Patents

Literature

366results about "Steering by jets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

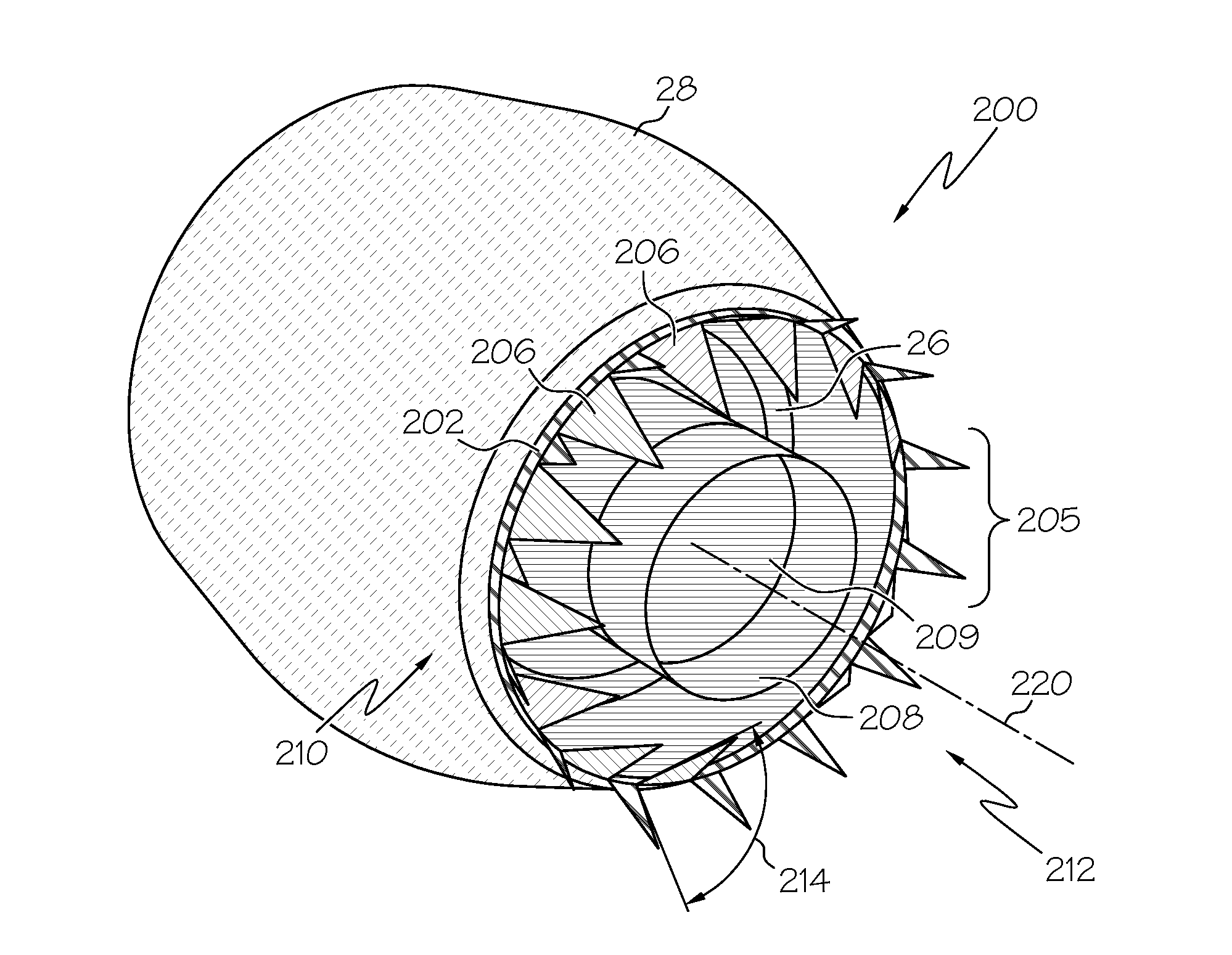

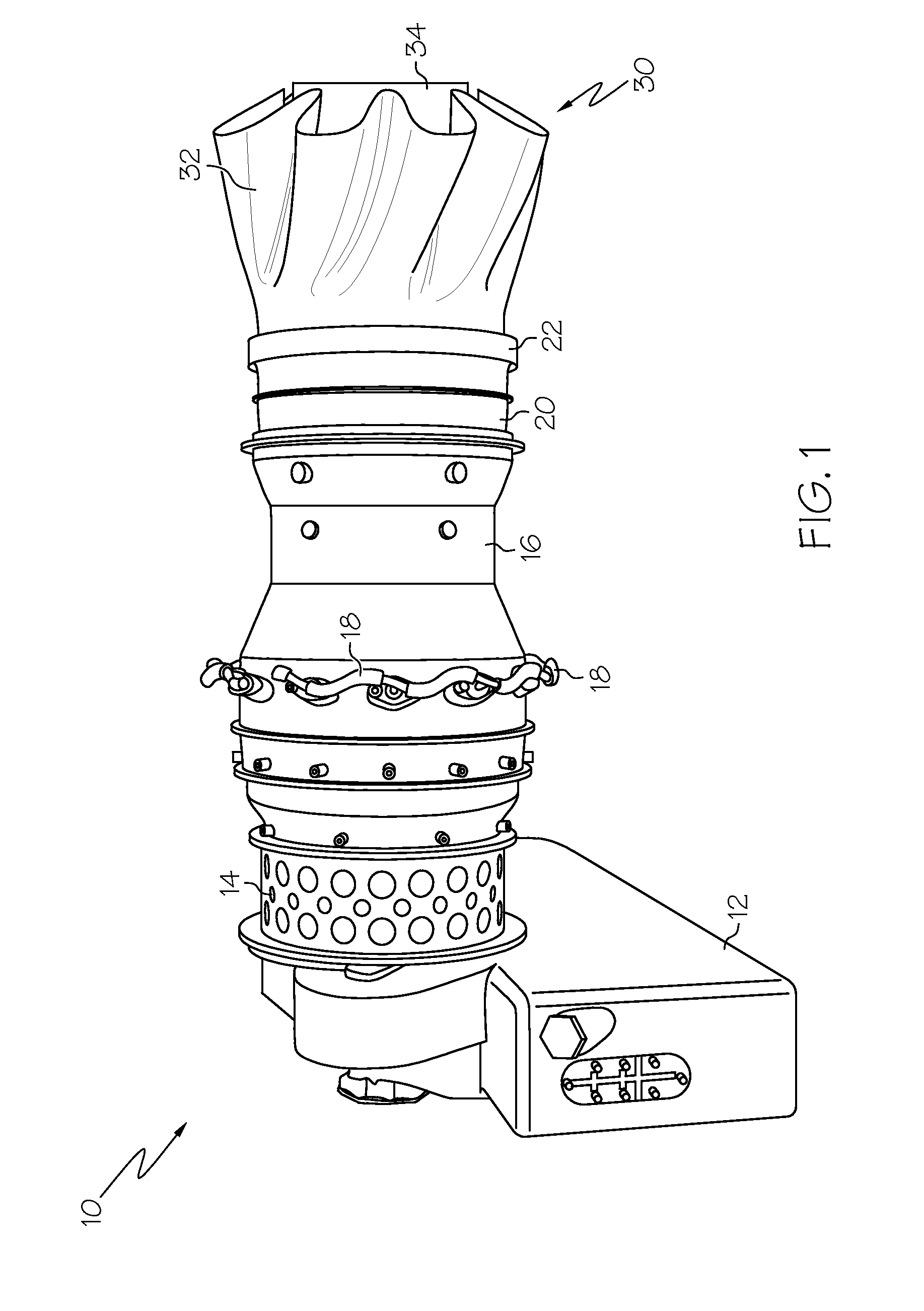

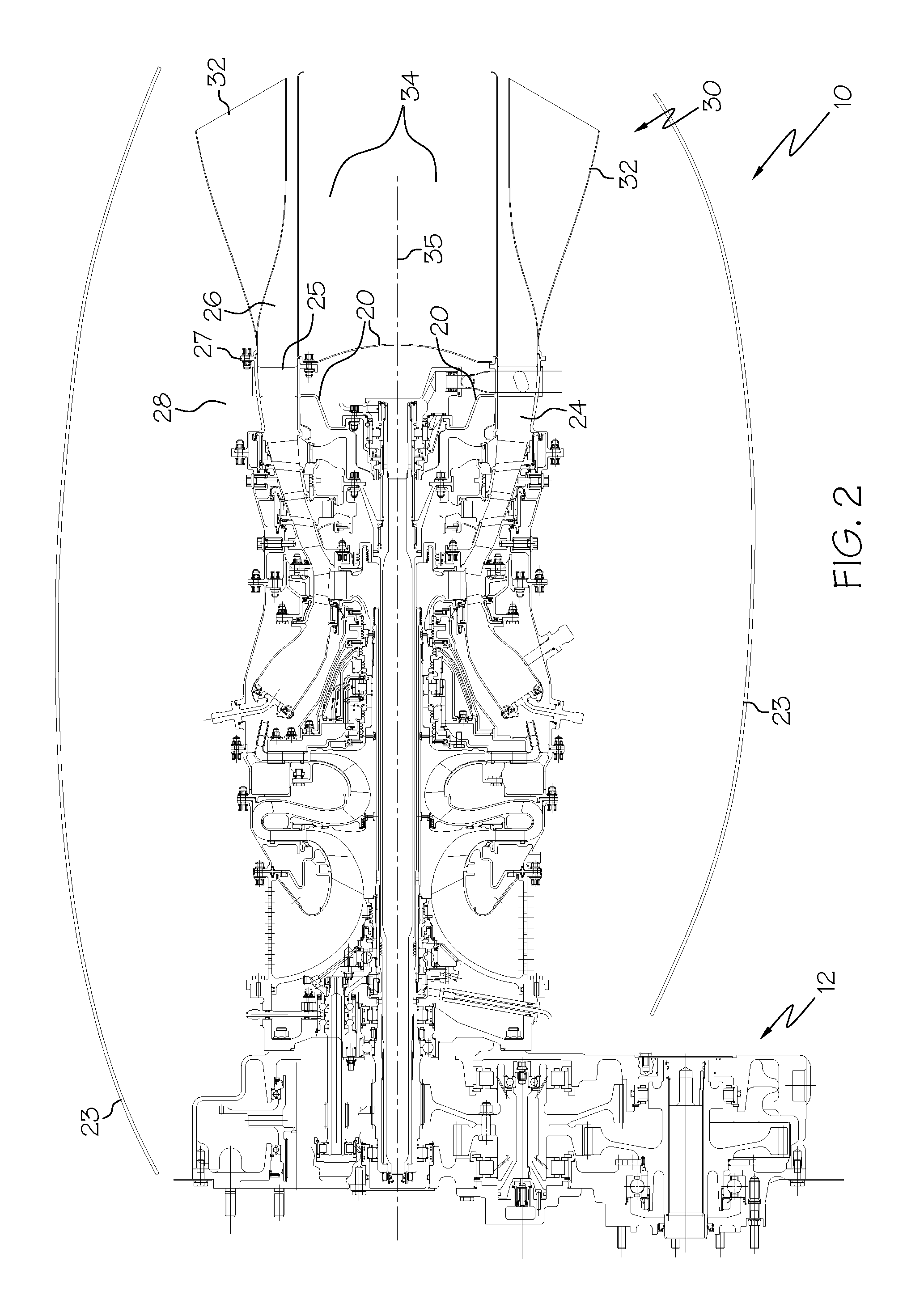

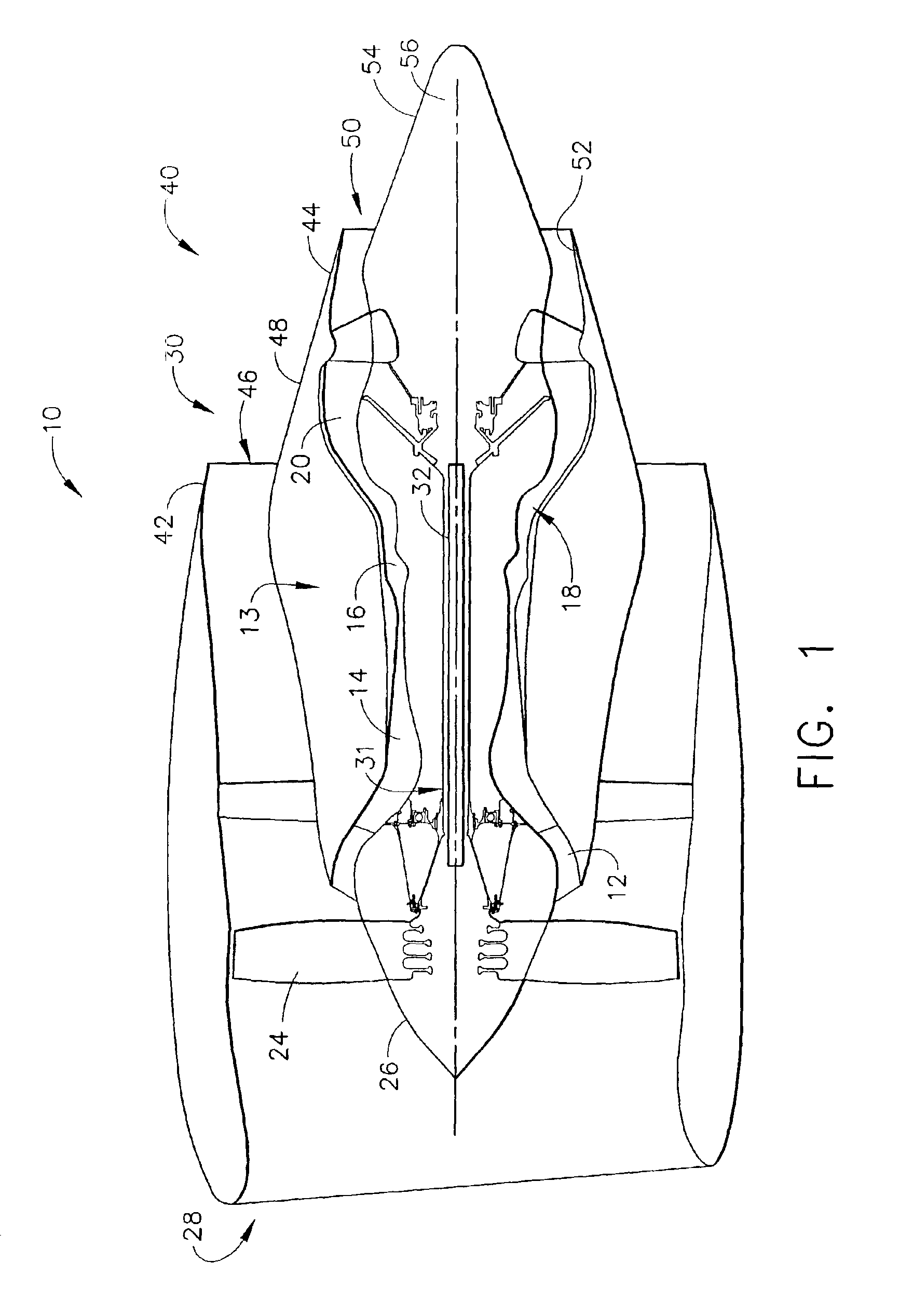

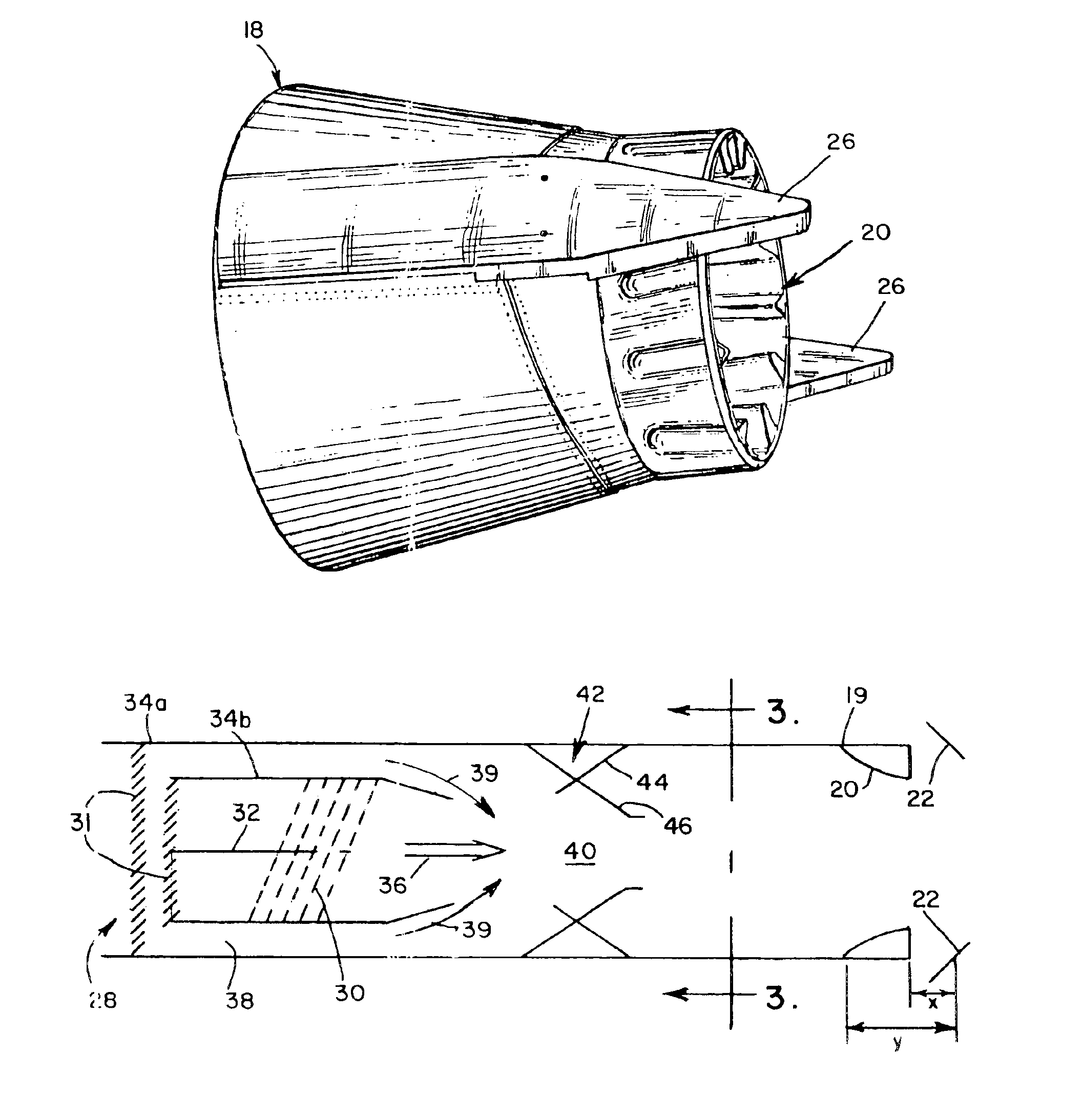

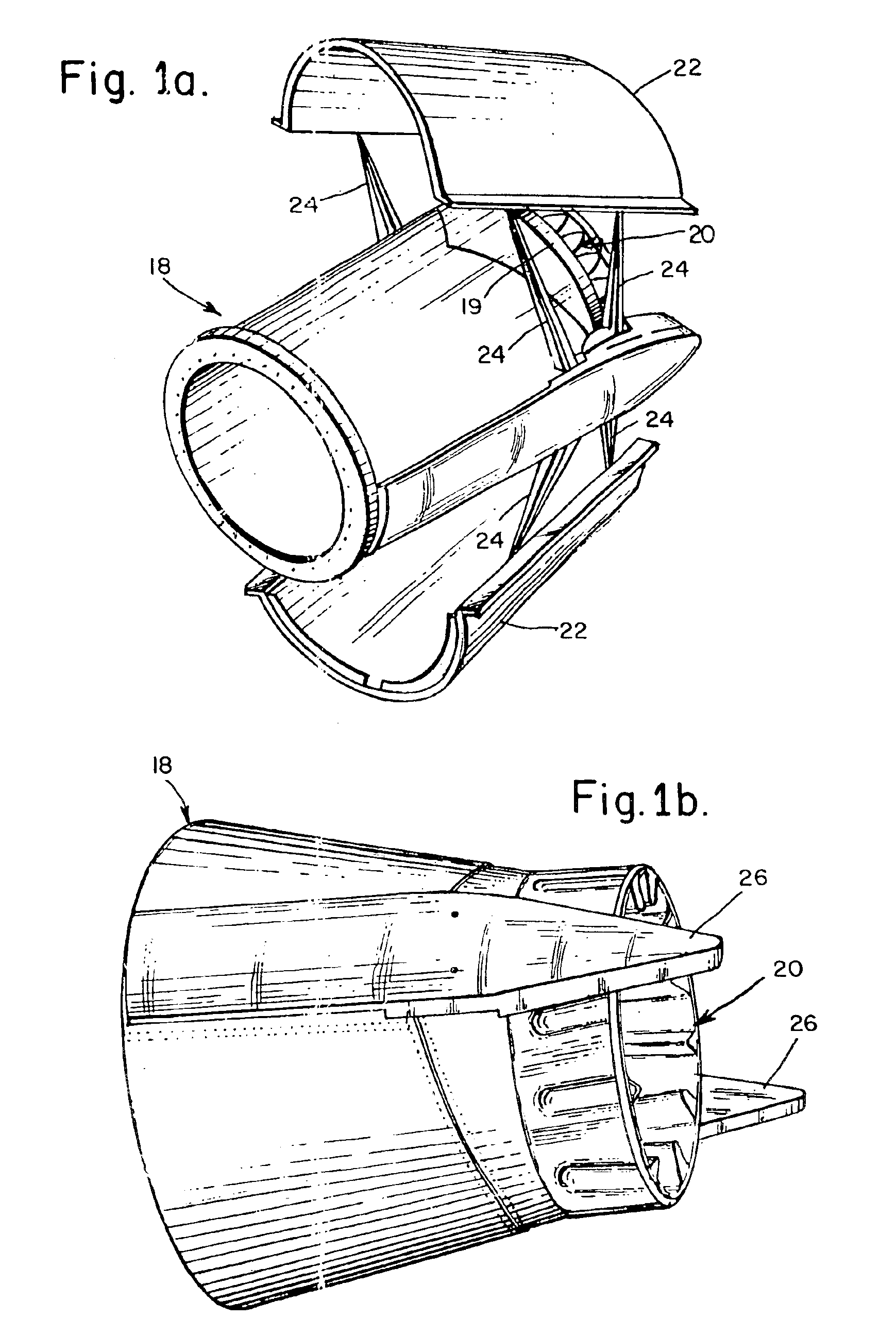

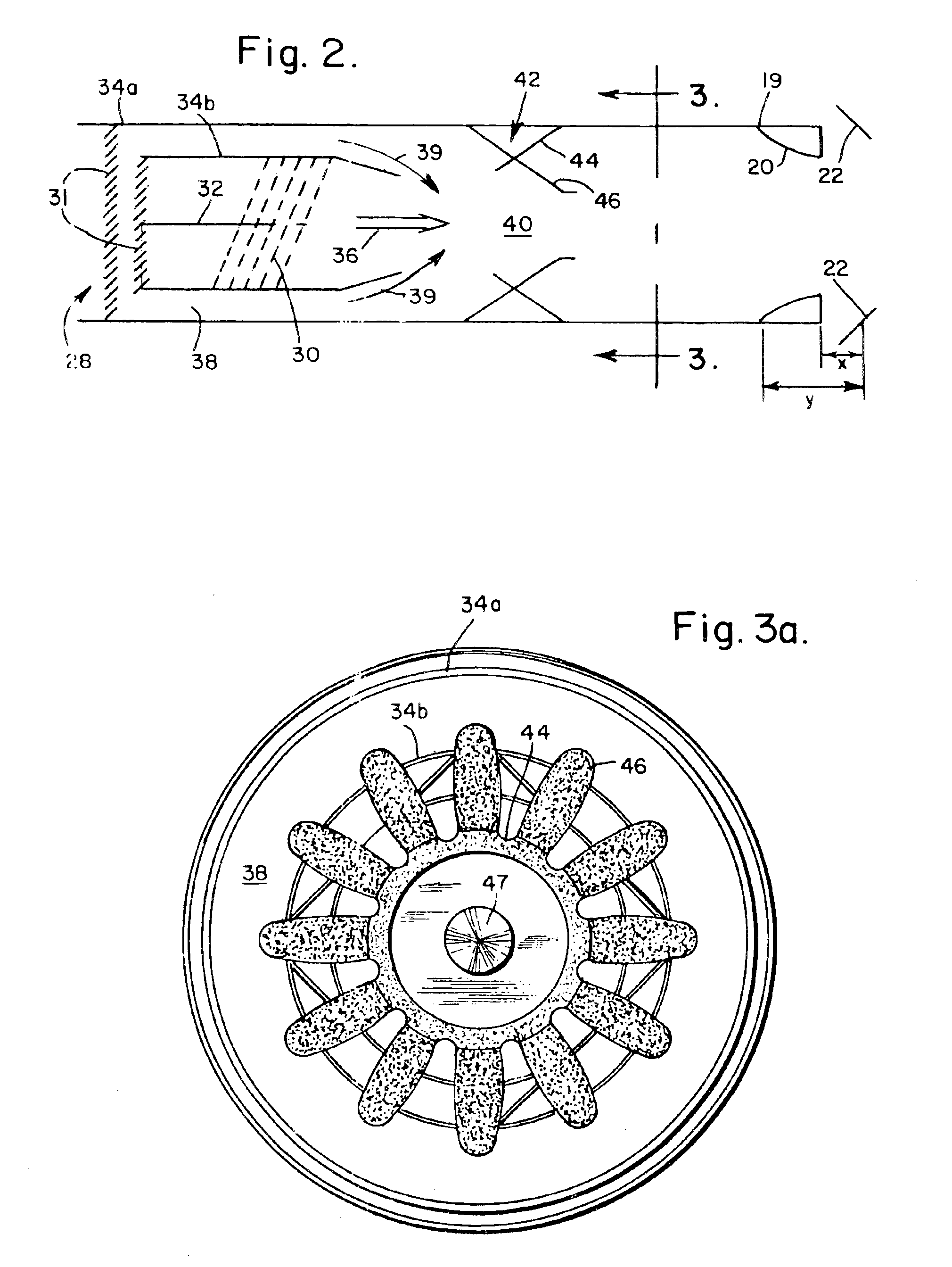

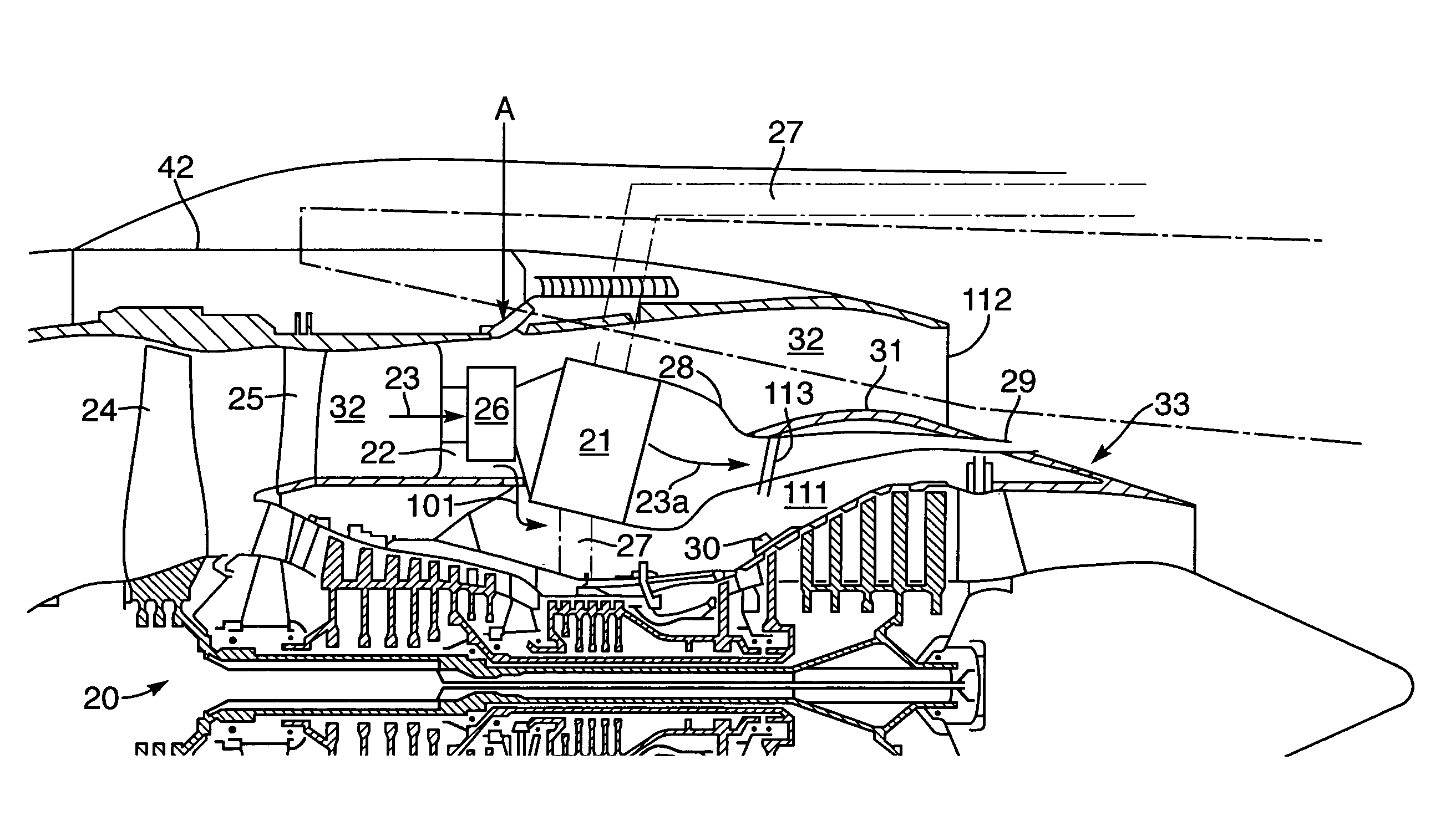

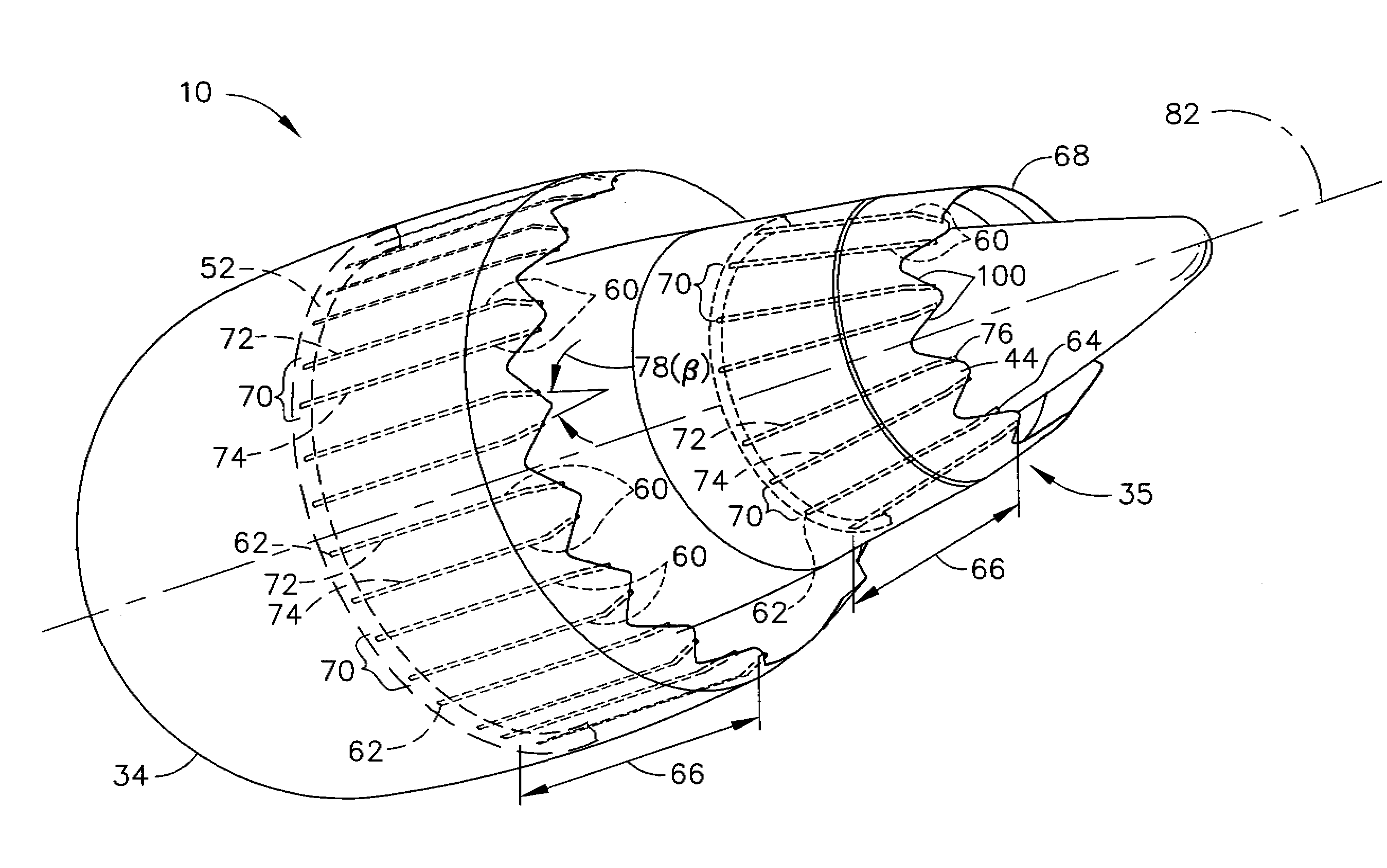

Compact mixer with trimmable open centerbody

ActiveUS7506501B2Power plant exhaust arrangementsEngine manufactureEngineeringMechanical engineering

Compact exhaust mixer assemblies comprising a compact mixer and a trimmable open centerbody are provided. The trimmable center body allows for adjustments of the open centerbody after manufacturing and during production testing. The trimmable open centerbody may be used to compensate for production tolerances making it possible to obtain the desired core effective area for proper engine operation. The compact mixer may be either lobed or serrated. The compact exhaust mixer assemblies have a length of about half that of conventional exhaust mixer assemblies.

