Direction-changing spray pipe for air inlet passage multi-point injection of dual-fuel engine

A dual-fuel engine and air intake technology, which is applied in the directions of machines/engines, jet propulsion devices, etc., can solve the problem of invariability in the vertical direction, and achieve the effects of convenient processing, reduced occupation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

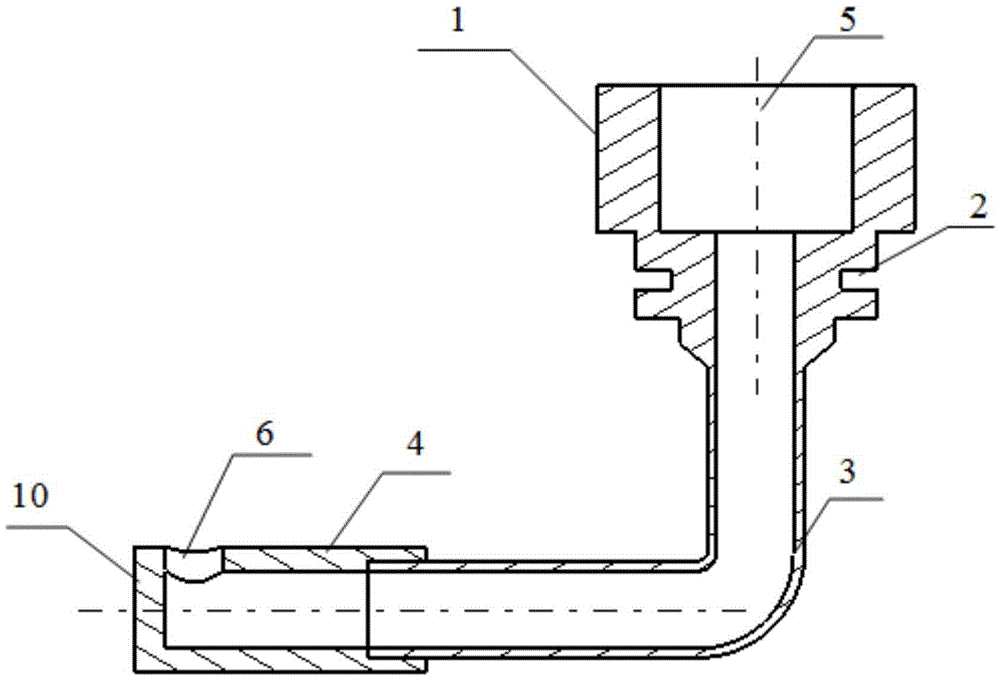

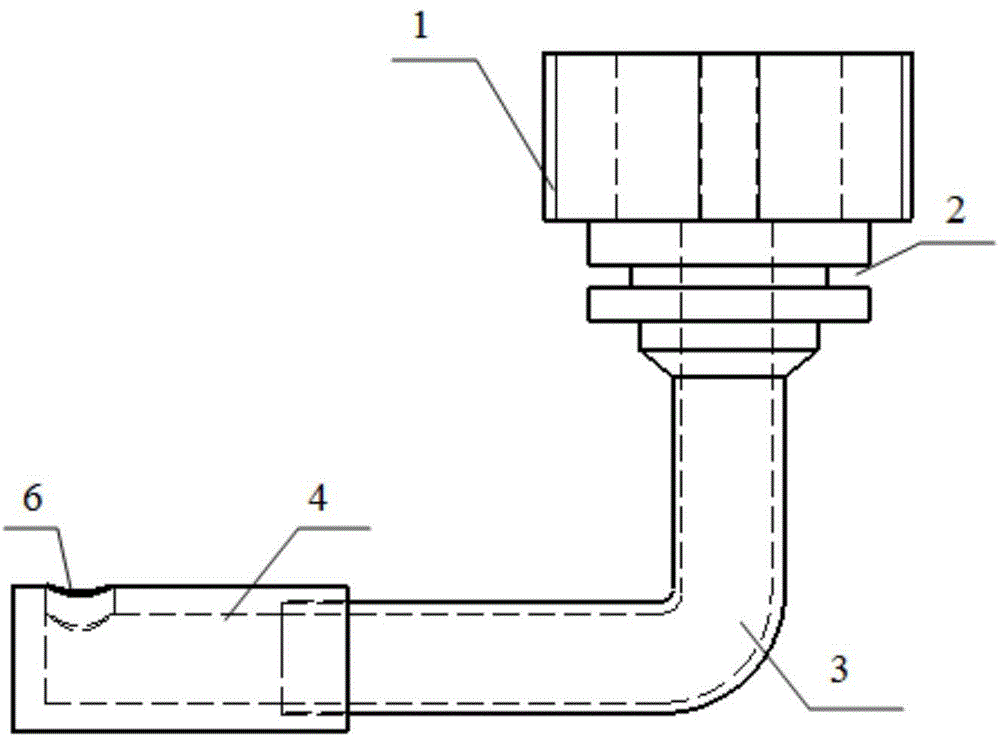

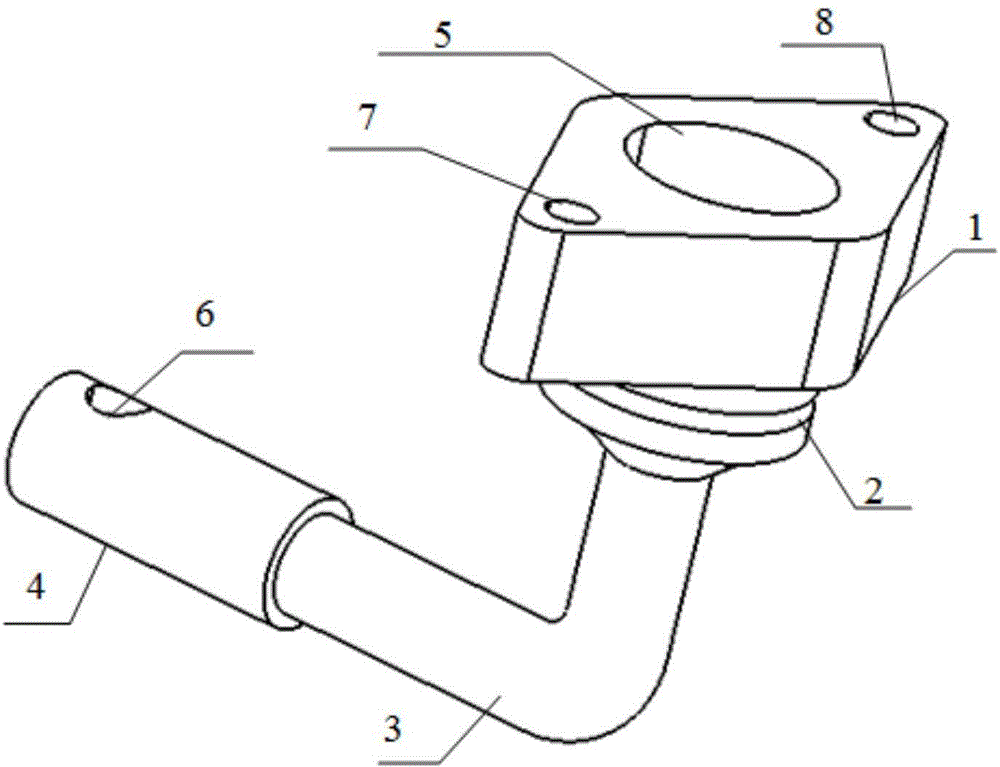

[0027] refer to Figure 1 to Figure 3 According to the present invention, the variable-direction nozzle of dual-fuel engine intake port multi-point injection is composed of a natural gas nozzle seat 1, a sealing seat 2, a guide pipe 3 and a nozzle 4.

[0028] refer to image 3 , the natural gas nozzle seat 1 is a rhombus-shaped cylindrical structure in cross-section, i.e. a diamond-shaped cylinder structure. The center of the body is processed with a cylindrical nozzle inlet 5, and the long axis of the diamond-shaped cylinder on both sides of the nozzle inlet 5 is symmetrically provided with a No. 1 natural gas nozzle holder fixing through hole 7 and a No. 2 natural gas nozzle holder fixing through hole 7 Hole 8, nozzle inlet 5, No. 1 natural gas nozzle seat fixing through hole 7 and No. 2 natural gas nozzle seat fixing through hole 8 are parallel to each other and in the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com