Multi-runner pipe electrode and system and single circulation electrolysis cutting method

A multi-channel, electrode technology, applied in the direction of electrode manufacturing, processing electrodes, electric processing equipment, etc., can solve the problems of difficult electrolyte renewal and electrolysis product discharge, and achieve the effect of easier discharge and uniform flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

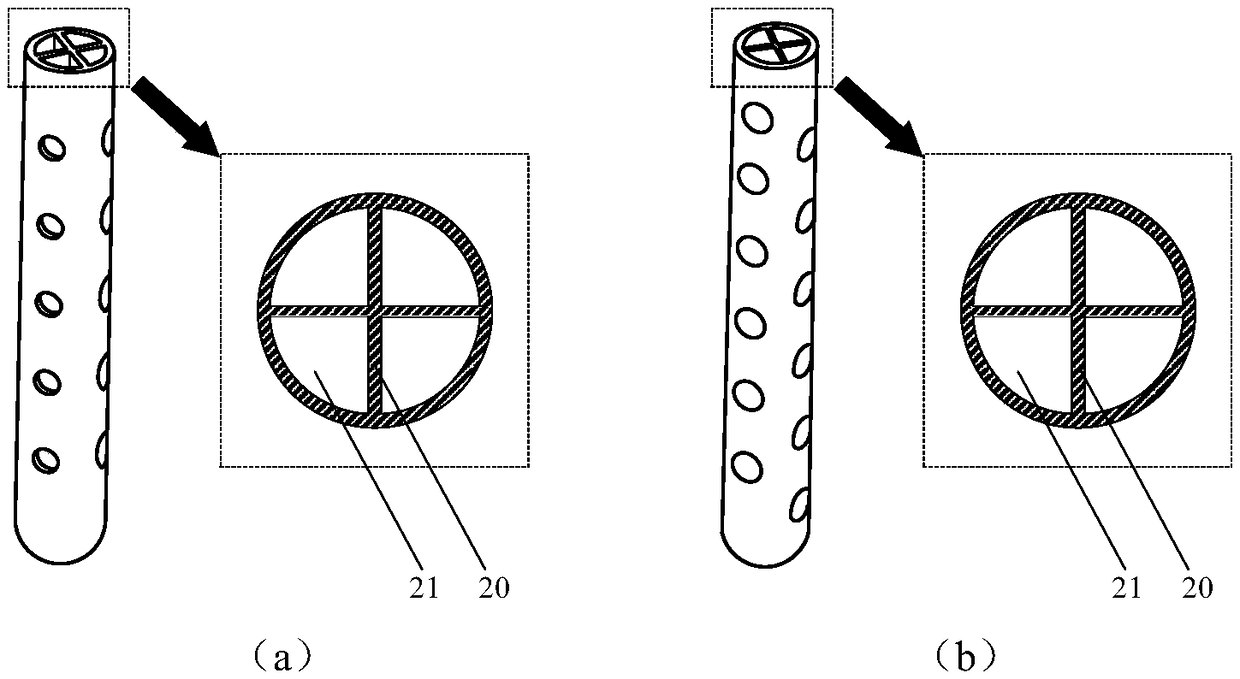

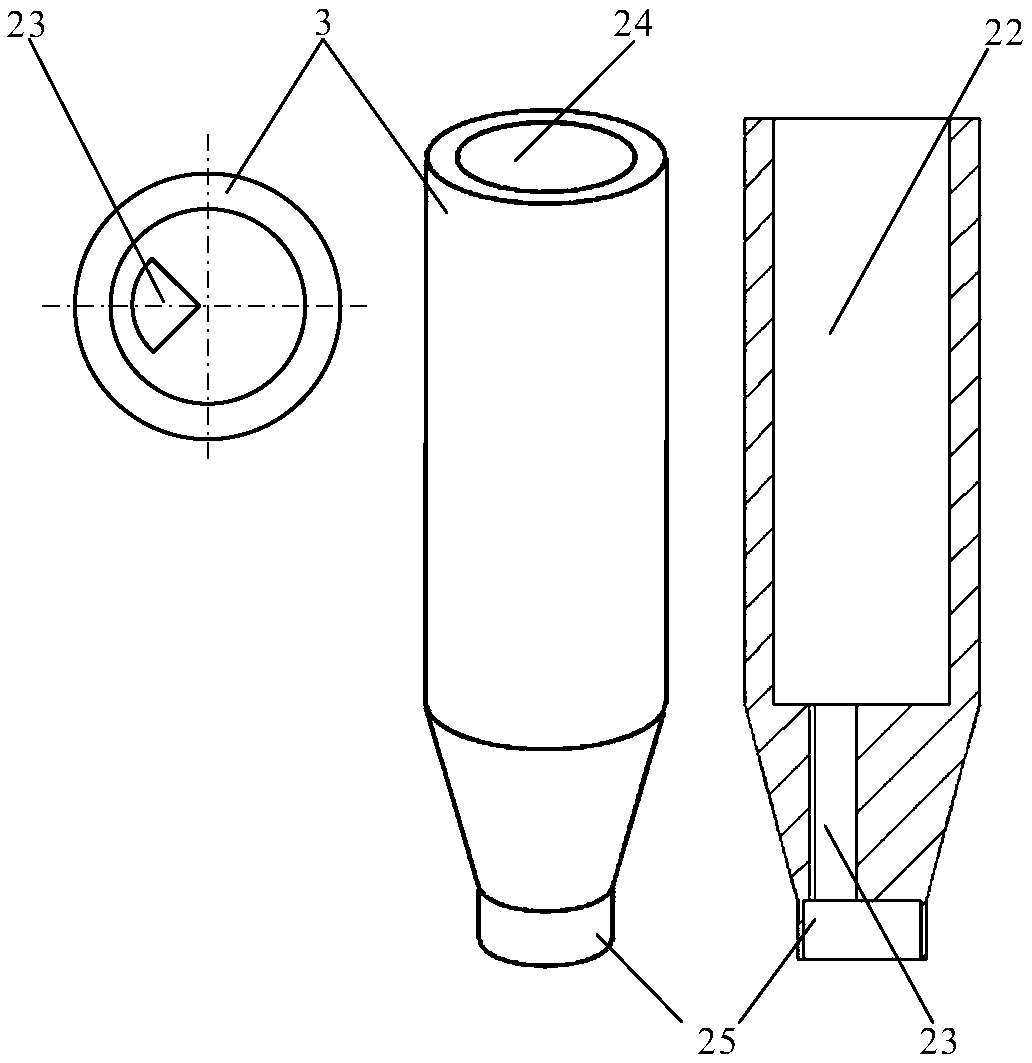

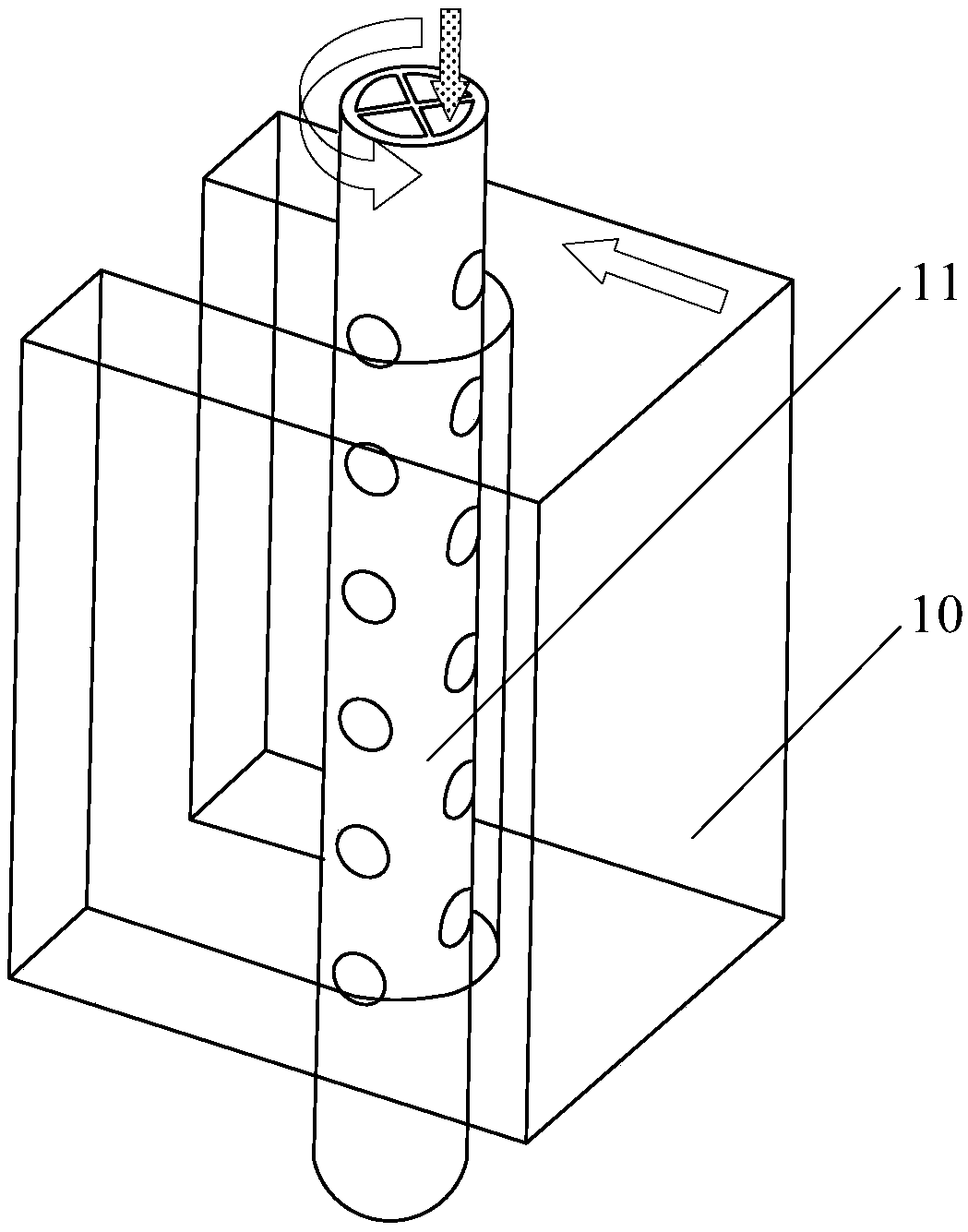

[0022] according to figure 1 As shown, a multi-channel tube electrode 11 proposed by the present invention is a metal round tube with a closed lower end, and a plurality of partitions 20 arranged axially in the tube are evenly arranged to divide the inner cavity of the tube into a plurality of identical flow channels 21; The outer wall of the multi-channel tube electrode 11 corresponding to each flow channel 21 is arranged with an array of small holes; and in the thickness direction of the workpiece 10, the distribution range length of the small hole array is greater than or equal to the thickness of the workpiece, ensuring that the electrolyte solution jetted out of the small hole array 15 can cover the entire processing area; the small hole arrays corresponding to adjacent flow channels 21 are different; the so-called different small hole arrays refer to one or more of the following parameters: hole diameter, hole spacing, hole height, hole angle, The hole angle refers to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com