Owner:HONEYWELL INT INC

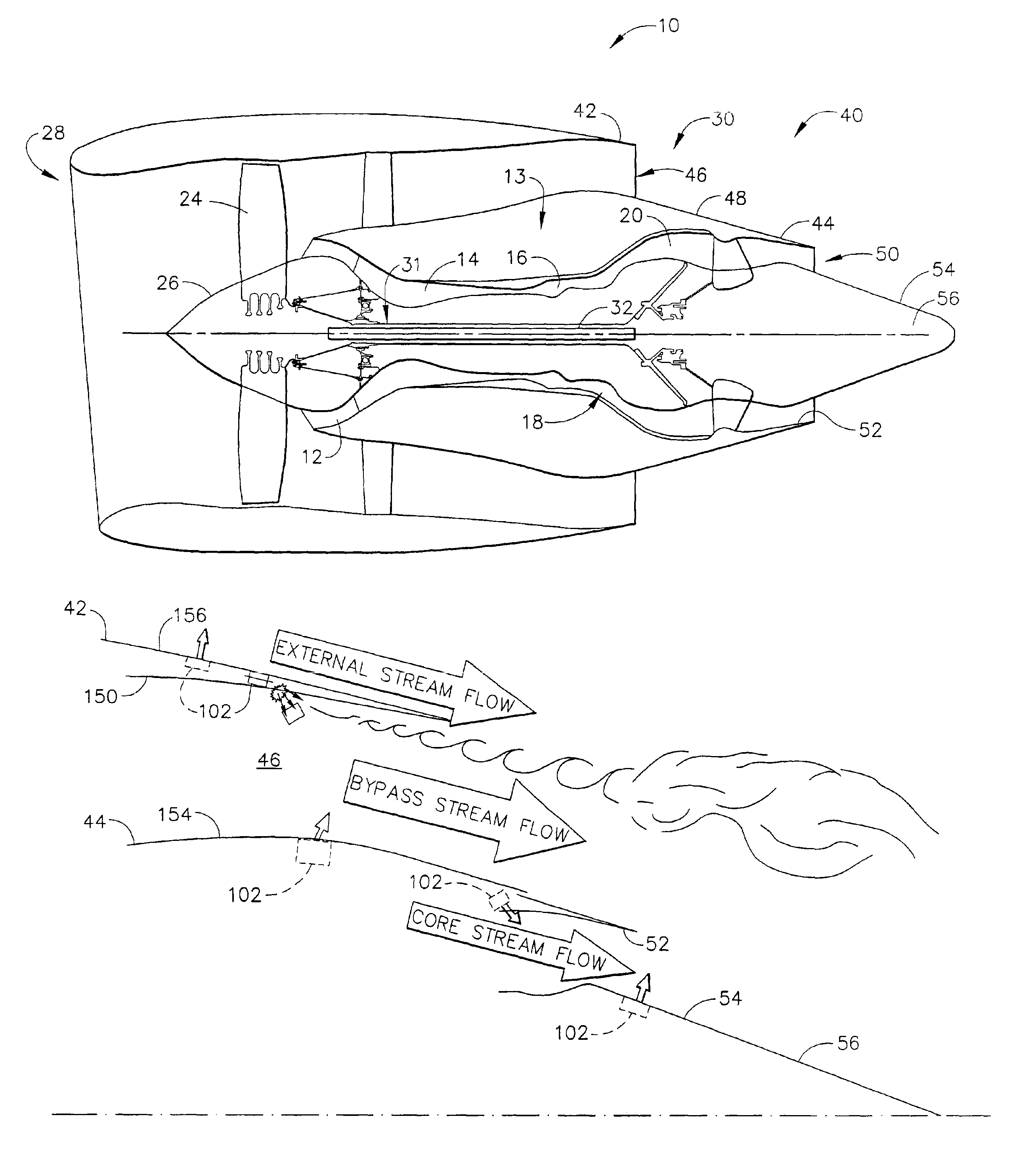

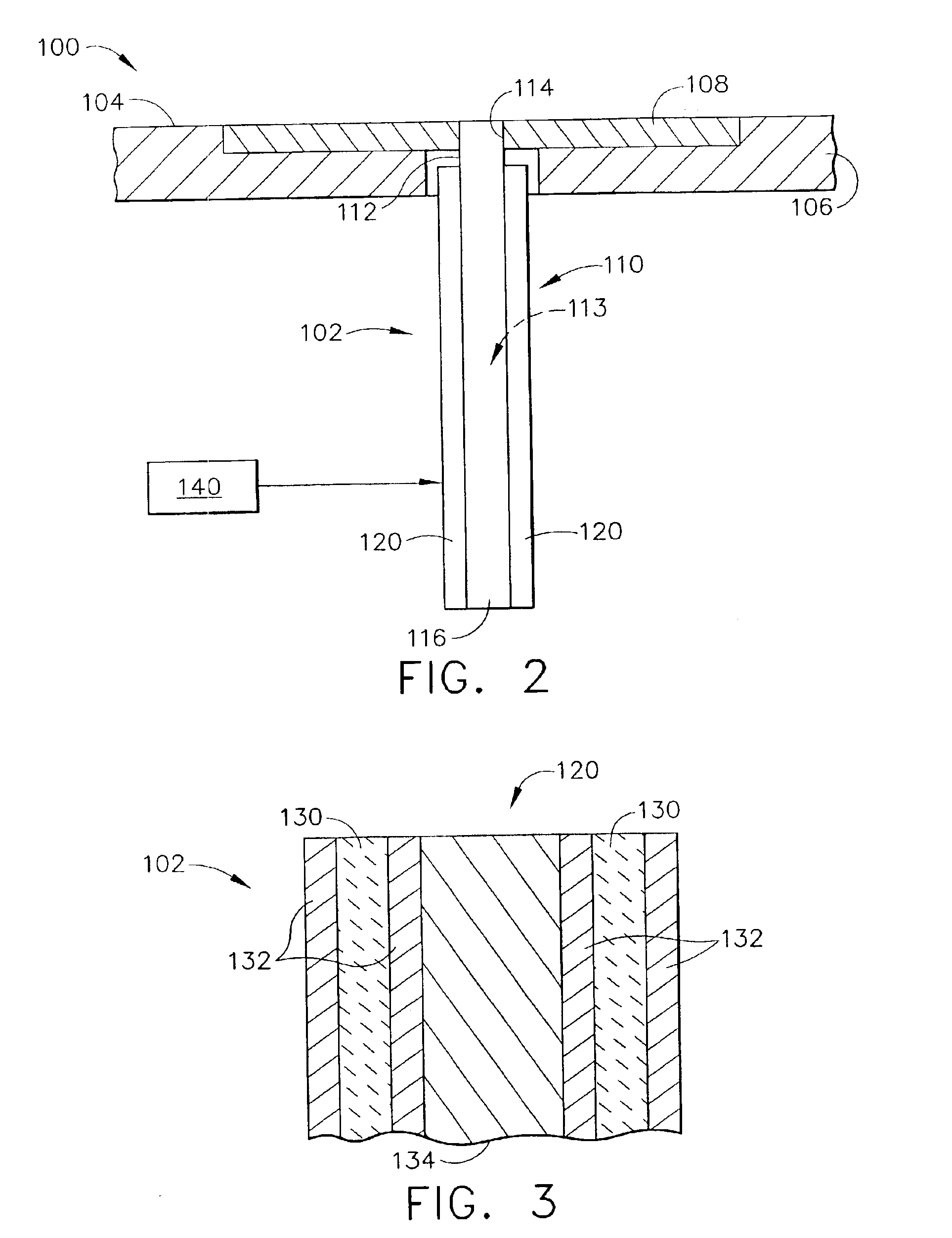

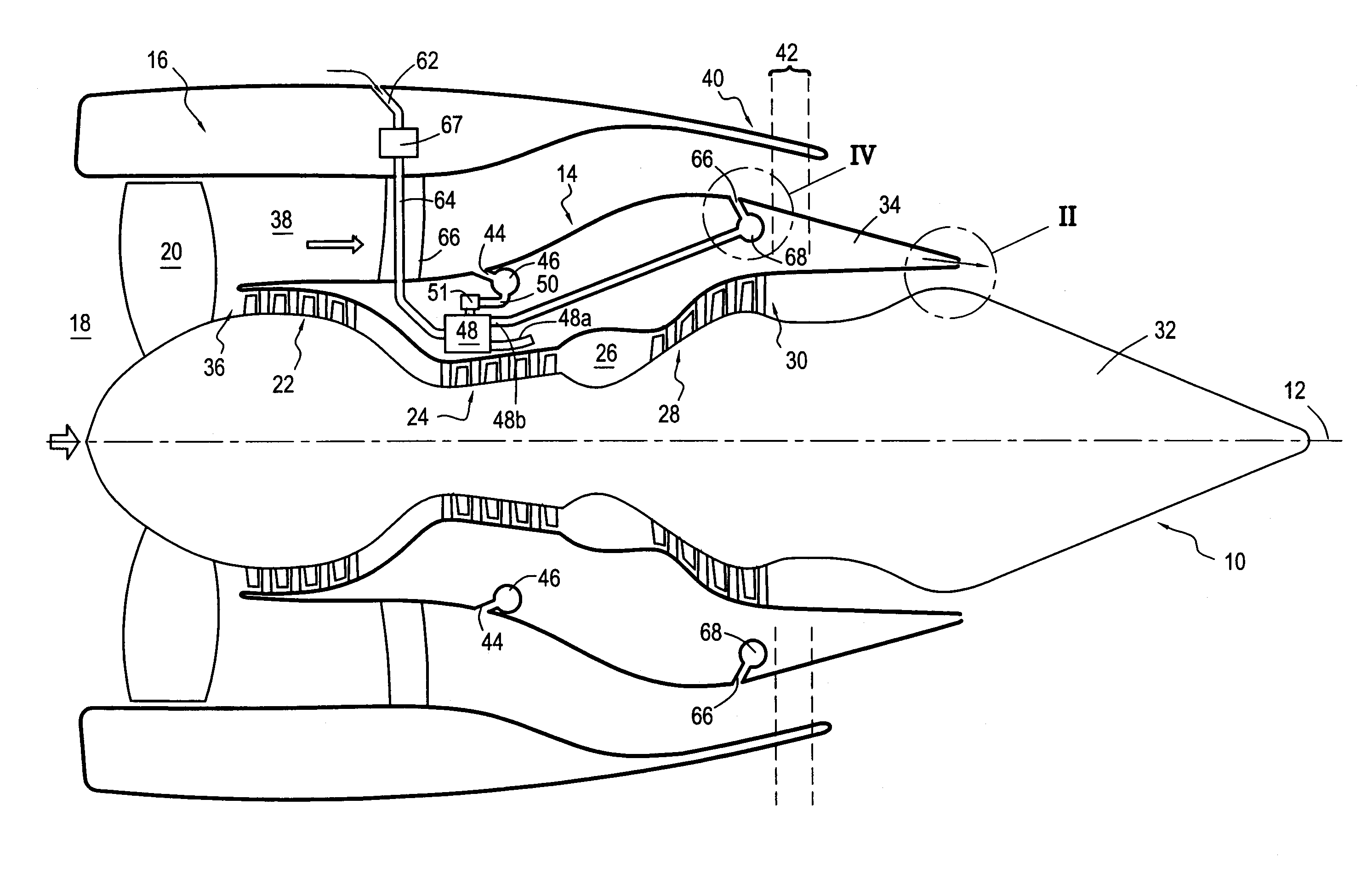

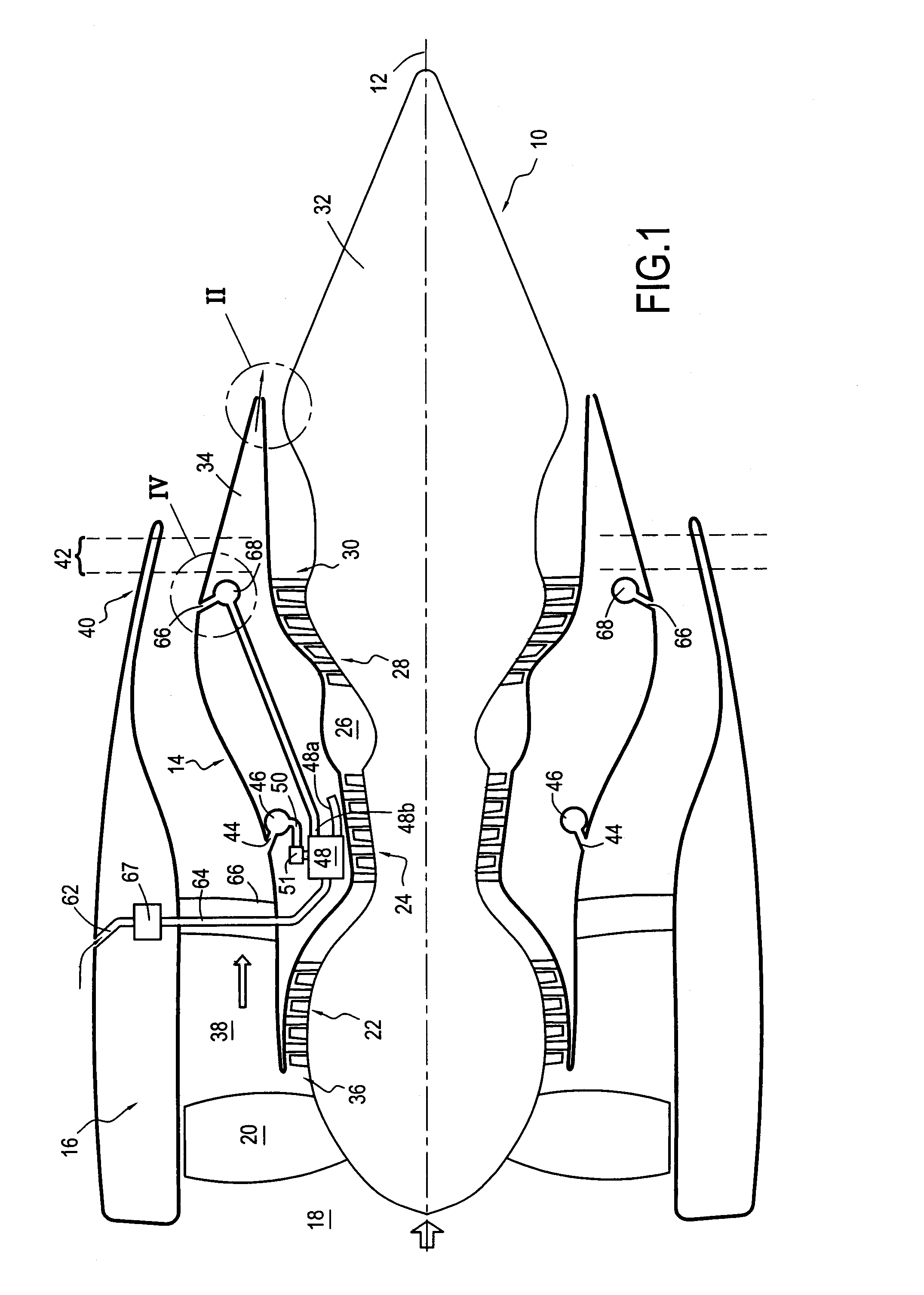

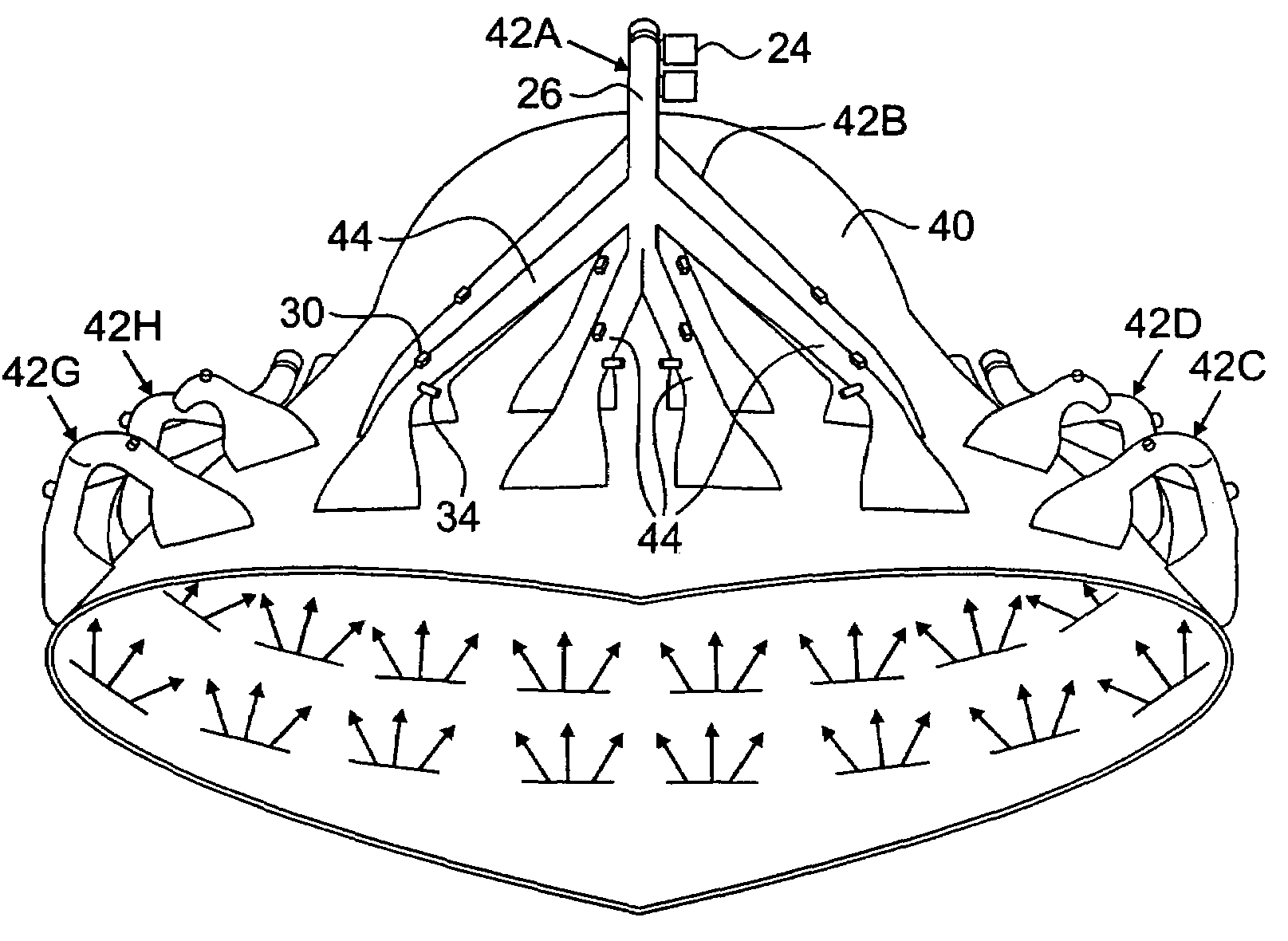

Method and apparatus for noise attenuation for gas turbine engines using at least one synthetic jet actuator for injecting air

ActiveUS7055329B2Facilitate attenuating jet noiseEasy to operatePower plant exhaust arrangementsCosmonautic vehiclesActuatorNoise suppression

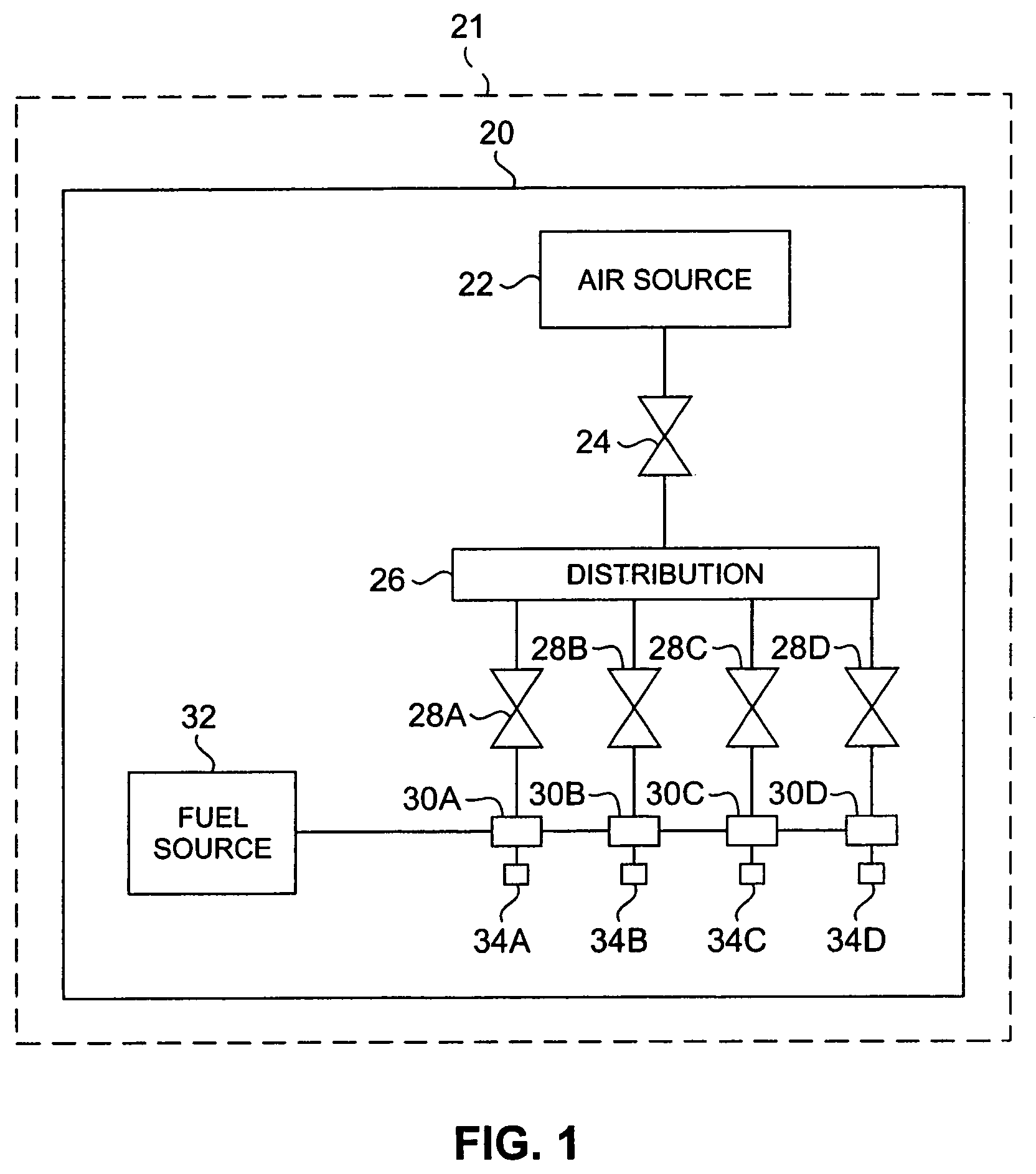

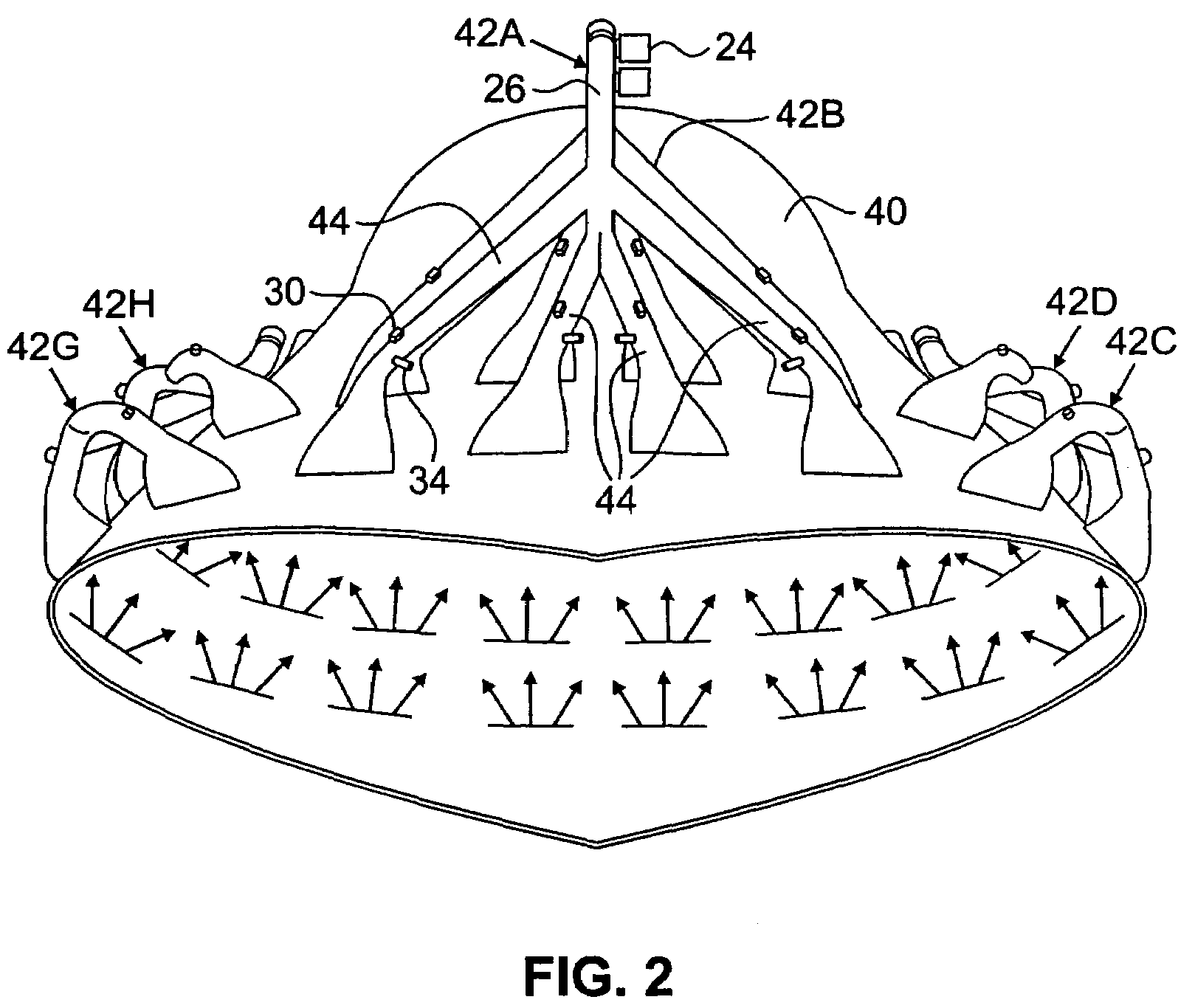

A method enables a gas turbine engine to be operated. The method comprises channeling exhaust gases from a core engine through an exhaust assembly and past at least one flow boundary surface, and selectively operating a noise suppression system extending from the at least one flow boundary surface to facilitate attenuating noise generated during engine operation.

