Dust falling system for cast-in-place integral reinforced concrete construction

A reinforced concrete, integral technology, used in cleaning methods, using liquid separators, road cleaning, etc., can solve problems such as small spray range, and achieve the effect of wide spray range and increased spray range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

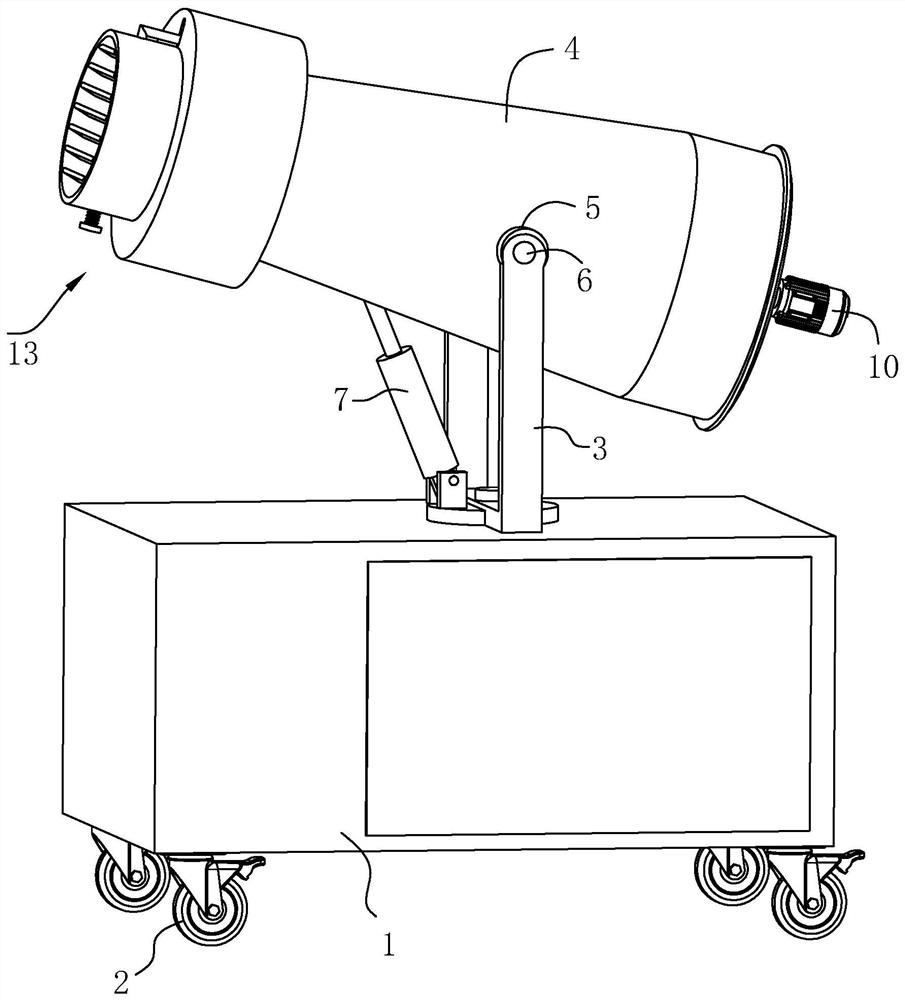

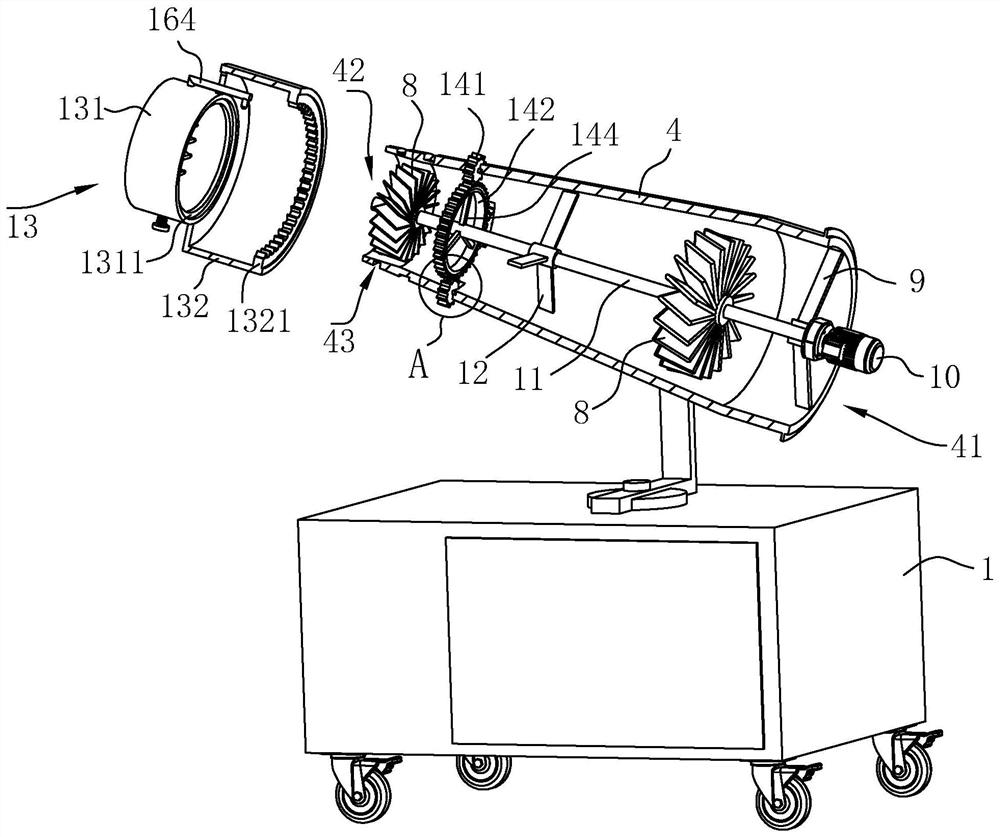

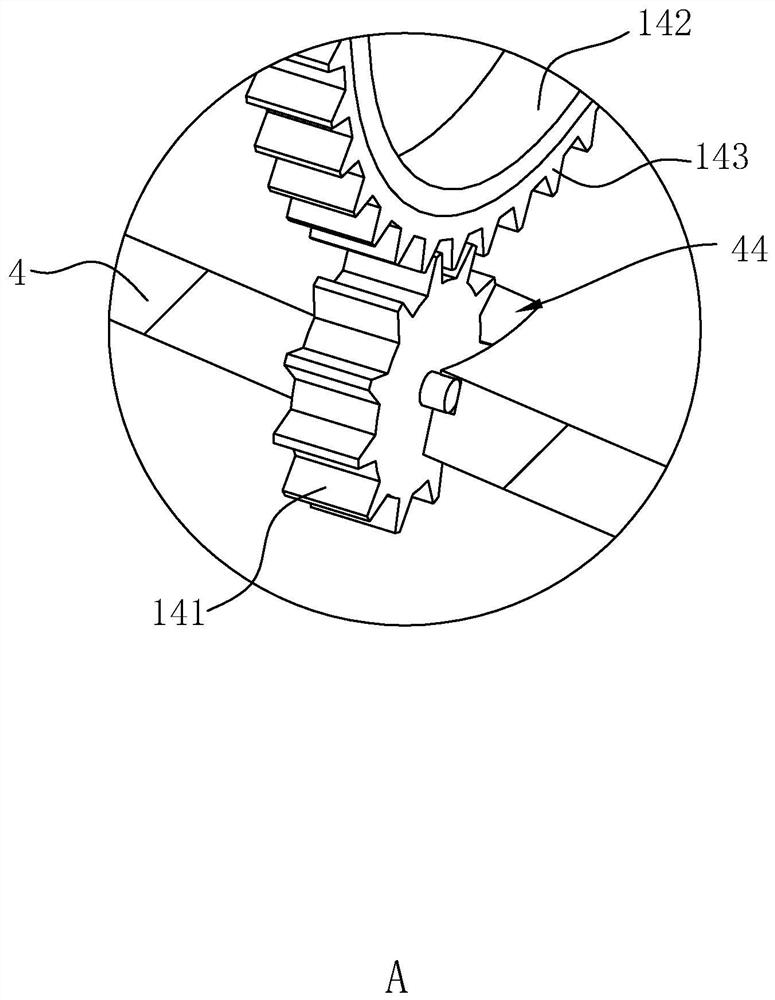

[0036] A dust suppression system for cast-in-place integrated reinforced concrete construction, such as figure 1 As shown, including the bottom support 1, four casters 2 are installed on the lower surface of the bottom support 1, and the casters 2 are installed at the four corners of the lower surface of the bottom support 1. A turret 3 is installed on the bottom support 1, and the turret 3 is arranged in a zigzag shape. combine figure 2 , Spraying device is installed on the turret 3, and spraying device comprises the spray tube 4 that is arranged in hollow, and spray tube 4 is arranged in similar cylinder shape, and the two ends of spray tube 4 are air inlet 41 and spray port 42 respectively, spray tube The outer diameter of 4 gradually decreases from the air inlet 41 to the spray port 42. Both sides of the spray tube 4 are symmetrically welded with moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com