Patents

Literature

33results about How to "Full injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

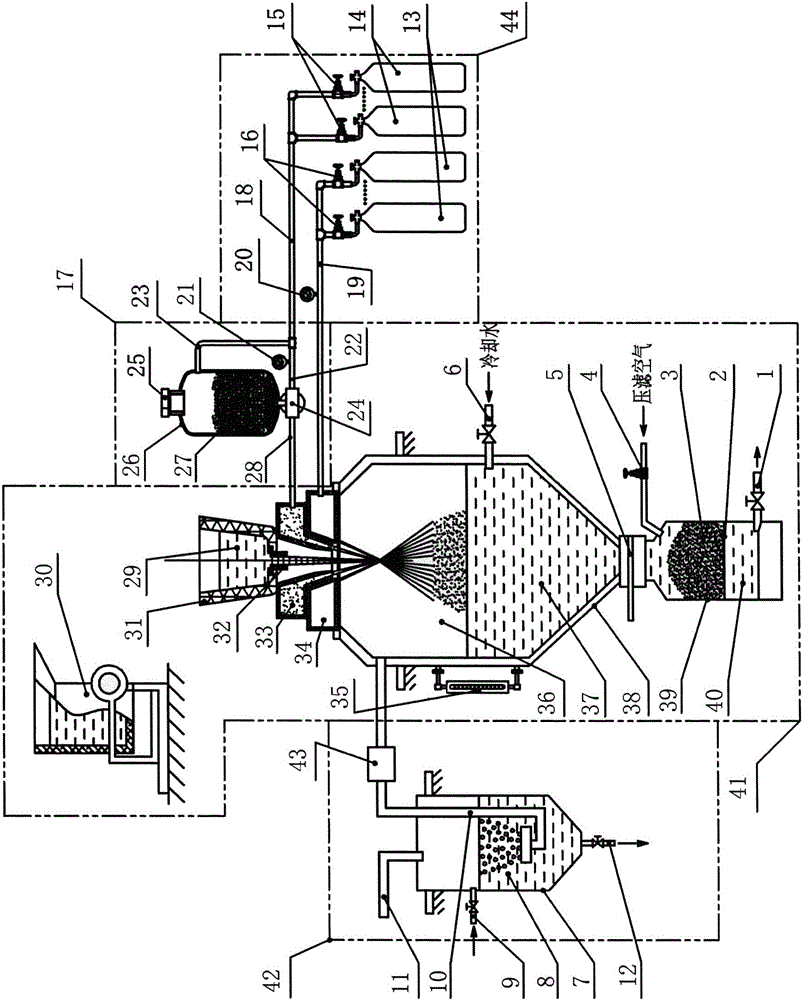

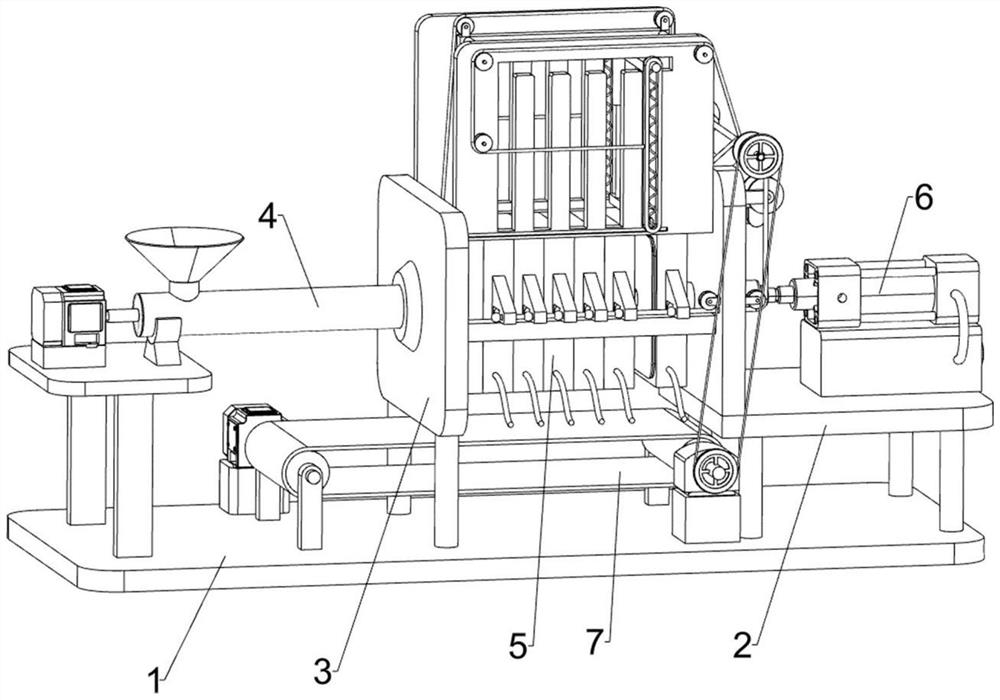

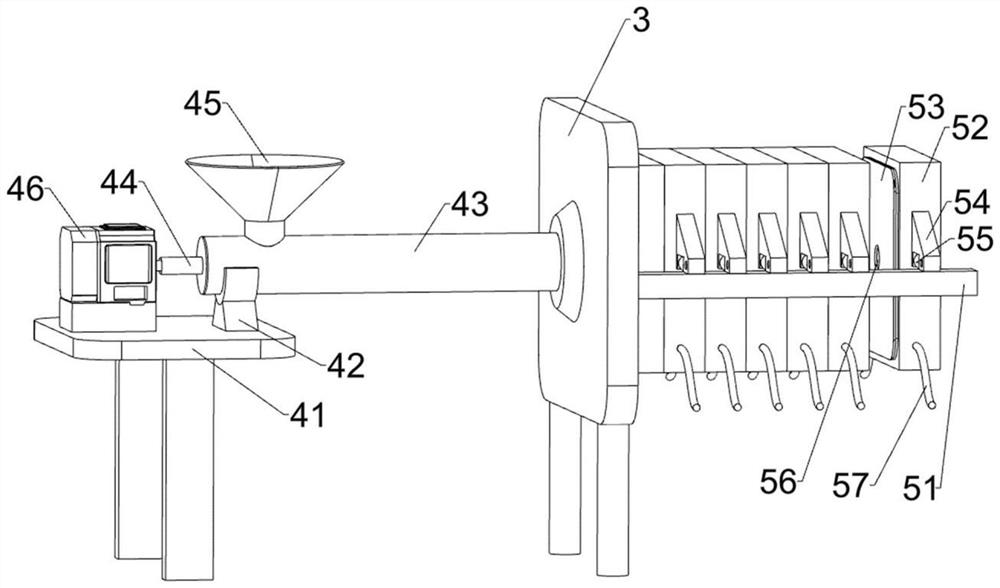

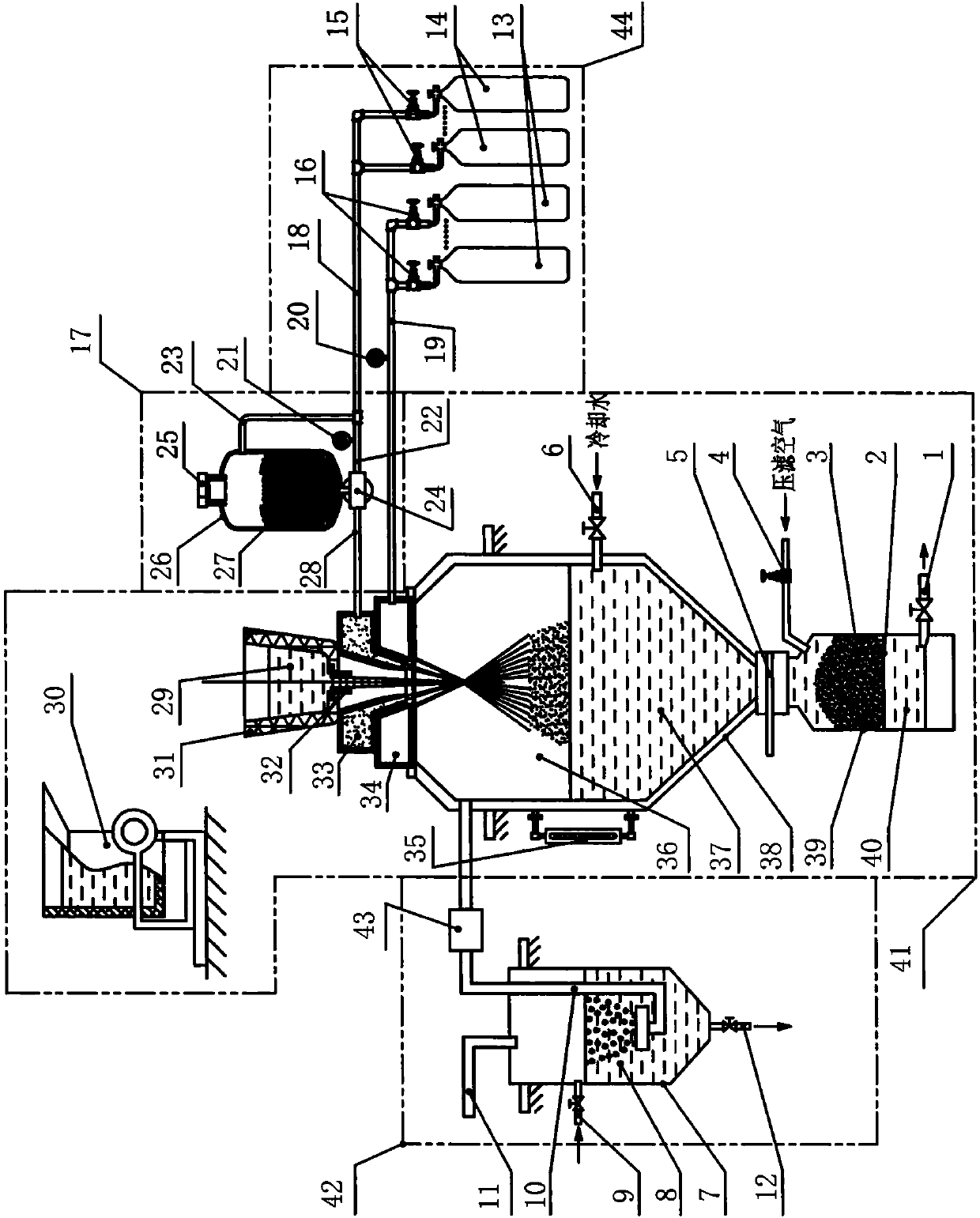

Free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing equipment

The invention provides free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing equipment which comprises a double-nozzle atomizing and water cooling device (41), a spiral mixed powder conveying device (17), a water seal dust removing device (42) and a gas station (44). In the atomizing process, a low-pressure mixed powder jetting nozzle and a high-pressure gas flow nozzle are adopted, and therefore the problem that when a single nozzle is used, erosive wear is caused is solved; a free-falling manner is adopted, and therefore the problems that erosive wear to a molten metal flow guide pipe is caused and molten metal flows back and is sprayed upwards are avoided; a cooling manner of water cooling and fast setting is adopted, the problem that hard abrasive particles drift away from a metal matrix and the problem of control over the depth of distribution are solved, and hard abrasive is controlled to be distributed on a surface shallow layer of the magnetic abrasive; meanwhile, the flight distance of powder mixed molten metal drops is shortened, and the overall height of the free-falling atomizing and condensing chamber and equipment is reduced. The equipment is new equipment provided for realizing a free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing method and preparing the high-performance magnetic abrasive.

Owner:SHANDONG UNIV OF TECH

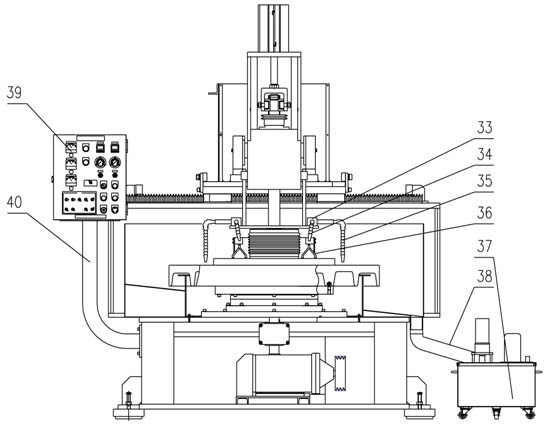

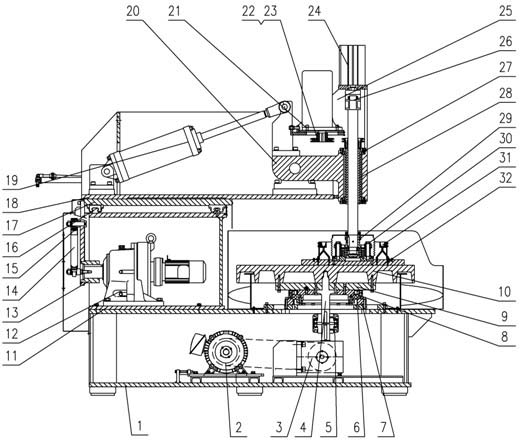

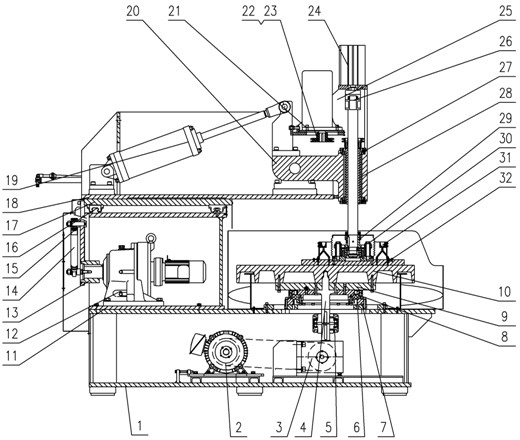

Down-attached single-side polisher

InactiveCN102303278AImprove processingImprove polishing efficiencyPolishing machinesElectric machinePolishing

A down-attached single-side polisher is disclosed, wherein a lower fixed disc capable of rotating within the horizontal plane is arranged in a lower body portion, and connected to a main motor on the bottom of the lower body through a supporting plate and a bearing; in addition, an absorption pad is further glued to the lower fixed disc; besides, liquid filling hoses on both sides and a middle liquid filling hose of an upper fixed disc are connected to an upper fixed disc structure by means of a three-way structure arranged thereon; a branch liquid filling hose is further arranged on the lower portion of the middle liquid filling hose; moreover, a shifting wheel and a shifting rod are further arranged on the upper portion of the upper fixed disc structure; the upper ends of the shifting wheel and the shifting rod are connected to a rotating motor and a tilting cylinder through a chain and a mounting base; simultaneously, a lifting cylinder is further connected to the upper portion of the upper fixed disc structure through a main shaft; and the lifting cylinder is capable of applying polishing pressure to the upper fixed disc through the main shaft. The down-attached single-side polisher is convenient to operate, and capable of processing glass products 1.5-2 times larger than the maximal dimension that can be processed in the past by means of the machine of the same dimension without affecting the processing accuracy.

Owner:湖南永创机电设备有限公司

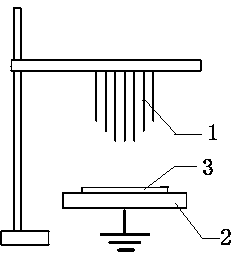

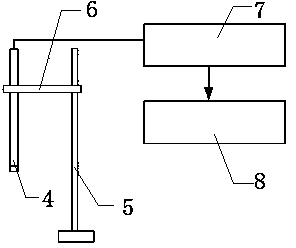

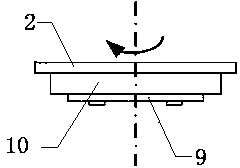

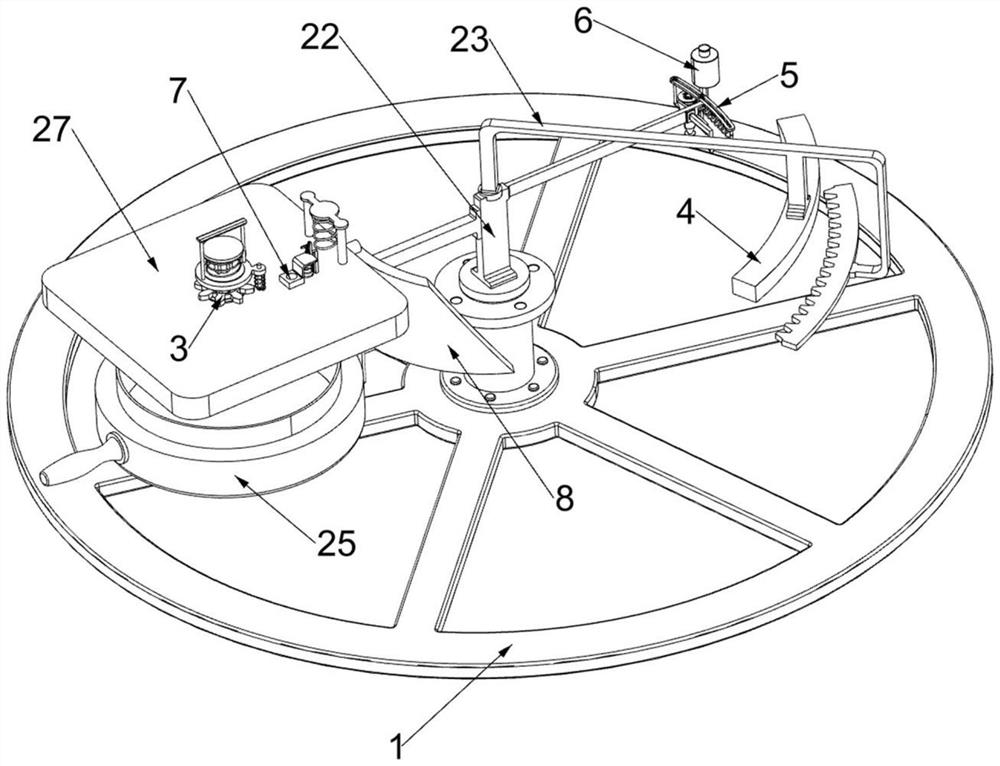

System for acquiring trap parameters of solid dielectric material

InactiveCN104198823AEasy to operateWide applicabilityResistance/reactance/impedenceNeedle electrodeMeasurement precision

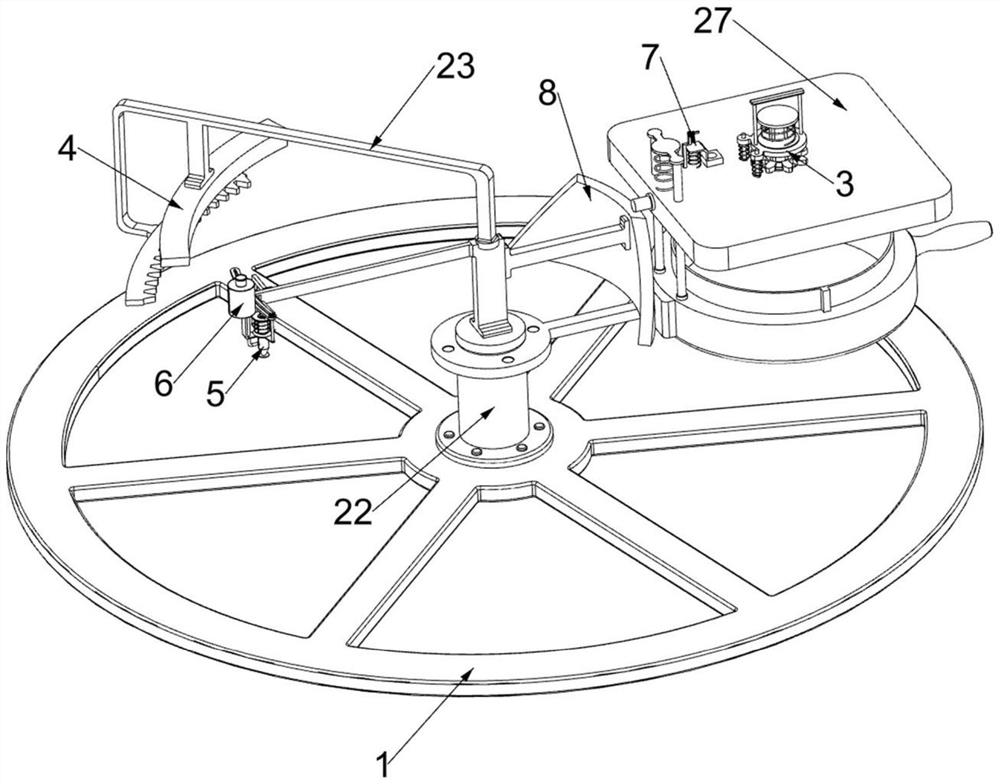

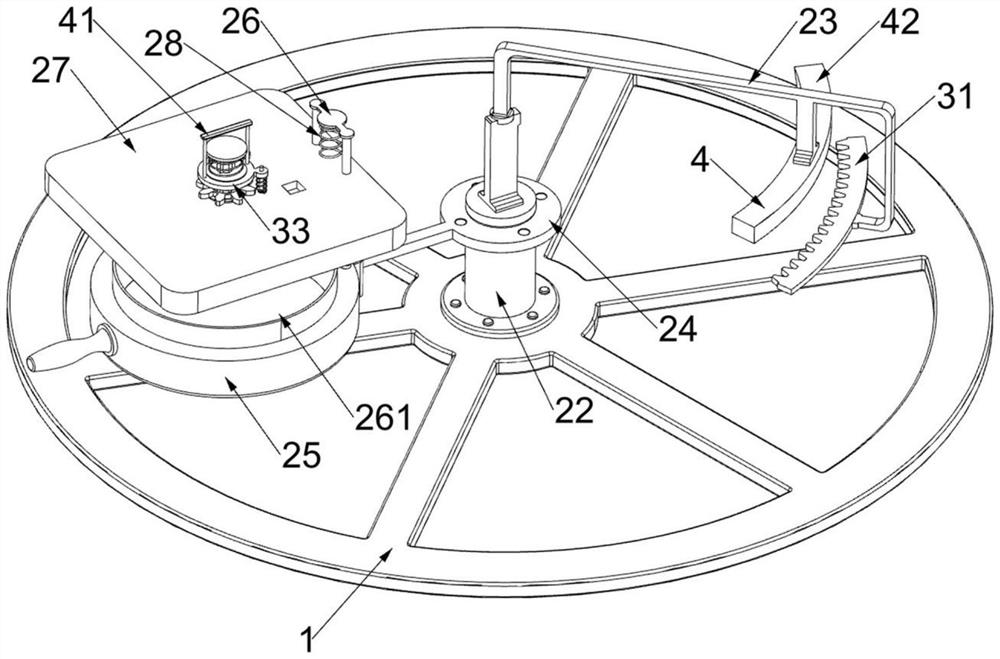

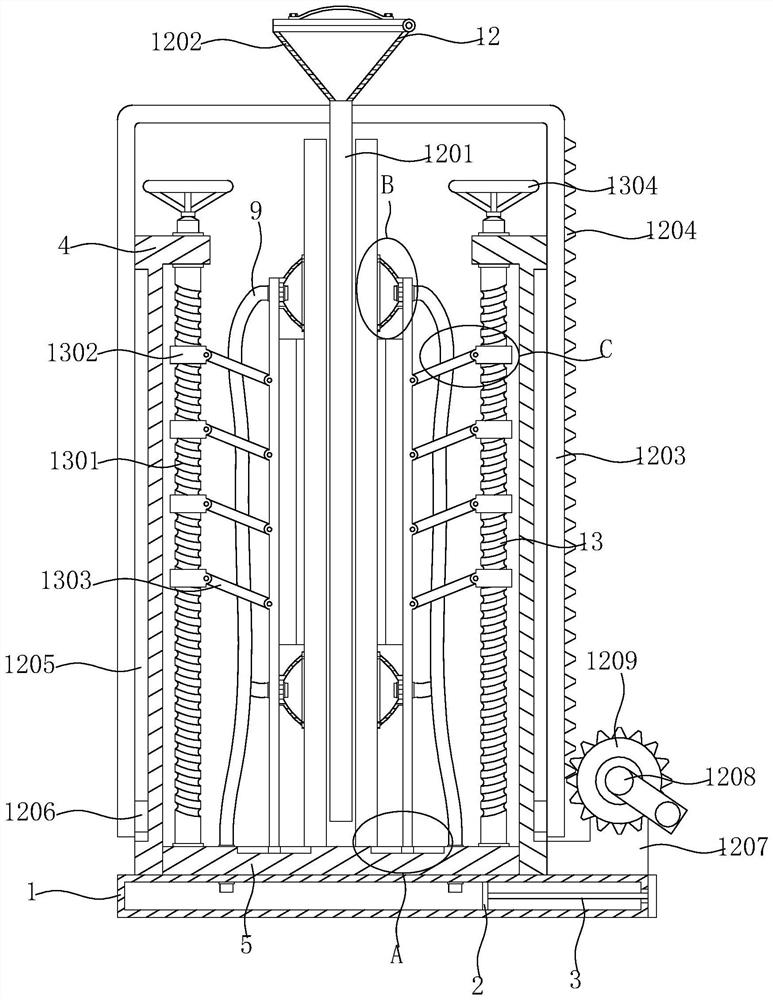

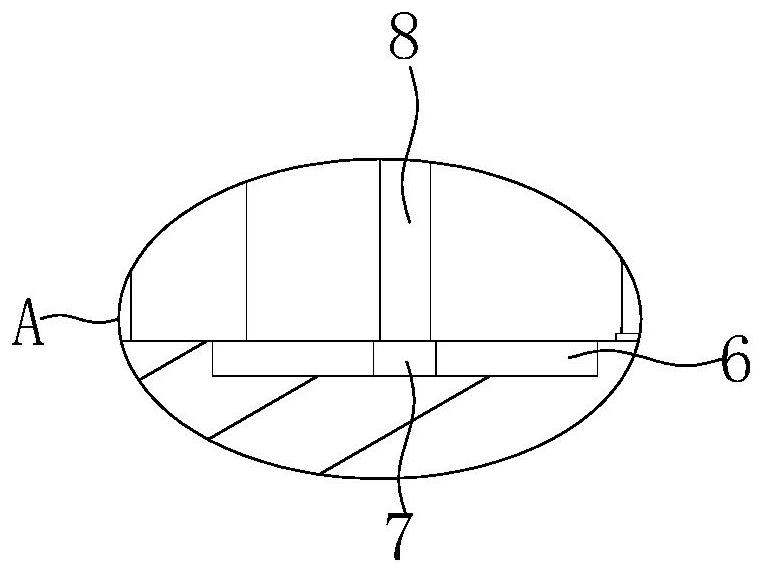

The invention discloses a system for acquiring trap parameters of solid dielectric material. The system comprises a constant temperature box, a three-electrode corona charging system, a surface potential measurement system, a rotary support system and a temperature control system; the three-electrode corona charging system, the surface potential measurement system, the rotary support system and the temperature control system are arranged within the constant temperature box. The three-electrode corona charging system comprises a plurality of needle electrodes and a meal disc electrode; the needle electrodes are coaxially arranged from top to bottom; the metal disc electrode is grounded. The surface potential measurement system comprises a capacitive static probe disposed on an adjustable insulating holder. The rotary support system comprises an insulating support; a metal turnplate and a metal heating box are arranged on the upper surface of an aluminum plate. The temperature control system comprises a first heater and a second heater. The system is applicable to the acquisition of parameters, such as trap level and trap density, of the solid dielectric material and has the advantages of wide range of application, high measurement precision and simplicity and convenience in operation, and an effective analysis method is provided for the research on surface electrification of the solid dielectric material, surface flashover and the like.

