Microtube Electrode System for Electrolytic Cutting of Large Thickness Workpiece Method

A technology of electrode system and microtube, which is applied in the direction of electrochemical processing equipment, supply of processing working medium, manufacturing tools, etc., can solve problems such as difficulty in updating electrolyte and discharge of electrolysis products, so as to improve capacity and speed up electrolysis reaction , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

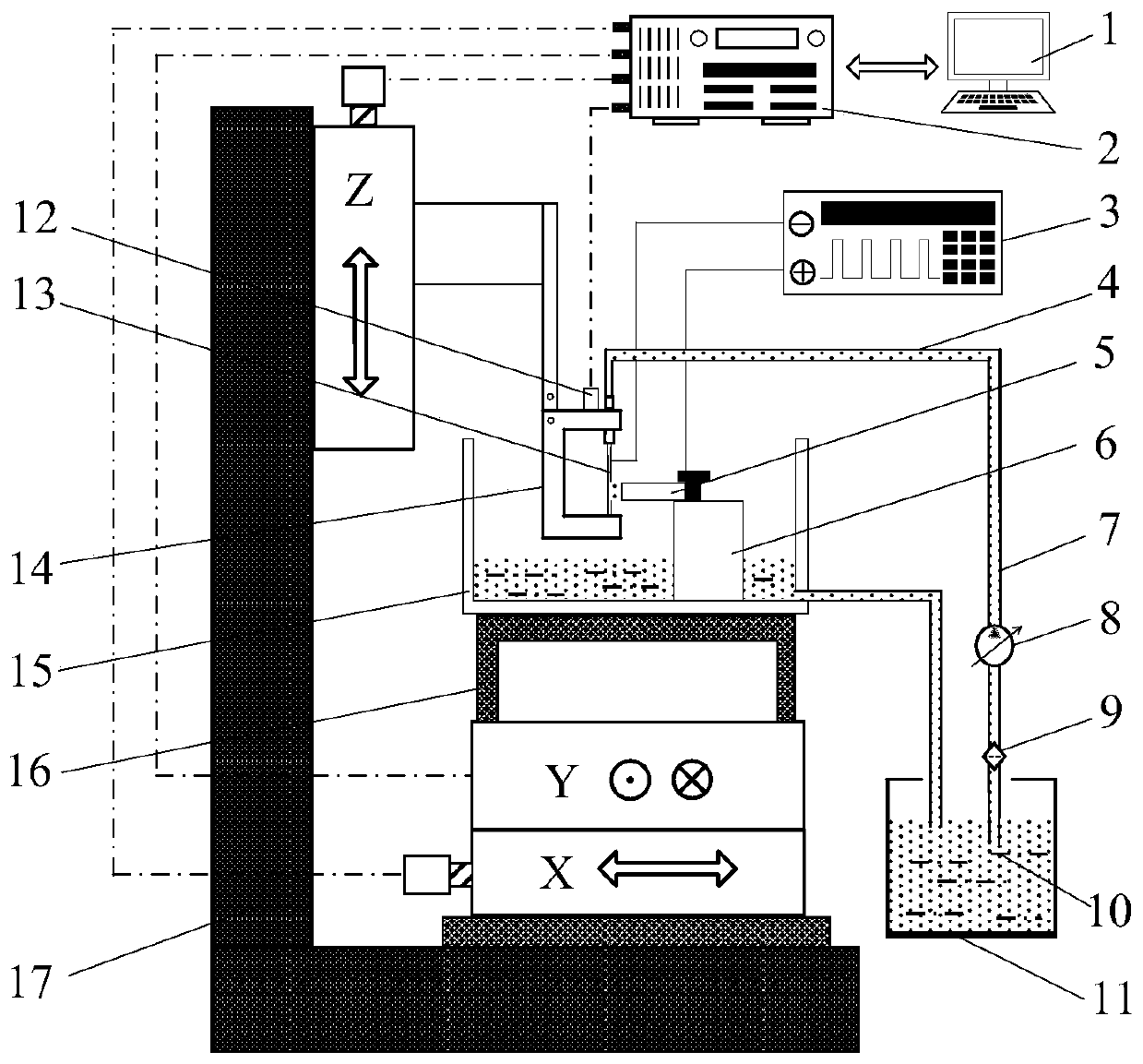

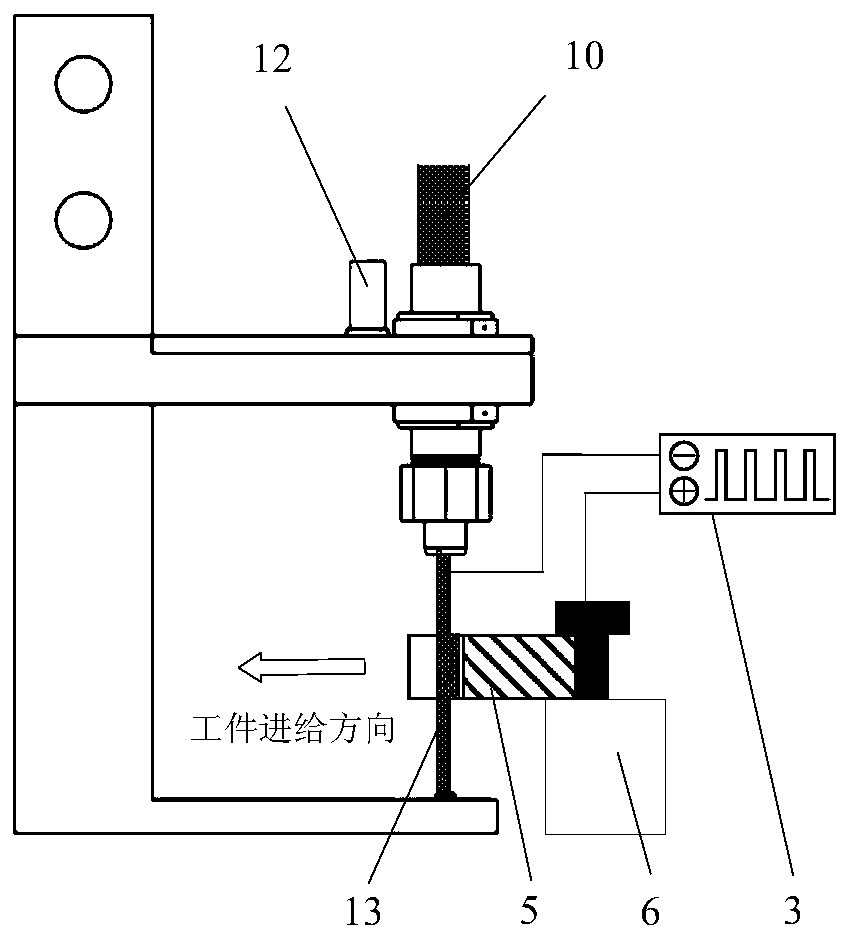

[0024] according to figure 1 As shown, the overall structure of a microtube electrode electrolytic cutting large-thickness workpiece device proposed by the present invention mainly includes a pulse power supply 3, an industrial computer 1, a three-coordinate machine tool 17, an electrolyte circulation system 4, a microtube electrode system 14, and a workpiece fixture 6. The electrolyte circulation system 4 includes a liquid storage tank 11, a circulation pipe 7, a filter 9, a hydraulic pump 8, a diversion tube 30, a diversion nozzle 32, a microtube electrode 13, and an electrolyte tank 15.