Owner:GENERAL ELECTRIC CO

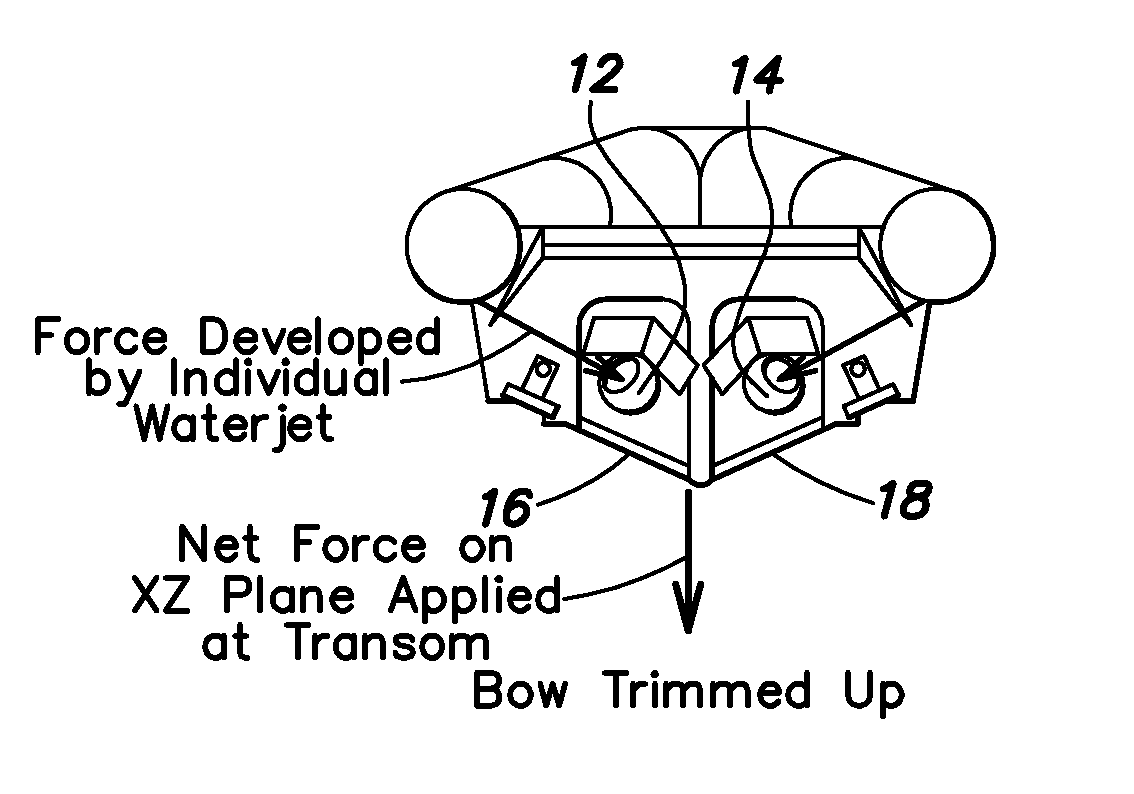

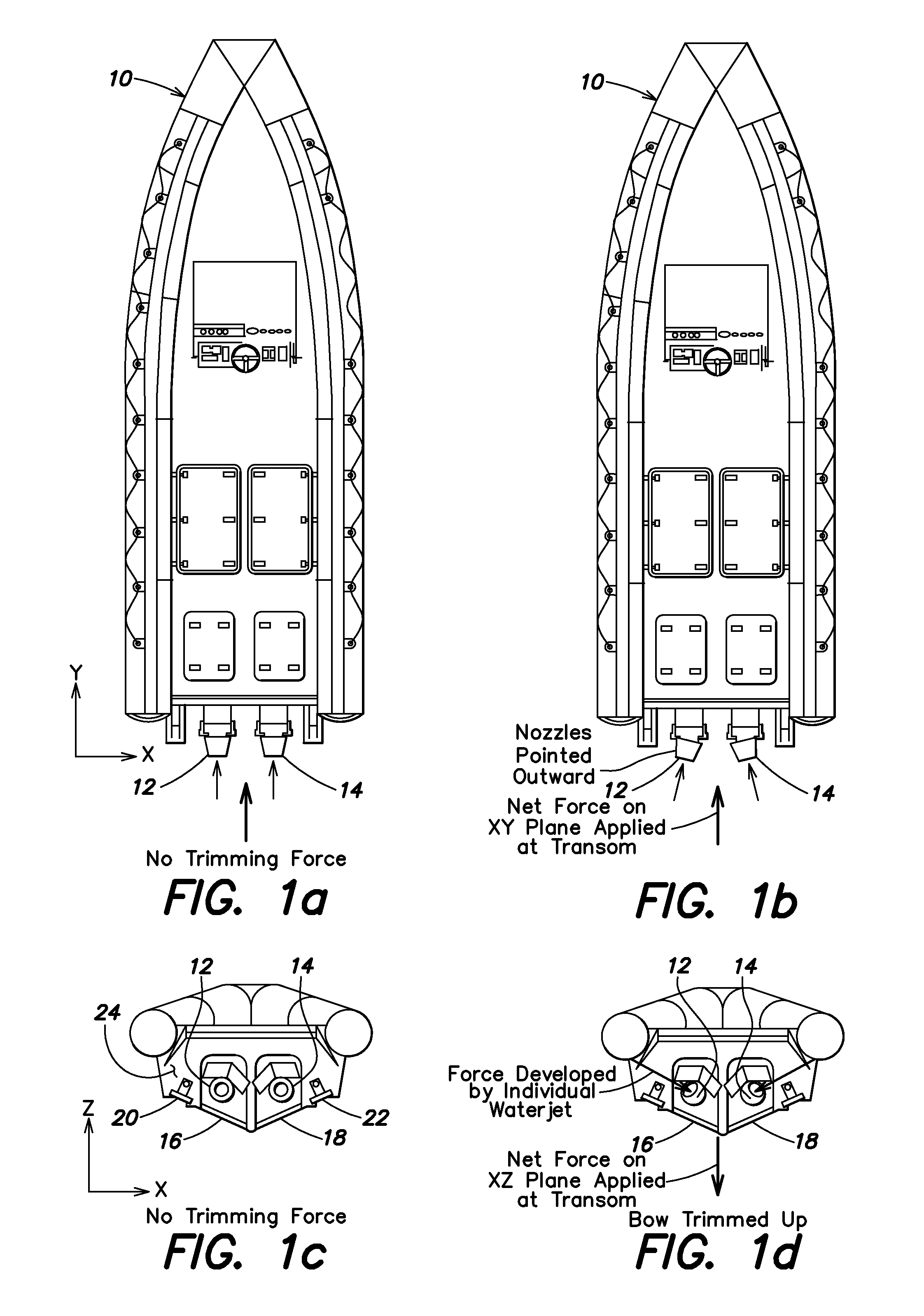

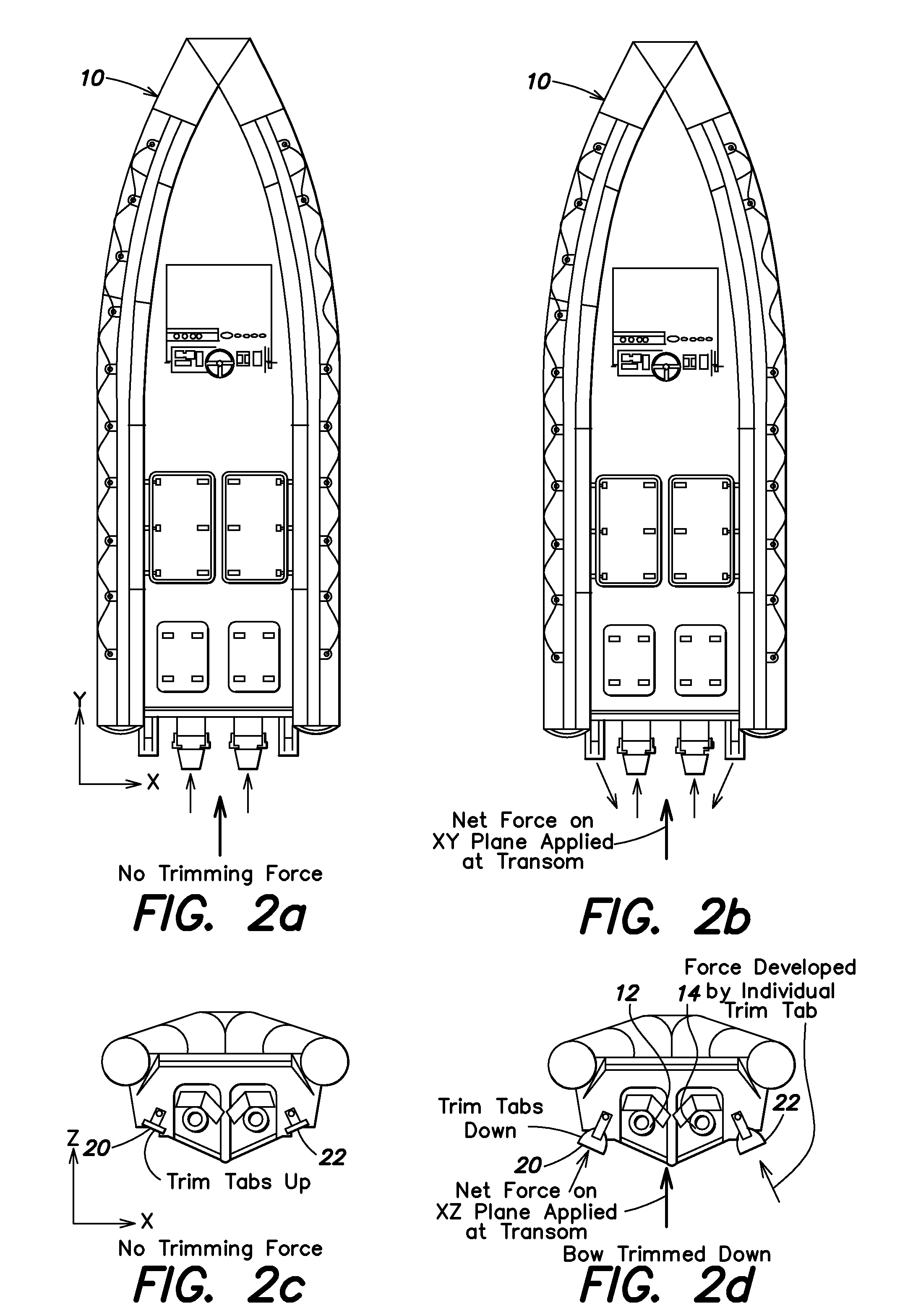

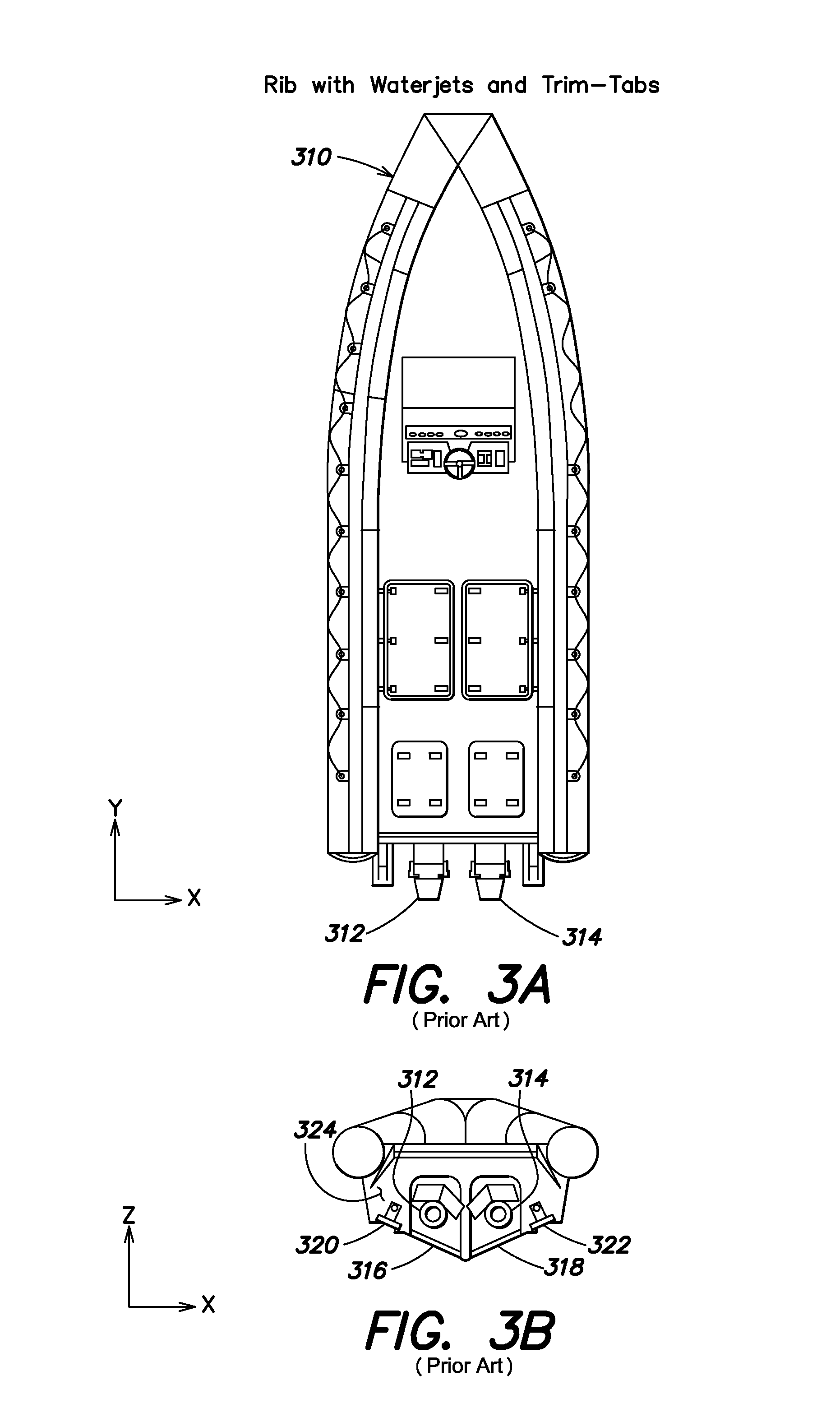

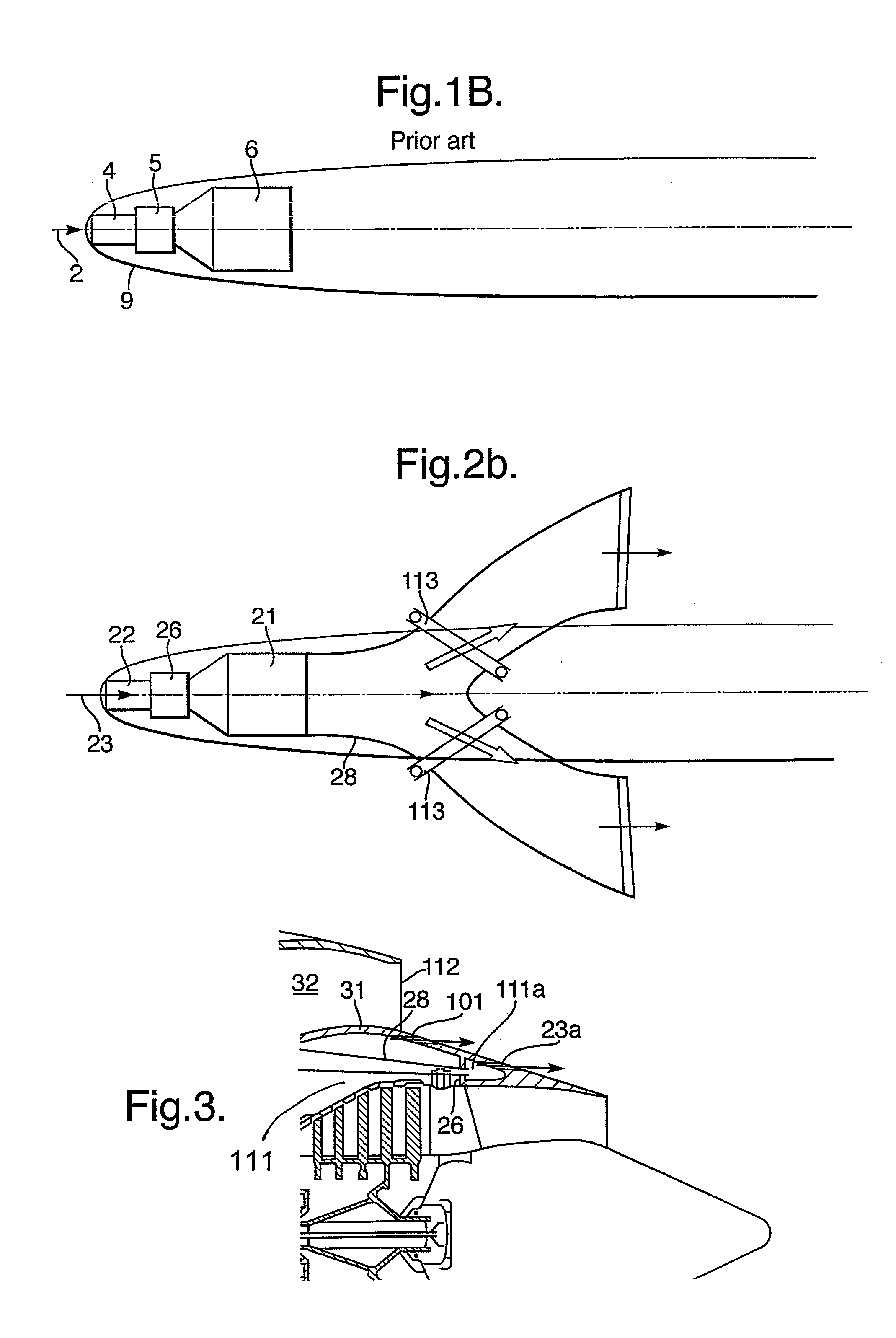

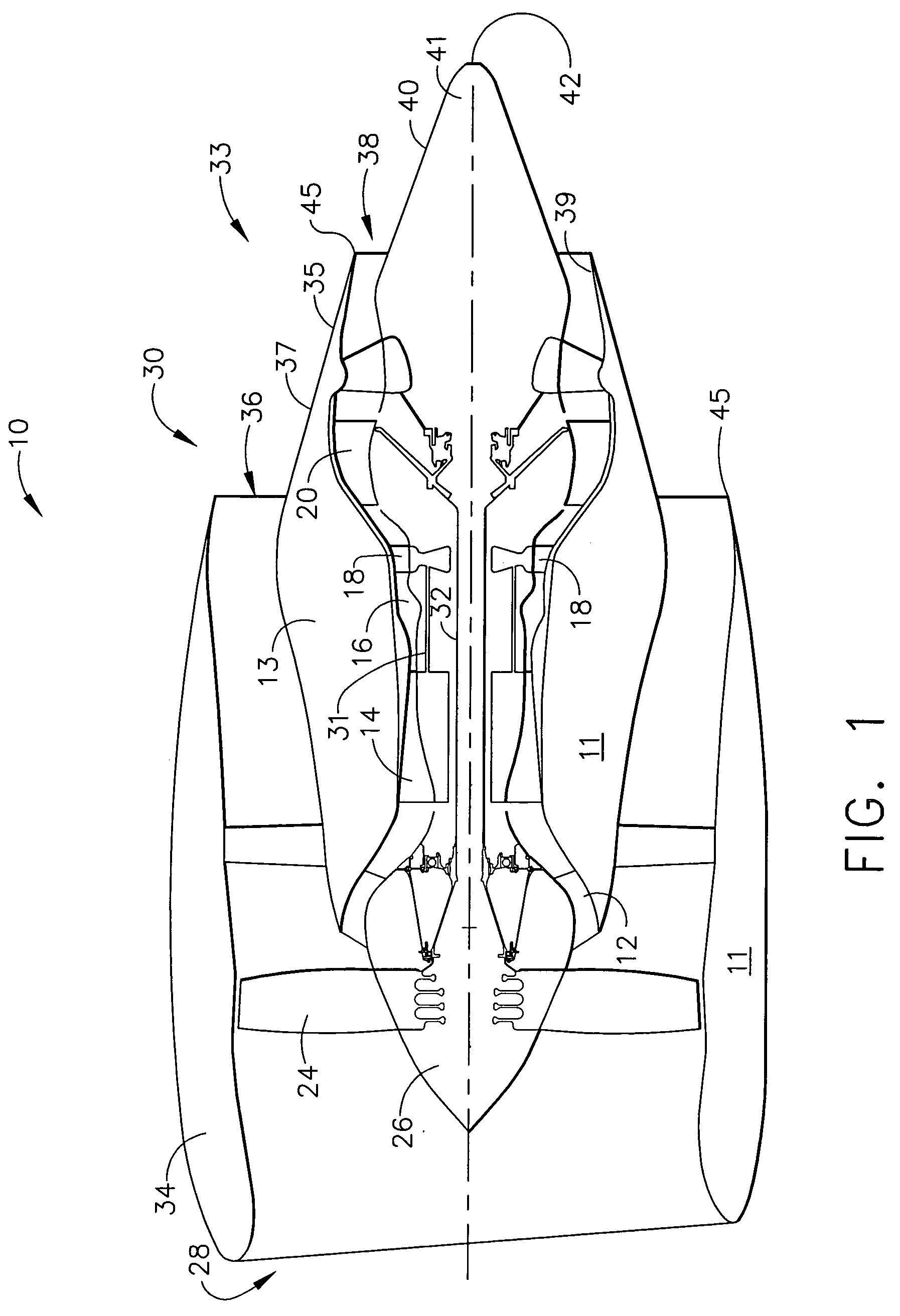

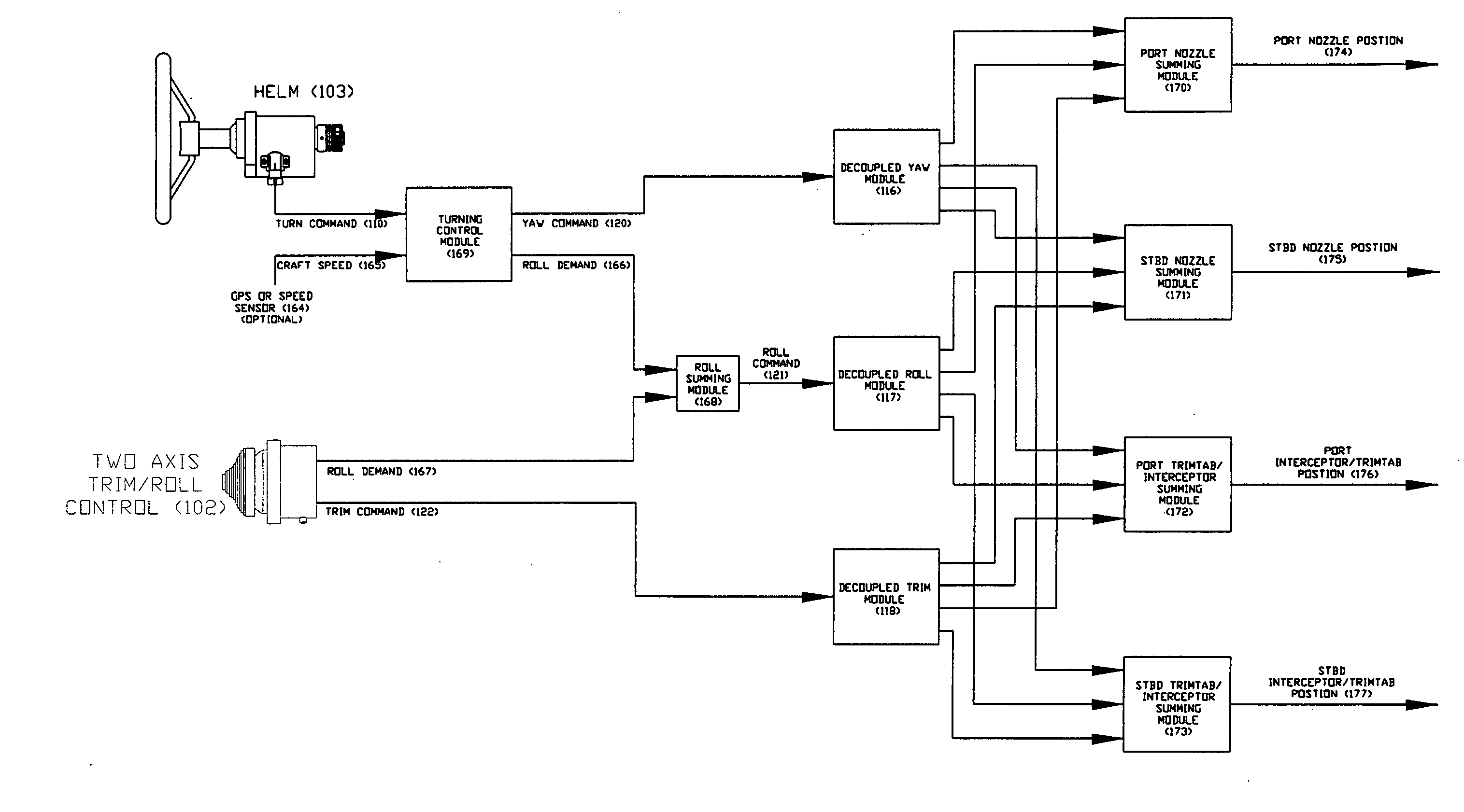

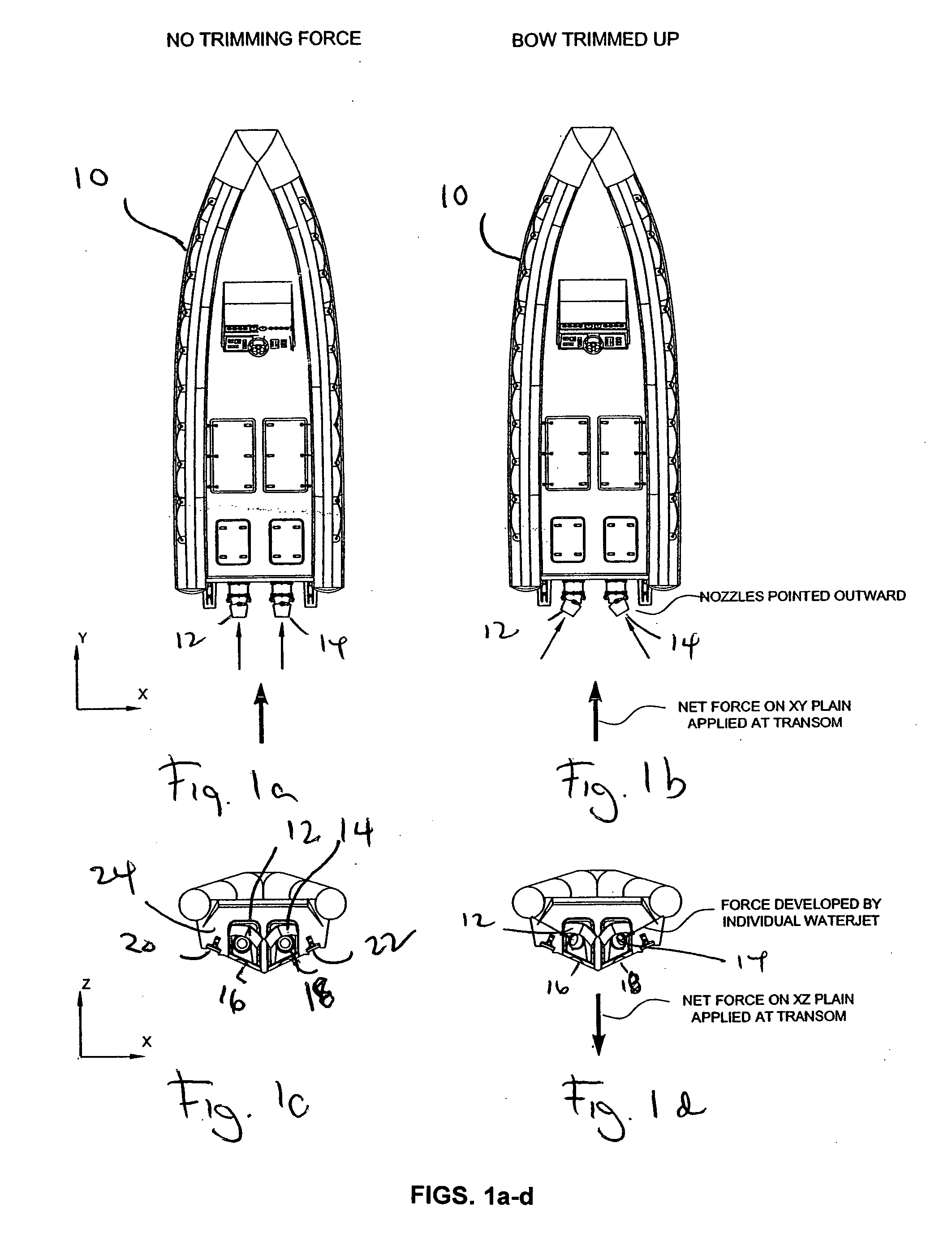

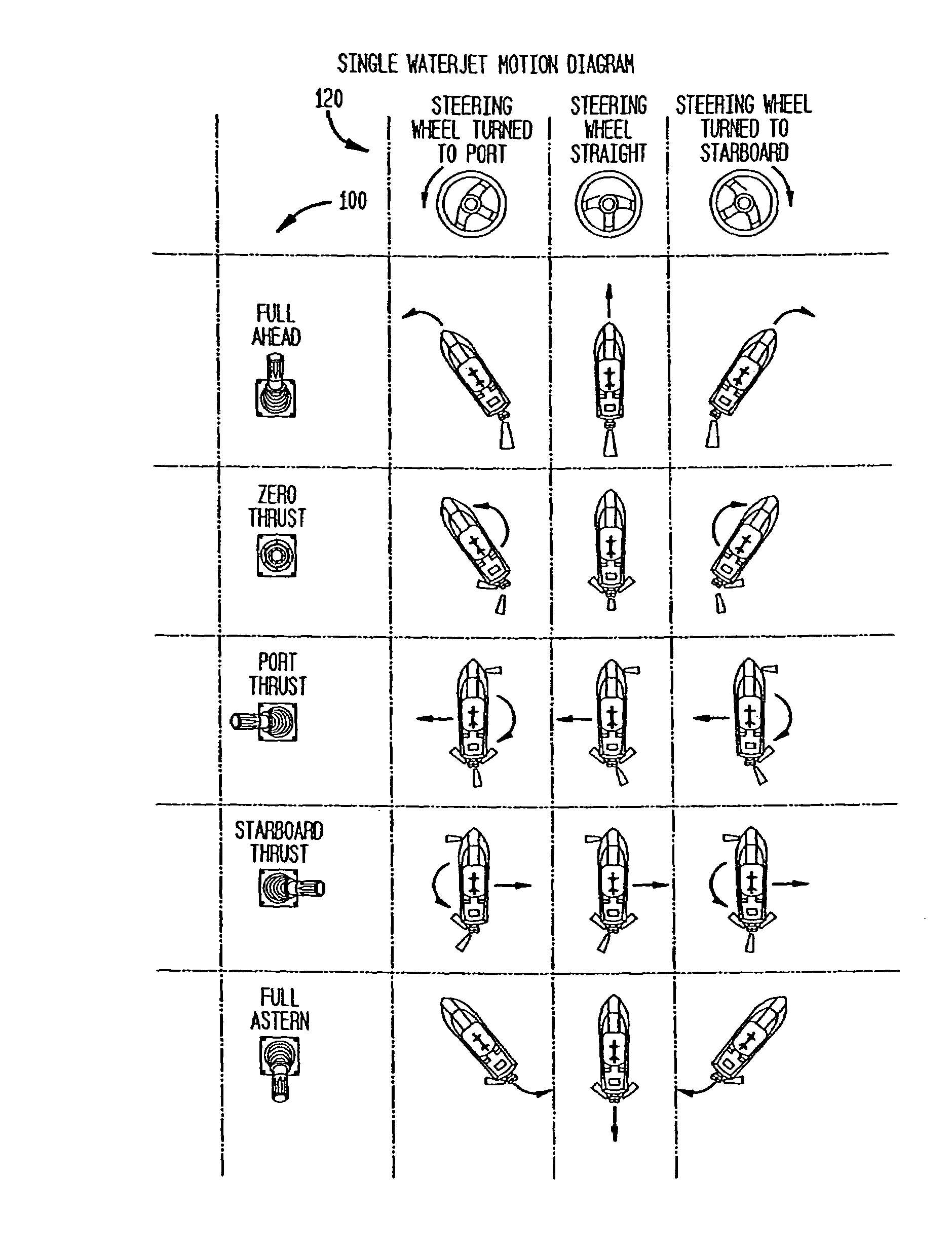

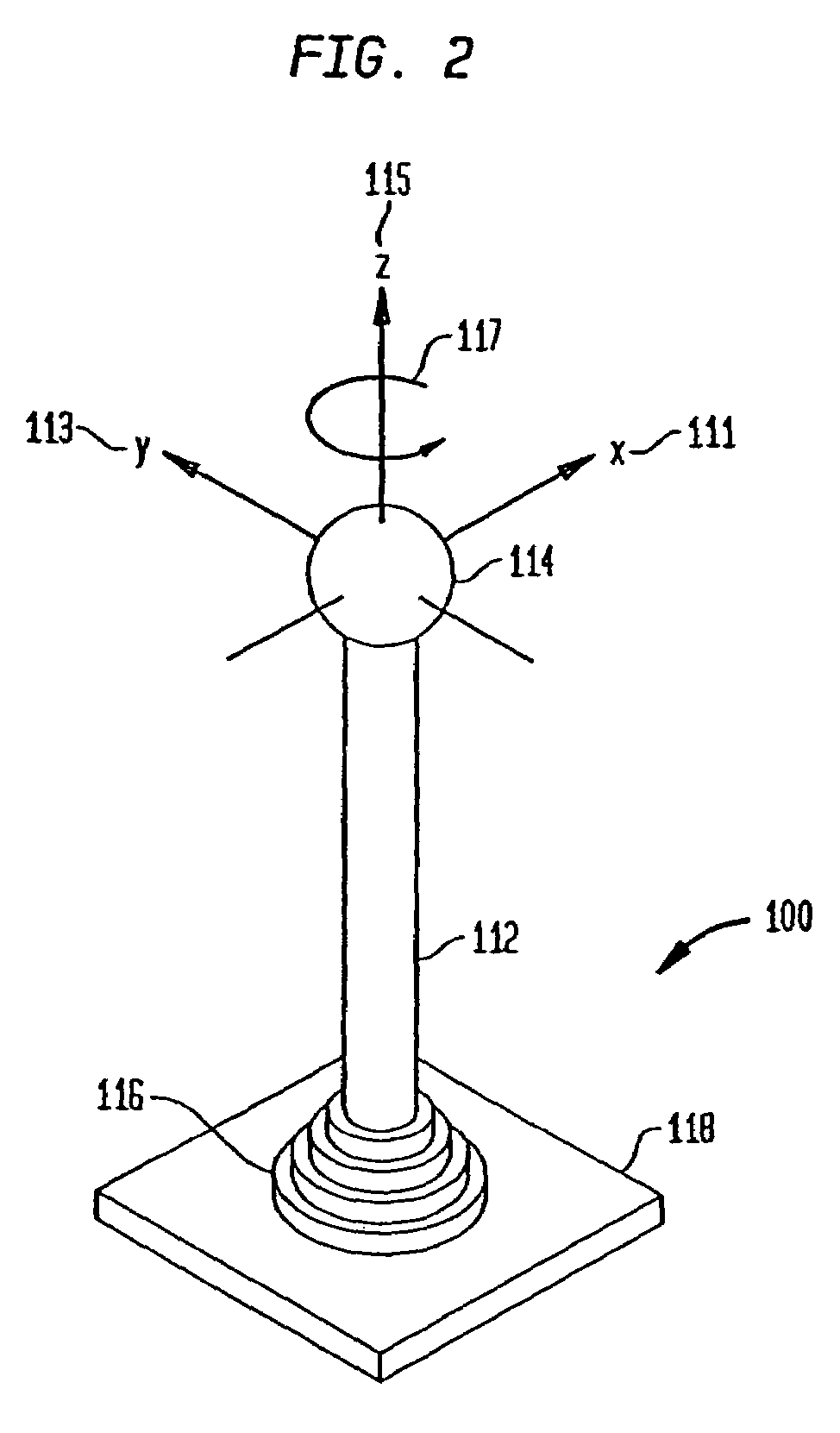

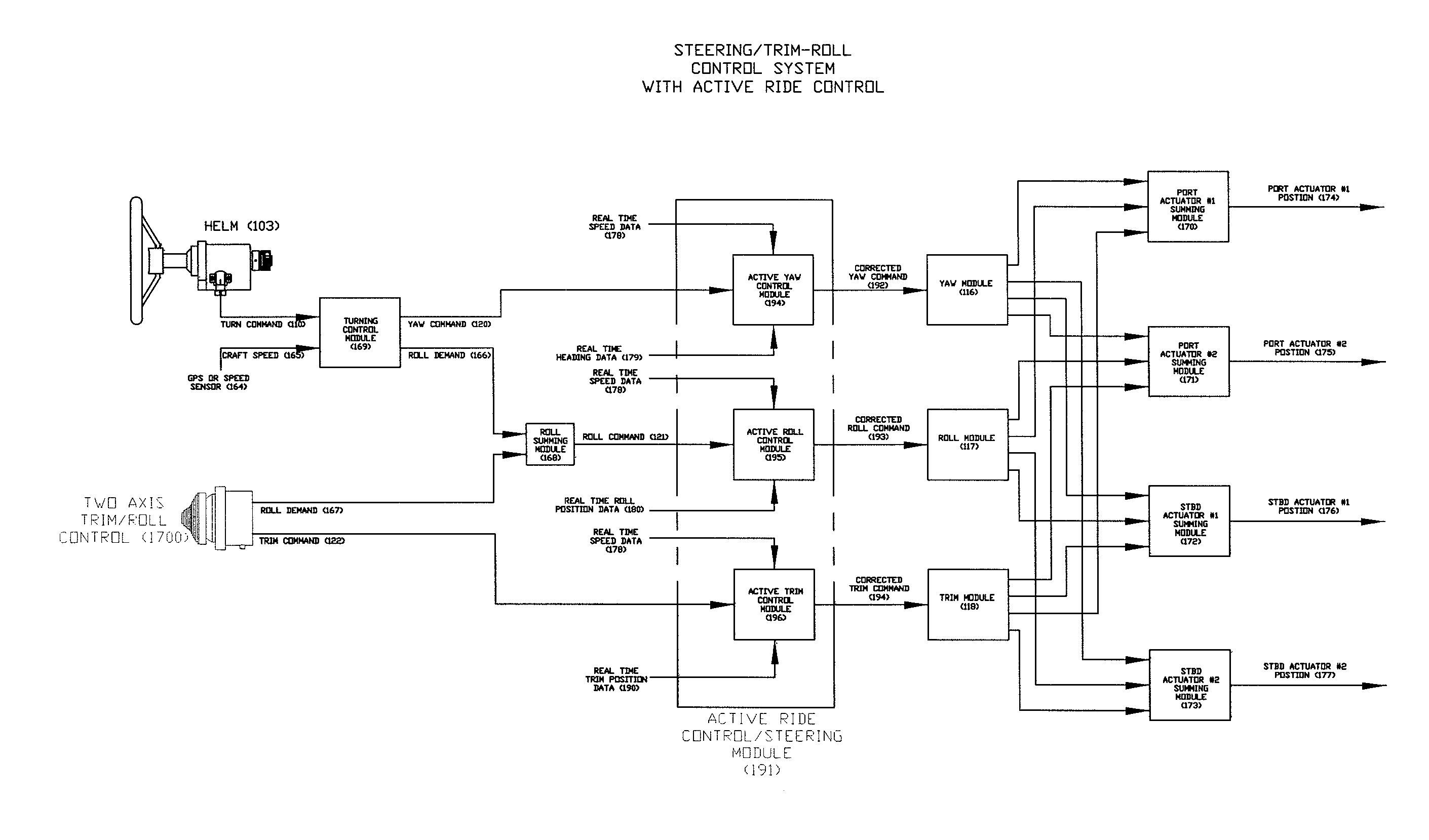

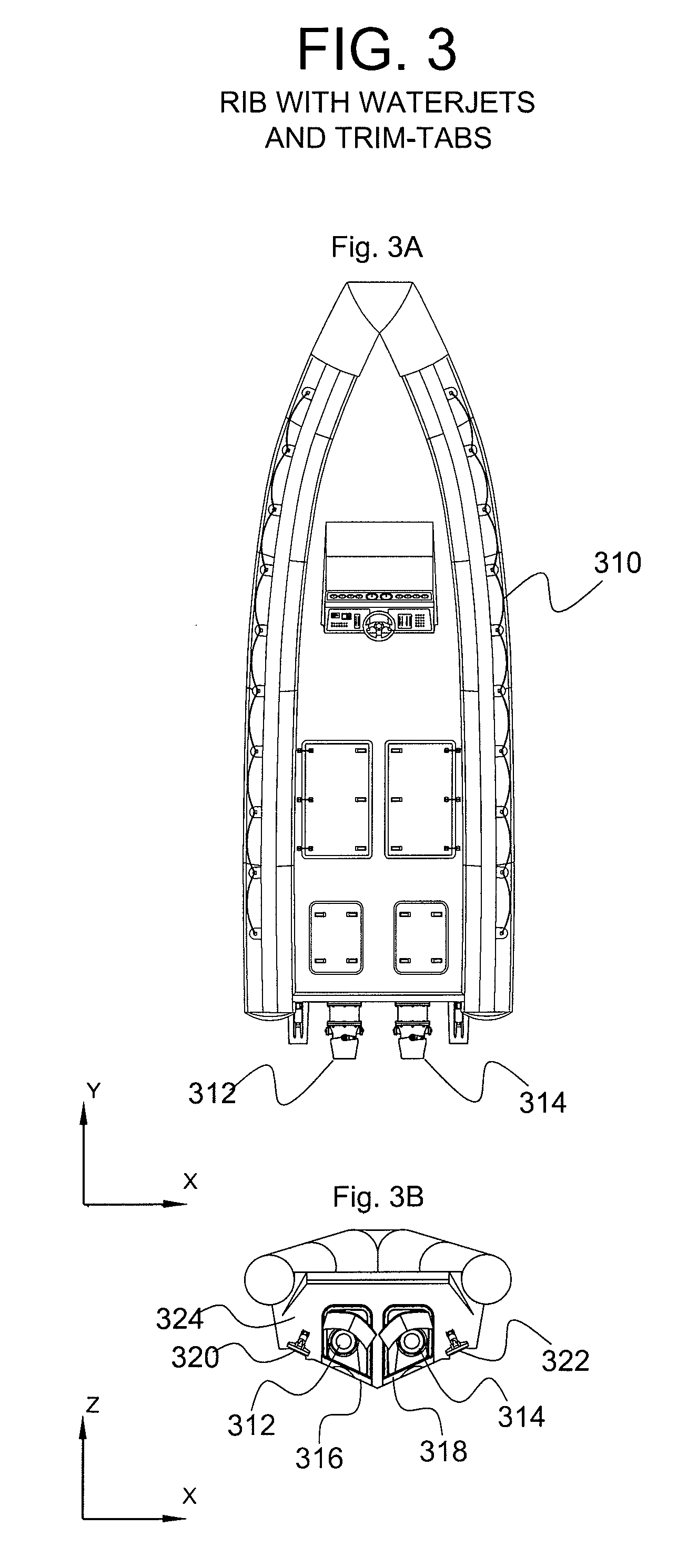

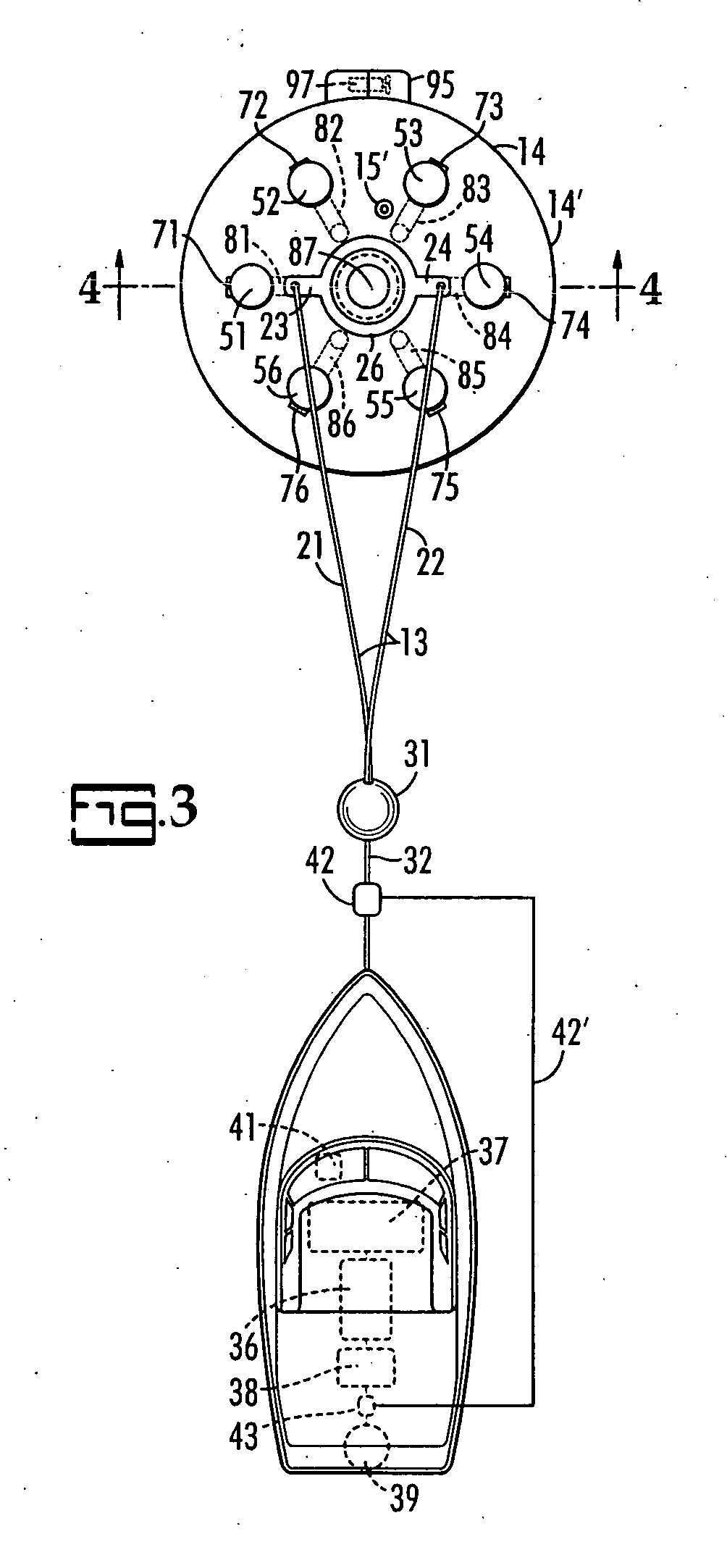

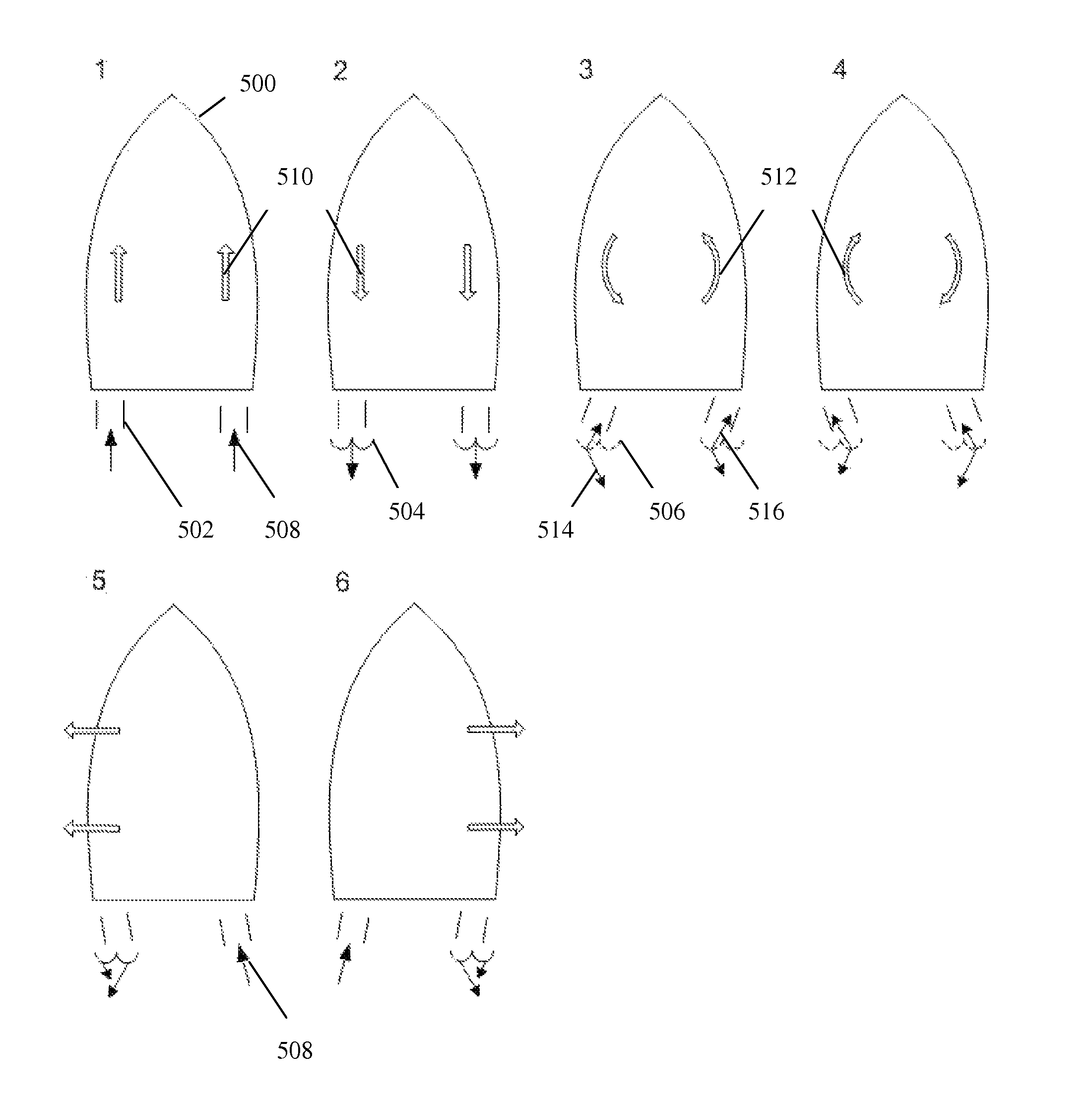

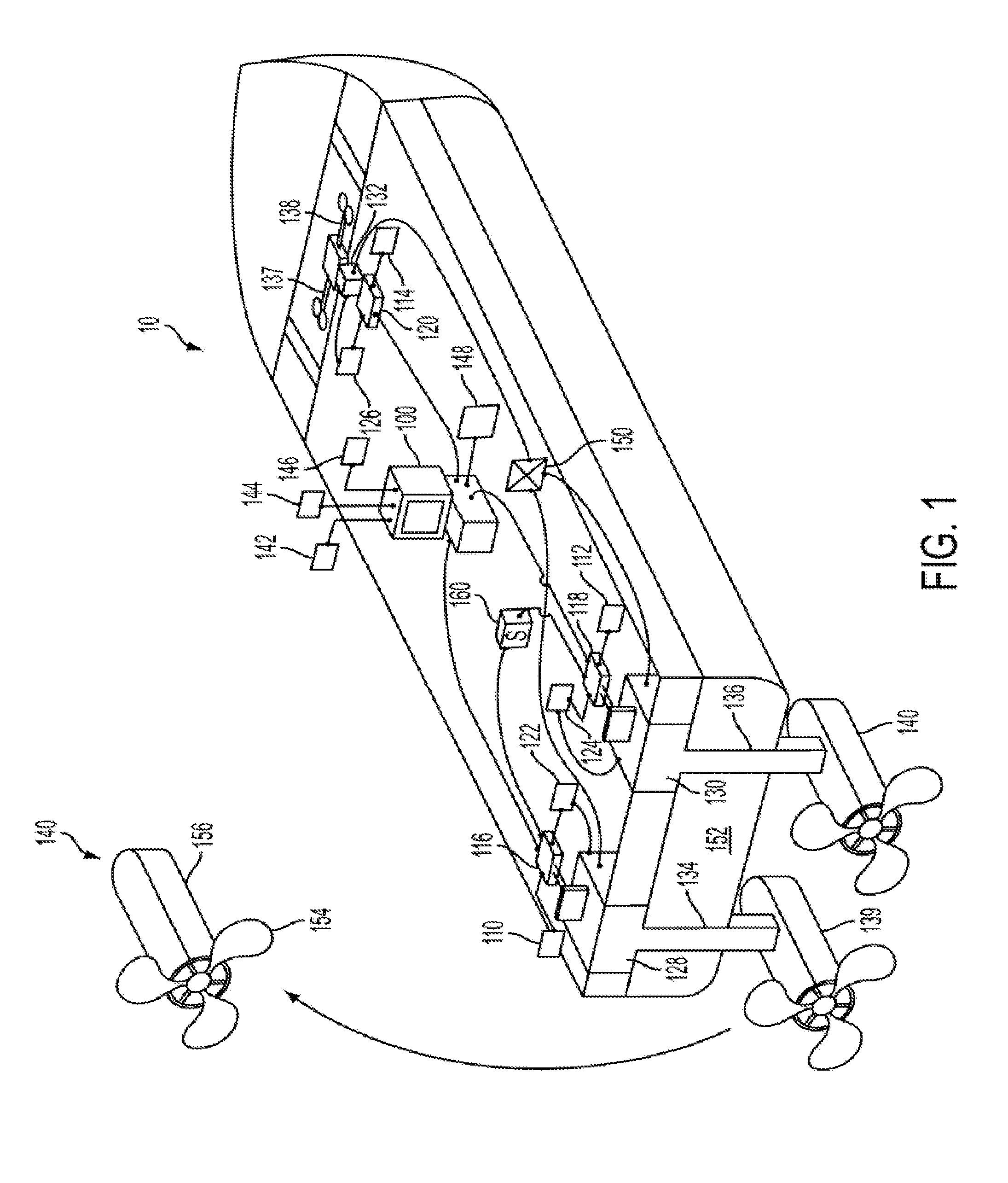

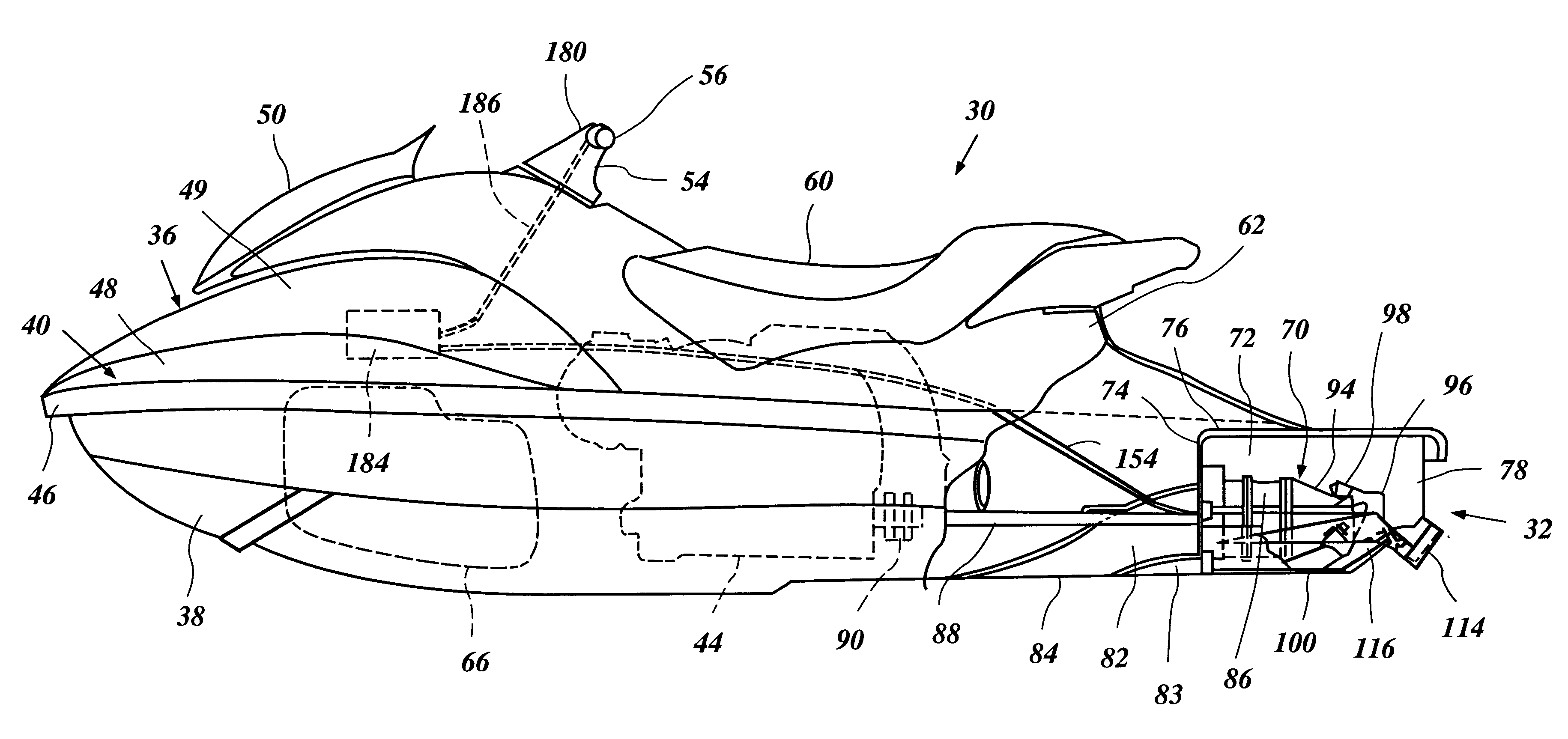

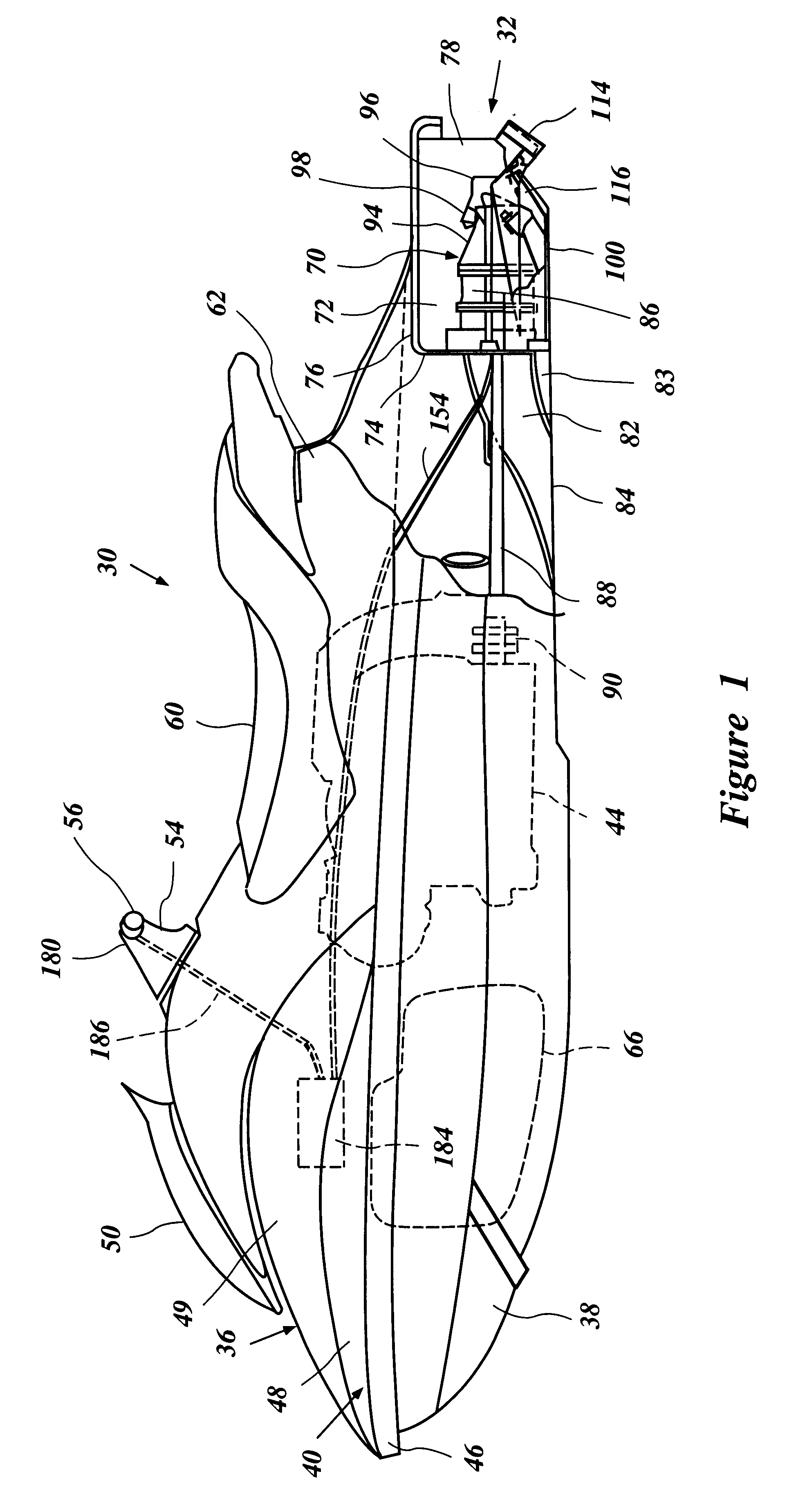

System and method for controlling a waterjet driven vessel

A method for controlling a marine vessel having first and second steering nozzles and first and second trim deflectors comprises generating at least a first set of actuator control signals and a second set of actuator control signals. The first set of actuator control signals is coupled to and controls the first and second steering nozzles, and the second set of actuator control signals is coupled to and controls the first and second trim deflectors. The acts of generating and coupling the first set of actuator control signals and the second set of actuator control signals result in inducing any of a net yawing force, a net rolling force, and a net trimming force to the marine vessel without inducing any other substantial forces to the marine vessel by controlling the first and second steering nozzles and the first and second trim deflectors. Also disclosed is a system for controlling a marine vessel.

Owner:MORVILLO ROBERT A

Jet nozzle mixer

InactiveUS6854260B2Reduce noiseAvoid problemsAircraft navigation controlCosmonautic vehiclesJet engineThrust efficiency

An external jet nozzle mixer (20) includes identically formed lobes (48), equal in number those of the internal mixer (42). External mixer (20) works with internal mixer (42), further to mix the engine internal bypass flow with the internal jet engine core flow, to level the disparate exhaust flow velocities, to reduce the peak velocities from the jet engine core and increase the lower bypass velocities of the engine internal bypass flow, and thereby to reduce noise. The internal lobe contours act as lifting flutes, causing mixing of the primary hot and cold flows before exiting the nozzle. The external lobe contours act as venturi chutes, accelerating the cooler ambient air secondary flow. The lobes thus act collectively as an injector to force the cooler ambient secondary flow into the previously mixed primary flow as it exits the nozzle. Also obtained is an increased thrust efficiency and a consequently decreased fuel consumption and engine emissions.