Owner:STATE GRID CORP OF CHINA +2

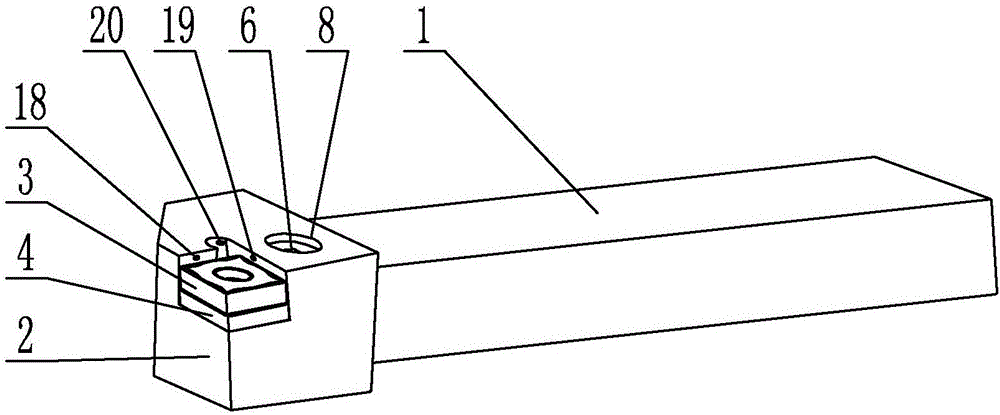

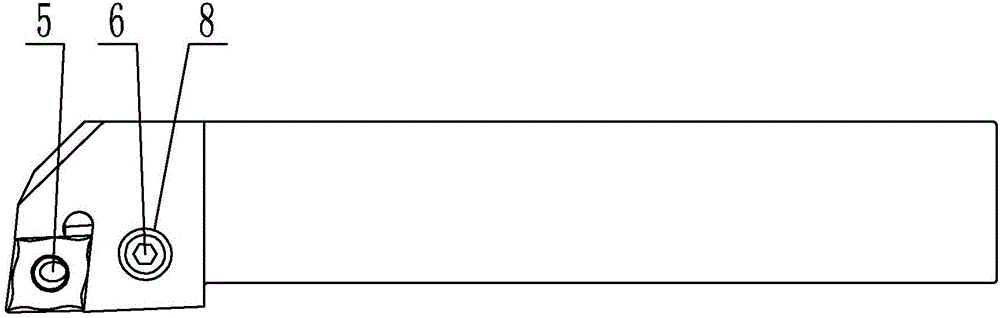

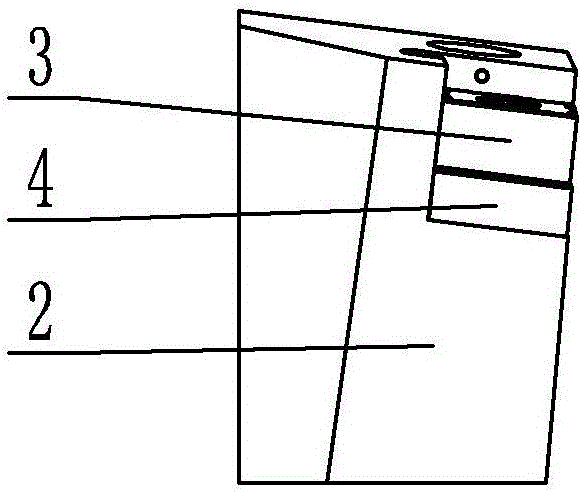

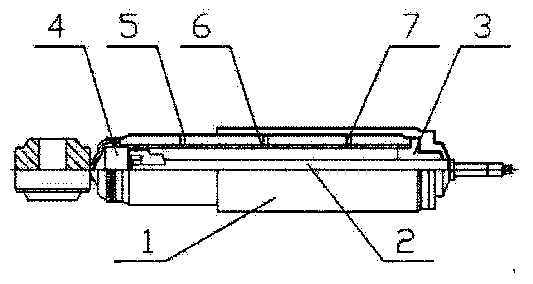

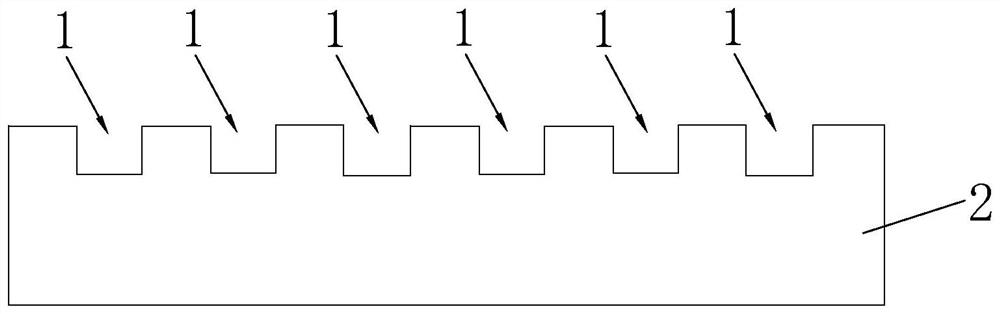

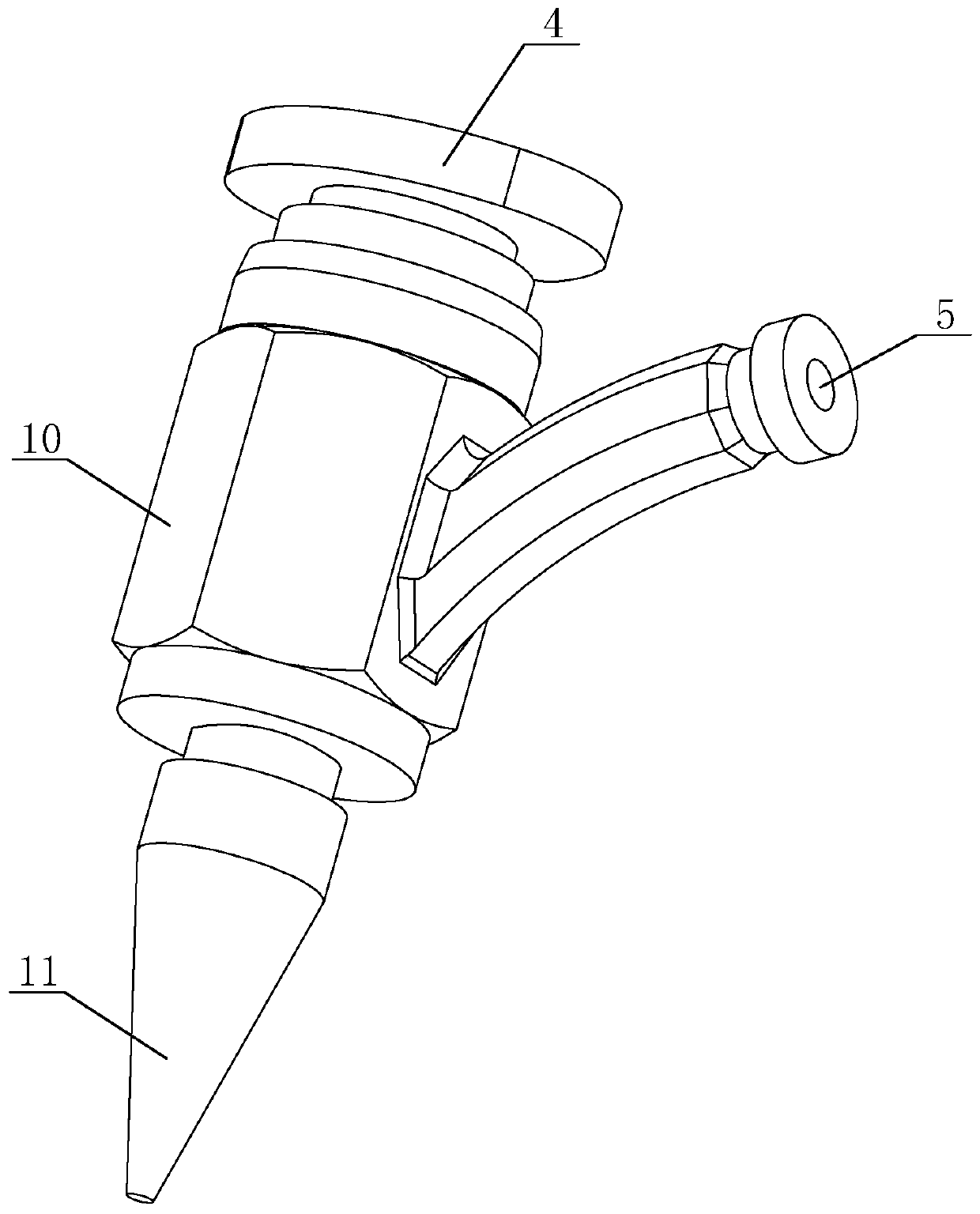

High-pressure cooling turning tool

InactiveCN106424786AImproved chip breaking performanceImprove cooling and lubrication effectCutting insertsTurning toolsInsufficient CoolingMetallic materials

The invention discloses a high-pressure cooling turning tool, relates to a turning tool, and solves the problems that when the conventional turning tool turns a difficultly-machined material, cutting fluid cannot be sufficiently sprayed to a cutting area due to insufficient cooling and lubricating capacity, and cut chip winds a workpiece and is difficultly broken off due to insufficient chip breaking capacity. The high-pressure cooling turning tool comprises a tool handle, a tool bit and a tool blade, wherein the tool bit is fixedly connected to the front end of the tool handle; the tool blade is embedded into the front end of the upper end surface of the tool bit; the tool blade is fixedly connected with the tool bit through a fastening mechanism; a threaded bind hole is formed in the lower end surface of the tool bit; the tool bit is connected with a high-pressure pipe head through the threaded bind hole; a plurality of cooling liquid passages are formed in the tool bit; one end of each of the plurality of cooling liquid passages is communicated with the threaded bind hole; the other ends of the plurality of cooling liquid passages are arranged towards the front end of the tool blade. The high-pressure cooling turning tool is used for turning a difficultly-machined metal material.

