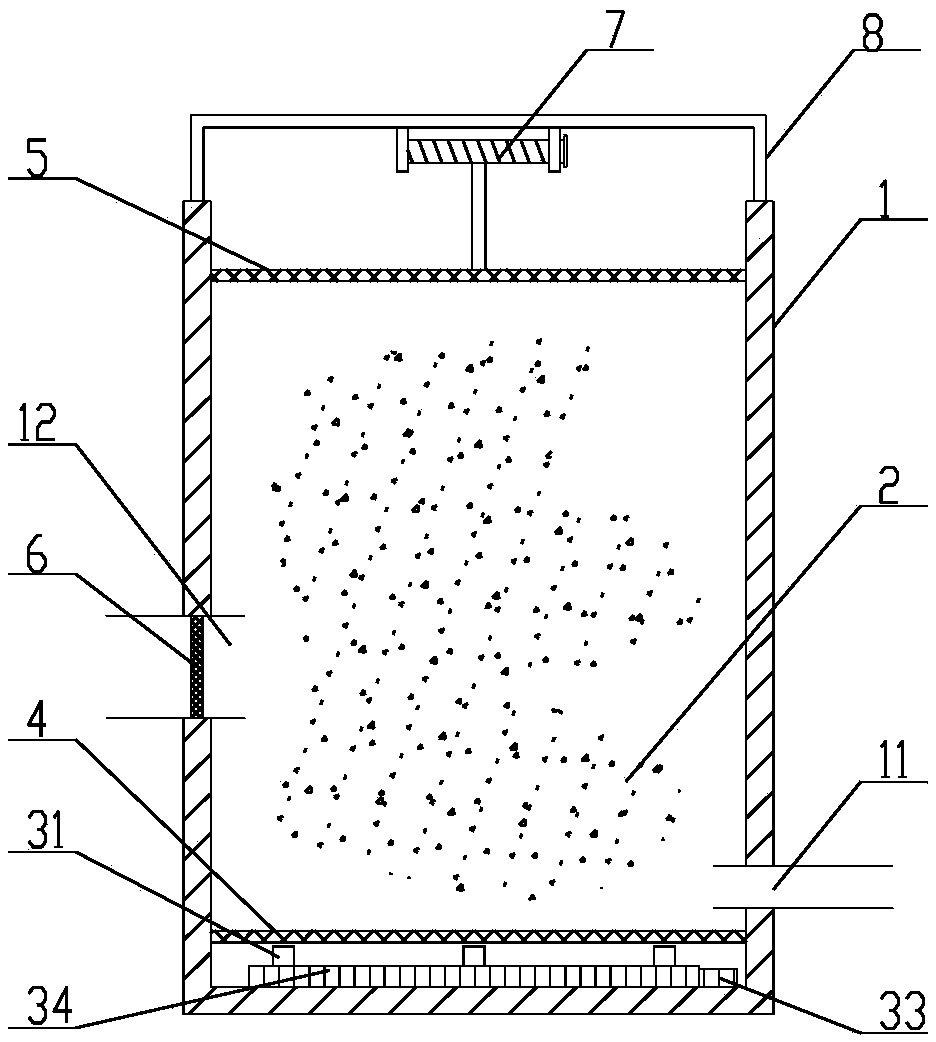

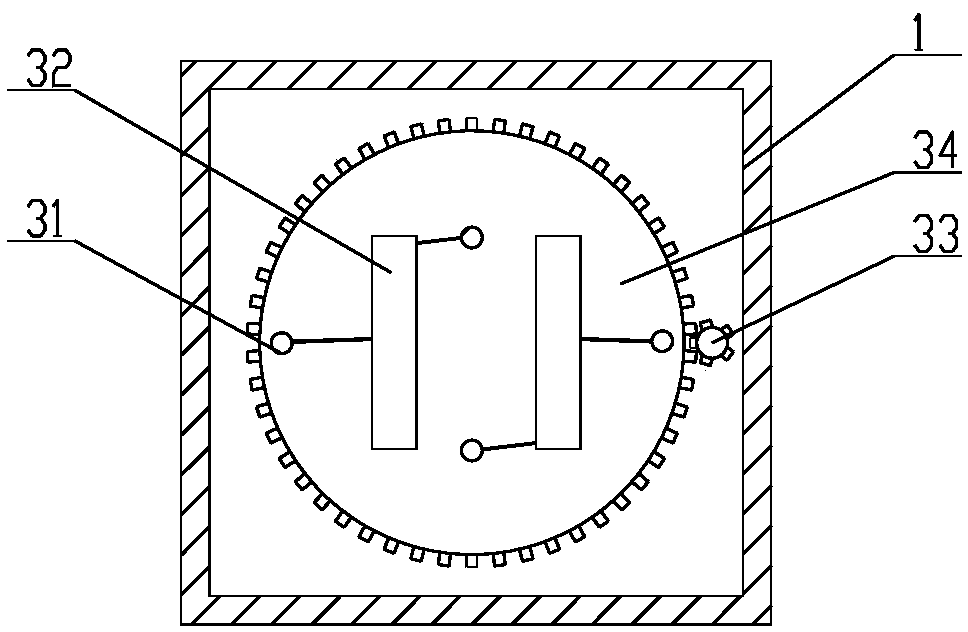

Rotation-type activated carbon cleaning device

InactiveCN110653198AAchieve cleaningChange spray directionCleaning using gasesCleaning using liquidsActivated carbonComposite material

The invention discloses a rotation-type activated carbon cleaning device and relates to the technical field of cleaning equipment, in particular to a rotation-type activated carbon cleaning device. The rotation-type activated carbon cleaning device is compact in structure and low in water consumption amount and has a good cleaning effect. The rotation-type activated carbon cleaning device comprises a rectangular shell, the lower portion of the shell is provided with a water inlet and a water outlet, and to-be-cleaned activated carbon is arranged in the shell; the device further comprises a rotation air-blowing mechanism, and the rotation air-blowing mechanism comprises air blowing heads, air chambers, drive teeth and driven teeth. The drive teeth are engaged with the driven teeth, the airchambers are formed in the driven teeth, the air blowing heads are arranged at the tops of the driven teeth and communicate with the air chambers, and the upper portion of the rotation air-blowing mechanism is provided with a first filter screen. The overall rotation-type activated carbon cleaning device has the advantages of being compact in structure, low in water consumption amount and capableof achieving a good cleaning effect.