Owner:COMTRAN LTD

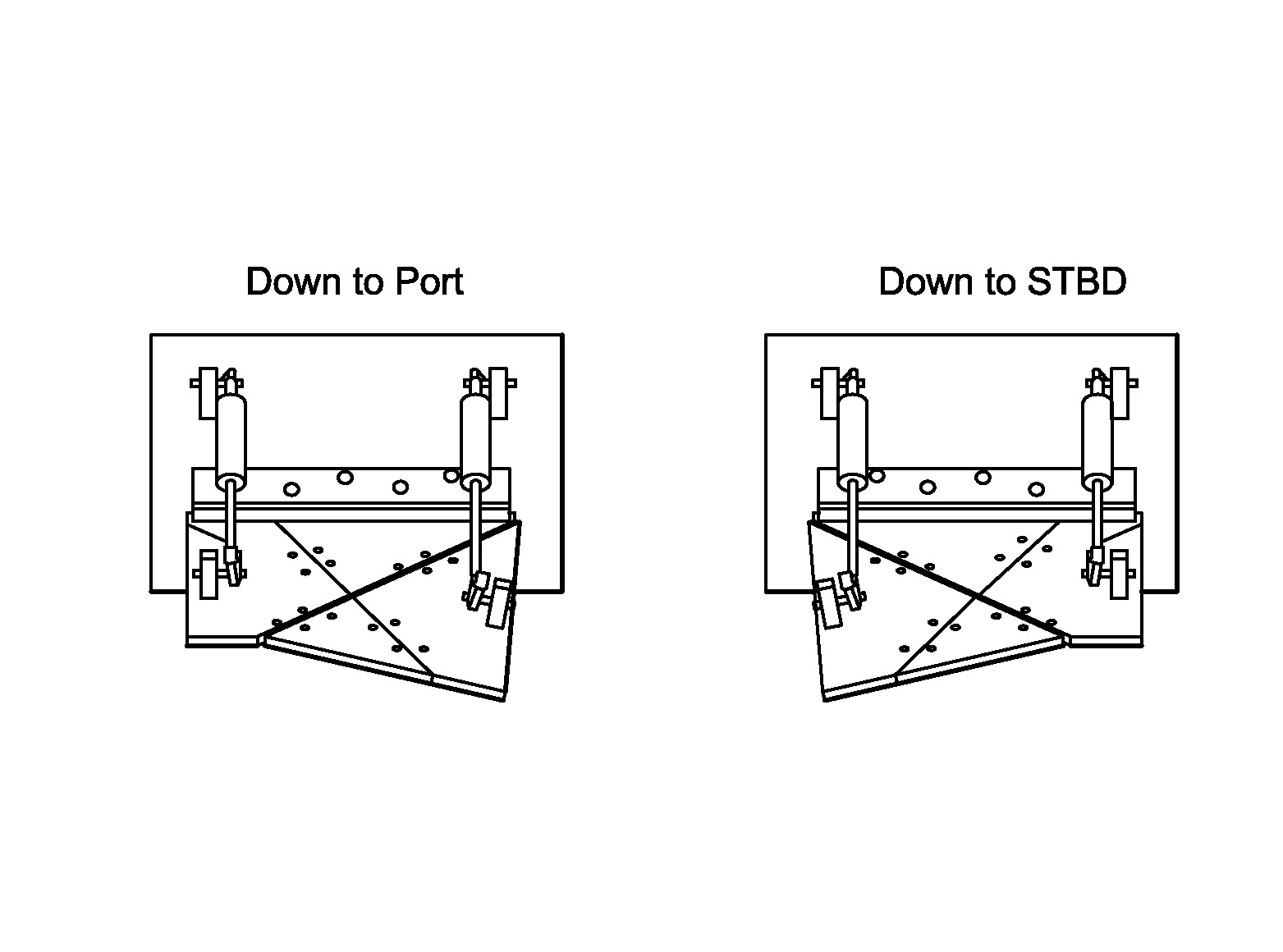

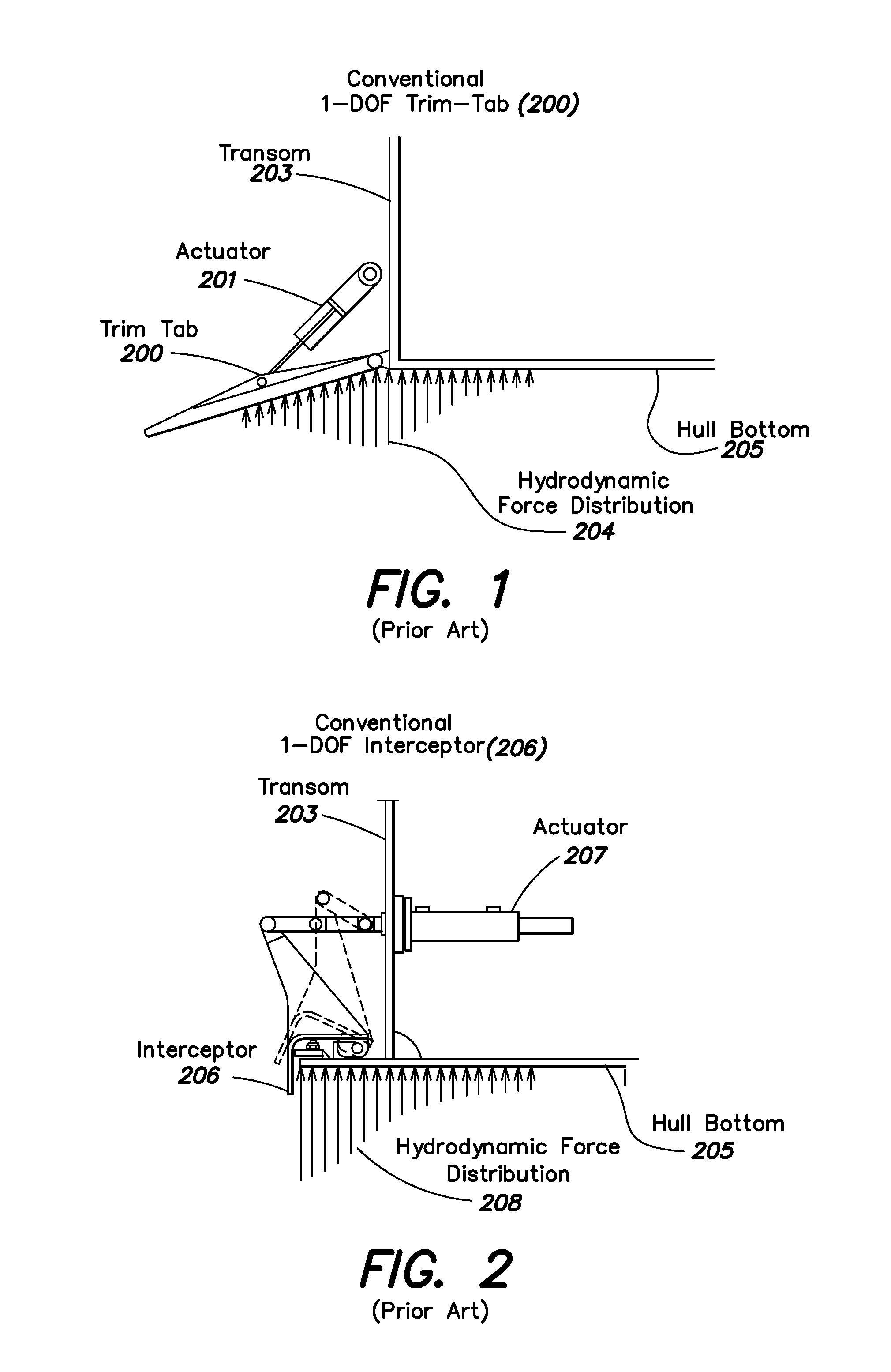

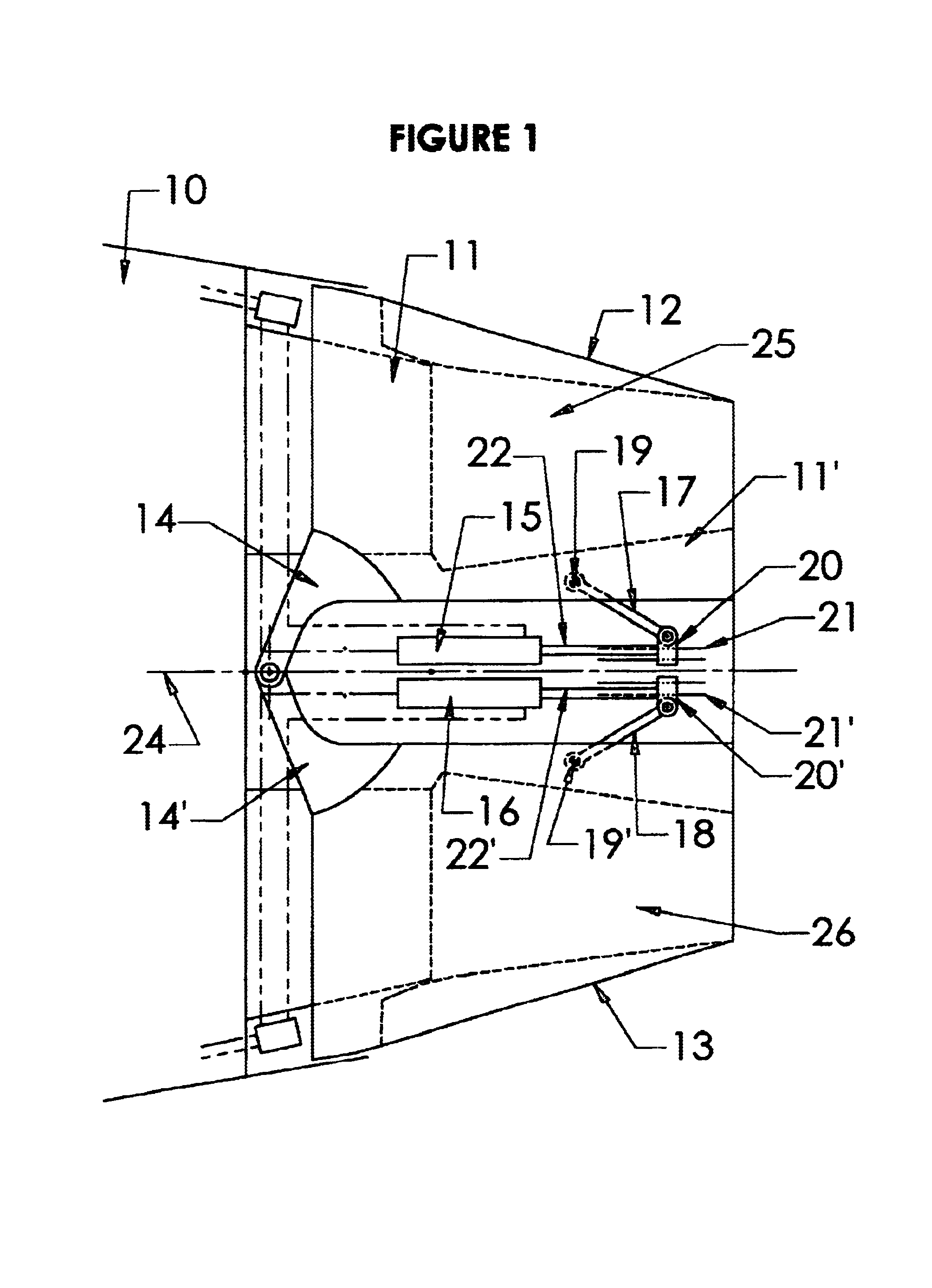

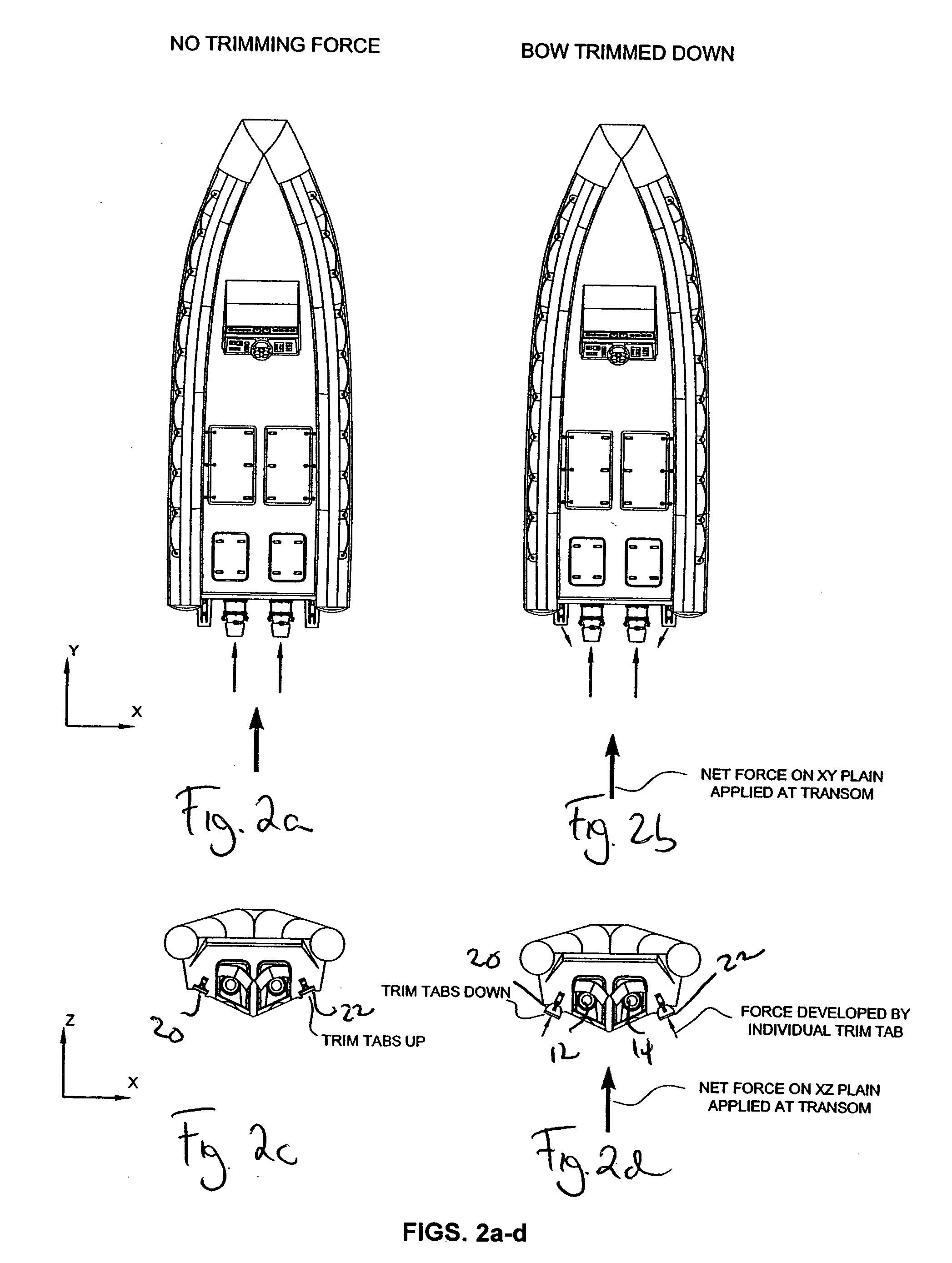

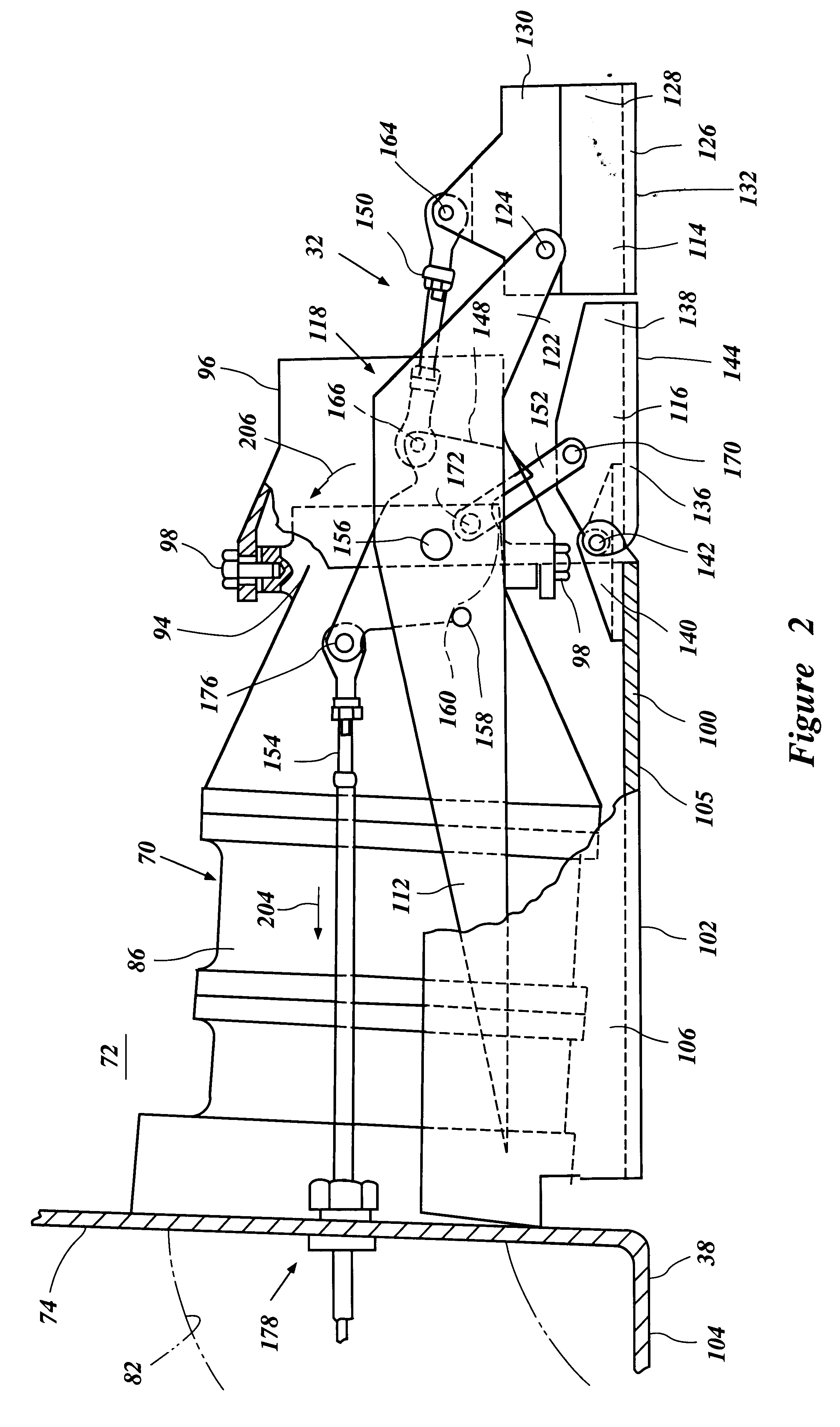

Variable trim deflector system and method for controlling a marine vessel

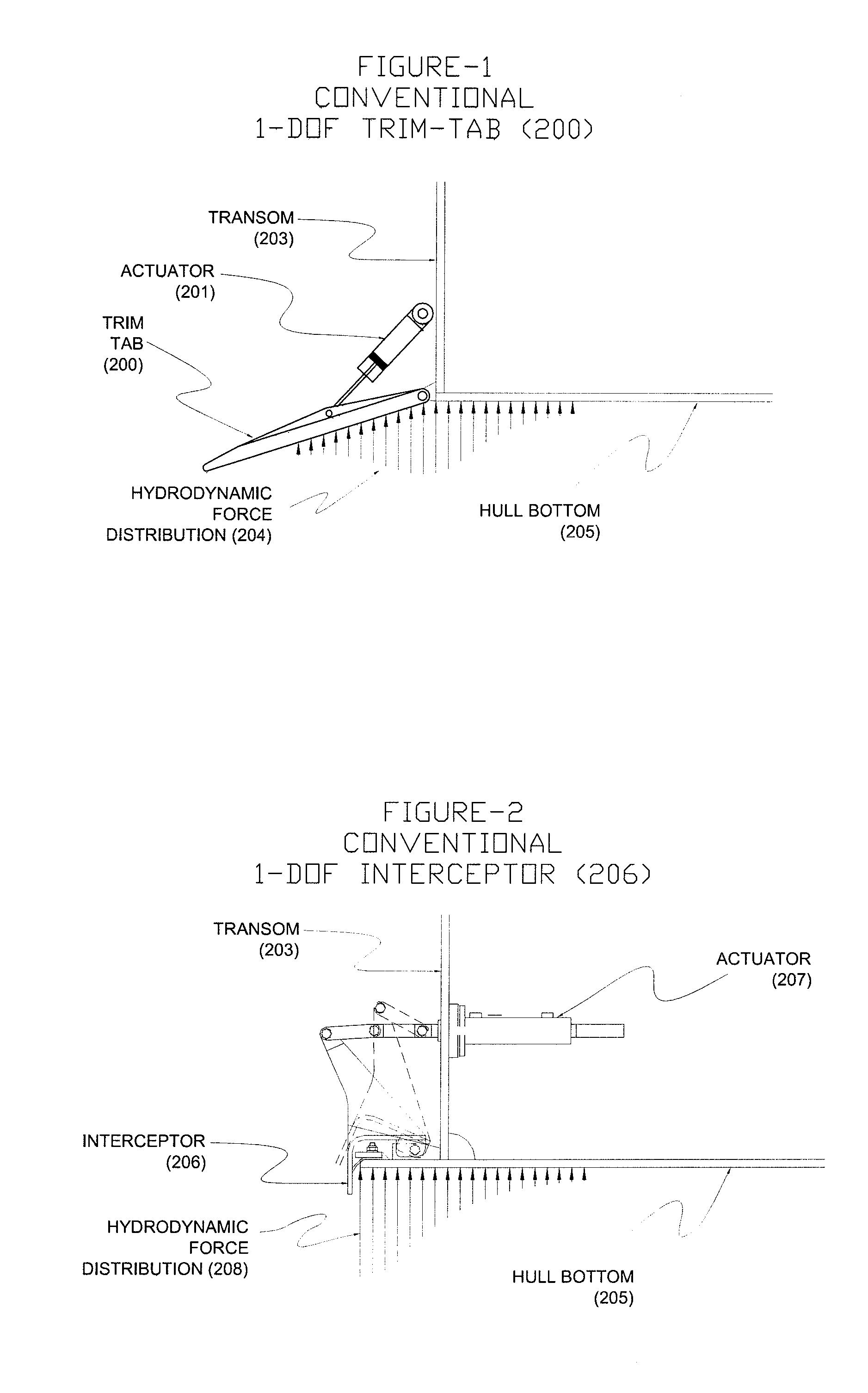

ActiveUS8631753B2Improve stabilitySteering initiationsDigital data processing detailsMarine engineering

A method and a system for controlling a marine vessel having first and second trim deflectors is disclosed. The first and second trim deflectors have a first surface having a first area and a second surface having a second area, wherein the second planar surface is coupled to the first surface. The method and system control the first and second trim deflectors to induce any of a net yawing force, a net rolling force, and a net trimming force to the marine vessel without inducing any other substantial forces to the marine vessel by controlling the first and second trim deflectors.

Owner:MORVILLO ROBERT A

Gas turbine engine

InactiveUS7886520B2Facilitate static pressure reductionAircraft navigation controlPower plant arrangements/mountingNacelleEngineering

Within a turbine engine a heat exchanger may be provided to cool compressor air flows to be utilized for cabin ventilation or other functions. A fluid flow acting as a coolant for the heat exchanger is generally drawn from the by-pass duct of the engine and a dedicated outlet duct is provided such that the exhausted fluid flow from the heat exchanger is delivered along the conduit duct to a low pressure region. In such circumstances, an appropriate pressure differential across the heat exchanger is maintained for operational efficiency when required, whilst the exhausted fluid flow is isolated and does not compromise the usual engine ventilation vent exit area sizing. Over-sized ventilation vents would create an aerodynamic step and therefore drag upon the thrust of the engine. Typically, the outlet end of the outlet duct has a variable geometry to enable adjustment in the pressure differential across the heat exchanger such that an air fan valve used to control flow rate through the heat exchanger may not be required.

Owner:ROLLS ROYCE PLC

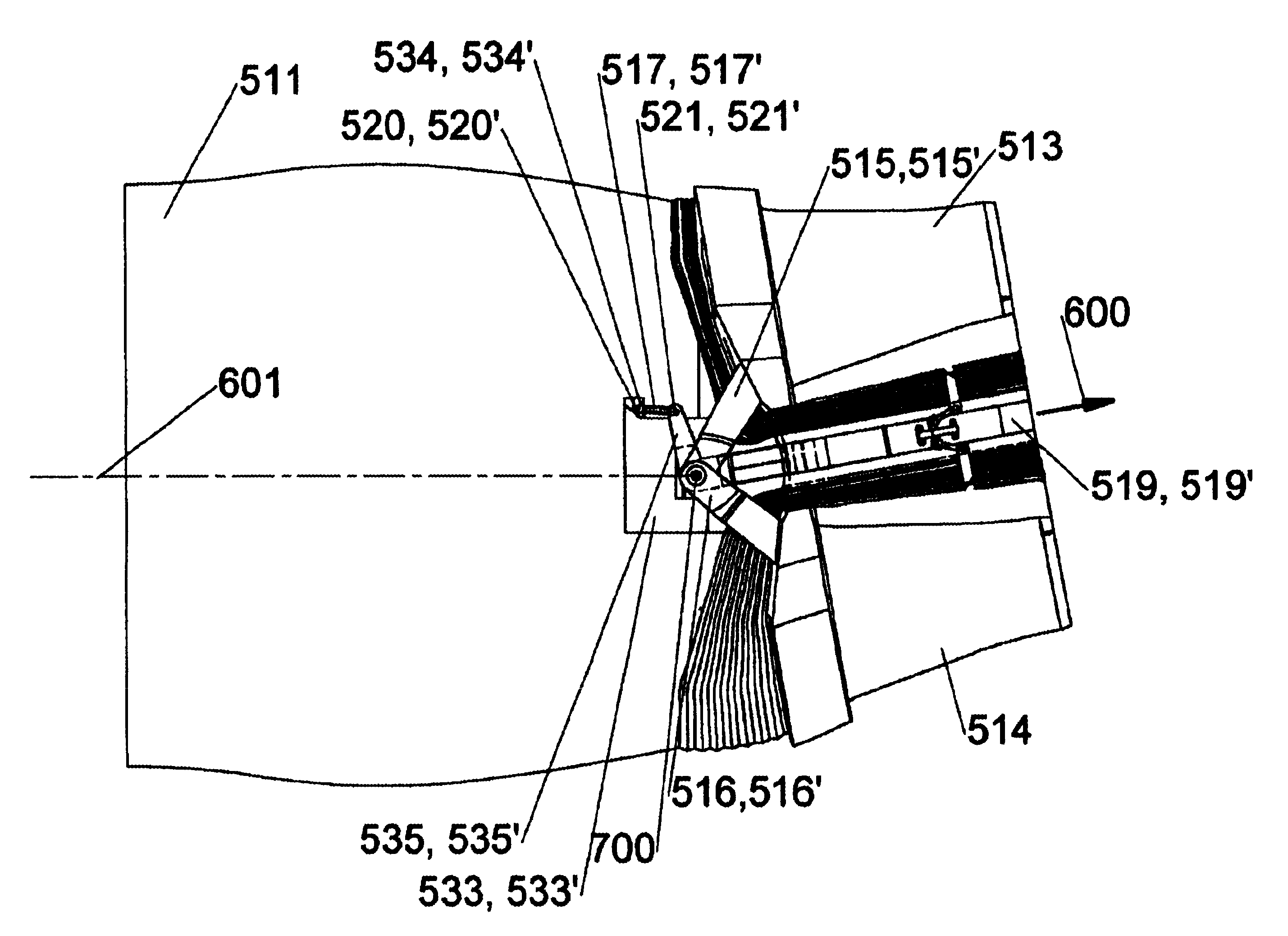

Thrust vectoring and variable exhaust area for jet engine nozzle

InactiveUS6938408B2Increased longitudinal stabilitySlow down the landing speedAircraft navigation controlSpraying apparatusJet engineThrust vectoring

A jet engine nozzle having a pair of pivoting extension arms and a pair of pivoting shells connected to a jet pipe is provided. The first extension arm is pivotally connected to the jet pipe at a first location, while the second extension arm is pivotally connected to the jet pipe at a second location. Each shell is pivotally connected at both the first and second locations. An axis of rotation associated with the first location is coaxial to an axis of rotation associated with the second location. Independent actuation means are provided to rotate the extension arms and the shells, thereby enabling adjustment of the thrust-vector angle or the exhaust area of the nozzle.