Owner:HARBIN UNIV OF SCI & TECH

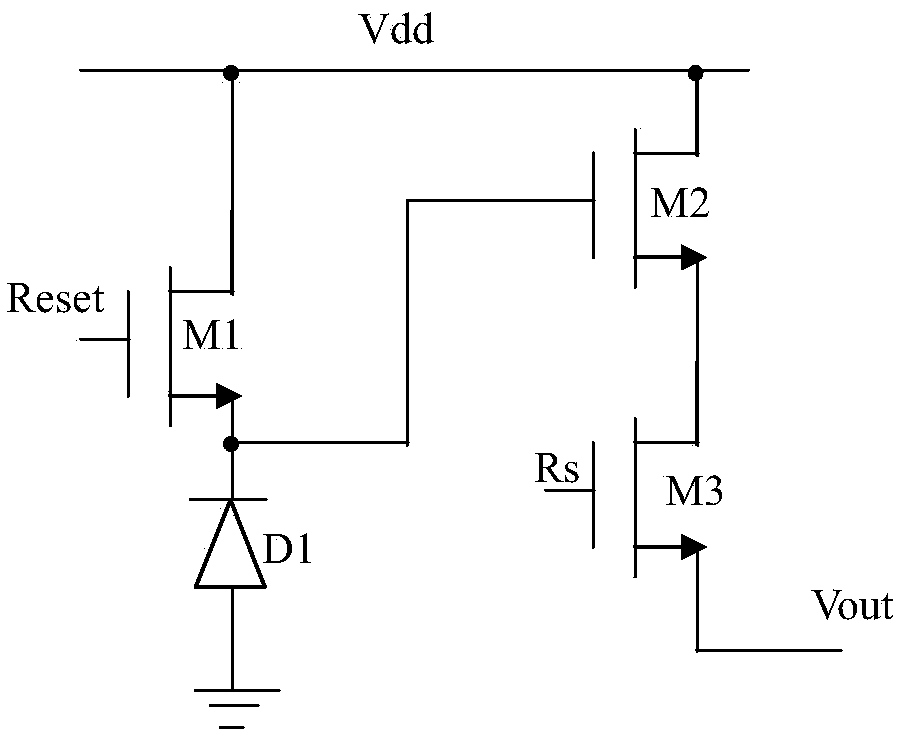

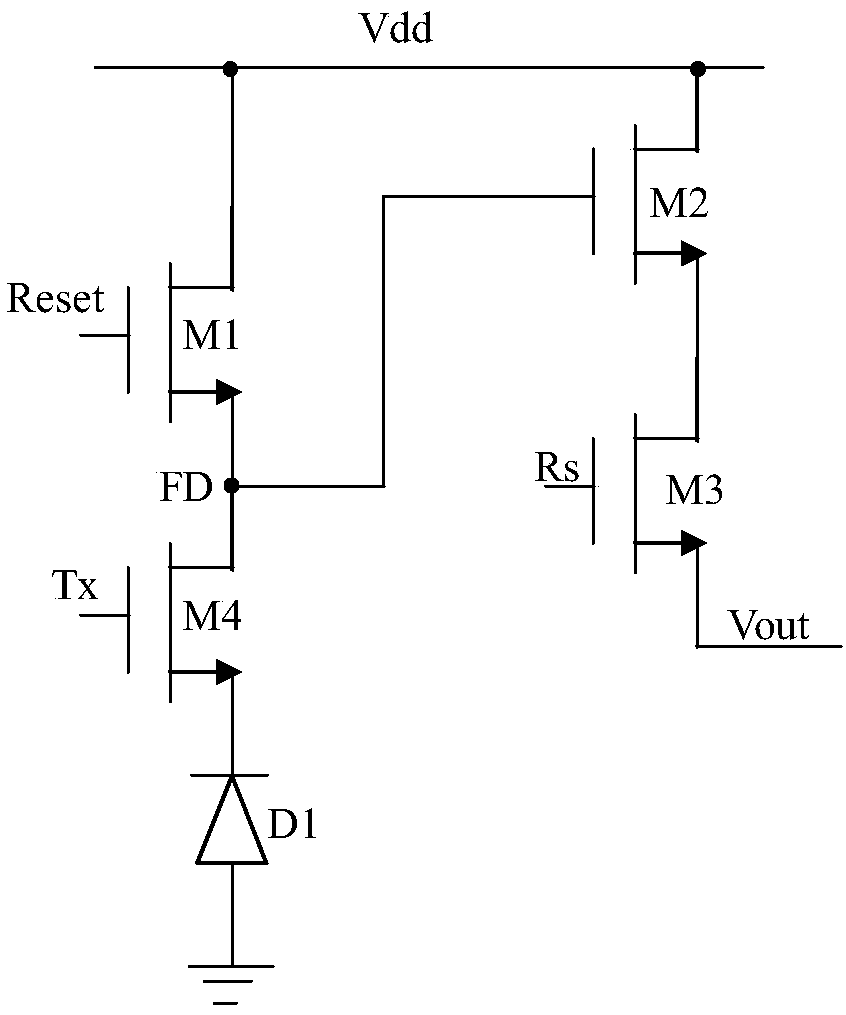

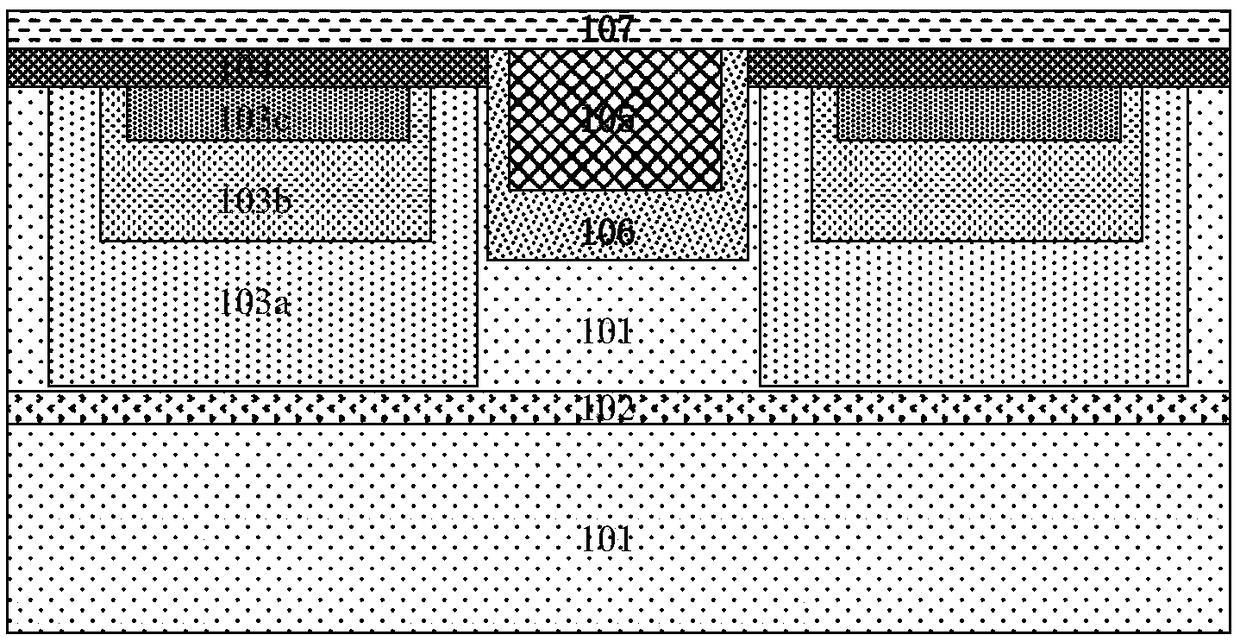

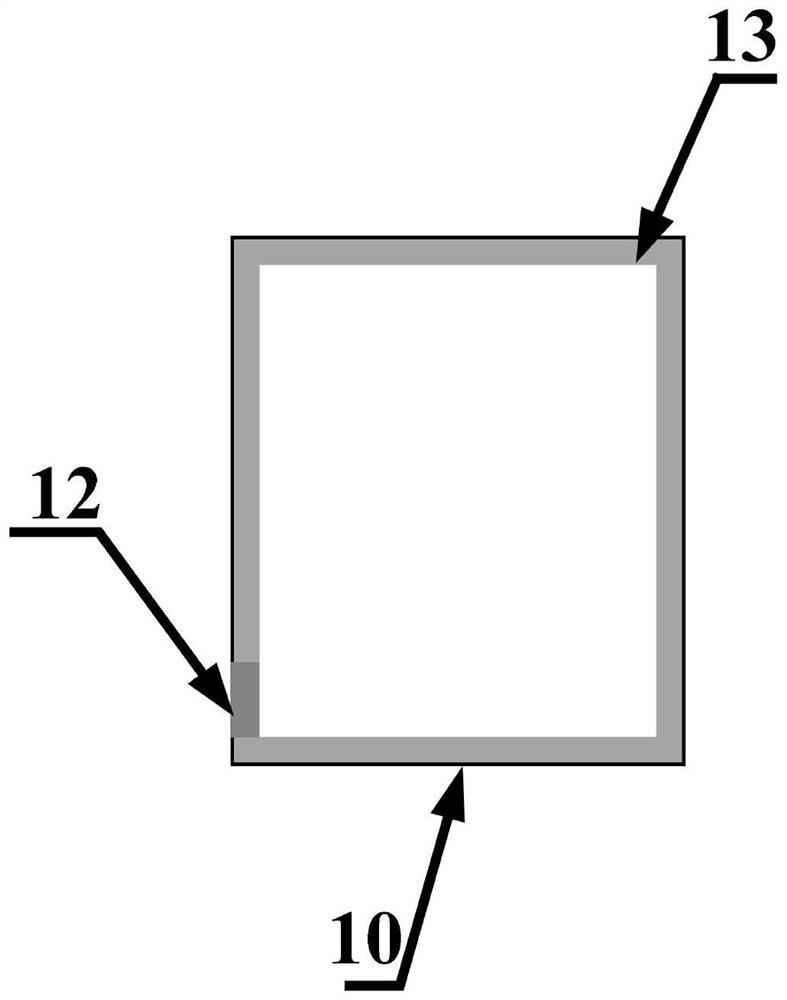

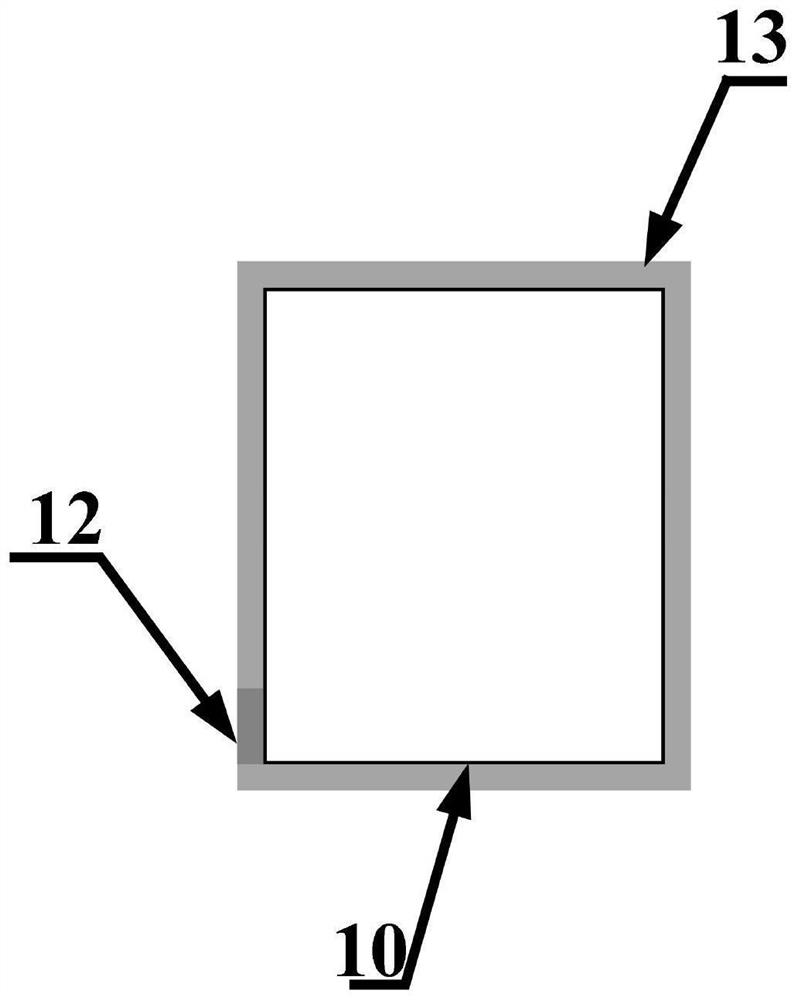

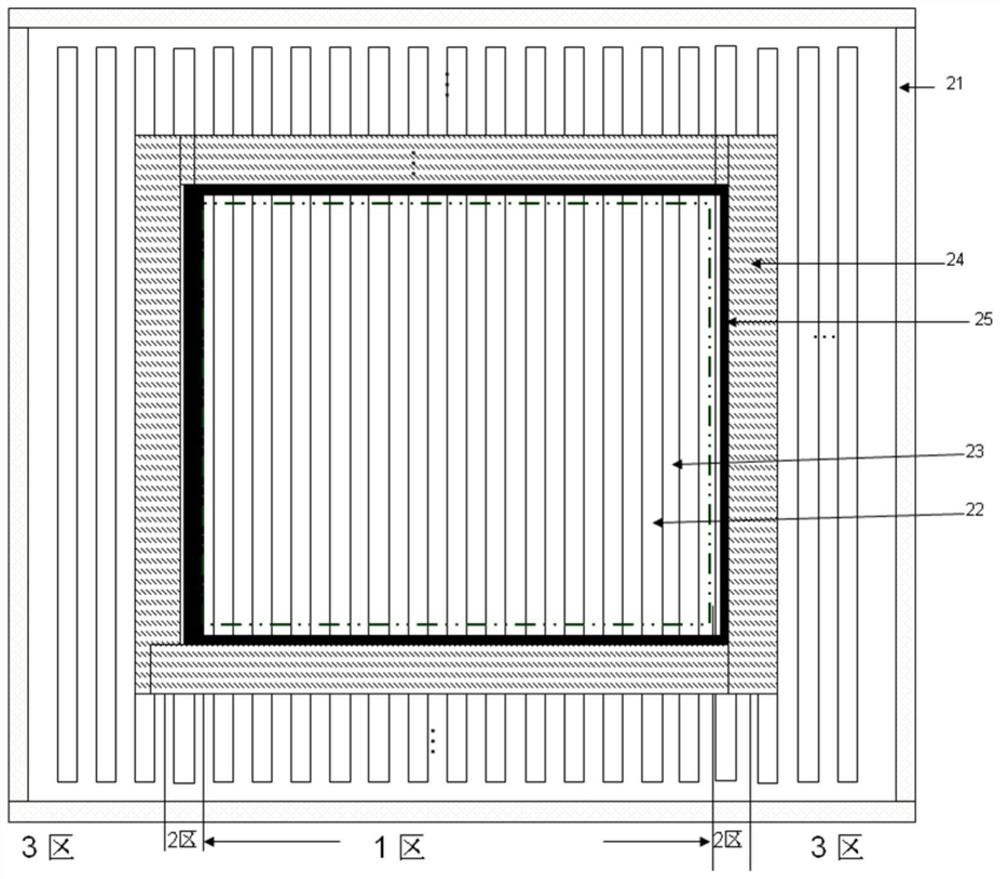

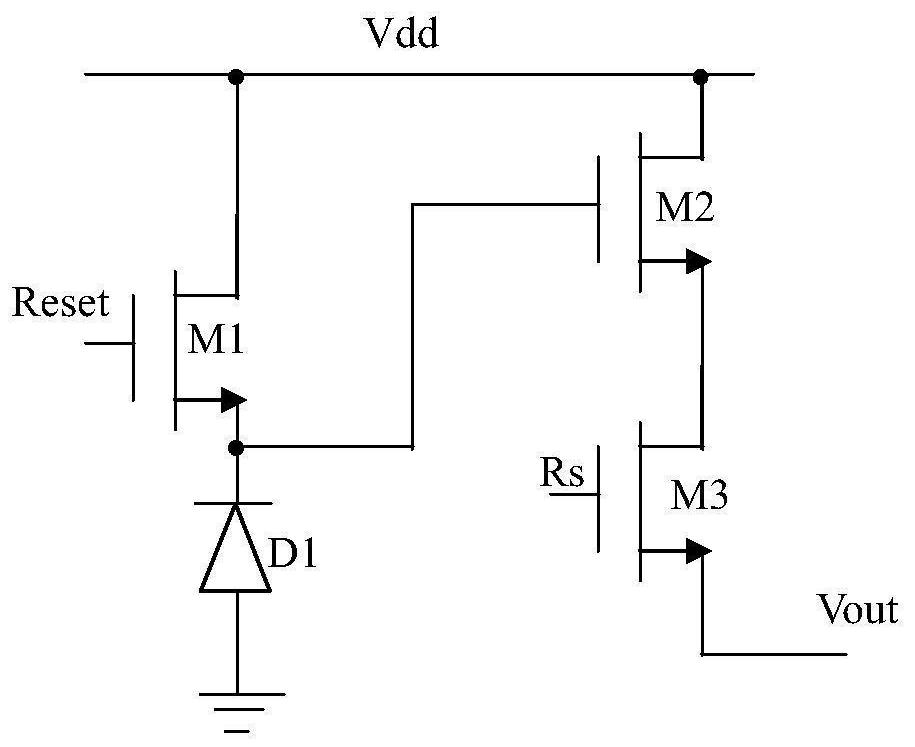

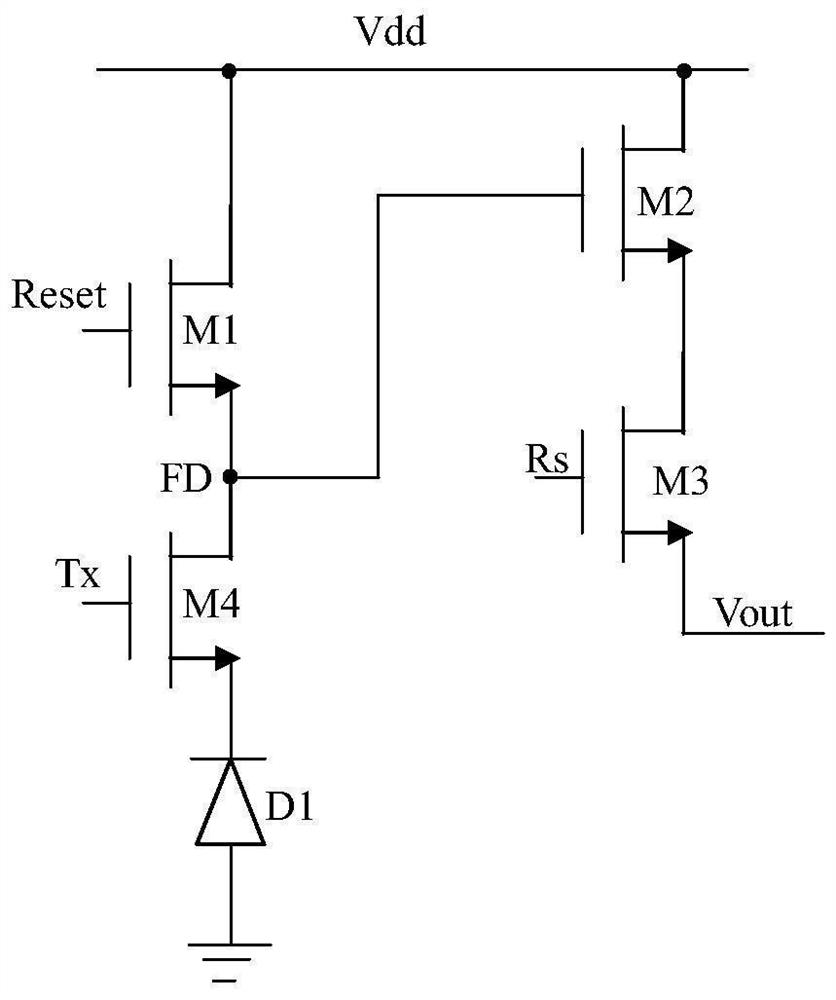

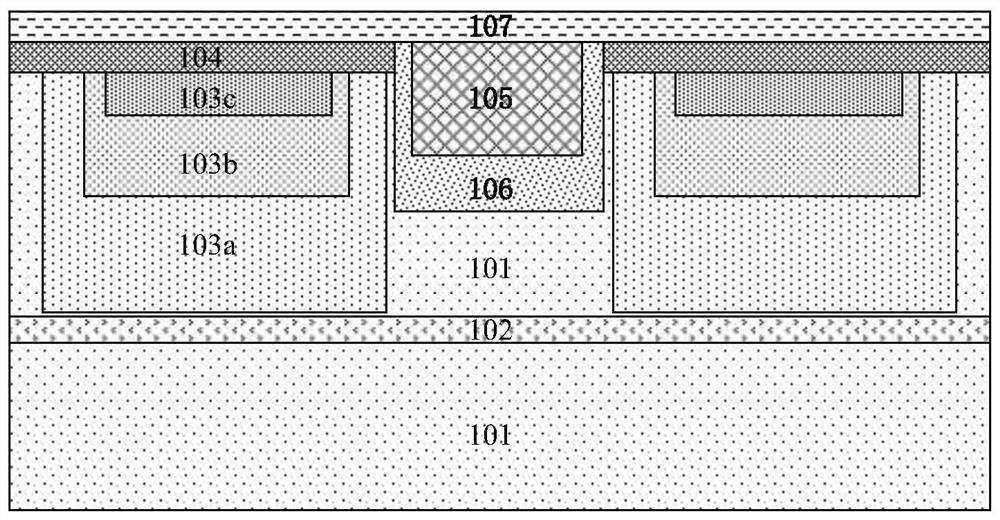

CMOS image sensor and production method thereof

ActiveCN108807440ADeepen the depthFull injectionSolid-state devicesRadiation controlled devicesCMOSPhotodiode

The invention discloses a CMOS image sensor, which is formed on a P-type semiconductor substrate and comprises a plurality of pixel units, wherein each pixel unit comprises a surface clamp photodiode;each clamp photodiode comprises an N-type buried layer formed in the P-type semiconductor substrate and a surface P+ layer formed on the surface of the N-type buried layer; field oxide layers are formed on the surface of the P-type semiconductor substrate between the adjacent surface clamp photodiodes; a first P-type doped isolation region is formed at the bottom of each field oxide layer; a fully injected second P-type doped isolation region is formed at the bottoms of the N-type buried layers; and the depths of the bottom surfaces of the first P-type doped isolation regions are greater thanor equal to that of the top surface of the second P-type doped isolation region, so that the bottoms of the first P-type doped isolation regions are overlapped with the second P-type doped isolationregion. The invention further discloses a production method of the CMOS image sensor. According to the CMOS image sensor, reduction of the cost under the condition of achieving noise isolation of thesubstrate can be ensured.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

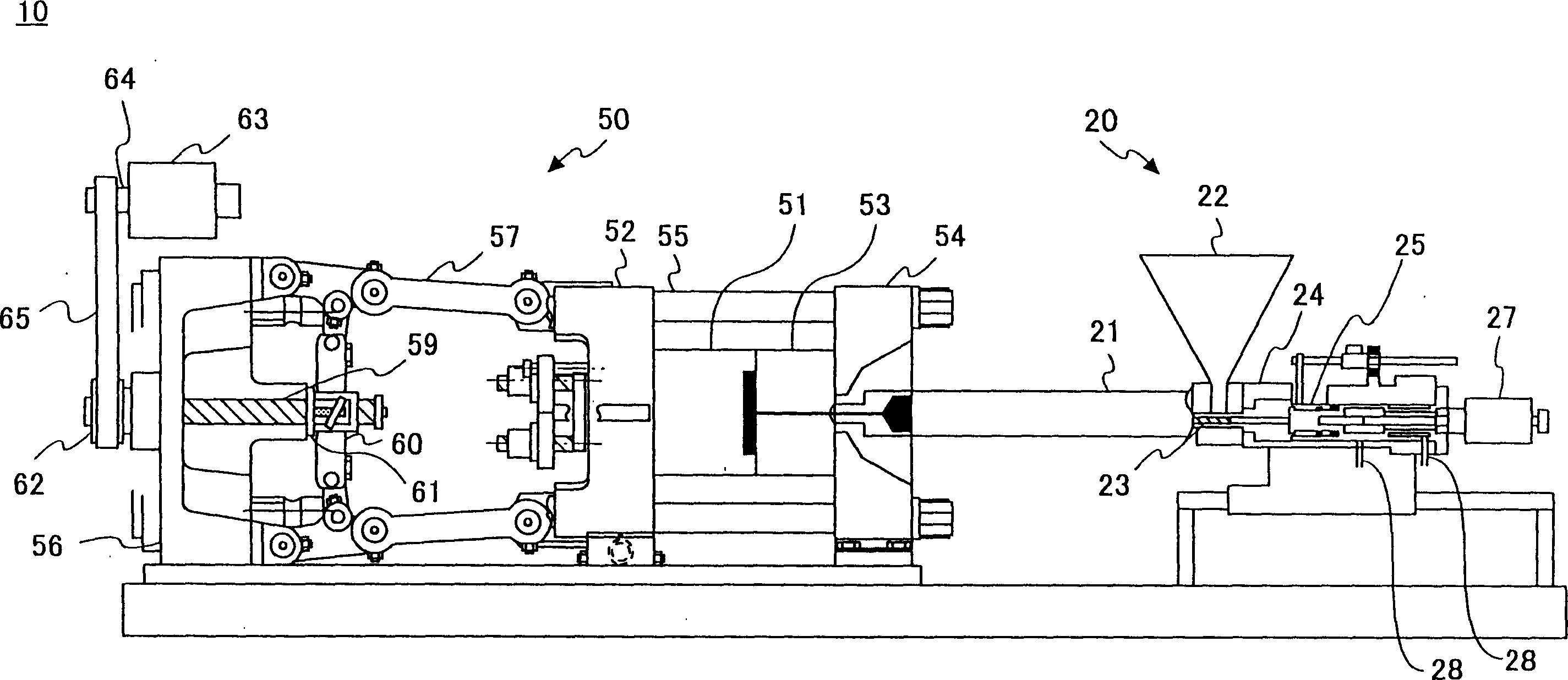

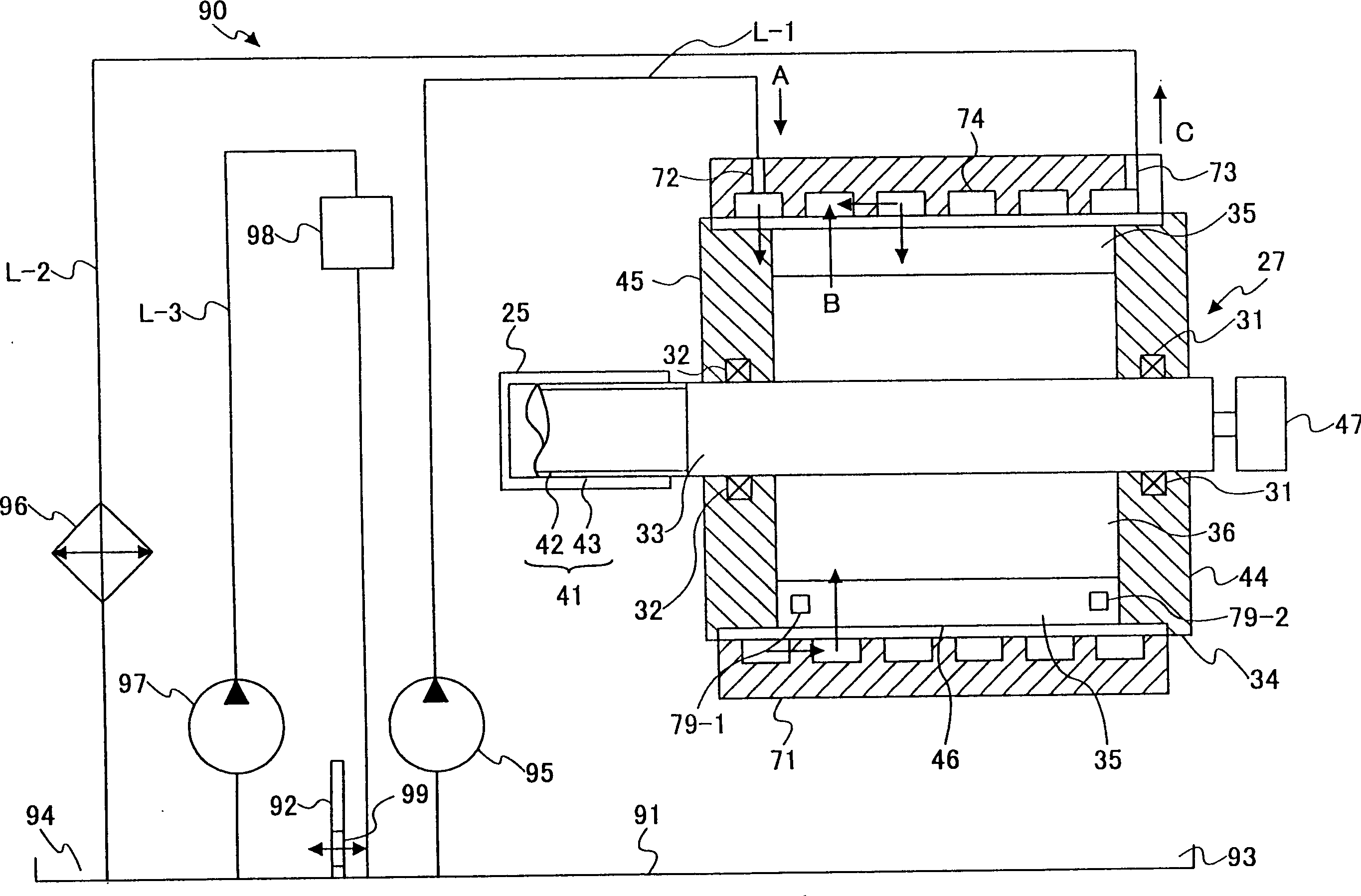

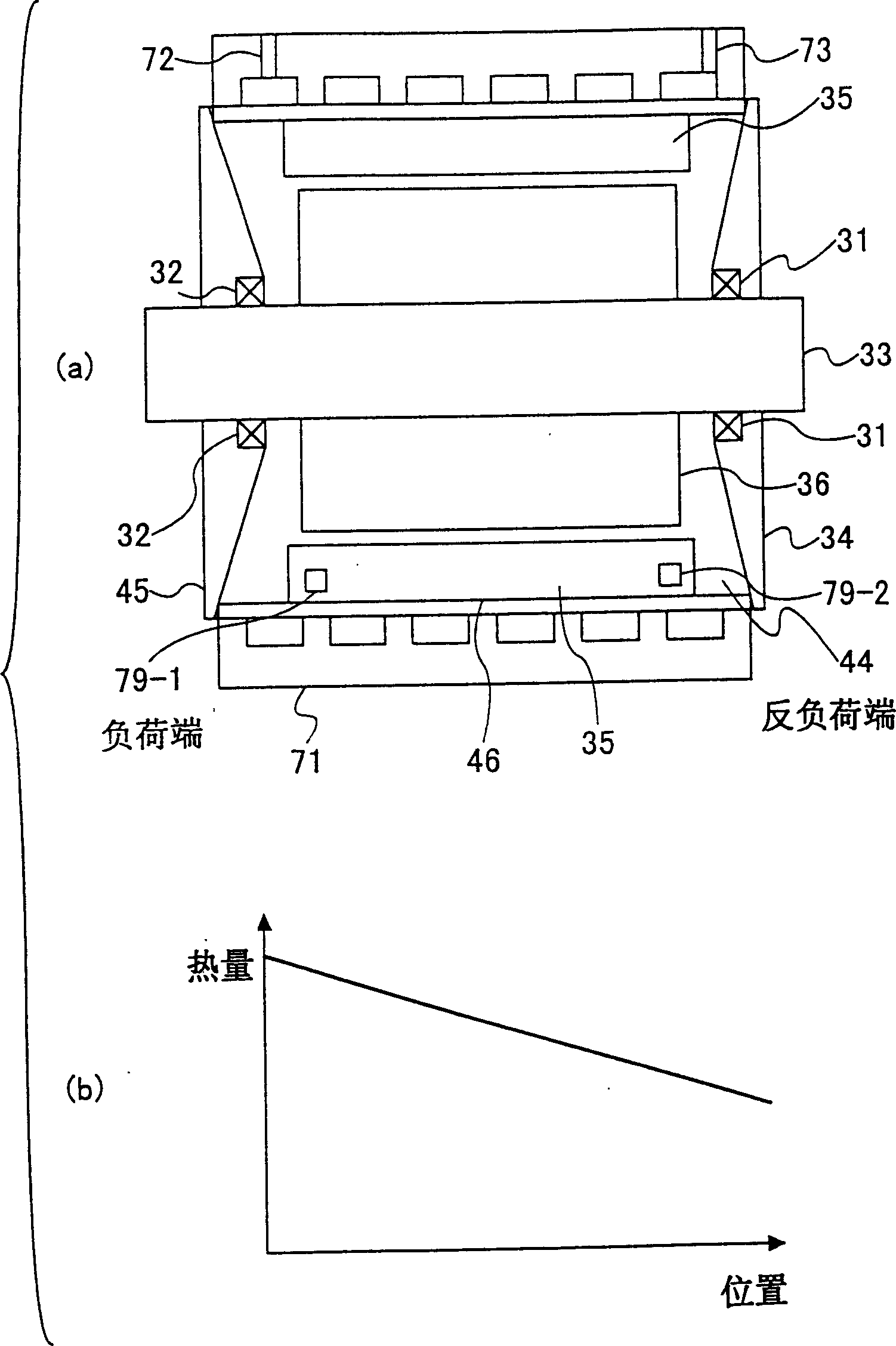

Cooling mechanism and cooling method for driving element of injection moulding machine

A cooling mechanism for cooling an electric driving part of an injection molding machine, includes a cooling part for cooling the electric driving part; and an actuating part actuated by being supplied an actuating fluid, the actuating fluid being in fluid communication with the cooling part. The actuating fluid may be used as a cooling fluid for cooling the electric driving part.

Owner:SUMITOMO HEAVY IND LTD

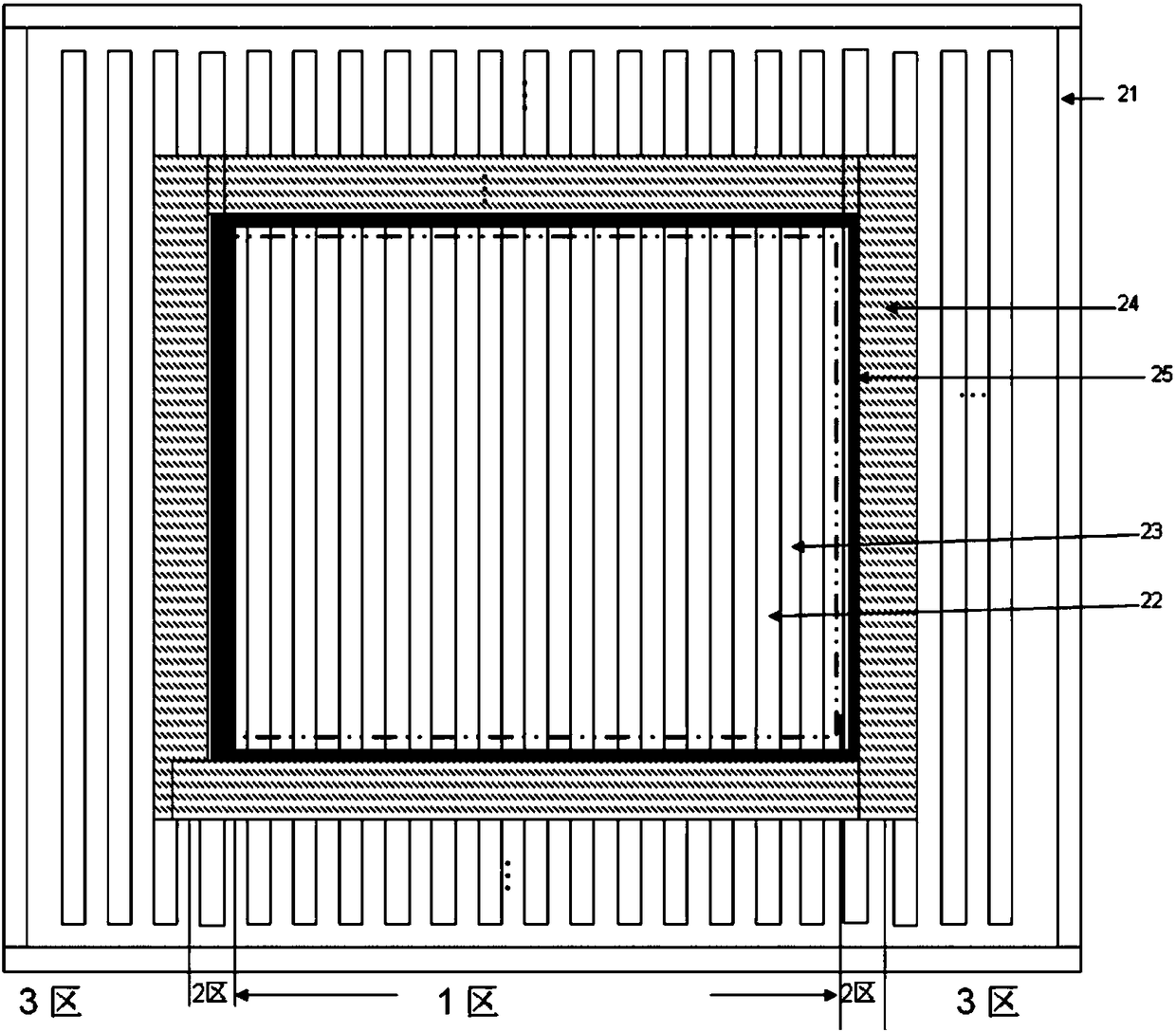

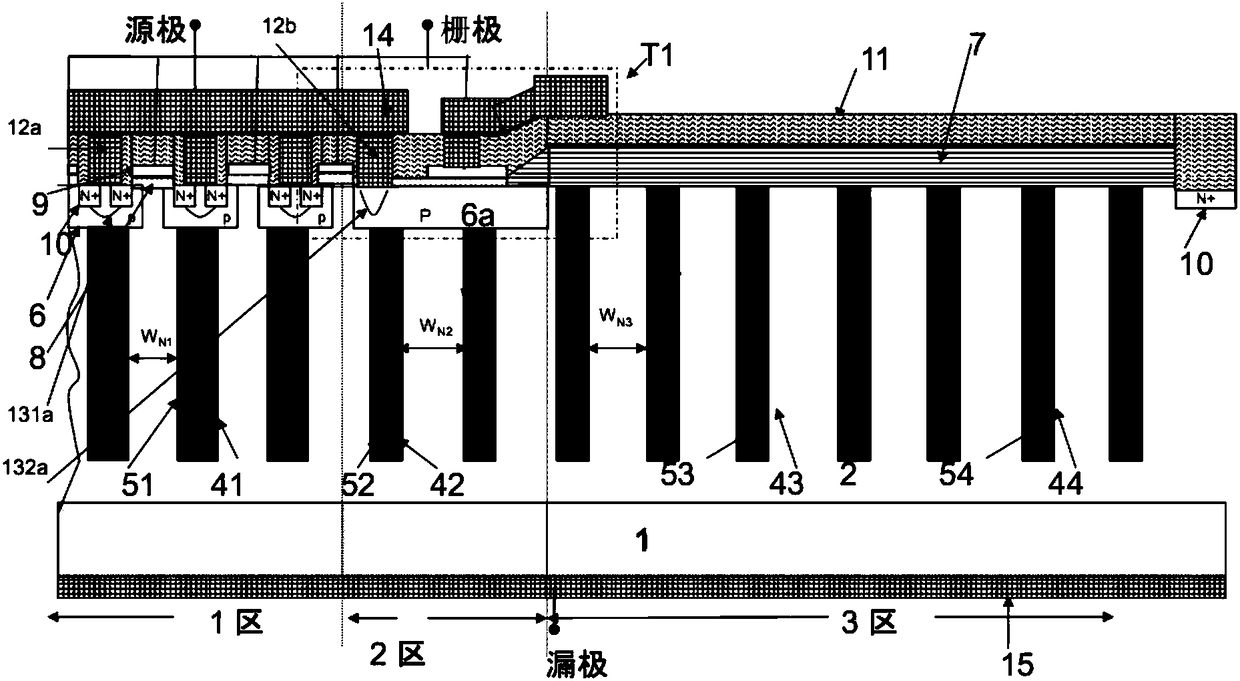

Super-junction device and manufacturing method thereof

ActiveCN108428732AImprove softness factorImprove reverse recovery characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesReverse recoveryEngineering

The invention discloses a super-junction device, which is characterized in that a protective epoxy film exposes a charge flow region, completely covers a transition region and completely or mostly covers a terminal region, a second contact hole at the top of a P-type ring of the transition region is enabled to penetrate deeper than a first contact hole at the top of a P-type well of the charge flow region by the thickness of one protective epoxy film, and thus the junction depth of a second P+ contact region at the bottom of the second contact hole is enabled to be less than the junction depthof a first P+ contact region at the bottom of the first contact hole, so that the distance between a hole collected by the P-type ring to the second P+ contact region, and a softness factor of reverse recovery of a body diode of the device is increased. The invention further discloses a manufacturing method of the super-junction device. According to the invention, the reverse recovery characteristics of device can be improved, and the avalanche tolerance of the device is enhanced at the same time.

