Spray type multifunctional water outlet device

A water outlet device and multi-functional technology, applied in water supply devices, indoor sanitary plumbing devices, buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

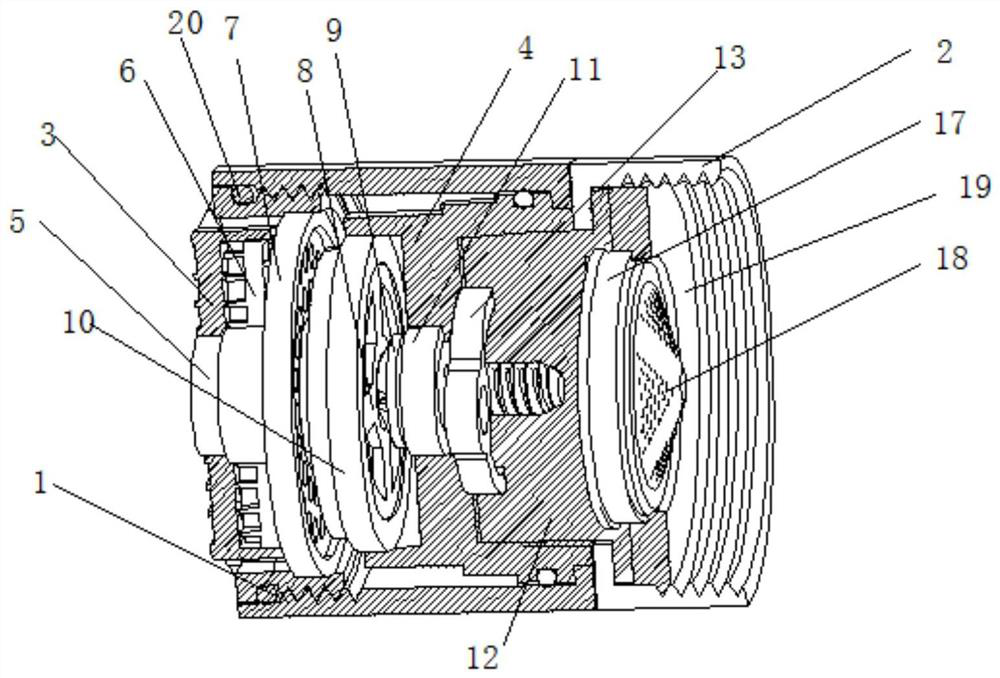

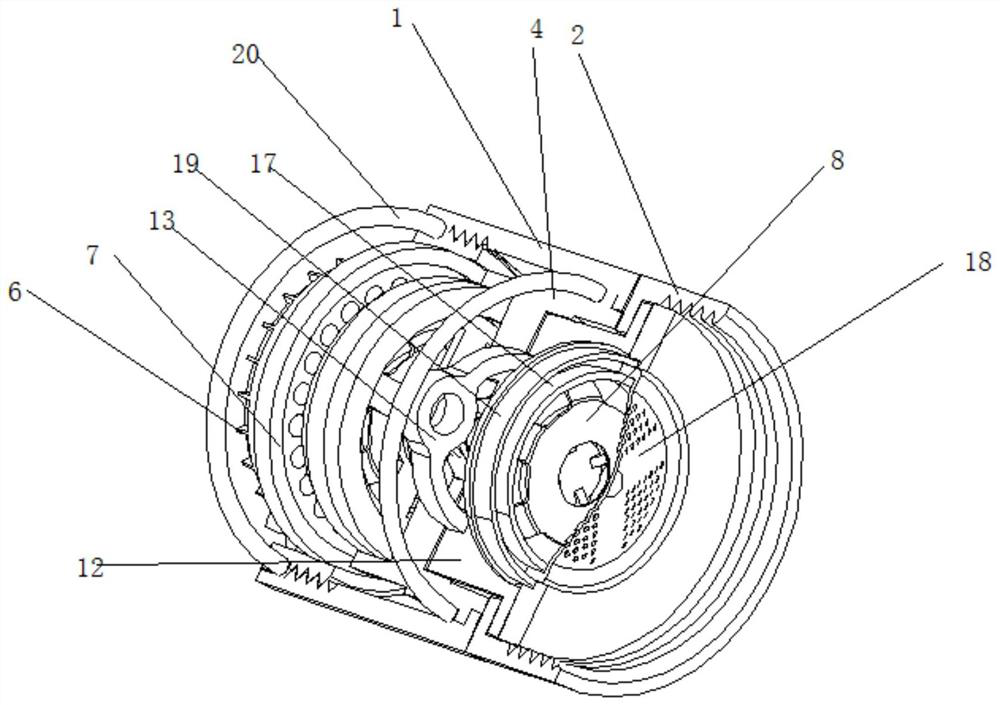

[0025] A spray type multifunctional water outlet device, such as Figure 1-Figure 5 As shown, it includes a front spray shell 1, the rear part of the front spray shell 1 is rotatably connected with a rear spray shell 2, the inner wall of the front spray shell 1 is threadedly connected with a spray seat 3, and the inner wall of the front spray shell 1 is welded with a fixed pillar 4 , the inner wall of the spray seat 3 is rotatably connected with a turntable 5, the surface of the turntable 5 is welded with a shunt net 6 and a shunt disc 7, the inner wall of the turntable 5 is clamped with a large water diversion seat 8, and the rear part of the large water diversion seat 8 is welded with a screw 9 , the rear part of the water seat 8 is slidingly connected with a sealing column 10, the surface of the screw 9 is sleeved with a connecting column 11, the surface of the screw 9 is welded with a fixed seat 12, and the inside of the fixed seat 12 is clamped with a valve disc 13, and th...