Owner:PROPULSION VECTORING

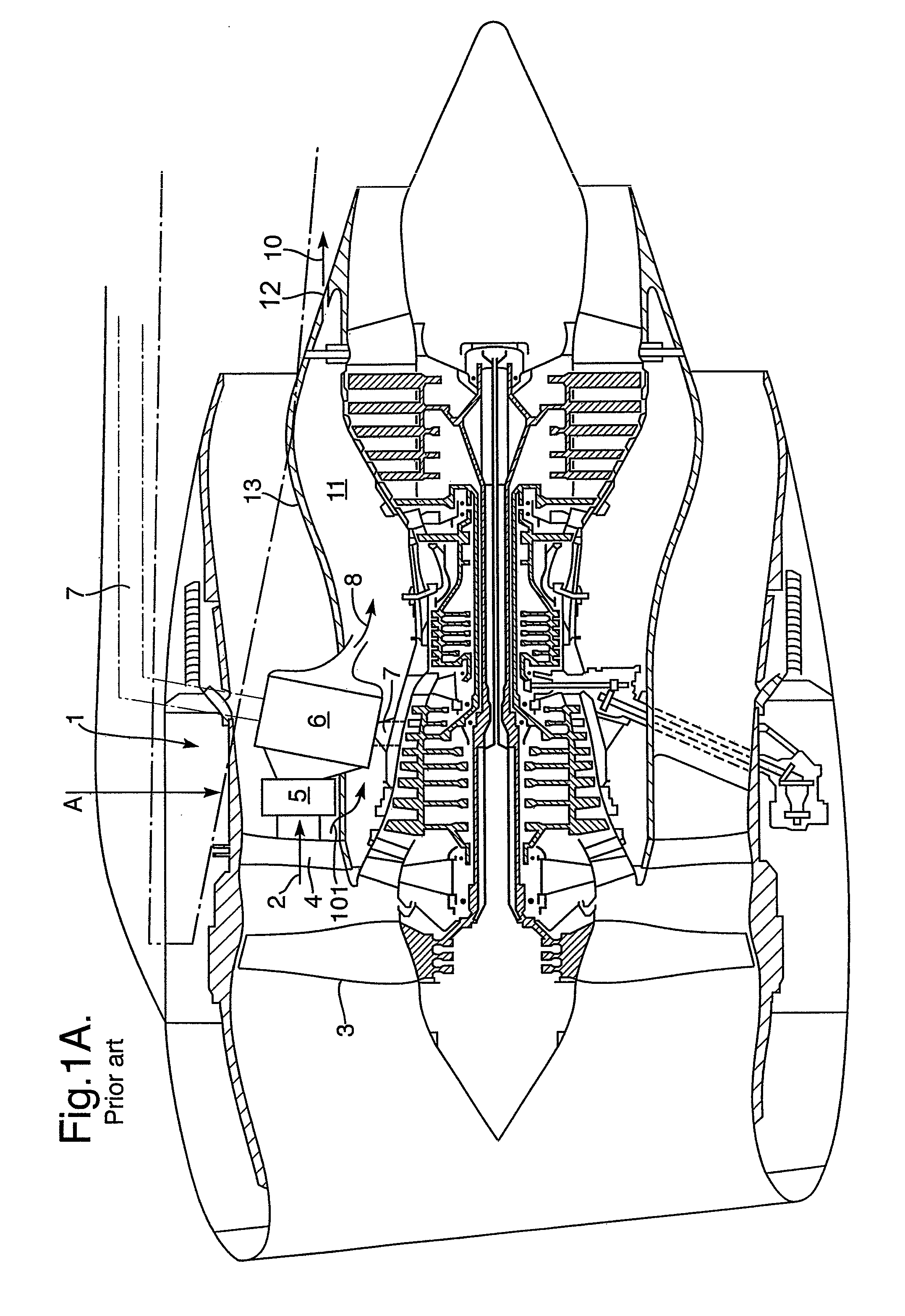

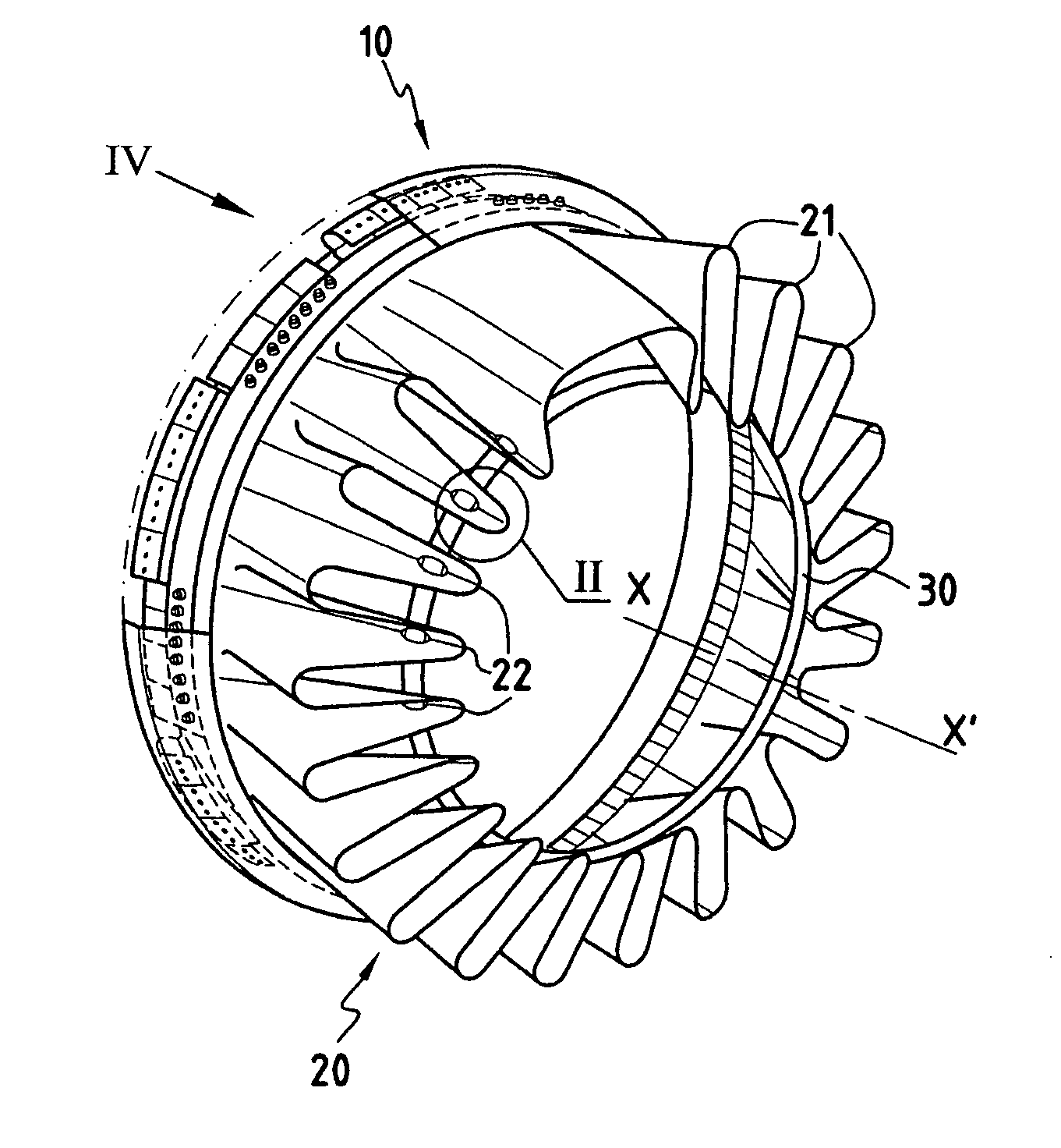

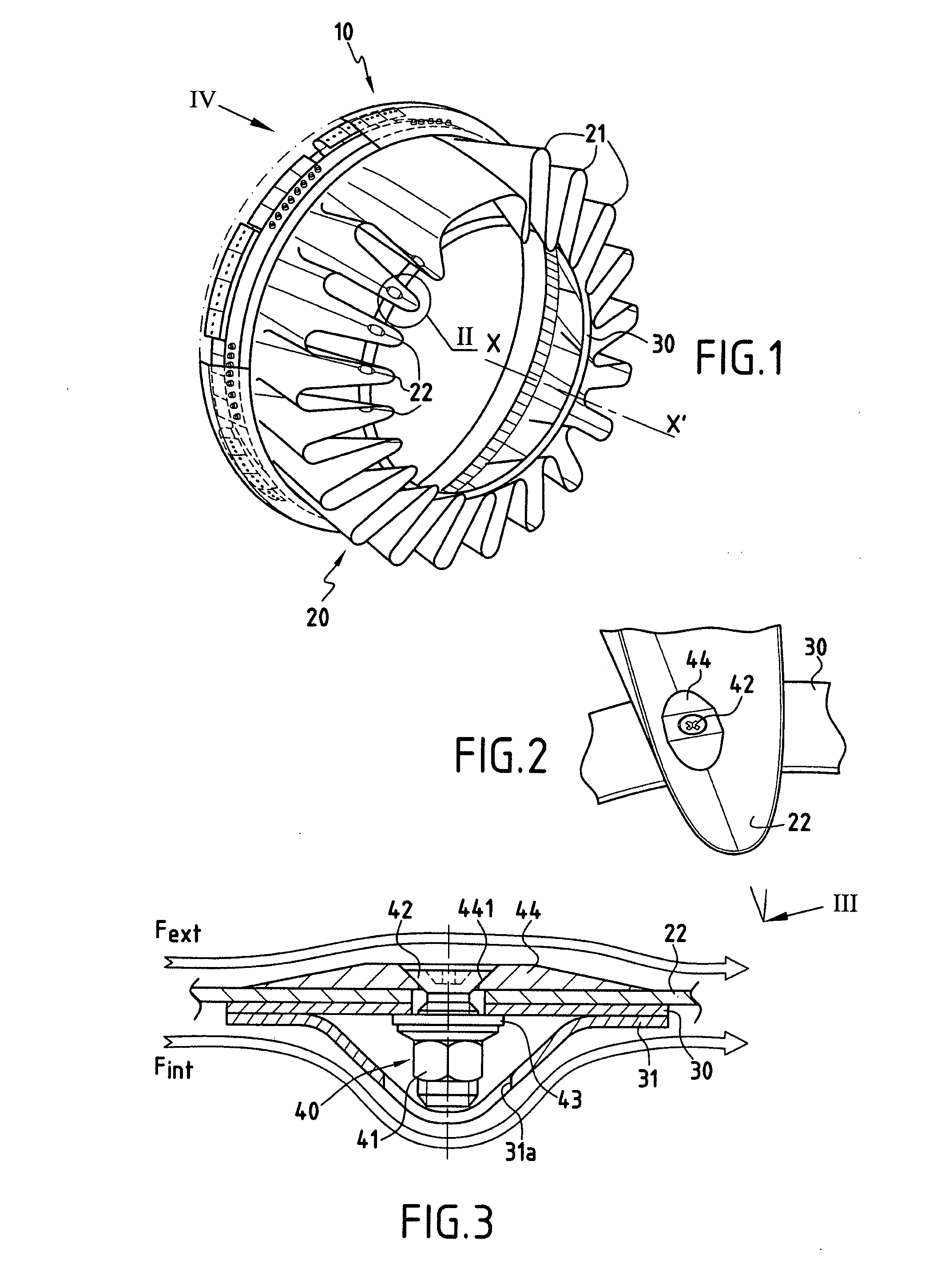

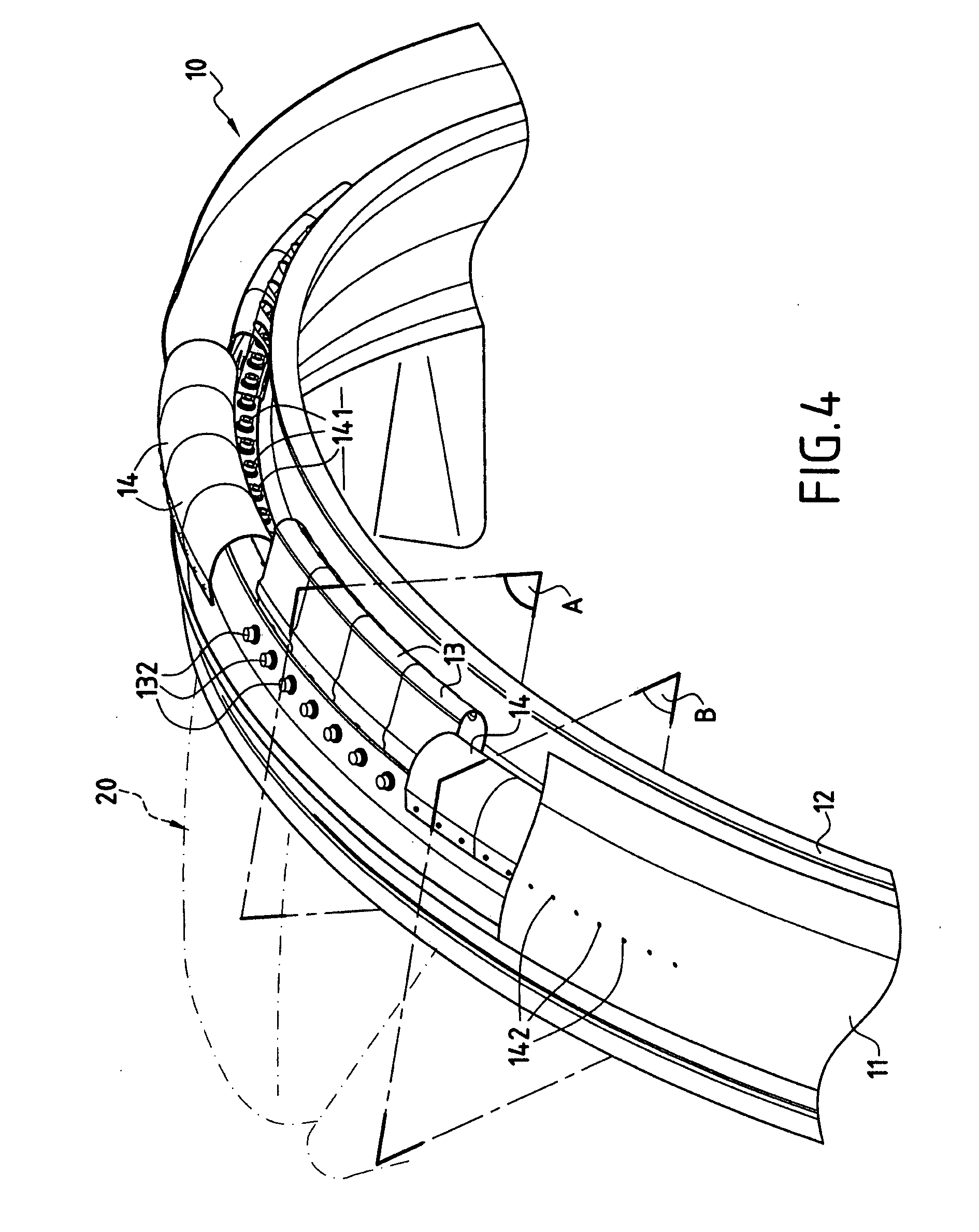

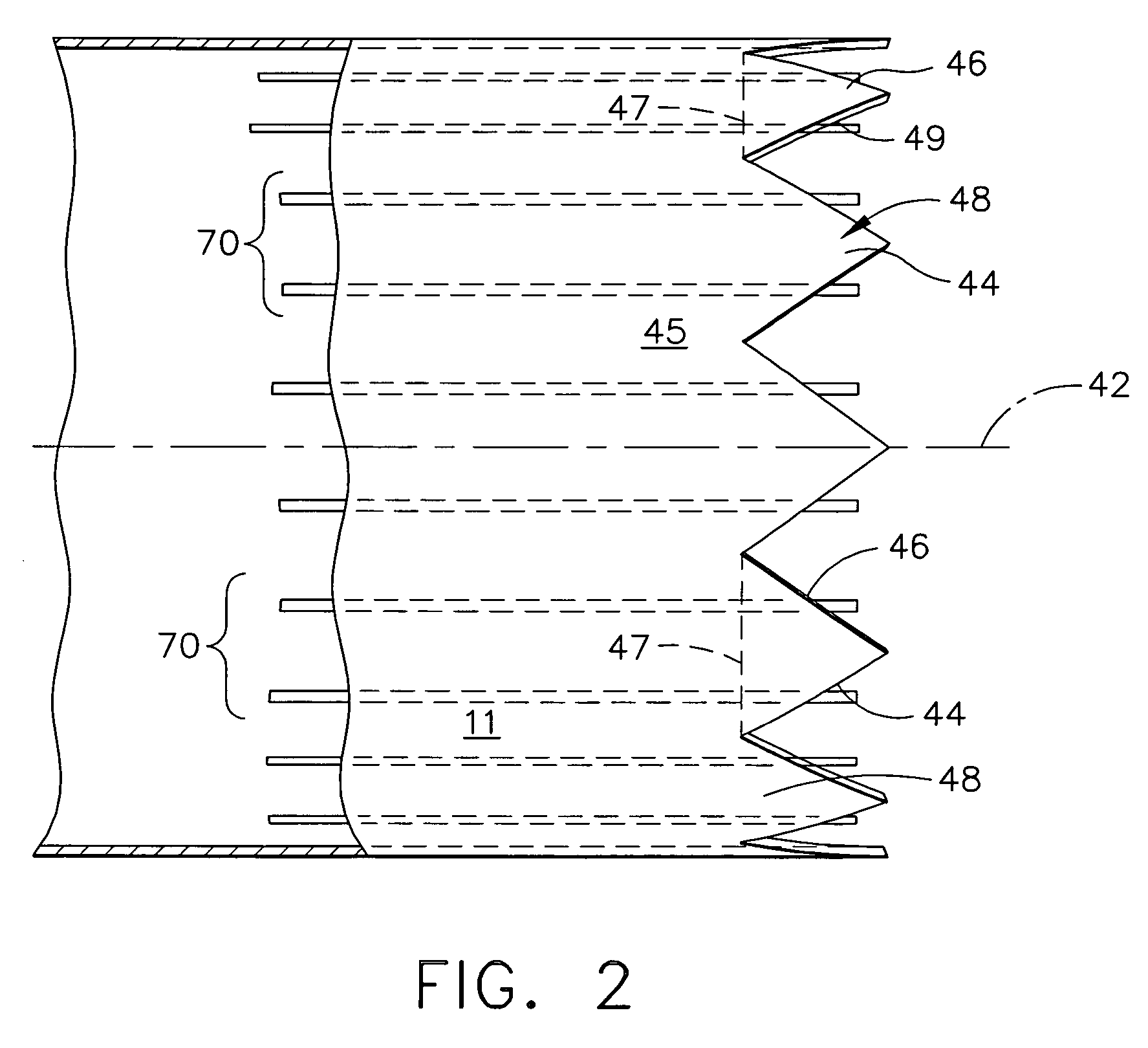

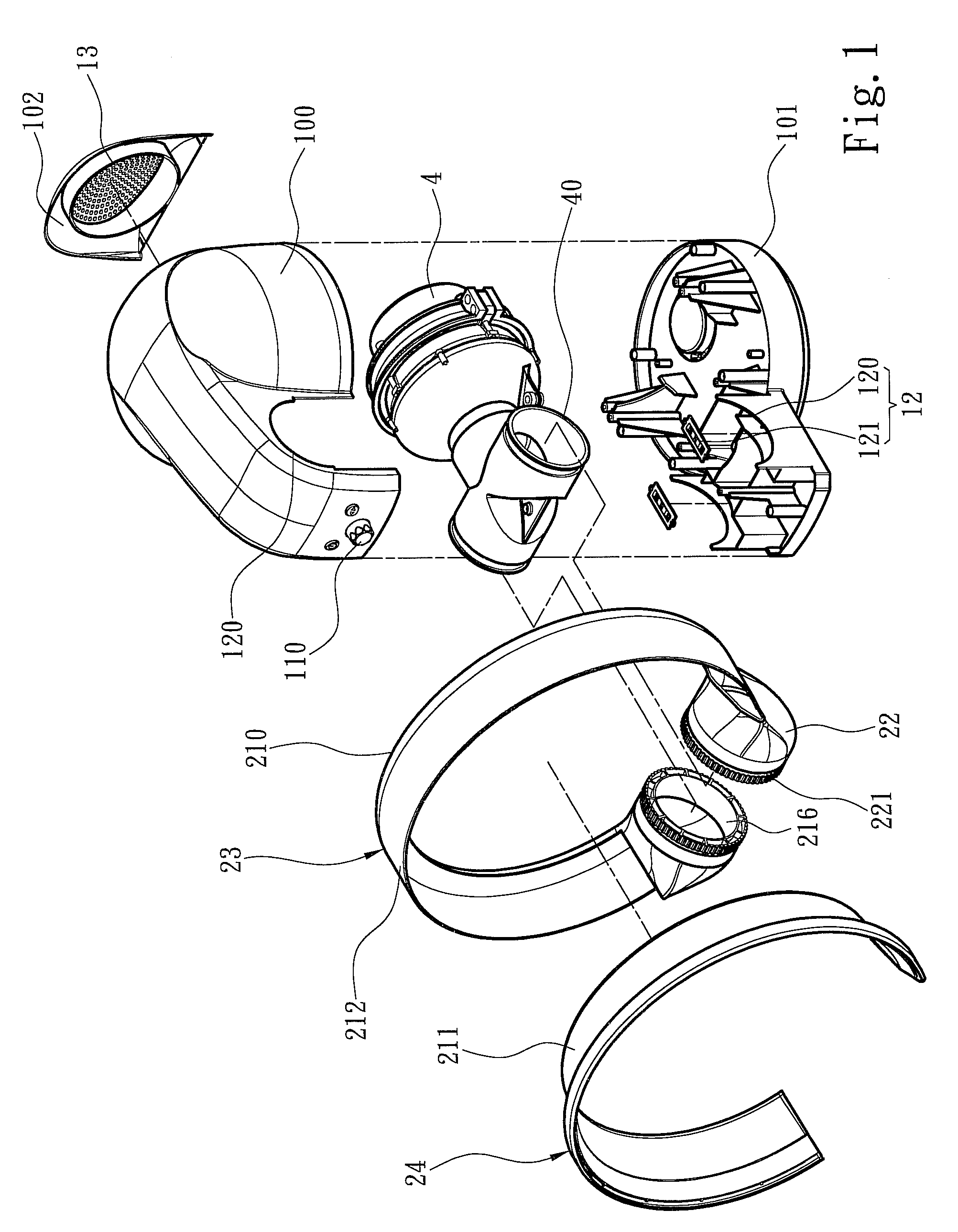

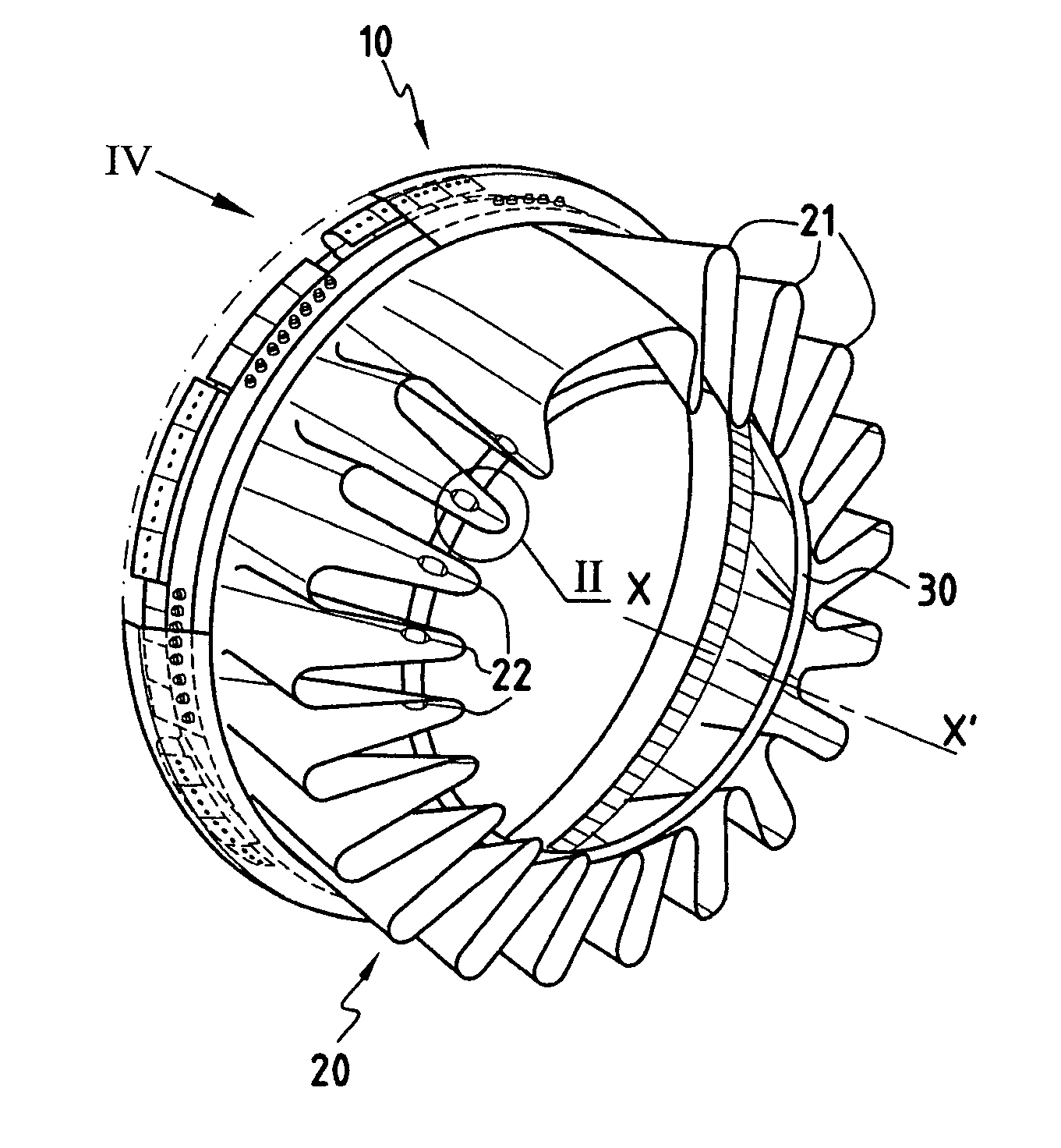

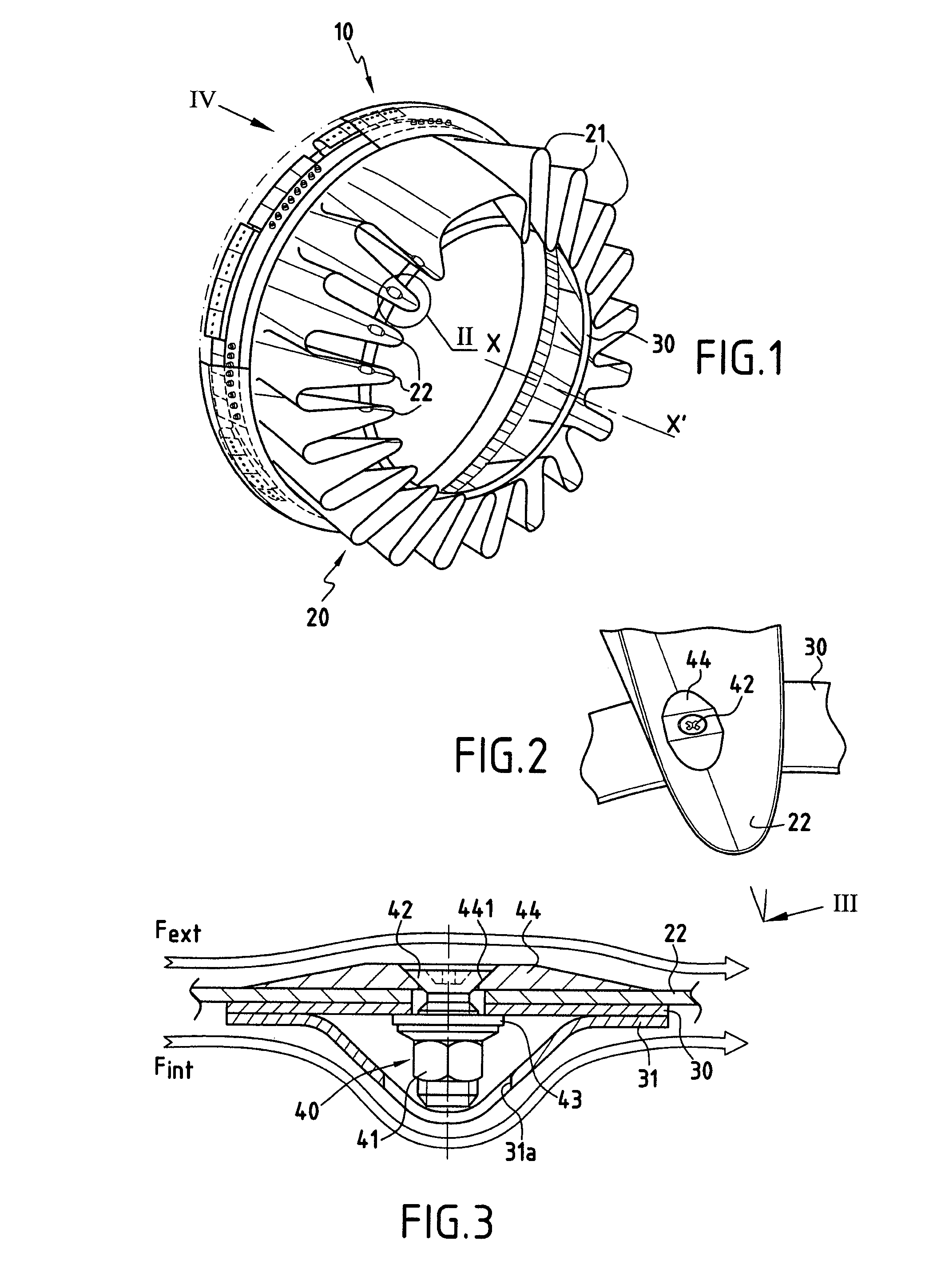

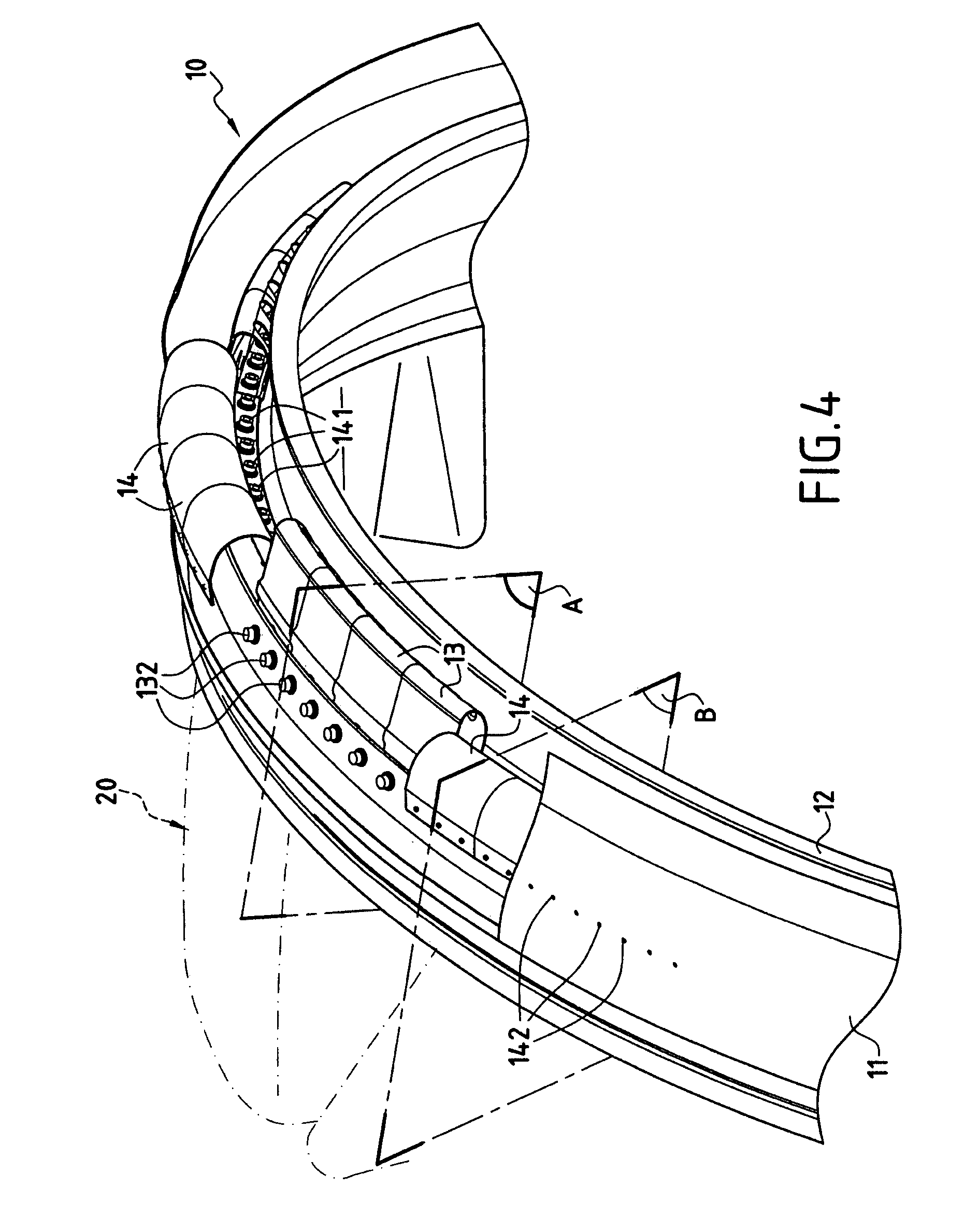

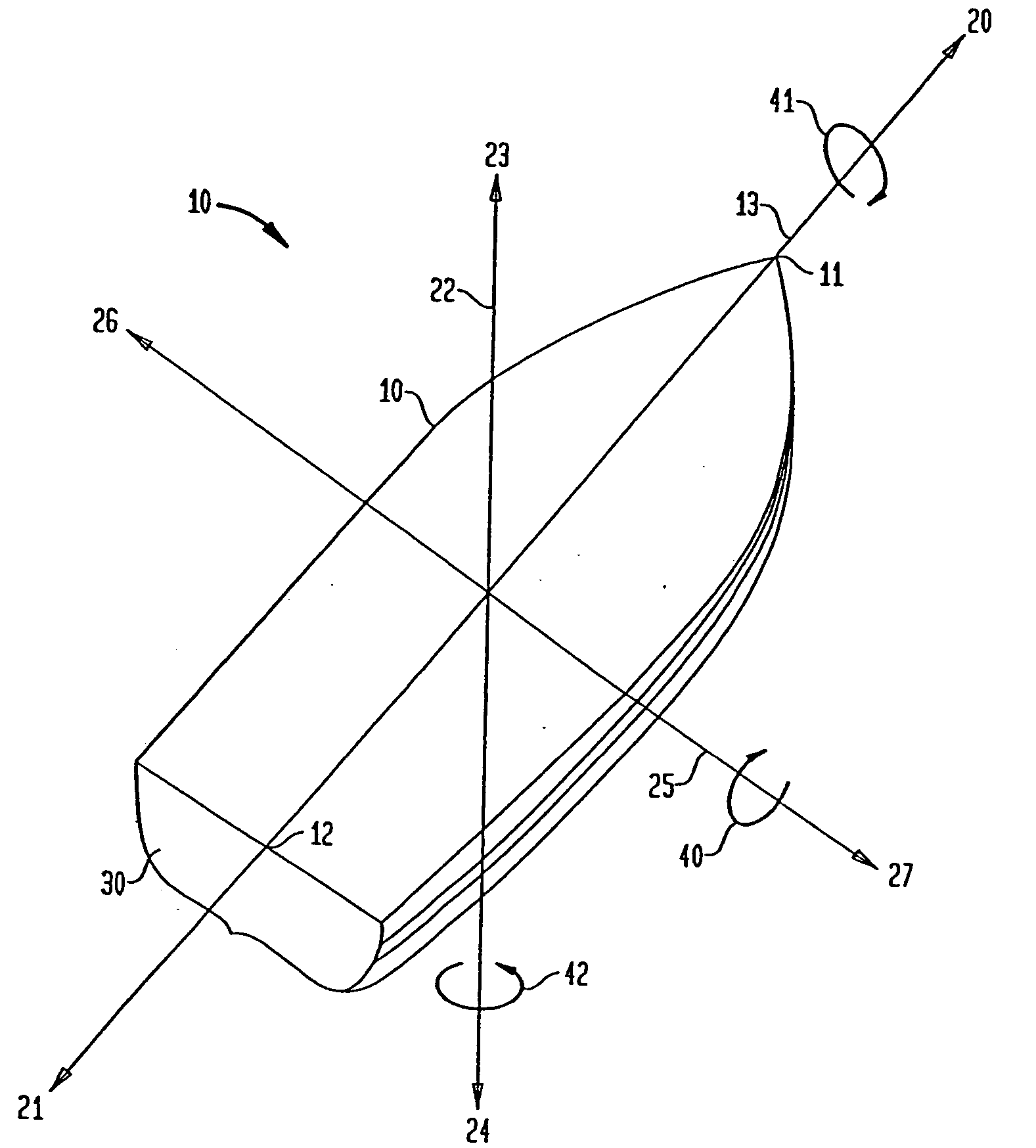

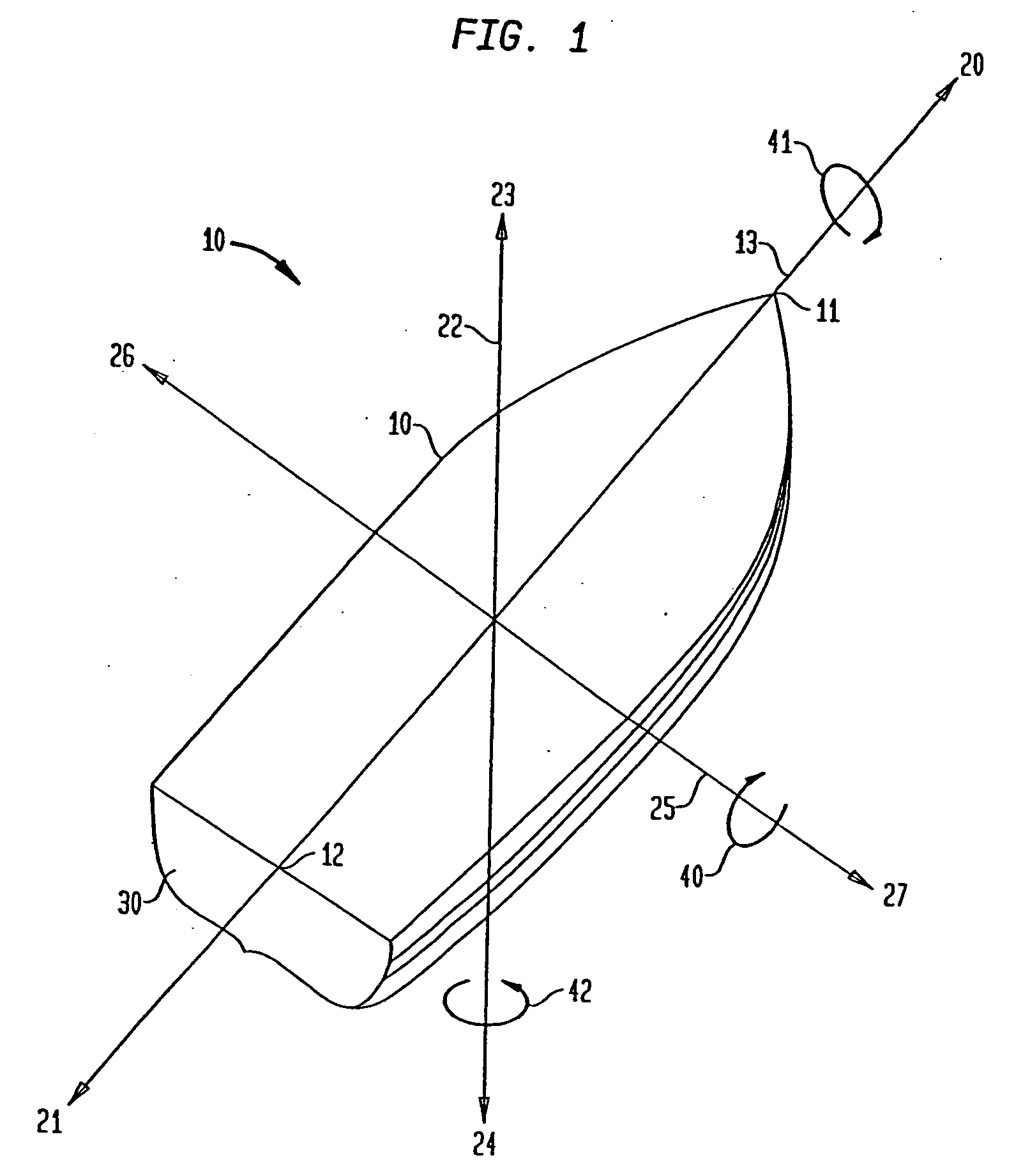

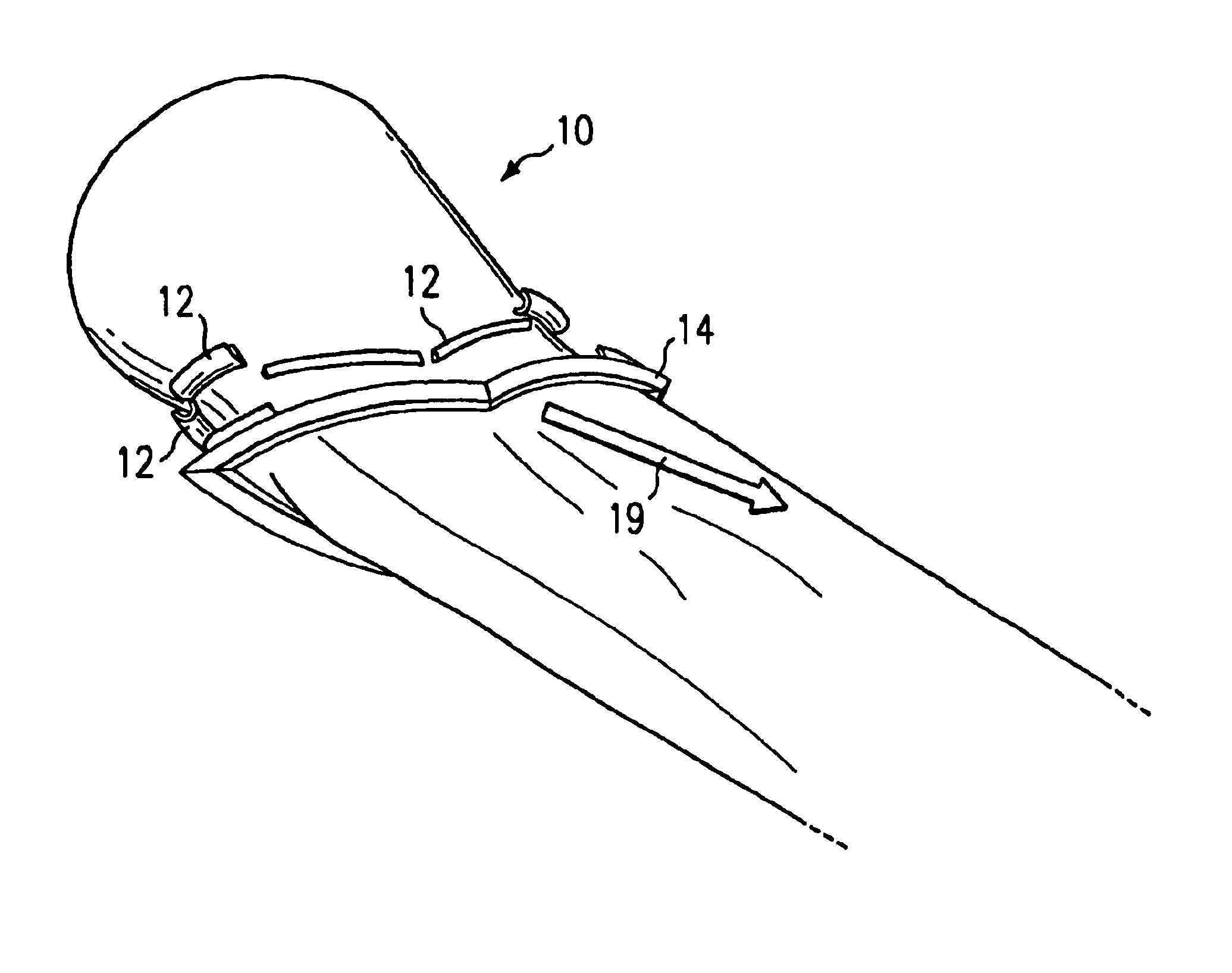

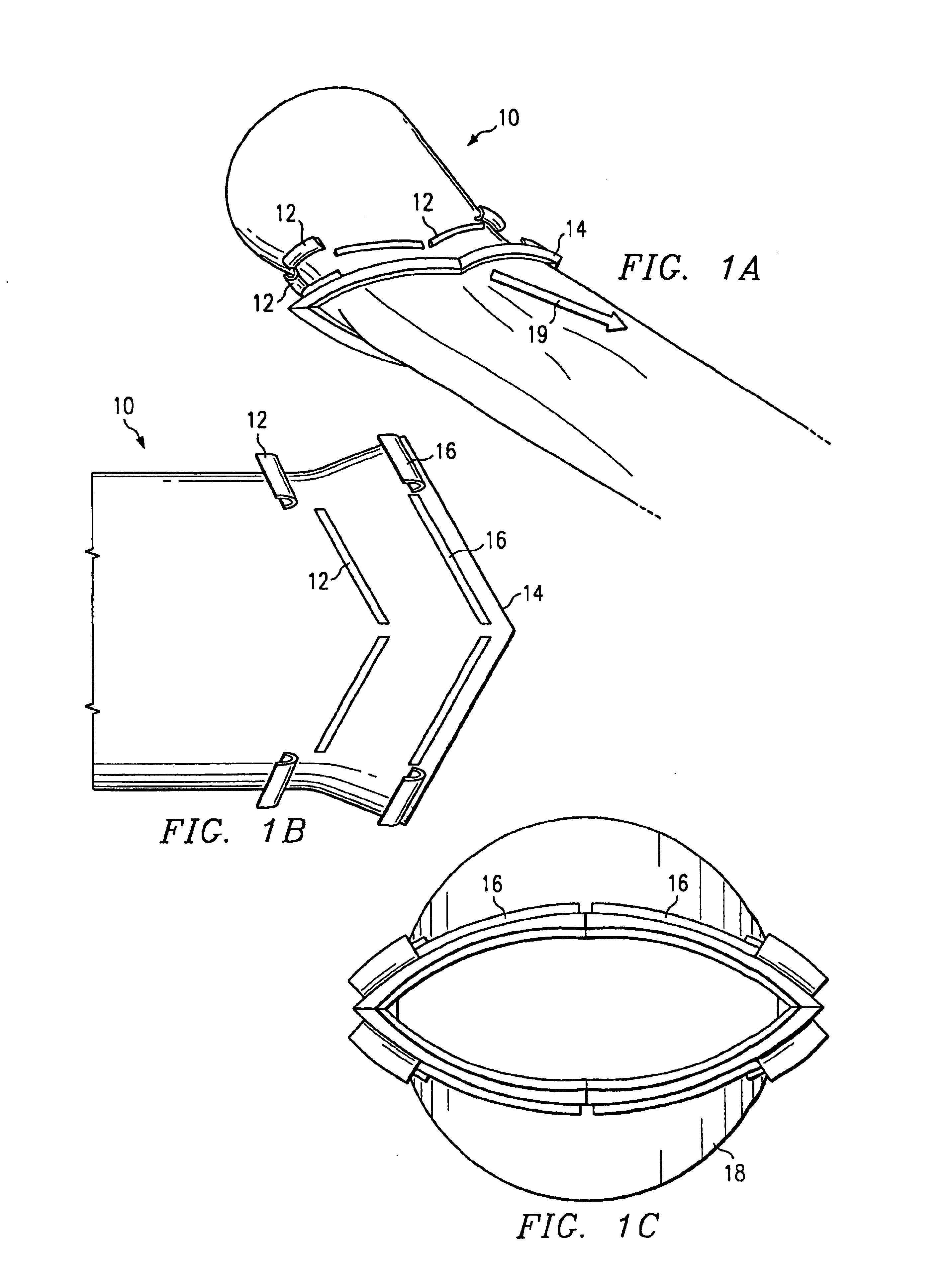

Mixer For Separate-Stream Nozzle

InactiveUS20080115484A1Reduce mechanical loadReduce weightPower plant exhaust arrangementsEngine fuctionsEngineeringTurbojet

A mixer for a separate-stream turbojet nozzle, the mixer comprising along a longitudinal axis (X-X′) both a fastener shroud (10) for connecting said mixer to the exhaust casing of the nozzle, and a lobe structure (20) presenting a succession of inner and outer lobes (22 and 21) distributed circumferentially around the longitudinal axis (X-X′) of the mixer. The lobe structure (20) is made of a ceramic matrix composite material and further comprises a stiffener ring (30) that forms a connection between at least some of the lobes of said structure. Thus, the major portion of the mixer, i.e. the lobe structure, is made of a ceramic matrix composite material, thereby significantly reducing the weight of the mixer, and consequently reducing the weight of the nozzle.

Owner:SAFRAN CERAMICS SA

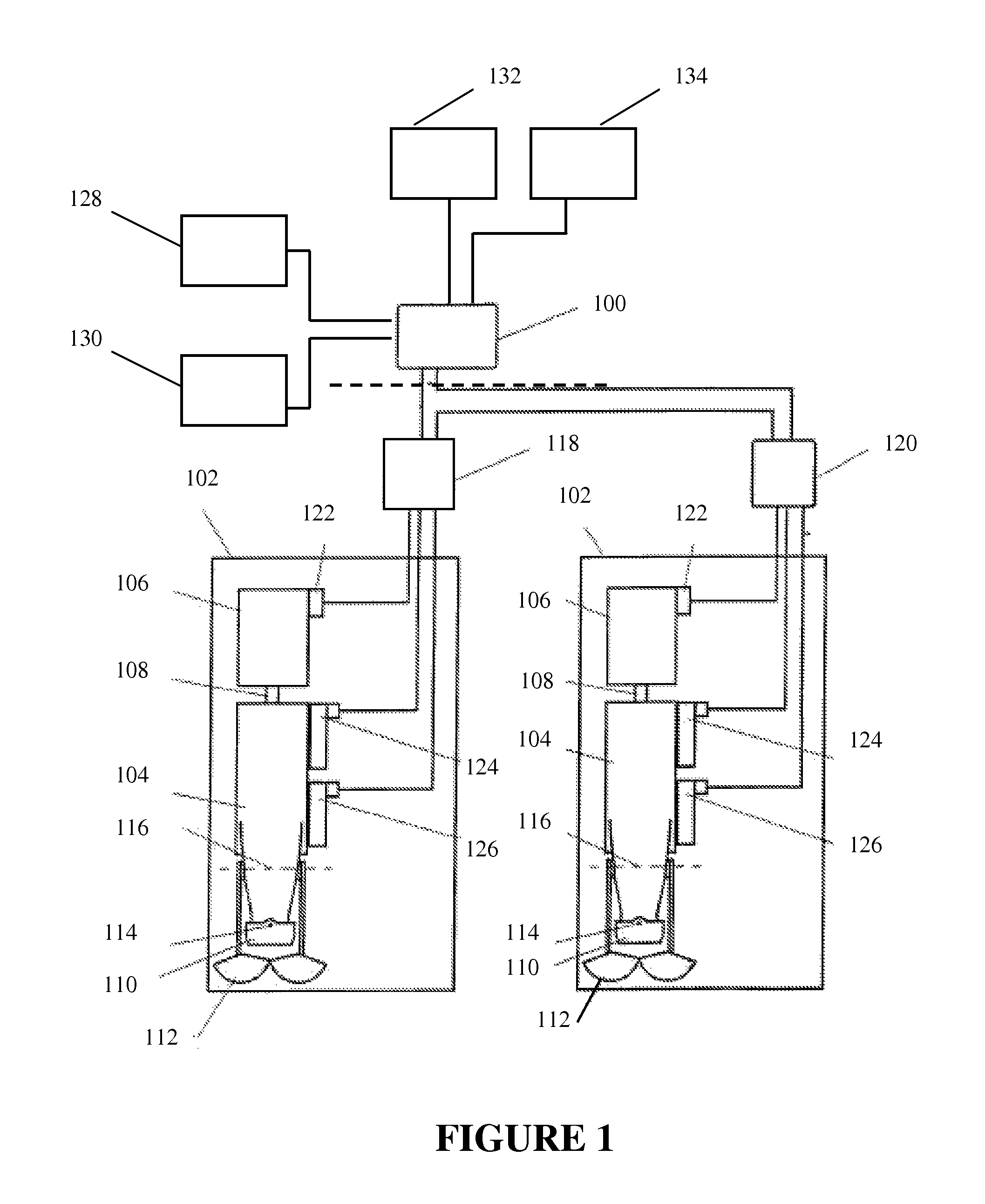

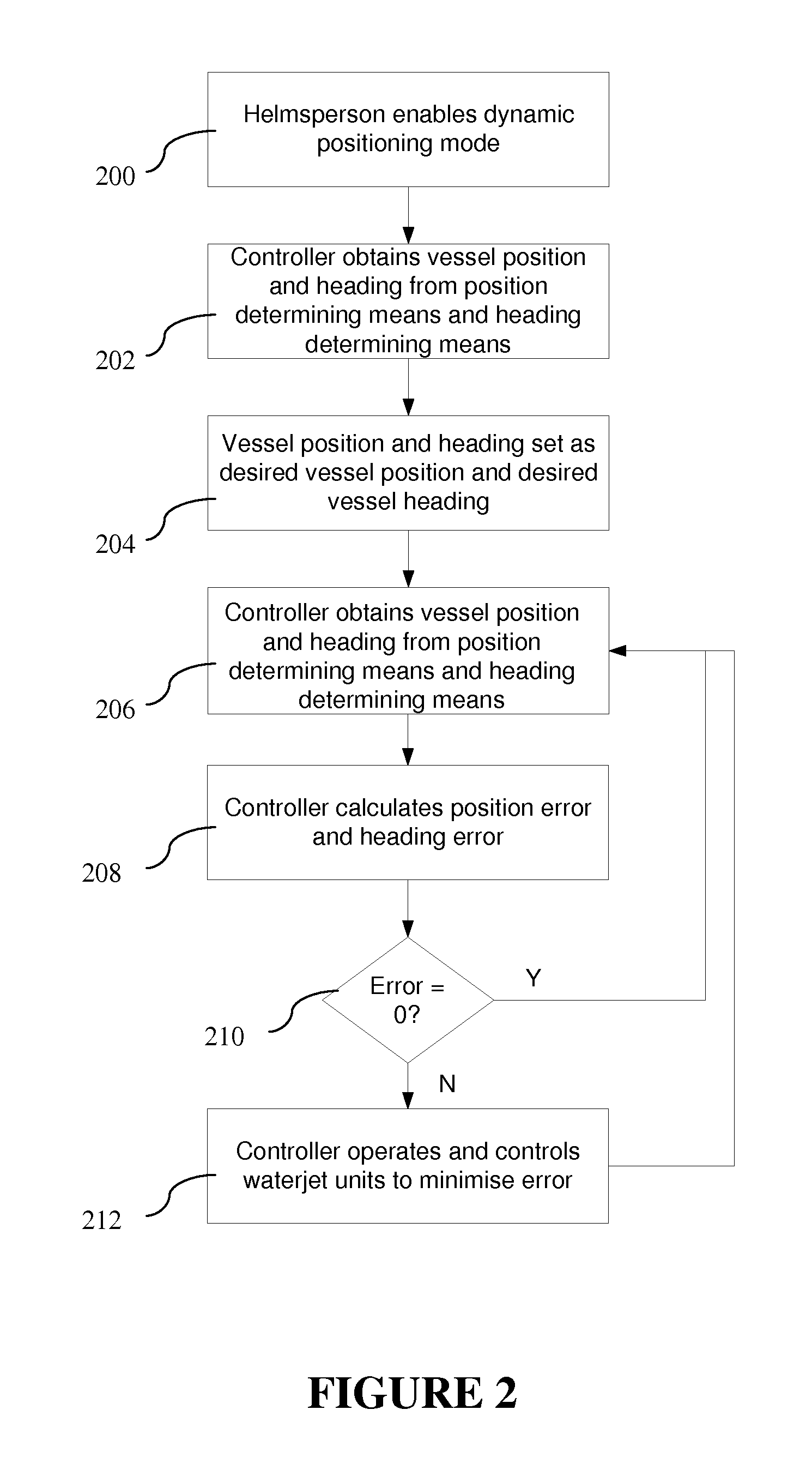

Relating to Control of Marine Vessels

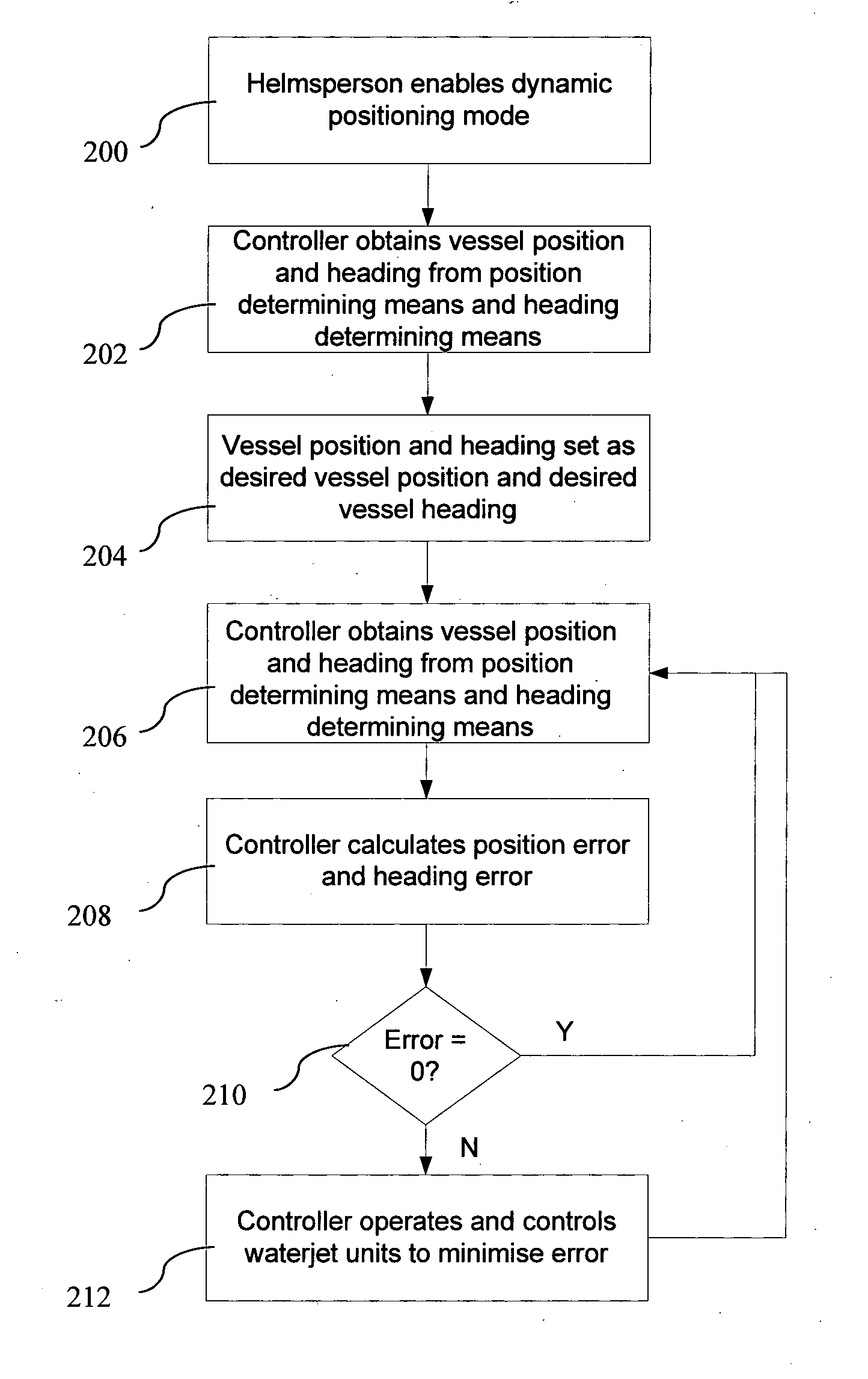

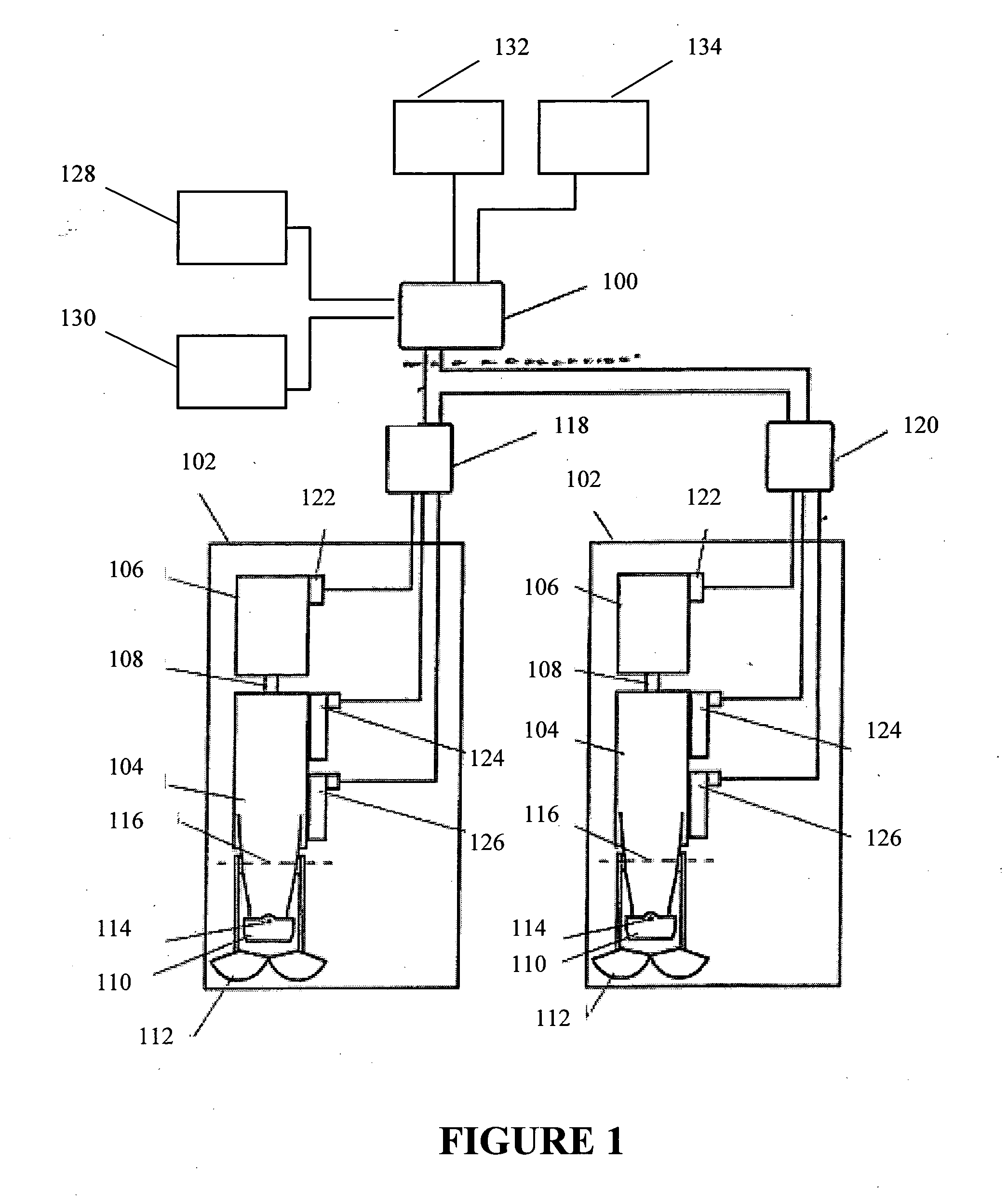

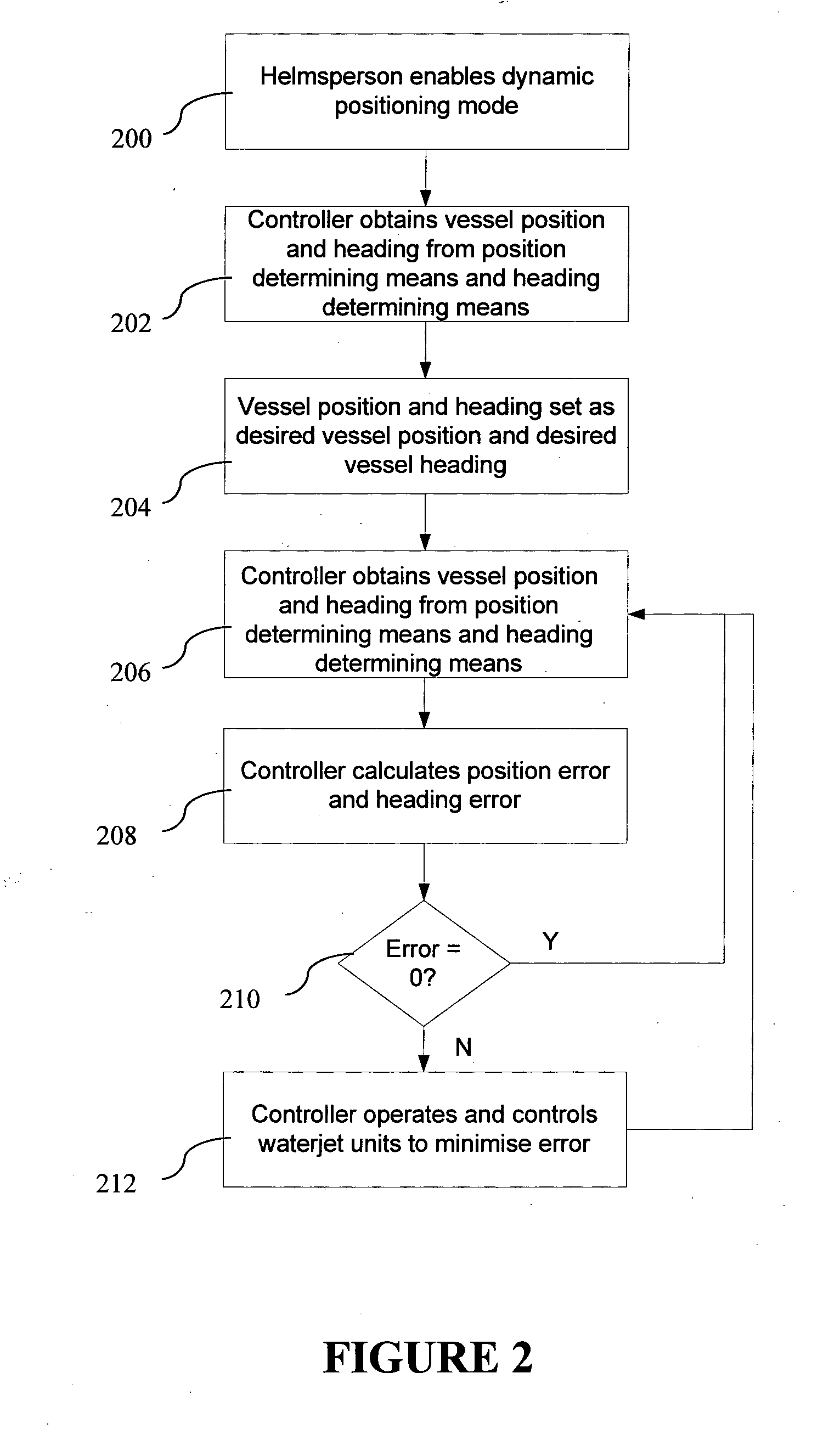

ActiveUS20100023192A1Minimize errorMinimize positionAuxillariesDigital data processing detailsAccelerometerMarine engineering

A dynamic control system for a marine vessel having two or more waterjet units as the primary propulsion system of the vessel, for maintaining vessel position or velocity when in a dynamic control mode, comprises a position or velocity indicator to indicate vessel position or velocity or deviations in vessel position or velocity; such as a satellite-based positioning system indicator, or accelerometers as a relative position indicator, a heading indicator to indicate vessel heading from position heading or yaw rate or deviations in vessel heading or yaw rate, such as a compass as an absolute heading indicator or a yaw rate sensor as a relative heading indicator, and a controller to control the operation of the waterjet units to substantially maintain the vessel position or velocity, and vessel heading or yaw rate when the dynamic control mode is enabled.

