Patents

Literature

76results about How to "Reduce jet velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

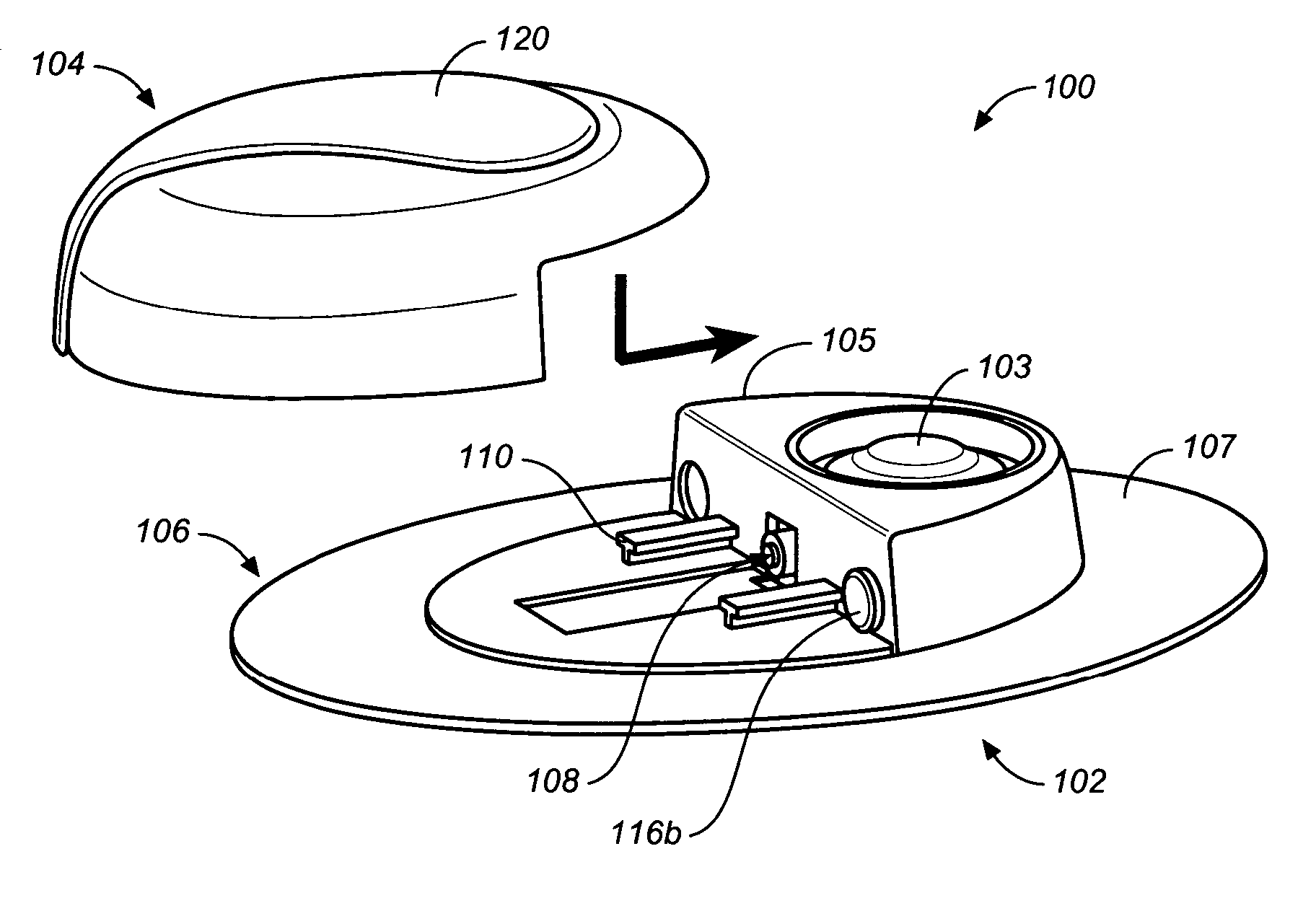

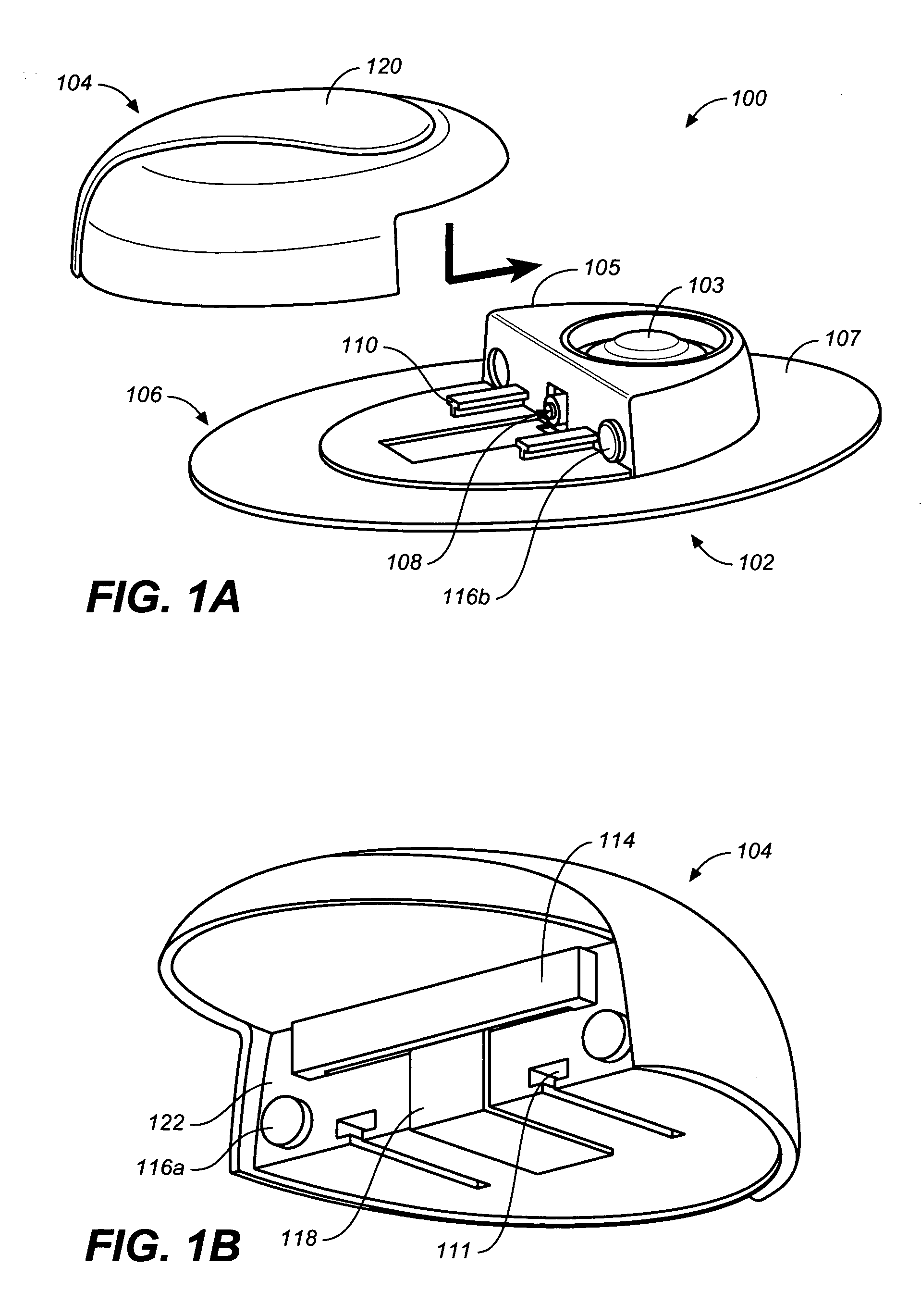

Methods, devices, and kits for microjet drug delivery

ActiveUS20080091139A1Reduce leakageEnhance nozzle contactJet injection syringesIntravenous devicesDrug reservoirEngineering

Described here are methods, devices, and kits for microjet drug delivery. The devices described here may be modular or non-modular. The modular devices typically include a first module having a drug reservoir and a nozzle in fluid communication with the drug reservoir and a second module having an actuator and a power supply. The power supply provides power to the actuator and when the first and second modules are coupled, the actuator is capable of acting on a dispensing member causing it to dispense a drug in liquid form from the drug reservoir via the nozzle at a velocity sufficient to penetrate skin. Other devices described include a nozzle, a reservoir in fluid communication with the nozzle, a dispensing member, and an actuator. In these devices, the nozzle has at least one feature that enhances nozzle contact with the skin in order to reduce lateral drug leakage about the nozzle.

Owner:CORIUM PHARMA SOLUTIONS INC

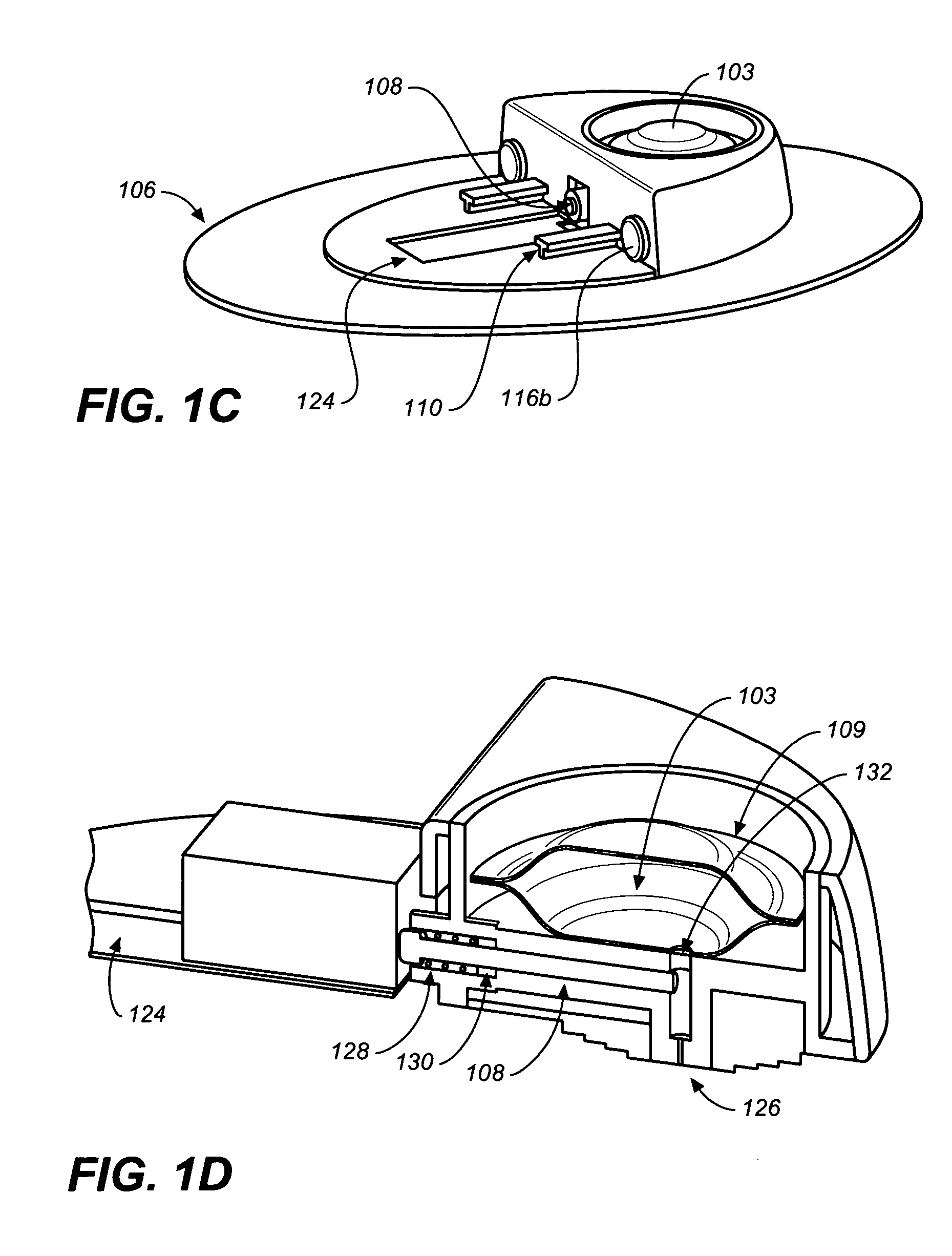

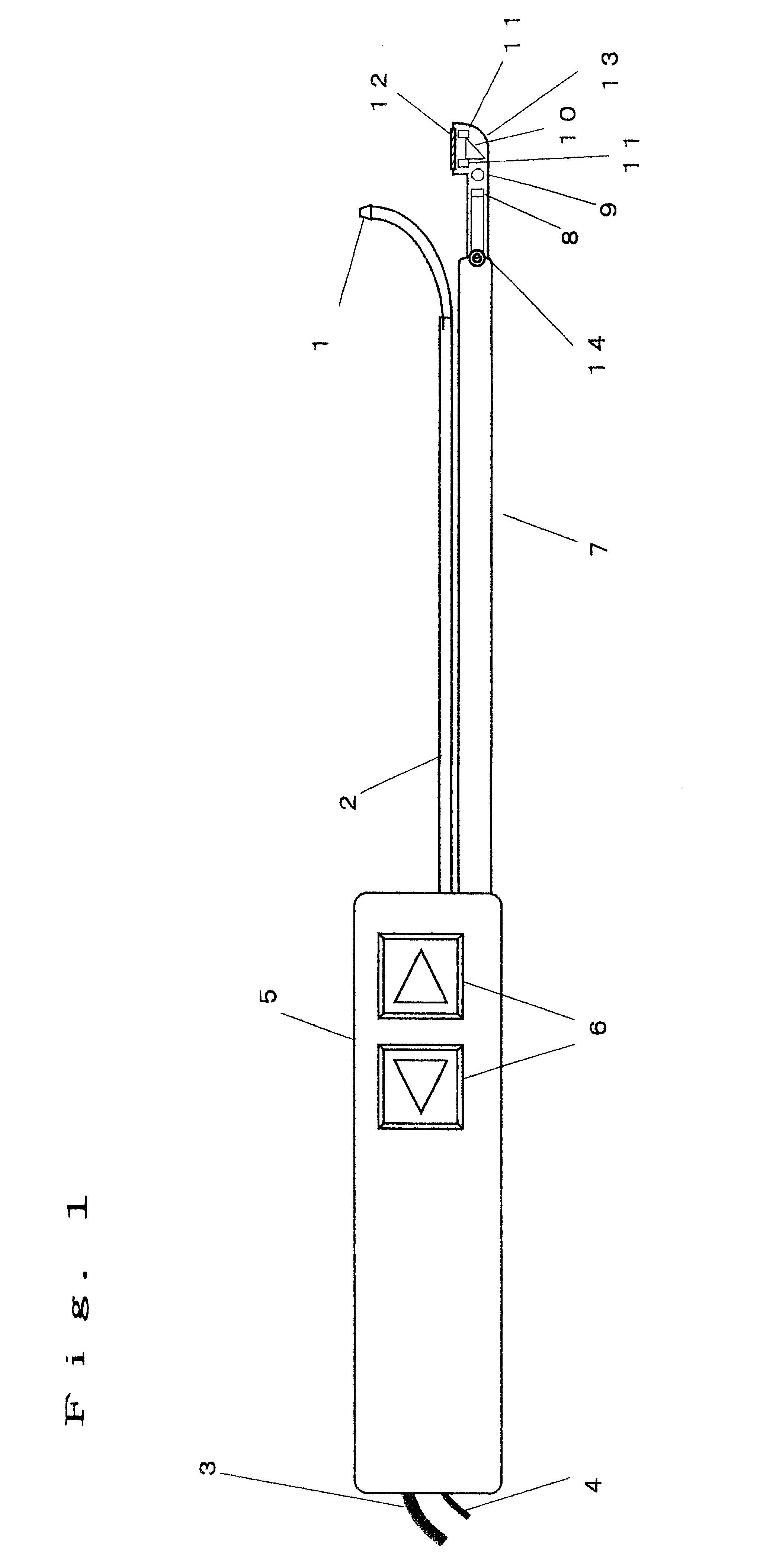

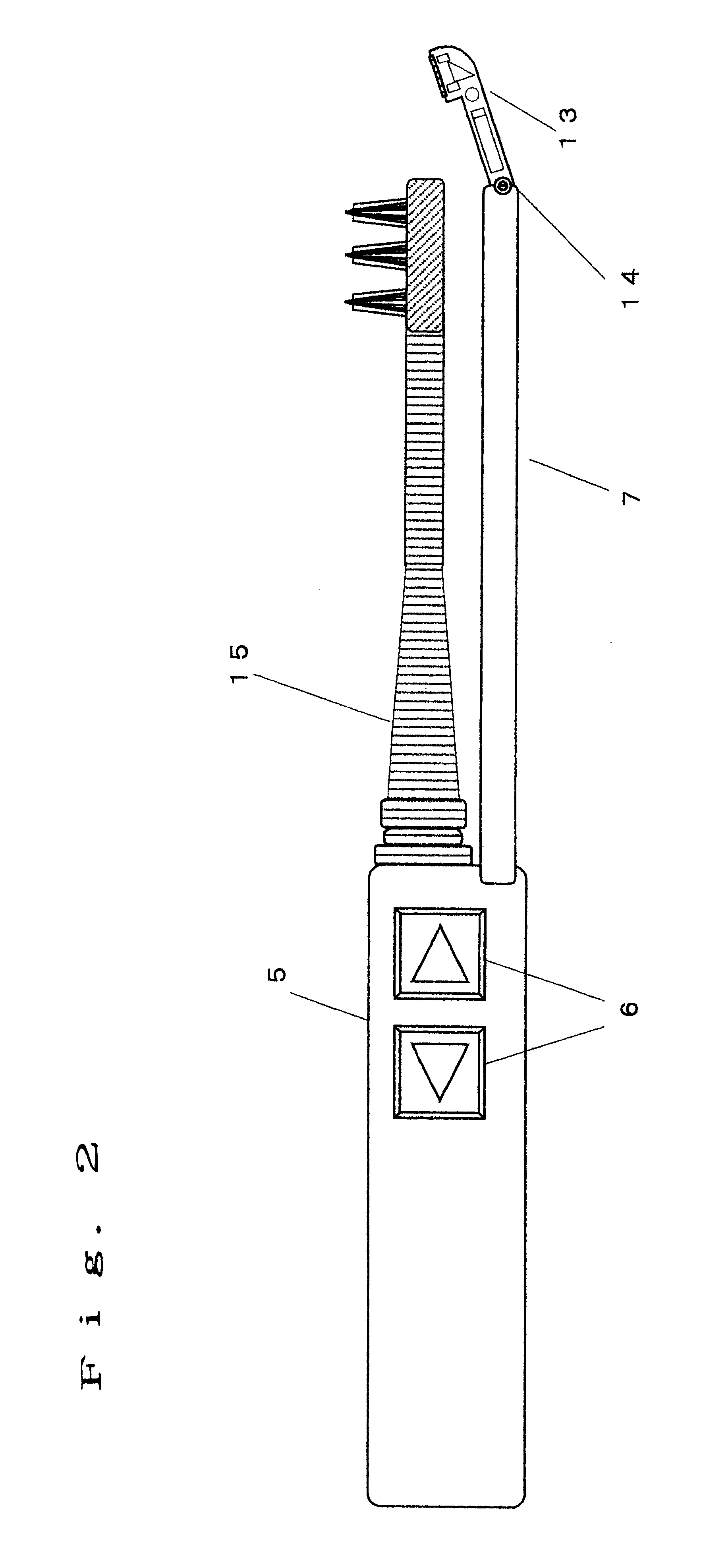

Oral cavity washer with video scope

InactiveUS6468076B2Not be reduced to practiceReduce jet velocityDental toolsSomatoscopeComputer graphics (images)Display device

An oral cavity washer with a video scope, hasa video scope having image-forming means of forming an image from light from an object, an image pick-up device for converting the light from which the image is formed by the image-forming means into an electric signal, and a first grip portion for being held by an operator;a display for displaying an image picked up by the video scope; andan oral cavity washer having a nozzle for jetting a fluid and a second grip portion for being held by the operator, for washing an oral cavity by jetting the fluid to teeth or gums,wherein the first grip portion and the second grip portion are capable of being made integral with each other.

Owner:PANASONIC CORP

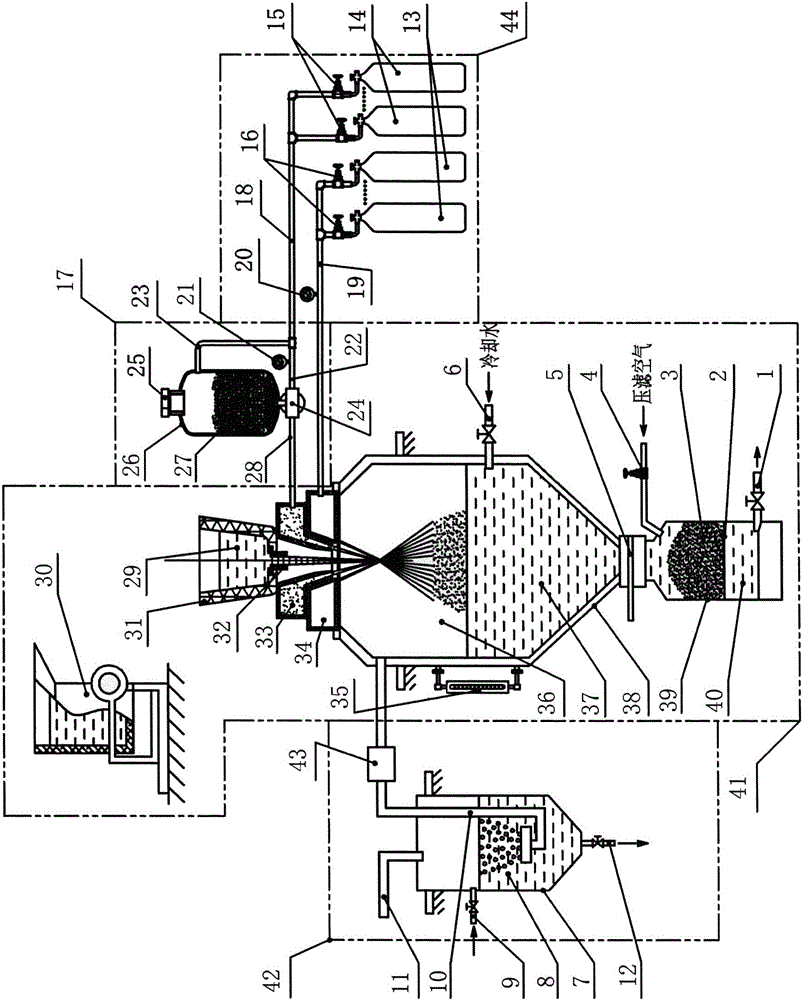

Free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing equipment

The invention provides free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing equipment which comprises a double-nozzle atomizing and water cooling device (41), a spiral mixed powder conveying device (17), a water seal dust removing device (42) and a gas station (44). In the atomizing process, a low-pressure mixed powder jetting nozzle and a high-pressure gas flow nozzle are adopted, and therefore the problem that when a single nozzle is used, erosive wear is caused is solved; a free-falling manner is adopted, and therefore the problems that erosive wear to a molten metal flow guide pipe is caused and molten metal flows back and is sprayed upwards are avoided; a cooling manner of water cooling and fast setting is adopted, the problem that hard abrasive particles drift away from a metal matrix and the problem of control over the depth of distribution are solved, and hard abrasive is controlled to be distributed on a surface shallow layer of the magnetic abrasive; meanwhile, the flight distance of powder mixed molten metal drops is shortened, and the overall height of the free-falling atomizing and condensing chamber and equipment is reduced. The equipment is new equipment provided for realizing a free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing method and preparing the high-performance magnetic abrasive.