Owner:王晨

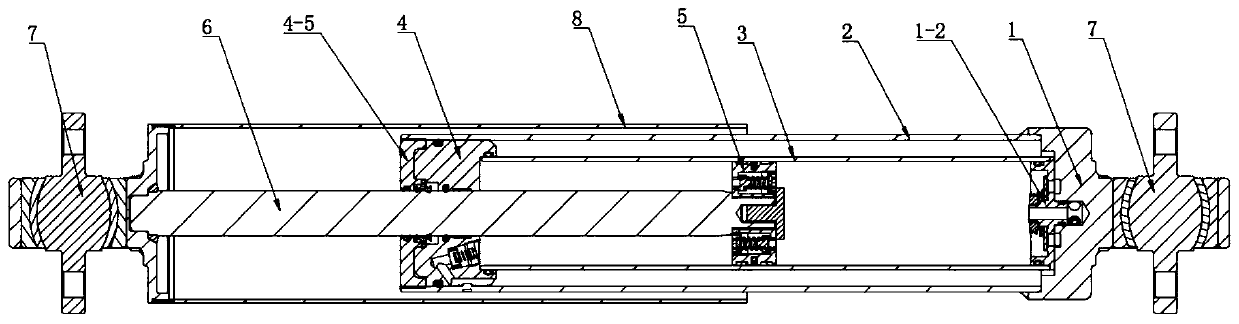

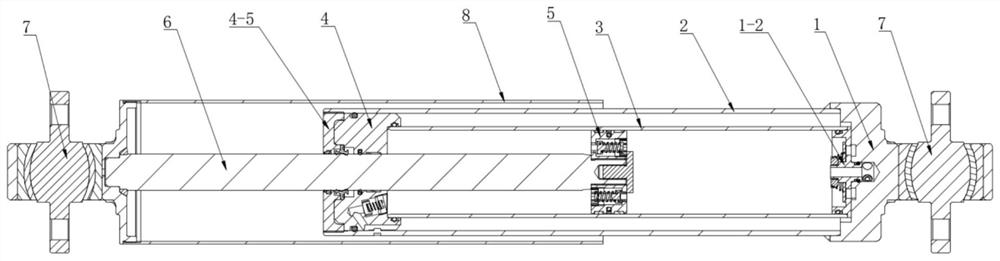

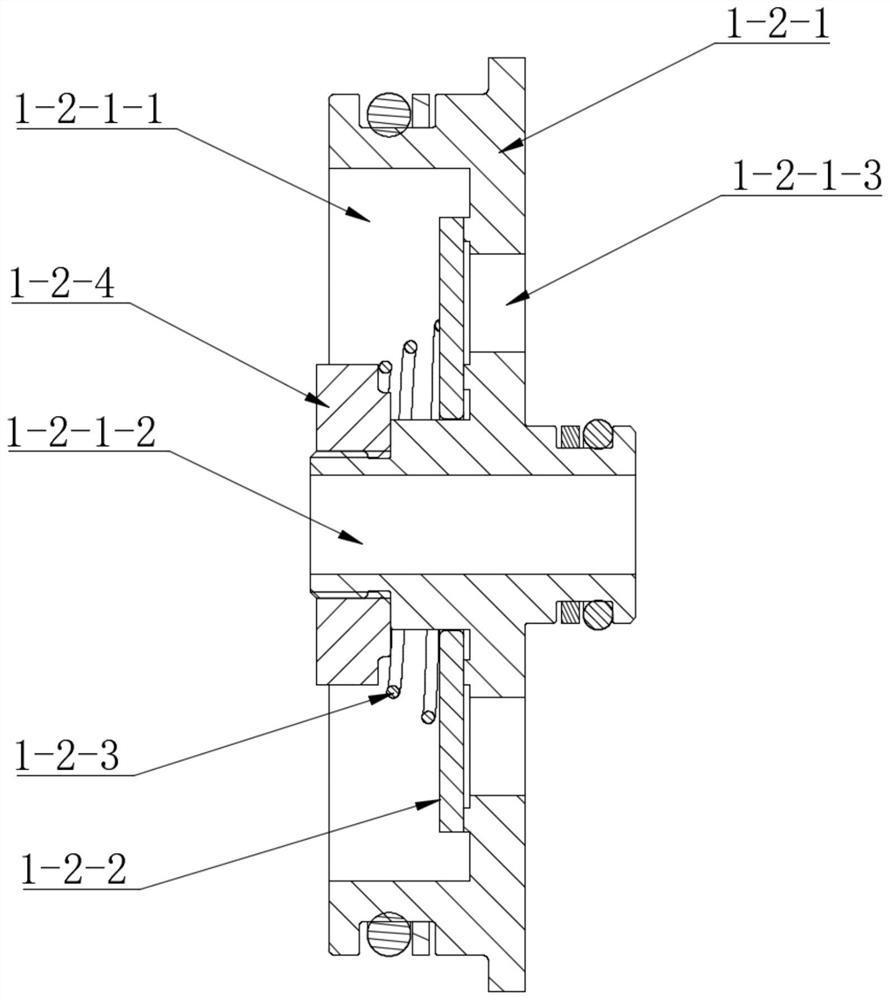

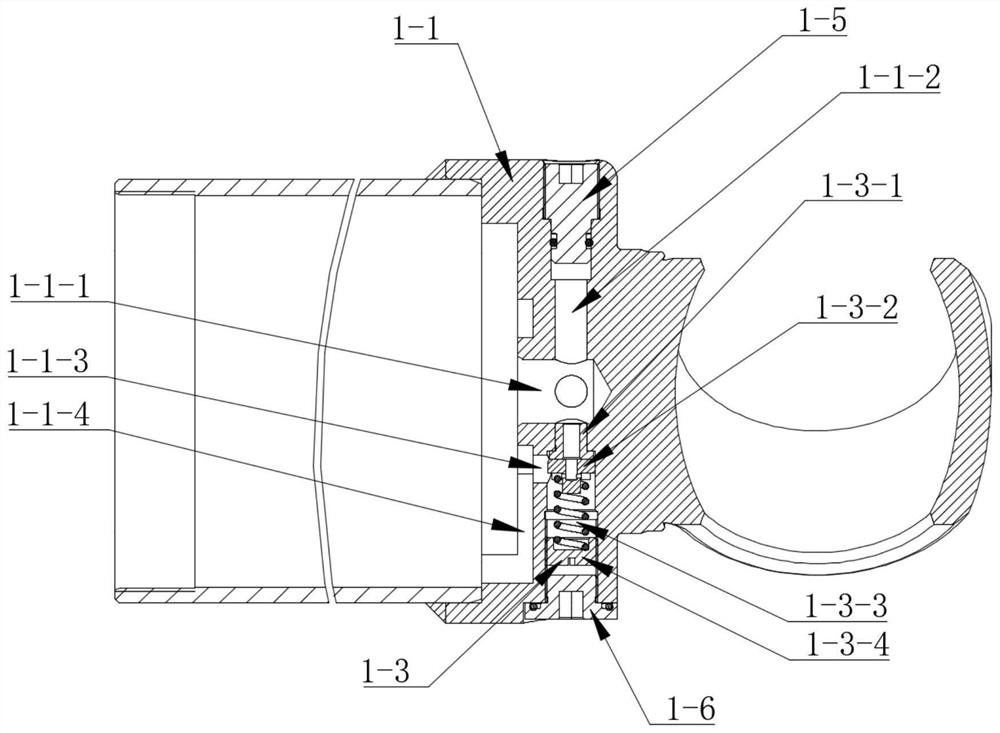

Rail vehicle shock absorber

ActiveCN111255847AImprove regulation efficiencyEasy to adjustSpringsSprings/dampers design characteristicsPiston rodShock absorber

