A rail vehicle shock absorber

A rail vehicle and shock absorber technology, which is applied in the direction of shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve problems such as improving work efficiency, unfavorable conditions, and high noise, and achieves stable damping force values and improved adjustment efficiency , Reduce the effect of fuel injection noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

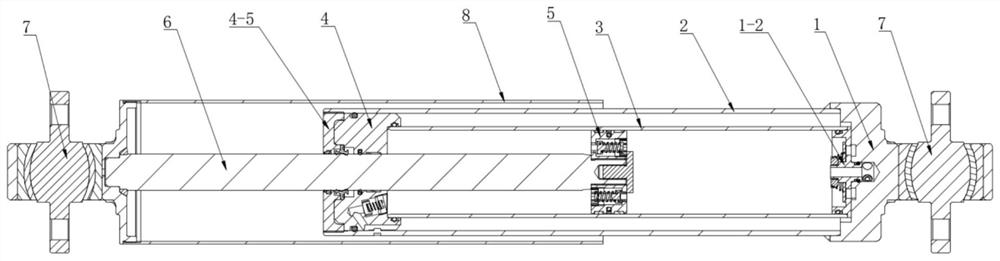

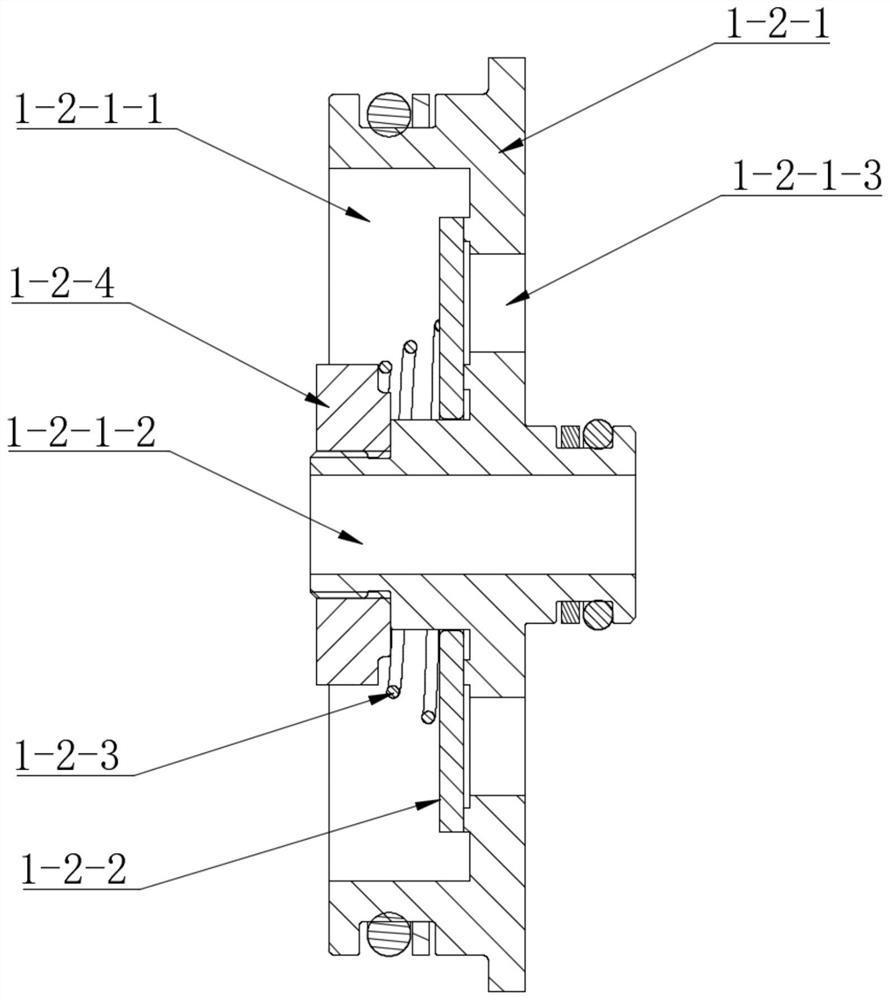

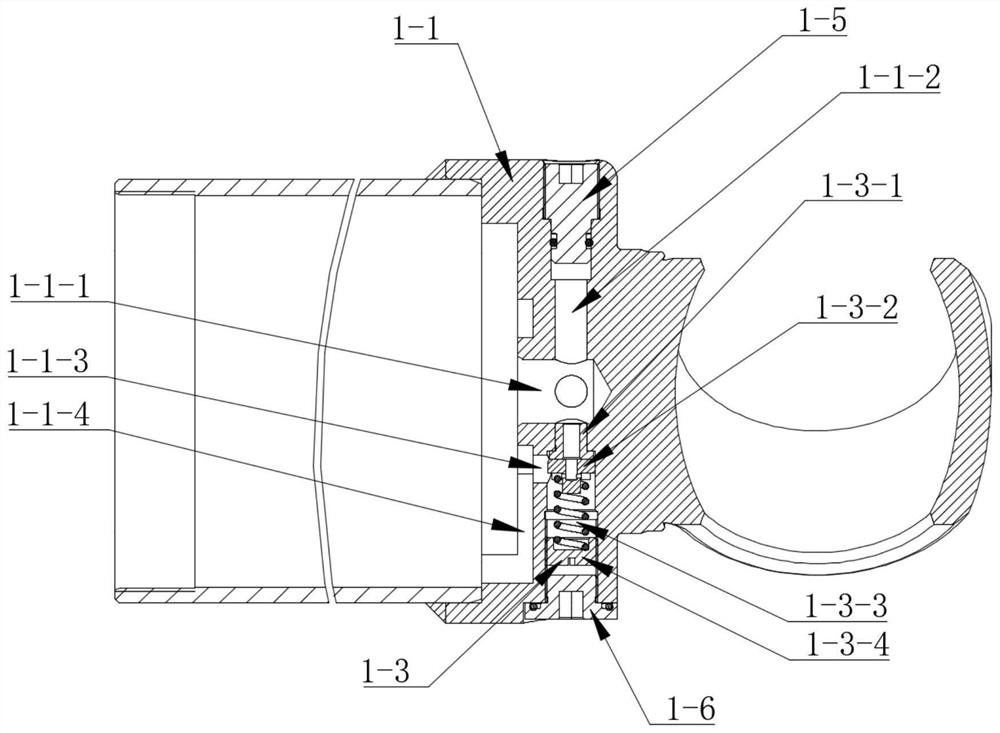

[0063] See figure 1 , The railway vehicle shock absorber of this embodiment includes a base assembly 1, an oil storage cylinder 2, an oil cylinder 3, an end cover assembly 4, a piston assembly 5, a piston rod assembly 6 and a rubber joint 7.

[0064] One end of the oil storage cylinder 2 is sealed and fixed to the inner end of the base assembly 1 . The oil cylinder 3 is arranged in the oil storage cylinder 2 , and one end of the oil cylinder 3 is in sealing connection with the inner end of the base assembly 1 . The end cover assembly 4 is in sealing connection with the other end of the oil cylinder 3 and the oil storage cylinder 2 . The piston assembly 5 is arranged in the oil cylinder 3 and is in sealing and sliding connection with the inner wall of the oil cylinder 3 . The piston rod assembly 6 runs through the end cover assembly 4 and is in sealing and sliding connection with the end cover assembly 4 . The inner end of the piston rod assembly 6 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com