Owner:SHANDONG UNIV OF TECH

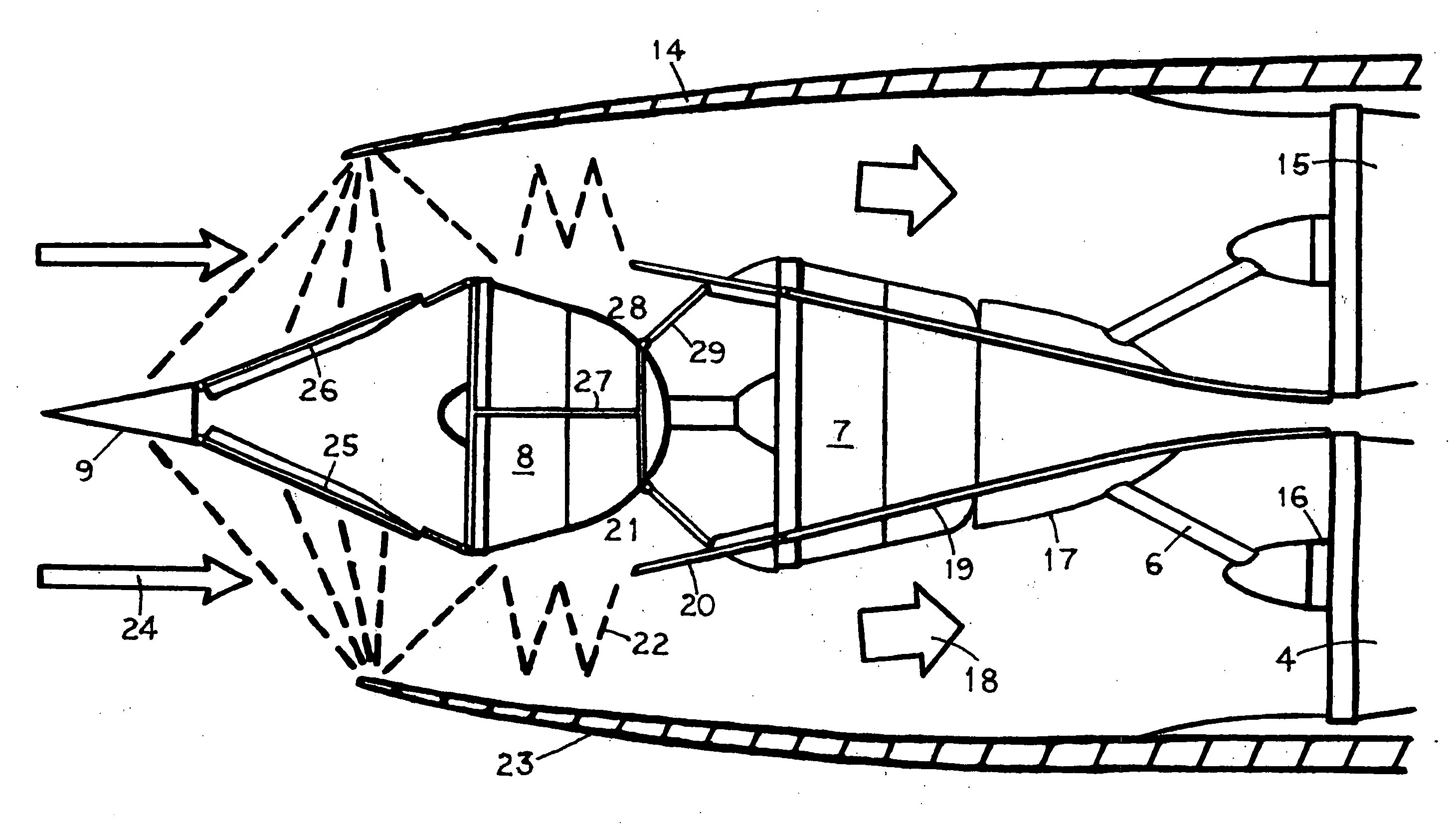

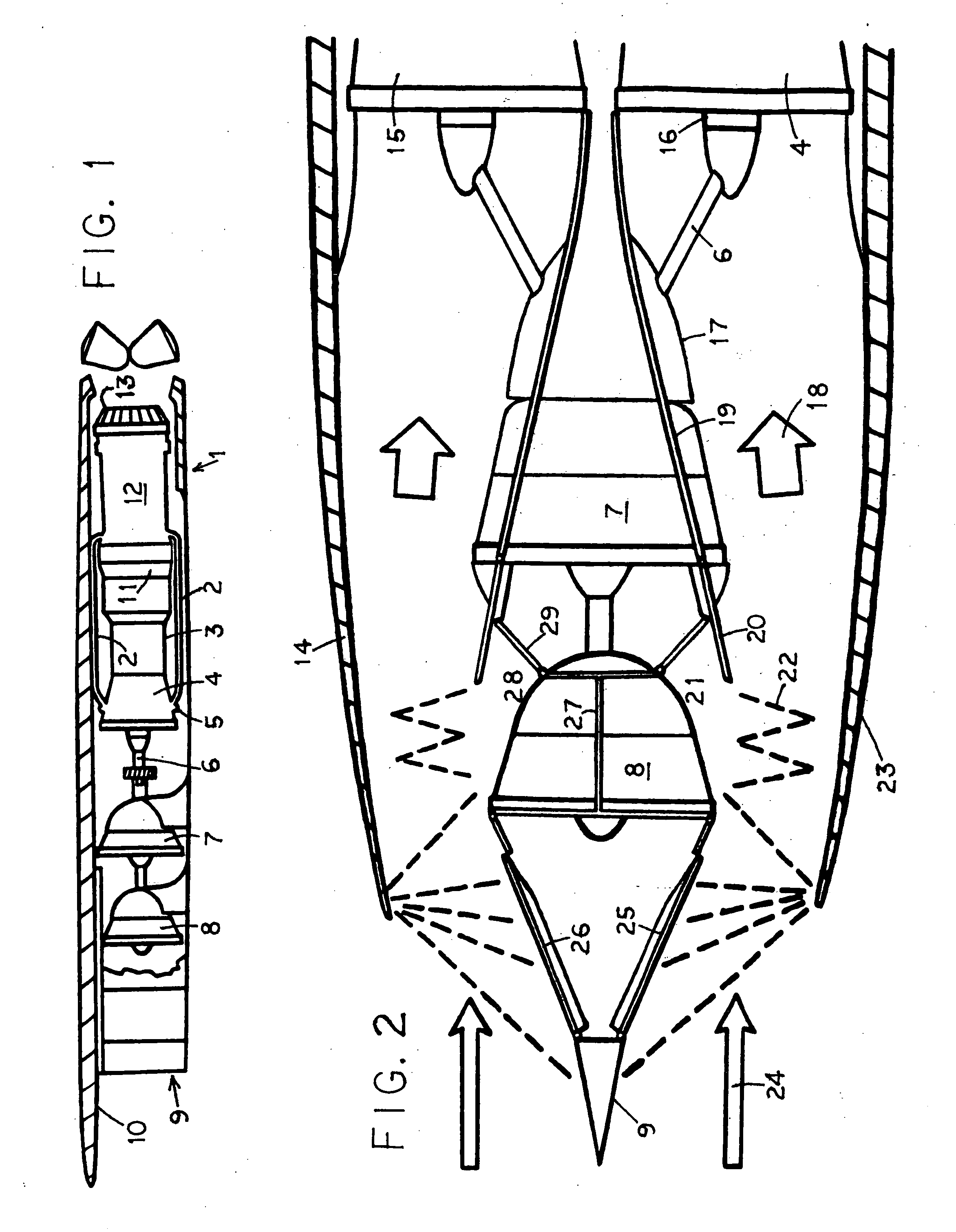

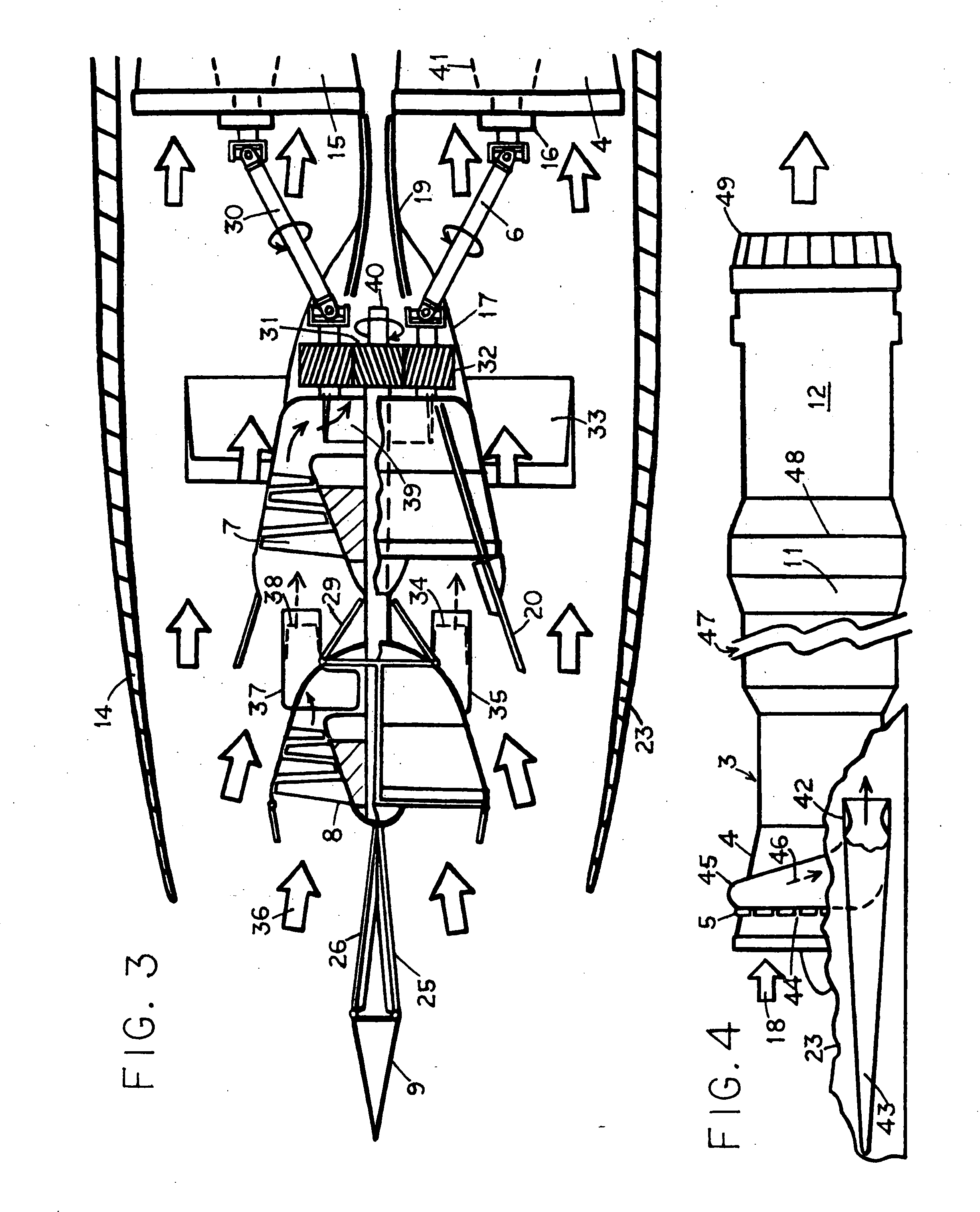

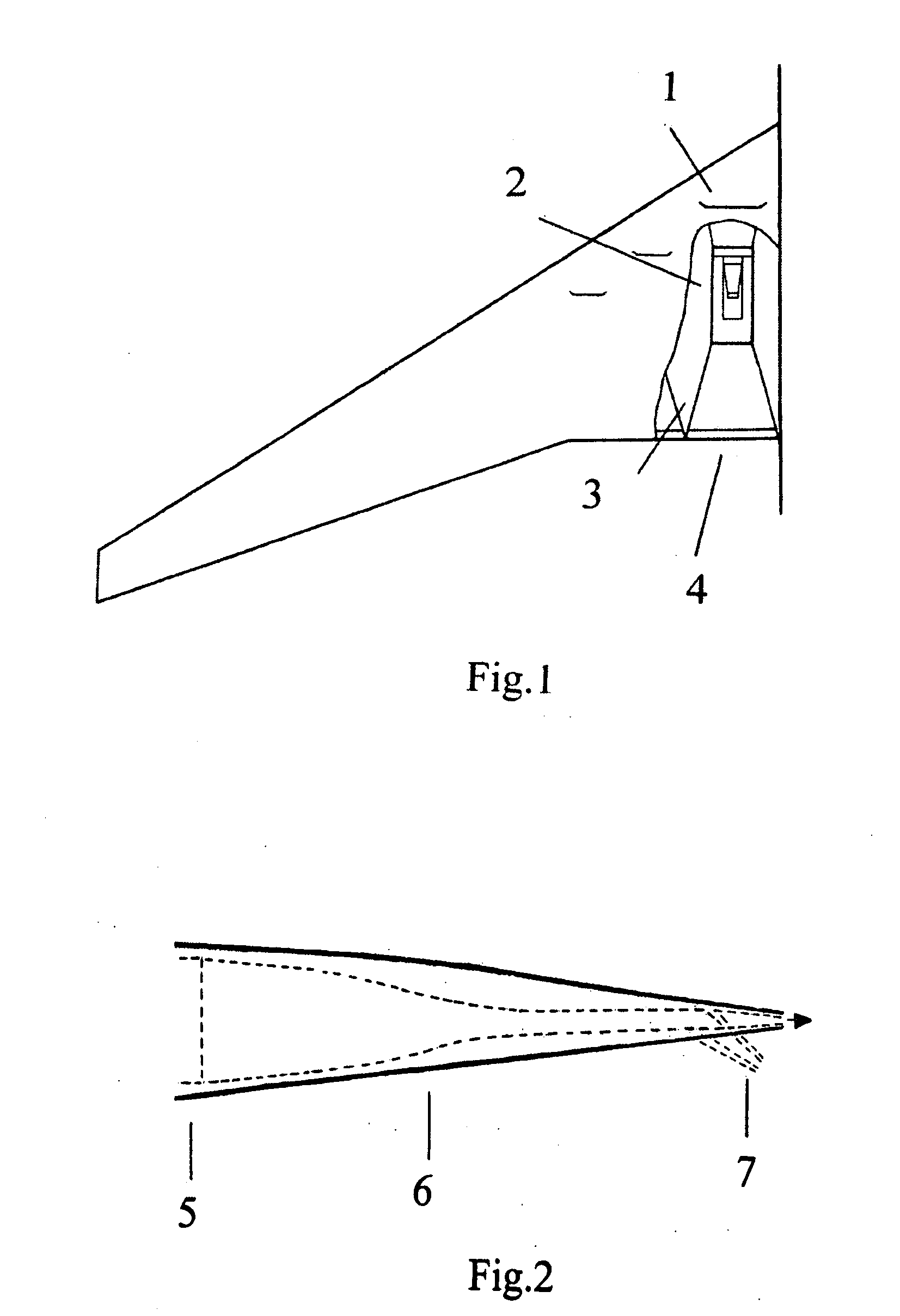

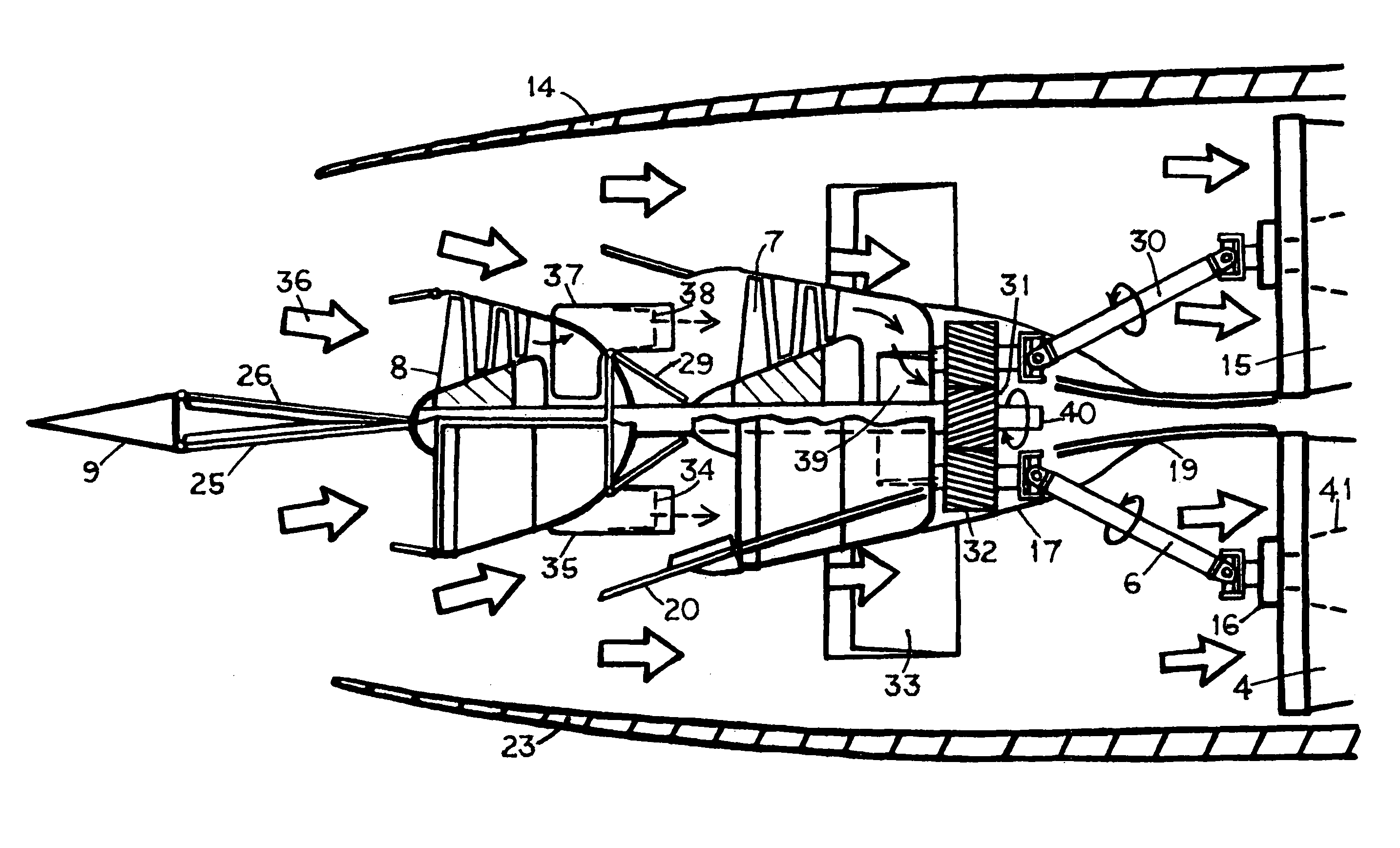

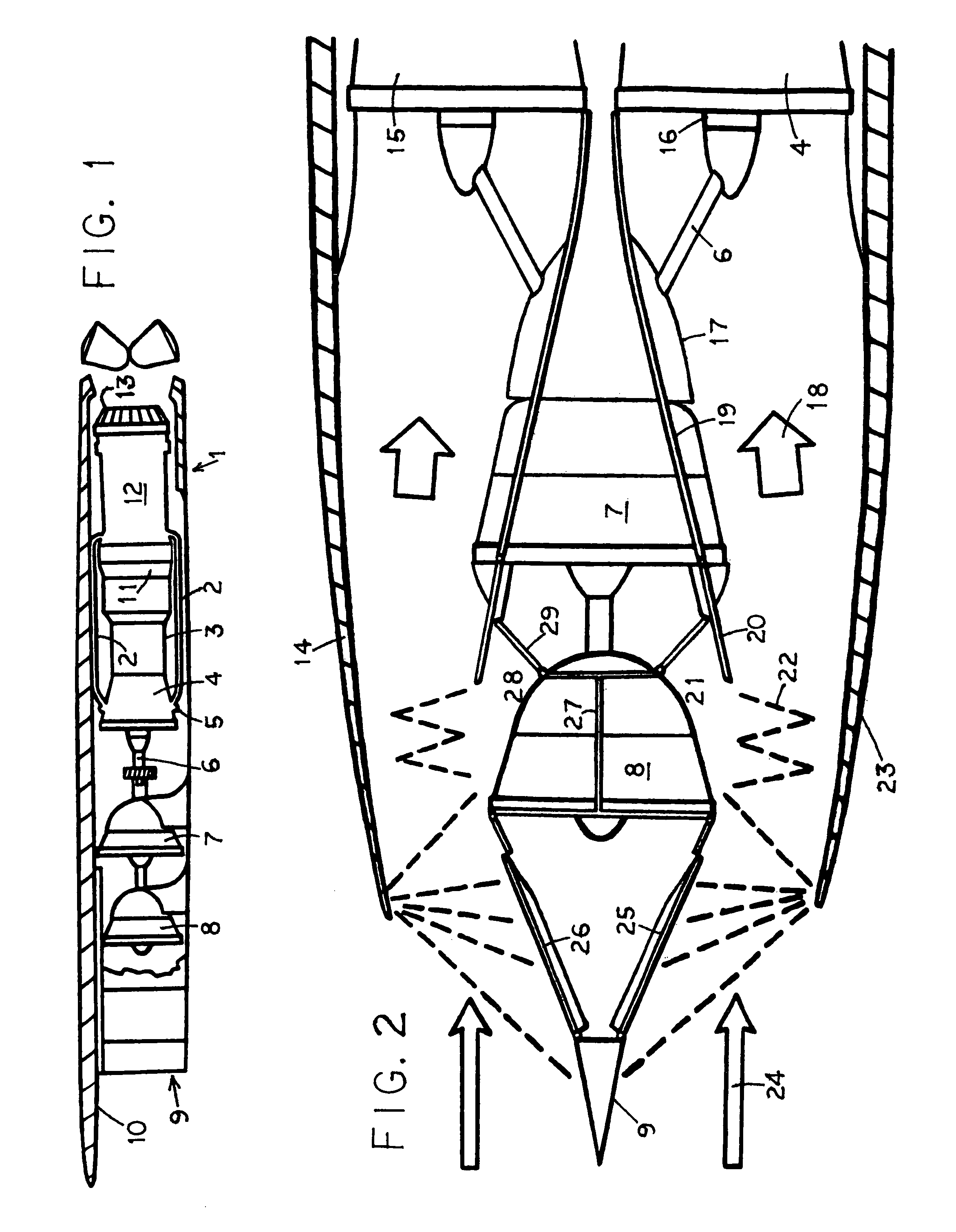

Mass flow increase at takeoff in supersonic airliner

InactiveUS20120292440A1Reduce noiseReduce jet velocityEngine fuctionsEfficient propulsion technologiesJet aeroplaneNacelle

In a supersonic aircraft, turbojet engine nacelles each containing two remote fans in the front half of the nacelle, for noise reduction at takeoff. During supersonic flight, a front wedge at the nacelle nose achieves external compression of intake air. The wedge is vertical, sending the airflow left and right inside the nacelle along its side walls. The two flows follow mirror image curved paths on their way to a turbojet, leaving unused space between them to house the fans in tandem. For takeoff, clutches connected to the turbojets's compressors are engaged. Driveshafts turn pinions against a gear on the same shaft as the remote fans. The fan output is discharged backward under the nacelle to produce thrust. The energy to turn the fans is taken from the turbojet cycle. The reduced exhaust jet velocity decreases its noise. Supercharging produces the extra power to turn the remote fans if multistage.

Owner:KOSHELEFF PATRICK A

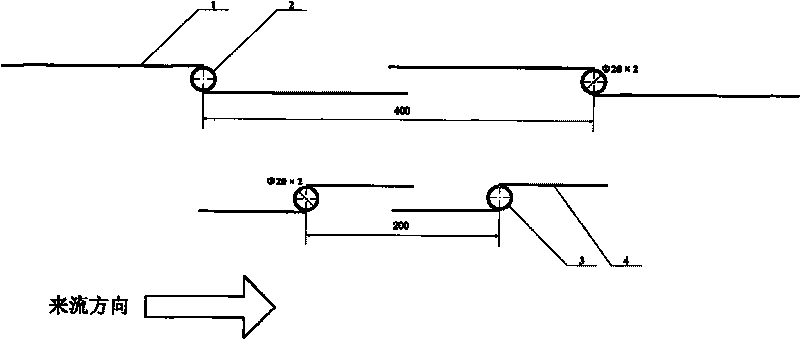

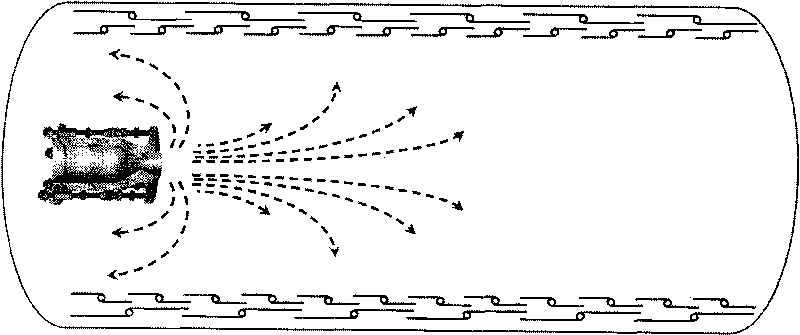

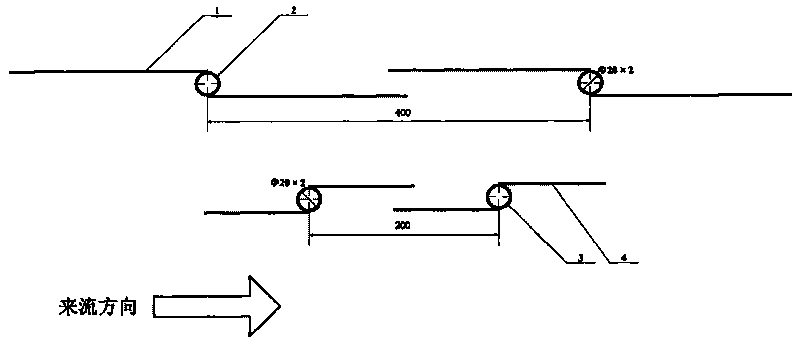

Heat sink wall panel structure arrangement for increasing absorption of plume gas

The invention relates to a heat sink wall panel for plume test, mainly consisting of a liquid nitrogen heat sink fin (1), a liquid nitrogen heat sink branch pipe (2), a liquid nitrogen heat sink branch pipe (3) and a liquid nitrogen heat sink fin (4). The liquid nitrogen heat sink is located inside the liquid nitrogen heat sink to reduce the heat load of a vacuum container to the liquid nitrogen heat sink; the liquid nitrogen heat sink directly faces to the gas in plume test ensuring high pumping speed and high plume absorption efficiency; the opening direction of the liquid nitrogen heat sink wall panel is opposite to the direction of the plume, and the plume gas can rapidly enter into the liquid nitrogen heat sink and the liquid nitrogen heat sink interlayer to reduce the plume ejection sped and improve the absorption efficiency via multiple bounce; the opening direction of the liquid nitrogen heat sink wall panel is in the plume direction and is in geometric symmetry with the opening direction of the liquid nitrogen heat sink wall panel so that the plume gas is easy to enter and difficult to come out, the capturing rate of gas is increased; gap is left between the fins so that both sides of the heat sink can absorb flume gas, thereby effectively increasing the plume absorption area; and the materials adopt stainless steel branch pipes and copper fins, thereby effectively improving the static and dynamic vacuum degree inside the vacuum container.

Owner:BEIHANG UNIV

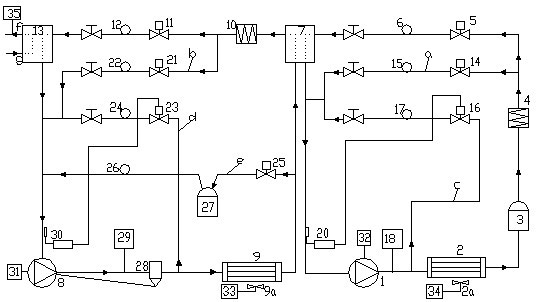

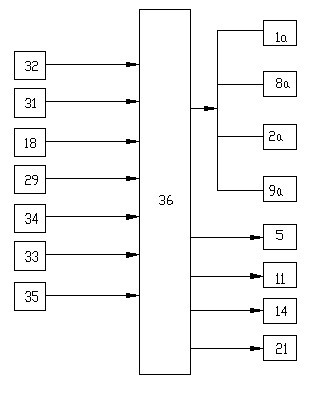

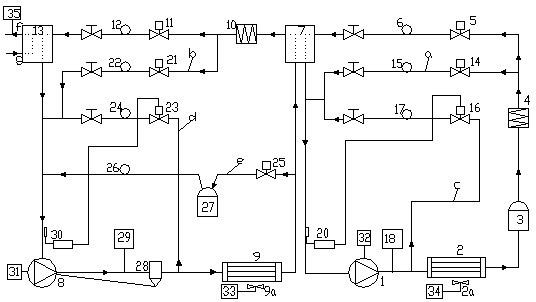

Low temperature cold air two-stage refrigeration system and cold air jet machine thereof

ActiveCN102003823AReduce jet velocityLower gas temperatureCompression machines with cascade operationFluid circulation arrangementEngineeringCold blast

The invention discloses a low temperature cold air two-stage refrigeration system and a cold air jet machine thereof. A two-stage refrigeration structure is used, and the gas temperature at a cold air jet outlet can be effectively decreased to -60 DEG C minimum; an air cooler is used, thereby having high jet speed, being beneficial to breaking and removing chips, and having low cooling temperature suitable for high speed and high accuracy machining; and simultaneously, the two-stage refrigeration structures is respectively with a refrigeration bypass used for cooling a medium at the inlet of a compressor; therefore, along with the prolonged life cycle, the temperature of the compressor can not rise without limit, thereby keeping a long-time proper operating state. Through the regulation of the flow rate of the medium of the refrigeration bypass, the temperature of the cold air is capable of being regulated indirectly; the structure is simple, the operation is convenient, and the use cost is decreased.

Owner:重庆高洁绿色机械设备智能制造研究院有限公司

Master nozzle structure of jet-type textile machine and mounting method thereof

The invention discloses a master nozzle structure of a jet-type textile machine. The master nozzle structure comprises a nozzle body, a tapered sleeve, a nozzle core and a yarn guiding tube which are arranged inside the nozzle body. The yarn guiding tube comprises a fixedly-connected fixing end and an adjusting end. The yarn guiding tube are formed by two segments, so that the size of the fixing end is processed and manufactured according to the largest diameter of a jet-type textile machine; and the diameter of the adjusting end can be adjusted by rotating a driving screw according to different types of the yarn, so that the size of a gap at the throat portion of the master nozzle is adjusted to meet the requirements of textile production. The process step of turning down the machine to change the master nozzle in working can be omitted, labor and raw materials are reduced, working efficiency is improved; and meanwhile, when yarns with small twist are adopted, air flow rate is constant, and the gap of the master nozzle can be accordingly increased by reducing the diameter of the adjustable end, so that jet flow speed is reduced, and energy is saved.