The invention discloses a rail vehicle shock absorber. The rail vehicle shock absorber comprises a base assembly, an oil cylinder, an end cover assembly, a piston assembly and a piston rod assembly. An oil storage oil cylinder is fixed to the inner end of the base assembly in a sealed manner. The oil cylinder is arranged in the oil storage cylinder, and one end of the oil cylinder is fixedly connected with the inner end of the base assembly in a sealed manner. The end cover assembly is fixedly connected with the other ends of the oil cylinder and the oil storage cylinder in a sealed manner. The piston assembly is arranged in the oil cylinder and is in sealed sliding connection with the inner wall of the oil cylinder. The piston rod assembly penetrates the end cover assembly and is in sealed sliding connection with the end cover assembly. The inner end of the piston rod assembly is fixedly connected with the piston assembly. Rubber joints fixedly connected with the piston rod assembly and the base assembly are correspondingly arranged at the outer ends of the piston rod assembly and the base assembly. Damping valves capable of adjusting the resistance from the outer side are correspondingly arranged on the base assembly and the end cover assembly. According to the rail vehicle shock absorber, the damping valves capable of adjusting the resistance from the outer side are correspondingly arranged on the base assembly and the end cover assembly, the adjustment is quite convenient, and it is not necessary to disassemble the whole shock absorber, so that the adjusting efficiencyof the damping force of the valve system can be greatly increased.