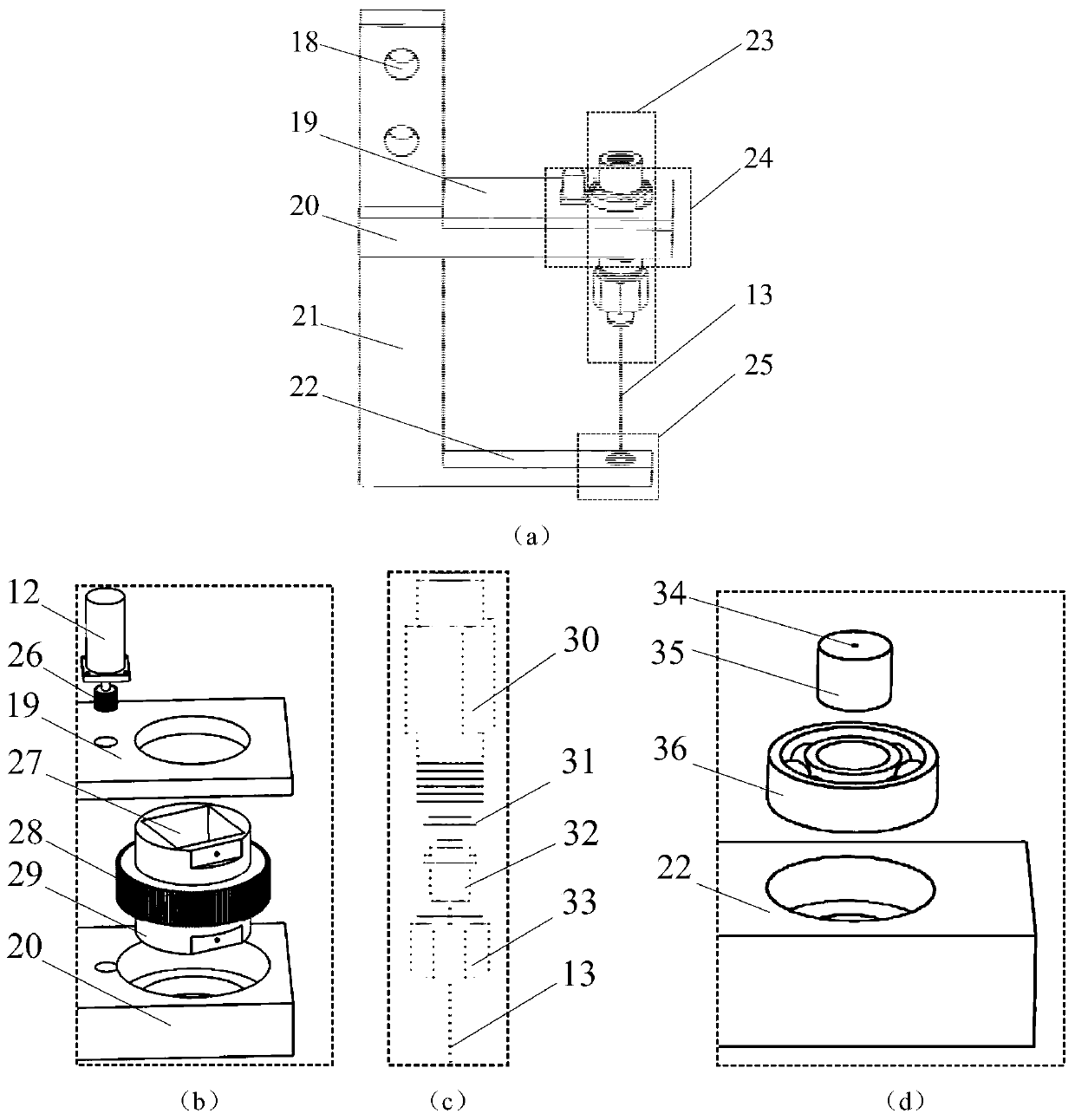

[0025] according to Figure 2-Figure 3As shown, the microtube electrode system includes a support 21, a steering device 24, a flow guiding device 23, a limiting device 25, and a microtube electrode 13; the support 21 includes an upper bracket cover plate 19, an upper bracket 20 and a lower bracket 22; It includes a servo motor 12 and a turntable 29, wherein the servo motor 12 is fixedly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com