Owner:SHENZHEN SANRISE TECH CO LTD

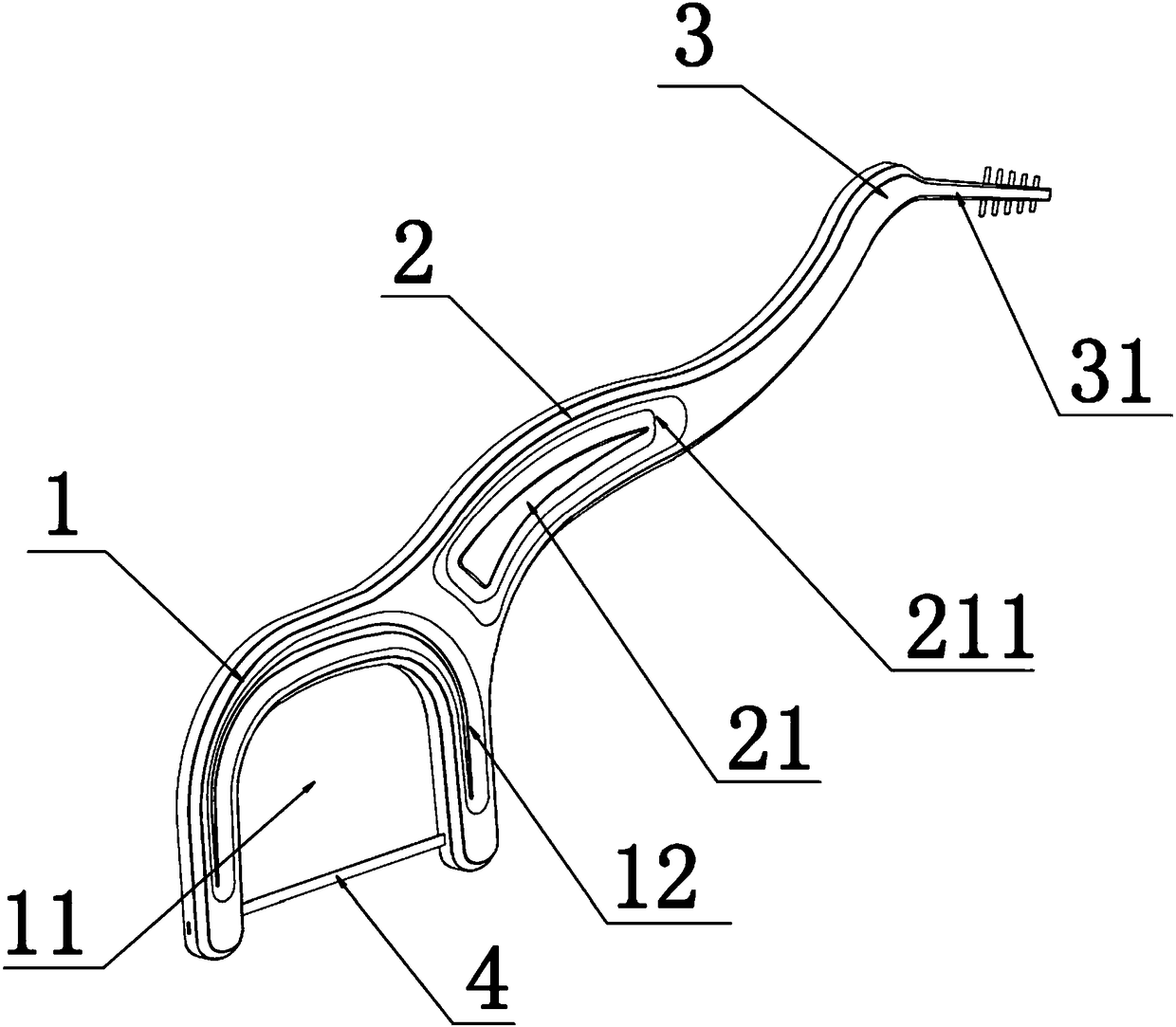

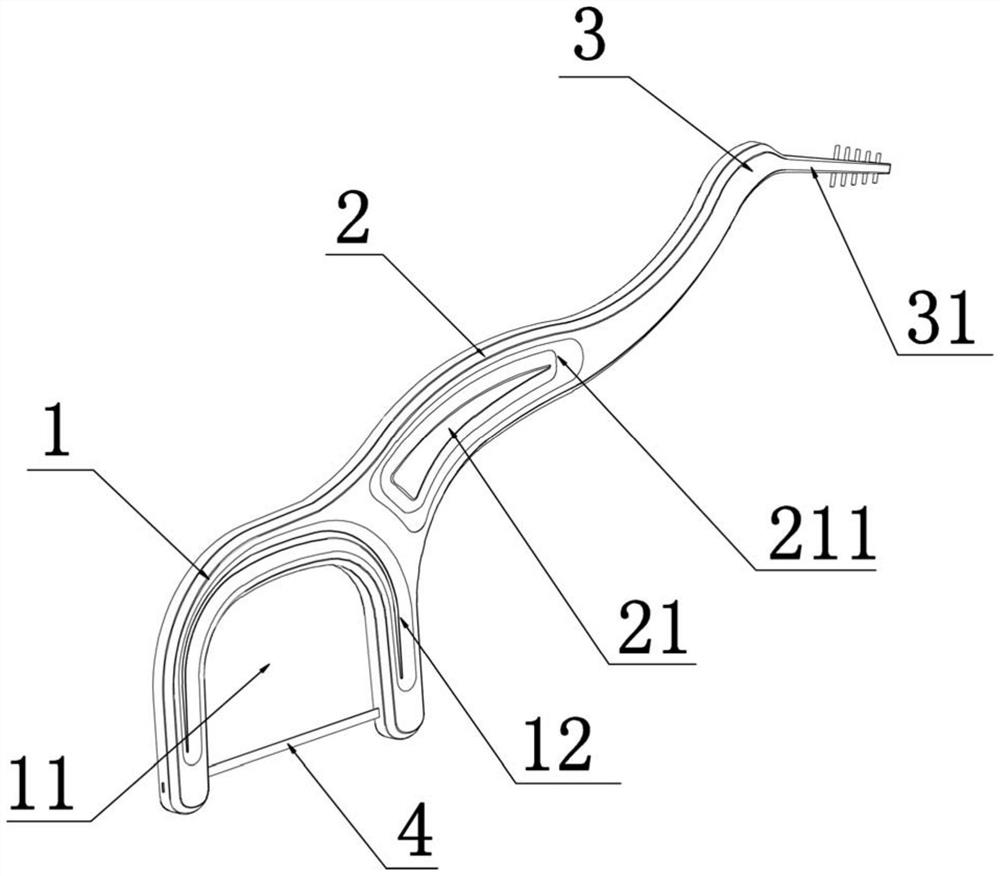

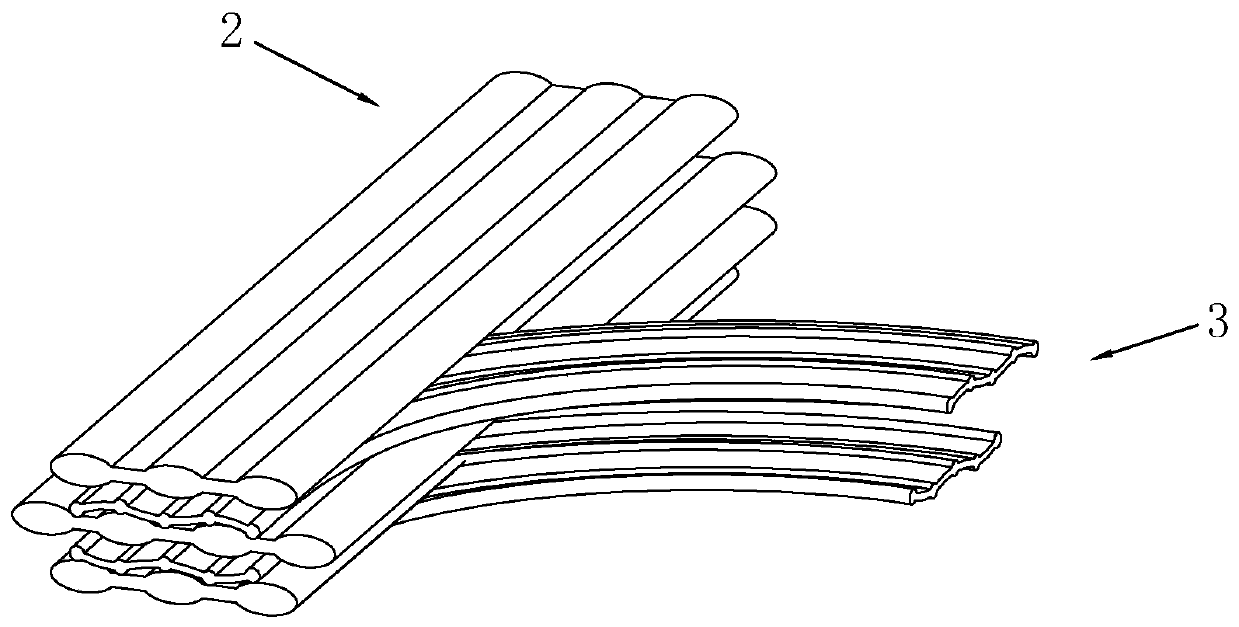

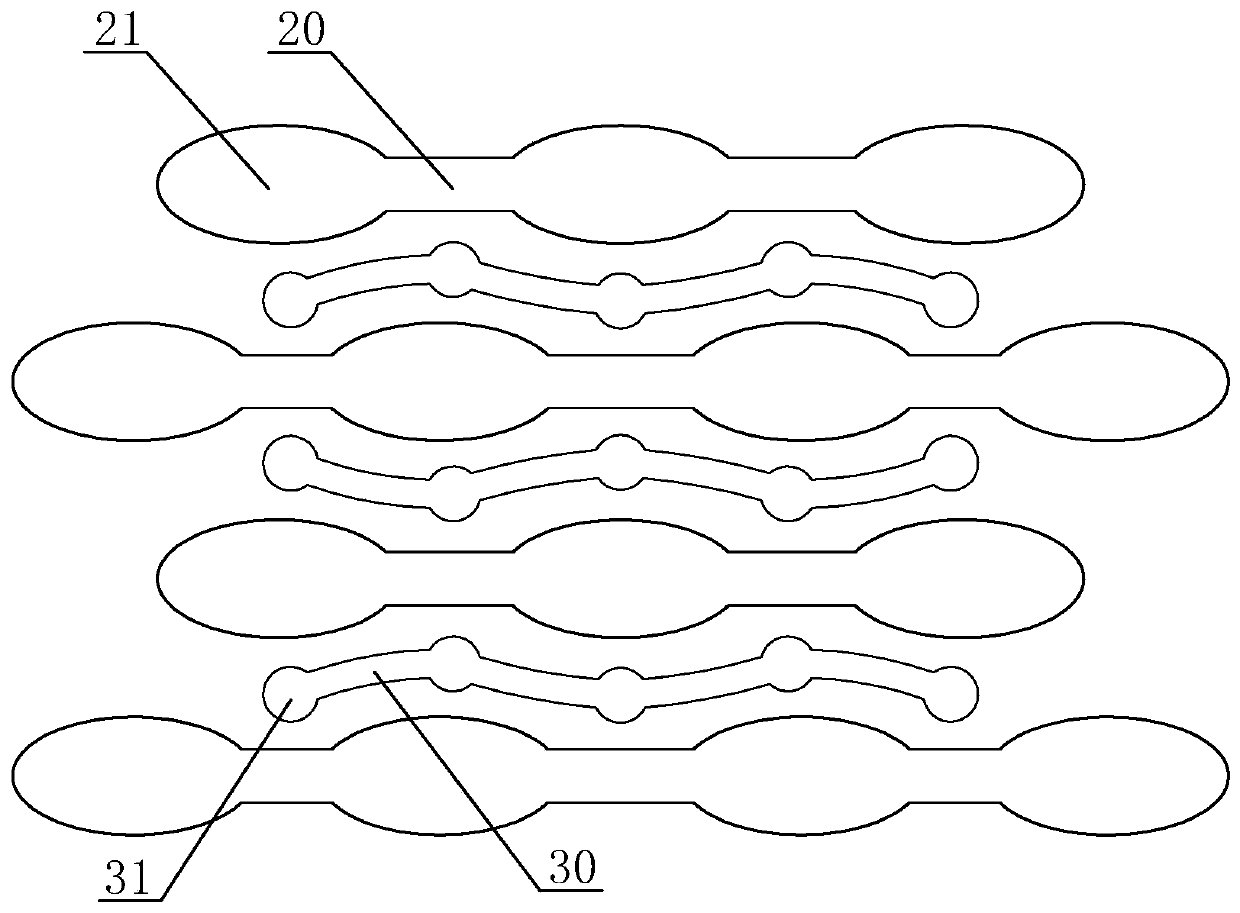

Floss pick and preparation process thereof

ActiveCN108186143AReduce cut resistanceReduce bleeding riskGum massageDental flossEngineeringDental floss

The invention discloses a floss pick which comprises a floss part (1), a handhold part (2) and a toothpick part (3) which are sequentially integrally connected, wherein the floss part (1) is distributed at the front end of the handhold part (2), and the toothpick part (3) is distributed at the rear end of the handhold part (2); a U-shaped groove (11) is formed in the lower end of the floss part (1), and a floss (4) is mounted at an opening of the U-shaped groove (11) in a matched manner; a tooth gap brush (31) integrally connected with the toothpick part (3) is arranged at the tail end of thetoothpick part (3). With the adoption of the structure, the floss can be used for clearing positions, where a toothbrush cannot brush, in teeth, the tooth gap brush can be used for cleaning residues left in gaps between teeth, and the floss pick is simple to use and comprehensive in cleaning.

Owner:余姚市科琳日用品有限公司

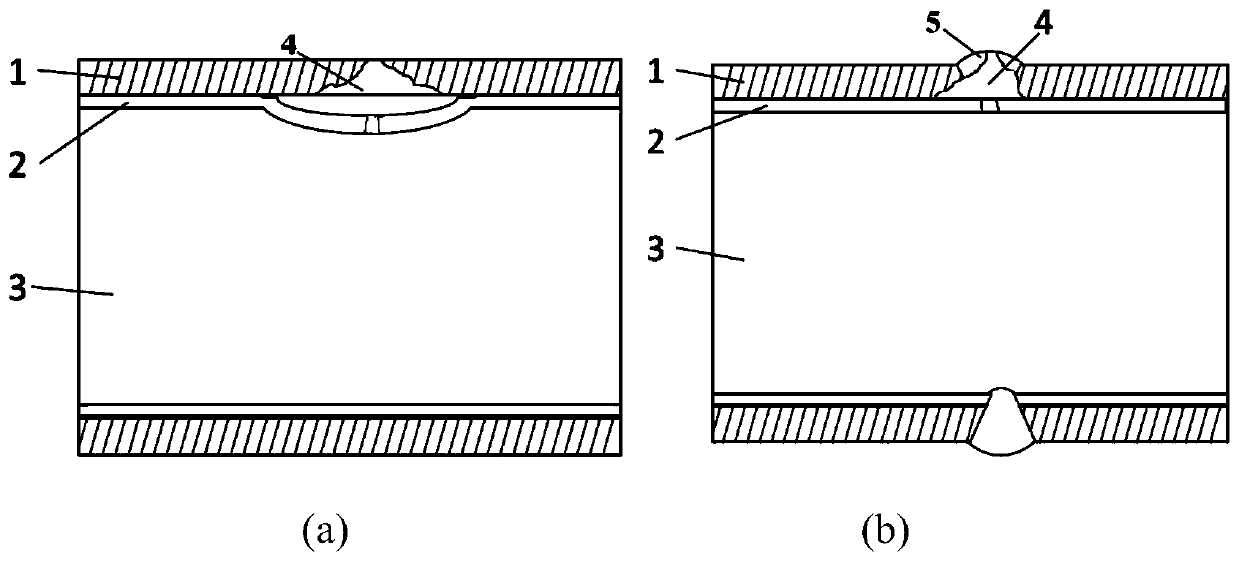

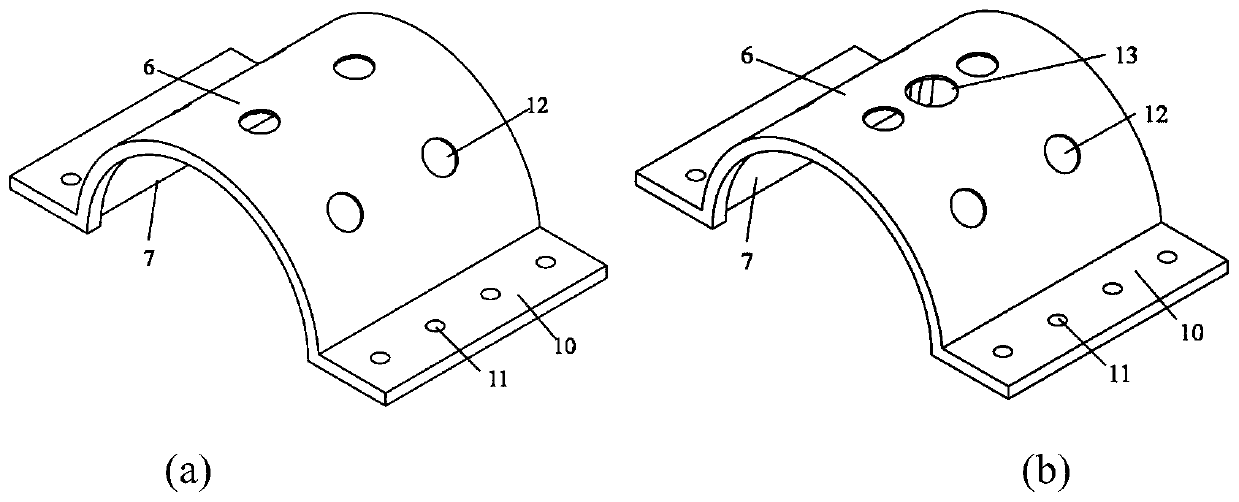

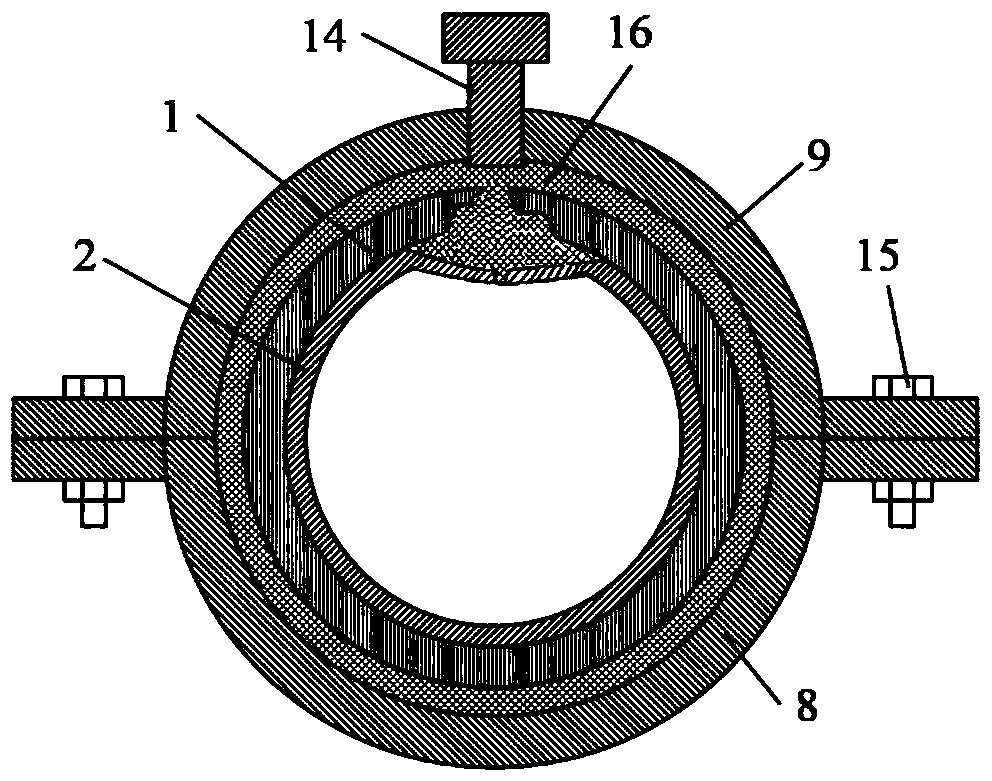

Drainage type fixture and method for plugging bimetal composite pipe piercement under pressure by utilizing drainage type fixture

InactiveCN111237583AEasy to disassembleTo achieve the effect of plugging leaksPipe elementsPipeline systemsCollapsed cavityPipe

The invention discloses a drainage type fixture and a method for plugging bimetal composite pipe piercement under pressure by utilizing the drainage type fixture, and belongs to the field of petroleumpipelines. The method for plugging bimetal composite pipe piercement under pressure by utilizing the drainage type fixture comprises the following steps of (1) installing the drainage type fixture onthe periphery of a bimetal composite pipe, wherein a resin injection hole is located above a leakage point; and (2) injecting resin into the resin injection hole, wherein the resin enters an annularcavity between the bimetal composite pipe and the drainage type fixture through the resin injection hole so as to fill a corrosion or collapse part caused by piercement on the bimetal composite pipe.The resin is filled in the cavity formed by the drainage type fixture and the outer wall of the pipeline, and penetrates through a piercement hole so as to fill an inner erosion pit and a collapse cavity, so that a plugging effect is achieved; and the drainage type fixture is simple to operate, solves the problem that suspend production, evacuation and pipe replacement are needed, and accomplishesthe plugging of the leakage point caused by bimetal composite pipe piercement under the condition that a flowing medium still exists in the pipeline.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