Owner:CRRC CHANGZHOU DIESEL ENGINE COMPONENTS CO LTD +1

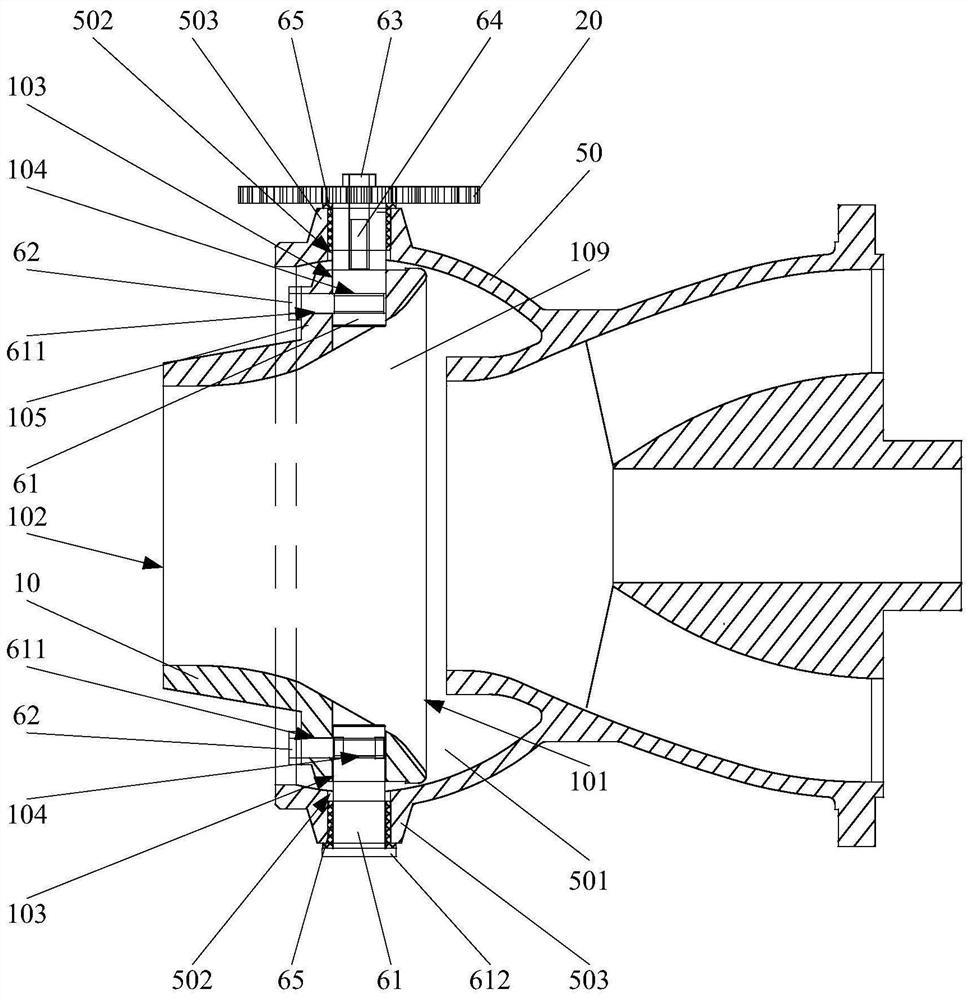

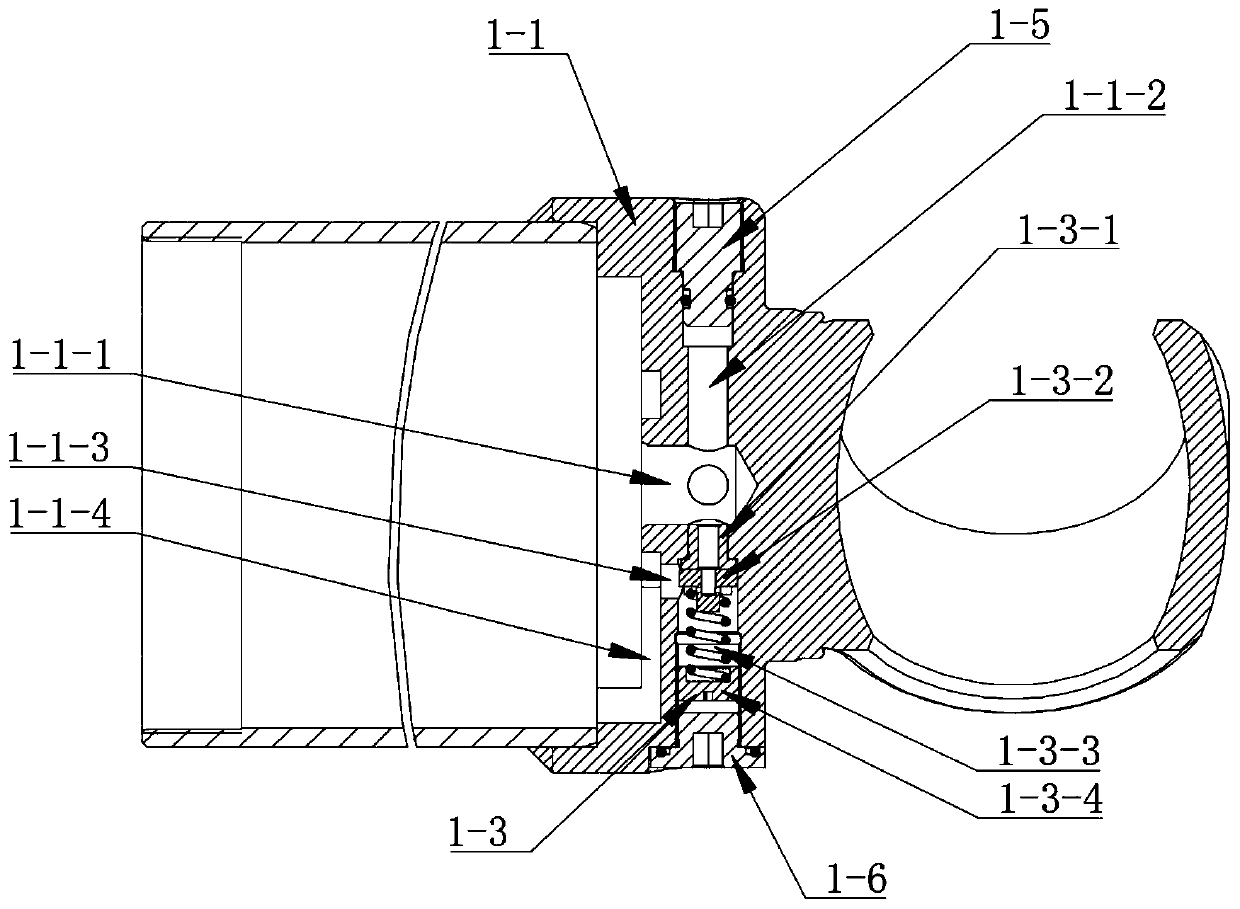

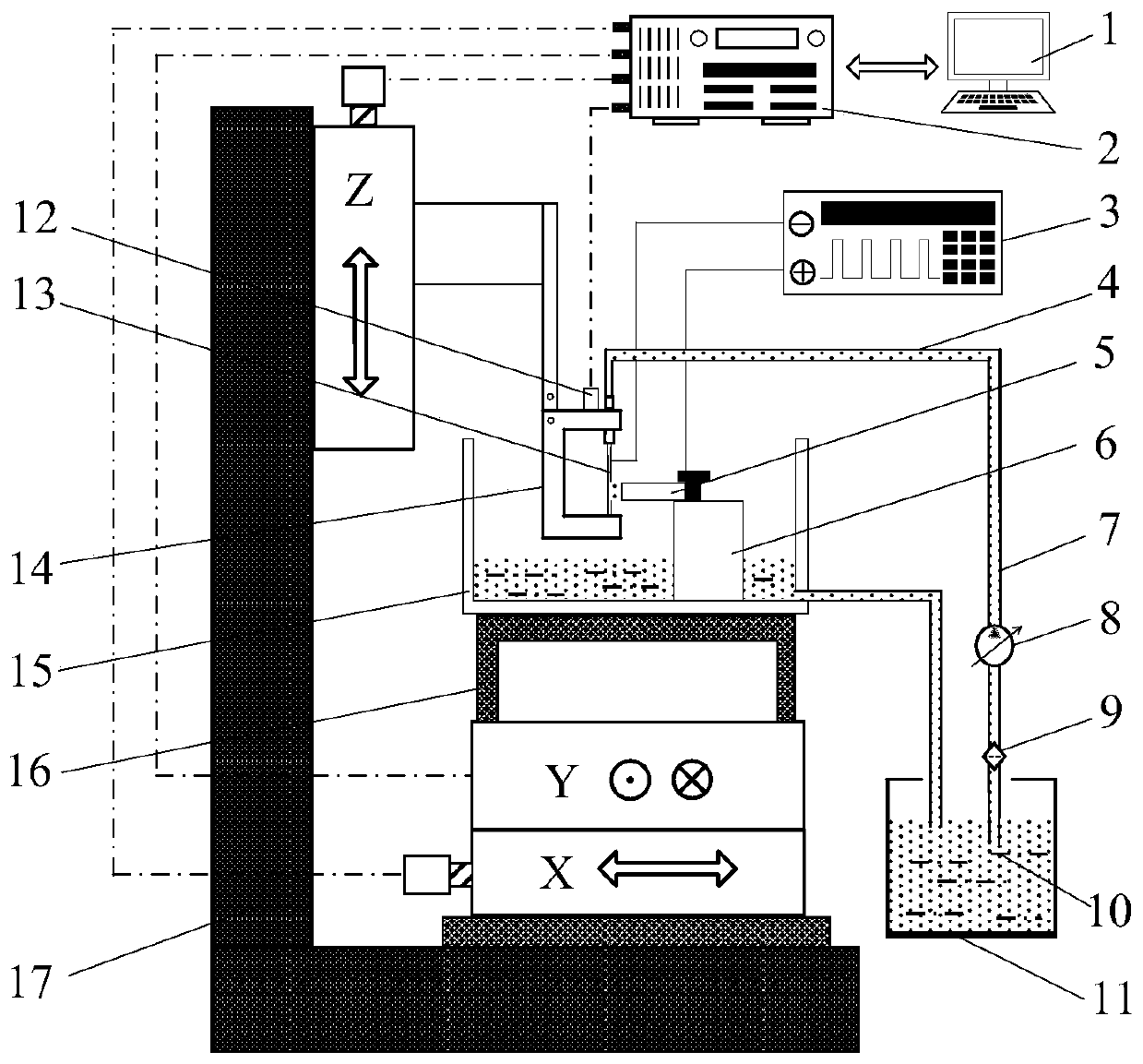

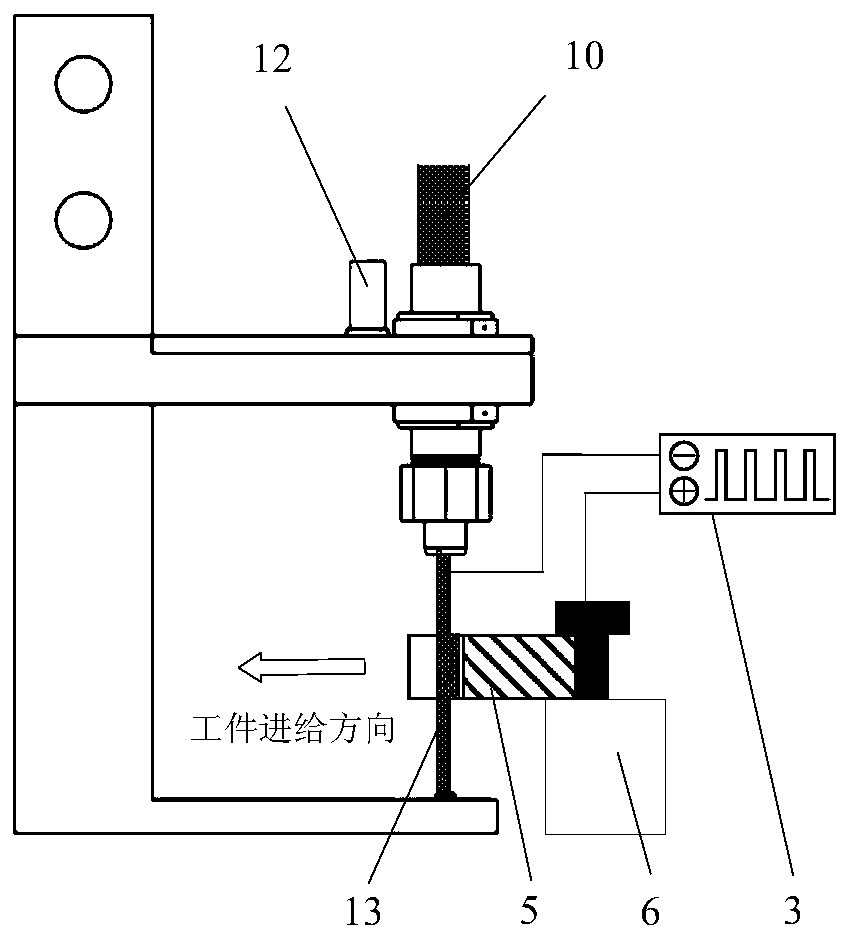

Microtube Electrode System for Electrolytic Cutting of Large Thickness Workpiece Method

ActiveCN108406025BImprove stabilitySpeed up the electrolytic reactionMachining working media supply/regenerationNumerical controlElectrolysis

The invention relates to a method and device for performing electrolytic cutting on a large-thickness workpiece by using a micro tube electrode, and belongs to the technical field of electrochemical machining. The method is mainly characterized in that a micro hollow metal tube with grouped holes or grouped seams or a hollow non-metal tube with a conductive coating is selected to replace an existing metal-wire-shaped electrode to cut the large-thickness workpiece; structures of the grouped holes or the grouped seams are formed in the micro tube electrode with one closed end, an electrolyte with certain pressure is injected from one end of the micro tube electrode and is jetted out from the grouped holes or the grouped seams, the fresh electrolyte flowing at a high speed can directly reacha machining area to perform etching cutting on the