Owner:苏州通捷纺织有限公司

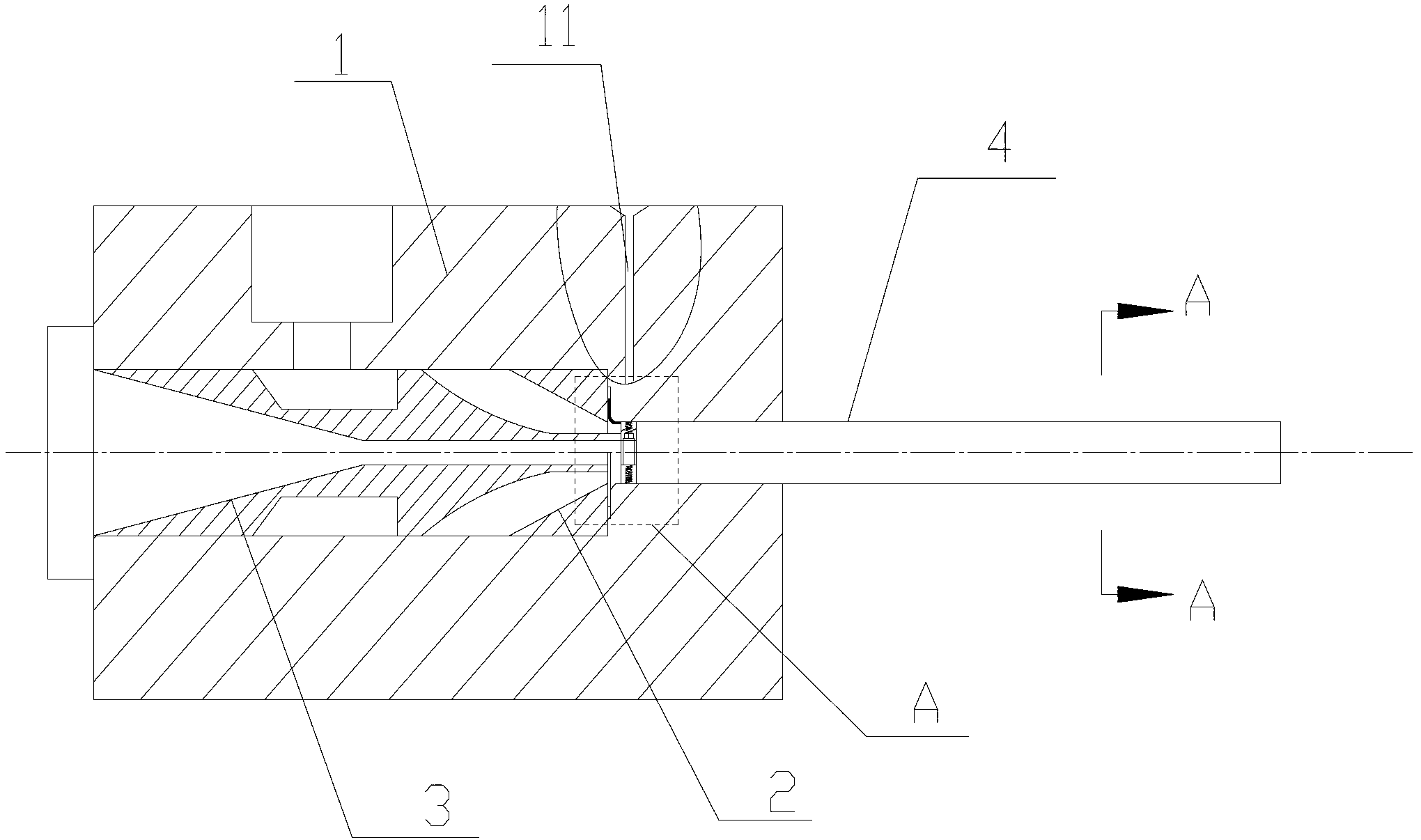

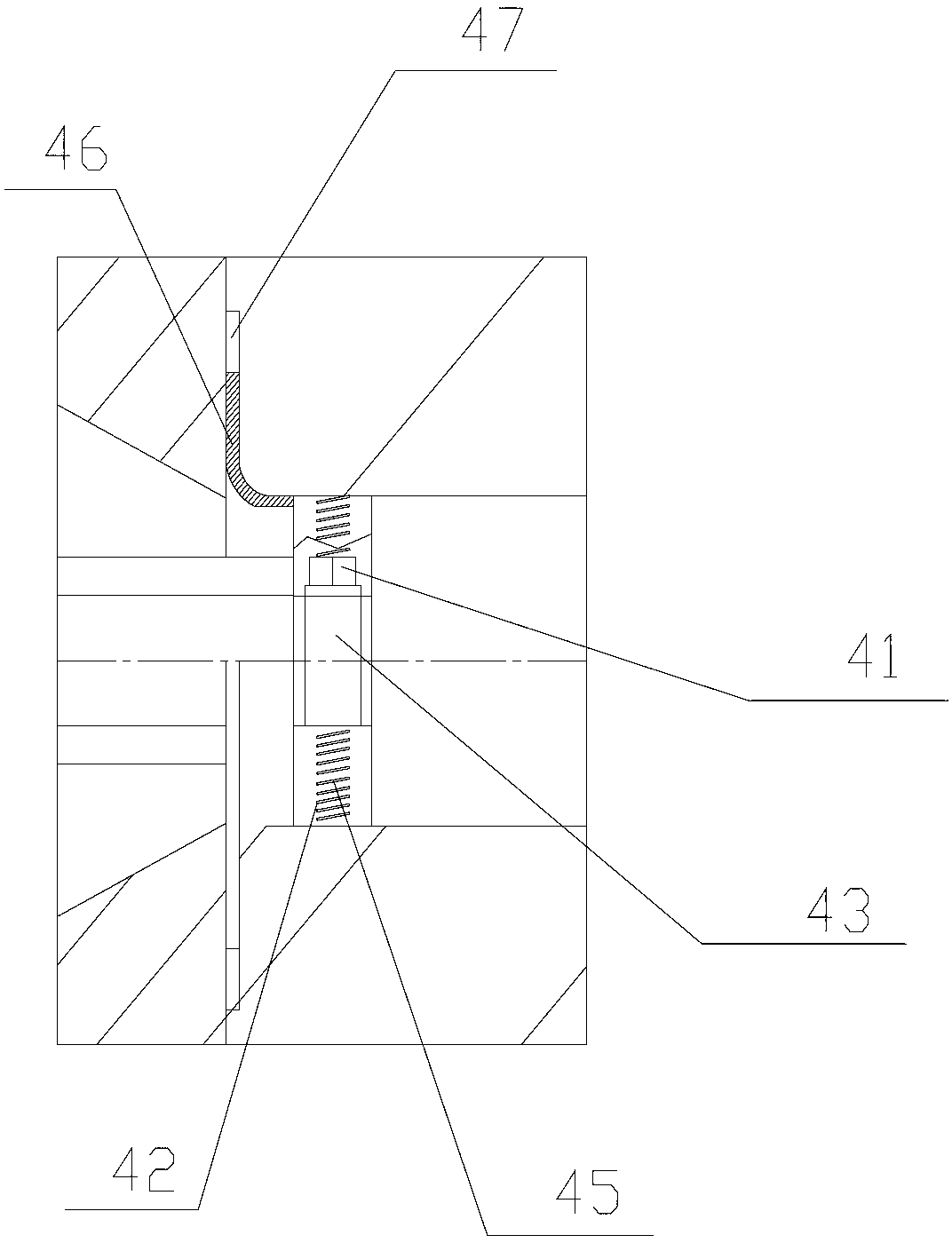

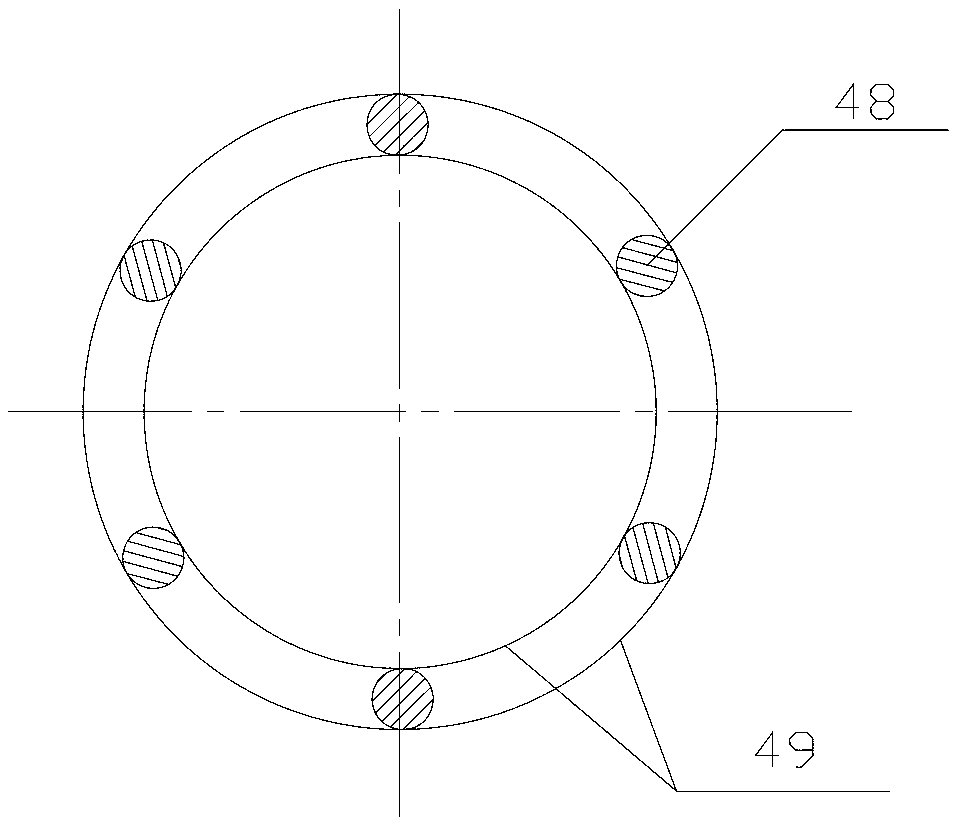

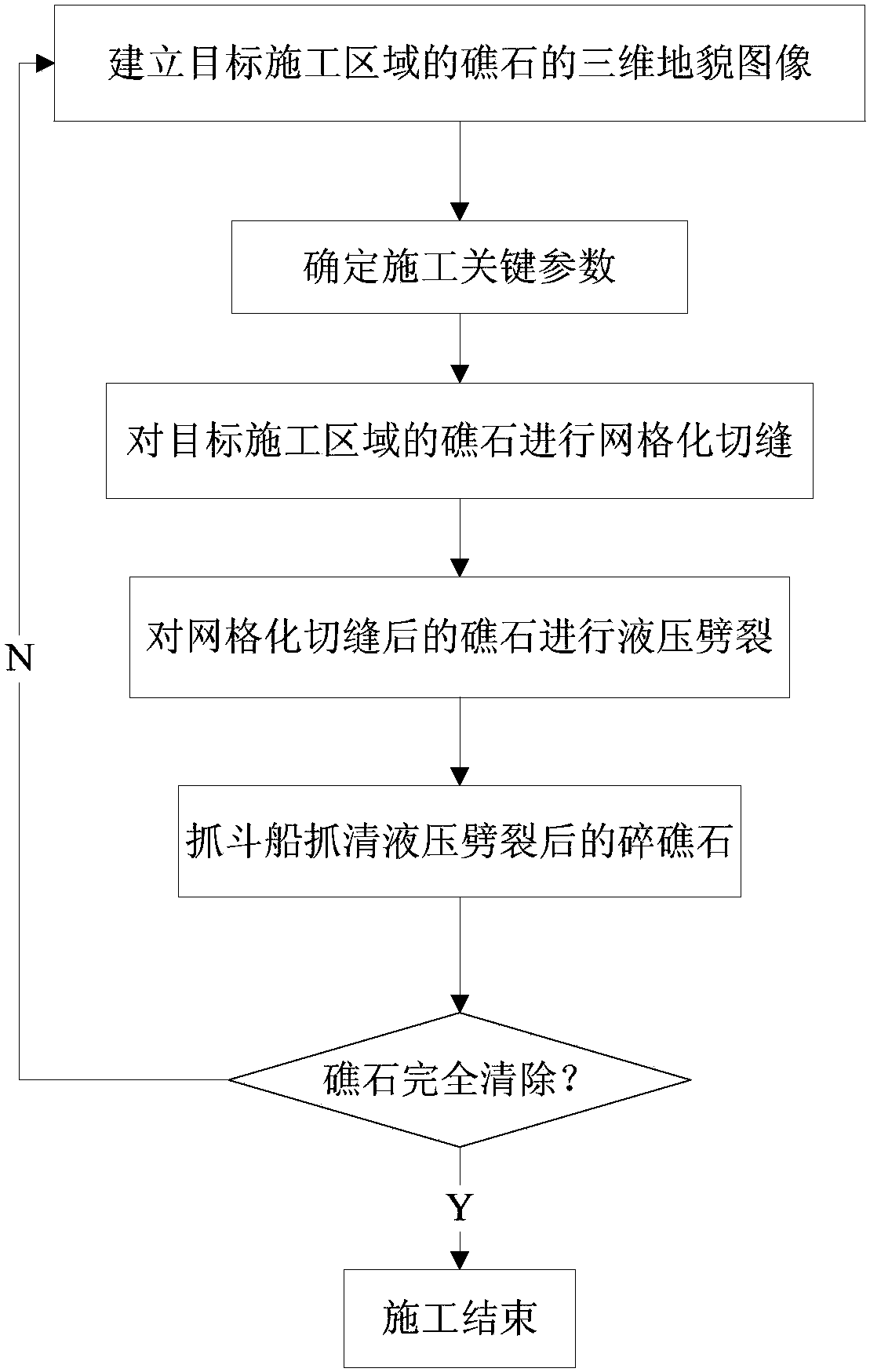

Method for removing underwater reefs

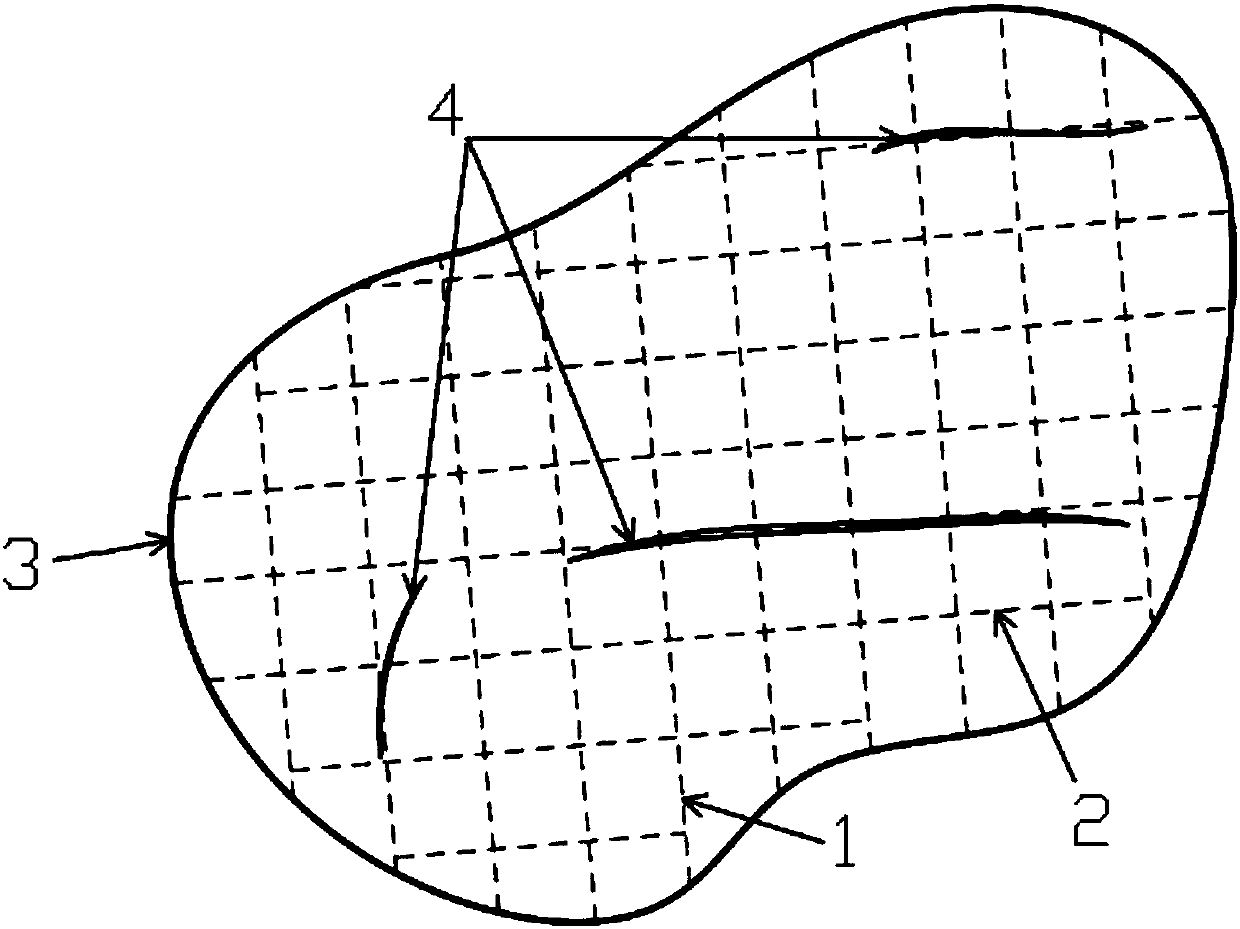

InactiveCN107905178AThe construction process is safe and controllableChange the rigid structureStream regulationEcological environmentUnderwater

The invention discloses a method for removing underwater reefs. The method for removing the underwater reefs comprises the following steps: establishing a three-dimensional landform image of reefs ina target construction area based on a three-dimensional landform imaging system; according to the three-dimensional landform image and the designed channel navigation capability, determining construction key parameters; performing gridding seam-cutting on the reefs in the target construction area by a high-speed jet flow seam forming system; automatically positioning a splitting mechanism to be placed into a seam groove and performing hydraulic splitting on the reefs subjected to gridding seam-cutting; and removing the broken reefs after hydraulic splitting. The removing method is less harmfulto the ecological environment and high in construction safety.

Owner:CHONGQING JIAOTONG UNIVERSITY

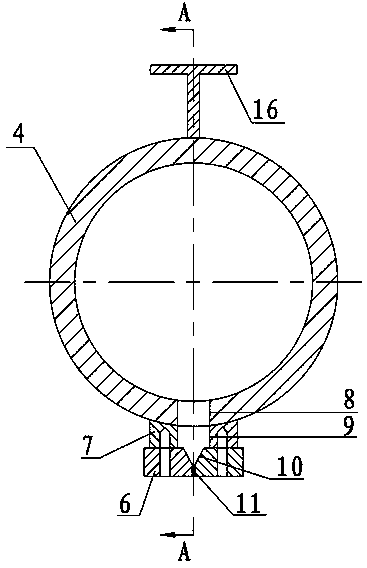

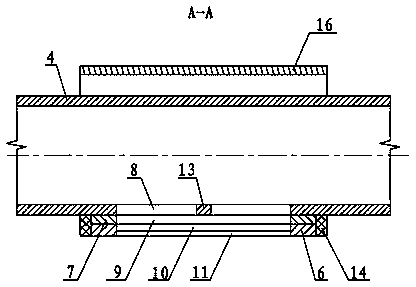

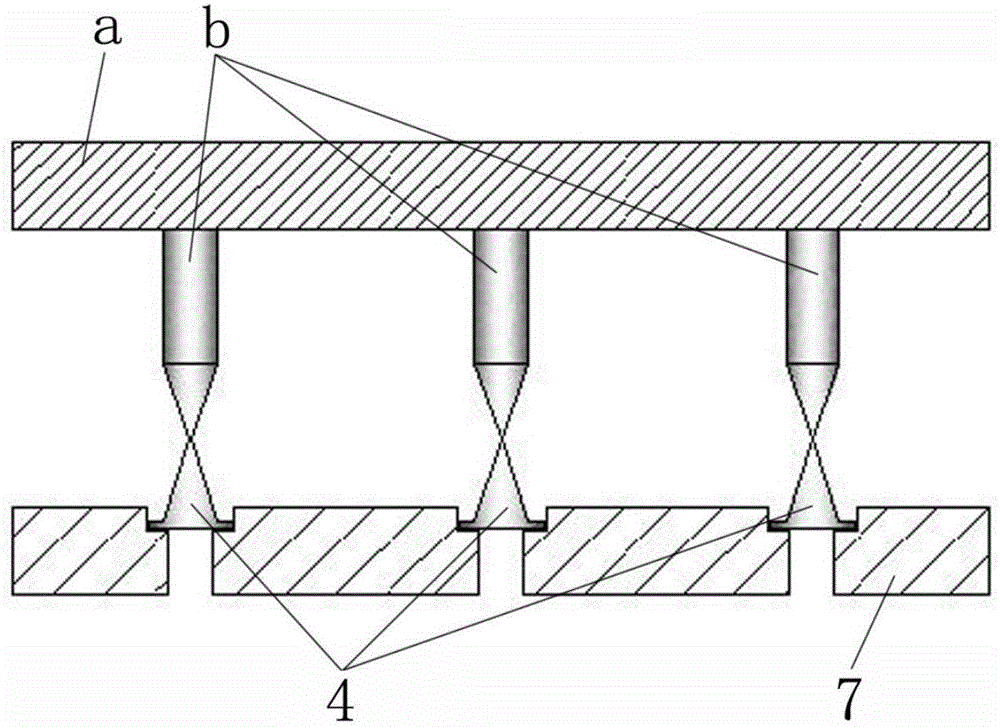

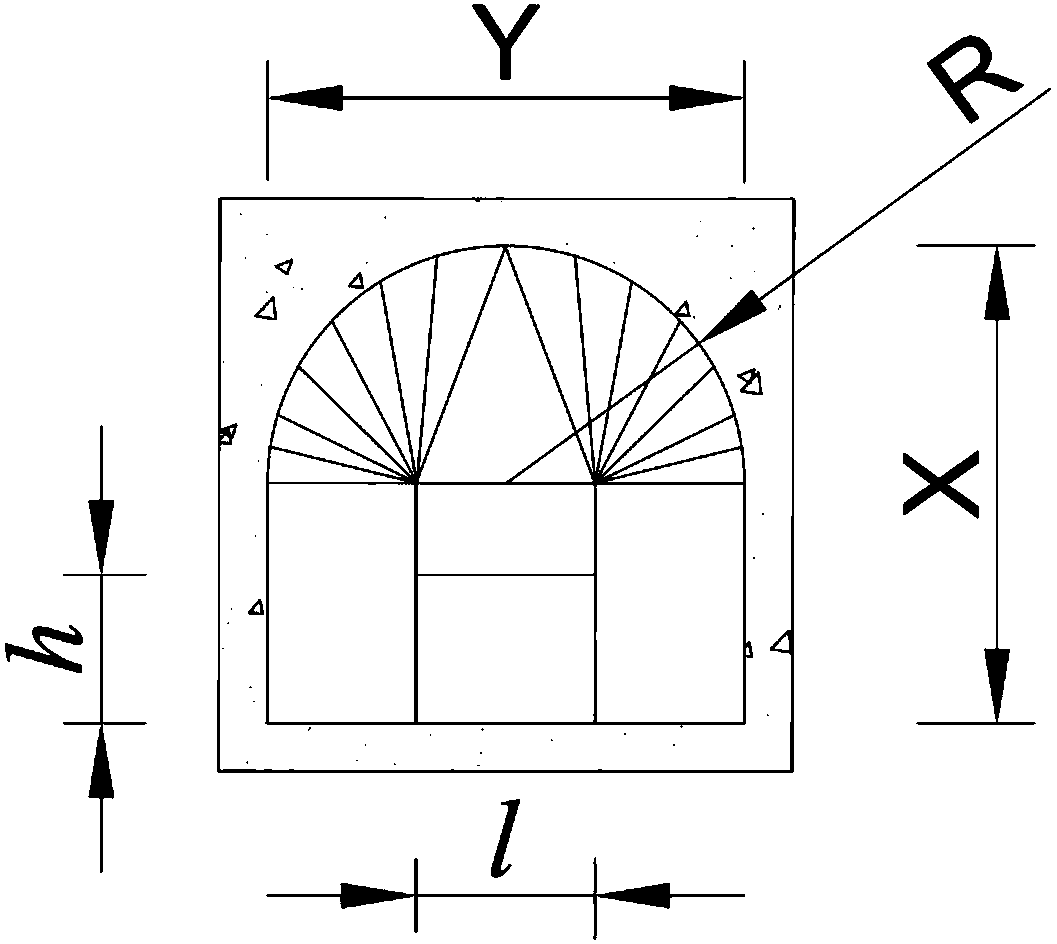

High-efficiency dephosphorization method and high-efficiency dephosphorization device

InactiveCN103861880AExtended service lifeReduce jet velocityWork treatment devicesMetal rolling arrangementsMetalMaterials science

The invention relates to a high-efficiency dephosphorization method and a high-efficiency dephosphorization device. The high-efficiency dephosphorization device comprises a pressure-bearing cavity for circulating a phosphorization medium, wherein the pressure-bearing cavity is provided with a phosphorization medium inlet, the side wall, adjacent to the surface of a to-be-dephosphorized metal blank, of the pressure-bearing cavity is provided with an injection outlet passage of the dephosphorization medium, the injection outlet passage is a slender slot, so that the stream injected to the surface of the metal blank is in a non-dispersion sheet shape. The pressure-bearing cavity is a pipeline with an circular axial cross section, the pipeline is integrally formed or formed by splicing two semicircular grooves, and the pressure-bearing cavity is in a bar shape, an annular shape or a special shape. The dephosphorization medium is in a non-dispersion sheet form after being injected, the pressure is basically not scattered, so that the utilization efficiency of the pressure is improved, the injection speed of the dephosphorization stream is reduced, the service life of the dephosphorization device is prolonged; moreover, the high-efficiency dephosphorization device is not subjected to the limitation of the installation condition, the injection distance of the dephosphorization stream can be reduced, and the flow efficiency can be improved.

Owner:FUJIAN DEXING ENERGY CONSERVATION TECH

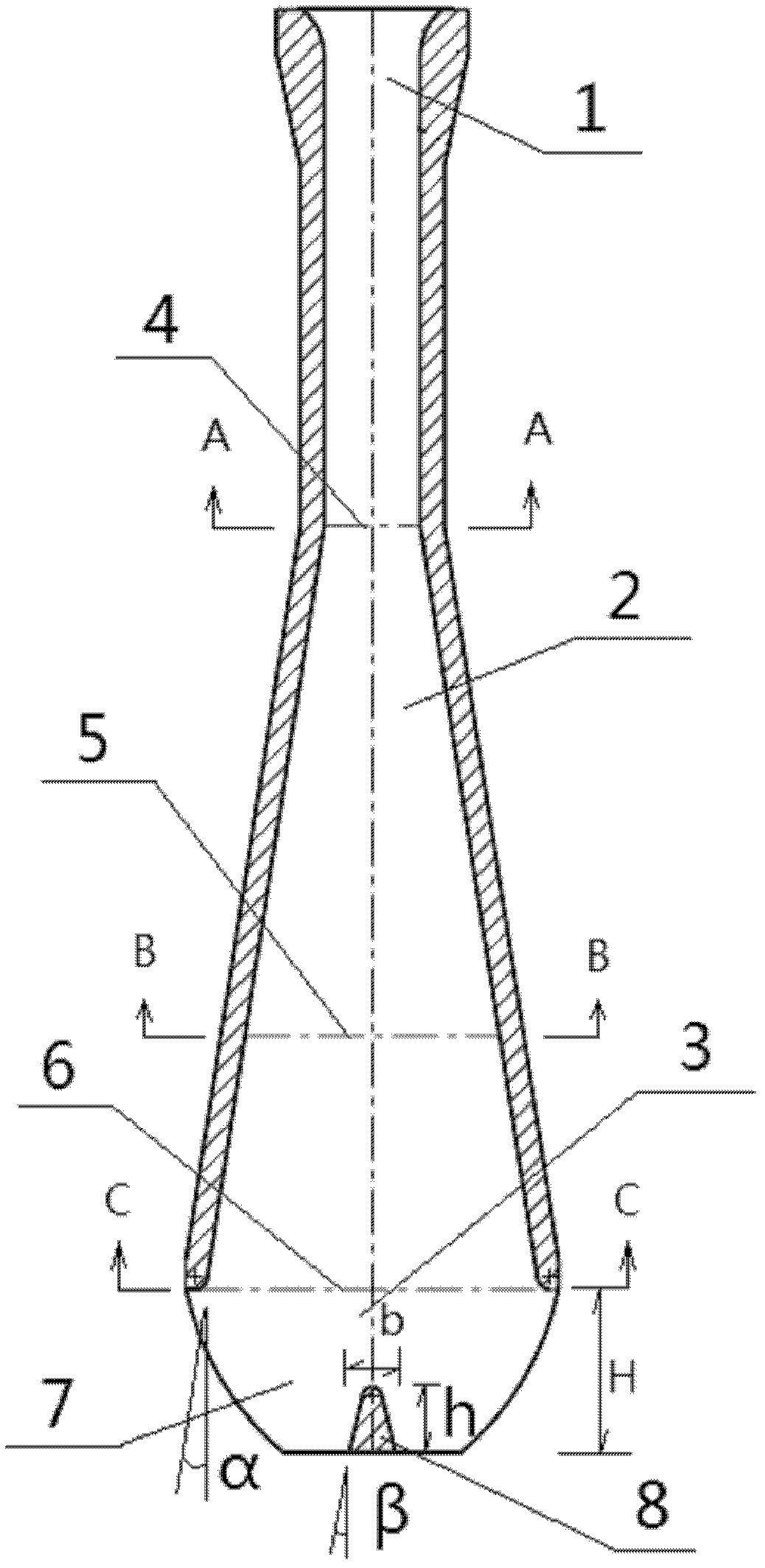

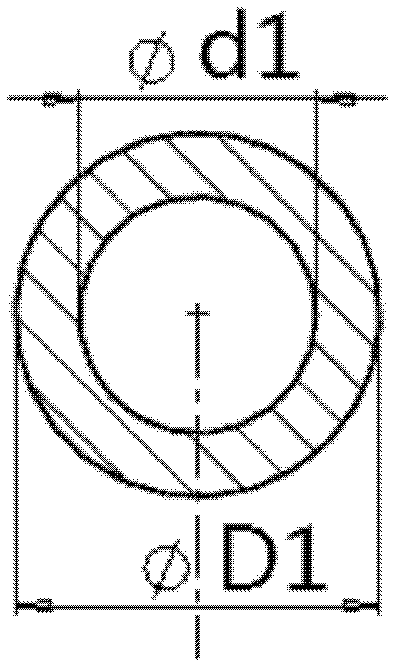

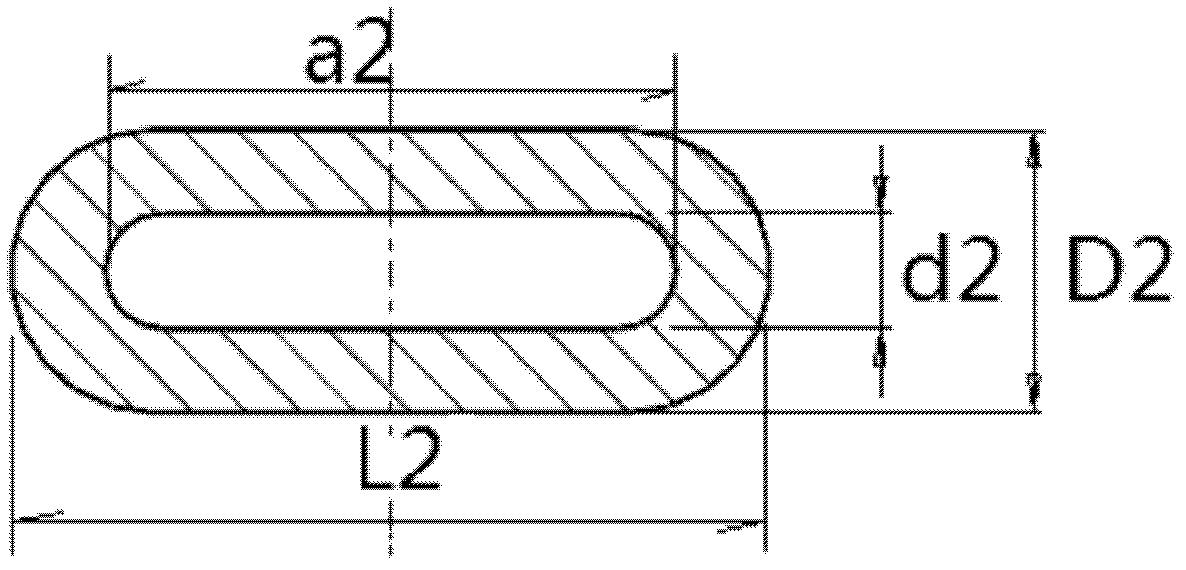

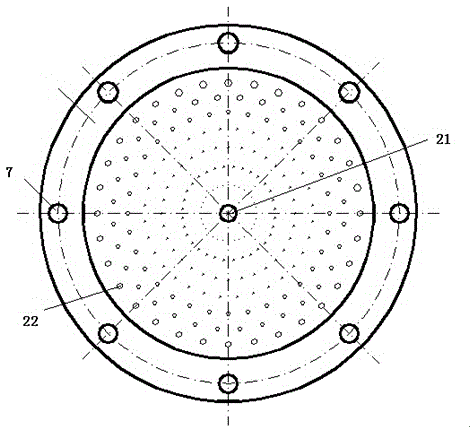

Double-hole immersed waterslot for flexible thin slab casting (FTSC) crystallizer

The invention relates to the field of waterslot of metallurgical continuous casting equipment, in particular to a double-hole immersed waterslot for an FTSC crystallizer, which comprises an upper molten steel inflow end, a middle runner and a lower outflow end, which are connected in turn, wherein the lower inflow end is provided with outlet holes which are symmetric on two sides, and sub fluid flows between the outlet holes. The double-hole immersed waterslot for the FTSC crystallizer is characterized in that: two outlet holes are formed; the inclination angle of the outlet holes is 11 to 13DEG; the height H of the outlet holes is 133 to 138 millimeters; and the width d of the outlet holes is 27 to 28 millimeters. Compared with the prior art, the double-hole immersed waterslot for the FTSC crystallizer has the advantages that: 1) the flowing of molten steel around the waterslot is promoted, and the solidifying blank shell is prevented from being adhered with the waterslot; 2) the nonmetallic impurities in molten steel can float up easily to be absorbed by protective slag and thus removed; 3) the phenomenon that slag is carried on the surface of the molten steel in a crystallizeris avoided; and 4) the molten steel can solidify easily to form initial crystal blank shell with uniform thickness around, and consequently the surface quality of the thin plate blank can be ensured.