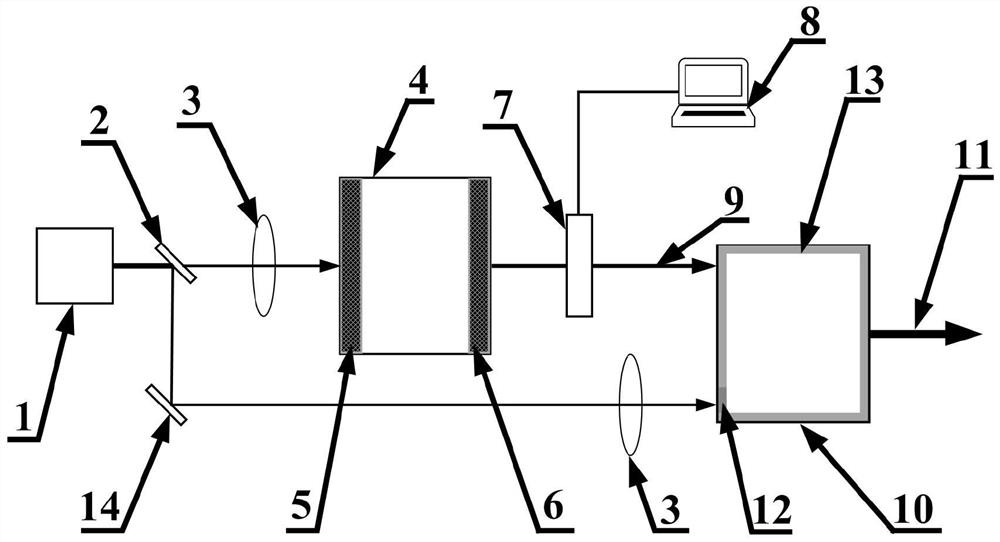

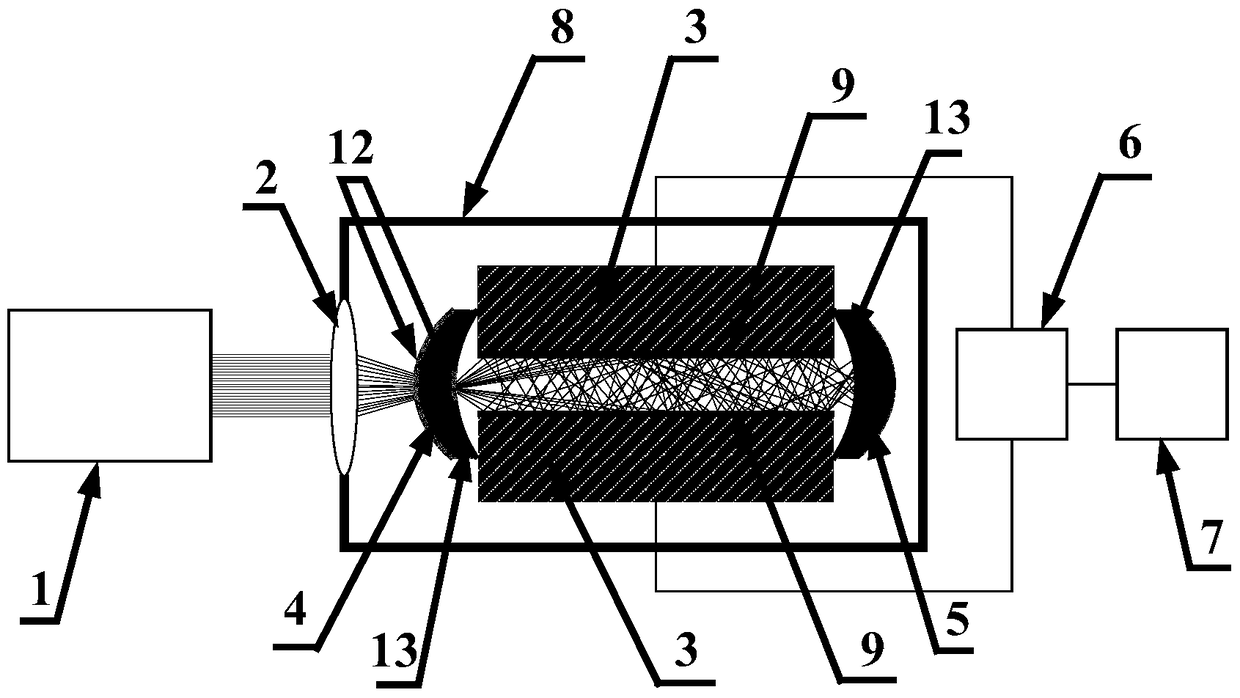

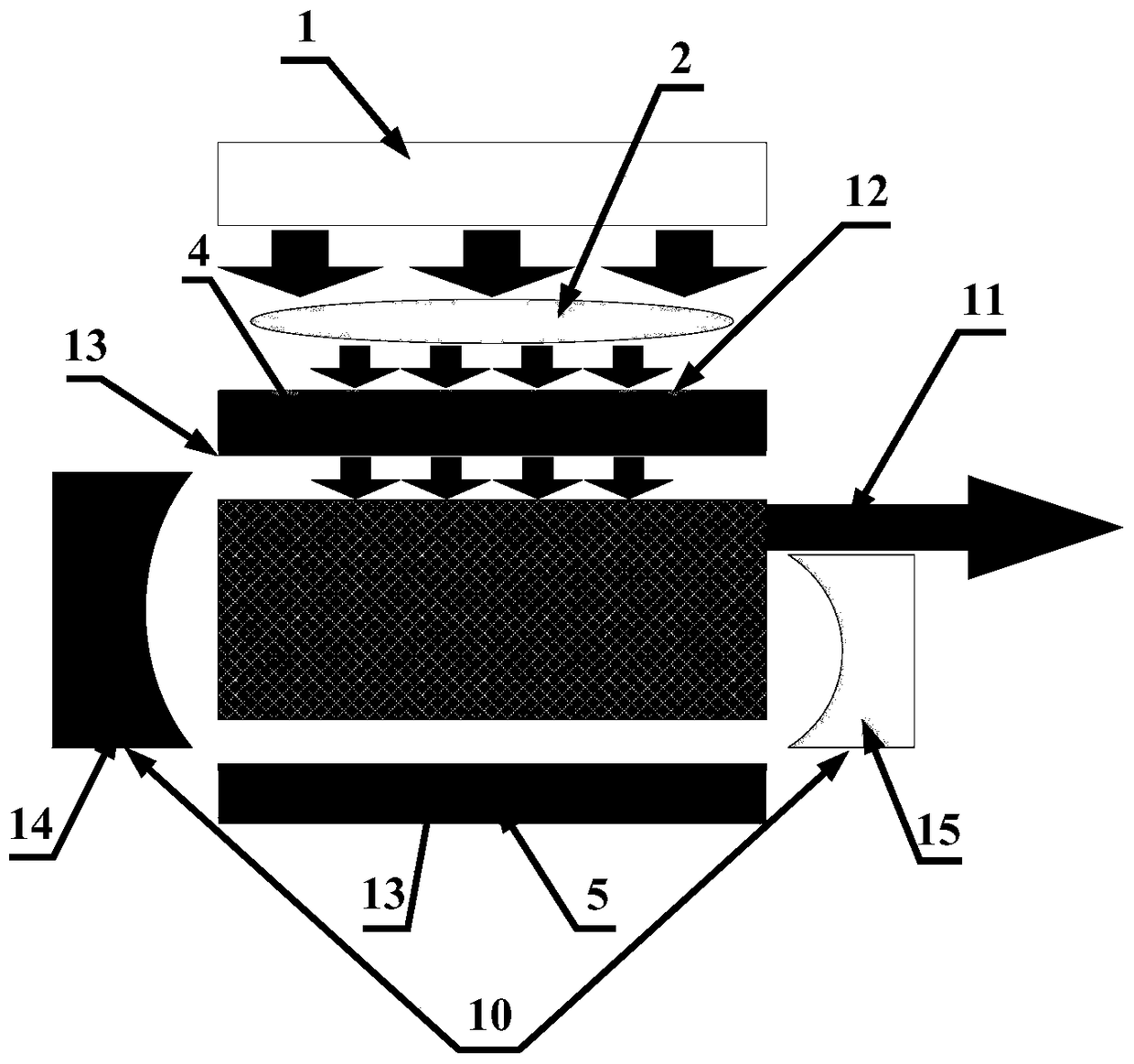

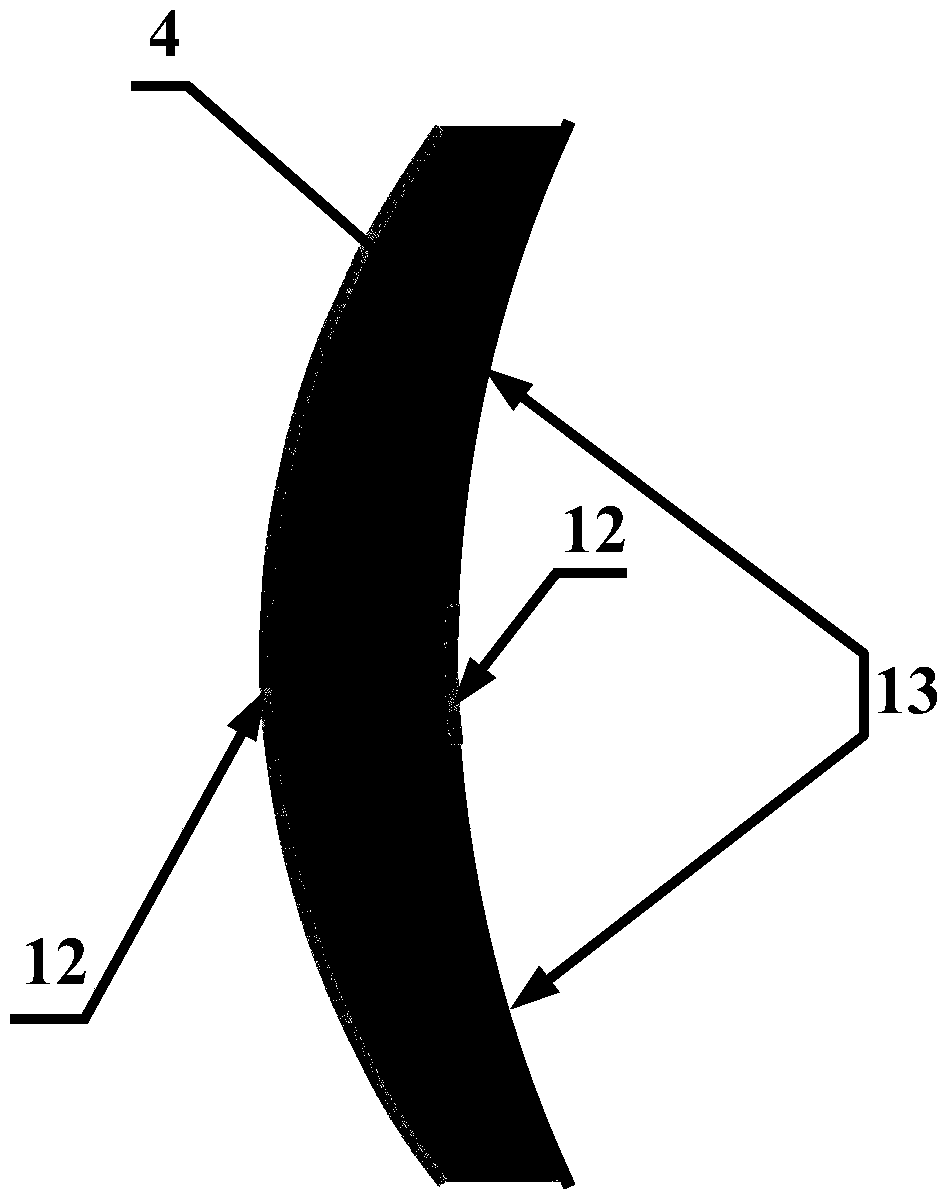

Laser amplifier

PendingCN114400491AStable chemical propertiesIncreased chance of collisionActive medium shape and constructionSpatial light modulatorPicosecond

The invention discloses a laser amplifier which comprises a semiconductor laser, a first optical shaping system, a resonant cavity, a spatial light modulator, a computer and an amplification cavity. The optical shaping system I, the resonant cavity, the spatial light modulator, the computer and the amplification cavity are sequentially arranged at the tail end of the semiconductor laser; the spatial light modulator is controlled by a computer and is used for regulating and controlling the laser mode of the resonant cavity for outputting the seed light; and the semiconductor laser generates pump light, the emitted pump light is transmitted by the optical shaping system I and is sequentially injected into the resonant cavity and the amplification cavity, and amplified laser is output. The device has the characteristics of compact structure, uniform discharge, high pumping efficiency, convenient laser mode change, high mode purity and the like, and can effectively prevent the nonlinear effect of high-power continuous single-mode laser and high-power picosecond and femtosecond laser; and high-power laser output under the conditions of high light beam quality, good atmosphere and optical fiber transmission characteristics and high processing efficiency is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Double-cushion airbag shock absorber

InactiveCN104251278AOvercoming Flow Fill HysteresisAvoid vacuumingSpringsGas and liquid based dampersWorking environmentEngineering

The invention discloses a double-cushion airbag shock absorber. The double-cushion airbag shock absorber comprises a shock absorber body, a piston rod, an oil deflector, a piston component and an oil storage tank, wherein the oil storage tank is arranged in a working cylinder of the shock absorber body; the piston rod is inserted into the oil storage tank; the piston component is arranged at the tail end of the piston rod; the oil deflector is arranged at the upper end of the oil storage tank; the working cylinder comprises a first cylinder body and a second cylinder body with different diameters; a transition section is arranged between the first cylinder body and the second cylinder body; an oil groove which is arranged in a helix way is arranged on the surface of a tube body of the piston rod body; a cylindrical airbag is arranged at the bottom of the oil storage tank; the airbag is filled with inert gas; a high-pressure airbag adjusting device is arranged on the cylindrical airbag. Compared with the prior art, the double-cushion airbag shock absorber has the advantages that the shock absorber can perform double-cushion shock absorption, has good shock absorption performance and a simple structure, and can be applied to various work environments, and particularly to oversize vehicles.