workpiece, and electrolysate and bubbles in micro cut seams can be rapidly washed away; and in the machining process, a servo motor drives the microtube electrode to rotate through a steering device so as to change the jetting direction of the electrolyte, and meanwhile, the relative movement of the micro tube electrode to the workpiece can be controlled by utilizing the movement of a numerical control machine tool workbench, so that steering cutting of the workpiece can be realized. The method and the device have the advantages that the update rate of the electrolyte in machining clearances can be increased, the electrolytic reaction speed can be increased, the electrolytic cutting stability can be improved, and meanwhile the electrolytic cutting capacity of the large-thickness workpiece can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A cleaning device and cleaning method for solar panels

ActiveCN104201980BPrevent agingAchieve large area cleaning effectPhotovoltaicsFlexible article cleaningCells panelHigh pressure

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

A rail vehicle shock absorber

ActiveCN111255847BImprove regulation efficiencyEasy to adjustSpringsSprings/dampers design characteristicsDamperControl theory

The invention discloses a rail vehicle shock absorber, which comprises: a base assembly, an oil storage cylinder is sealed and fixed at the inner end; an oil cylinder is arranged in the oil storage cylinder, and one end of the oil cylinder is sealed and fixedly connected with the inner end of the base assembly; an end cover assembly , is sealed and fixedly connected with the other end of the oil cylinder and the oil storage cylinder; the piston assembly is arranged in the oil cylinder and is sealed and slidably connected with the inner wall of the oil cylinder; the piston rod assembly runs through the end cover assembly and is sealed and slidably connected with the end cover assembly The inner end of the assembly is fixedly connected with the piston assembly; the outer end of the piston rod assembly and the outer end of the base assembly are provided with rubber joints fixedly connected with it; the base assembly and the end cover assembly are provided with externally adjustable damping Force size damping valve. Both the base assembly and the end cover assembly of the present invention are equipped with damping valves that can adjust the damping force from the outside, and the adjustment is very convenient without dismantling the entire shock absorber, thereby greatly improving the adjustment efficiency of the damping force of the valve system.