Owner:UNIV OF SCI & TECH LIAONING +1

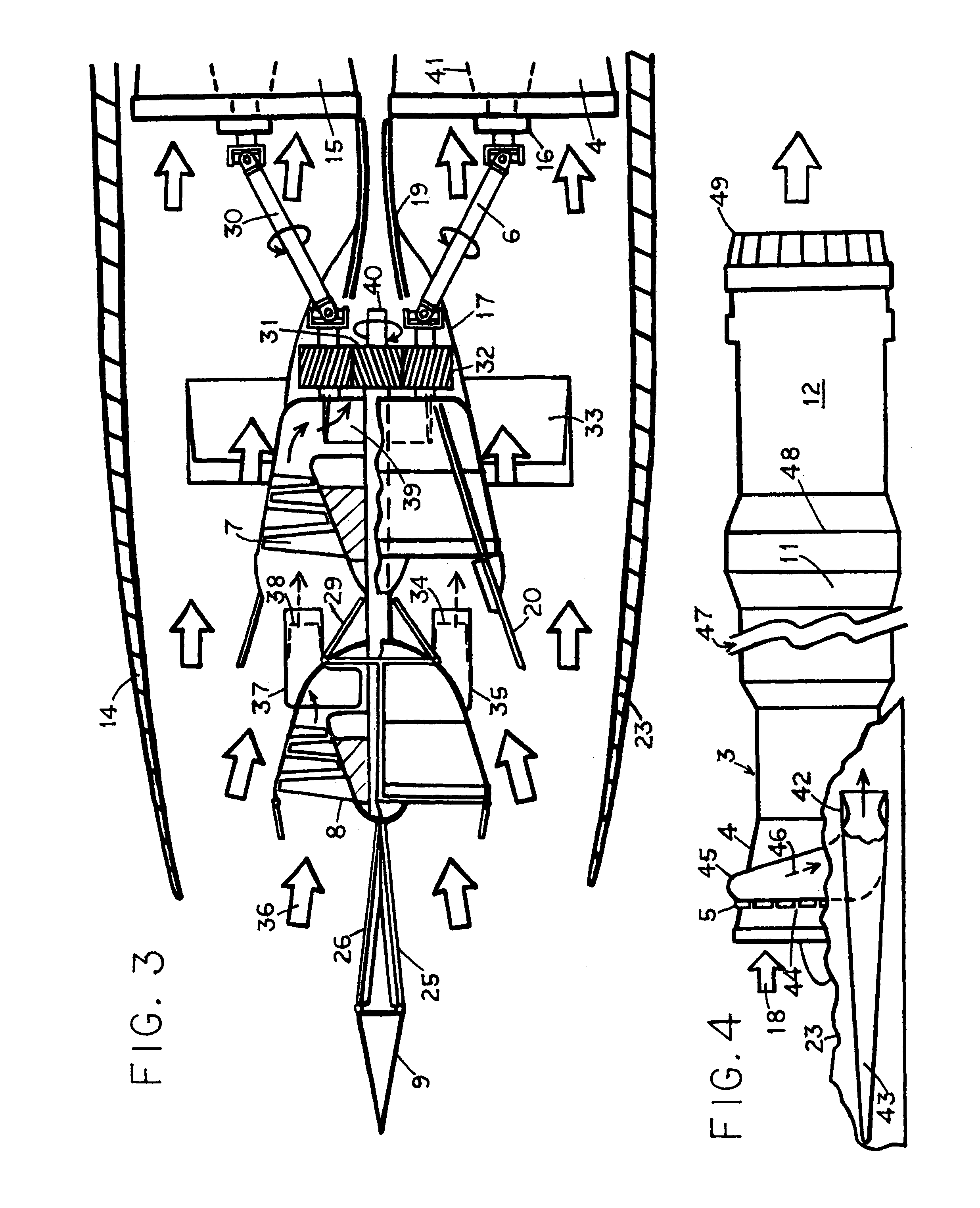

Integrated aircraft

InactiveUS20110240804A1Improve efficiencyReduce jet velocityAircraft navigation controlPower plant exhaust arrangementsJet engineTrailing edge

In a jet aircraft according to the invention the jet engines are embedded in the wings and exhaust through fishtail diffuser ducts, from high aspect ratio nozzles located at a small control flap at the wing trailing edge. The jet engines are very-high bypass ratio geared turbofans operating at a lower than typical temperature. The jet aircraft according to the invention exhibits exceptionally low zero-lift drag leading to exceptionally high lift-to-drag ratios.

Owner:KEHAYAS NIKOLAOS

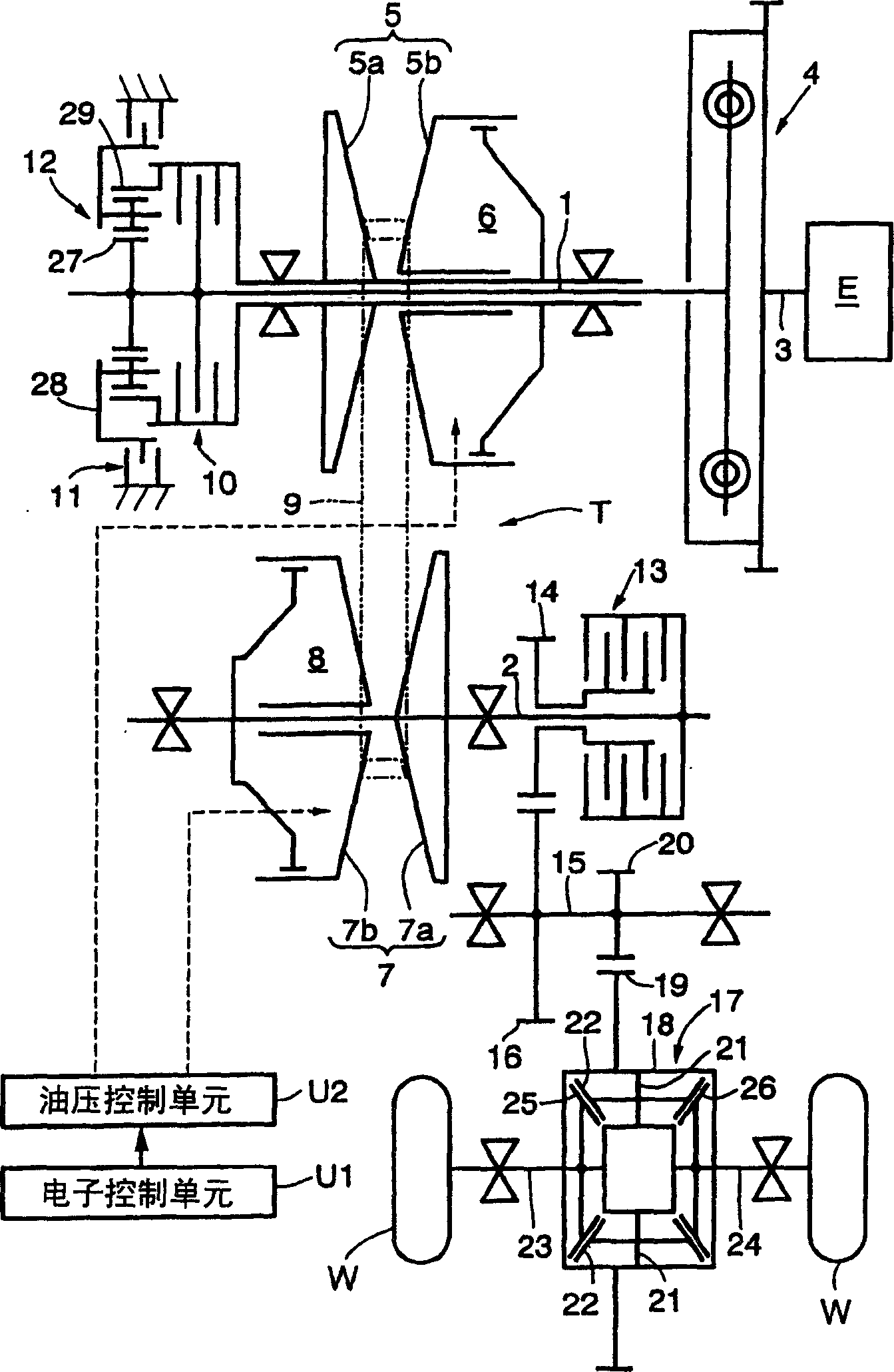

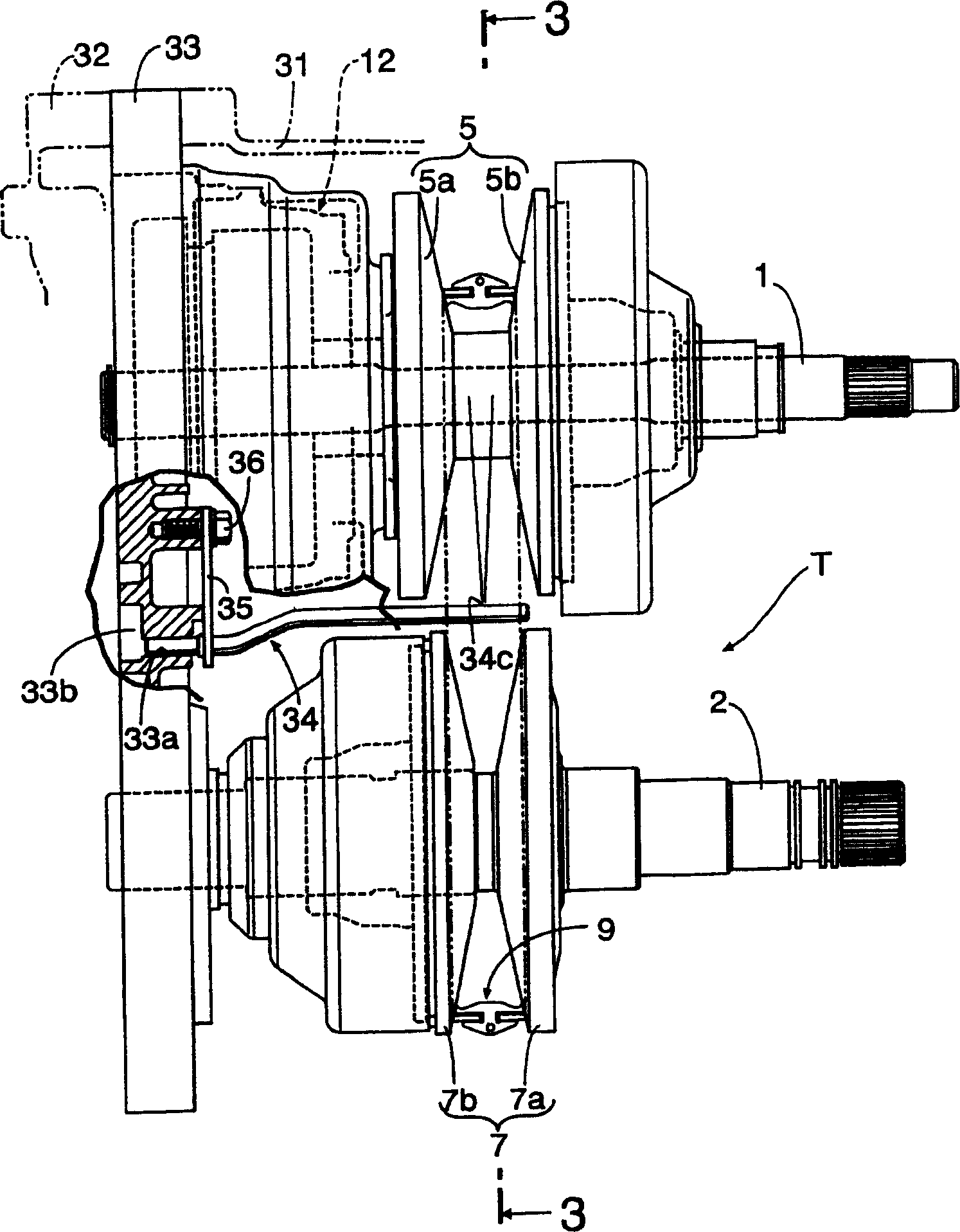

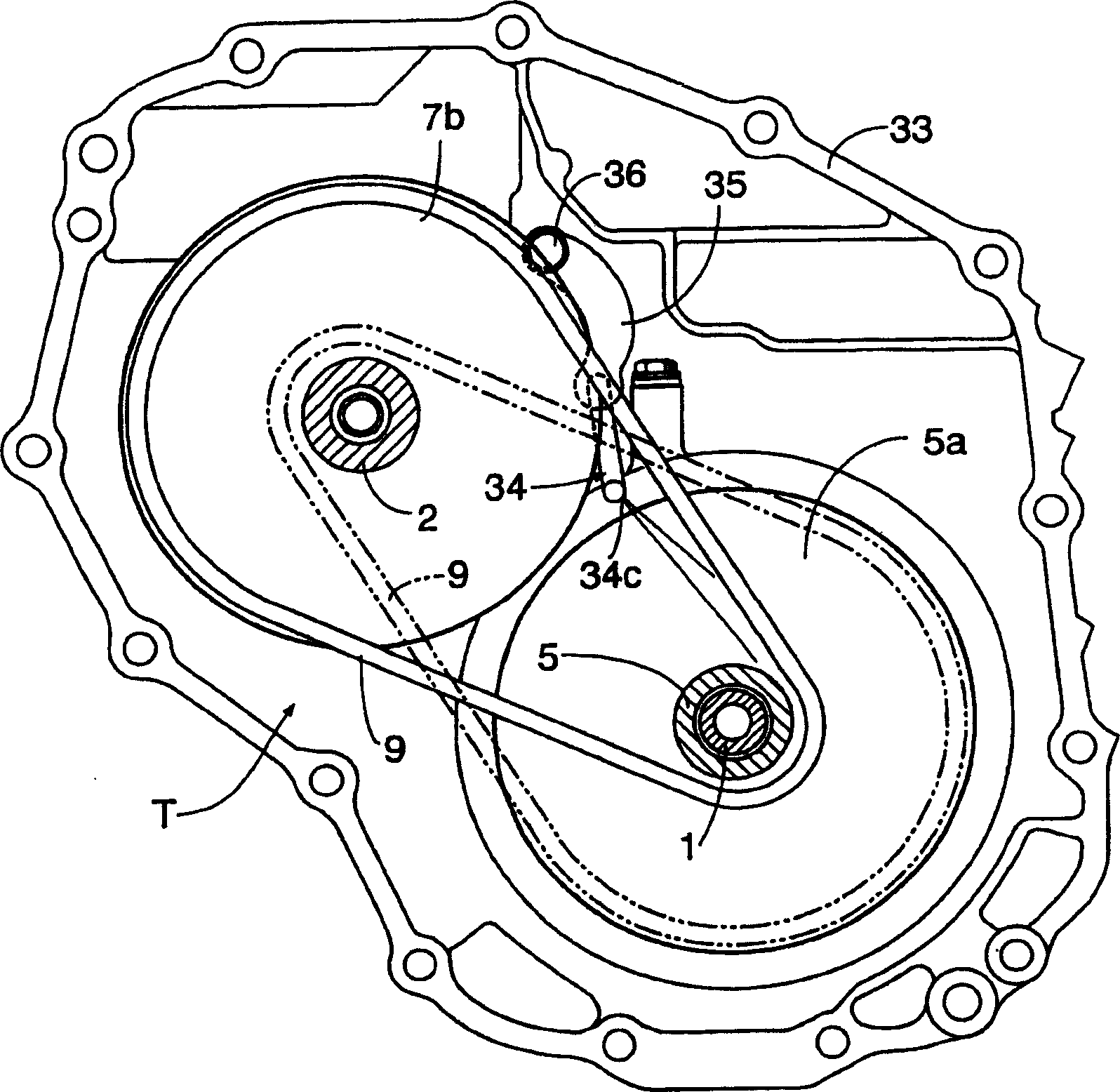

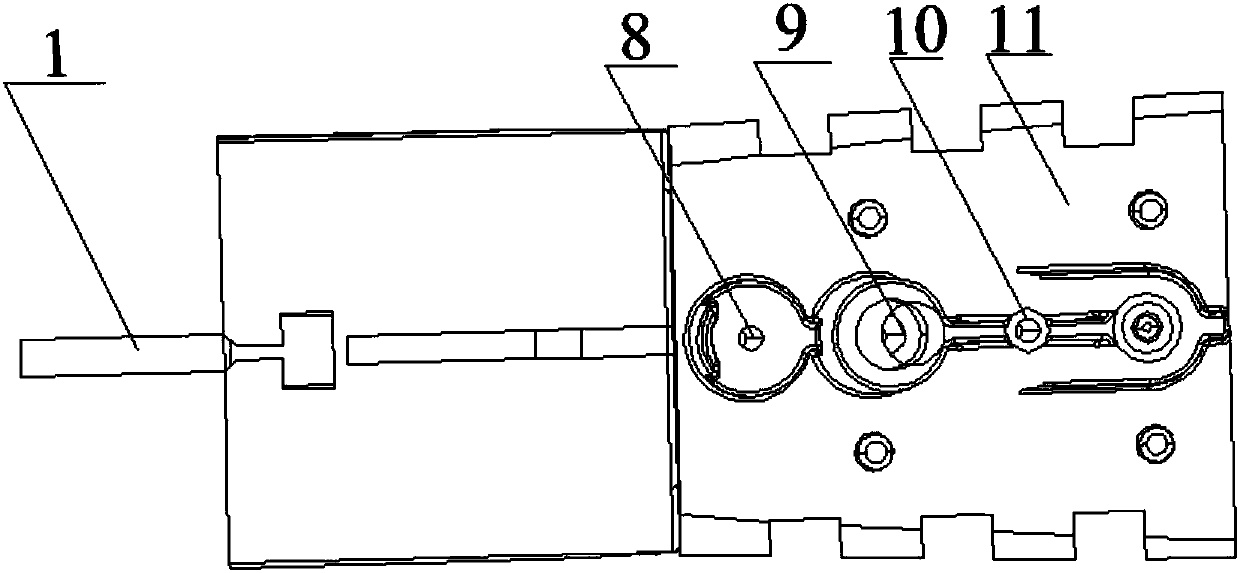

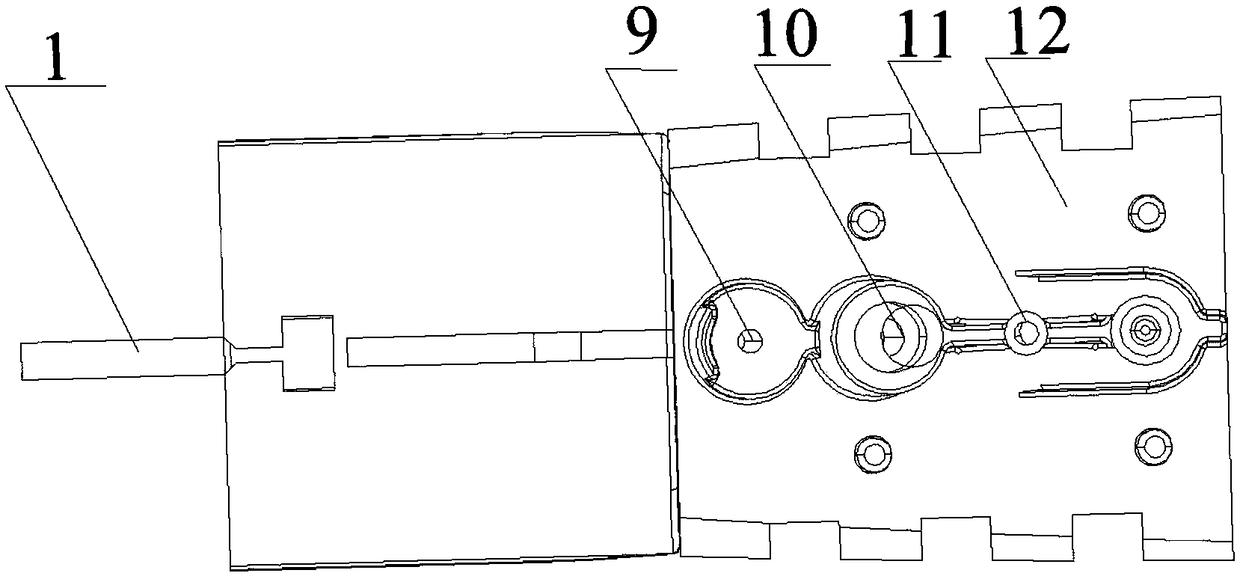

Metal band type stepless speed variator lubricating device

ActiveCN1619190AReduce jet velocityEnsure adequate lubricationGearingGear lubrication/coolingMetal stripsGroove width

The invention provides a lubricating device for a metal belt type continuously variable transmission. The device hangs the metal belt on the driving pulley and the driven pulley with variable groove width, and the lubricating oil sprayed by the nozzle (34) acts on the driving belt. The pulley, driven pulley and metal belt are lubricated, wherein: the nozzle (34) has a lubricating oil spray hole (34c) for spraying lubricating oil, and a lubricating oil supply connected to the upstream side of the lubricating oil spray hole (34c) The flow control part (34e) of the passage (34a). Since the flow control part (34e) is provided in addition to the lubricating oil injection hole (34c), the lubricating oil flow rate can be controlled at the desired flow rate while reducing the amount of lubricating oil sprayed from the lubricating oil injection hole (34c). Speed, so that the lubricating oil is sprayed radially to ensure sufficient lubricating effect.

Owner:HONDA MOTOR CO LTD

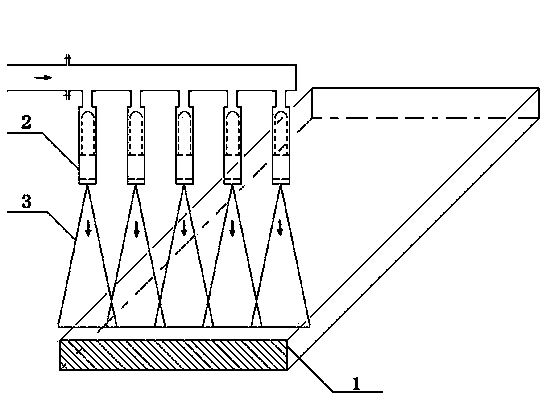

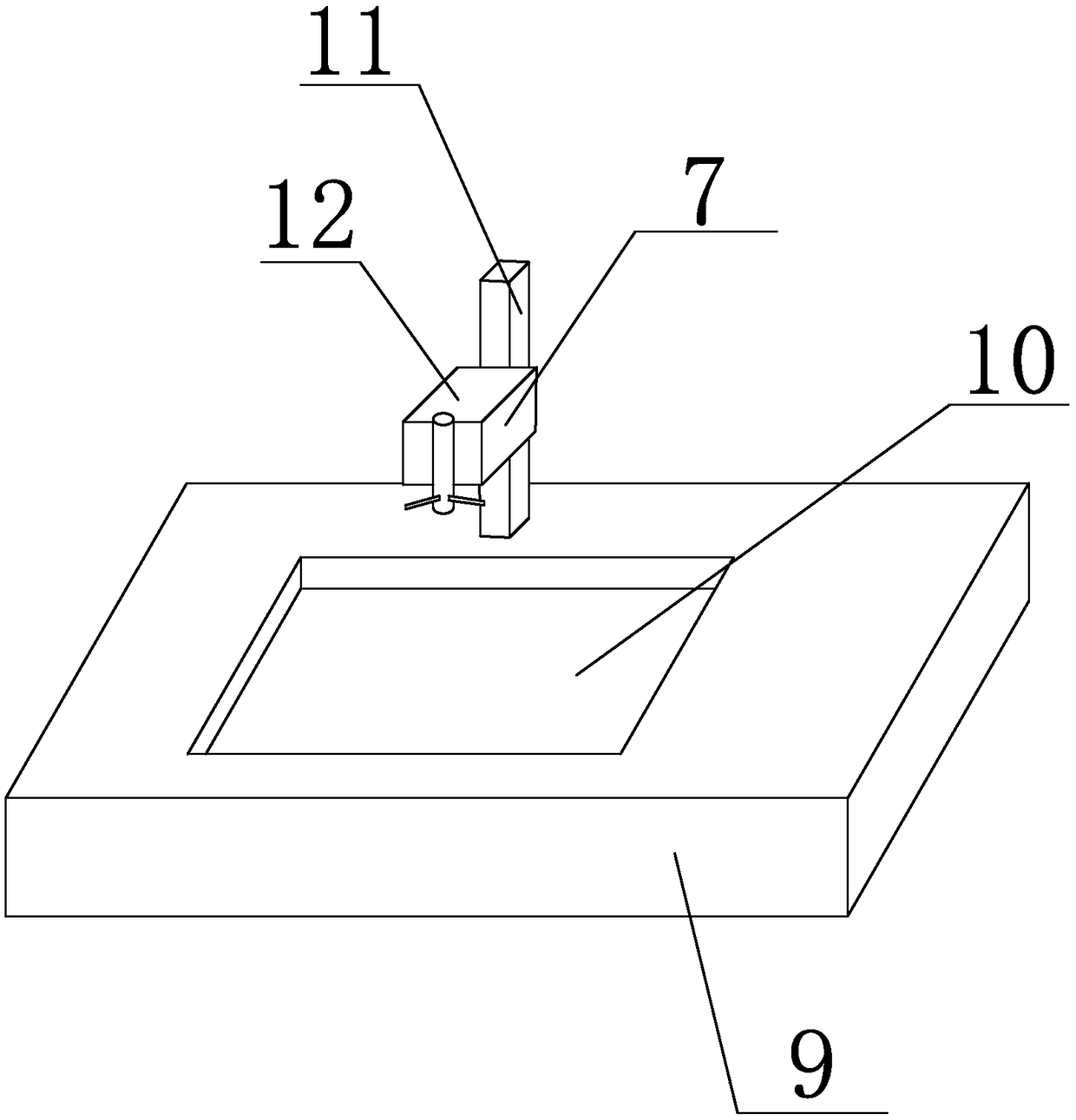

Spraying equipment for improving spraying efficiency of inner wall of furniture

The invention discloses spraying equipment for improving spraying efficiency of an inner wall of furniture. The spraying equipment comprises a workbench, a placement groove is formed in the workbench,a stand column is arranged on one side of the placement groove, a mounting block is connected to the stand column in a sliding mode, the front end of the mounting block is provided with a vertically-arranged feeding pipe, four spraying heads are vertically arranged on the side wall of the bottom end of the feeding pipe, the spraying heads comprise coating spraying pipes, the outlet ends of the coating spraying pipes are connected with nozzles, the nozzles are in a circular truncated cone shape, a plurality of liquid spraying holes are formed in the liquid outlet ends of the nozzles, circulartruncated cone-shaped cavities are formed in the liquid spraying holes, triangular convex teeth are arranged on the inner walls of the liquid outlet ends of the liquid spraying holes, the outer wallsof the liquid outlet ends of the nozzles are sleeved with shielding covers, and the openings of the shielding covers are covered with spraying isolation nets. The efficient spray heads can be used forsimultaneously spraying a plurality of wall surfaces of the inner wall of the furniture, the spraying efficiency is improved, uniform spraying can be carried out, the spraying quality is improved, meanwhile, the surfaces of the spray heads and the surface of the furniture can be well protected, so that the spray heads are prevented from colliding with the furniture to pollute the spray heads.