Owner:丁小双

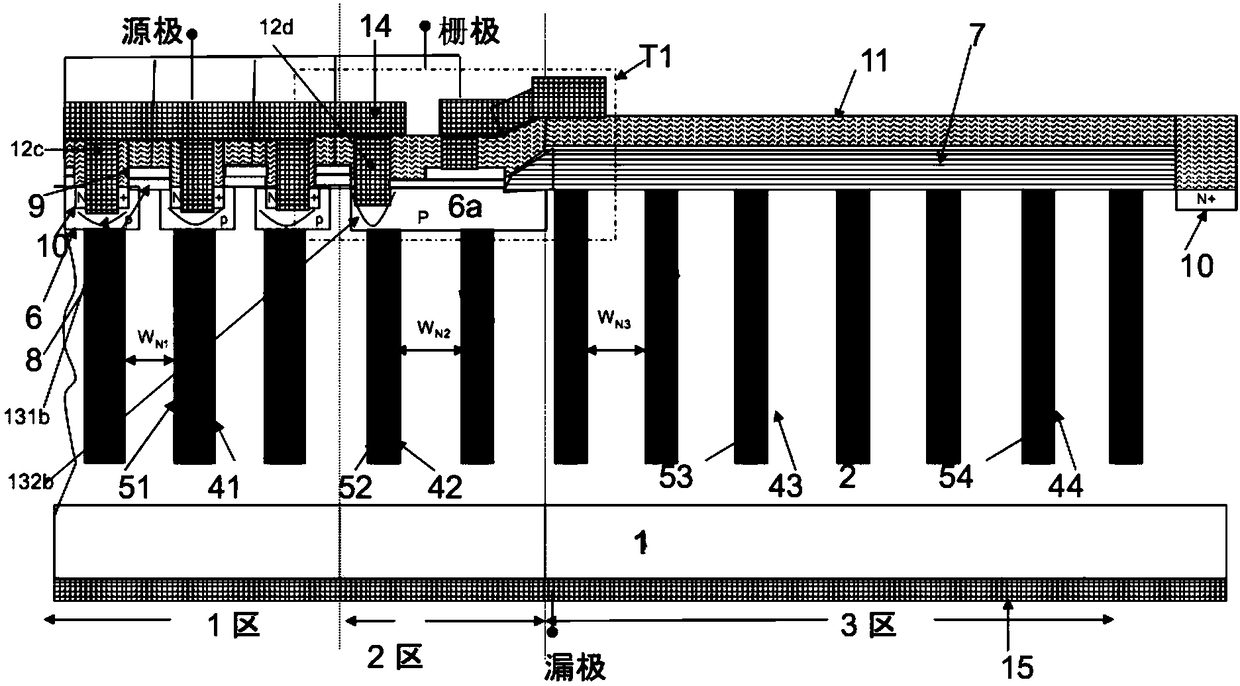

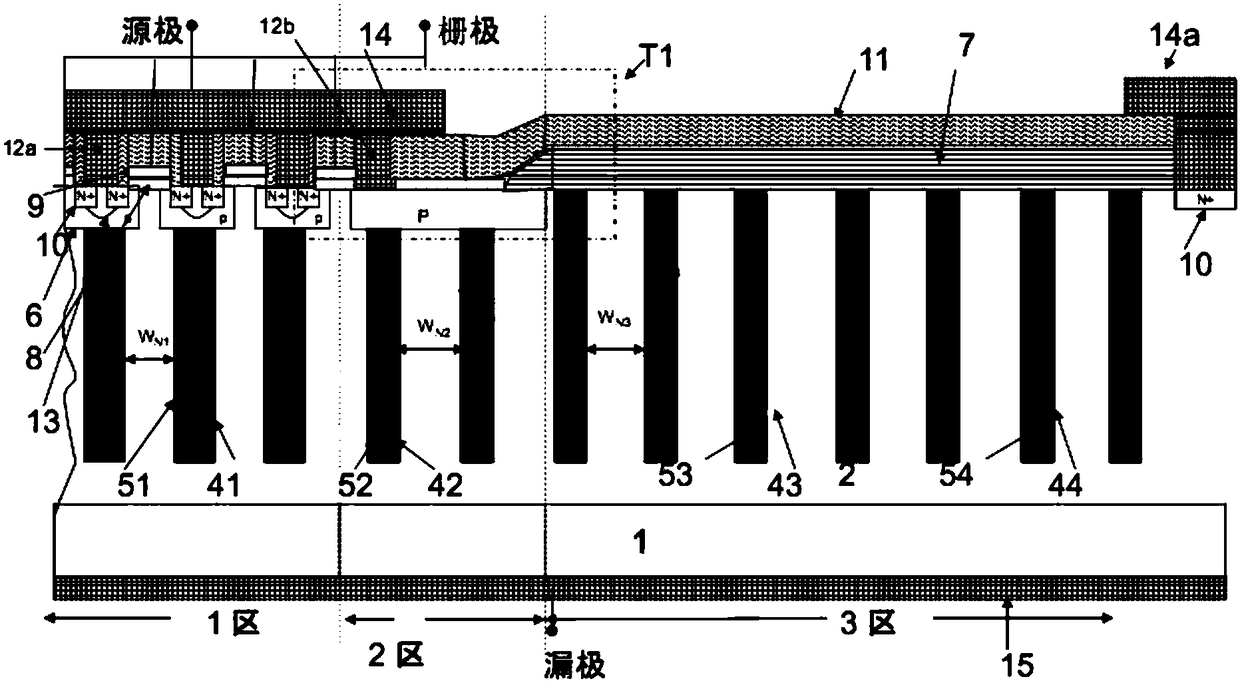

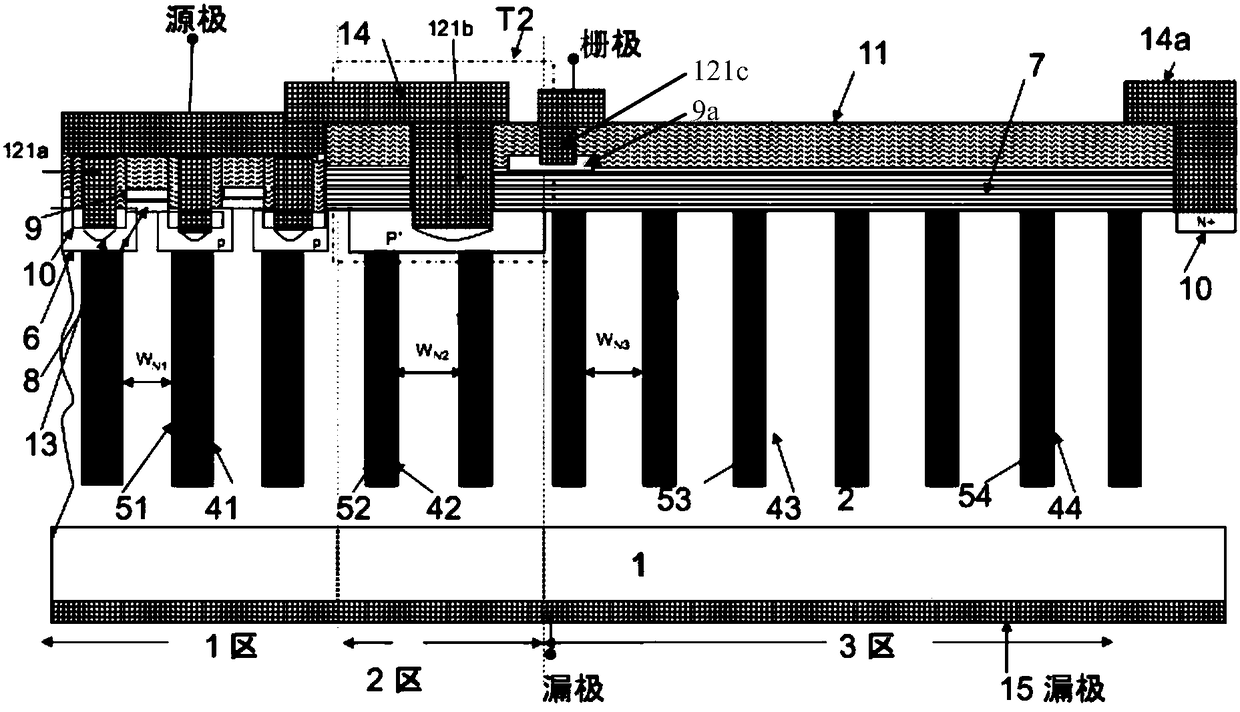

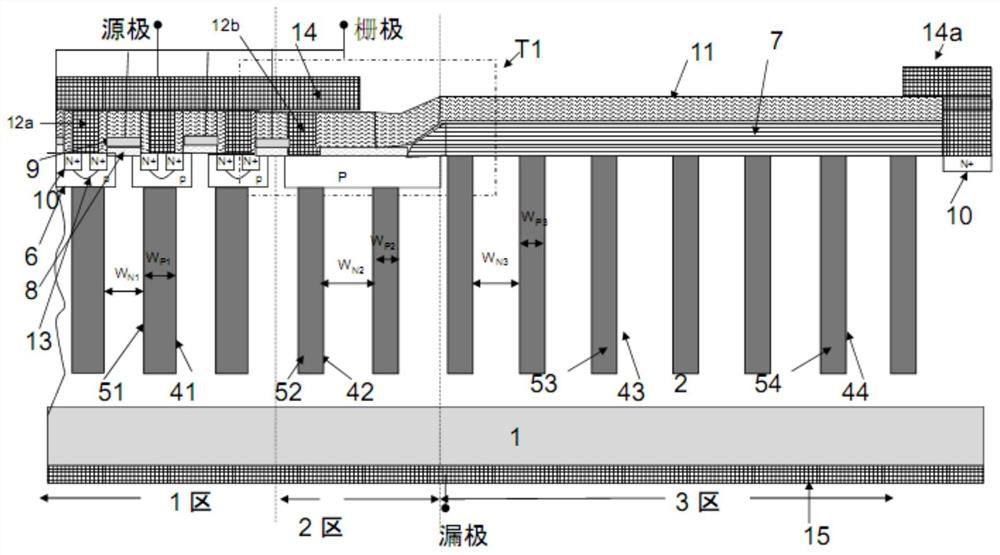

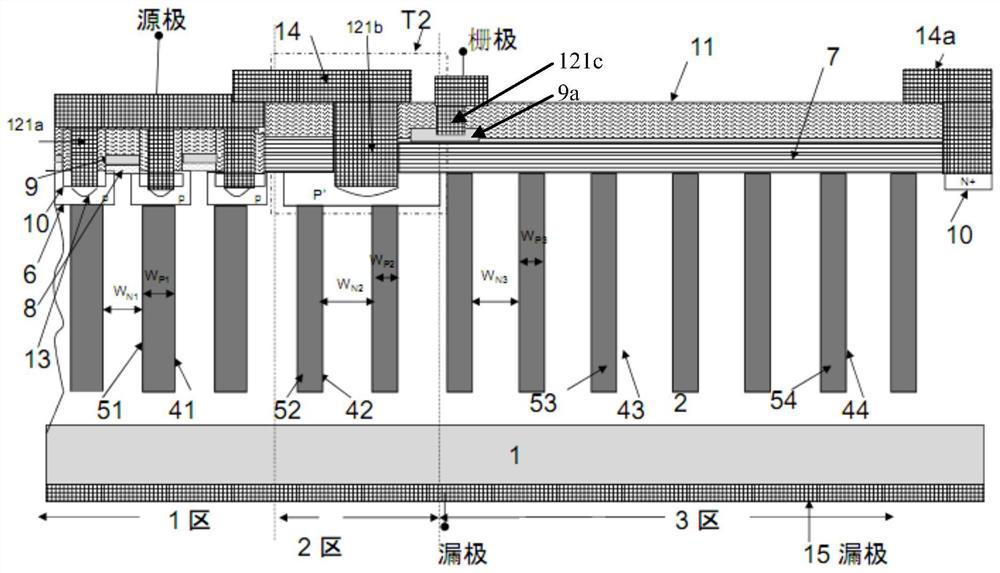

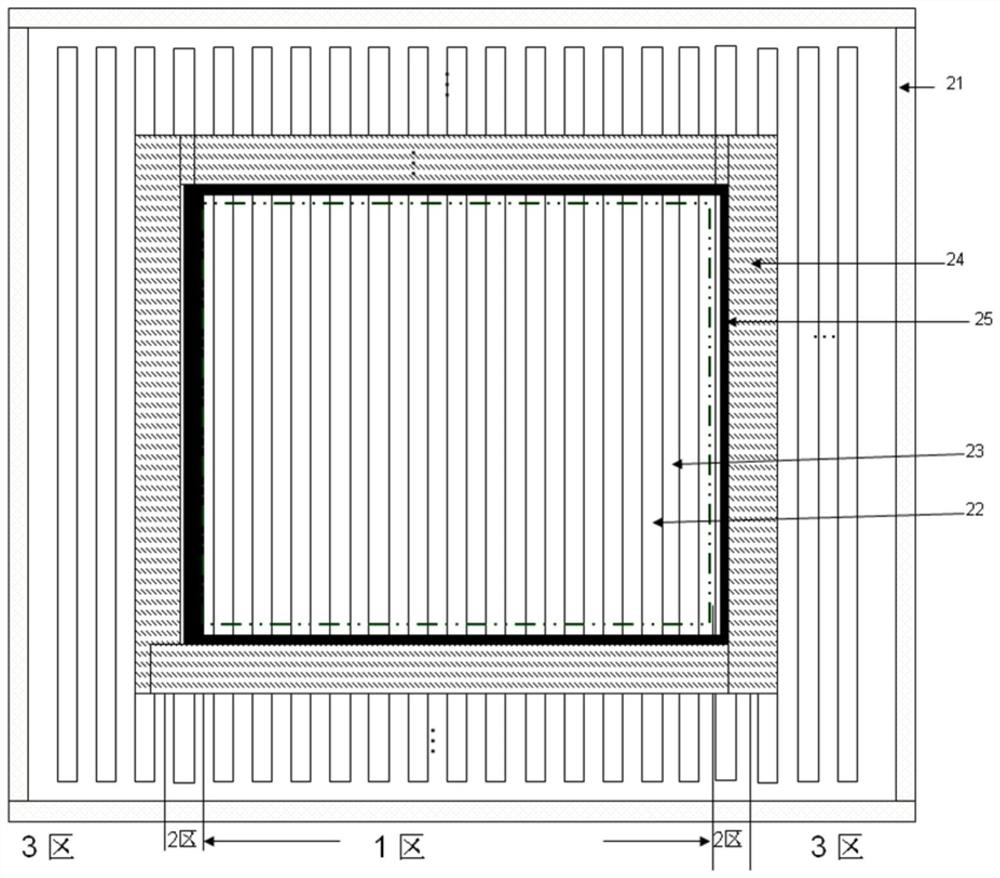

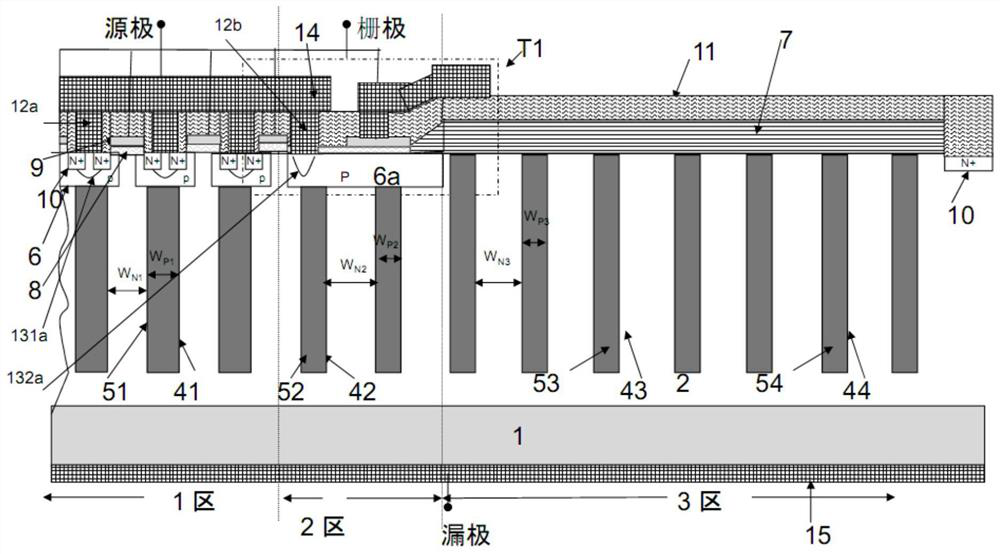

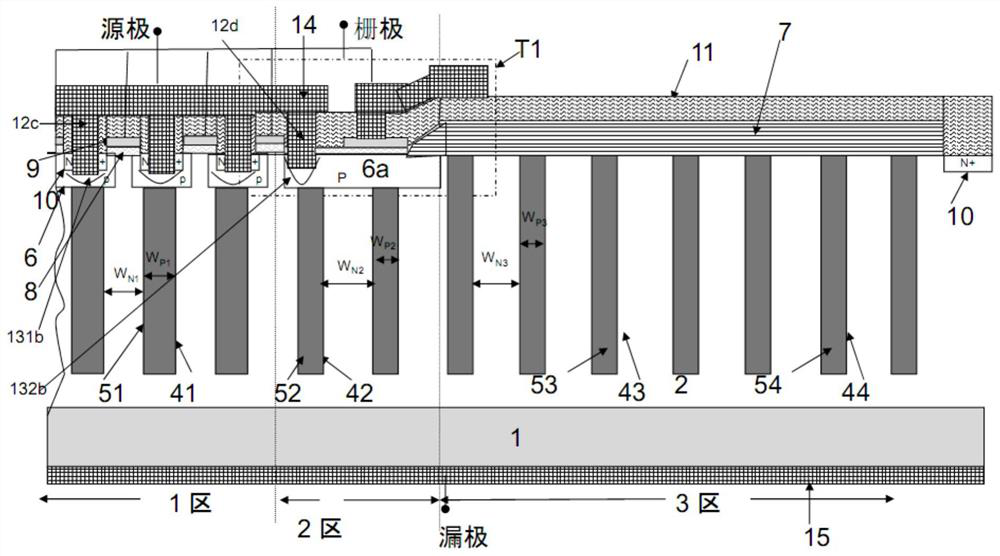

Super-junction device and manufacturing method thereof

ActiveCN108428733AReduce photolithography processReduce injectionSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringJFET

The invention discloses a super-junction device, which is characterized in that a protective epoxy film exposes a charge flow region, completely covers a transition region and completely or mostly covers a terminal region, the setting of the protective epoxy film enables a JFET region and a source region to realize comprehensive injection, and the JFET region is enabled to be overlapped with eachP-type well and reduces the doping concentration on the surface of each corresponding P-type well, thereby enabling the overall doping concentration of the P-type wells to be increased under the condition of maintaining the threshold voltage of the device to be unchanged, and being capable of improving the avalanche current tolerance of the device. The invention further discloses a manufacturing method of the super-junction device. The super-junction device can keep the threshold voltage of the device to be unchanged while improving the injection dose of the P-type wells, so that the charge flow region and the transition region are enabled to be improved in avalanche current tolerance, and thus the performance of the device is improved; and the number of times of the photoetching process can also be reduced, the performance and reliability of the device can be maintained, the manufacturing cost can be reduced, and the production cycle can be shortened.

Owner:SHENZHEN SANRISE TECH CO LTD

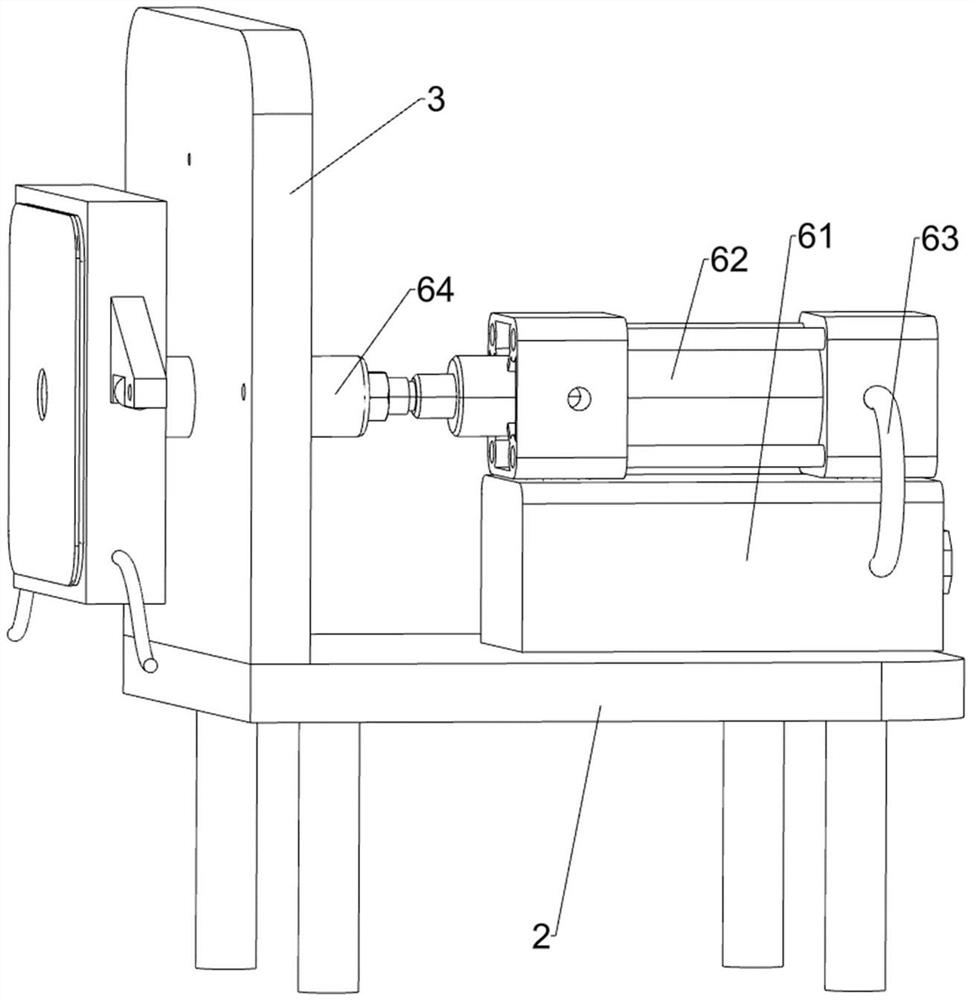

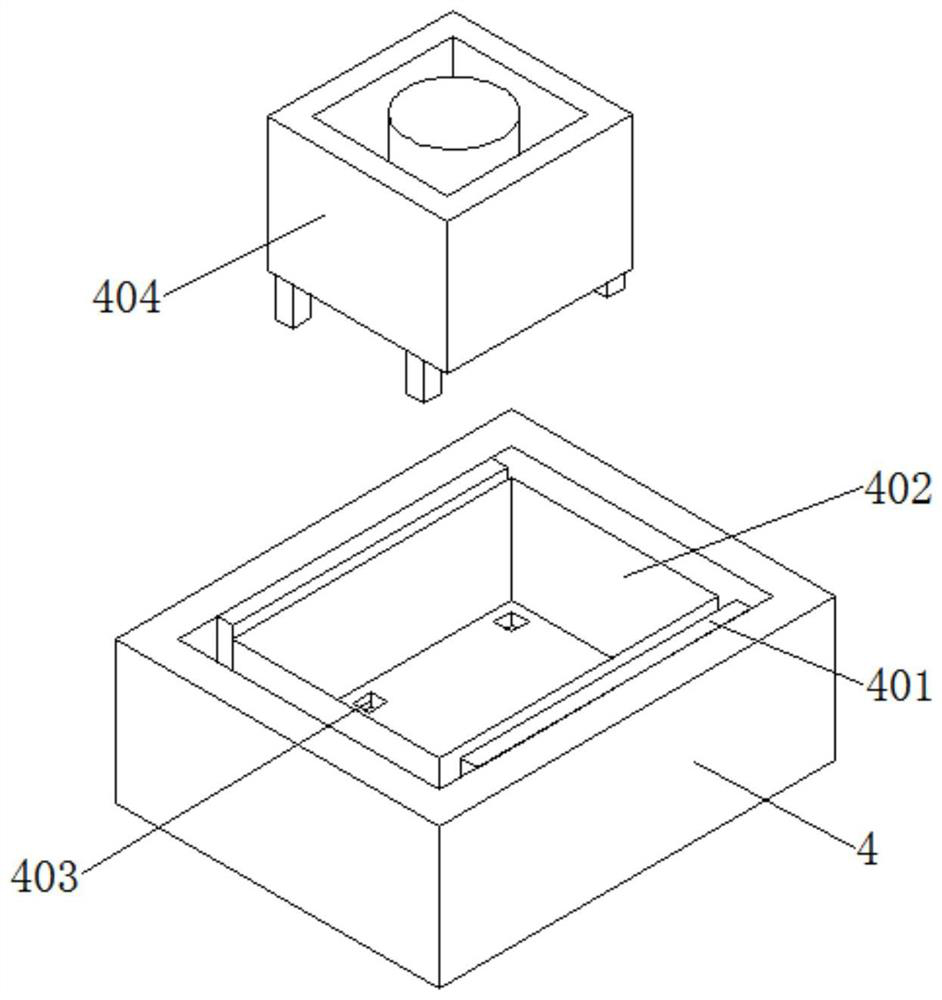

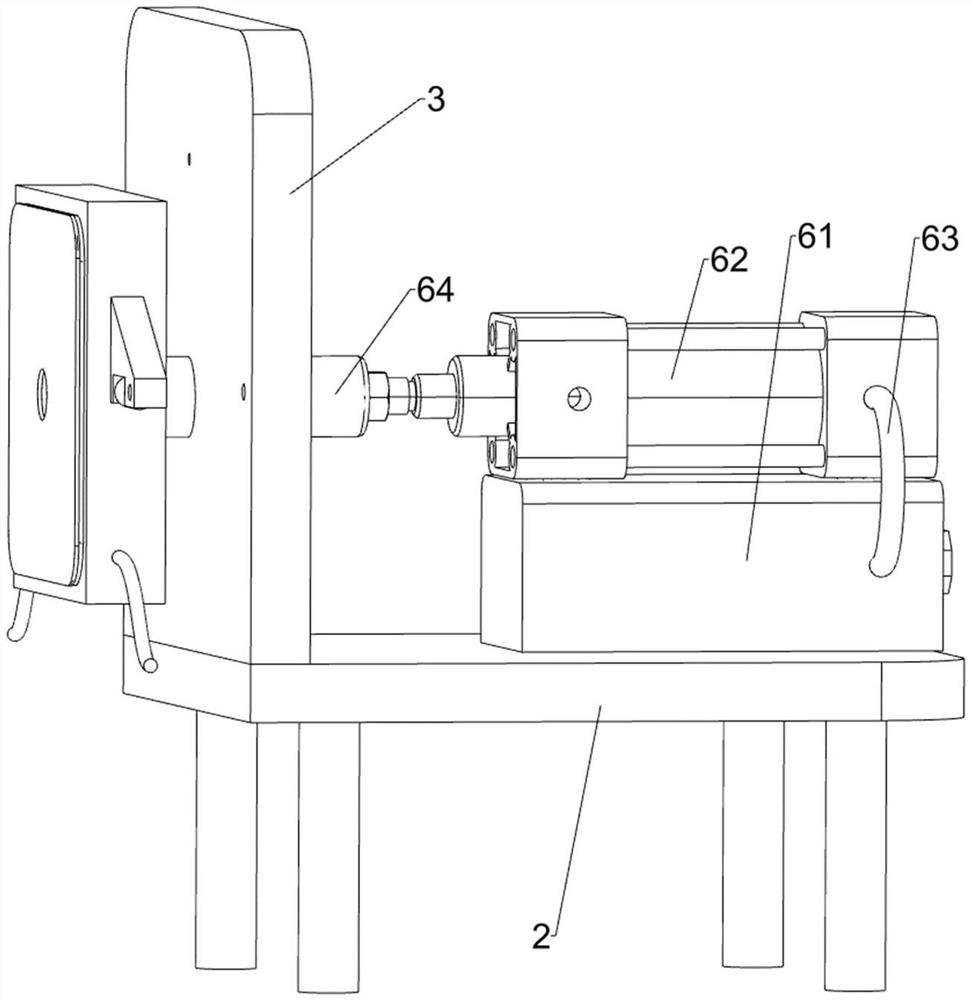

Filter pressing device for producing nanometer calcium carbonate

ActiveCN112337152ASimple structureImprove efficiencyFiltration separationPhysical chemistryFilter press

The invention relates to a filter pressing device, in particular to a filter pressing device for producing nanometer calcium carbonate. The filter pressing device for producing nanometer calcium carbonate in the invention can realize automatic plate pulling so as to facilitate removal of residual solids. The filter pressing device comprises: a bottom plate, wherein a first supporting frame is arranged on one side of the bottom plate; two supporting plates, which are arranged at the middle portion of the bottom plate at an interval; a feeding mechanism, which is arranged on the side, away fromthe first supporting frame, of the bottom plate; a filtering mechanism, which is arranged between the two supporting plates; and a discharging mechanism, which is arranged at the bottoms of the two supporting plates. Intermittent movement of the discharging mechanism is matched with a first inhaul cable to sequentially and intermittently pull plate frames so as to separate the plate frames, a structure is simple, and efficiency is stable.

Owner:江西若水新材料科技有限公司

a laser

ActiveCN105305215BStable chemical propertiesWith anti-reflection propertiesOptical resonator shape and constructionFemto second laserPicosecond

The invention discloses a laser device. The laser device comprises a semiconductor laser device, an optical shaping system, a coupling reflector, a reflector, a plate electrode pair, a discharge cavity, a matching network, a radio-frequency power supply, a tail mirror and an output mirror, and is characterized in that the discharge cavity is filled with working gas; the plate electrode pair is symmetrically placed inside the discharge cavity, and the surface of the electrode pair has high reflection characteristic for semiconductor pump laser and output gain laser; the semiconductor laser is pump light, the central wavelength of the semiconductor laser is matched with gas particle absorption spectral lines after radio-frequency discharge of the working gas inside the discharge cavity, and the semiconductor laser is injected into the discharge cavity through the coupling reflection mirror. The laser device has the characteristics of compact structure, small size, uniform discharge, high pumping efficiency and the like, can effectively prevent nonlinear effect of high-power continuous single-mode laser and high-power picosecond and femtosecond laser, and realizes high laser beam quality, good atmosphere and optical fiber transmission characteristic and laser output of medium and high power under high processing efficiency condition.

Owner:HUAZHONG UNIV OF SCI & TECH

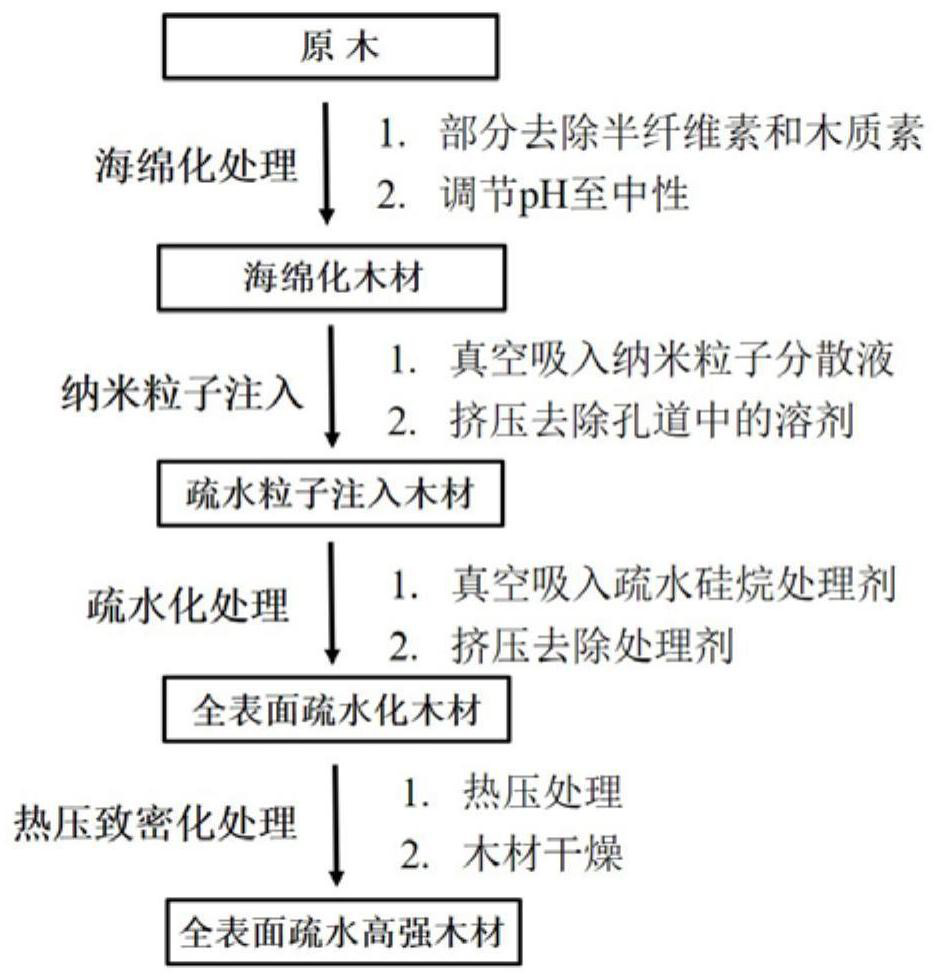

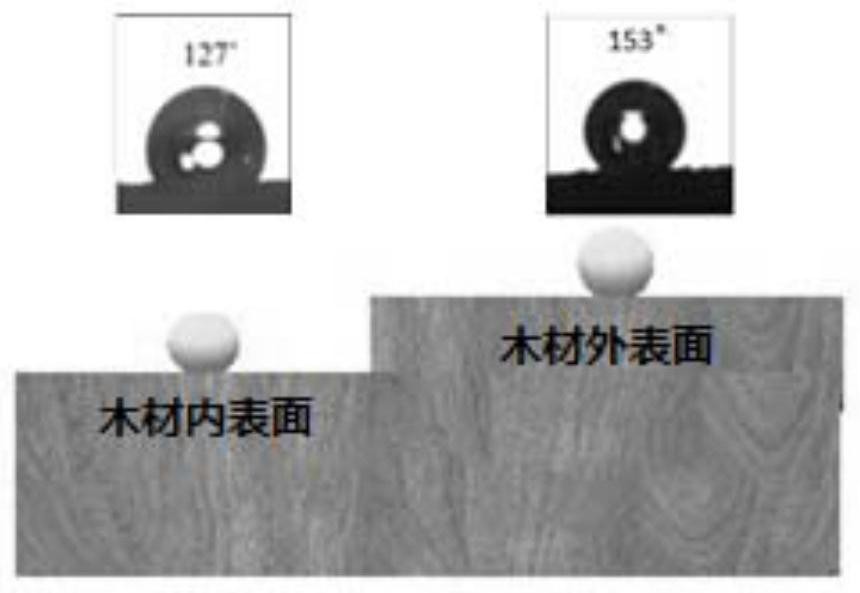

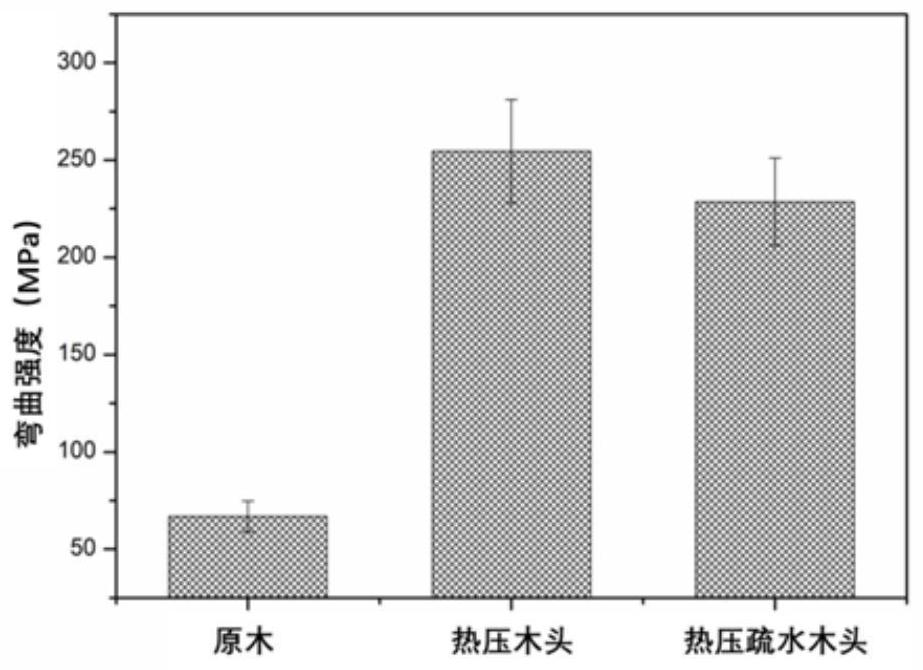

A full-surface super-hydrophobic antifreeze high-strength wood and its manufacturing method

ActiveCN111015857BImprove frost resistanceExcellent high strengthWood treatment detailsPretreatment apparatusPolymer scienceHemicellulose

Owner:DONGHUA UNIV

Superjunction device and method of manufacturing the same

ActiveCN108428733BReduce photolithography processReduce injectionSemiconductor/solid-state device manufacturingSemiconductor devicesJFETMaterials science

The invention discloses a super-junction device, which is characterized in that a protective epoxy film exposes a charge flow region, completely covers a transition region and completely or mostly covers a terminal region, the setting of the protective epoxy film enables a JFET region and a source region to realize comprehensive injection, and the JFET region is enabled to be overlapped with eachP-type well and reduces the doping concentration on the surface of each corresponding P-type well, thereby enabling the overall doping concentration of the P-type wells to be increased under the condition of maintaining the threshold voltage of the device to be unchanged, and being capable of improving the avalanche current tolerance of the device. The invention further discloses a manufacturing method of the super-junction device. The super-junction device can keep the threshold voltage of the device to be unchanged while improving the injection dose of the P-type wells, so that the charge flow region and the transition region are enabled to be improved in avalanche current tolerance, and thus the performance of the device is improved; and the number of times of the photoetching process can also be reduced, the performance and reliability of the device can be maintained, the manufacturing cost can be reduced, and the production cycle can be shortened.