Owner:CWF HAMILTON

Methods and apparatus for operating gas turbine engines

A method for operating a gas turbine engine includes channeling compressed air from the gas turbine engine to a noise suppression system, and selectively operating the noise suppression system such that air discharged from the noise suppression system generates a streamwise vortex downstream from each respective chevron.

Owner:GENERAL ELECTRIC CO

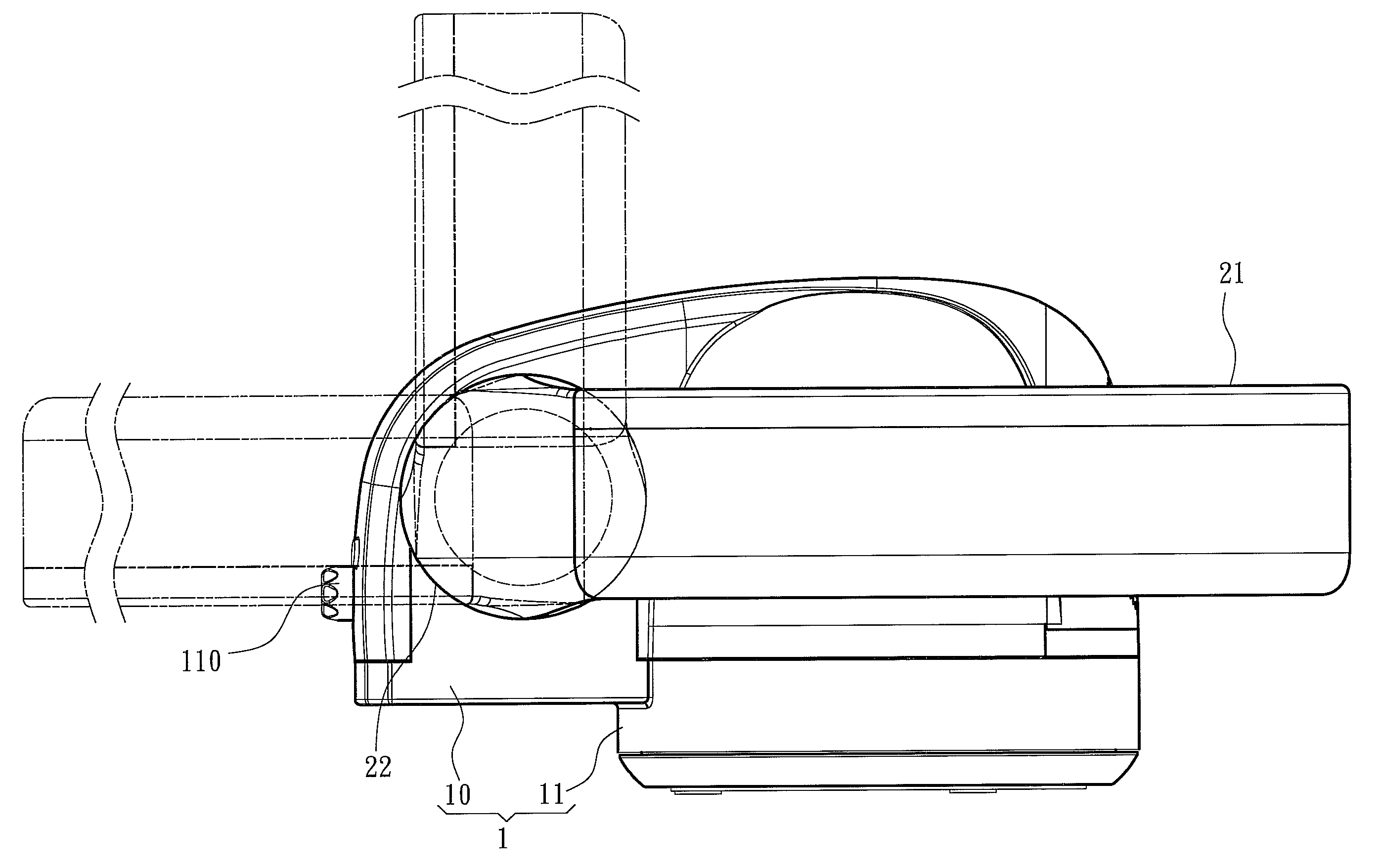

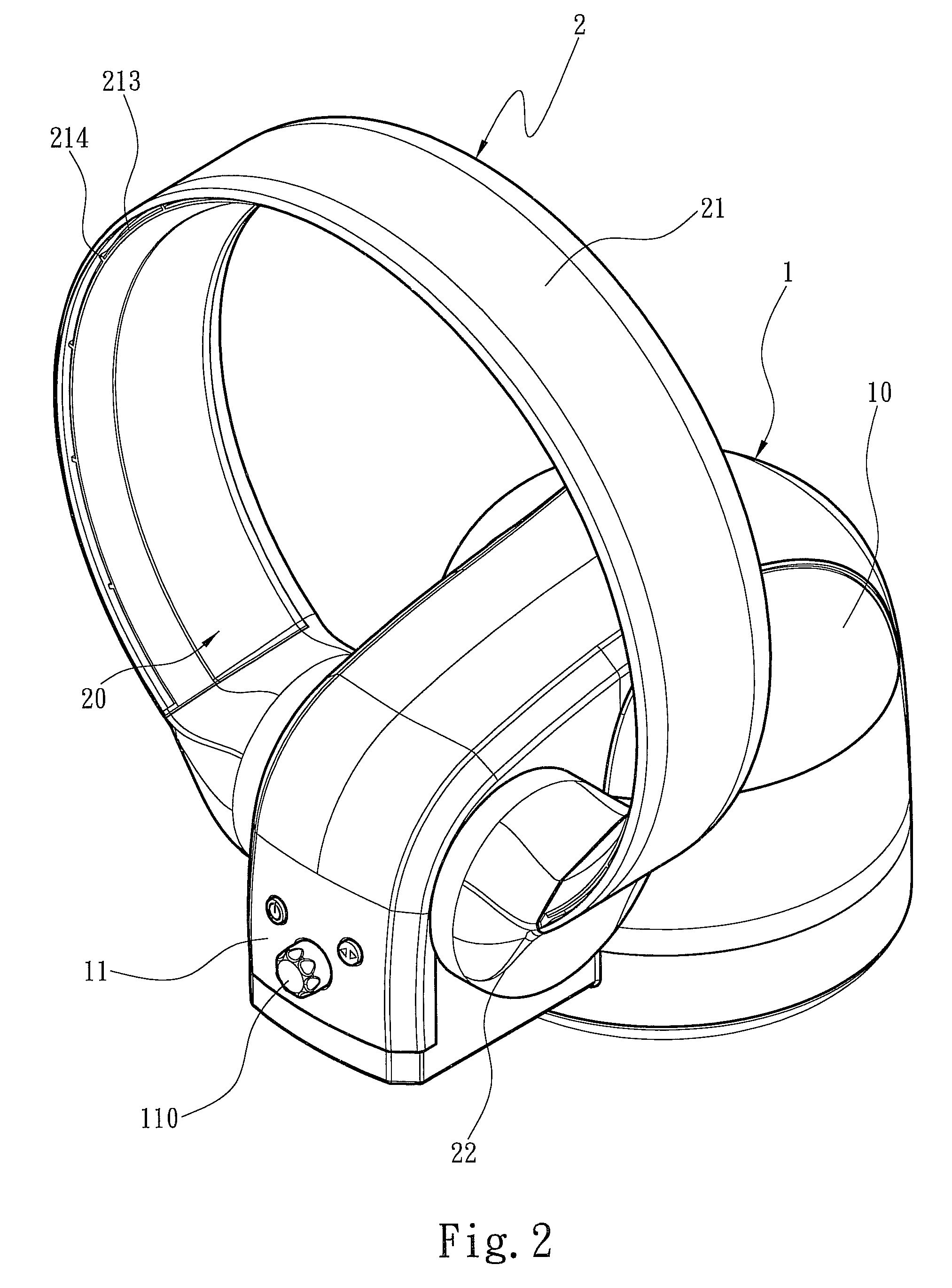

Bladeless air fan

InactiveUS8529226B2Increase rangeIncrease air velocityCircuit elementsSpray nozzlesAirflowAerospace engineering

A bladeless air fan includes a host and an airflow guiding frame. The host divides into a housing section to hold an airflow generator and a pivoting section to include two first pivoting portions. The airflow generator is connected to an airflow guiding manifold extended from the housing section to the pivoting section. The airflow guiding frame includes an air discharging portion and an airflow guiding passage and two second pivoting portions being annular to form two air intake ports communicating with the airflow guiding passage. The second pivoting portions are rotatably coupled with the first pivoting portions such that the airflow guiding passage communicates with the airflow guiding manifold. The air discharging portion encircles an airflow passage being formed at an inner diameter allowing the housing section to pass through to enlarge the range of the second pivoting portions rotating against the first pivoting portions.

Owner:KABLE ENTERPRISE

Mixer for separate-flow nozzle

InactiveUS7677026B2Reduce mechanical loadReduce weightPower plant exhaust arrangementsEngine fuctionsEngineeringTurbojet

A mixer for a separate-stream turbojet nozzle, the mixer comprising along a longitudinal axis (X-X′) both a fastener shroud (10) for connecting said mixer to the exhaust casing of the nozzle, and a lobe structure (20) presenting a succession of inner and outer lobes (22 and 21) distributed circumferentially around the longitudinal axis (X-X′) of the mixer. The lobe structure (20) is made of a ceramic matrix composite material and further comprises a stiffener ring (30) that forms a connection between at least some of the lobes of said structure. Thus, the major portion of the mixer, i.e. the lobe structure, is made of a ceramic matrix composite material, thereby significantly reducing the weight of the mixer, and consequently reducing the weight of the nozzle.

Owner:SAFRAN CERAMICS SA

System and method for controlling a waterjet driven vessel

A method for controlling a marine vessel having first and second steering nozzles and first and second trim deflectors comprises generating at least a first set of actuator control signals and a second set of actuator control signals. The first set of actuator control signals is coupled to and controls the first and second steering nozzles, and the second set of actuator control signals is coupled to and controls the first and second trim deflectors. The acts of generating and coupling the first set of actuator control signals and the second set of actuator control signals result in inducing any of a net yawing force, a net rolling force, and a net trimming force to the marine vessel without inducing any other substantial forces to the marine vessel by controlling the first and second steering nozzles and the first and second trim deflectors. Also disclosed is a system for controlling a marine vessel.

Owner:MORVILLO ROBERT A

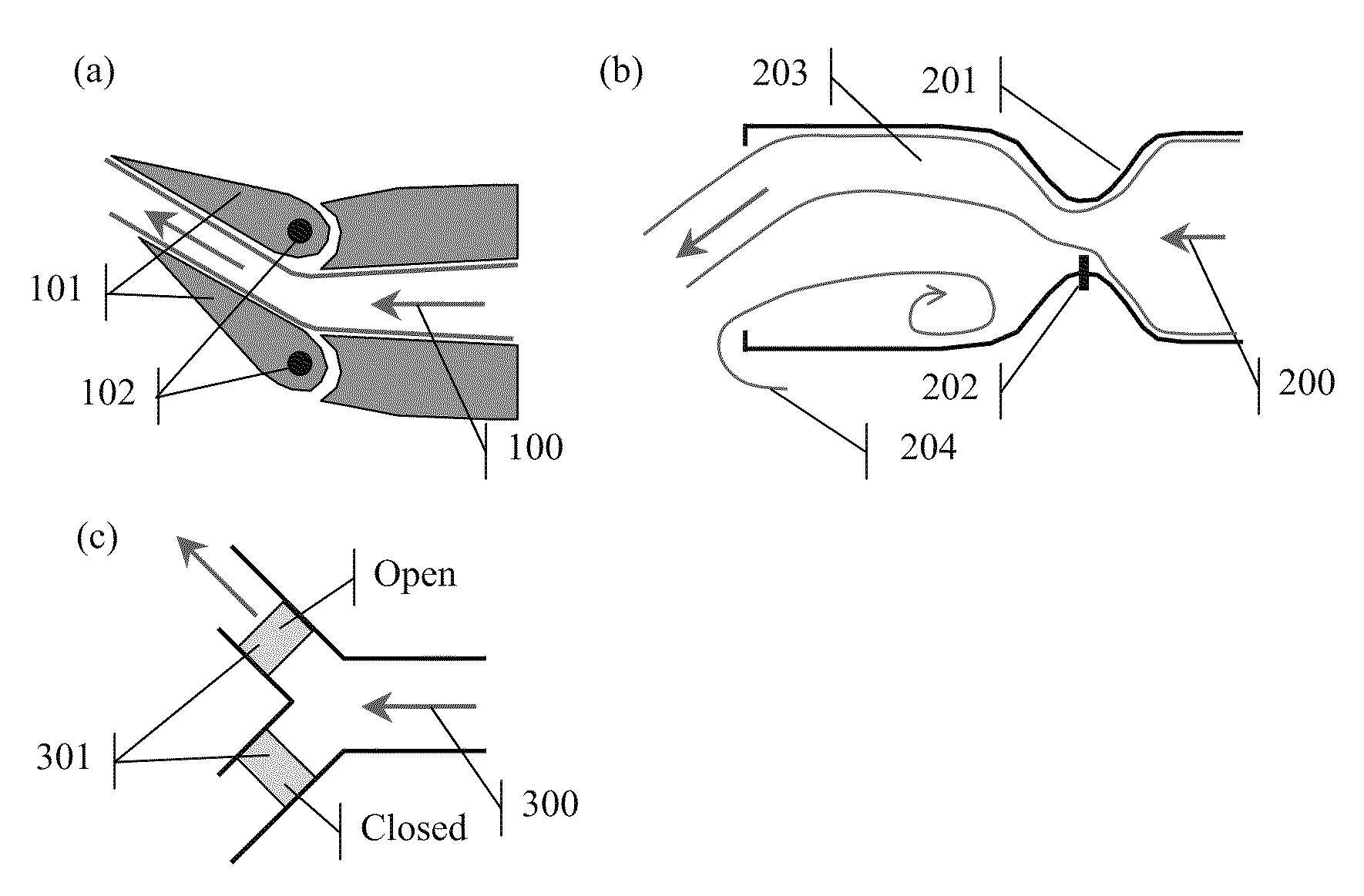

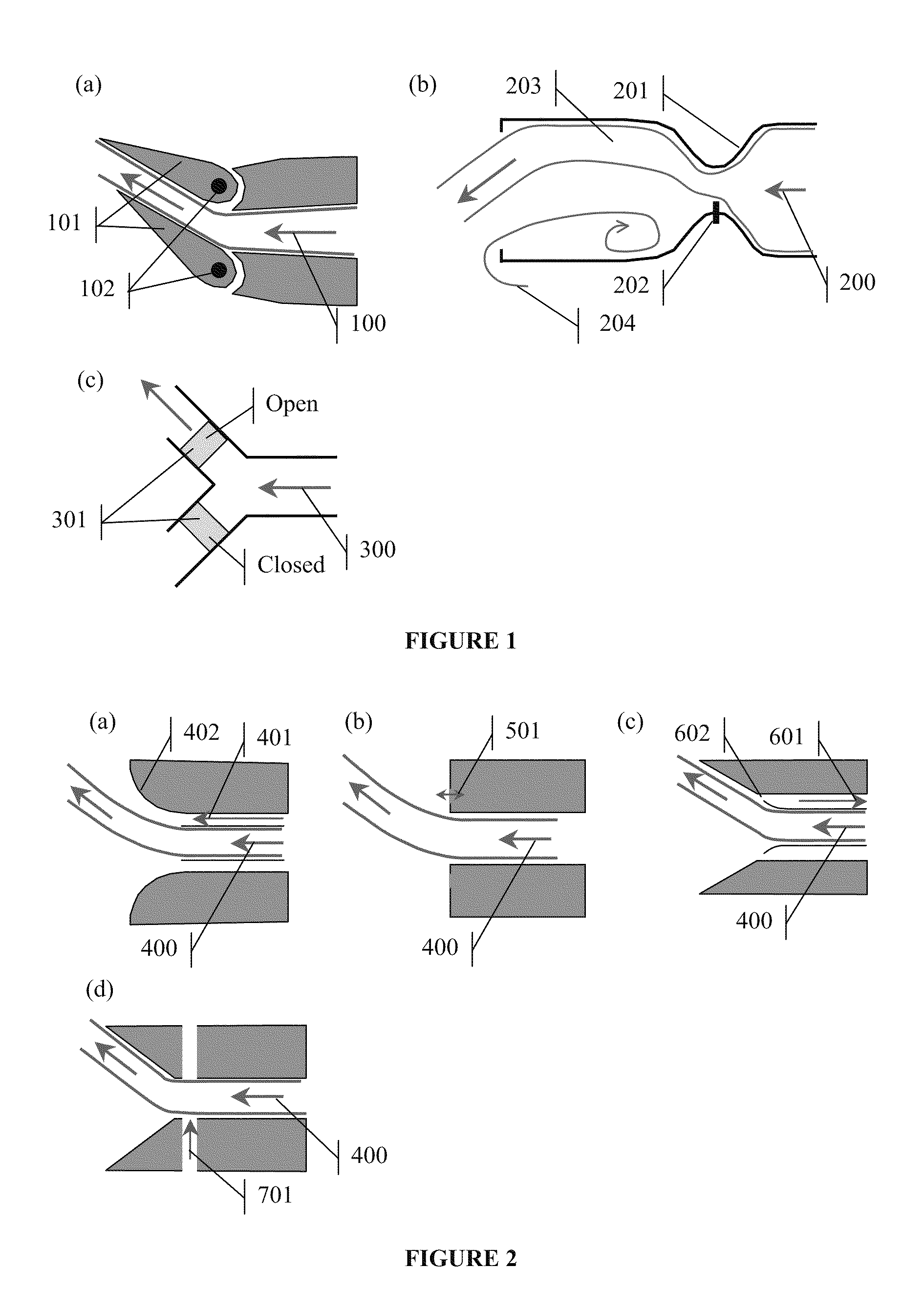

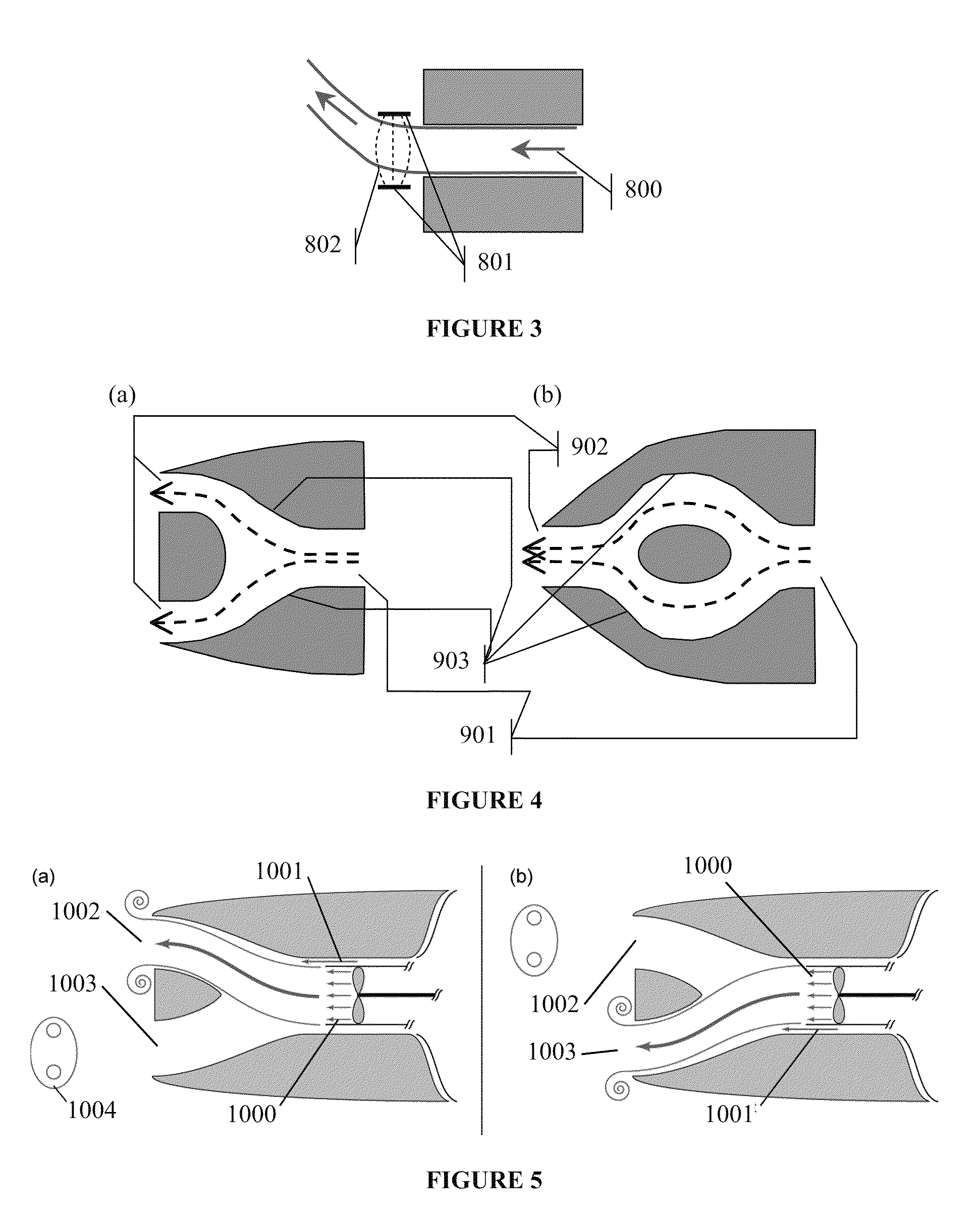

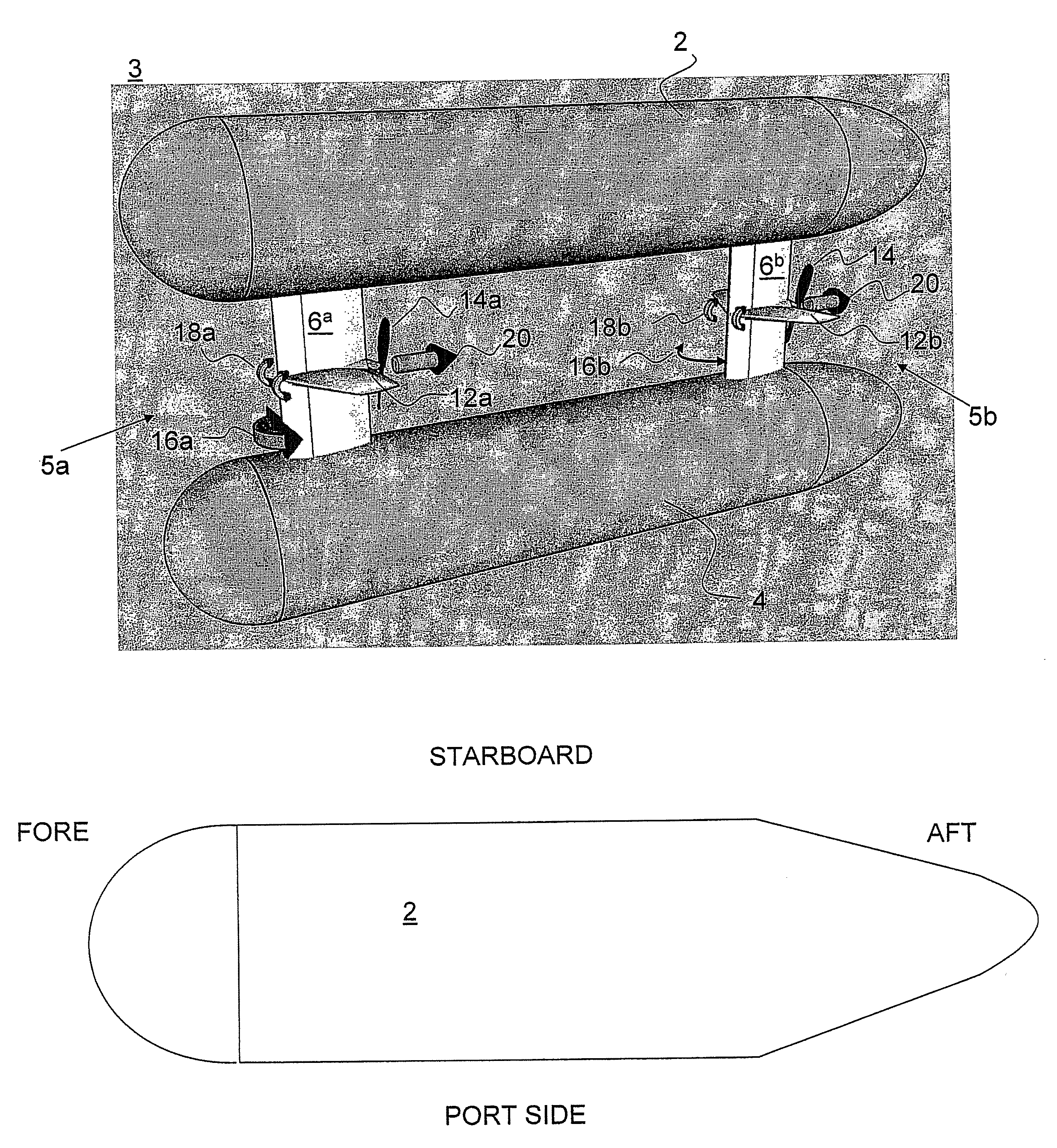

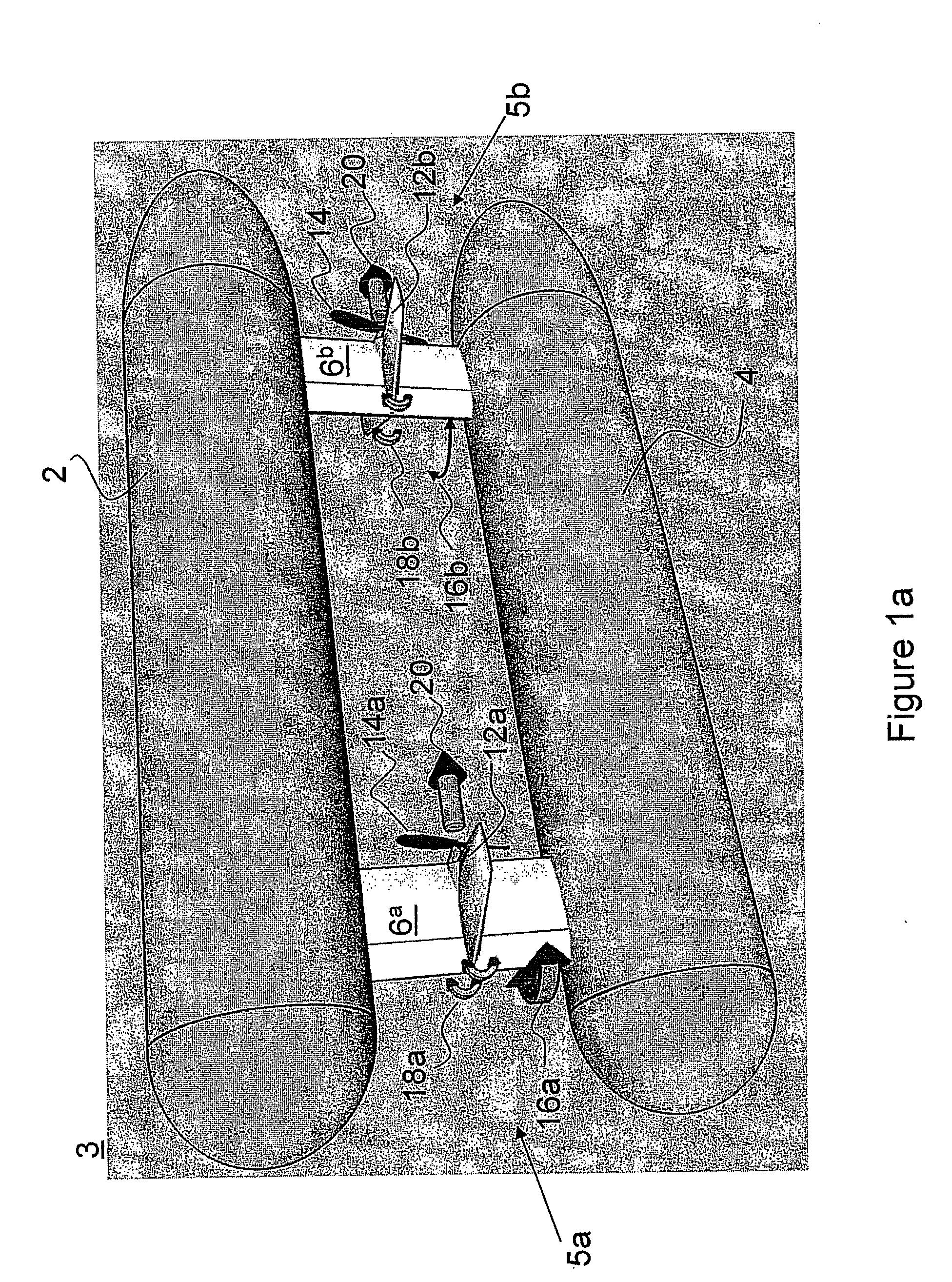

Generation of a pulsed jet by jet vectoring through a nozzle with multiple outlets

A method of producing a pulsatile jet flow from a substantially constant flow primary jet in a way that is mechanically efficient, easy to implement, and allows direct control over pulse duration and pulsing frequency is disclosed herein. The invention includes at least two components: (a) a constant flow fluid jet produced by any normal method (e.g., propeller) that can be directionally vectored fluidically, mechanically, or electromagnetically and (b) a nozzle with multiple outlets (orifices) through which the vectored jet may be directed. By alternately vectoring the jet through different outlets, a transient (pulsatile) flow at an outlet is obtained even with a substantially constant primary jet flow. Additionally, the nozzle outlets may be oriented in different directions to provide thrust vectoring, making the invention useful for maneuvering, directional control, etc.

Owner:SOUTHERN METHODIST UNIVERSITY

Method and apparatus for controlling a waterjet-driven marine vessel

A system for controlling a marine vessel having at least first and second steering nozzles and corresponding first and second reversing buckets is disclosed. The system comprises a processor configured to receive a first vessel control signal and to provide a first set and a second set of actuator control signals. The first set of actuator control signals are to be coupled to and control the first and second steering nozzles and the second set of actuator control signals are to be coupled to and control the first and second reversing buckets. The processor is configured to provide the second set of actuator control signals so that the first reversing bucket and the second reversing bucket are each positioned in one of two discrete positions, in response to receipt of a translational thrust command having least one component in an athwart ship direction.

Owner:MORVILLO ROBERT A

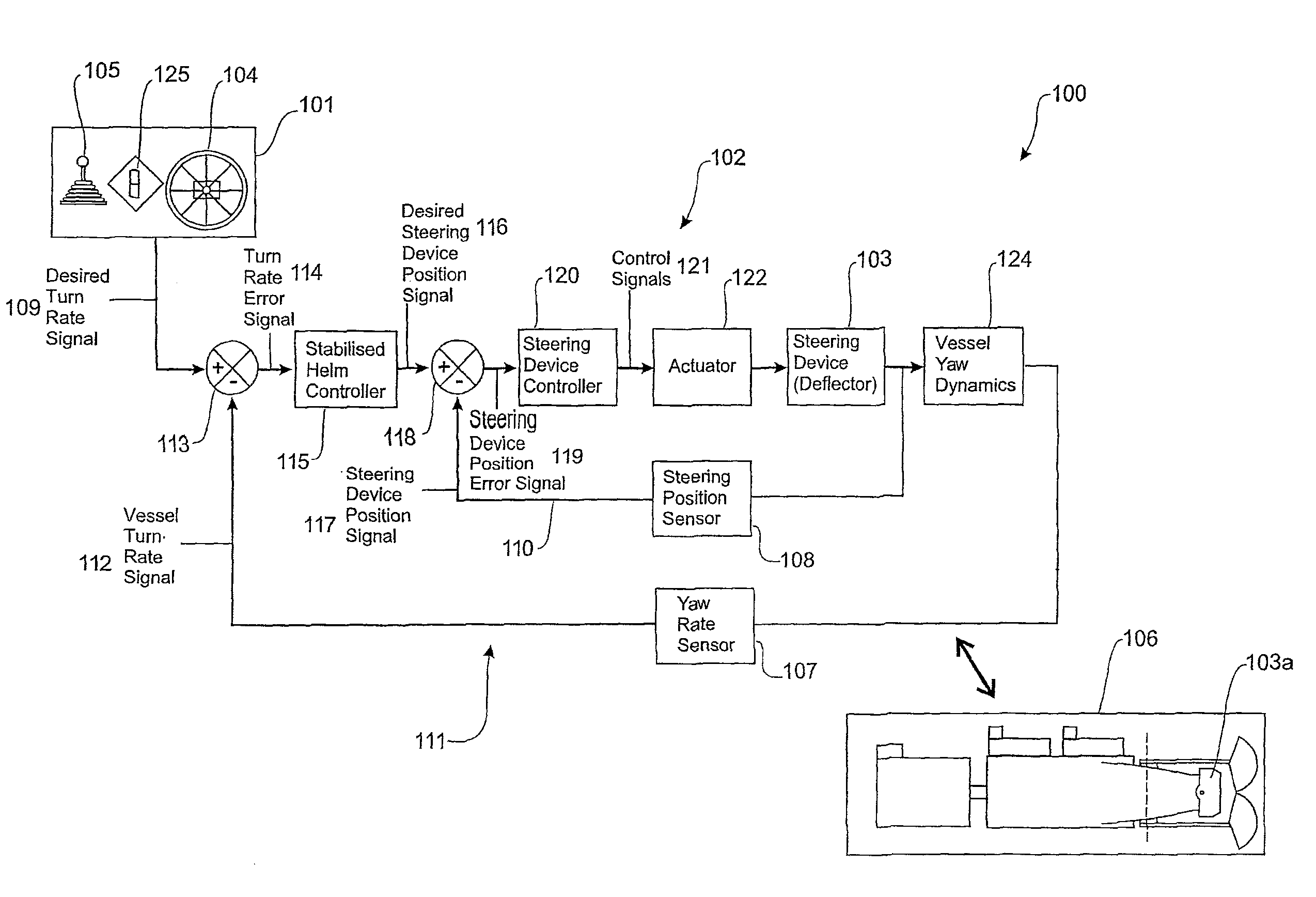

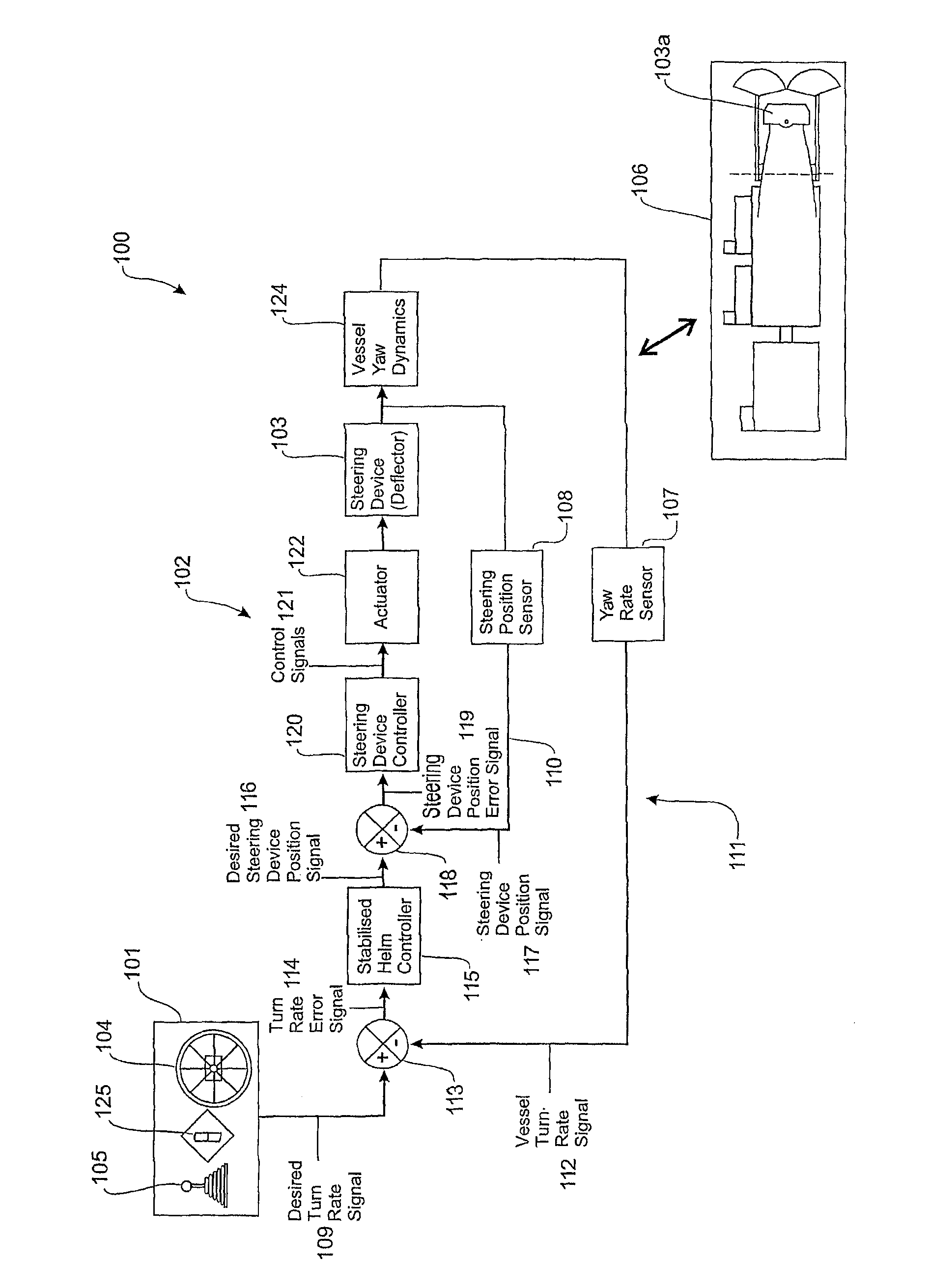

Steering system for a marine vessel

ActiveUS8145370B2Minimize the differenceSpeed controllerElectric devicesMarine engineeringControl system

A steering system for a marine vessel includes one or more steering devices operable to turn a marine vessel; a steering input device arranged to generate a desired turn rate signal; a rate sensor arranged to generate a turn rate signal indicative of vessel turn rate; and a control system configured to receive the vessel and desired turn rate signals and to control the steering device(s) to turn the marine vessel so as to minimise any difference between the signals.