Owner:蒋祥春

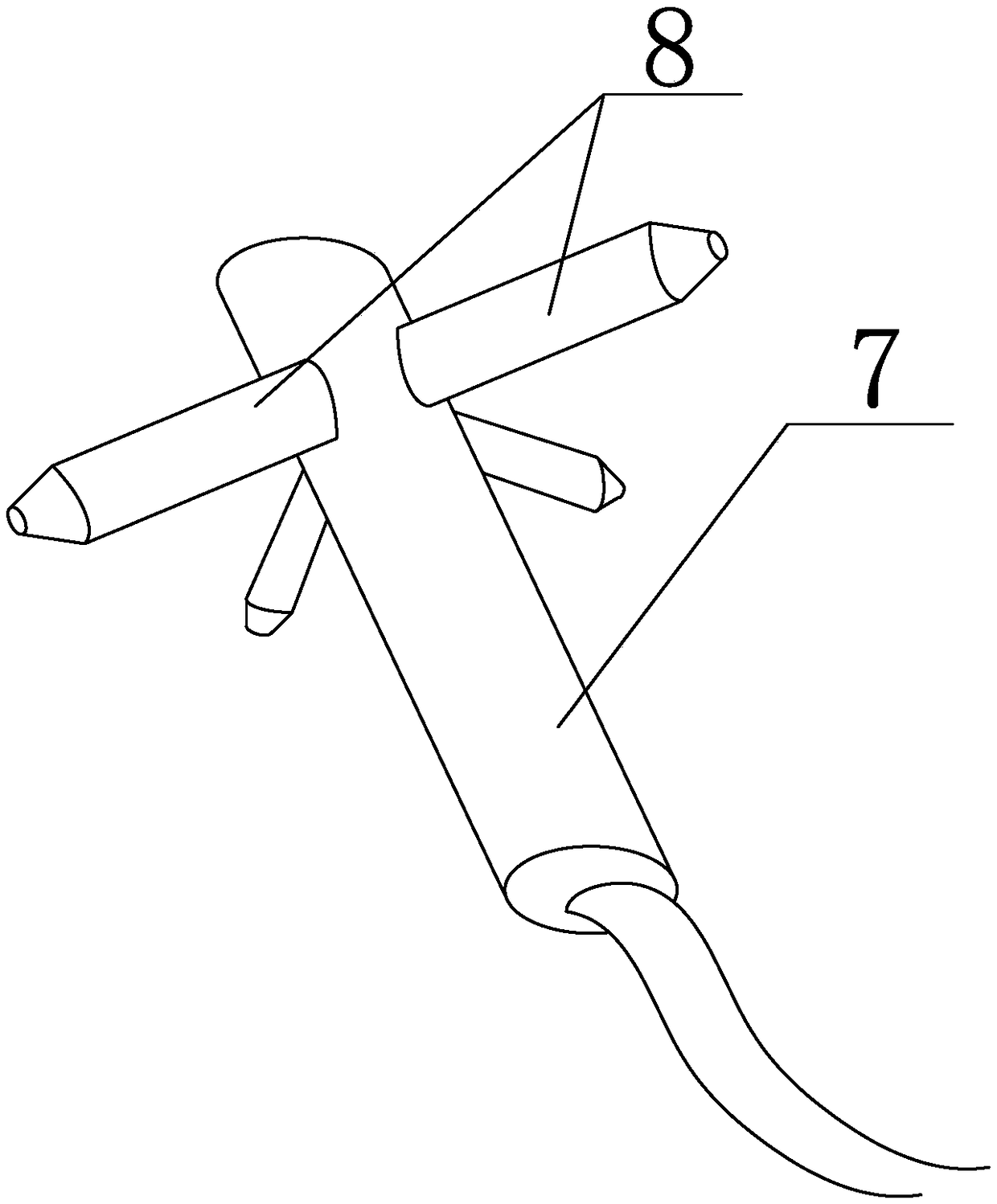

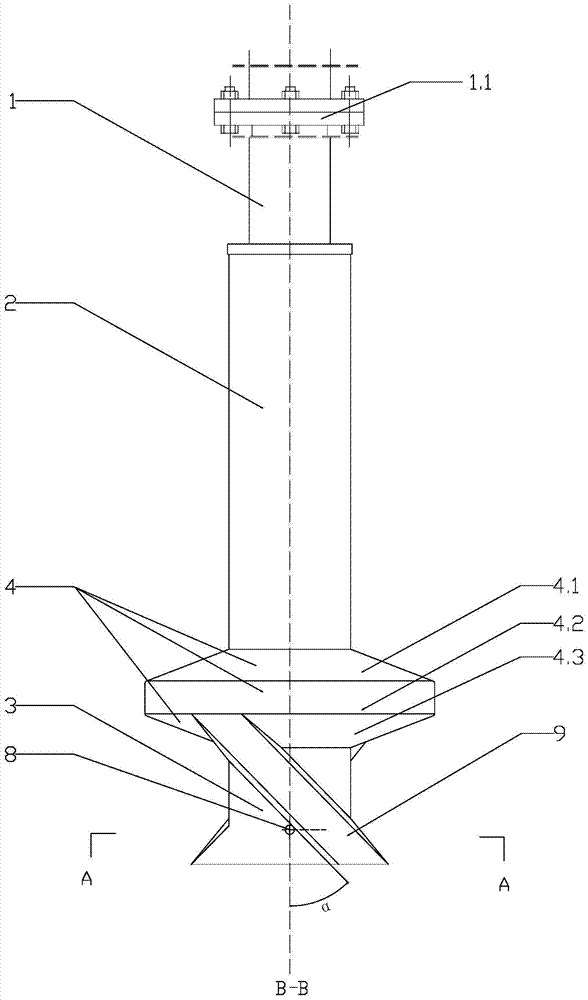

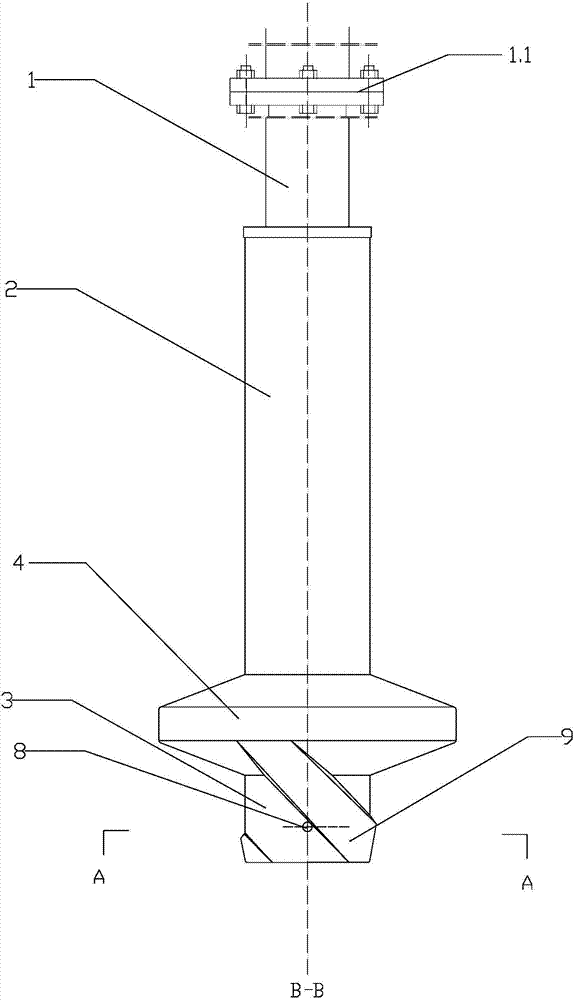

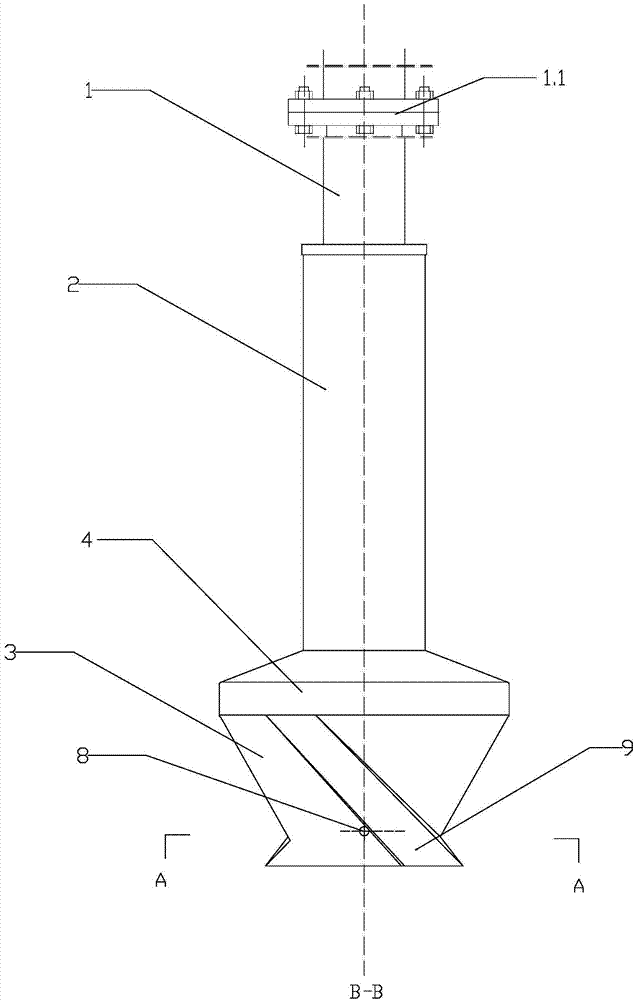

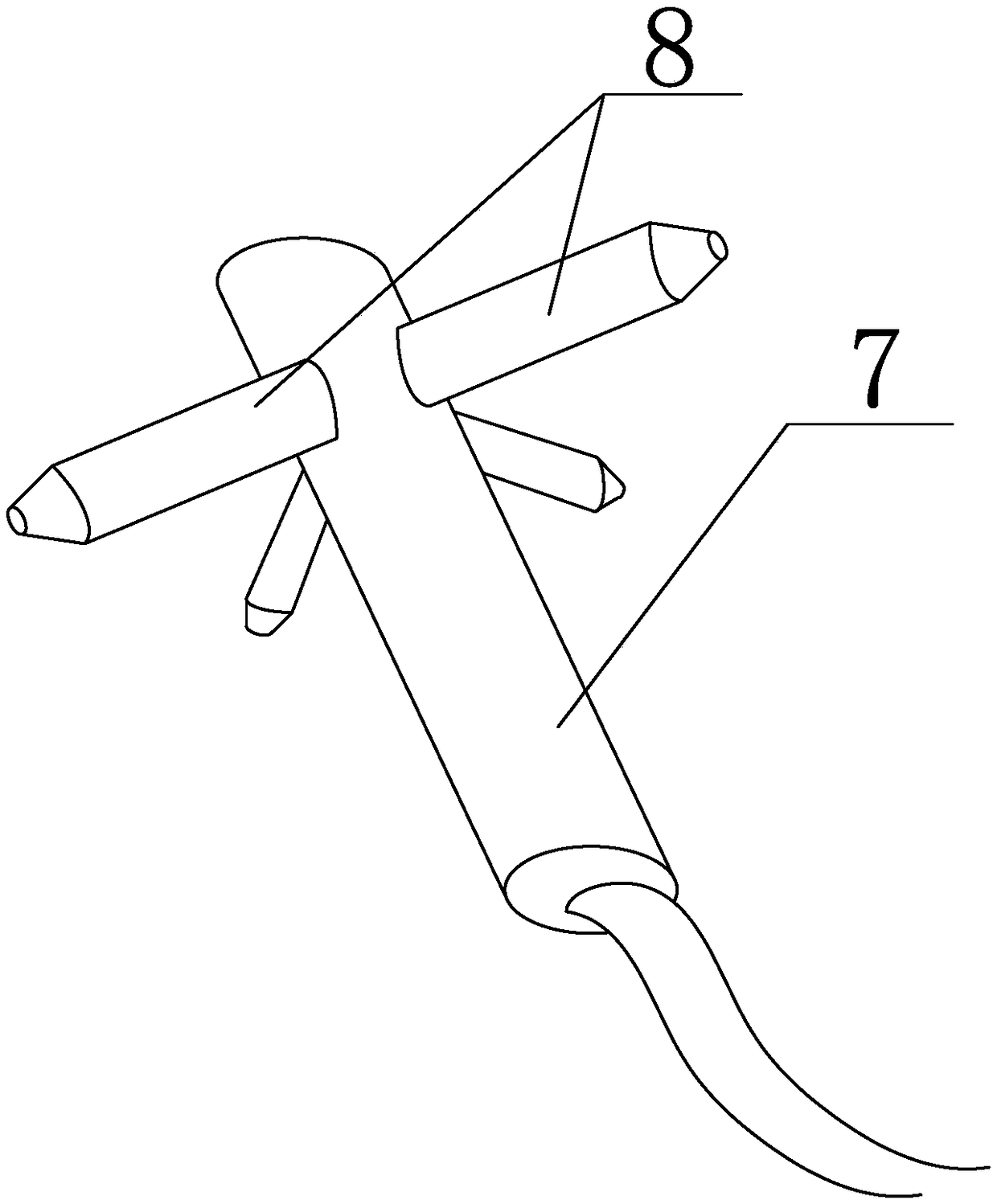

High-performance spray gun for molten iron injection pretreatment

The invention discloses a high-performance spray gun for molten iron injection pretreatment. The high-performance spray gun comprises a connection segment, a gun body segment and an injection segment, which are sequentially communicated, wherein a swirling diffuser is arranged between the gun body segment and the injection segment and comprises an upper cone, a cylinder and a lower reversed cone, which are sequentially communicated; 2-4 nozzles are uniformly formed between a main pipe of the spray gun and a seal head in the circumferential direction of the spray gun and positioned in the side wall of the injection segment; swirling pieces obliquely arranged on the outer wall from the top end of the lower reversed cone to the bottom end surface of the injection segment and positioned above the nozzles. By strengthening three key kinetic parameters of molten iron injection pretreatment, the spray gun significantly improves the kinetic conditions of molten iron injection pretreatment and achieves the comprehensive purposes of improving the sulfur removal efficiency of injection pretreatment and the utilization rate of desulfurizer reaction, shortening the injection time and increasing the production capacity of desulfurization equipment.

Owner:武汉钢铁有限公司

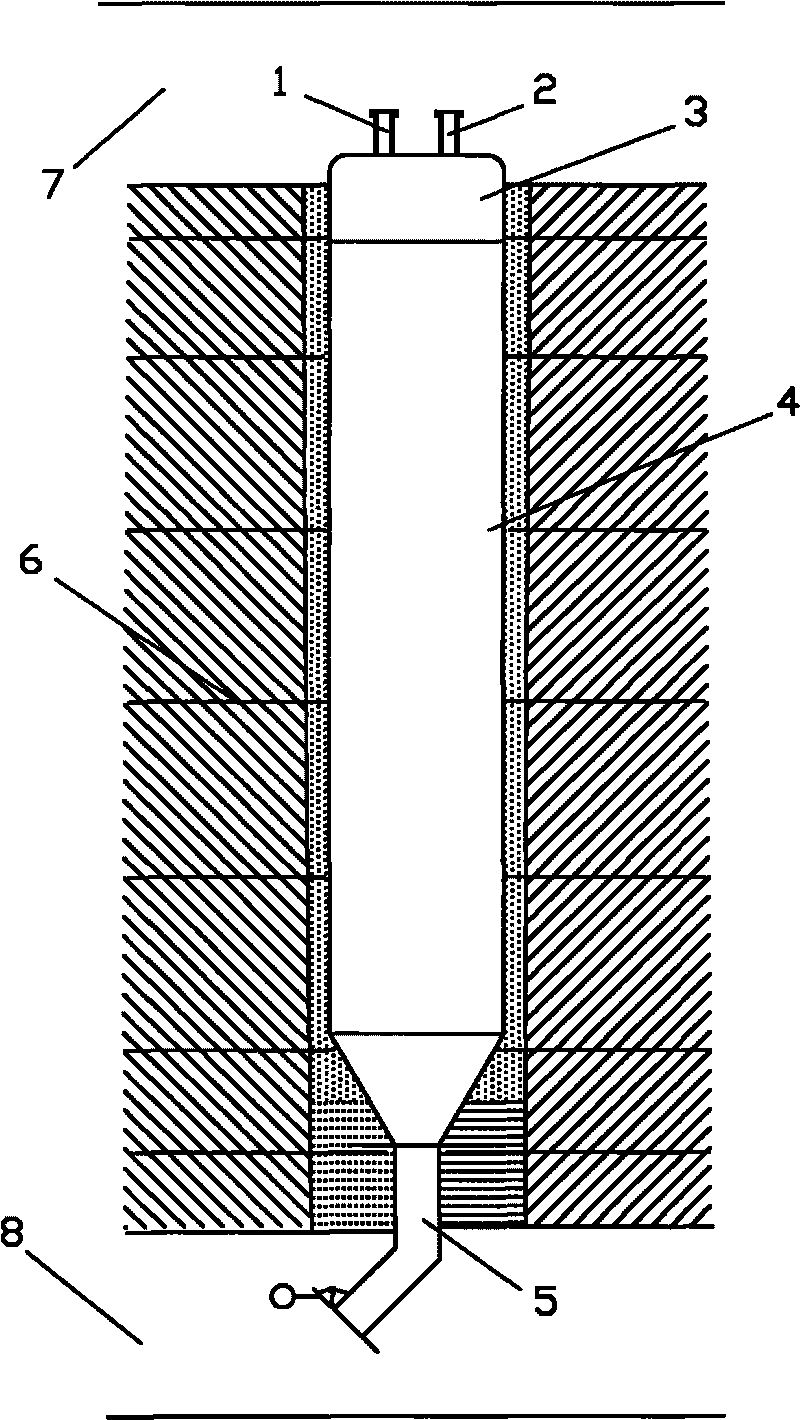

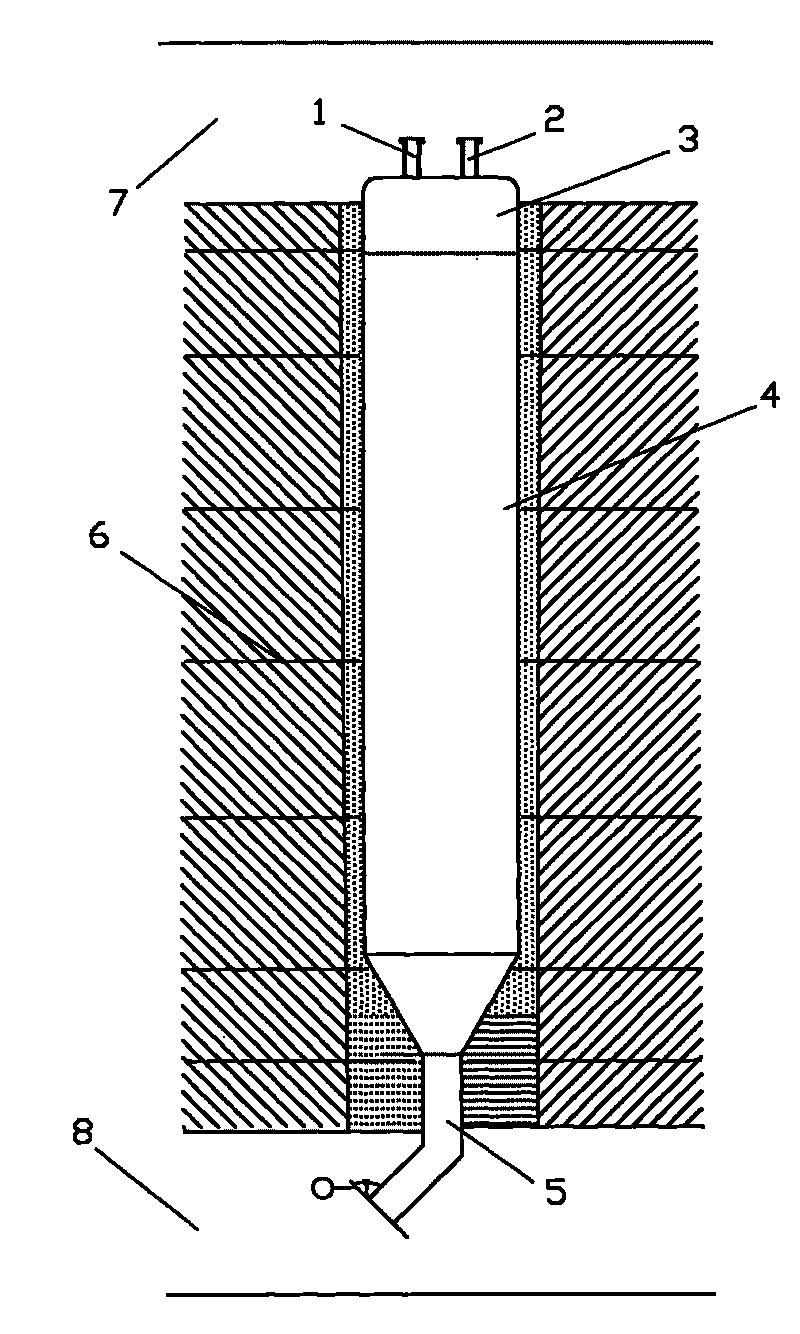

Coal and gas separation bin and method thereof

The invention relates to a coal and gas separation bin and a method thereof. The separation bin is integrally poured with concrete reinforced by anchor rods; the bottom of the separation bin is funnel-shaped; the lower part of the separation bin is a coal discharge pipe, and the upper part of the separation bin is a cover; the top part of the cover of the separation bin is provided with a jet pipe flanged joint and a drawing pipe flanged joint; and a coal discharge opening of the coal discharge pipe of the separation bin is provided with a counterbalance type bin gate. Jet materials protruding out of an excitation borehole are introduced into the separation bin, the drawing pipe is used for drawing gas so that the interior of the separation bin is in a negative pressure state to weaken the jet flow impact and achieve the separation of the coal and the gas; the coal entering the separation bin automatically opens the coal discharge opening of the separation bin and flows out under the action of gravity, and then the coal is carried away by a transporter on a lower laneway; and when the coal in the bin is emptied, under the action of a counterbalance at the coal discharge opening, the coal discharge opening is closed automatically so that the interior of the bin is kept in the negative pressure state. The jet materials with repeated coal and gas protrusions on a coal layer in the excitation borehole are separated to achieve that tens of thousands of coals are mined through a single hole. The coal and gas separation bin has a simple structure, simple and convenient method, and has easy construction and good effect.

Owner:CHINA UNIV OF MINING & TECH

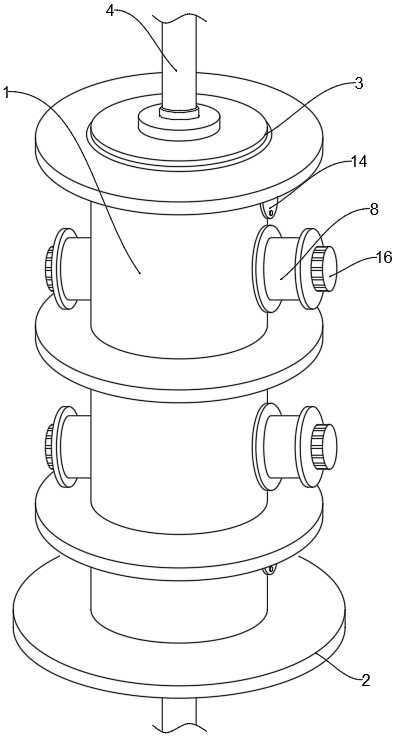

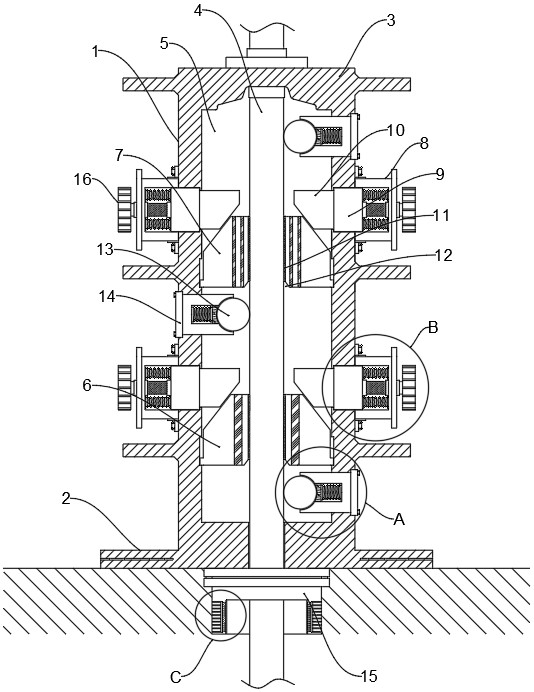

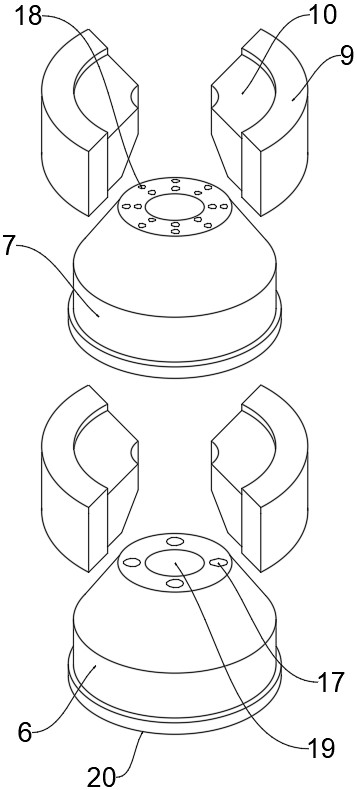

Safety blowout preventer for oilfield wellhead

Owner:山东尤科斯石油装备有限公司

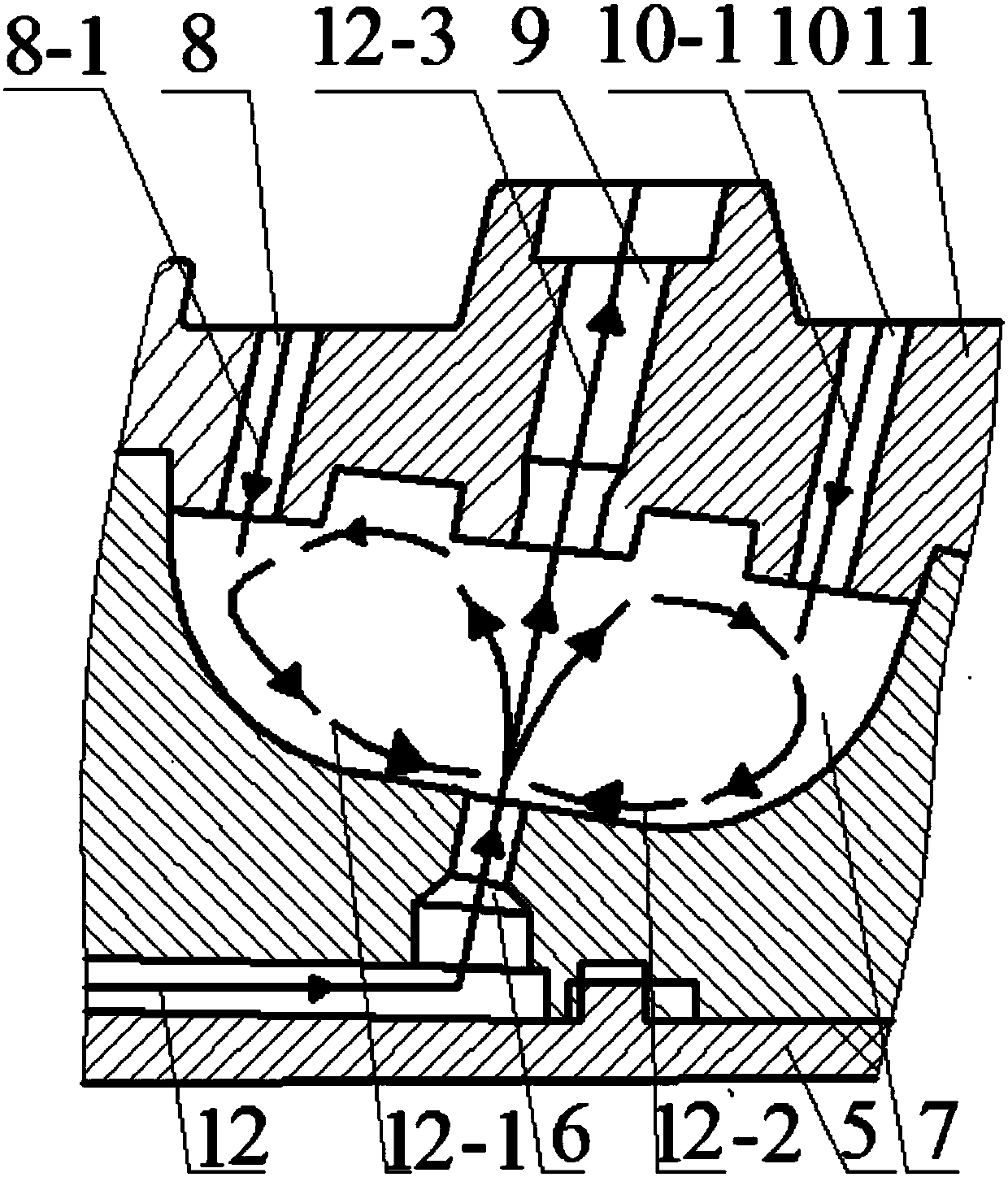

Gas mixed pulse cleaning device for intelligent toilet bowl

The invention discloses a gas mixed pulse cleaning device for an intelligent toilet bowl, and relates to the field of water jet cleaning devices low in pressure and small in flow. The gas mixed pulsecleaning device comprises a hollow shaft, a water supply pipe, a nozzle fixing device, a water supply path, a bottom plate, a throttling pipe, a gas mixing chamber, a gas suction pipe A, a gas mixed pulse nozzle, a gas suction pipe B and an upper cover. The nozzle fixing device is arranged on the hollow shaft in a sleeving mode and can move leftward and rightward. The water supply pipe is placed in the hollow shaft. One end of the water supply path is connected with the water supply pipe, and the other end of the water supply path is connected with the throttling pipe. The water supply path isarranged on the bottom plate. The bottom plate is connected with the gas mixing chamber through laser welding. The throttling pipe is connected at the center of the gas mixing chamber. The center ofthe gas mixed pulse nozzle and the center of the throttling pipe coincide and are connected to the gas mixing chamber. The gas suction pipe A and the gas suction pipe B are arranged on the two sides of the gas mixed pulse nozzle, and the gas suction pipe A, the gas suction pipe B and the gas mixed pulse nozzle are arranged on the upper cover. The upper cover is connected with the gas mixing chamber through laser welding. Lots of water and electricity resources can be saved, the structure is simple, and the gas mixed pulse cleaning device is good in cleaning effect, water saving effect and energy saving effect through actual trial use.