Owner:SHENZHEN SANRISE TECH CO LTD

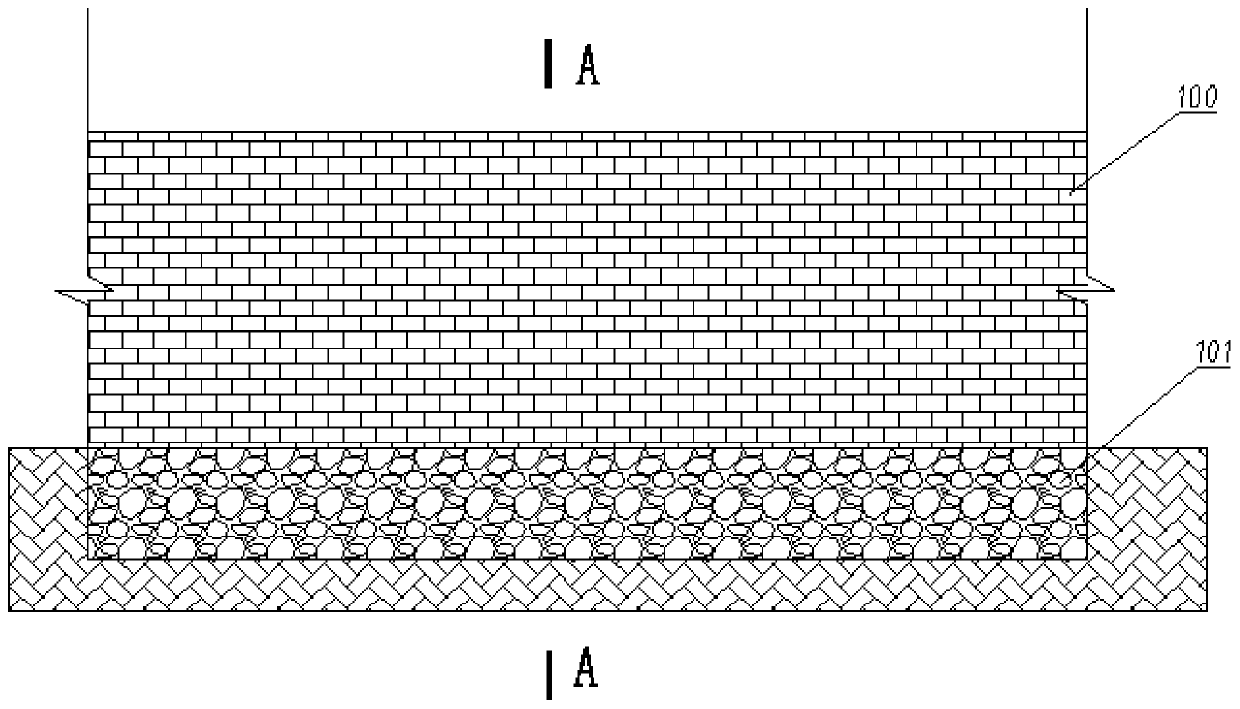

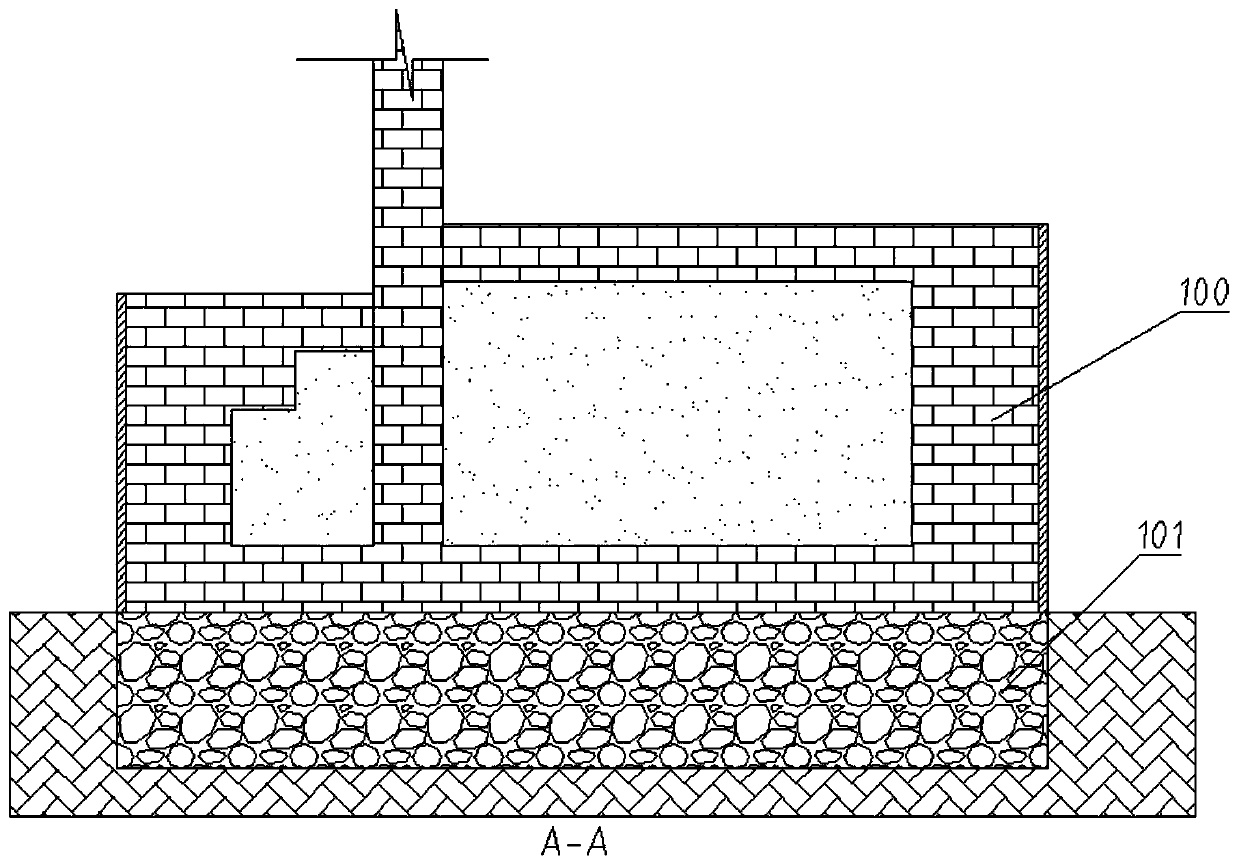

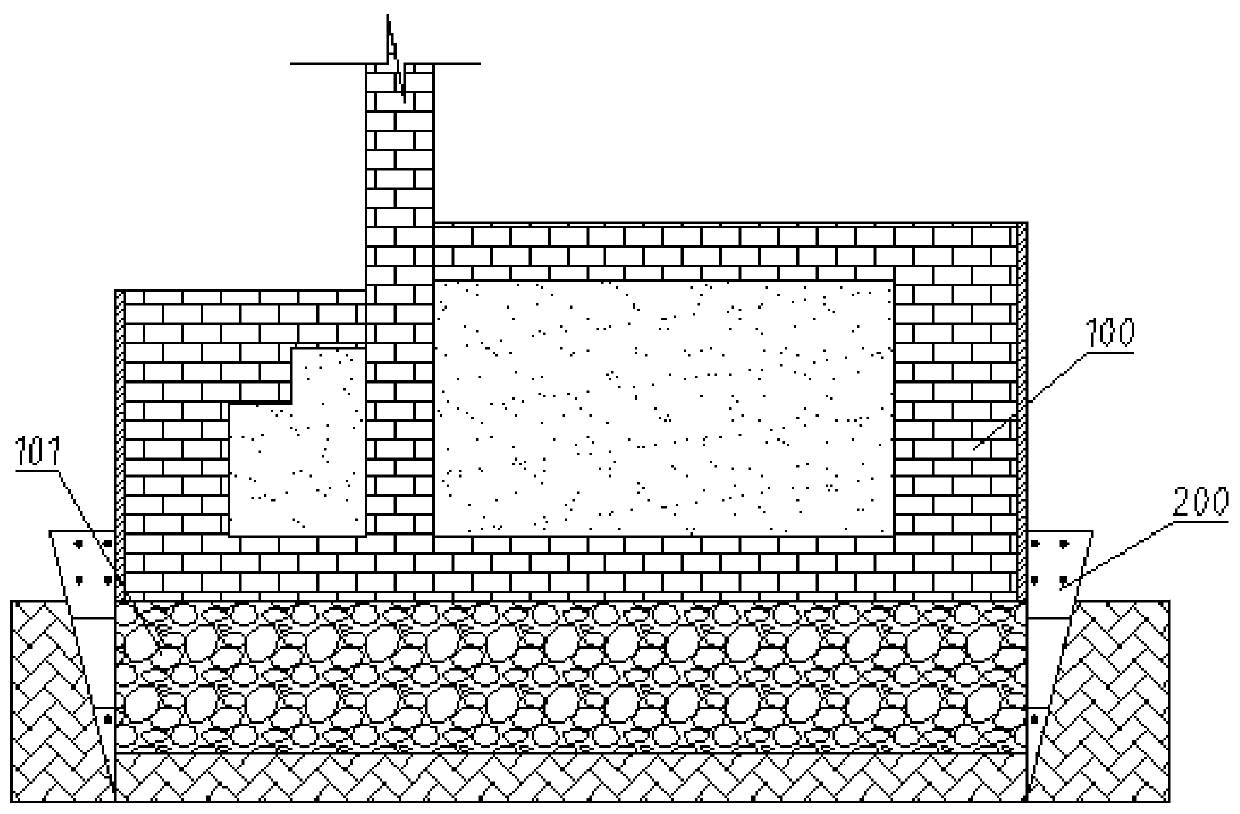

An Integral Underpinning Method for Discrete Brick-laying Platforms

ActiveCN108252533BPrevent lateral deformationGuaranteed integralBuilding repairsArchitectural engineeringSuperstructure

The invention provides an integral underpinning method for a discrete type bricking platform. The integral underpinning method specifically comprises the following steps that S1, a platform foundationis surrounded by concrete retaining plates; S2, grouting reinforcement is carried out for the platform foundation at the corresponding position after installing the concrete retaining plates; S3, cross drilling is carried out on the platform foundation after grouting; S4, underpinning profile steel is inserted into the drilled holes, and the two ends of the underpinning profile steel can extend out from the corresponding concrete retaining plates to the outside; and S5, grouting is carried out in the holes in which the underpinning profile steel is placed so as to enable the underpinning profile steel and the platform to form a whole. According to the integral underpinning method, the stability of the platform foundation is increased by grouting the discrete and loose bricking platform foundation, through the insertion of a dense underpinning plate, the structure located above the platform foundation is underpinned integrally, the integral underpinning of the discrete type bricking platform foundation is realized, and the stability of the superstructure of the underpinning platform is guaranteed.

Owner:SHANGHAI NO 4 CONSTR +1

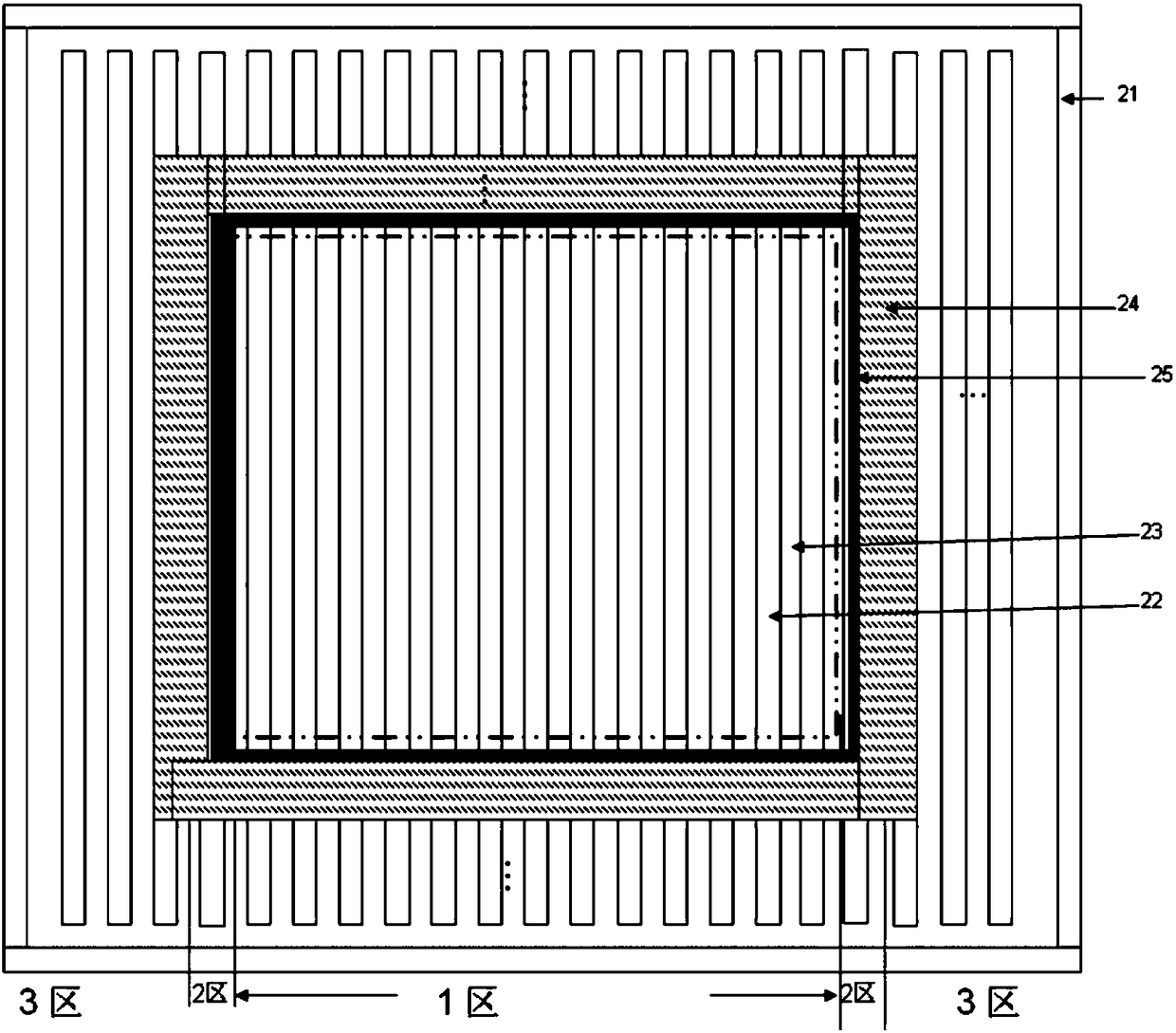

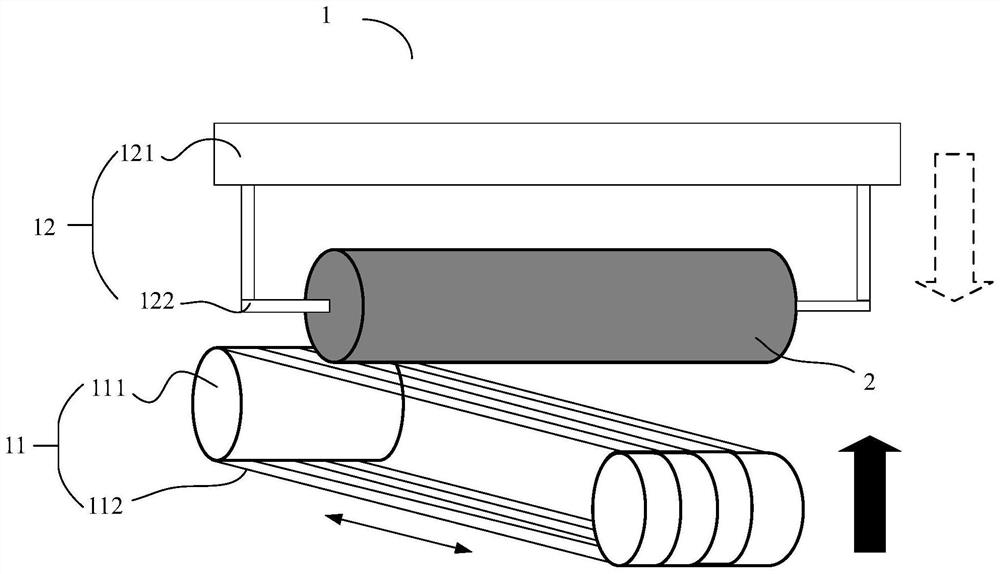

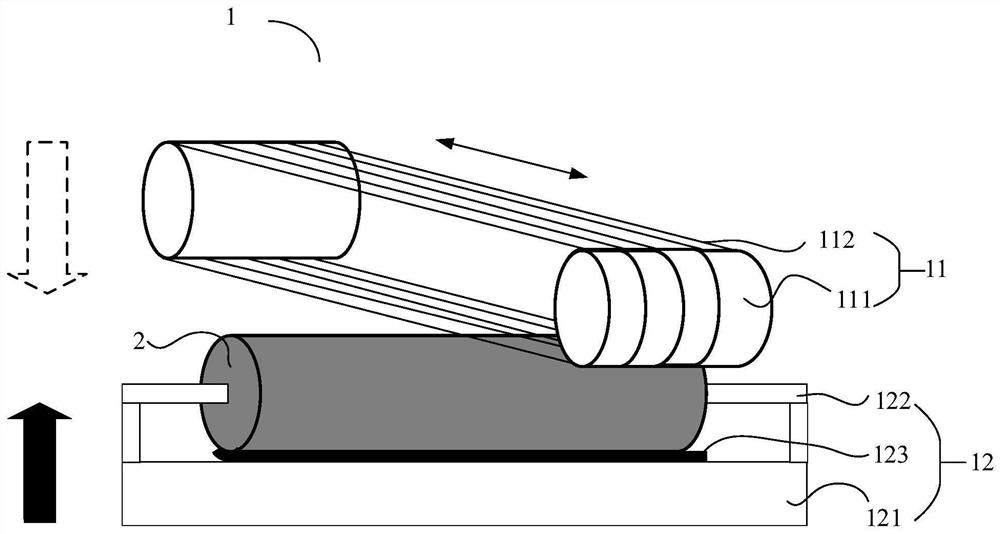

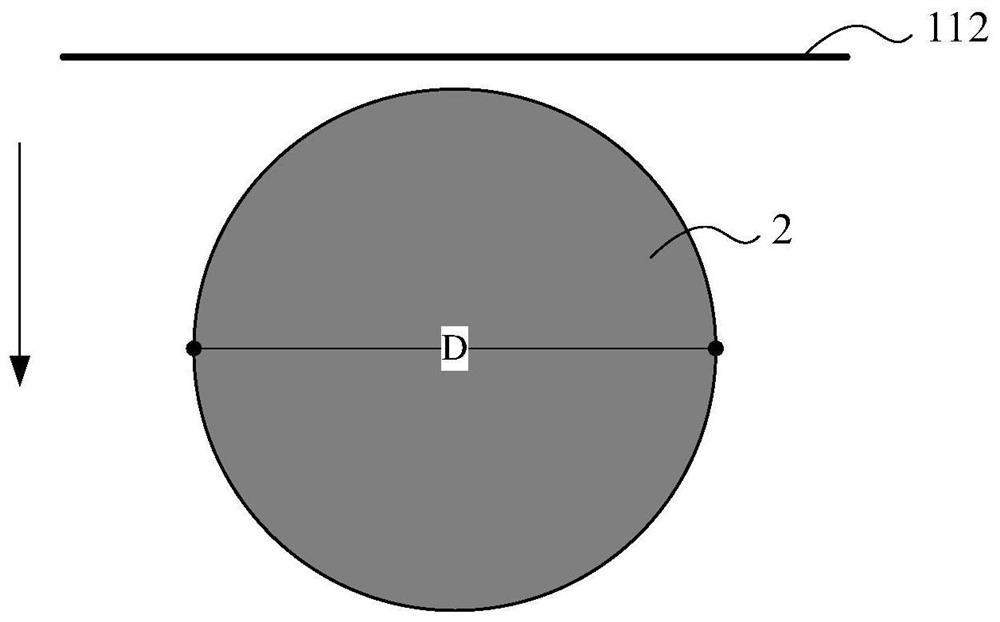

Method and device for multi-wire cutting of crystal bar

ActiveCN112936627AEasy to slide outFull injectionWorking accessoriesFine working devicesReciprocating motionWire cutting

The embodiment of the invention discloses a method and device for multi-wire cutting of a crystal bar. The method can comprise the steps that on the basis of opposite movement between the to-be-machined crystal bar and a cutting line in high-speed reciprocating motion in the vertical direction, the cutting line makes contact with the to-be-machined crystal bar, and the to-be-machined crystal bar is cut; and in the process that the to-be-machined crystal bar is cut by the cutting line, the to-be-machined crystal bar is controlled to rotate around the axis according to a set rotation strategy.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

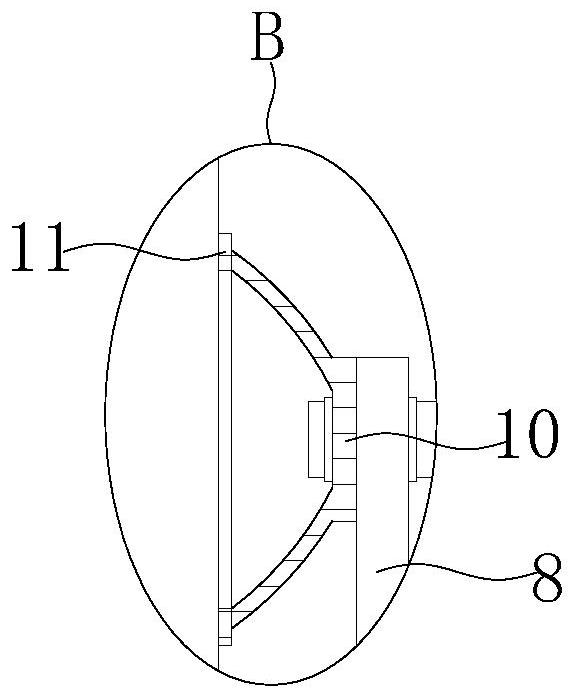

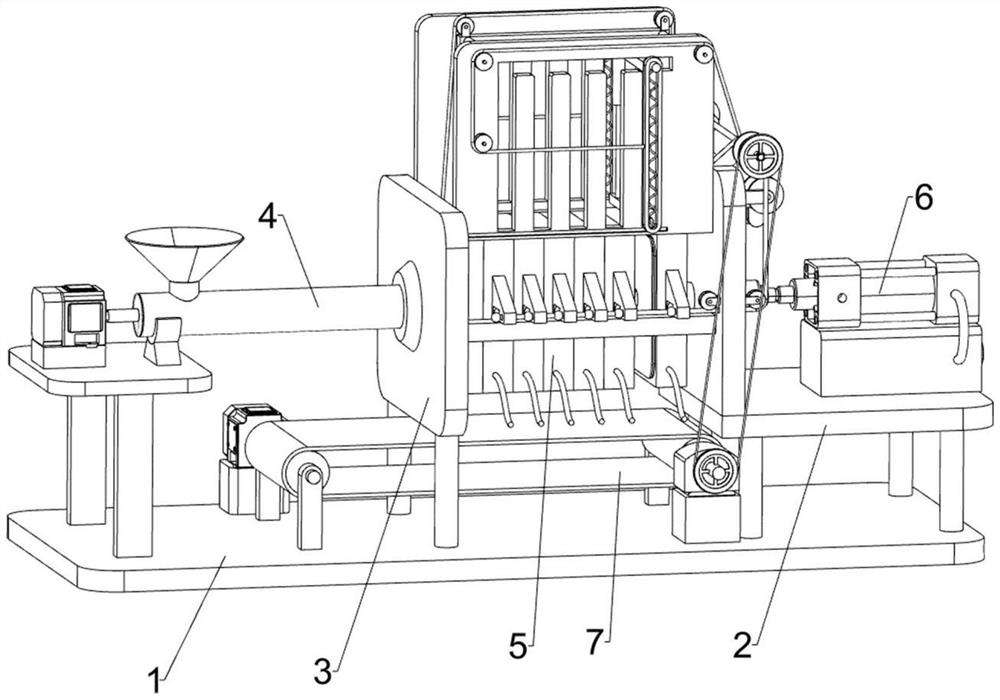

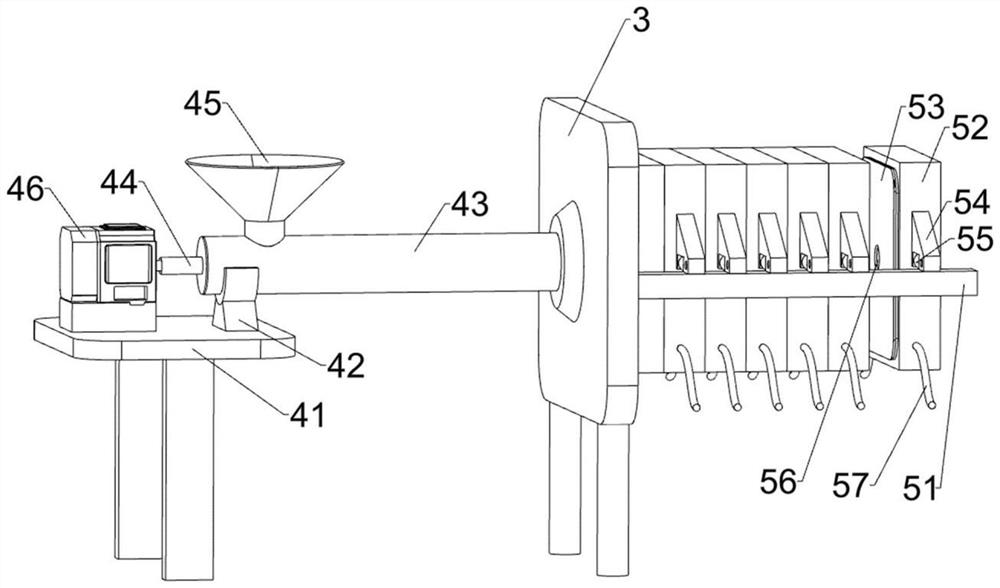

Free-fall mixed powder gas atomization water-cooled quick-setting magnetic abrasive preparation equipment

ActiveCN105665719BEasy particle size controlUniform particle sizeOther chemical processesFree fallingSpray nozzle

A free-fall powder mixing gas atomization water-cooled quick-setting magnetic abrasive preparation equipment, including a double-nozzle atomization water cooling device (41), a screw powder mixer (17), a water-sealed dust removal device (42), and a gas station (44) . The atomization process of the present invention adopts two nozzles, a low-pressure powder-mixing jet nozzle and a high-pressure air-flow nozzle, which solves the problem of erosion and wear of a single nozzle; adopts a free fall method, avoiding the erosion and wear of the metal liquid flow conduit, the metal liquid The problem of backflow and upper spraying; the cooling method of water cooling and rapid condensation is adopted, which solves the problem of hard abrasive particles dissociated from the metal matrix and the control of depth distribution, controls the distribution of hard abrasives in the superficial layer of magnetic abrasives, and reduces The flight distance of the powder-mixed metal droplets, the reduced free-fall atomization condensation chamber and the overall height of the equipment are improved. The invention provides a new device for the realization of the preparation method of the free-fall mixed powder gas atomization water-cooled quick-setting magnetic abrasive and the preparation of the high-performance magnetic abrasive.