Owner:CWF HAMILTON

Variable trim deflector system and method for controlling a marine vessel

ActiveUS20110320072A1Improve stabilityDigital data processing detailsSteering by extensible flapsMarine engineering

A method and a system for controlling a marine vessel having first and second trim deflectors is disclosed. The first and second trim deflectors have a first surface having a first area and a second surface having a second area, wherein the second planar surface is coupled to the first surface. The method and system control the first and second trim deflectors to induce any of a net yawing force, a net rolling force, and a net trimming force to the marine vessel without inducing any other substantial forces to the marine vessel by controlling the first and second trim deflectors.

Owner:MORVILLO ROBERT A

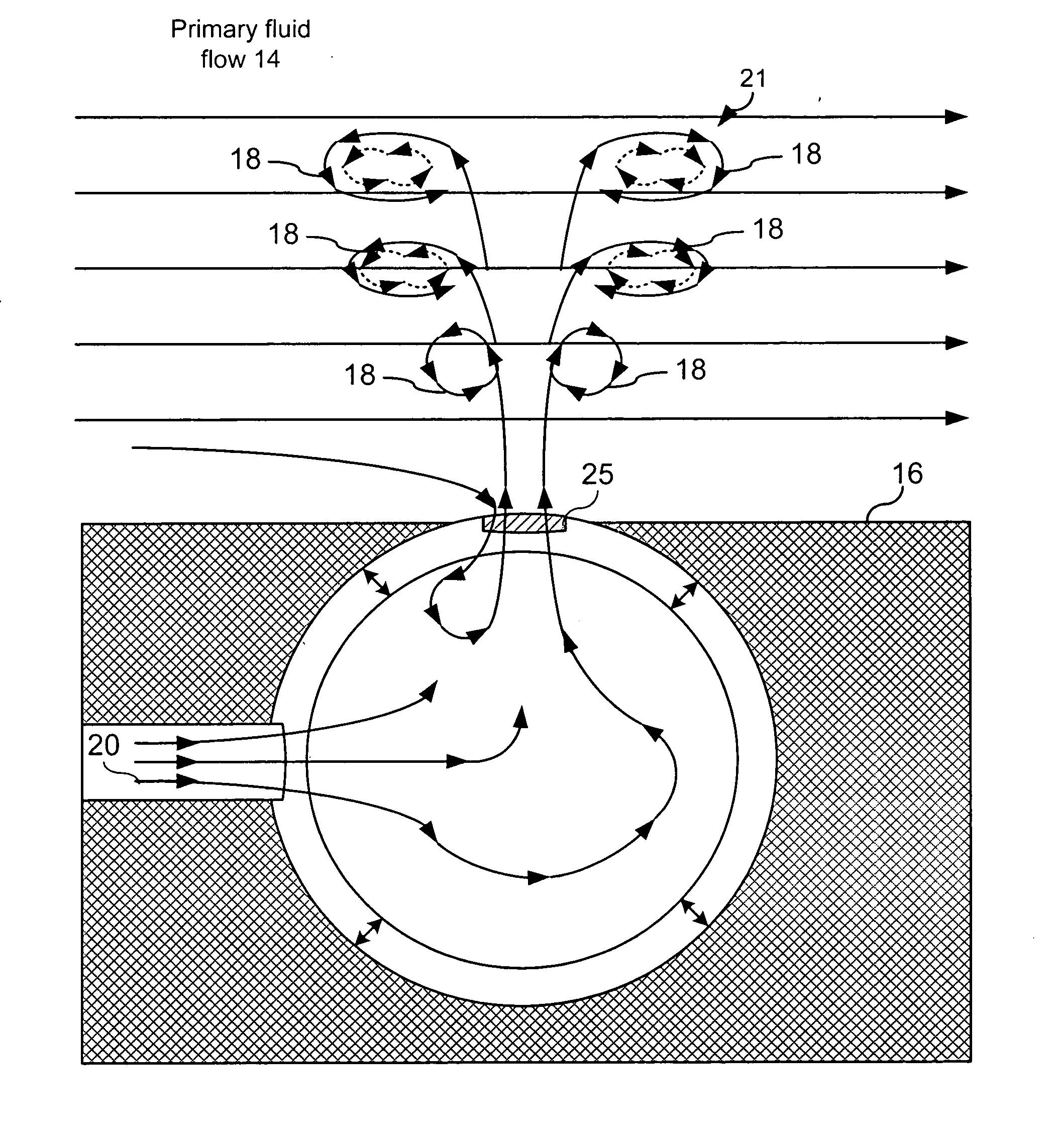

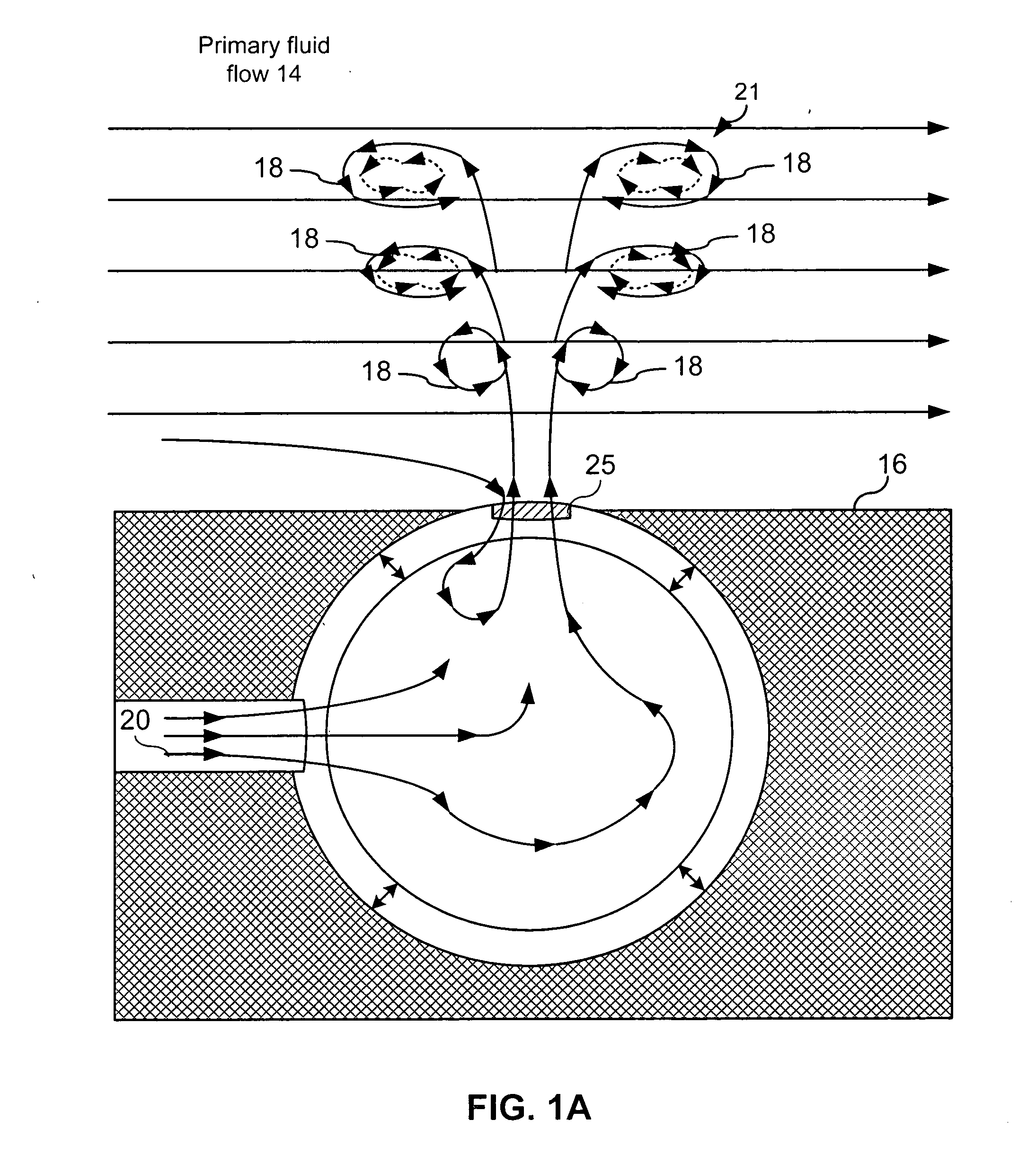

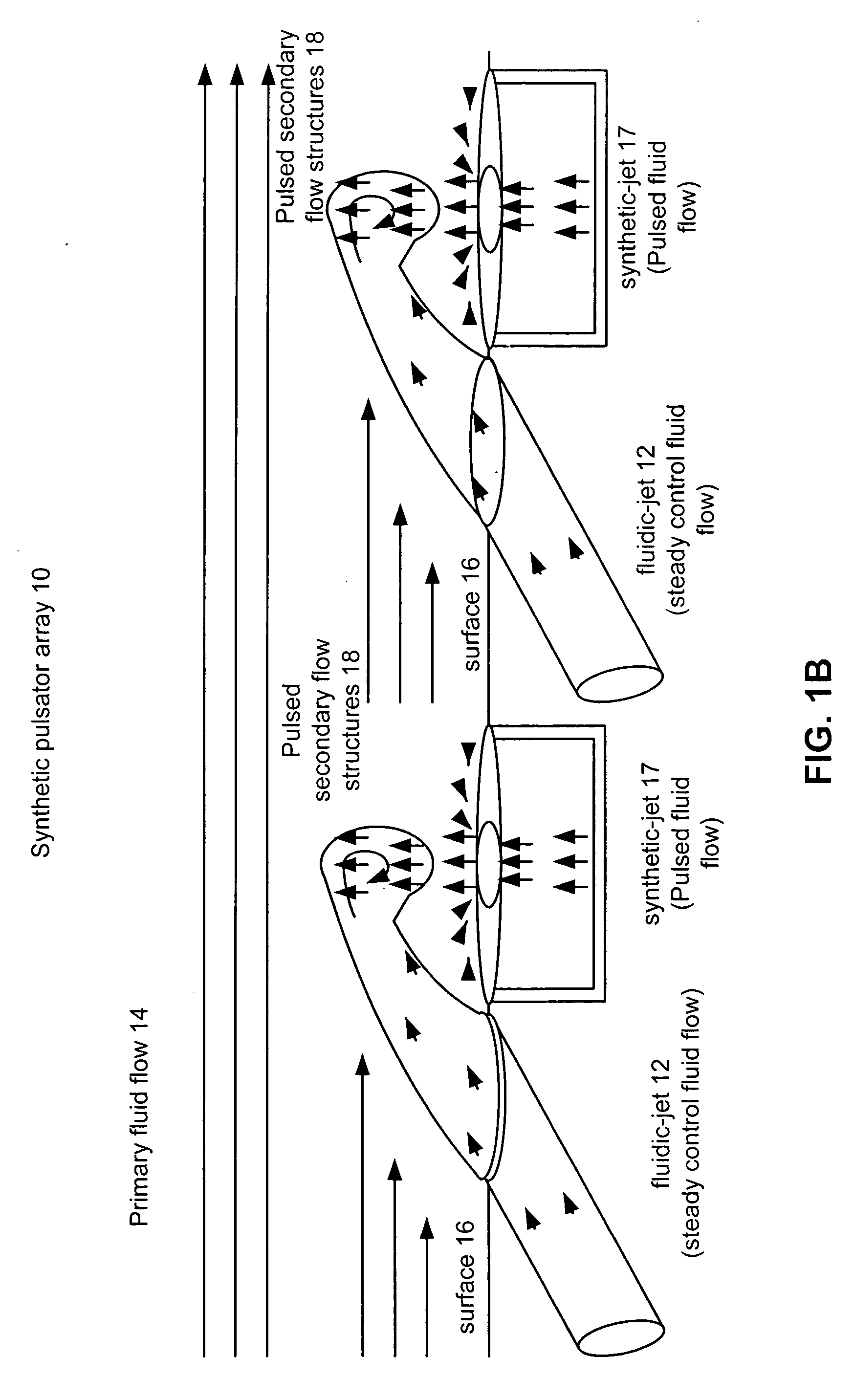

Dual bimorph synthetic pulsator

The present invention provides a system and method for actively manipulating fluid flow over a surface using synthetic pulsators. Synthetic pulsators produce pulsed jet operable to manipulate the primary fluid flow proximate to the synthetic pulsator. The synthetic pulsator includes a synthetic jet actuator(s) operable to produce an oscillatory flow, and fluidic jet(s) operable to provide a continuous fluid flow. The oscillatory flow of the synthetic jet(s) and the continuous fluid flow of the fluidic jet(s) combine or mix to produce the pulsed jet operable to manipulate the primary fluid flow. These synthetic pulsators may then be actively manipulated to control the flow behavior of the ducted fluid flow, influence the inception point and trajectory of flow field vortices within the fluid flow, and reduce flow separation within the primary fluid flow.

Owner:LOCKHEED MARTIN CORP

Propulsion System for an Autonomous Underwater Vehicle

An underwater vehicle is provided to move in various orientations and directions, including pitch, yaw, roll, heave, surge and sway. The underwater vehicle comprises an upper body and a lower body, wherein both bodies are separated by two rudders. One rudder is positioned towards the fore of the underwater vehicle, while the other is positioned towards the aft. Each rudder forms the basis of a propulsion system, such that the underwater vehicle has at least two independently controlled propulsion systems. Each propulsion system further comprises an elevator extending horizontally from the sides of each rudder and a thrust generator attached to the elevator. The elevator and thrust generator are able to pitch about an axis extending horizontally through the sides of the rudder, and the rudder is able to yaw about an axis extending vertically through the top and bottom of said rudder.

Owner:NAT RES COUNCIL OF CANADA

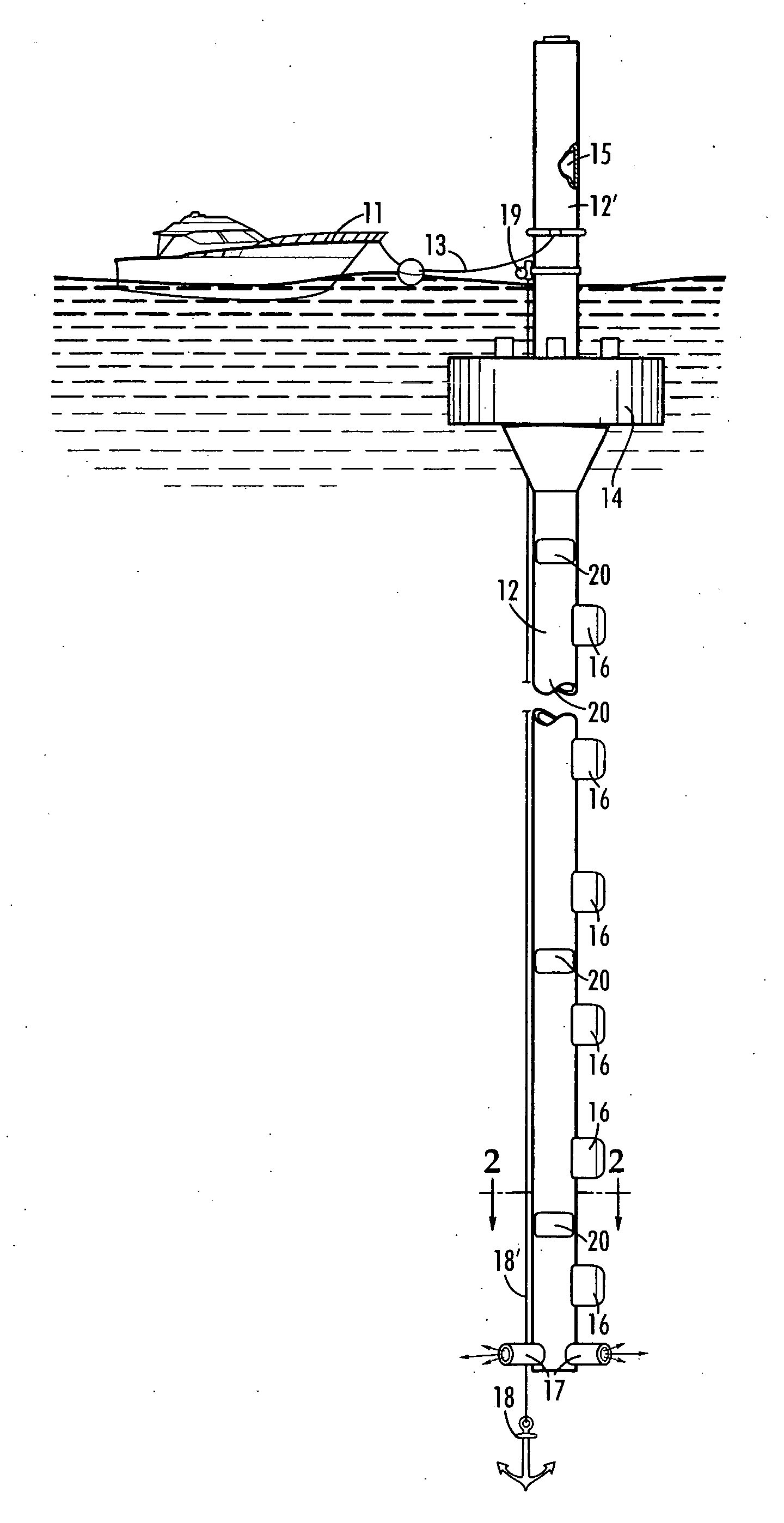

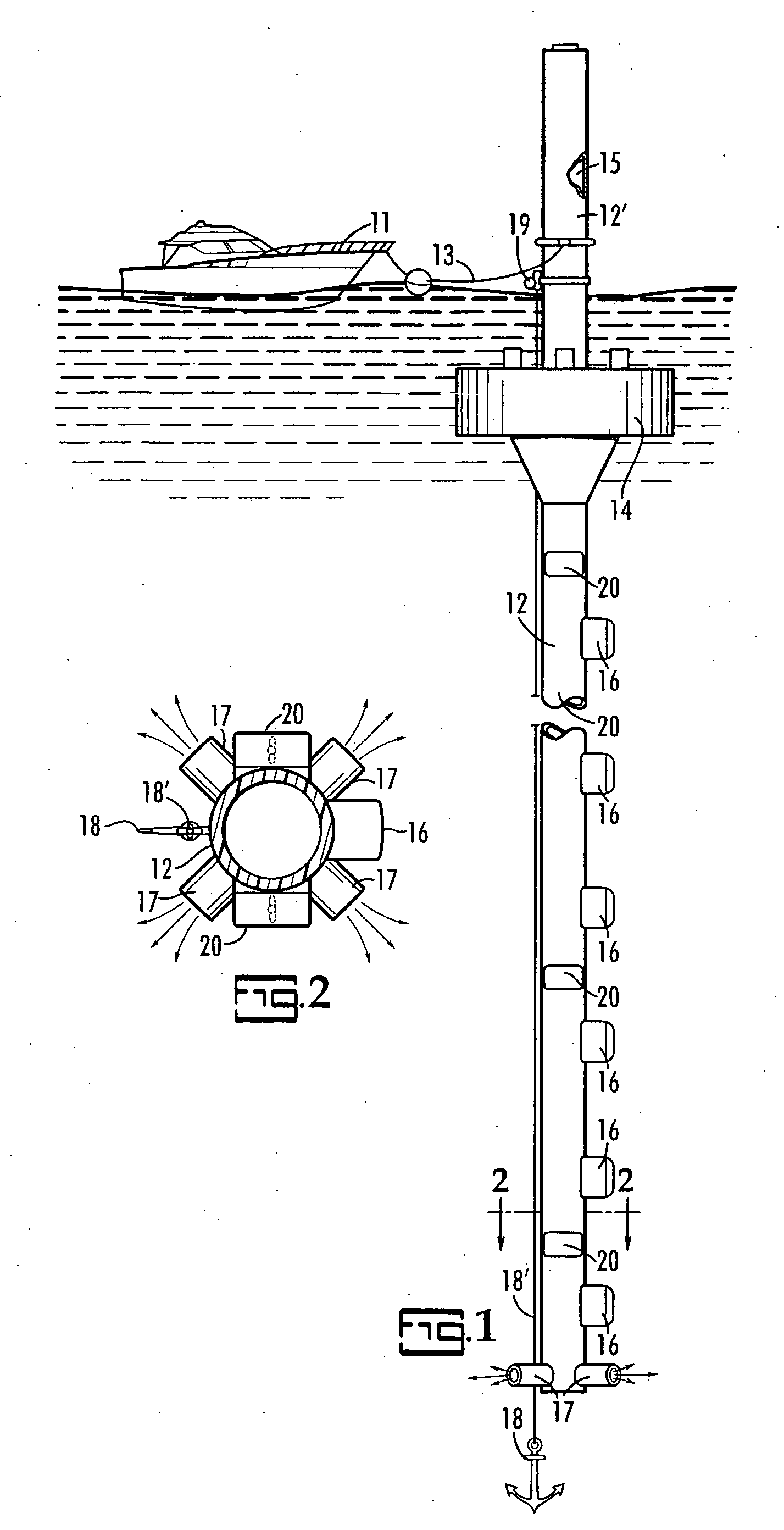

Marine water conversion

InactiveUS20070084768A1Reduce surface temperaturePromote formationFog dispersionSedimentation separationMarine engineeringSurface water

A marine water conversion apparatus capable of pumping ocean surface water several hundred feel below the surface to cause sufficient cooler water to rise to the surface to prevent formation of or to moderate hurricanes. The apparatus is remotely controlled and includes a propulsion system for moving it to a new location or in predetermined patterns through use of a global positioning system and computerized controls. Power for driving the pumps may be provided by a wind turbine driven electric generator at the upper end of an upper tube section pivotally connected to a float tank on a vertical axis.

Owner:BARBER GERALD L

Method and apparatus for controlling a waterjet-driven marine vessel

A system for controlling a marine vessel having at least first and second steering nozzles and corresponding first and second reversing buckets is disclosed. The system comprises a processor configured to receive a first vessel control signal and to provide a first set and a second set of actuator control signals. The first set of actuator control signals are to be coupled to and control the first and second steering nozzles and the second set of actuator control signals are to be coupled to and control the first and second reversing buckets. The processor is configured to provide the second set of actuator control signals so that the first reversing bucket and the second reversing bucket are each positioned in one of two discrete positions, in response to receipt of a translational thrust command having least one component in an athwart ship direction.

Owner:MORVILLO ROBERT A

Dynamic control system for a marine vessel

ActiveUS8145371B2Minimize errorMinimize positionSpeed controllerElectric devicesAccelerometerMarine engineering

A dynamic control system for a marine vessel having two or more waterjet units as the primary propulsion system of the vessel, for maintaining vessel position or velocity when in a dynamic control mode, comprises a position or velocity indicator to indicate vessel position or velocity or deviations in vessel position or velocity; such as a satellite-based positioning system indicator, or accelerometers as a relative position indicator, a heading indicator to indicate vessel heading from position heading or yaw rate or deviations in vessel heading or yaw rate, such as a compass as an absolute heading indicator or a yaw rate sensor as a relative heading indicator, and a controller to control the operation of the waterjet units to substantially maintain the vessel position or velocity, and vessel heading or yaw rate when the dynamic control mode is enabled.

Owner:CWF HAMILTON

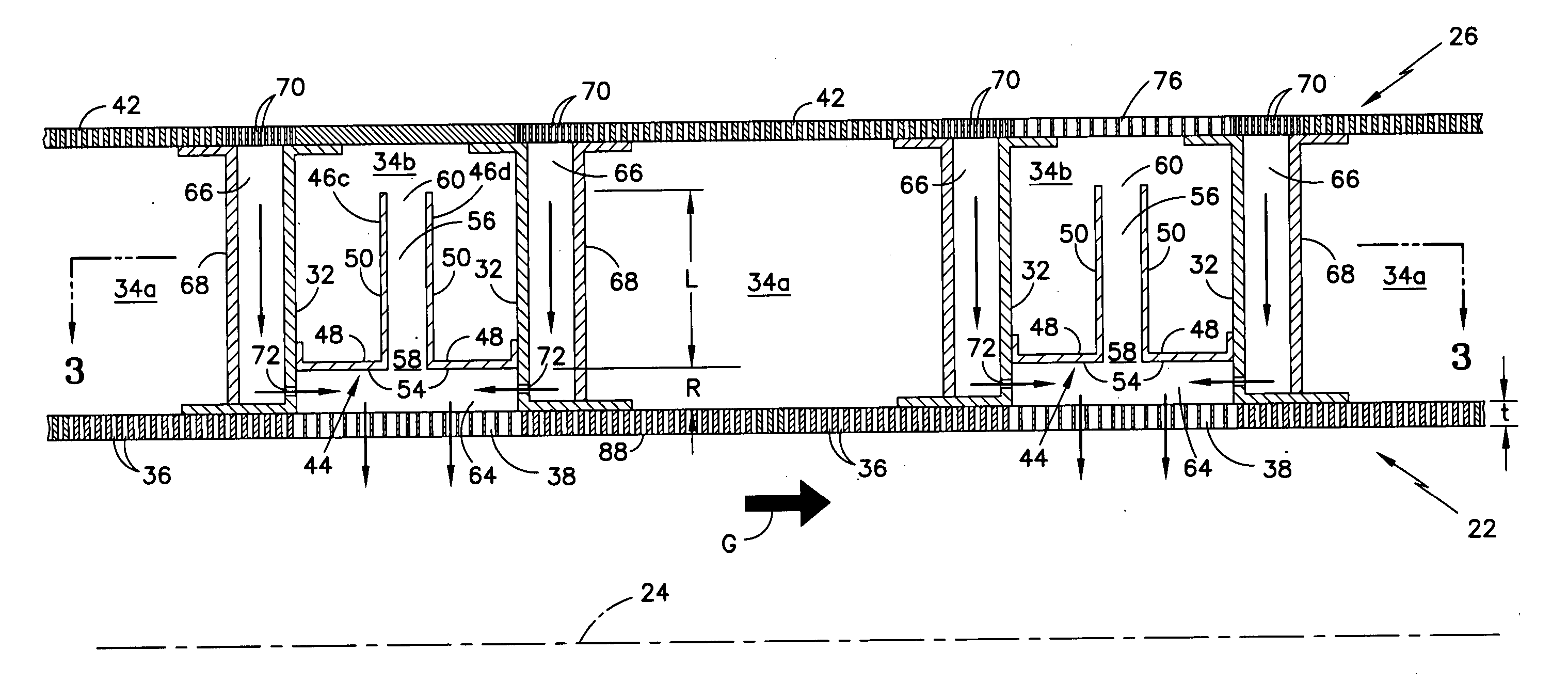

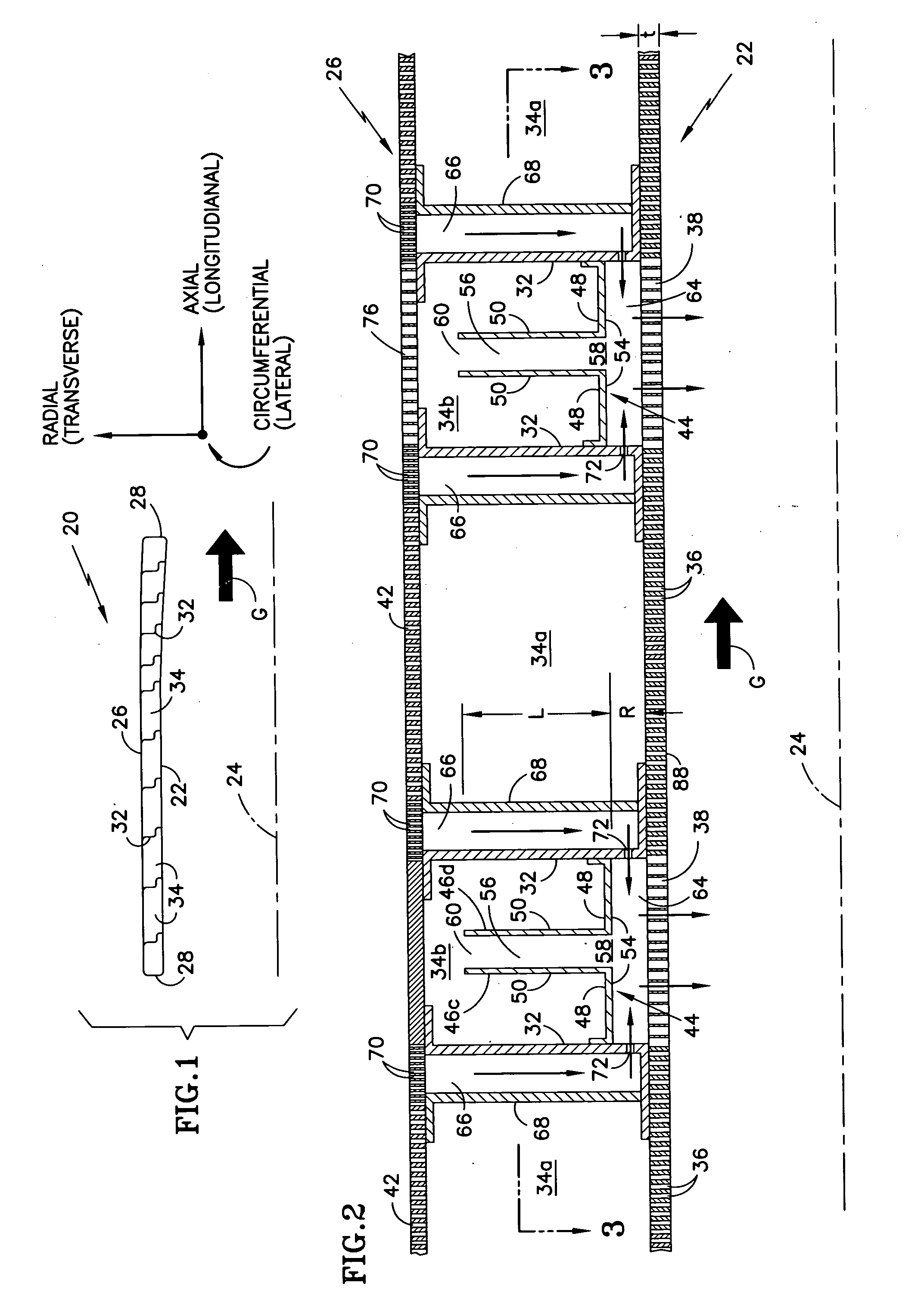

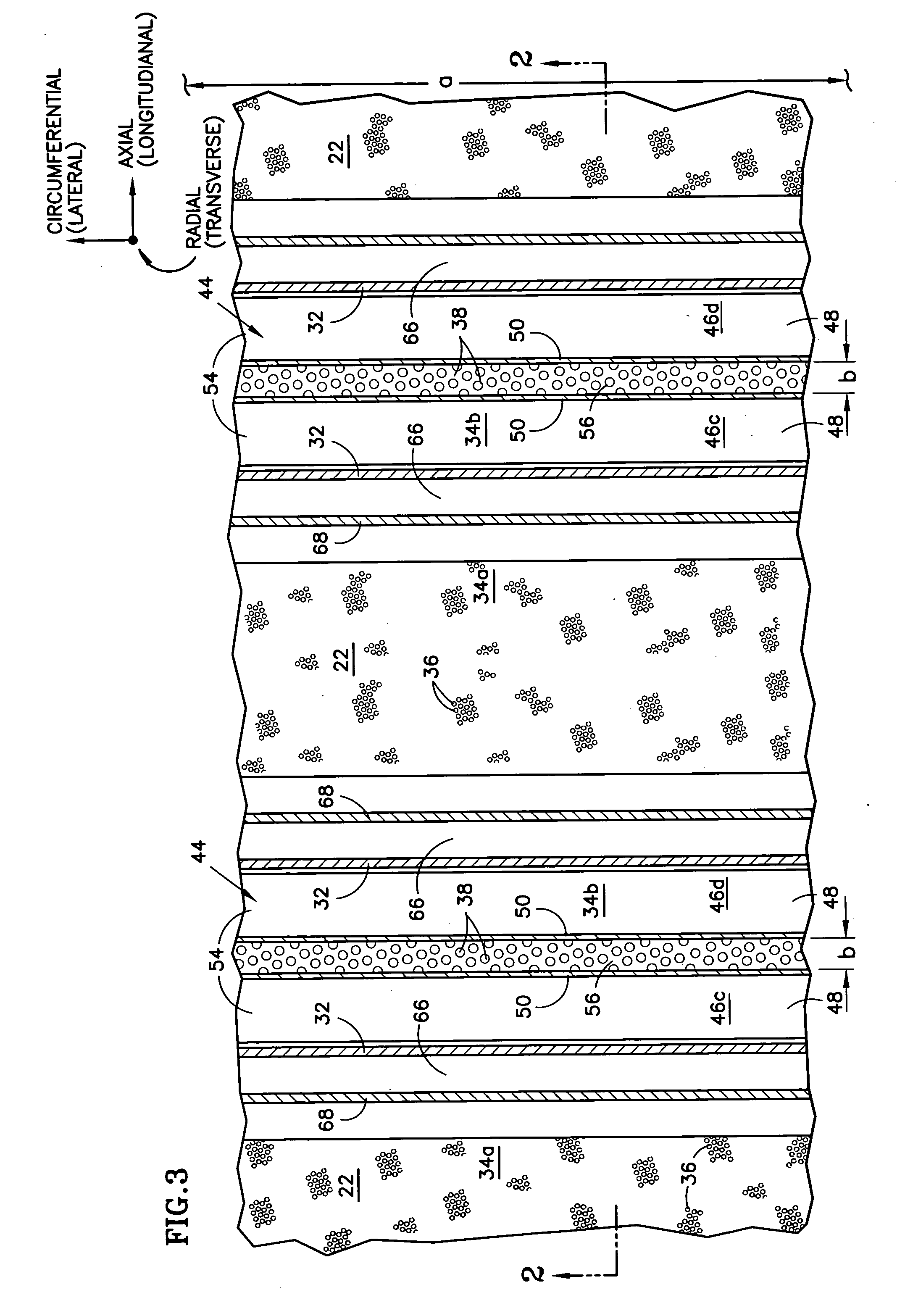

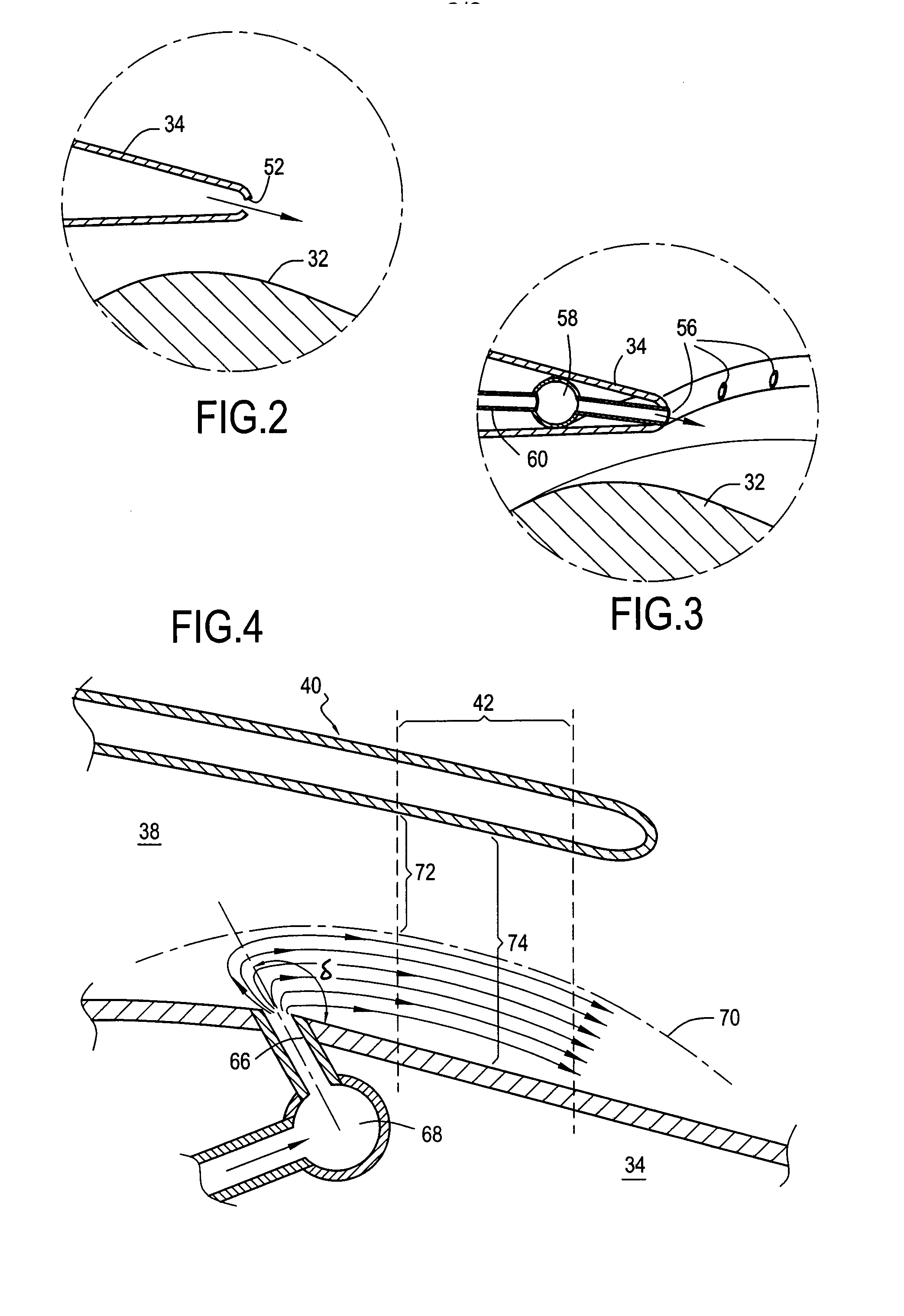

Acoustic liner with bypass cooling

An acoustic liner 20 includes a remote panel 26, a proximate panel 28 transversely spaced from the remote panel and a resonator chamber 34b residing between the panels. Perforations 38 penetrate the proximate panel in registration with the resonator chamber 34b. A neck 56 with an inlet 58 recessed from the proximate panel establishes communication between the chamber and a fluid stream G flowing past the proximate panel. A bypass coolant passage 66 guides coolant through the perforations without guiding it through the resonator chamber.

Owner:RAYTHEON TECH CORP

Bypass turbomachine with artificial variation of its throat section

ActiveUS20080141656A1Mitigate such drawbackIncrease ratingsCosmonautic vehiclesCosmonautic propulsion system apparatusThroatNacelle

The invention relates to a bypass turbomachine comprising a gas turbine engine provided with a fan disposed on a longitudinal axis of the turbomachine, and an annular nacelle surrounding the engine so as to define a cold stream flow channel, the nacelle having an upstream end surrounding the fan of the engine and a stationary downstream end forming a gas exhaust nozzle, the nozzle having a throat section that corresponds to its smallest cross-section. The turbomachine further comprises means for taking in air from the cold stream flow channel upstream from the nozzle throat section, and means for injecting the taken-in air downstream from the nozzle throat section so as to open the throat section artificially.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Combustion nozzle fluidic injection assembly

Owner:UNITED TECH CORP

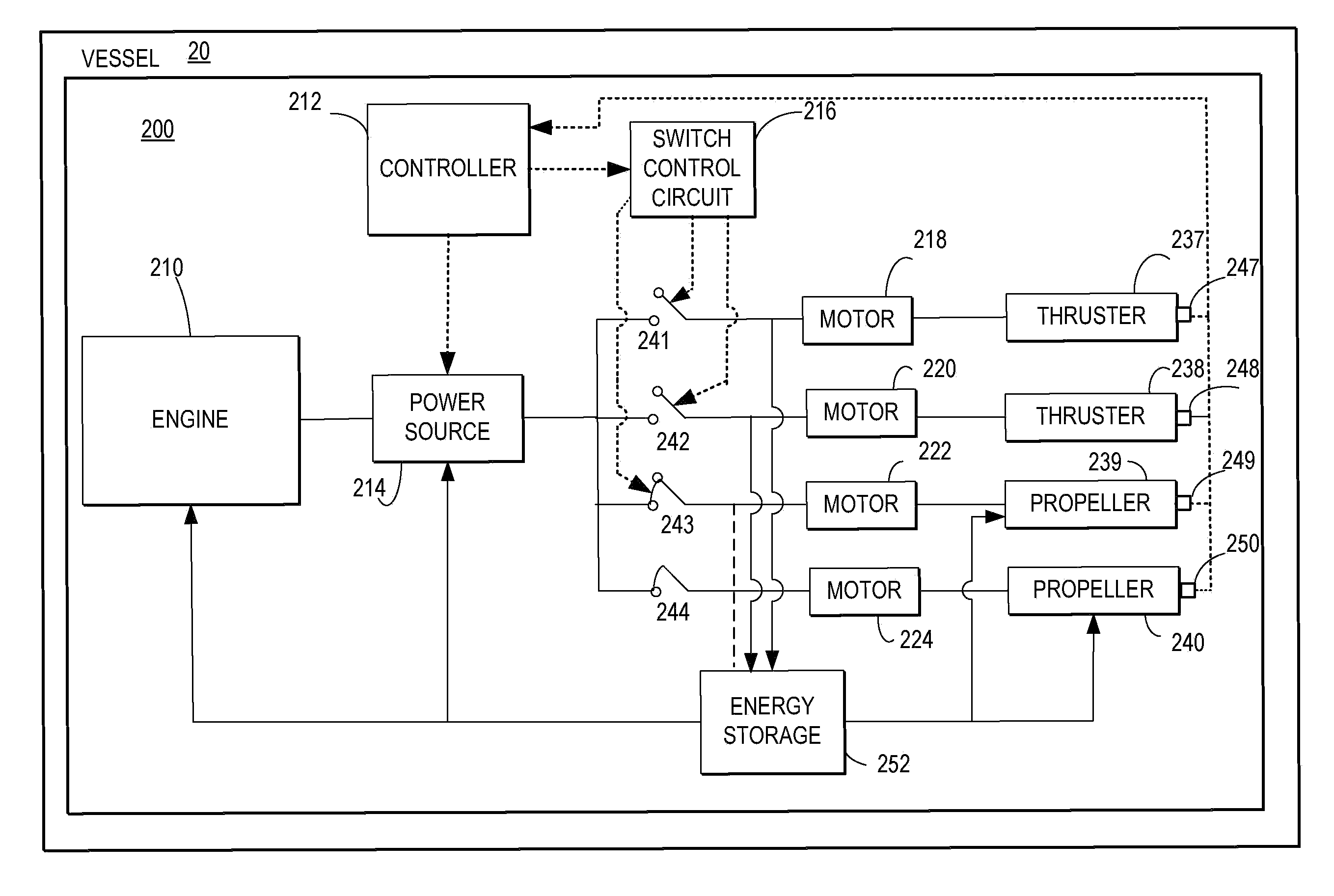

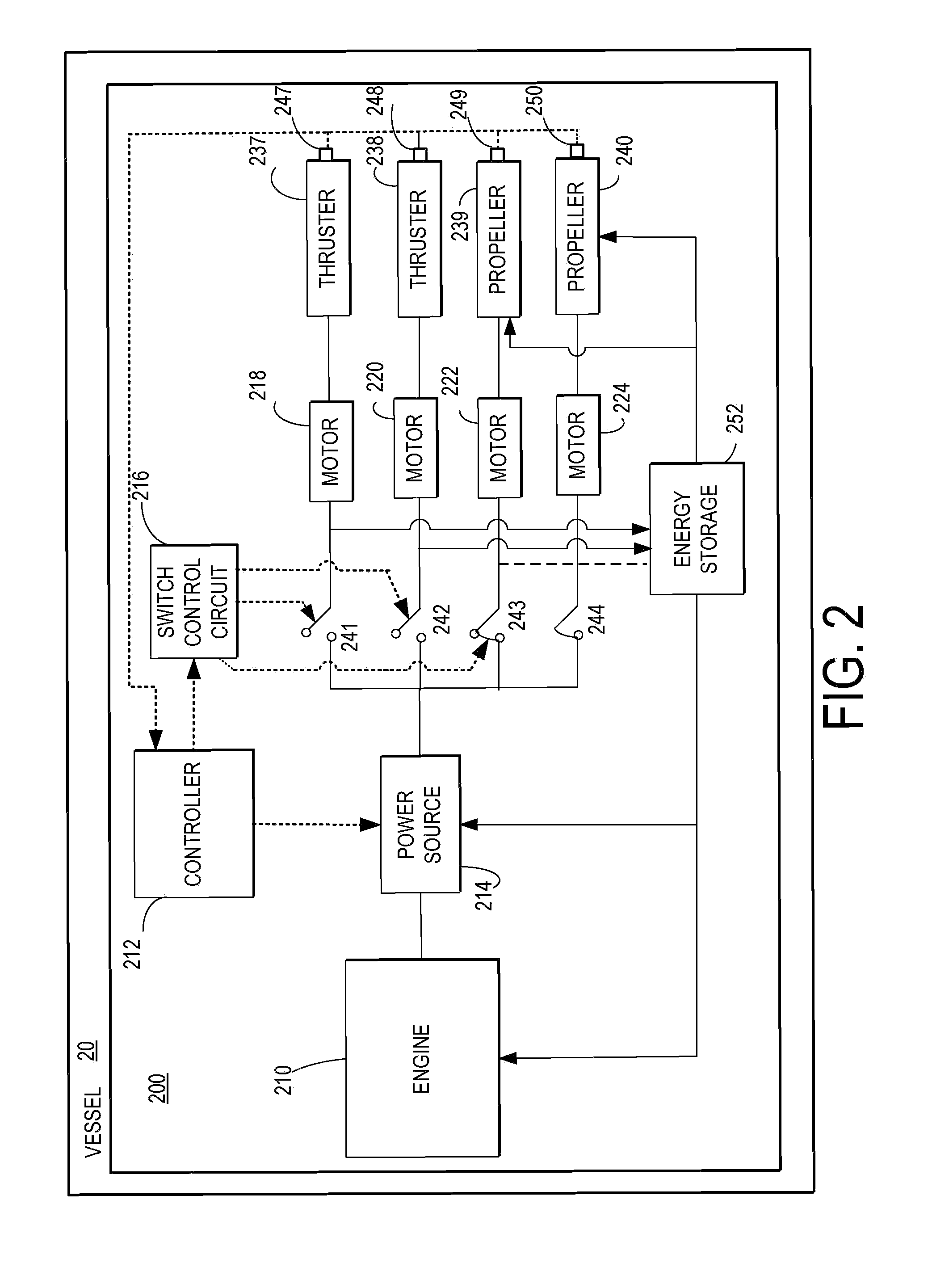

System and method for dynamic energy recovery in marine propulsion

ActiveUS20100009578A1Extend its range of actuationImprove dynamic rangeAuxillariesPropulsion power plantsMarine propulsionEnergy recovery

Owner:GE GLOBAL SOURCING LLC

Thrust reverser system electro-mechanical brake manual release mechanism

A manual release mechanism for a thrust reverser actuation system electromechanical brake includes a first release plate, a second release plate, at least two balls, and a handle. The first and second release plates each have grooves formed therein that have a cam surface located at a predetermined angle. The release plates face one another such that the grooves in each plate are substantially aligned, and the balls are each positioned in the aligned grooves. The first release plate is configured to rotate, and the second release plate is configured to translate. The handle is coupled to the first release plate to allow manual rotation thereof. In response to rotation of the first release plate, the second release plate will translate and disengage the electromechanical brake.