Embodiment 2

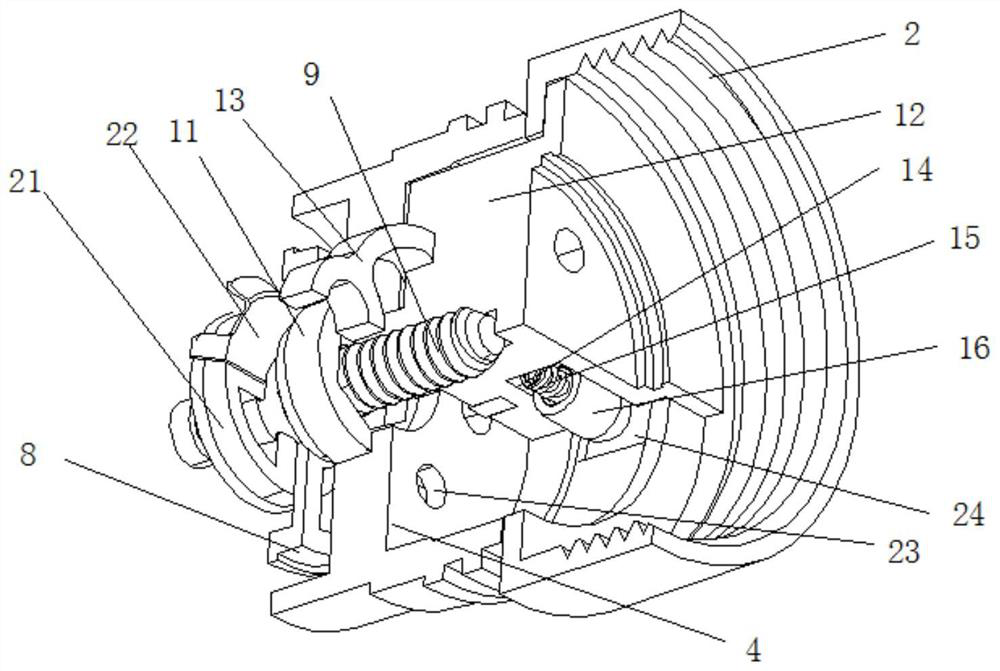

[0030] Such as Figure 4 As shown, the inside of the fixed seat 12 is provided with a sliding groove 14, the inner wall of the sliding groove 14 is welded with a spring 15, and the bottom end of the spring 15 is welded with a bullet post 16. By setting the sliding groove 14, the spring 15 and the bullet post 16 are fixed on the The effect inside the fixed seat 12, and the bullet column 16 is constantly moving in and out under force when it is in contact with the inner wall of the fixed post 4 during the rotation of the fixed seat 12 .

[0031] In this embodiment, the bullet post 16 is slidably connected to the inner wall of the sliding groove 14, the surface of the bullet post 16 is slidingly connected to the inner wall of the fixed seat 12, and the surface of the bullet post 16 is engaged with the inner wall of the card slot 24. 16 is slidably connected to the inner wall of the sliding groove 14 to achieve the effect of fixing the sliding track of the bullet post 16, and to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com