Owner:SHANDONG UNIV OF TECH

Preparation method of free-fall two-stage powder-mixing gas-atomized water-cooled fast-setting magnetic abrasive

Owner:SHANDONG UNIV OF TECH

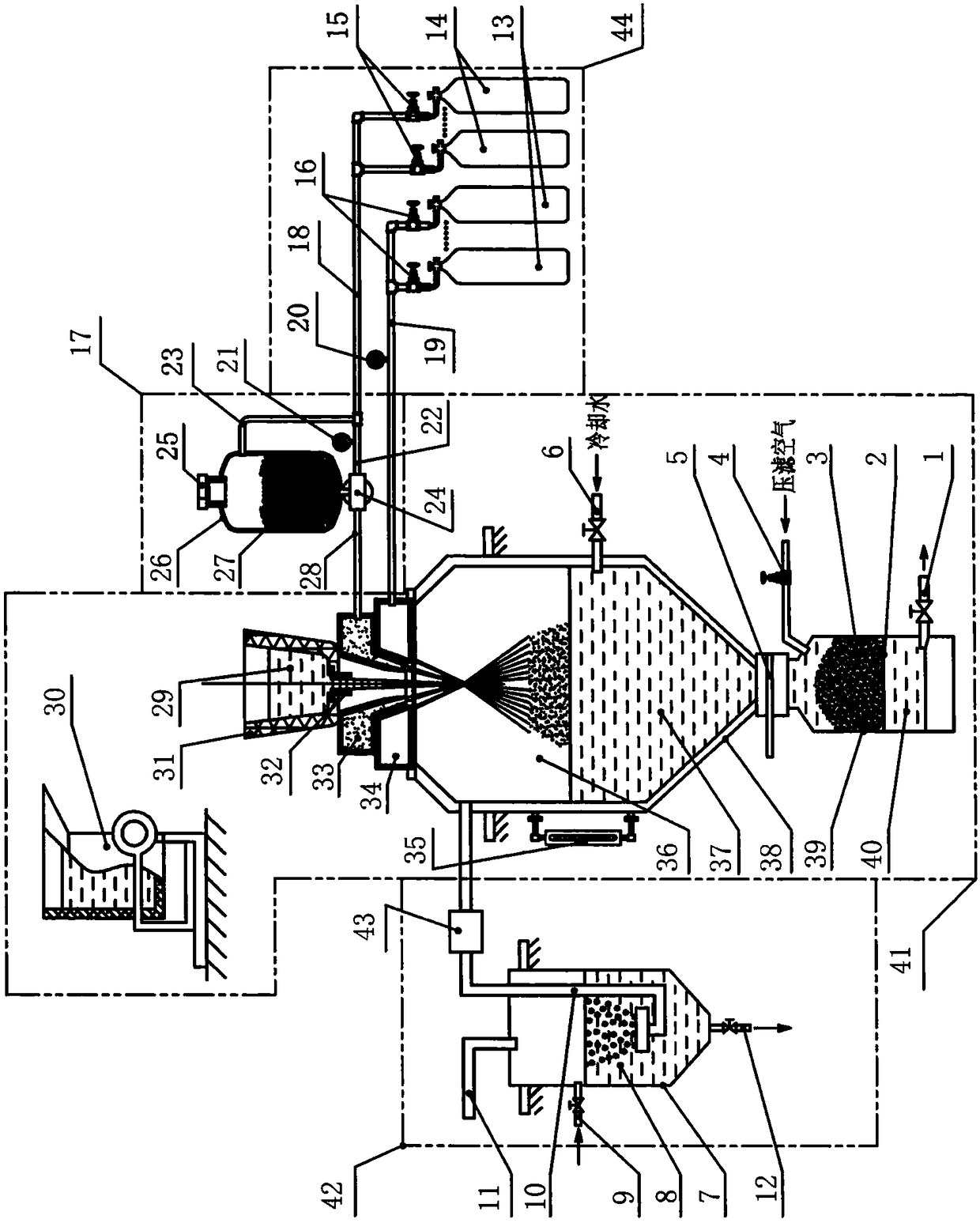

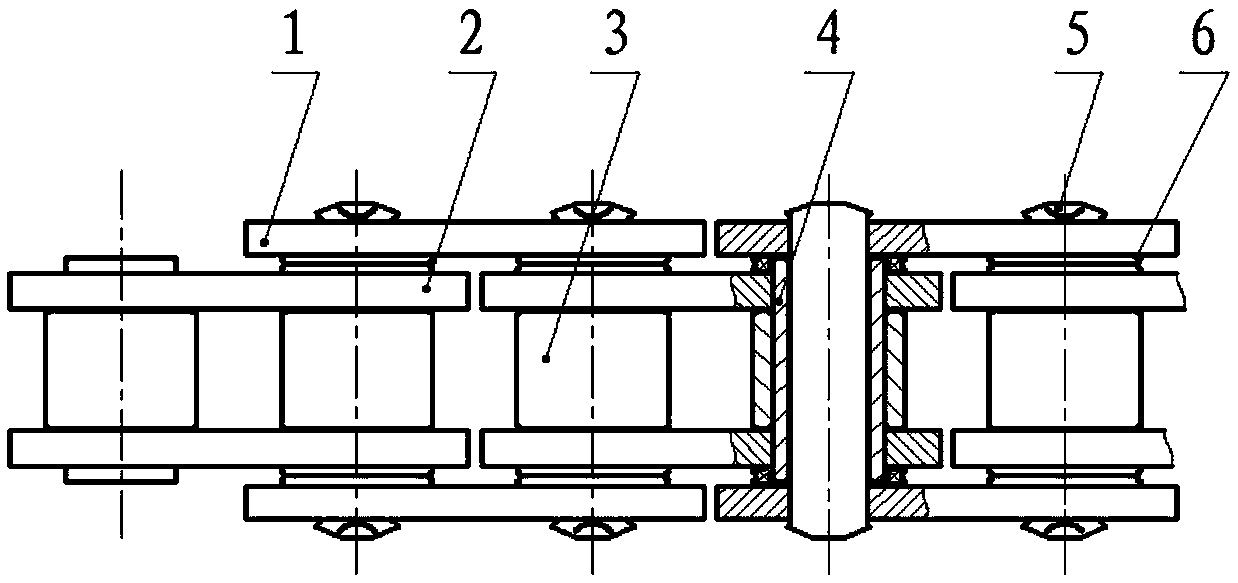

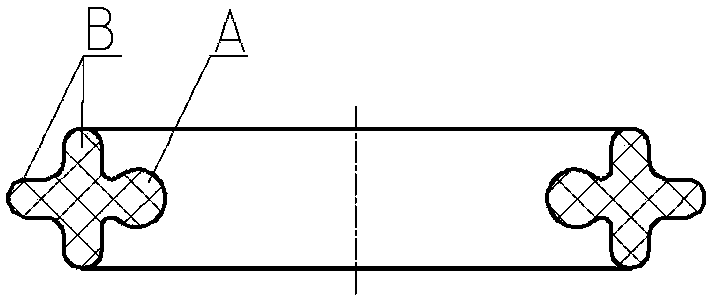

Light-weight X-ring oil seal chain of large-displacement locomotive

The invention relates to a light-weight X-ring oil seal chain of a large-displacement locomotive. The light-weight X-ring oil seal chain comprises outer single links, inner single inks and seal ringsfor cooperation. The inner single links are formed by combining sleeves, rollers and inner chain plates. The outer single links are composed of pins arranged in the sleeves and outer chain plates in an interference fit mode. The seal rings are located between the contact surfaces of the inner and outer chain plates. The end face of each seal ring is shaped like a star. The star-shaped cross section is of a cross and circle combined structure. The star-shaped structure has the advantages of excellent wear resistance of an X-ring and excellent compression resistance of an O-ring. The four ends of each star-shaped ring are all of a circular arc structure. The diameter of the circular arc of the end, making contact with the sleeve and the corresponding outer chain plate, of each star-shaped ring is 1.4 times greater than the diameter of the circular arcs of the other three ends of the star-shaped ring. Through the technical scheme, the tensile strength and fatigue strength of the chain areimproved, the service life of the chain is prolonged, and the chain has excellent reliability.

Owner:青岛征和链传动有限公司

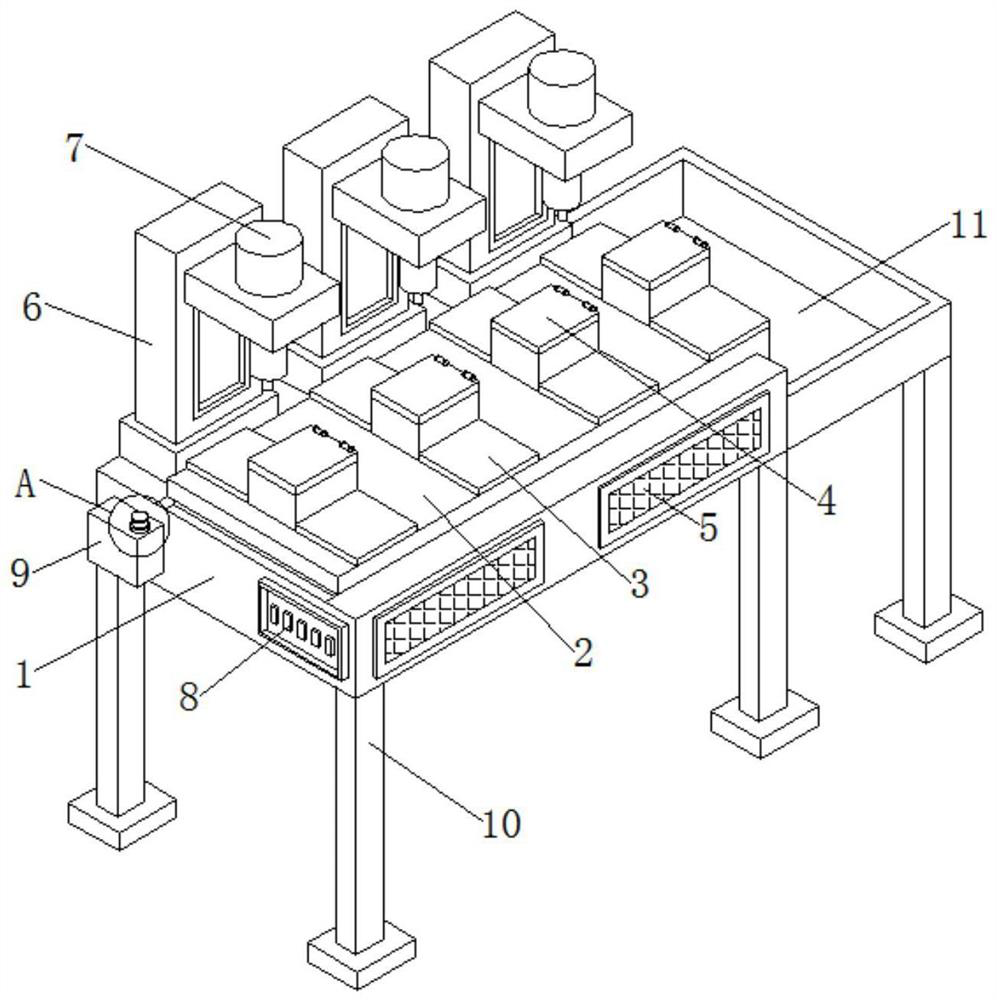

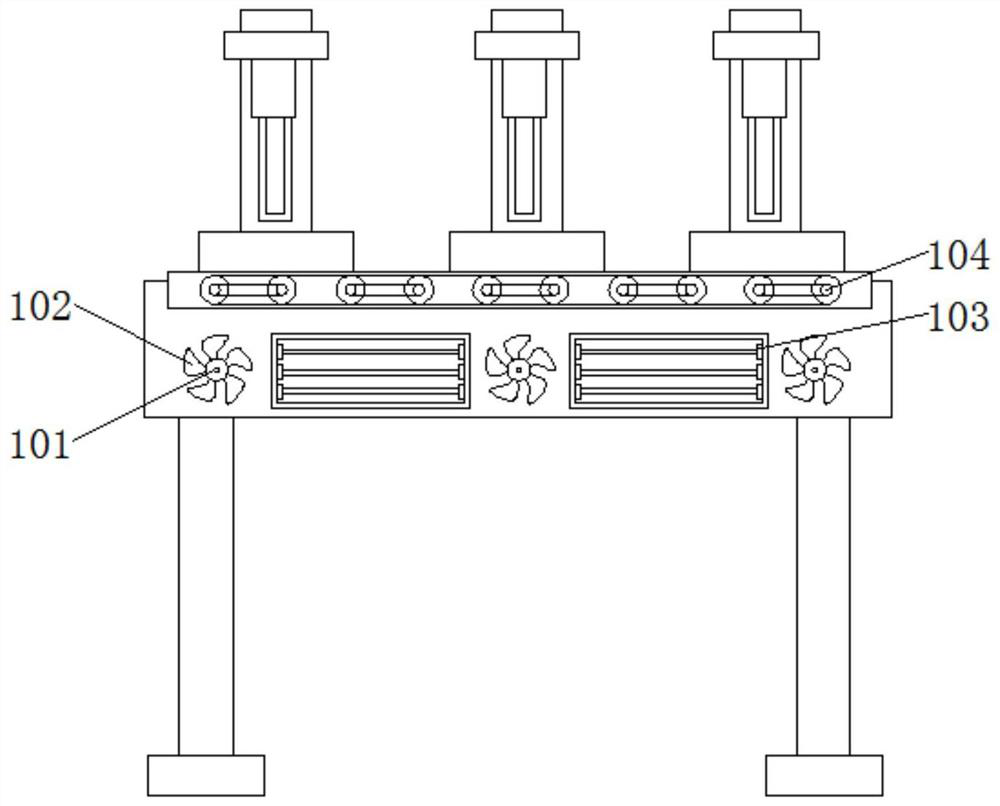

Cooling device applied to plastic production line

InactiveCN112895357ANot easy to spillAvoid the phenomenon of injection overflowInjected materialMachine

The invention discloses a cooling device applied to a plastic production line. The cooling device comprises a machine tool, wherein the upper end of the machine tool is movably connected with a movable panel, the upper end of the movable panel is provided with a fixed plate, and the upper end of the fixed plate is movably provided with a cooling mechanism. The cooling device has the beneficial effects that when the device is used, the cooling mechanism of the device can be moved at the upper end of the machine tool through the movable panel, when the cooling mechanism is moved to the lower end of an injection machine, material injection work can be carried out on the interior of the cooling mechanism, a mold is arranged inside the cooling mechanism, refrigeration plates are fixedly connected to the two ends of the exterior of the mold, when plastic is injected into a mold box, then the interior of the mold box with the refrigeration plates is cooled through the refrigeration plates outside the mold box, and when the device performs plastic injection work, in order to make the plastic injection angle moderate and make the plastic not prone to overflow out of the mold box, the injection angle of the injection machine of a moving mechanism can be controlled through the moving mechanism, so that the injection machine achieves the effect that the injected materials are moderate and not prone to overflow.

Owner:赵淑婷

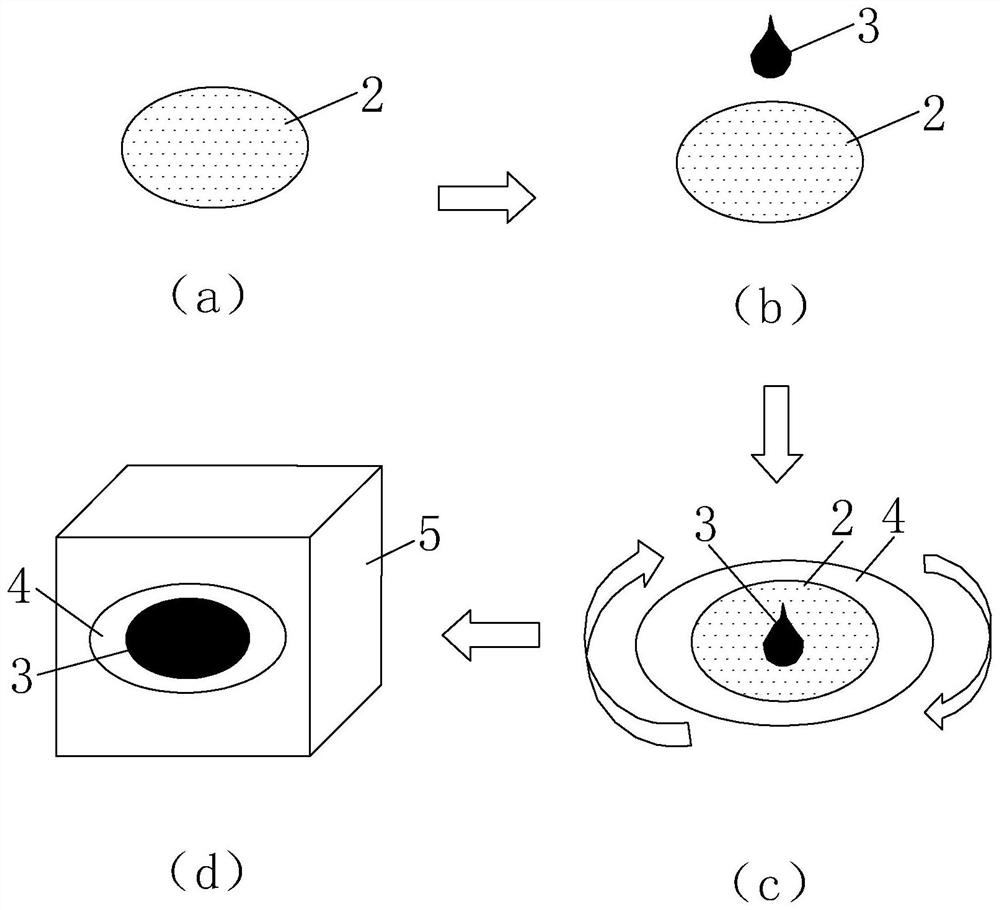

Quantum dot solution injection method, light color conversion structure and light-emitting chip

PendingCN114725251AStrong penetrating powerFull injectionSemiconductor devicesPhysical chemistryQuantum dot

The invention discloses a quantum dot solution injection method which comprises the following steps: firstly, carrying out pretreatment operation on a porous structure, removing water vapor of the porous structure and cleaning stains on the surface and / or in holes of the porous structure, so that a quantum dot solution can better permeate into the holes; then, a quantum dot solution is arranged on the surface, where the holes are exposed, of the porous structure, vacuumizing is conducted to enable the environment where the porous structure is located to be a vacuum environment, gas in the holes can be pumped out through vacuumizing, the quantum dot solution can permeate into the holes conveniently, the quantum dot solution can be fully injected into the holes, light leakage can be avoided, and the quality of the product is improved. According to the light color conversion structure, a good color conversion effect is achieved, gas in the quantum dot solution can be pumped out while vacuumizing is conducted, and the light color conversion structure with better performance is obtained. Meanwhile, the invention further provides a light color conversion structure and a light-emitting chip which adopt the injection method to inject the quantum dot solution.

Owner:HCP TECH CO LTD

A dental floss stick and its manufacturing process

ActiveCN108186143BReduce cut resistanceReduce bleeding riskGum massageDental flossDental flossingBiomedical engineering

Owner:余姚市科琳日用品有限公司

Superjunction device and method of manufacturing the same

ActiveCN108428732BImprove softness factorImprove reverse recovery characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesElectron holeReverse recovery

The invention discloses a super-junction device, which is characterized in that a protective epoxy film exposes a charge flow region, completely covers a transition region and completely or mostly covers a terminal region, a second contact hole at the top of a P-type ring of the transition region is enabled to penetrate deeper than a first contact hole at the top of a P-type well of the charge flow region by the thickness of one protective epoxy film, and thus the junction depth of a second P+ contact region at the bottom of the second contact hole is enabled to be less than the junction depthof a first P+ contact region at the bottom of the first contact hole, so that the distance between a hole collected by the P-type ring to the second P+ contact region, and a softness factor of reverse recovery of a body diode of the device is increased. The invention further discloses a manufacturing method of the super-junction device. According to the invention, the reverse recovery characteristics of device can be improved, and the avalanche tolerance of the device is enhanced at the same time.

Owner:SHENZHEN SANRISE TECH CO LTD

Strain culture device convenient to coat based on enzyme engineering

PendingCN114058488AIntegrity guaranteedPrevent bacteria sprayBioreactor/fermenter combinationsBiological substance pretreatmentsEnzymeMolecular biology

The invention relates to the field of enzyme engineering, in particular to a strain culture device convenient to coat based on enzyme engineering, which comprises a support base, a first support frame, a second support frame, a first rotating frame and the like; the first support frame is connected to the support base through bolts, the second support frame is connected to the top of the first support frame, and the first rotating frame is rotationally connected to the first support frame. A second rotating frame can be tightly attached to the surface of the agar culture medium and rotate, so that the bacterial liquid on the surface of the agar culture medium can be uniformly coated, the culture is convenient, the agar culture medium can be prevented from being damaged, and the effects of automatically, efficiently and uniformly coating the bacterial liquid on the surface of the agar culture medium and ensuring the integrity of the agar culture medium are achieved.

Owner:肖艳平

Intelligent processing equipment for laminated glass with glue overflow prevention mechanism

InactiveCN114872420AImprove stabilityAvoid affecting the effect of later useLamination ancillary operationsLaminationAdhesive glueStructural engineering

The invention discloses intelligent laminated glass processing equipment with a glue overflow prevention mechanism, and relates to the technical field of laminated glass processing. The intelligent processing equipment with the glue overflowing prevention mechanism for the laminated glass comprises a hollow plate, a glue injection mechanism and the overflowing prevention mechanism, a sealing plate is arranged in the hollow plate, a bottom plate is fixedly installed at the top of the hollow plate, two sets of cambered plates are fixedly installed at the top of the bottom plate, and two sets of vertical plates are arranged at the top of the bottom plate; the glue injection mechanism comprises a glue injection pipe and a funnel which are arranged at the top of the hollow plate, one end of the glue injection pipe is fixedly connected with the funnel and is communicated with the interior of the funnel, and the anti-overflow mechanism comprises a supporting plate and a sliding rod which are arranged on the front side of the hollow plate. According to the intelligent processing equipment with the glue overflow prevention mechanism for the laminated glass, through cooperative use of the glue injection pipe, the funnel, the L-shaped rod, the vertical clamping teeth, the L-shaped plate, the hand-cranking handle and the driving gear, glue can be injected into the glass.

Owner:重庆松大玻璃科技有限公司

A filter press device for nano calcium carbonate production

The invention relates to a filter press device, in particular to a filter press device for producing nanometer calcium carbonate. The invention provides a filter press device for nano calcium carbonate production which can automatically pull plates and conveniently remove residual solids. A filter press device for producing nano-calcium carbonate, comprising: a bottom plate, a first support frame is arranged on one side of the bottom plate; a support plate, two support plates are arranged at intervals in the middle of the bottom plate; a feeding mechanism, the bottom plate is far away from the first support frame A feeding mechanism is arranged on one side; a filtering mechanism is arranged between the two supporting plates; a discharging mechanism is arranged at the bottom of the two supporting plates. Through the intermittent movement of the discharge mechanism and the first cable intermittently pulling the plates and frames apart, the structure is simple and the efficiency is stable.

Owner:江西若水新材料科技有限公司

CMOS image sensor and its manufacturing method

ActiveCN108807440BDeepen the depthFull injectionSolid-state devicesRadiation controlled devicesCMOSEngineering

The invention discloses a CMOS image sensor, which is formed on a P-type semiconductor substrate and includes a plurality of pixel units; each pixel unit includes a surface-clamped photodiode, and the clamped photodiode includes an N sensor formed in a P-type semiconductor substrate. Type buried layer and the surface P+ layer formed on the surface of the N-type buried layer; a field oxygen layer is formed on the surface of the P-type semiconductor substrate between adjacent surface clamp photodiodes; a first field oxygen layer is formed at the bottom of the field oxygen layer P-type doped isolation region; a fully implanted second P-type doped isolation region is formed at the bottom of the N-type buried layer, and the depth of the bottom surface of the first P-type doped isolation region is greater than or equal to the second P-type doped isolation region The depth of the top surface of the region is such that the bottom of the first P-type doped isolation region and the second P-type doped isolation region overlap. The invention also discloses a manufacturing method of the CMOS image sensor. The invention can save cost under the condition of realizing substrate noise isolation.

Owner:SHANGHAI HUALI INTEGRATED CIRCUIT CORP

Quick fix print head for ceramic printer

ActiveCN107901187BFull injectionWell mixedAdditive manufacturing apparatusCeramic shaping apparatusMaterials scienceExtrusion

The invention discloses a quickly-curing spray head of a ceramic printer. The quickly-curing spray head comprises a nozzle, an inner cavity positioned in the middle, a mud pipe and a curing pipe; multiple mud channels which are arranged at intervals are arranged in the mud pipe, wherein the mud channels are in a gap shape, the mud channels are separated from one another, multiple curing channels are arranged in the curing pipe, and the curing channels are separated from one another; in the inner cavity, the curing channels and the mud channels are intersected in the inner cavity, the curing channels in the inner cavity are located between the adjacent mud channels, the mud channels and the curing channels are alternately arranged and are isolated from each other; and in the nozzle, the curing channels and the mud channels are gradually close to each other until the curing channels and the mud channels are combined, and after being combined, the curing channels and the mud channels communicate with an extrusion opening. According to the quickly-curing spray head of the ceramic printer, mud material is cured in the spray head so that the mud material can be rapidly cured and hardenedwhen being extruded from the spray head, the shape of a printing part required by a user is obtained, the problem of appearance deformation caused by flowing of the mud material is avoided, and printing precision is higher.

Owner:LONGQUAN JINHONG PORCELAIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com