Owner:HONEYWELL INT INC

Braking device for watercraft

InactiveUS6722932B2Steering by extensible flapsSteering by propeller slipstream deflectionEngineeringWatercraft

A watercraft includes an improved braking device to assist slowing the watercraft when operated. The braking device includes a baffle plate and a guide plate. The baffle plate is movable between a non-braking position and a fully braking position. The guide plate cooperates with the baffle plate and is movable between a normal position and a fully deployed position. With the guide plate in the fully deployed position and the baffle plate in the fully braking position, the guide plate directs water against the baffle plate in order to slow the watercraft.

Owner:YAMAHA MOTOR CO LTD

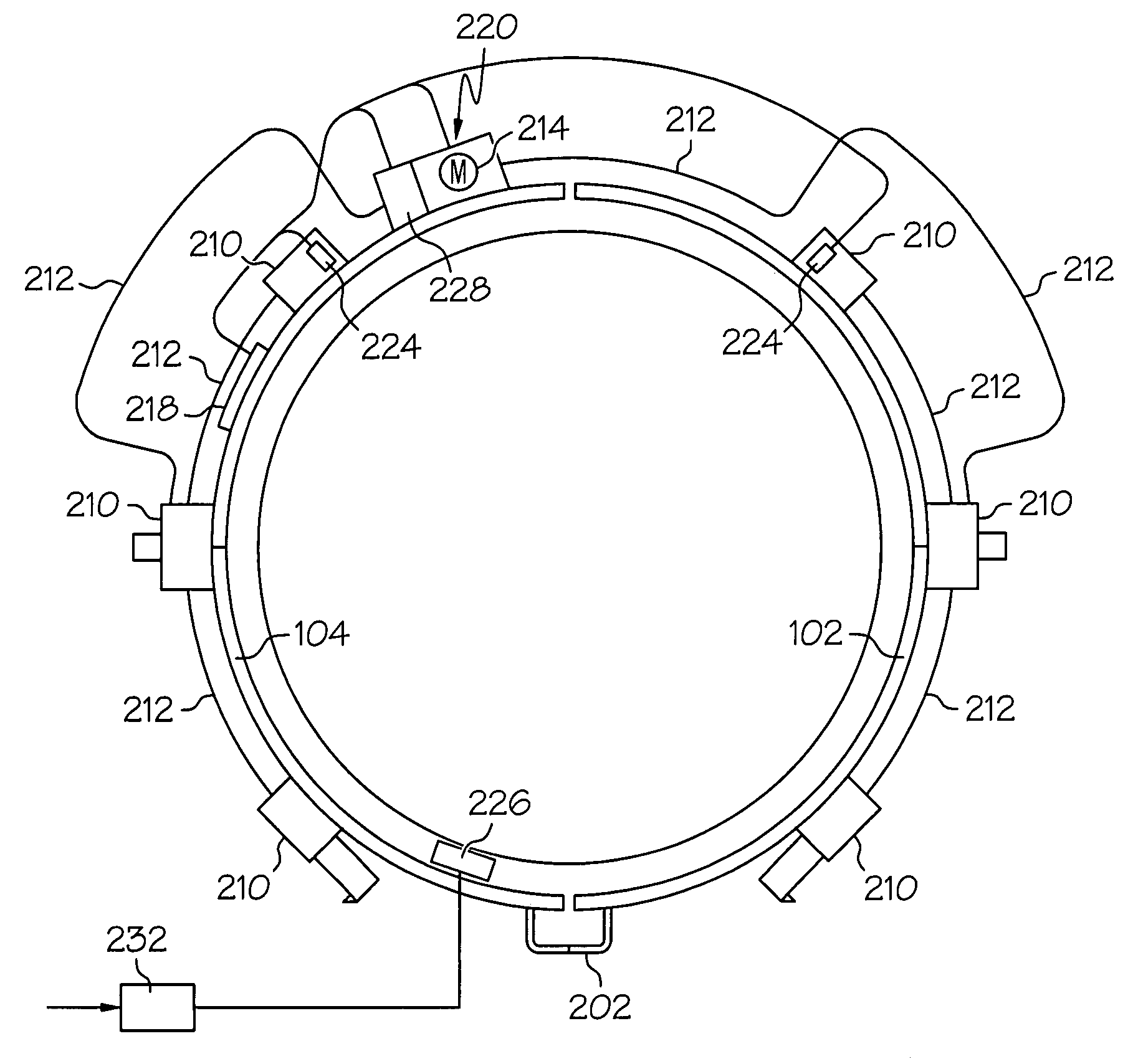

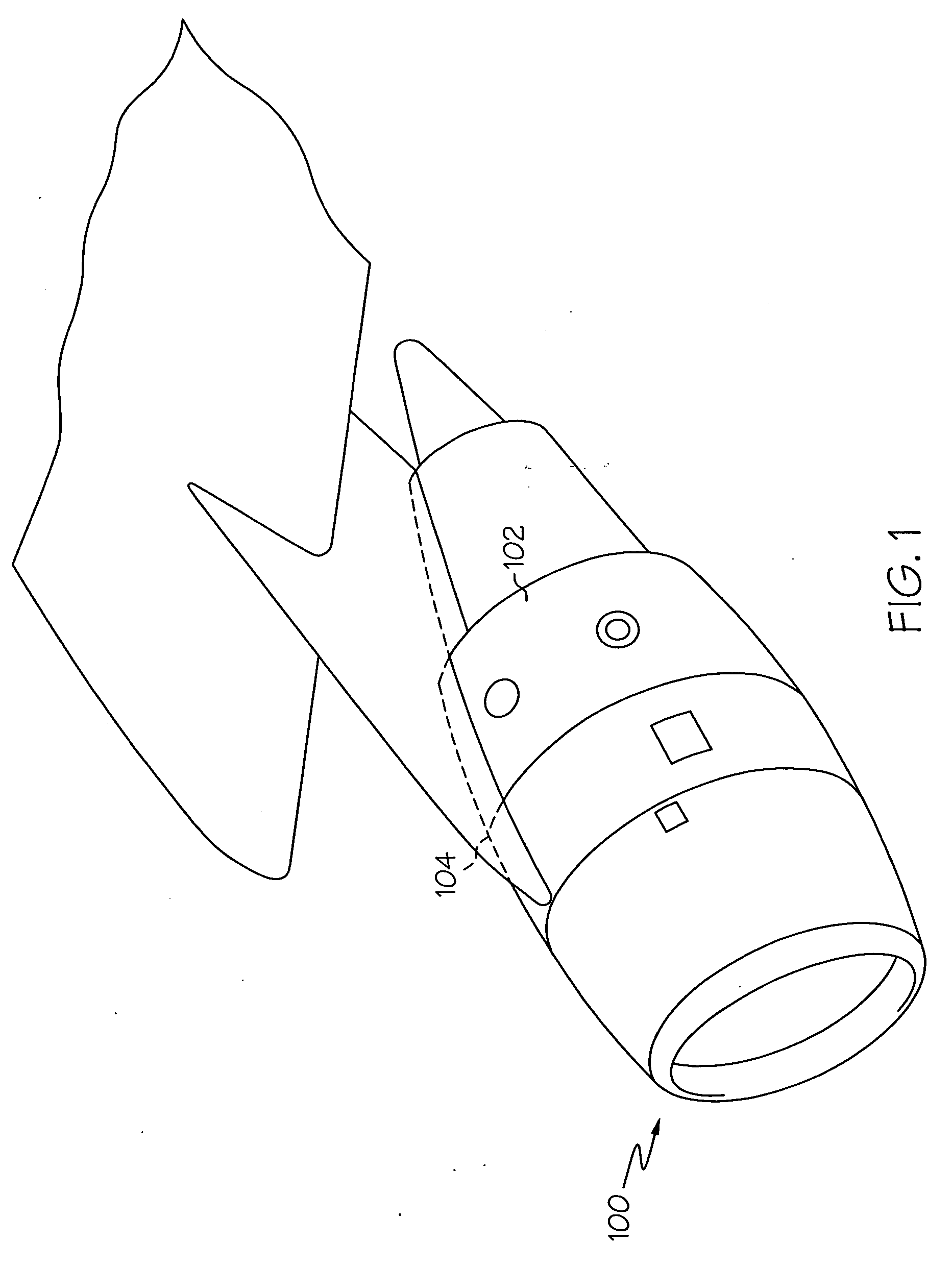

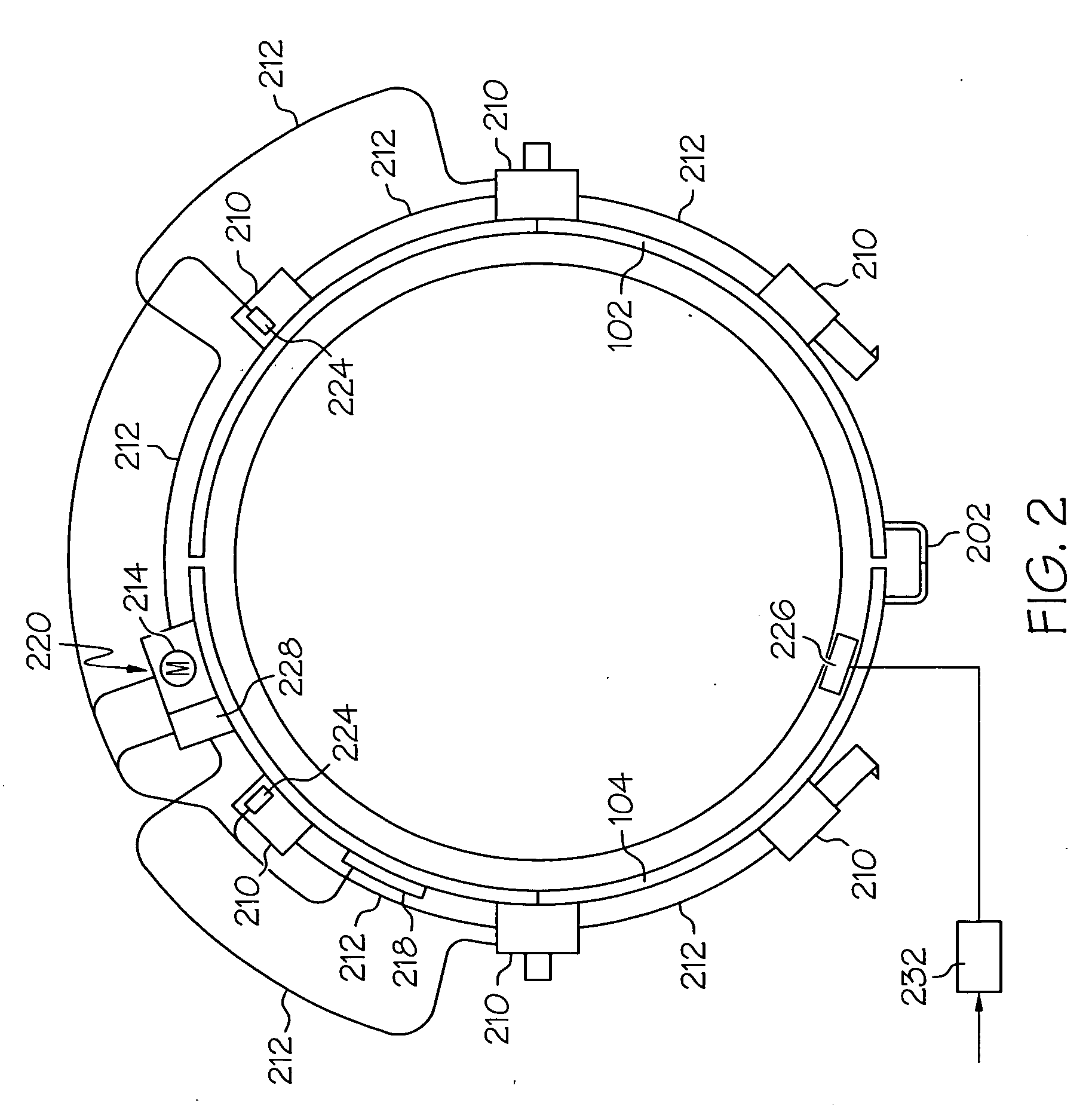

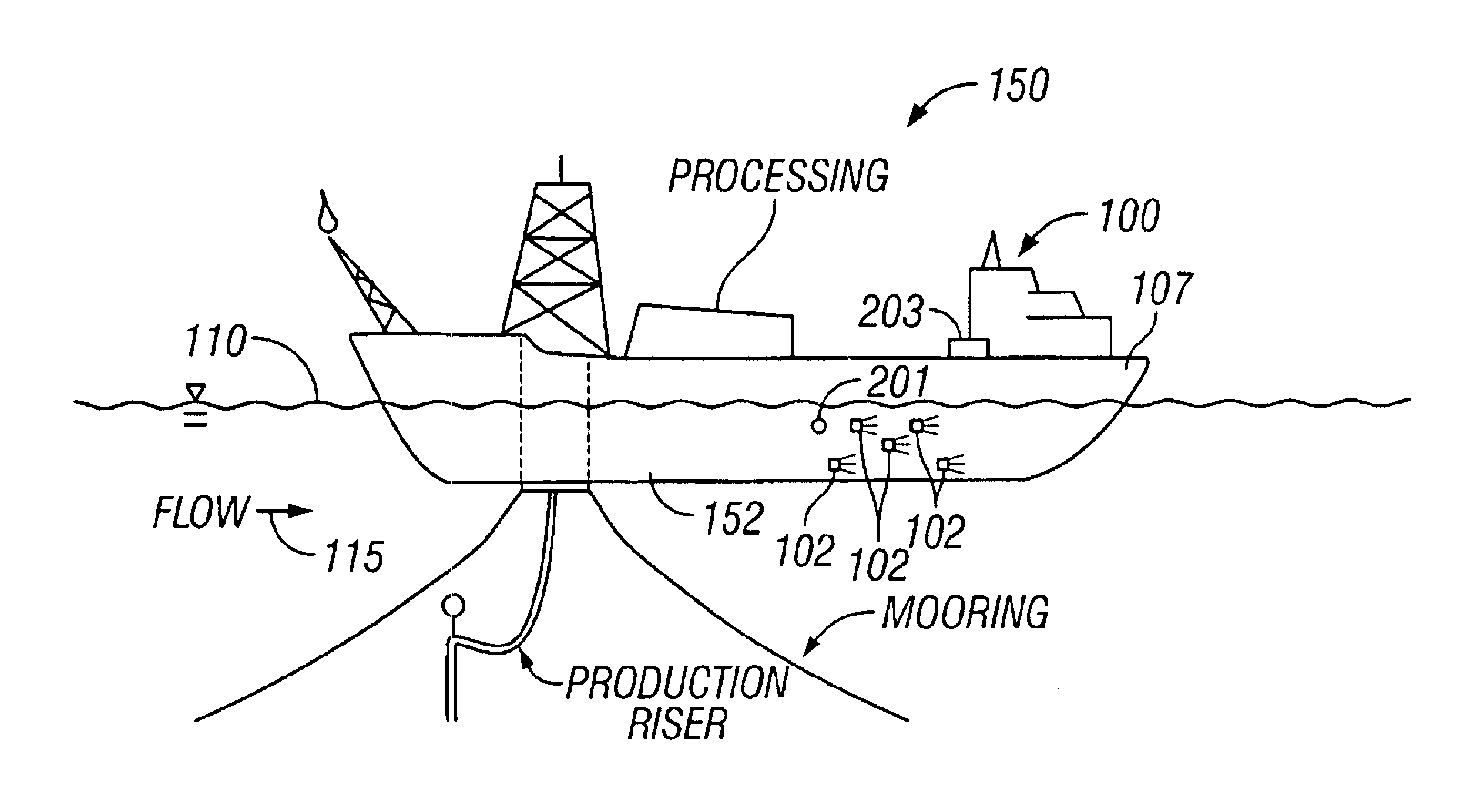

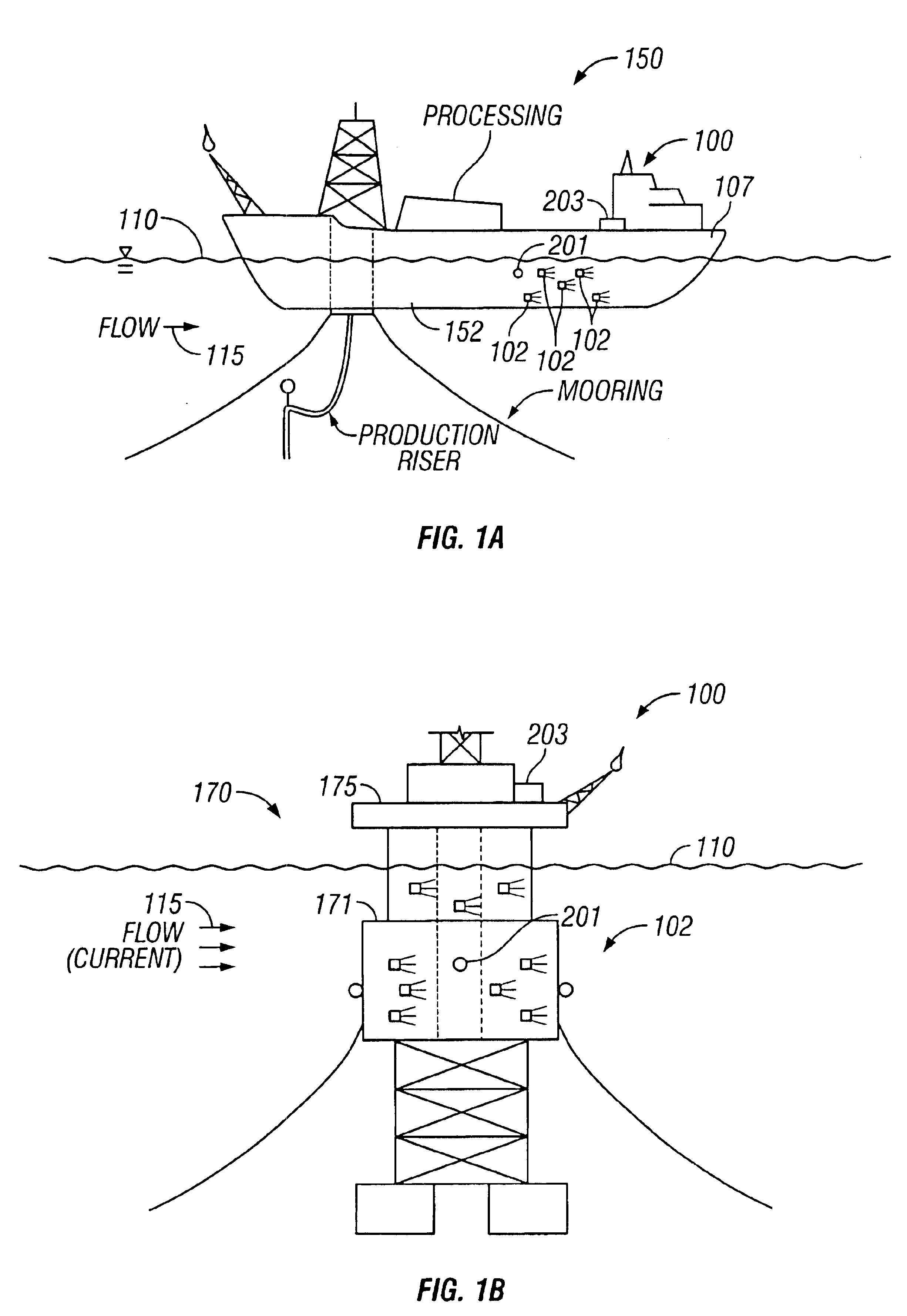

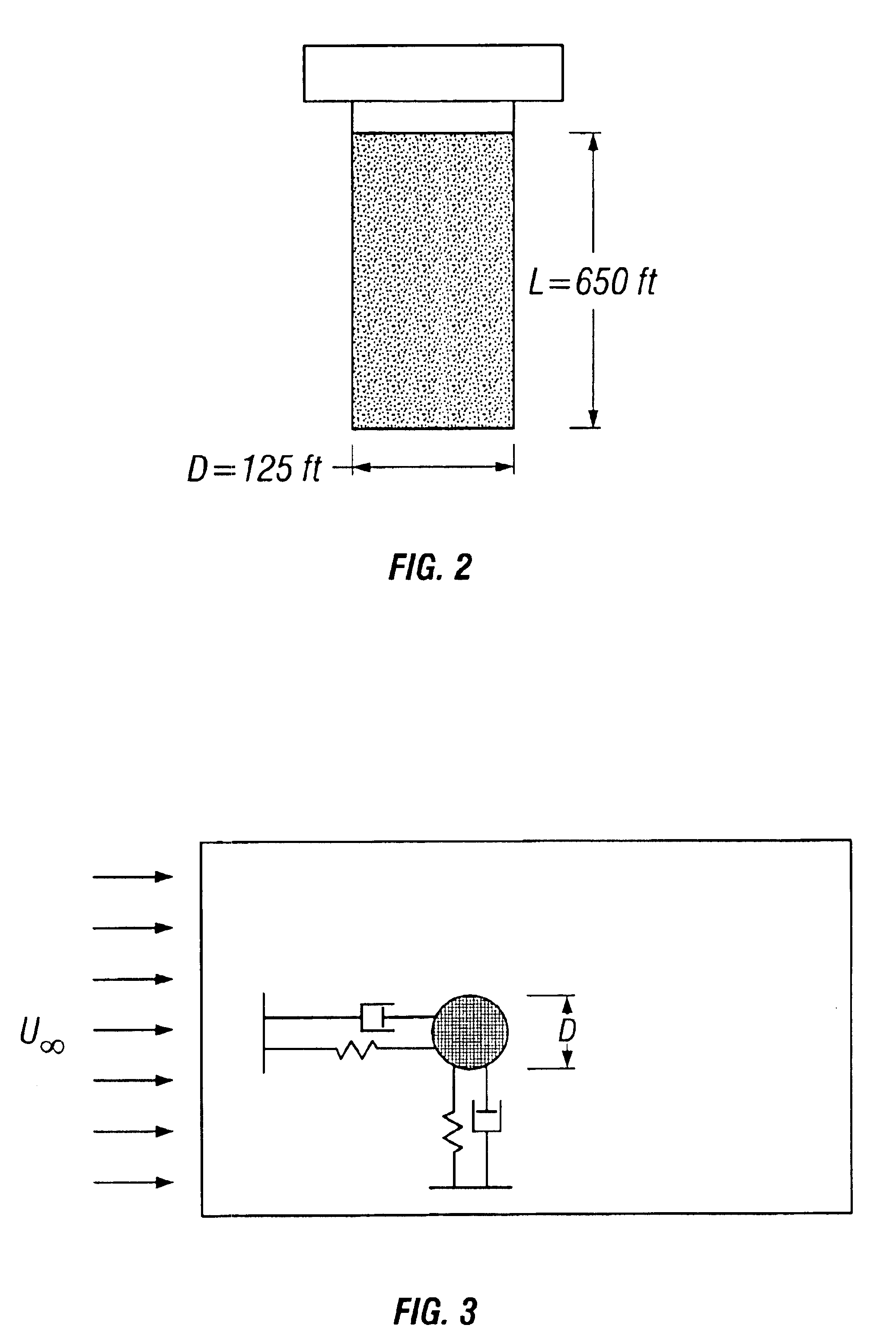

Thruster apparatus and method for reducing fluid-induced motions of and stresses within an offshore platform

Thrusters in communication with a feedback control system are provided on a cylindrical offshore marine member, such as a spar, for reducing and / or controlling vortex-induced-vibrations, low-frequency drift oscillations due to random waves, and low-frequency wind induced resonant oscillations. The thrusters are provided thrust instruction from the feedback control system based on marine member displacement and current velocity.

Owner:SHELL OIL CO

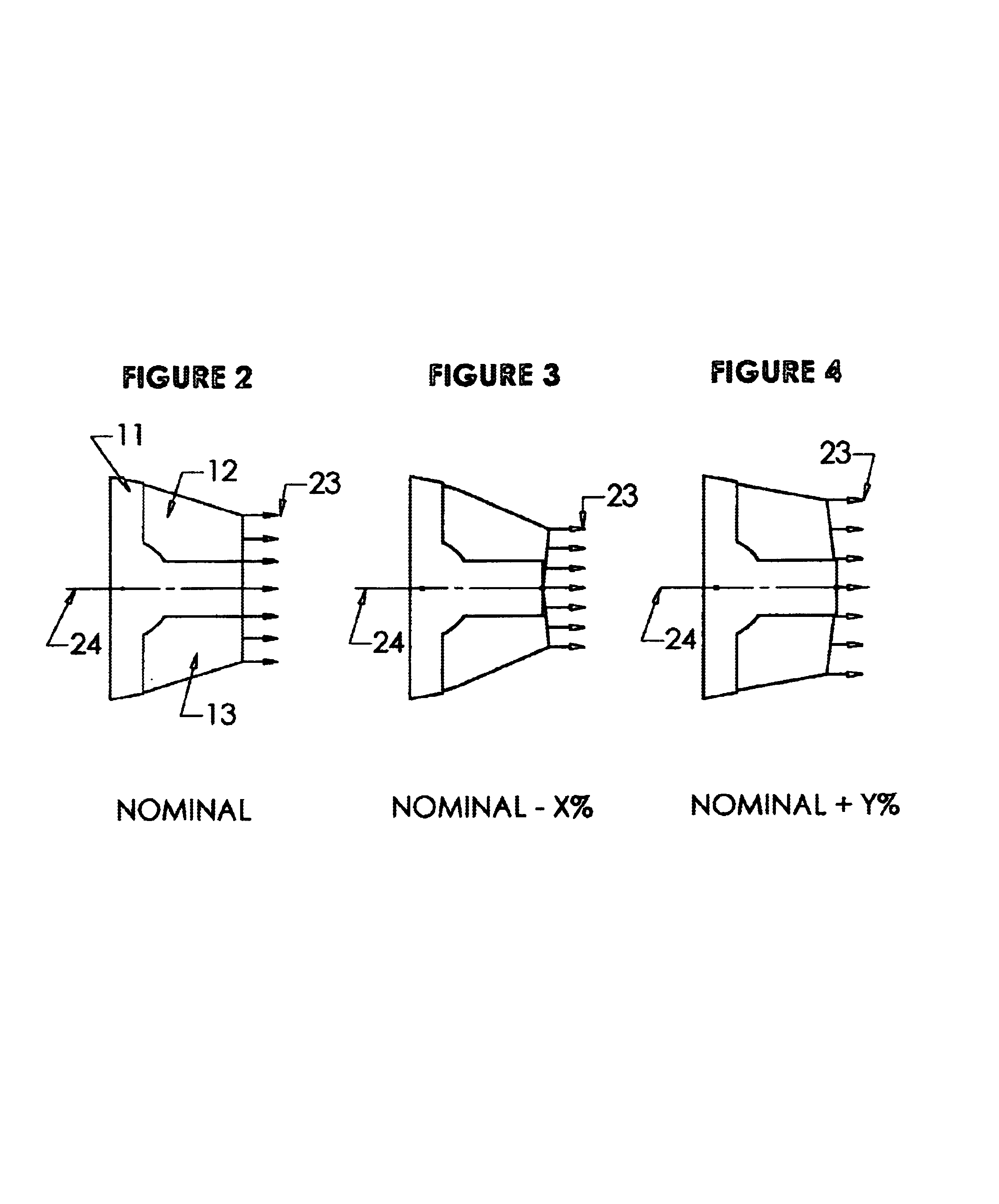

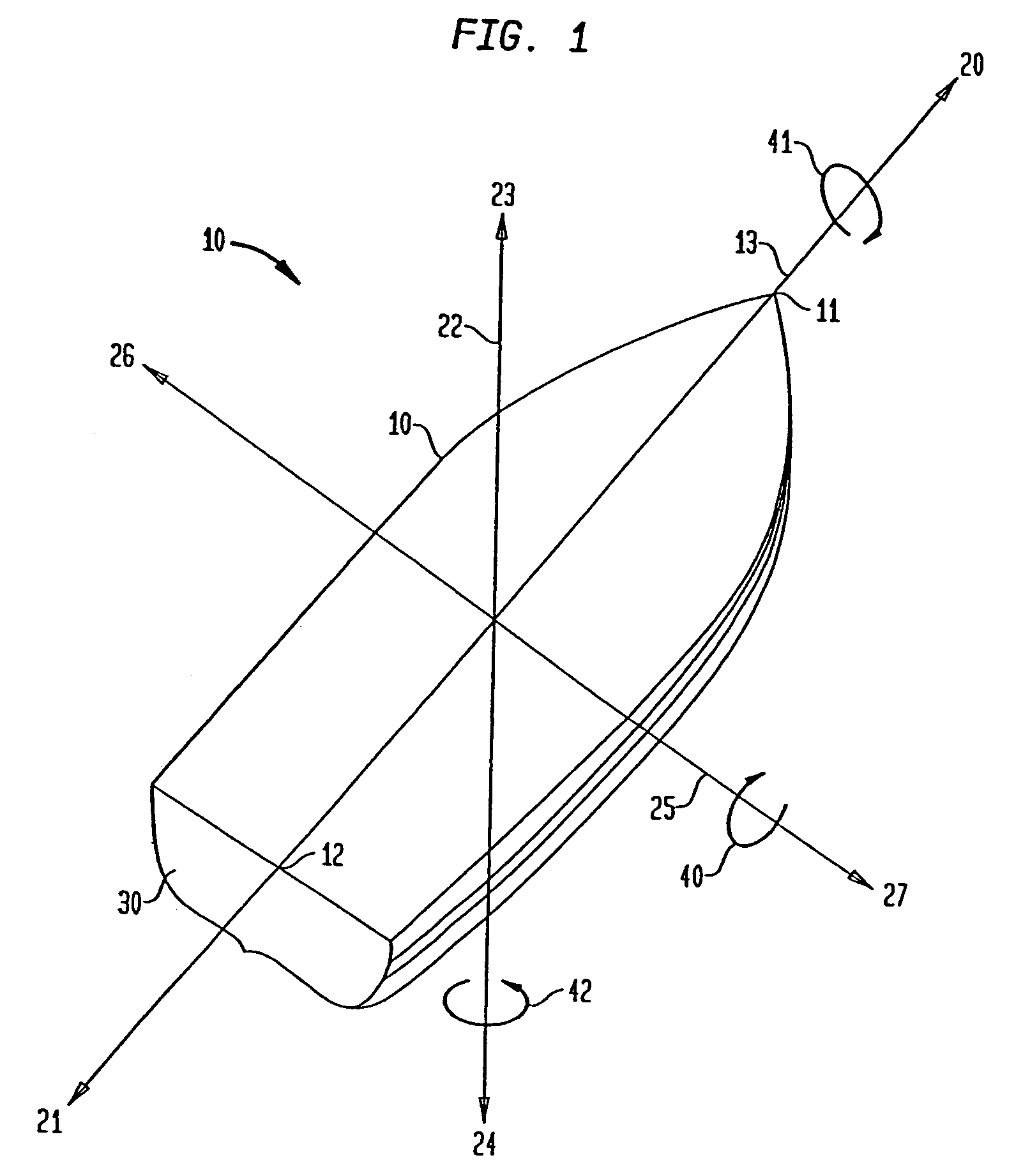

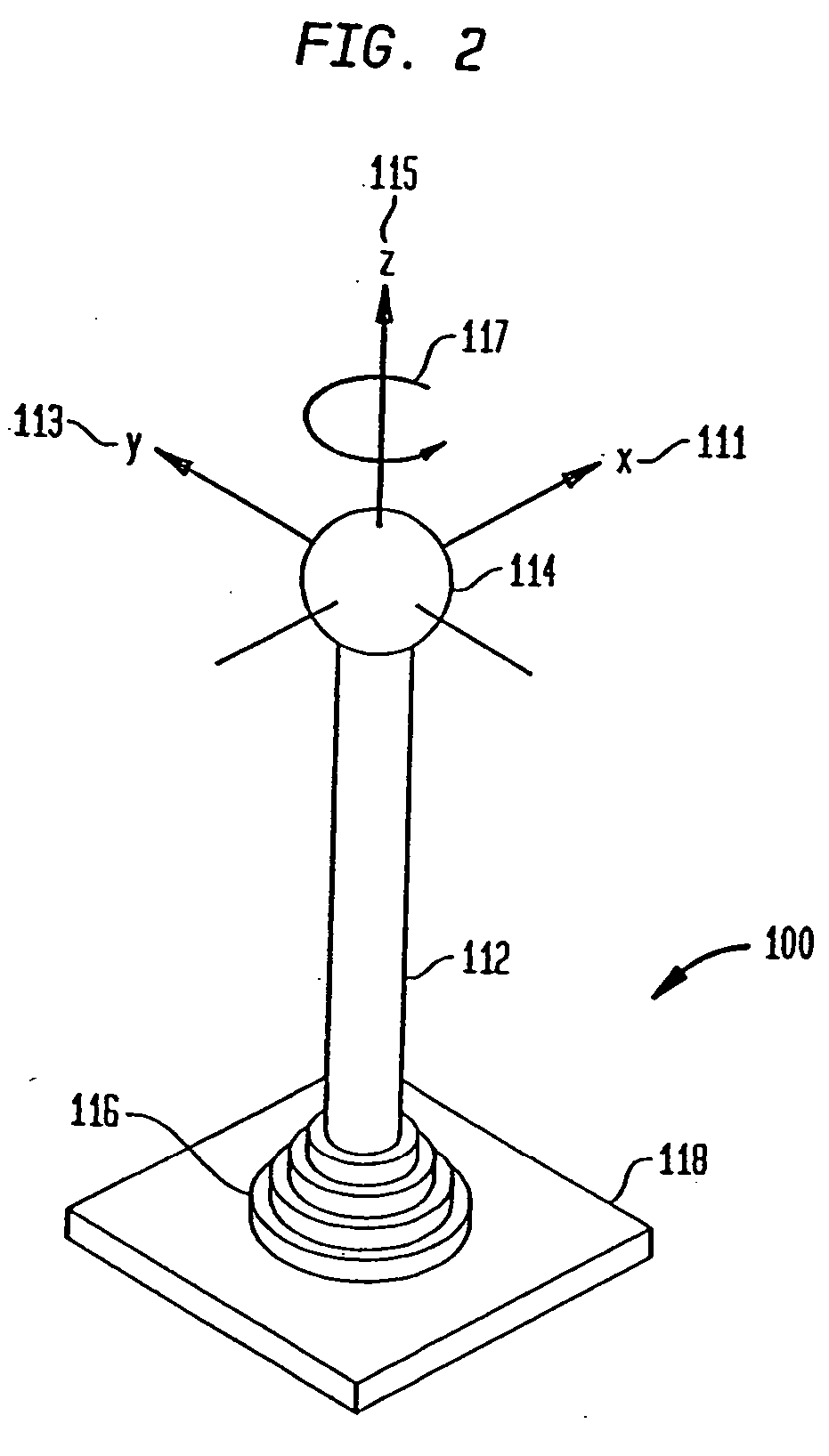

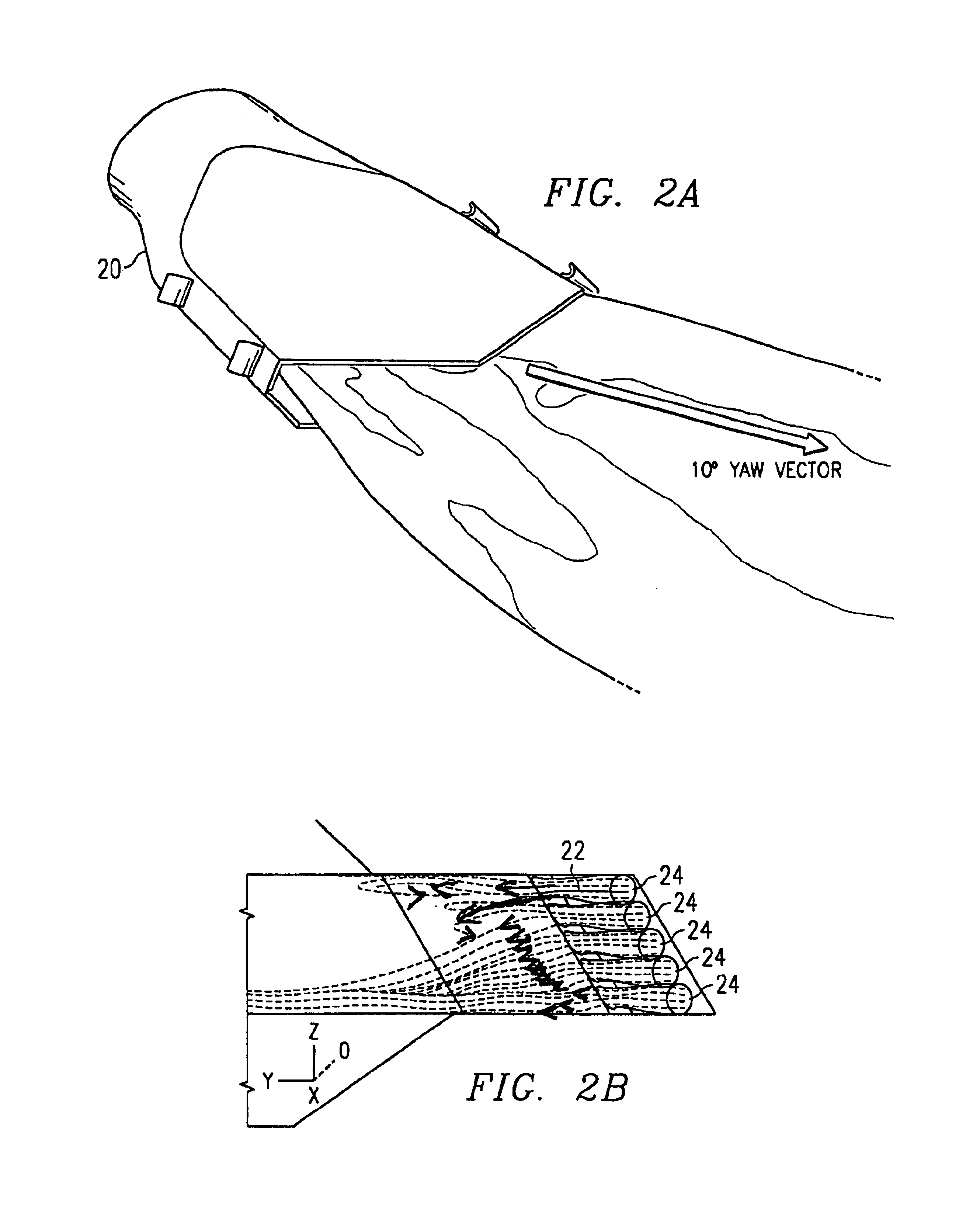

Method and apparatus of asymmetric injection into subsonic flow of a high aspect ratio/complex geometry nozzle

InactiveUS6962044B1Increased durabilityReduce complexitySteering by jetsJet propulsion plantsEngineeringVector angle

The present invention reveals a method and apparatus for controlling the effective area and thrust vector angle of a fluid flow. In one embodiment, the fluid flow is controlled in an advanced, high aspect ratio, complex aperture geometry nozzle using asymmetric injection into the subsonic portion of the fluid flow. The present invention vectors the primary flow by partially blocking the flow with an opposed flow across the flow field. A fluidic flow field is defined in a flow container that directs a pressurized, primary fluidic flow from the container towards an exit of the container. A nozzle may cooperate with the exit of the flow container to control the fluidic flow as it exits the flow container. One or more injectors associated with the container are proximate to the effect throat of the primary flow while other are located downstream of to introduce an opposing fluidic flow that interacts with the primary fluidic flow. A controller associated with the injectors directs the injectors to provide the opposing flow as needed to achieve a desired partial blockage of the primary flow, thereby vectoring the primary flow.

Owner:LOCKHEED MARTIN CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com