Owner:JIANGSU UNIV

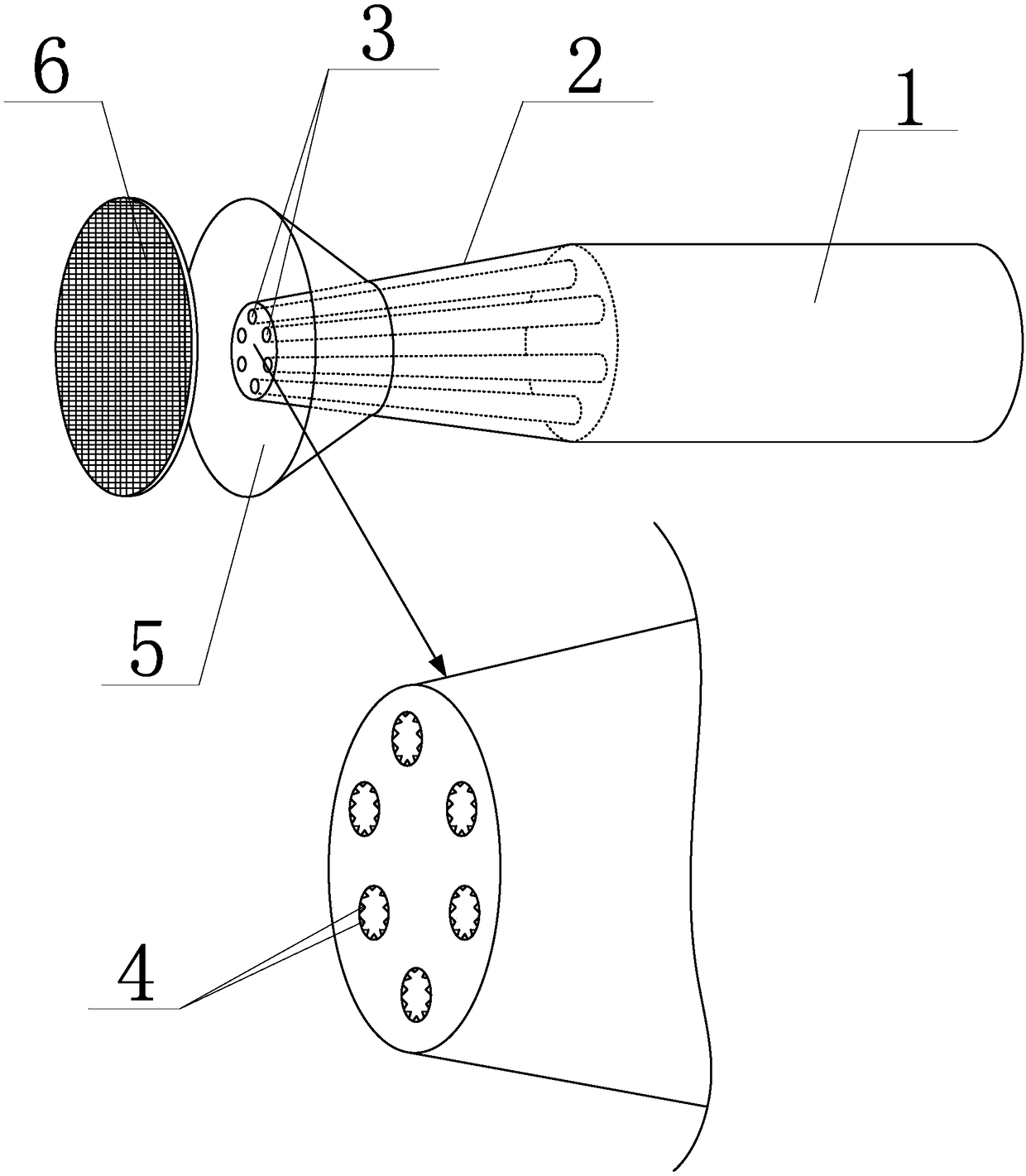

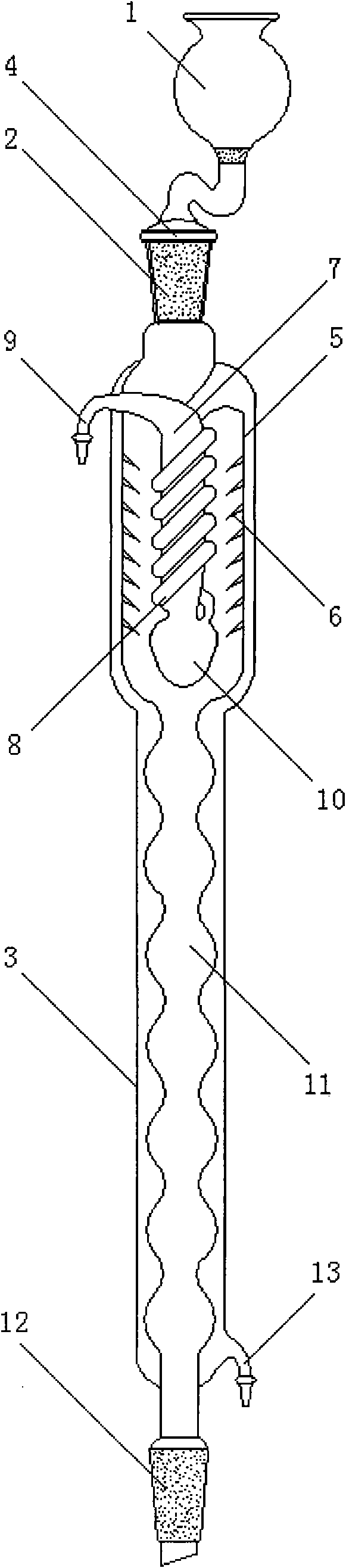

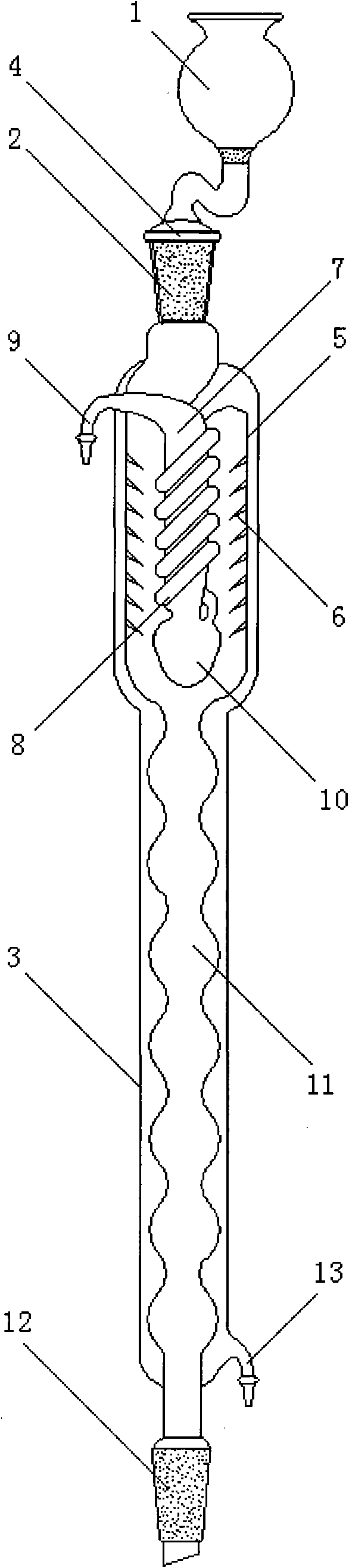

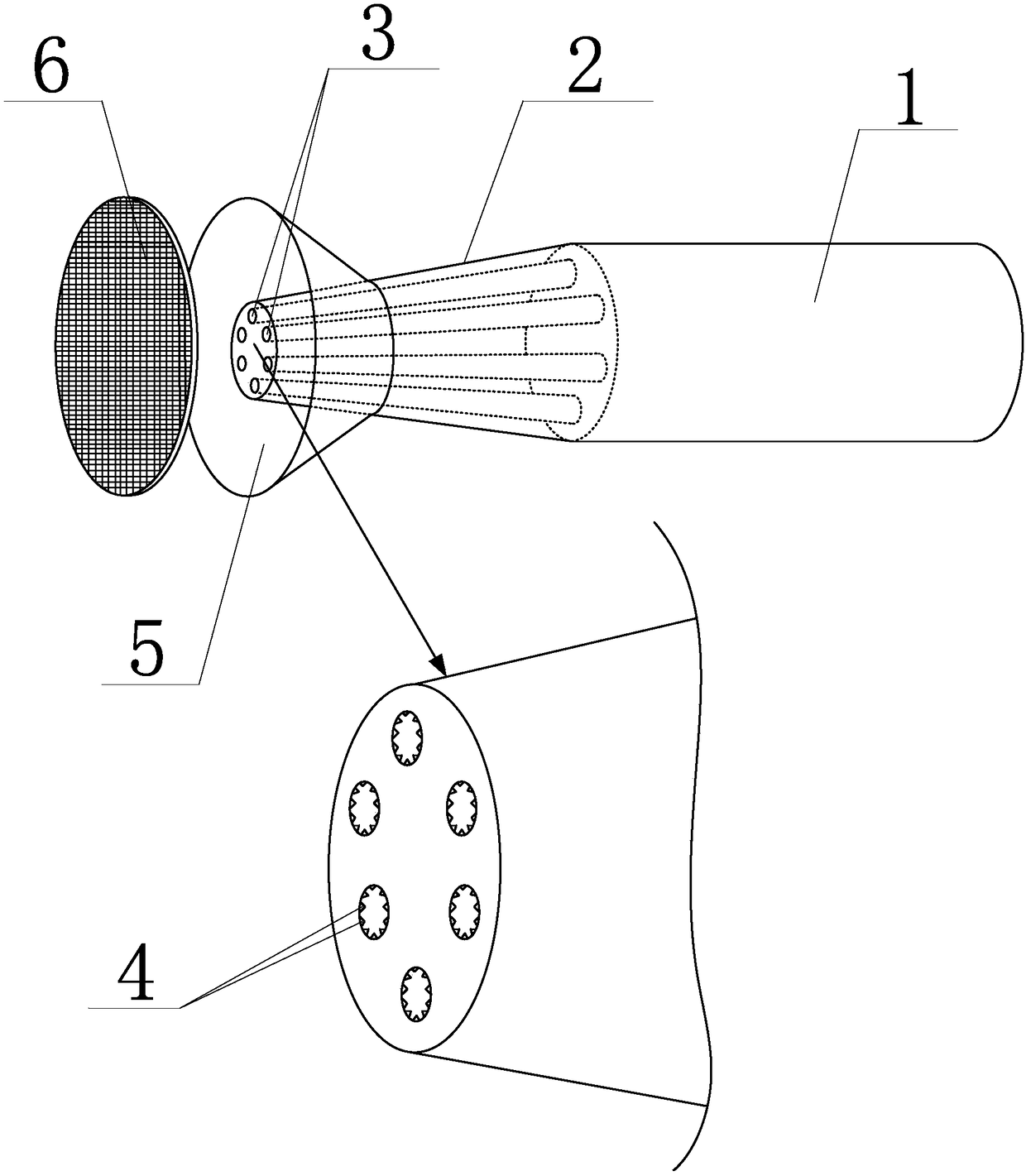

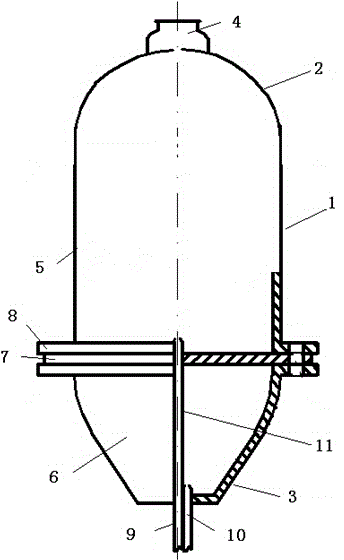

Reflux condenser pipe special for microwave chemistry

InactiveCN101780423AIncreased separation lossReduced separation lossSteam/vapor condensersLaboratory glasswaresRefluxOrganic solvent

The invention discloses a reflux condenser pipe special for microwave chemistry, which mainly comprises an external layer water sleeve (3), a standard ground (4), a barrel-shaped pipe (5), baffle stabs (6), an inner core pipe (7), a coil pipe (8), a water distribution head (10) and a serial ball pipe (11). The reflux condenser pipe special for the microwave chemistry is characterized in that: the standard ground (4) at the upper end of the external layer water sleeve (3) is welded with the barrel-shaped pipe (5) together; the baffle stabs (6) are uniformly distributed at the periphery of the inner wall of the barrel-shaped pipe (5); the lower end of the barrel-shaped pipe (5) is welded with the upper end of the serial ball pipe (11); the lower end of the inner core pipe (7) is connected with the water distribution head (10); and the coil pipe (8) is coiled outside the inner core pipe (7), and the lower end of the coil pipe (8) is connected with the water distribution head (10). Therefore, blasting explosion and high consumption of an organic solvent can be effectively prevented.

Owner:王锦化

High-efficiency inner wall coating spray head

InactiveCN109127227AAvoid Collision ContaminationAvoid pollutionSpraying apparatusSpray coatingEngineering

The invention discloses a high-efficiency inner wall coating spray head. The high-efficiency inner wall coating spray head comprises a feeding pipe; four spray heads are vertically arranged on the side wall of the feeding pipe; each spray head comprises a coating spraying pipe; the outlet end of the coating spraying pipe is connected with a nozzle; the nozzle is truncated cone shaped; the diameterof one end, far away from the coating spraying pipe, of the nozzle is less than the diameter of one end connected with the coating spraying pipe; a plurality of liquid spraying holes are formed at the liquid outlet end of the nozzle; the internal part of each liquid spraying hole is a truncated cone shaped cavity; a triangular convex tooth is arranged on the inner wall of the liquid outlet end ofeach liquid spraying hole; a shielding cover sleeves the outer wall of the liquid outlet end of the nozzle; a spraying and partitioning net covers the opening of the shielding cover; and the sprayingand partitioning net and the shielding cover wrap the liquid outlet end of the nozzle. The high-efficiency spray head can spray-coat a plurality of wall surfaces of the inner wall of furniture, greatly improves the spray-coating efficiency, can spray-coat uniformly, can improve the spray-coating quality, can achieve good protective effect on the surfaces of the spray head and the furniture and avoids pollution to the spray head caused by mutual collision of the spray head and the furniture.

Owner:蒋祥春

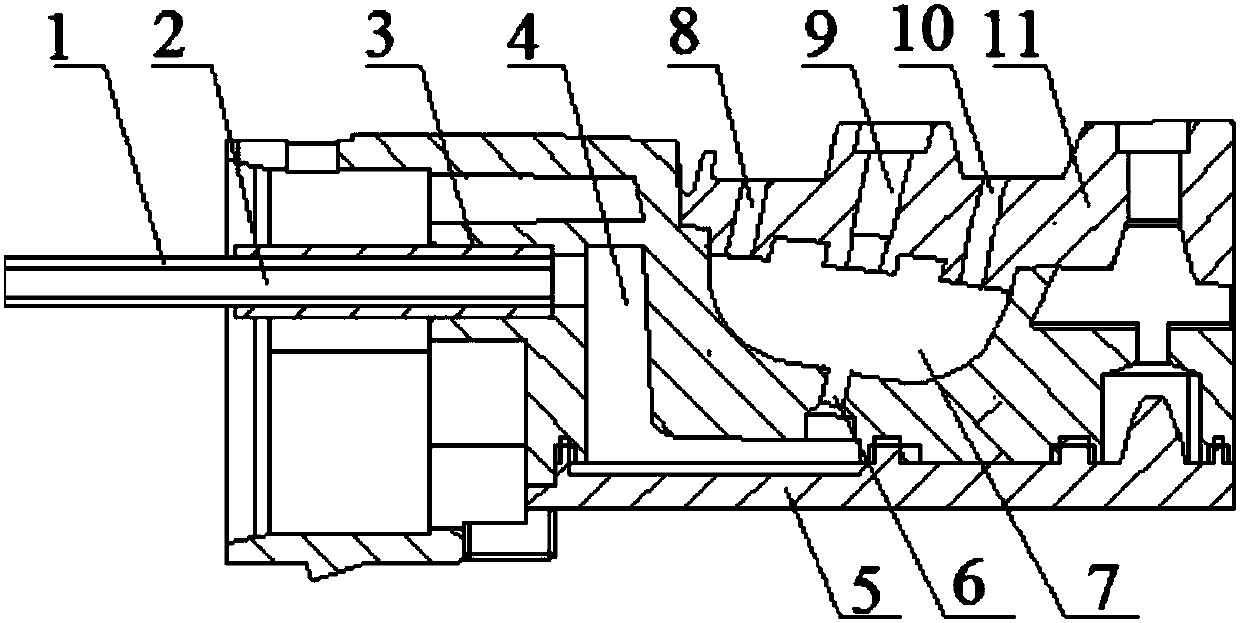

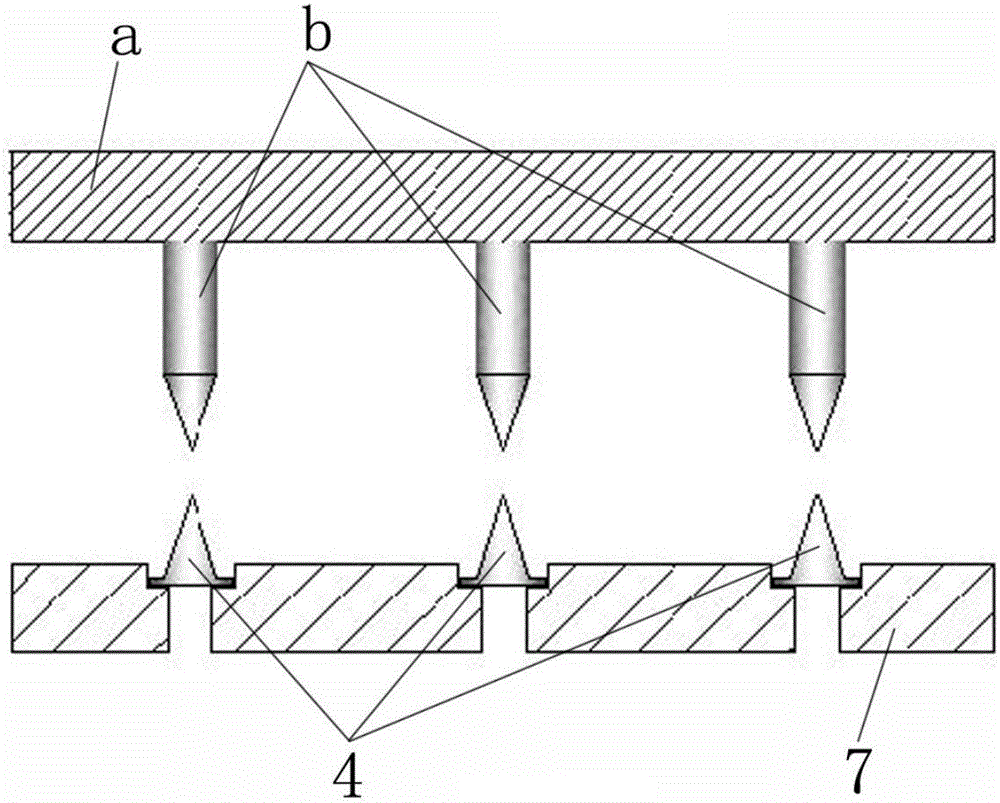

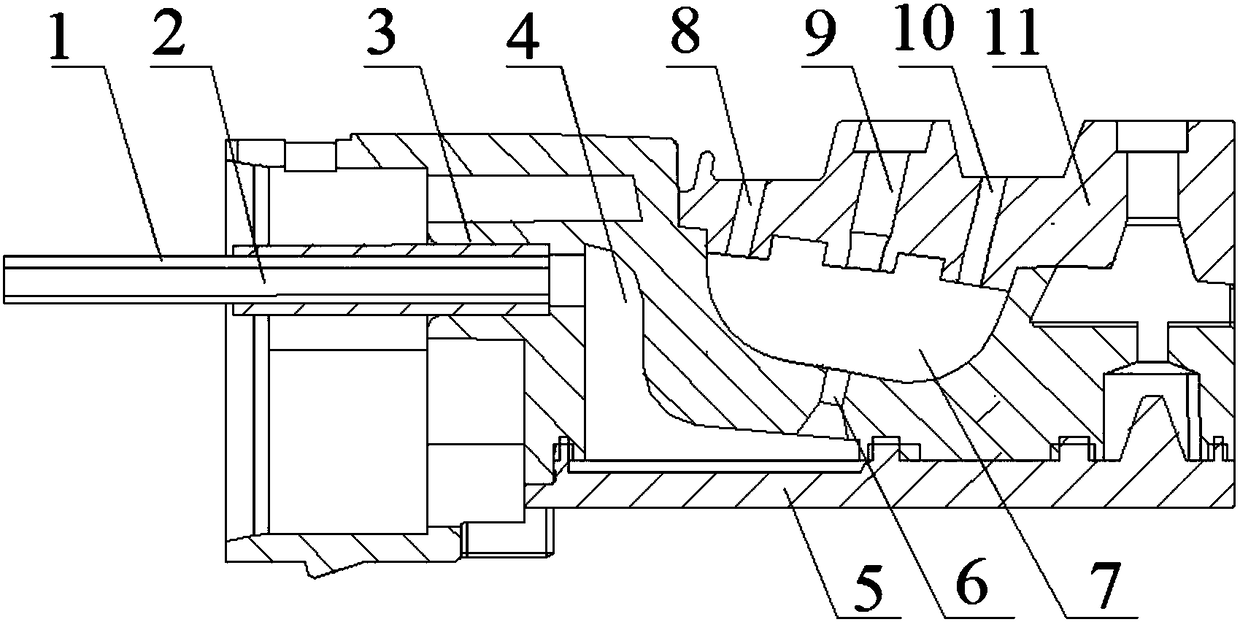

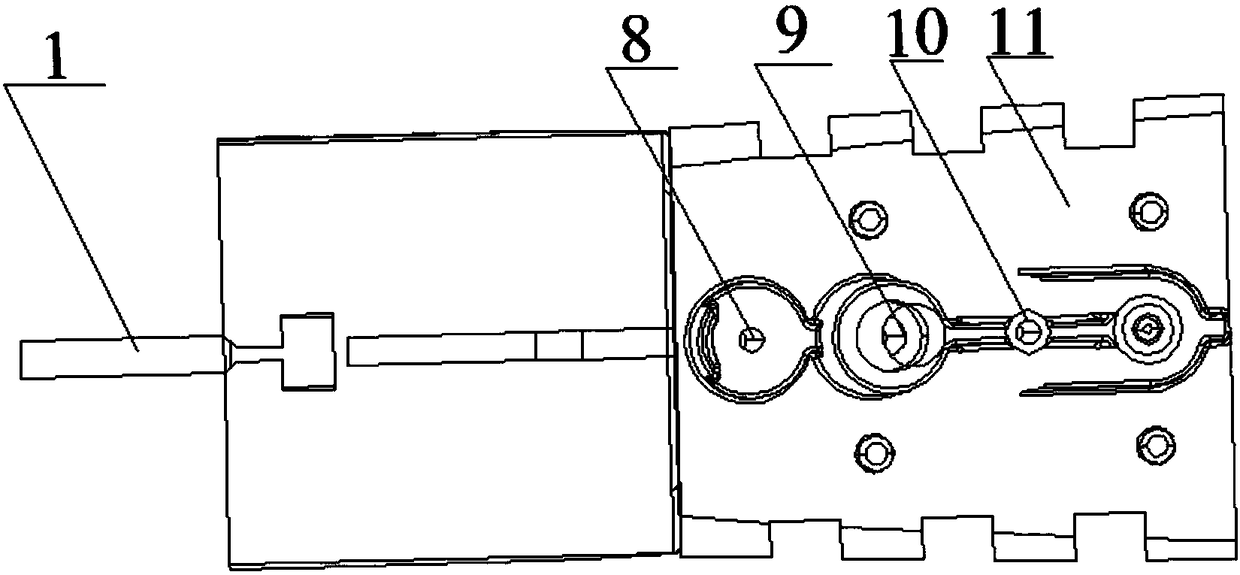

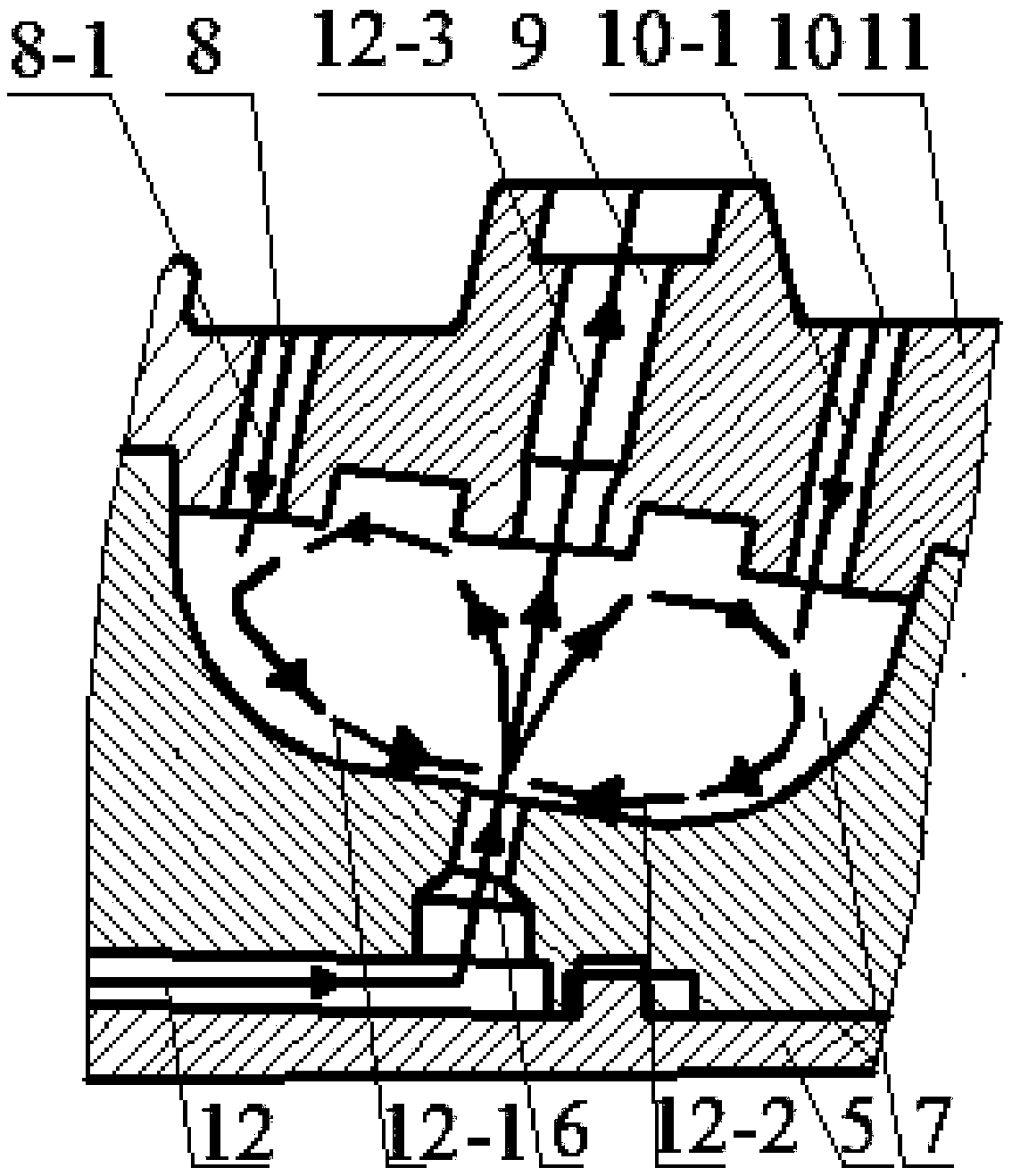

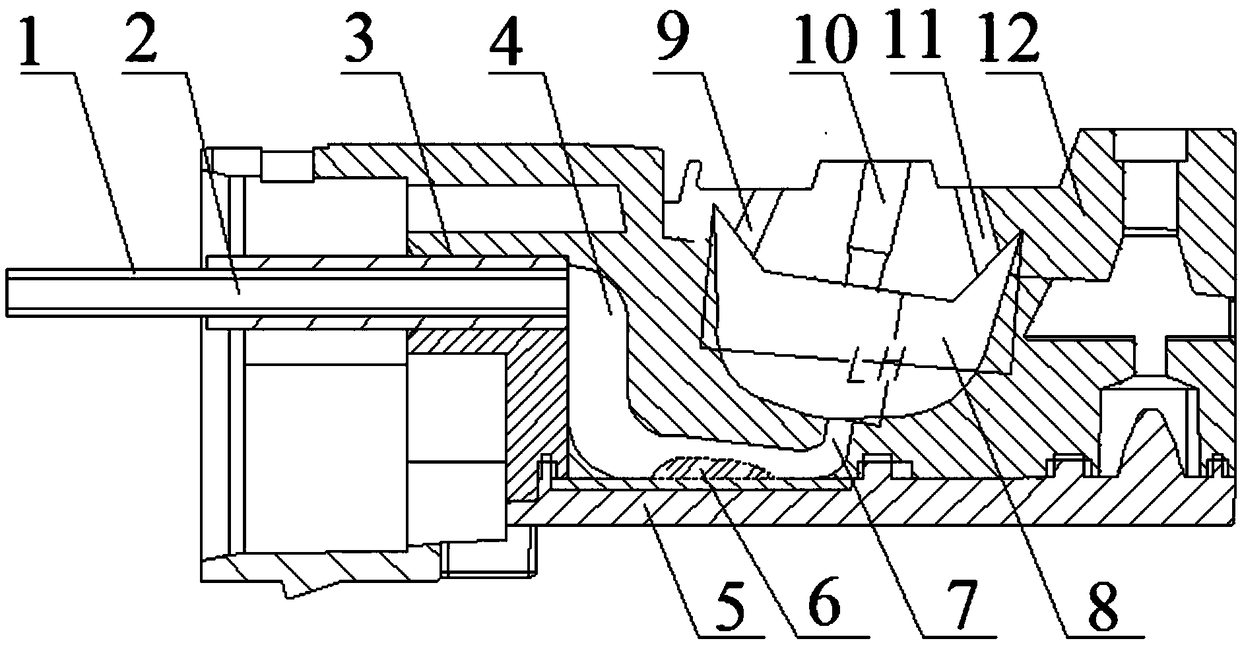

Jet micro-needle injection system

The invention relates to the technical fields of medical cosmetic apparatuses and medicine injection, and in particular to a jet micro-needle injection system. The jet micro-needle injection system comprises a medicine tube, a piston and a push rod, wherein both the piston and the push rod are arranged in the medicine tube; the piston is connected to the front end of the push rod, and the piston gets into sealed sliding contact with the inner wall of the medicine tube; and a soluble micro-needle is arranged in an injection port at the front end of the medicine tube. When the injection system is used for conducting injection, the soluble micro-needle is pierced into skin to form a small transdermal hole in the skin firstly, then medicine liquid in the medicine liquid, under push force of the push rod which is pushed, forms a medicine jet flow, and finally, medicines, in the form of the jet flow, are dissolved by virtue of the soluble micro-needle and are applied subcutaneous tissues from the opened small hole. The injection system is safer to use, and the injection system can conduct transdermal injection at a relatively low jet speed.