Owner:CRRC CHANGZHOU DIESEL ENGINE COMPONENTS CO LTD +1

Novel activated carbon cleaning device

InactiveCN110652976AImprove cleaning effectAvoid wastingOther chemical processesCombustible gas purificationActivated carbonAir pump

The invention provides a novel activated carbon cleaning device, and belongs to the technical field of cleaning equipment. The novel activated carbon cleaning device is compact in structure, small inwater consumption and good in cleaning effect, and comprises a rectangular shell; a water inlet and a water outlet are formed in the lower portion of the shell, activated carbon to be cleaned is arranged in the shell, and the water inlet and the water outlet are oppositely formed in the two side walls of the shell; the novel activated carbon cleaning device further comprises an air blowing mechanism, the air blowing mechanism comprises at least one pair of air blowing heads, the air blowing heads are connected with an air pump, and are arranged at the bottom of the shell, and a first filter screen is arranged on the upper portion of the air blowing mechanism; the novel activated carbon cleaning device comprises a second filter screen, the second filter screen is movably arranged in the shell and located above the water inlet, and the activated carbon is located between the first filter screen and the second filter screen. The novel activated carbon cleaning device has the advantages ofbeing compact in structure, small in water consumption and good in cleaning effect on the whole.

Owner:王晨

Nozzle for high-pressure cleaning machine with adjustable spray angle

The invention discloses a nozzle for a high-pressure cleaning machine with an adjustable spray angle, which includes a right-angle adapter fixed at the front end of the gun rod of the high-pressure cleaner, one end of the right-angle adapter is formed with a cylindrical protrusion, and the cylindrical protrusion is formed with a Water outlet hole, the other end of the right-angle adapter is formed with a water inlet hole communicating with the water outlet hole, and the connecting rod is connected with the water inlet hole; the front end of the cylindrical protrusion is sleeved with a nozzle part, and a transitional water tank is formed on the inner wall of the nozzle part , the inner wall of the transition tank is formed with a spray chamber, and the side wall of the spray chamber is formed with a spray hole with an outer opening; the front end of the cylindrical protrusion is formed with a plurality of through holes connecting the transition tank and the water outlet; the right-angle turn An adjustment mechanism for adjusting the angle of the nozzle part is provided on the joint. The invention can change the spraying direction of the nozzle, and can be stably fixed on the angle, can meet the requirements of various working conditions, and improve the practicability of the washing machine.

Owner:浙江金莎机械有限公司

Handheld low-temperature plasma jet device and use method thereof

PendingCN113543441AImprove stabilityIncrease frictionElectrotherapyPlasma techniquePlasma jetRotational axis

The invention discloses a handheld low-temperature plasma jet device and a use method thereof. The handheld low-temperature plasma jet device comprises a handle, a switch assembly, a rotating structure, a flow slowing structure, a swinging structure, an air duct, an air supplementing structure and a plasma pulser; the flow slowing structure is installed at the top end of the air duct; the rotating structure is adopted, during the use of the device, the surface side of the handle is held, frosted sponge is arranged on the handle, the friction force between the palm and the handle can be improved, the handheld stability can be improved; a motor is powered on, a driving gear is driven to rotate, and under cooperation of a matched gear, rotation of a rotating shaft can be achieved; and by changing the relative included angle between the handle and the air duct, the spraying direction of the air duct can be changed while a proper handheld position is guaranteed, the handheld stability is improved, arm fatigue caused by the fact that an arm keeps one action for a long time is avoided, the holding direction of the handle can be changed randomly, the holding direction of the arm can be adjusted randomly, and the arm can be better protected, and the stability of the handheld mode is improved.

Owner:汪嵘

Substrate wet process process method and substrate wet process process device

ActiveCN107170667BChange spray directionControl etch rateSolid-state devicesSemiconductor/solid-state device manufacturingWater flowProcess engineering

The invention discloses a substrate wet process technological method, and aims to solve the technical problem of potential damage in the substrate processing process in the existing wet etching process. The technological method comprises the steps of setting a bearing platform and fixing a substrate through the bearing platform; moving the bearing platform along a circumferential track to convey the substrate; setting processing equipment along the outer side of the circumferential track; and in the substrate conveying process, adjusting the orientation and / or height of the substrate by the bearing platform to be matched with the processing equipment. The moving technological beat of the bearing platform along the circumferential track is controlled by an annular conveyor belt, so that consumed resource, manpower, time and other maintenance cost in replacing a huge number of rolling wheels periodically can be saved; the etching process and cleaning technological method are further improved; the jetting direction of the medicinal liquid and net water flow is changed; etching rate and medicinal liquid take-out amount are controlled effectively; and the cost is lowered while the etching quality can be effectively ensured. The invention also provides a substrate wet process technological apparatus.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com