Owner:游学秋

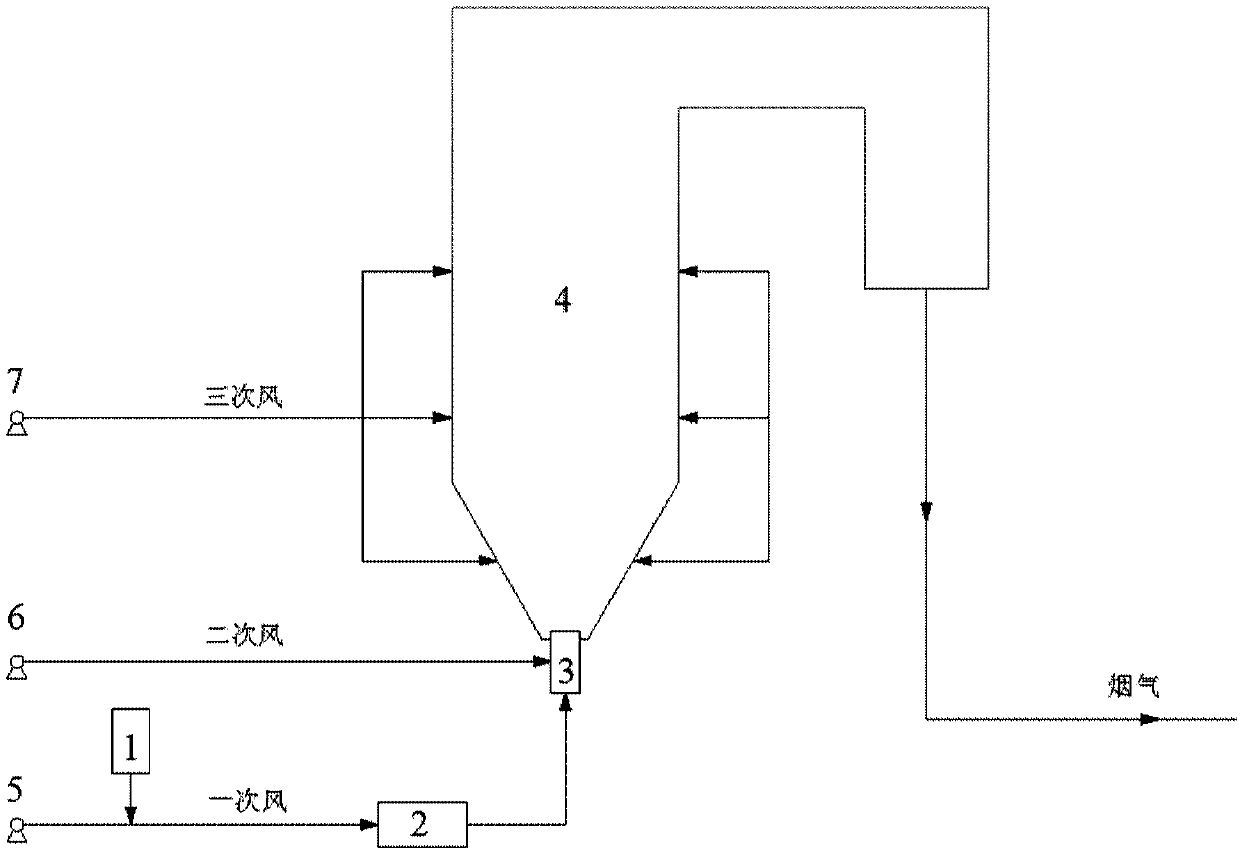

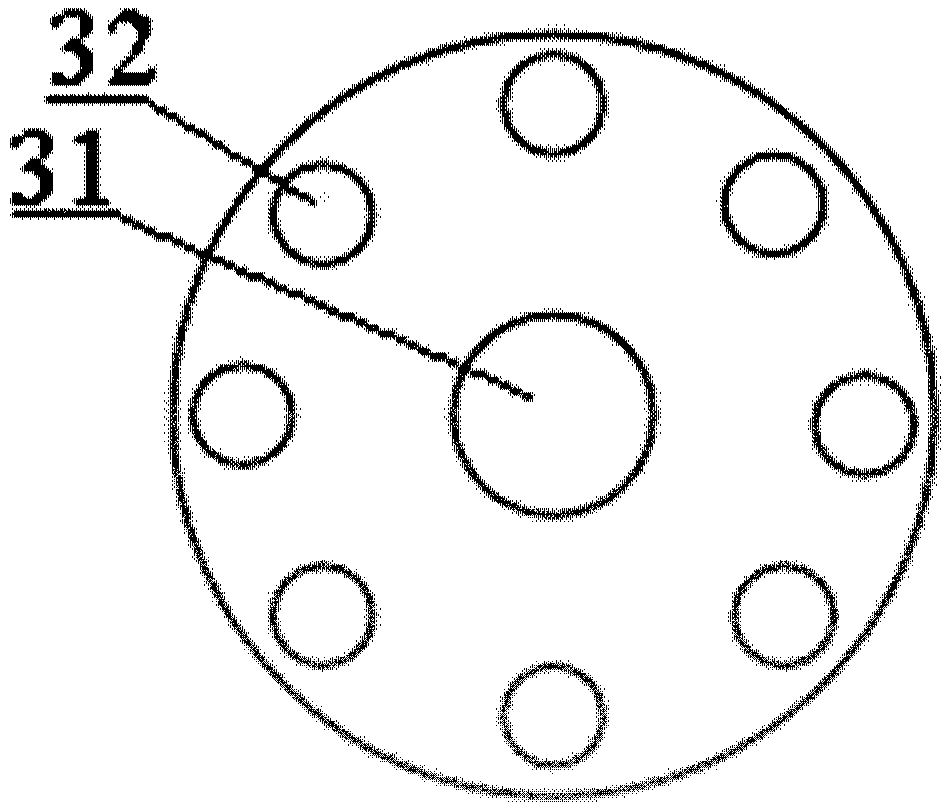

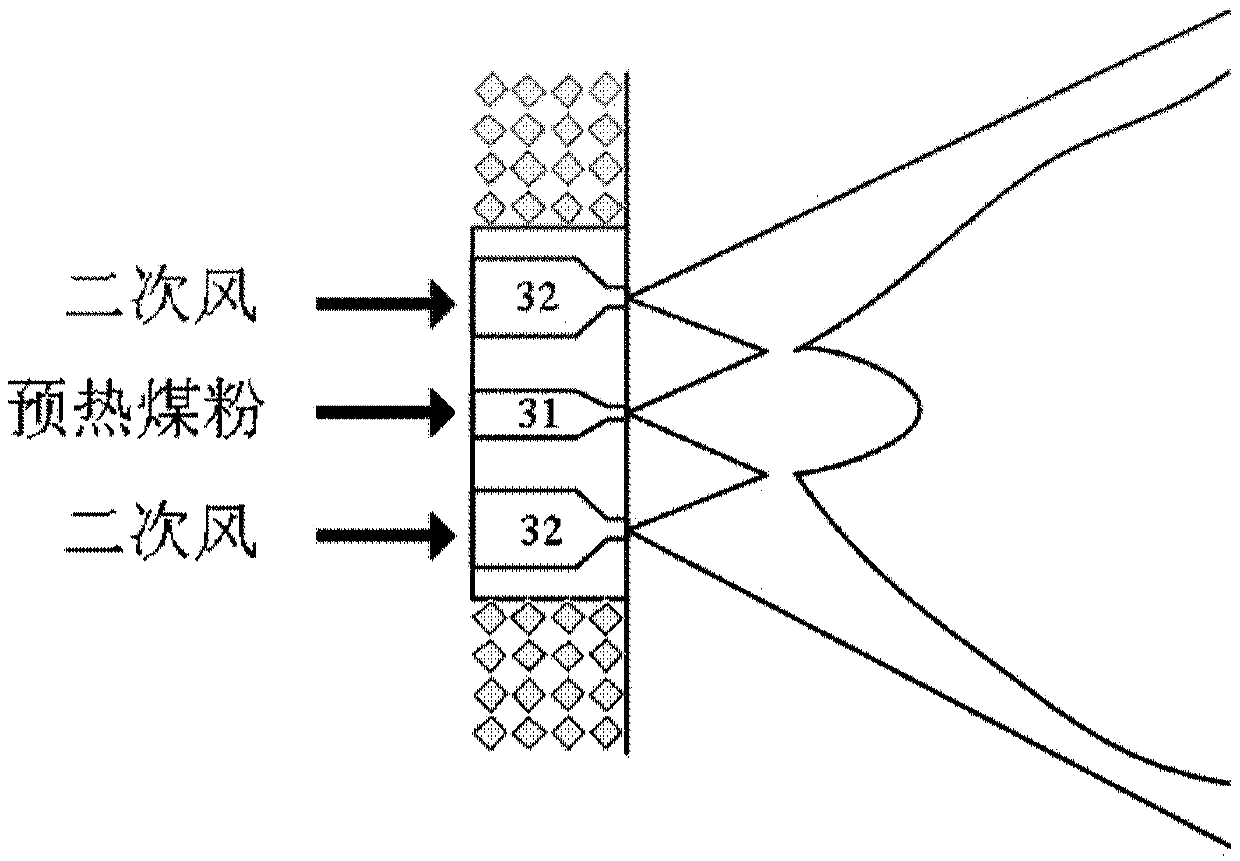

Pulverized coal flameless combustion system and method

InactiveCN110307538AReduce jet velocityReduce pressure headPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCoalPower consumption

The invention provides a pulverized coal flameless combustion system and method. The system comprises a hearth body and a pulverized coal preheater, wherein the hearth body comprises a pulverized coalflameless burner arranged at the bottom of the hearth body and tertiary air nozzles which are divided into at least two layers in the axial direction of the hearth body and arranged on the side wallof the hearth body, the pulverized coal flameless burner comprises a preheating fuel nozzle and a plurality of secondary air nozzles, and the pulverized coal preheater is connected to the preheating fuel nozzle and used for preheating pulverized coal and conveying the preheated pulverized coal to the pulverized coal flameless burner. The invention further provides the pulverized coal flameless combustion method using the system. By means of preheating fuel and grading air distribution, uniform flameless combustion is realized, the secondary air injection speed can be reduced, and fan pressurehead and power consumption can be reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Water spouting device for toilet

InactiveCN108240023ASimple structurePromote productionFlushing devicesLavatory sanitoryGas mixingToilet

The invention provides a water spouting device for a toilet. The water spouting device comprises a spray head fixing device, a chassis and an upper cover, wherein the chassis is arranged on the lowerend surface of the spray head fixing device, and a cavity formed between the spray head fixing device and the chassis is a water supply room; the upper cover is arranged on the upper end surface of the spray head fixing device, and a cavity between the spray head fixing device and the upper cover is a gas mixing room; the gas mixing room and the water supply room are communicated through a throttle pipe; the upper cover is provided with a first gas suction pipe, a second gas suction pipe and a gas mixing pulse nozzle penetrating through the gas mixing room; the spray head fixing device is provided with a water inlet channel; and the water inlet channel is communicated with the water supply room. In the invention, a gas mixing pulse jet flow can be generated perfectly, the same aim of cleaning can be achieved by using little water, and the electric quantity for heating water is reduced.

Owner:JIANGSU UNIV

Spraying device for intelligent toilet

The invention belongs to the field of wet-jet cleaning device and provides a spraying device for an intelligent toilet. The spraying device comprises a spraying device body and a water inlet pipe, andthe spraying device body is internally provided with an elbow-shaped water supply pipe, a throttling pipe, an air mixing chamber, an air suction pipe A, an air mixing pulse nozzle and an air suctionpipe B. The water inlet pipe is communicated with one end of the elbow-shaped water supply pipe, and the other end of the elbow-shaped water supply pipe is communicated with the bottom end of the throttling pipe which is a straight pipe. The air mixing chamber is positioned above the throttling pipe, the top end of the throttling pipe is communicated with the bottom end of the air mixing chamber,and inclined jet flow can be generated and ejected into the air mixing chamber. The top end of the air mixing chamber is communicated with the air mixing pulse nozzle, and the air suction pipe A and the air suction pipe B are positioned on two sides of the air mixing pulse nozzle respectively. The elbow-shaped water supply pipe comprises a bent elbow section A, a bent elbow section B, a linear shrinkage section and a bent elbow shrinkage section in sequential communication arrangement. The spraying device has advantages that air mixing pulse jet flow can be well generated, and identical cleaning effects can be achieved under low water consumption.

Owner:JIANGSU UNIV

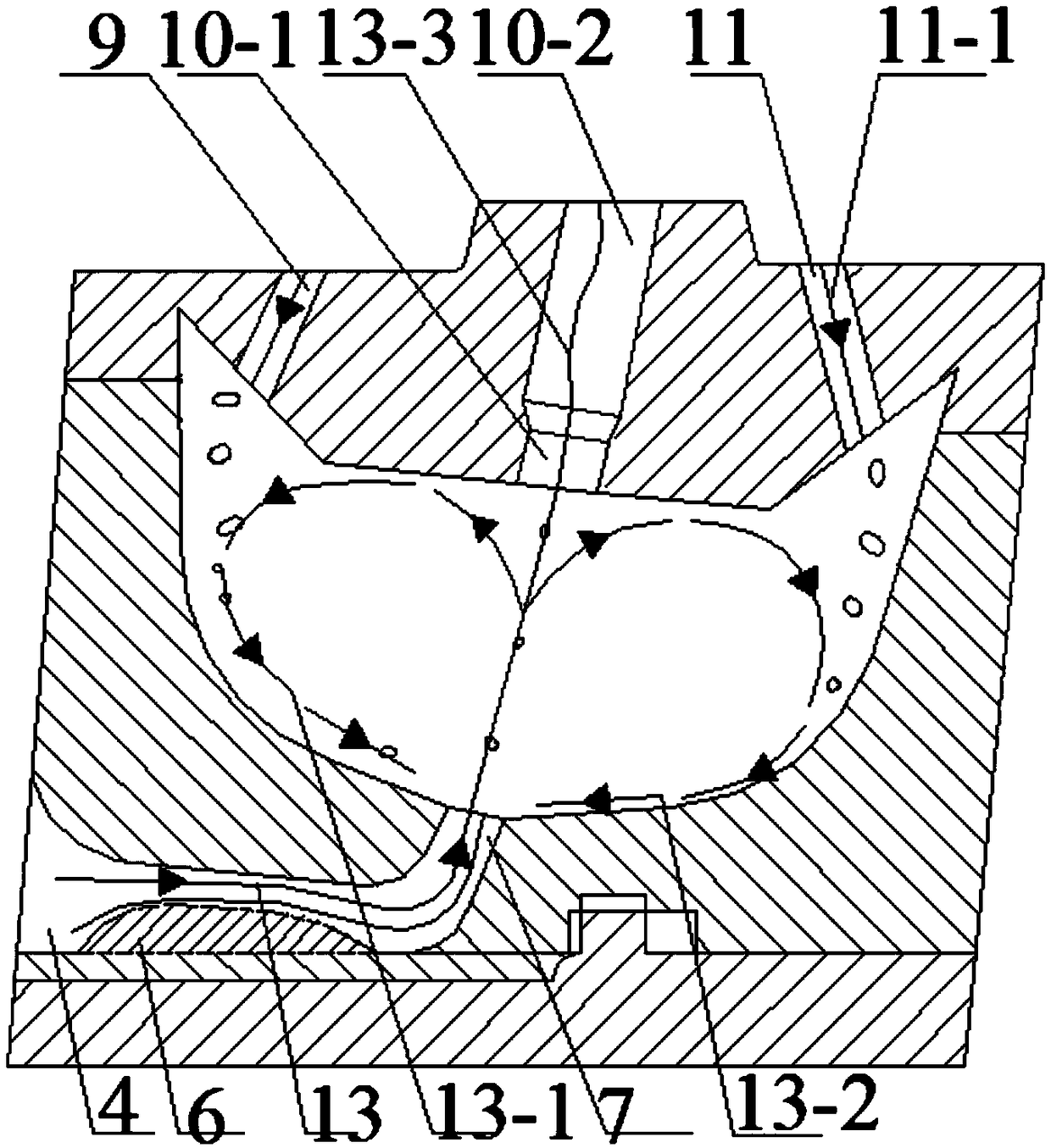

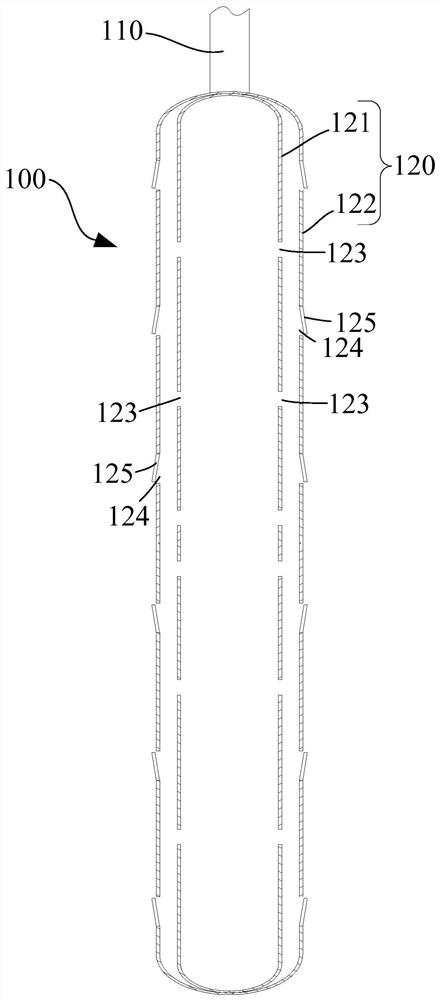

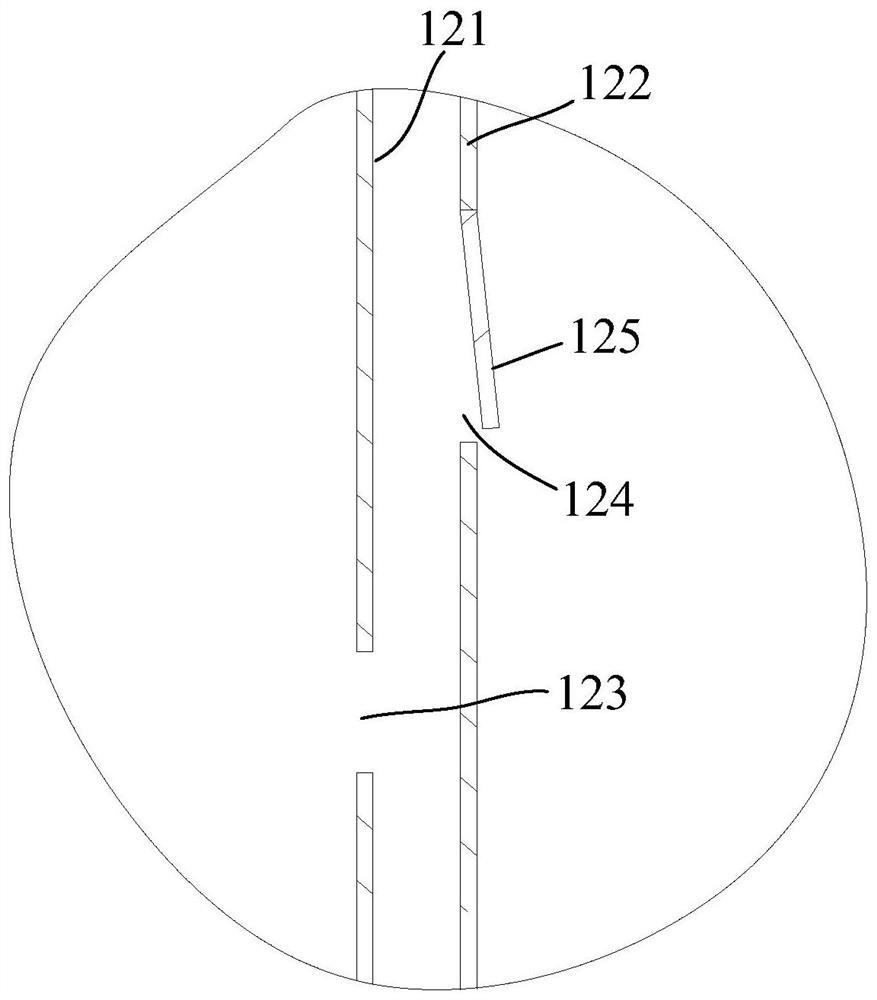

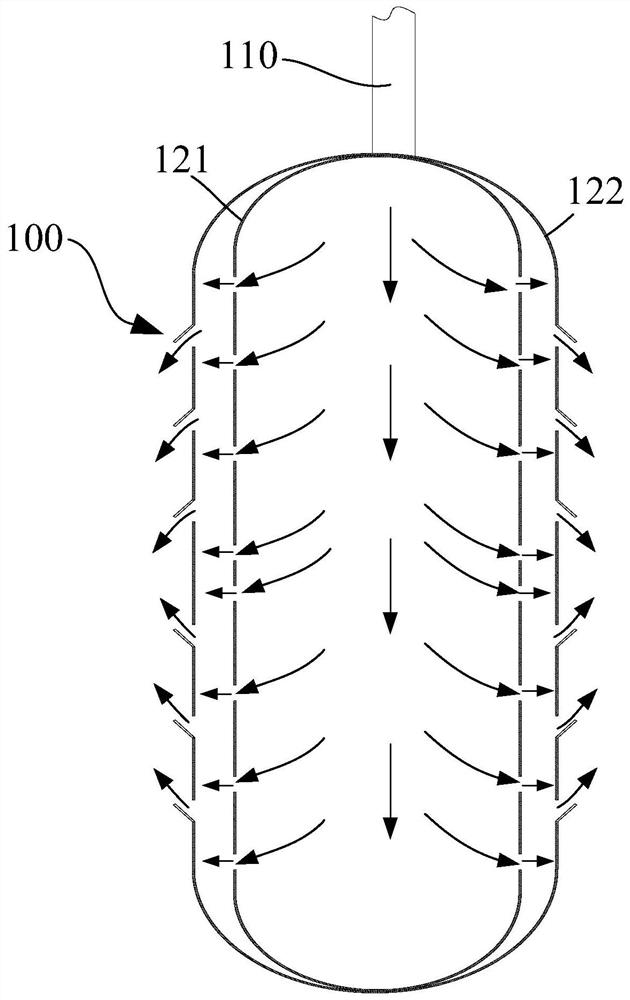

Novel coke tower and needle coke production method

ActiveCN105733650AReduce jet velocityAvoid radial maldistributionThermal non-catalytic crackingProcess engineeringMechanical engineering

The present invention relates to a novel coke tower and a needle coke production method. The coke tower includes a cylinder, an upper end socket and a lower end socket. The upper end socket is provided with a decoking port; the cylinder is provided with a coking segment and a filler segment; a baffle plate is between the coking segment and the filler segment; a feed inlet is arranged in the center of the baffle plate; the lower end socket is provided with an upper feed port and a lower feed port; the upper feed port communicates with the feed inlet of the baffle plate through a feed tube; and the lower feed port communicates with the filler segment. The invention also provides a needle coke production method, which employs the coke tower for production of needle coke. The needle coke prepared by the coke tower and process has strong needle texture structure.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mass flow increase at takeoff in supersonic airliner

InactiveUS8622339B2Reduce noiseReduce jet velocityEngine fuctionsAircraft power plant componentsJet aeroplaneNacelle

In a supersonic aircraft, turbojet engine nacelles each containing two remote fans in the front half of the nacelle, for noise reduction at takeoff. During supersonic flight, a front wedge at the nacelle nose achieves external compression of intake air. The wedge is vertical, sending the airflow left and right inside the nacelle along its side walls. The two flows follow mirror image curved paths on their way to a turbojet, leaving unused space between them to house the fans in tandem. For takeoff, clutches connected to the turbojets's compressors are engaged. Driveshafts turn pinions against a gear on the same shaft as the remote fans. The fan output is discharged backward under the nacelle to produce thrust. The energy to turn the fans is taken from the turbojet cycle. The reduced exhaust jet velocity decreases its noise. Supercharging produces the extra power to turn the remote fans if multistage.

Owner:KOSHELEFF PATRICK A

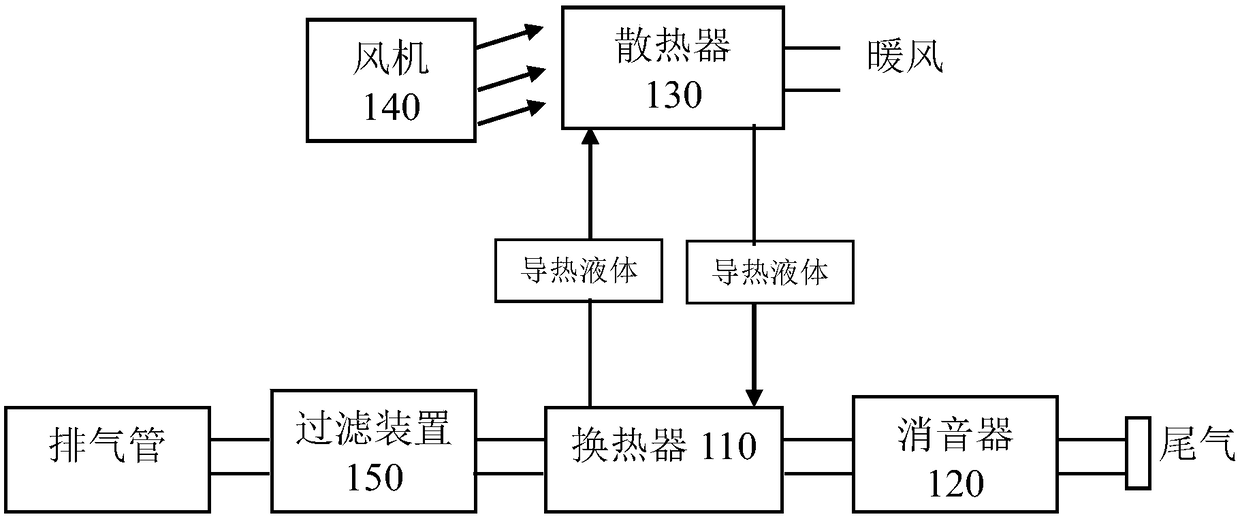

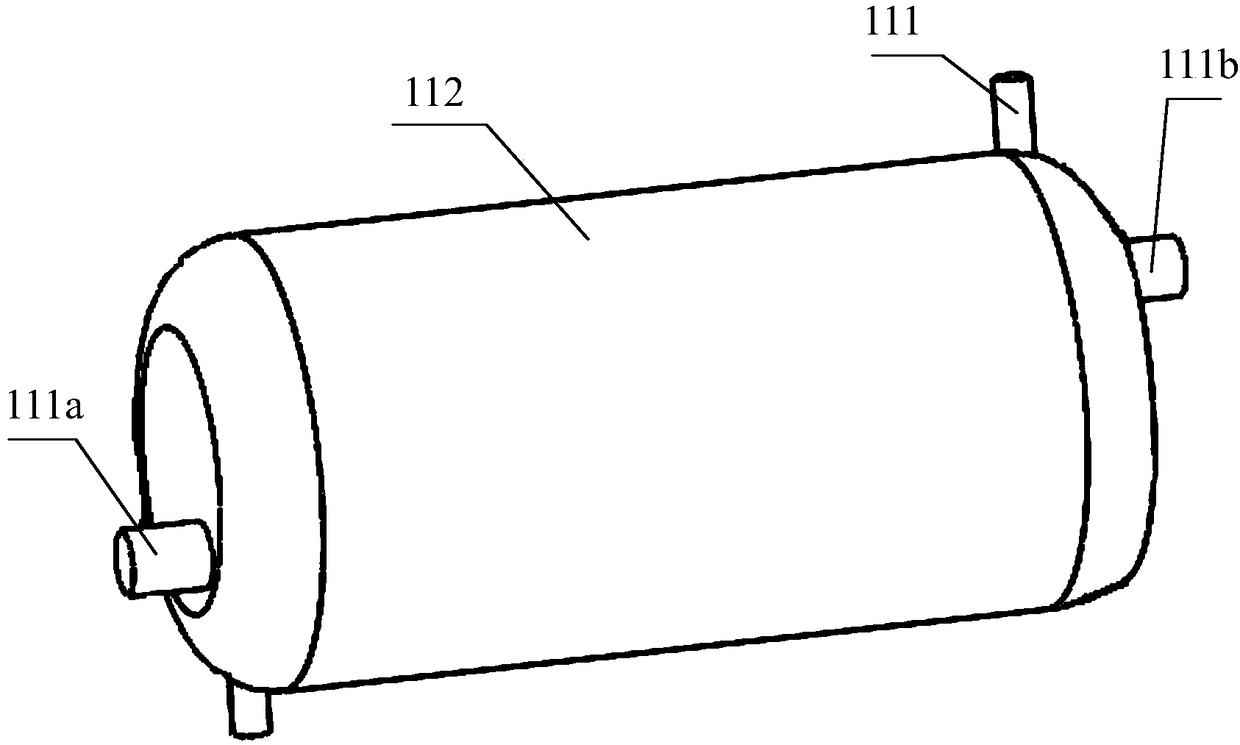

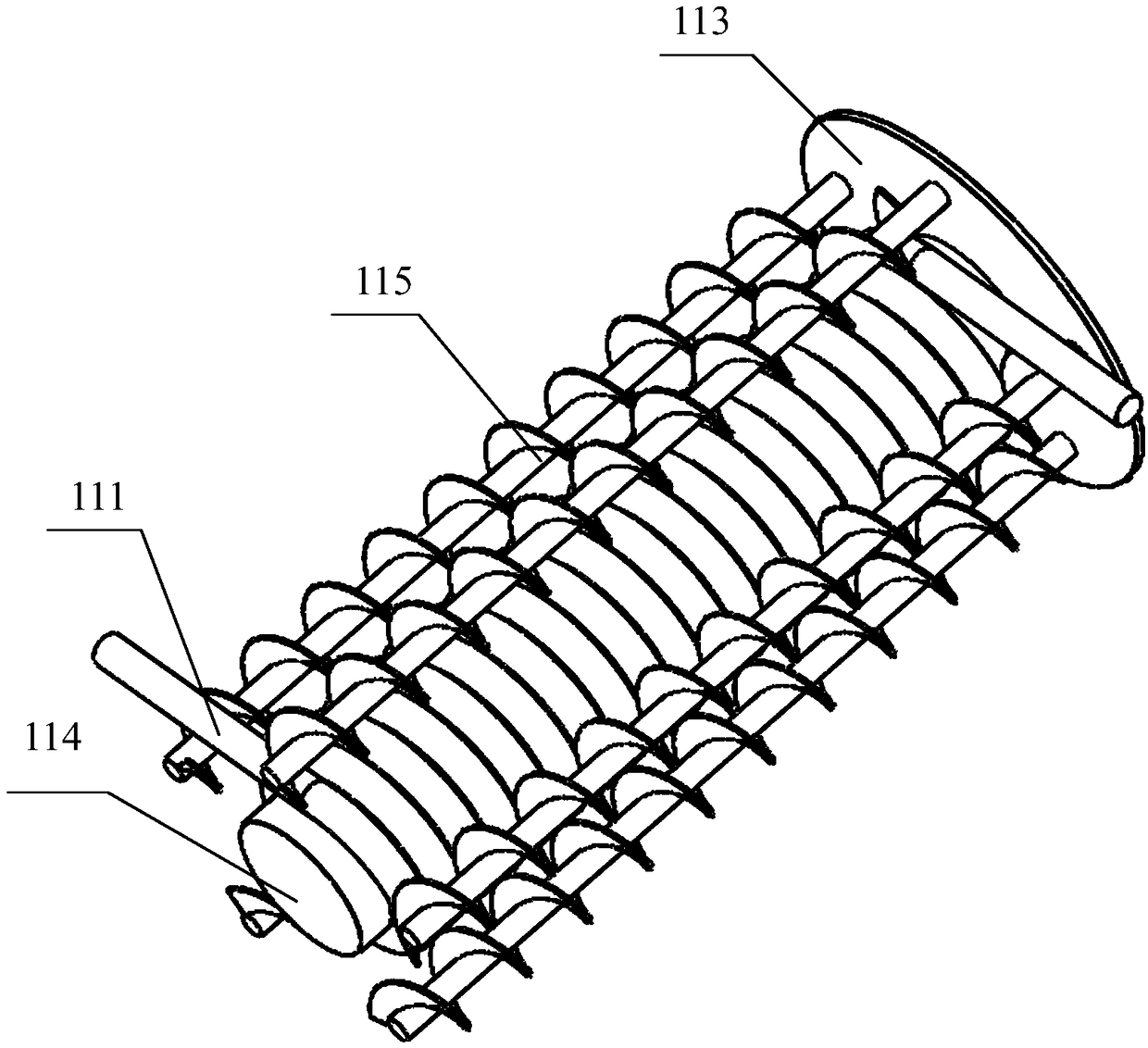

Residual heating device and control method thereof for exhaust of car

PendingCN108973595AExtended service lifeReduce jet velocityAir-treating devicesInternal combustion piston enginesHeat conductingEngineering

The invention discloses a residual heating device and a control method thereof for exhaust of a car , comprising: a heat exchanger, which comprises a heat exchange tube for accommodating a heat conducting liquid; A heat exchange cavity is sleeved on the outside of the heat exchange tube, and one end of the heat exchange cavity is connected with a bus exhaust pipe; A radiator communicating with theheat exchange tube, a water tank heating system communicating with the radiator, an engine cooling cycle system communicating with the radiator, and an engine coolant capable of circulating heating between the radiator and the engine; A fan arranged on one side of the radiator for blowing hot air into the bus for heating; A controller is arranged between the heat exchanger and the radiator, and communicates with the water tank heating system and the engine cooling cycle system, The invention also provides the control method thereof for exhaust of the car.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY +1

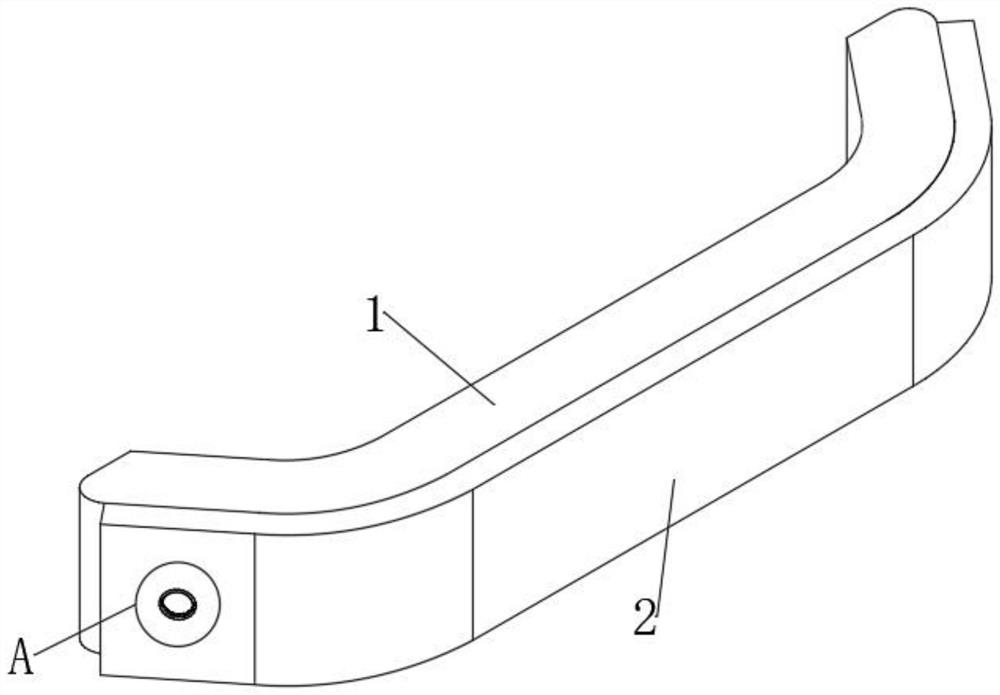

Self-damage type automobile bumper with protection function

ActiveCN112339690AReduce harmNot easy to hurtPedestrian/occupant safety arrangementBumpersControl theoryImpact

The invention discloses a self-damage type automobile bumper with a protection function, and belongs to the field of automobile bumpers. According to the self-damage type automobile bumper with the protection function, when an automobile running at a medium speed collides with pedestrians, large impact can be generated, and at the moment, the impact can cause breakage of a shell and breakage of aprefabricated groove of a ball chain, impact generated by impact is absorbed through breakage of the ball chain and the prefabricated groove, a through hole is also provided for the buffer ball through digging of the pressure relief hole, the buffer ball can be ejected out through the pressure relief hole under extrusion of external force, overall bursting of the pressure relief hole is avoided, and meanwhile in the process of the pressure relief hole in the ejection position of the buffer ball, friction between the buffering ball and the protection ball head reduces the spraying speed of thebuffering ball, the possibility of accidentally injuring pedestrians is greatly reduced, and energy generated by collision can be absorbed through damage of filler in the bumper in the medium-low-speed driving process of the automobile and when a collision accident with the pedestrians occurs, so that the impact force between the automobile and the pedestrians is reduced.

Owner:江苏永成汽车零部件股份有限公司

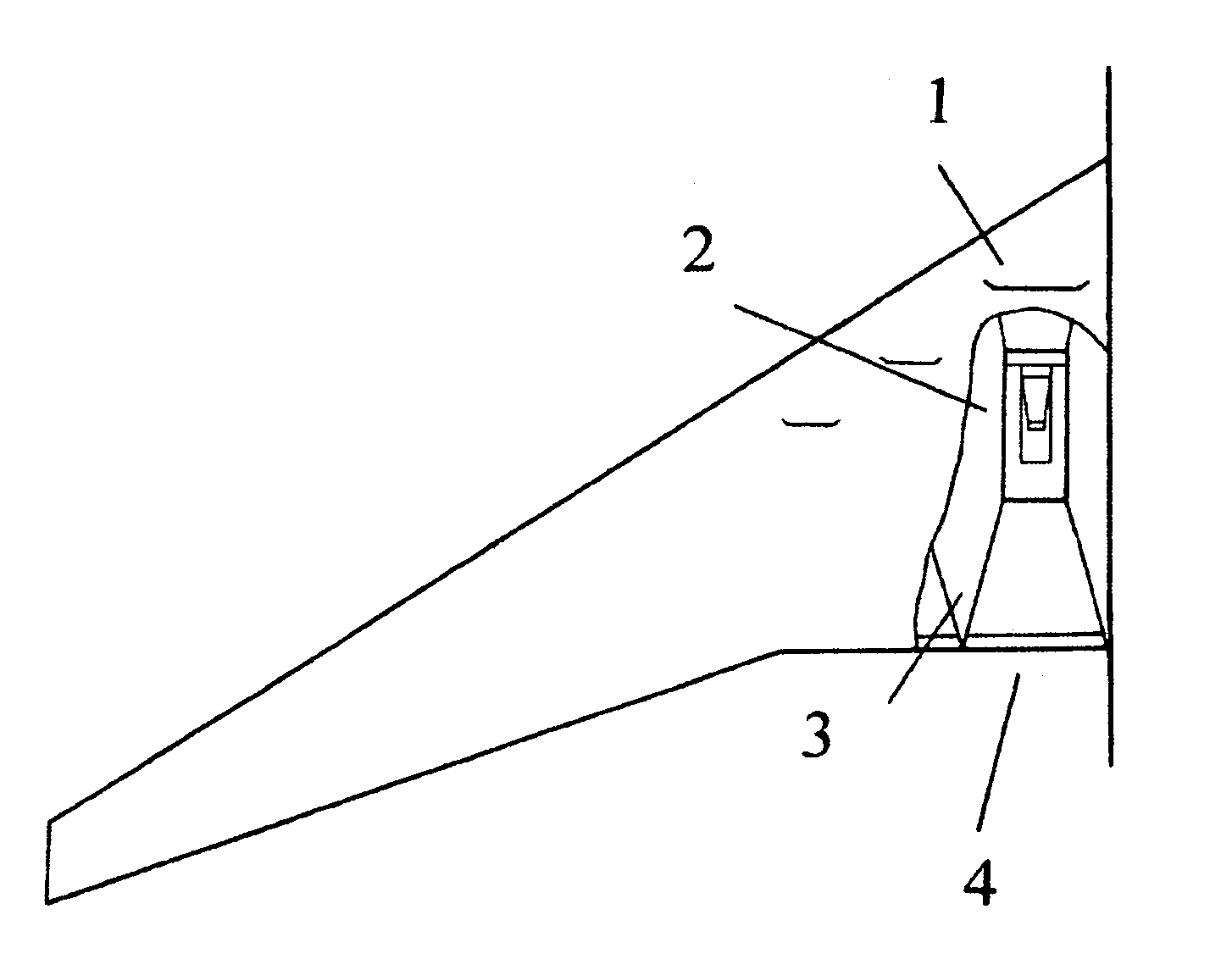

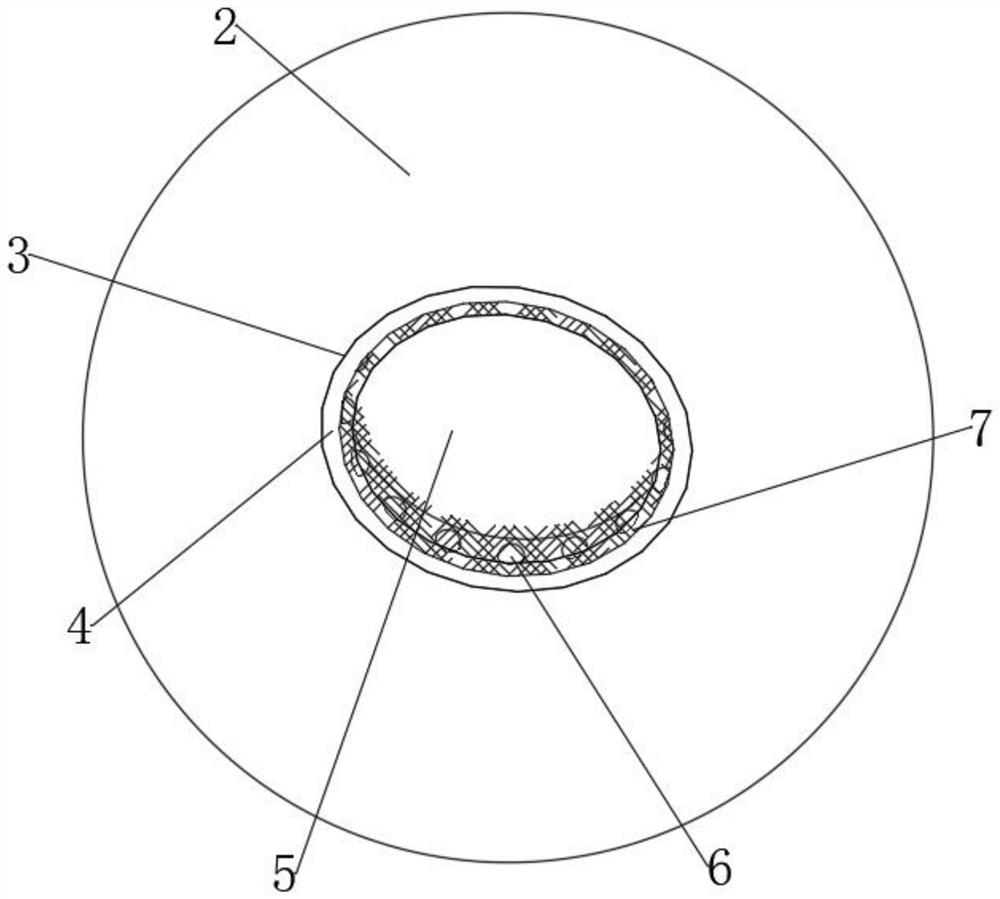

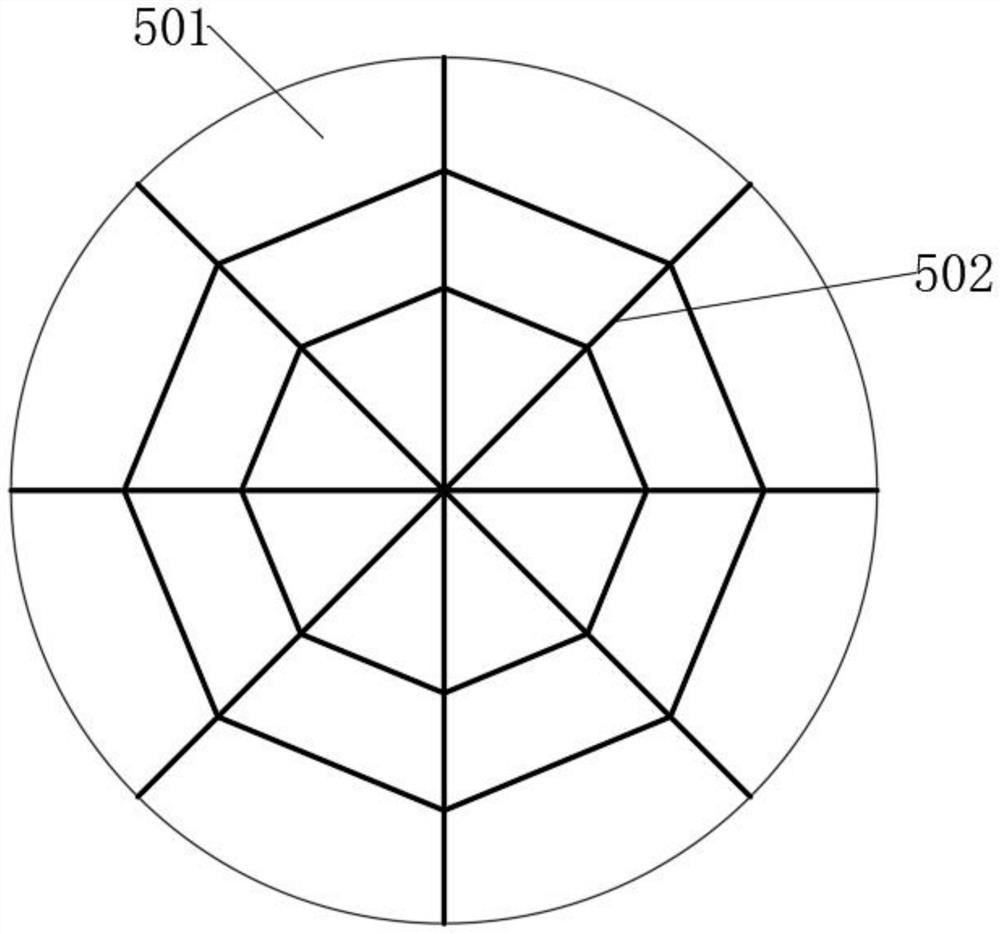

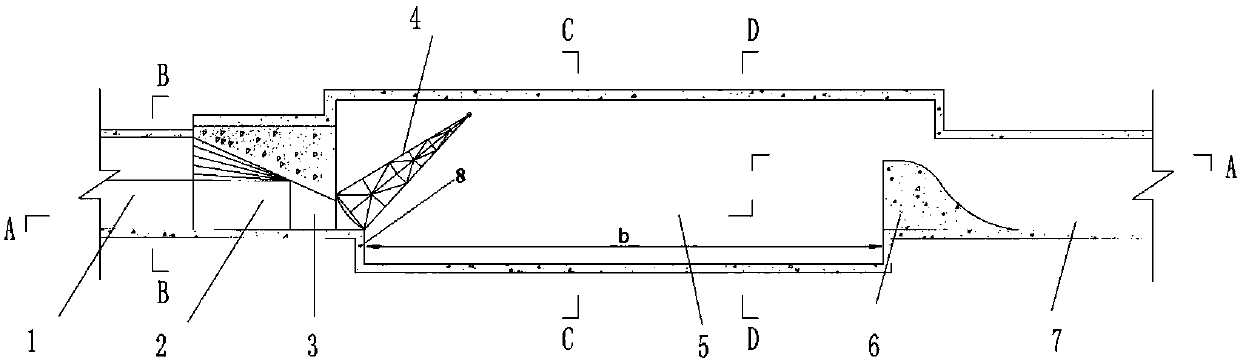

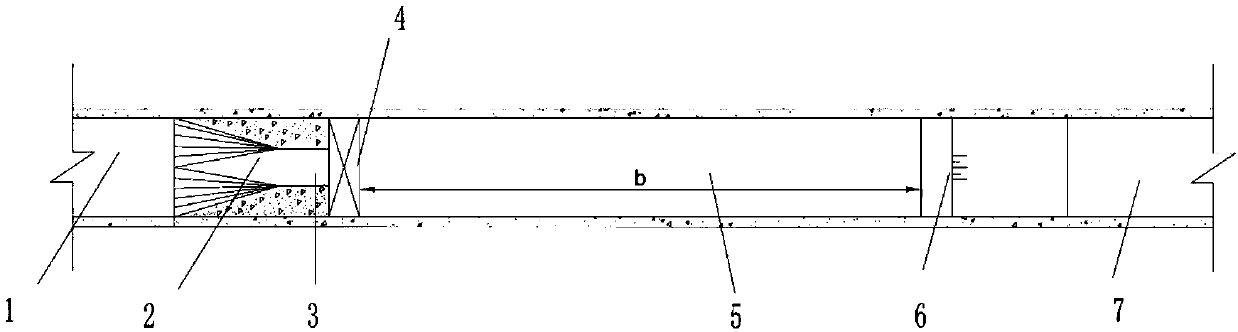

In-tunnel weak pressure sudden dropping and sudden expansion type jet flow stilling pool energy dissipation system

An in-tunnel weak pressure sudden dropping and sudden expansion type jet flow stilling pool energy dissipation system is composed of a jet flow hole section connected with an upstream tunnel section, a drop sill arranged at an outlet of the jet flow hole section, a low-pressure stilling pool connected with the drop sill, and a tail sill connected with the tail of the low-pressure stilling pool and a downstream tunnel section from the upstream section to the downstream section in sequence. A gate matched with jet flow hole outlets is arranged at the outlet of the jet flow hole section and located above the drop sill. The jet flow hole section is provided with at least one jet flow hole, and the jet flow holes are formed by connecting a contraction type transition section with a pressing slop section in the water flow direction. In the formula d=(1.3-1.5)X, wherein d is the height of the low-pressure stilling pool, and X is the height of an upstream tunnel. Through the in-tunnel weak pressure sudden dropping and sudden expansion type jet flow stilling pool energy dissipation system, the energy dissipation effect can be ensured, cavitation and cavitation erosion as well as bottom plate scouring can be avoided, meanwhile, the engineering excavated volume is decreased, and the safety and economical efficiency of engineering are improved.

Owner:SICHUAN UNIV

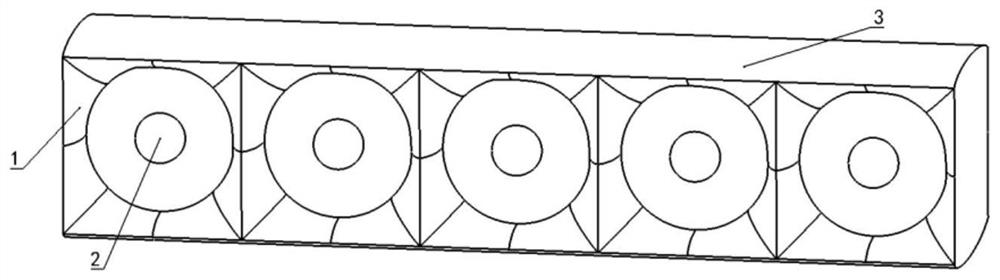

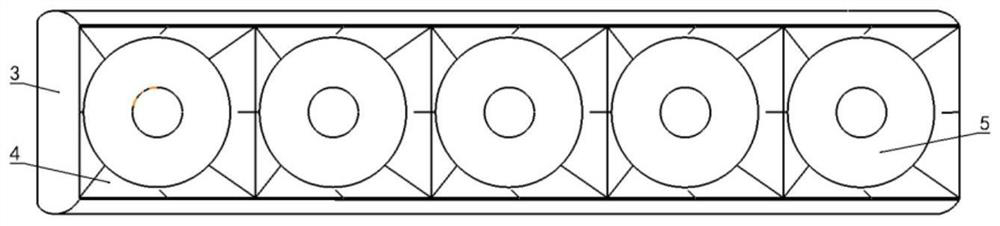

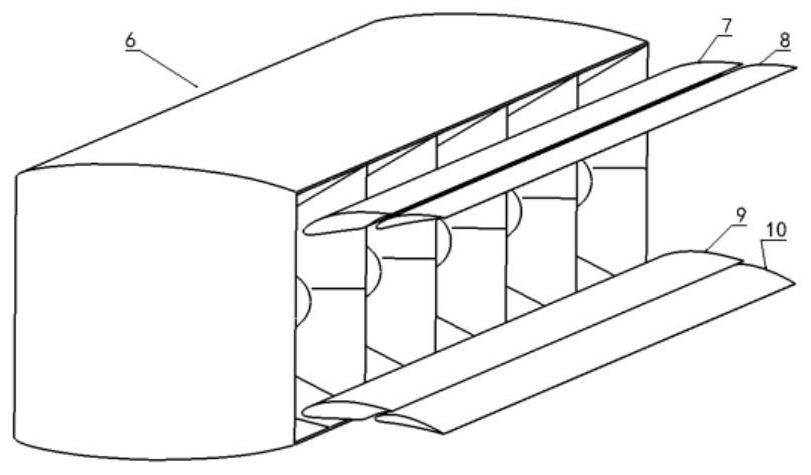

Distributed electric ducted fan power system for short-distance/vertical take-off and landing

ActiveCN112722243ASmooth and continuous shapeEasy to distribute and usePropellersAircraft controlAviationFlight vehicle

The invention discloses a distributed electric ducted fan power system for short-distance / vertical take-off and landing, and belongs to the field of aviation aircrafts. The system comprises a duct power unit, an upper high-lift airfoil and a lower high-lift airfoil, the duct power set comprises a plurality of duct power units which are arranged in parallel; the end faces of the two sides of the upper high-lift airfoil and the two sides of the lower high-lift airfoil are connected with steering engines installed on the fuselage through connecting rods and located above and below the outer side of an outlet of the duct power set correspondingly, and the rotating angles of the upper high-lift airfoil and the lower high-lift airfoil are controlled through the steering engines. The upper high-lift airfoil comprises an upper high-lift airfoil main wing and an upper high-lift airfoil flap, and the lower high-lift airfoil comprises a lower high-lift airfoil main wing and a lower high-lift airfoil flap. By changing the deflection angle and form of the upper high-lift airfoil and the lower high-lift airfoil, the limitation of a power system on aerodynamic layout is reduced, and distribution and utilization of power in different stages such as take-off and landing and cruising are facilitated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

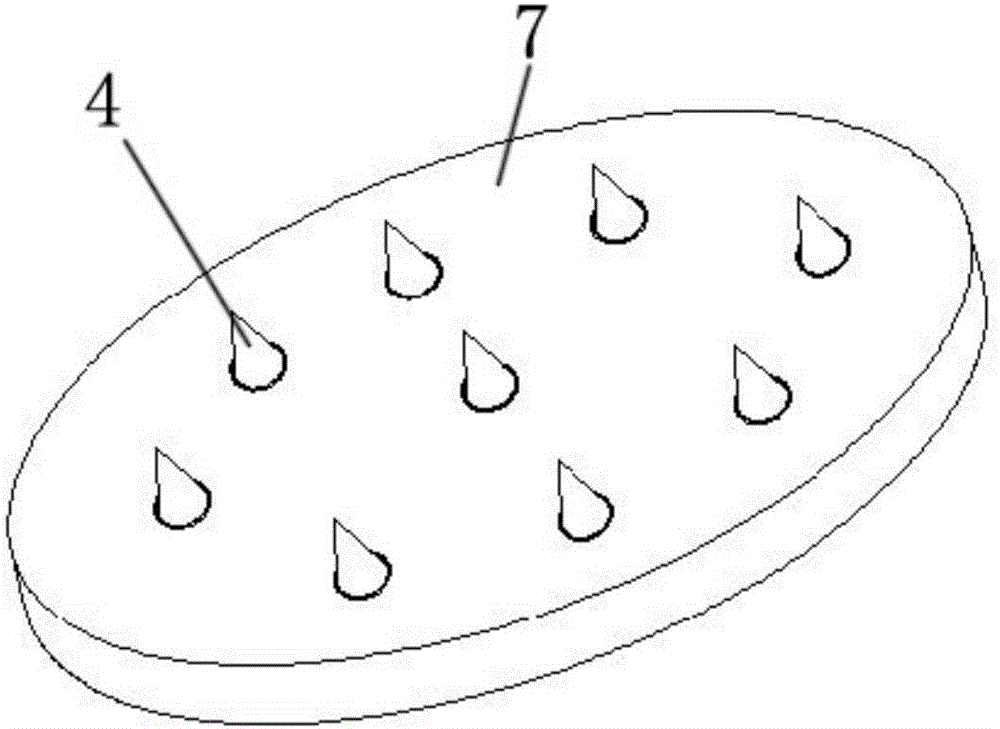

Balloon catheter and preparation method thereof

PendingCN113521505AReduce jet velocityChange spray directionBalloon catheterMedical devicesBlood vessel spasmBalloon dilations

The invention relates to a balloon catheter and a preparation method thereof. The balloon catheter comprises a catheter body and a balloon, the catheter body is sleeved with the balloon, the balloon comprises at least one first balloon, a plurality of first micropores are formed in the first balloon, and retaining walls are arranged at the first micropores; after the balloon is expanded, the retaining walls incline towards the corresponding first micropores so as to at least partially cover the first micropores, liquid medicine channels are reserved between the retaining walls and the first micropores, and the extending direction of the liquid medicine channels is not perpendicular to the longitudinal axis of the balloon catheter. The retaining walls are used for buffering liquid medicine, the spraying speed of the liquid medicine is reduced, the spraying direction of the liquid medicine is changed, and thus the stimulation effect of the liquid medicine on blood vessels is reduced, and vasospasm is reduced.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com