Patents

Literature

62results about How to "Prevent lateral deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

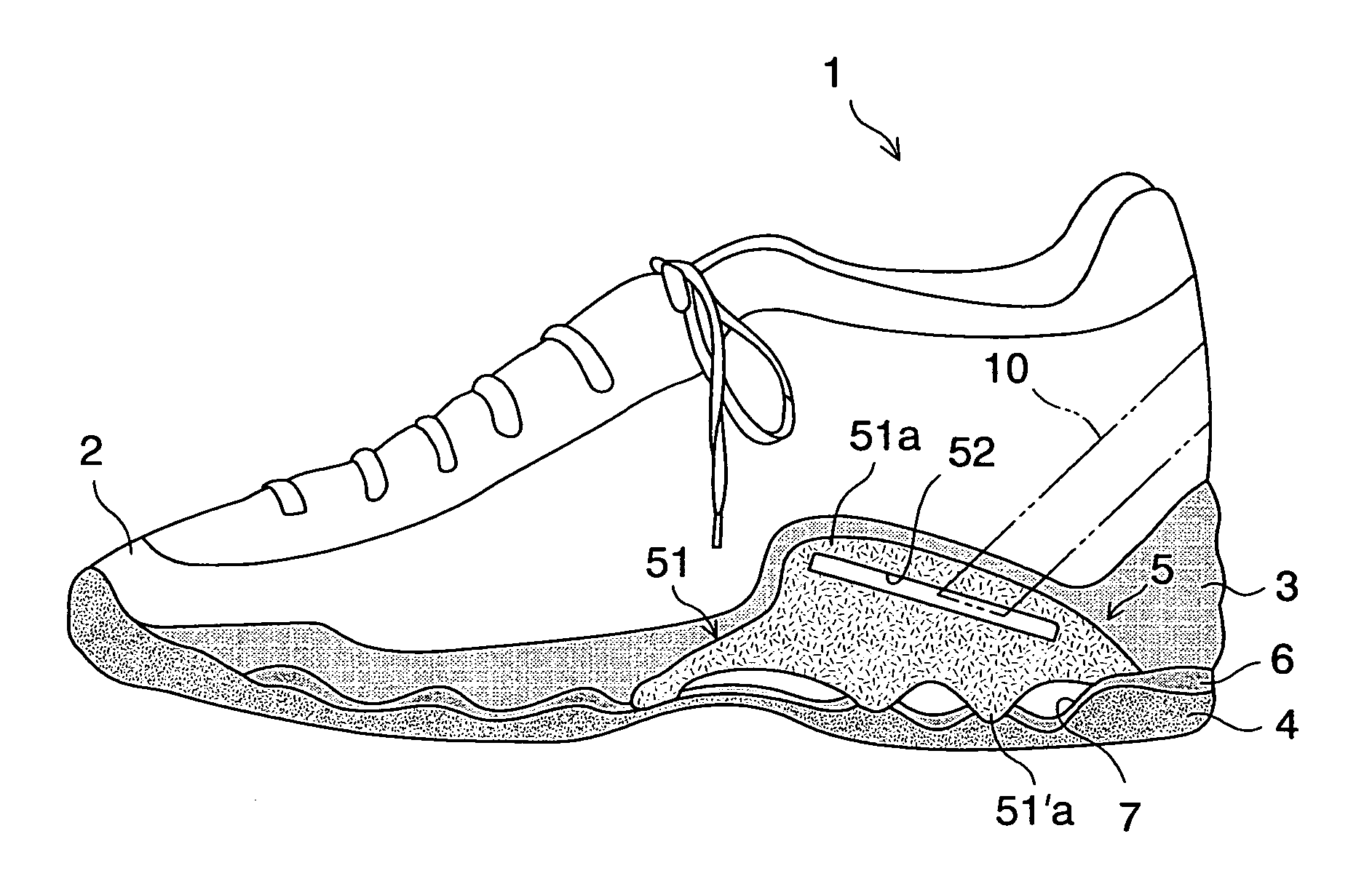

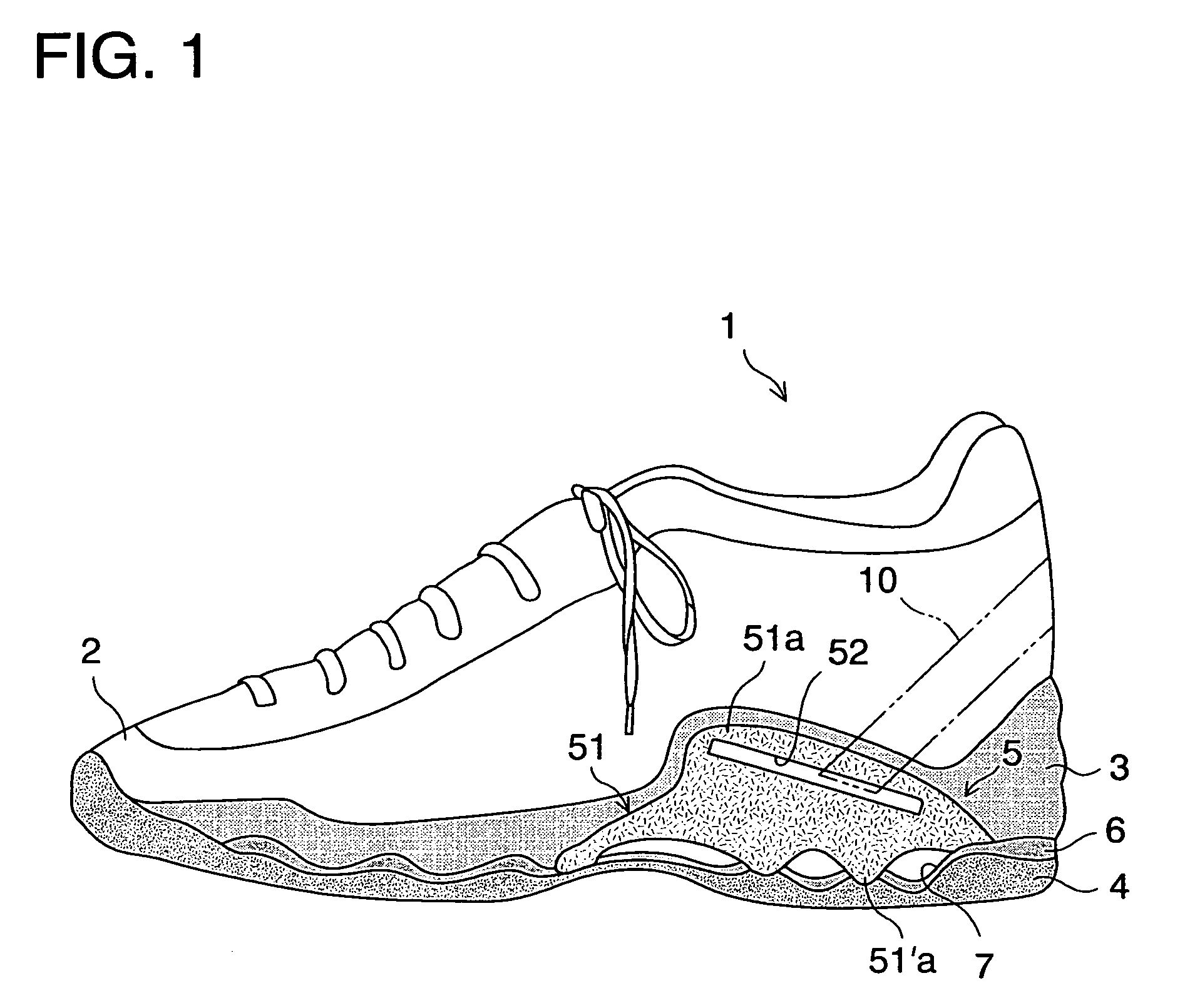

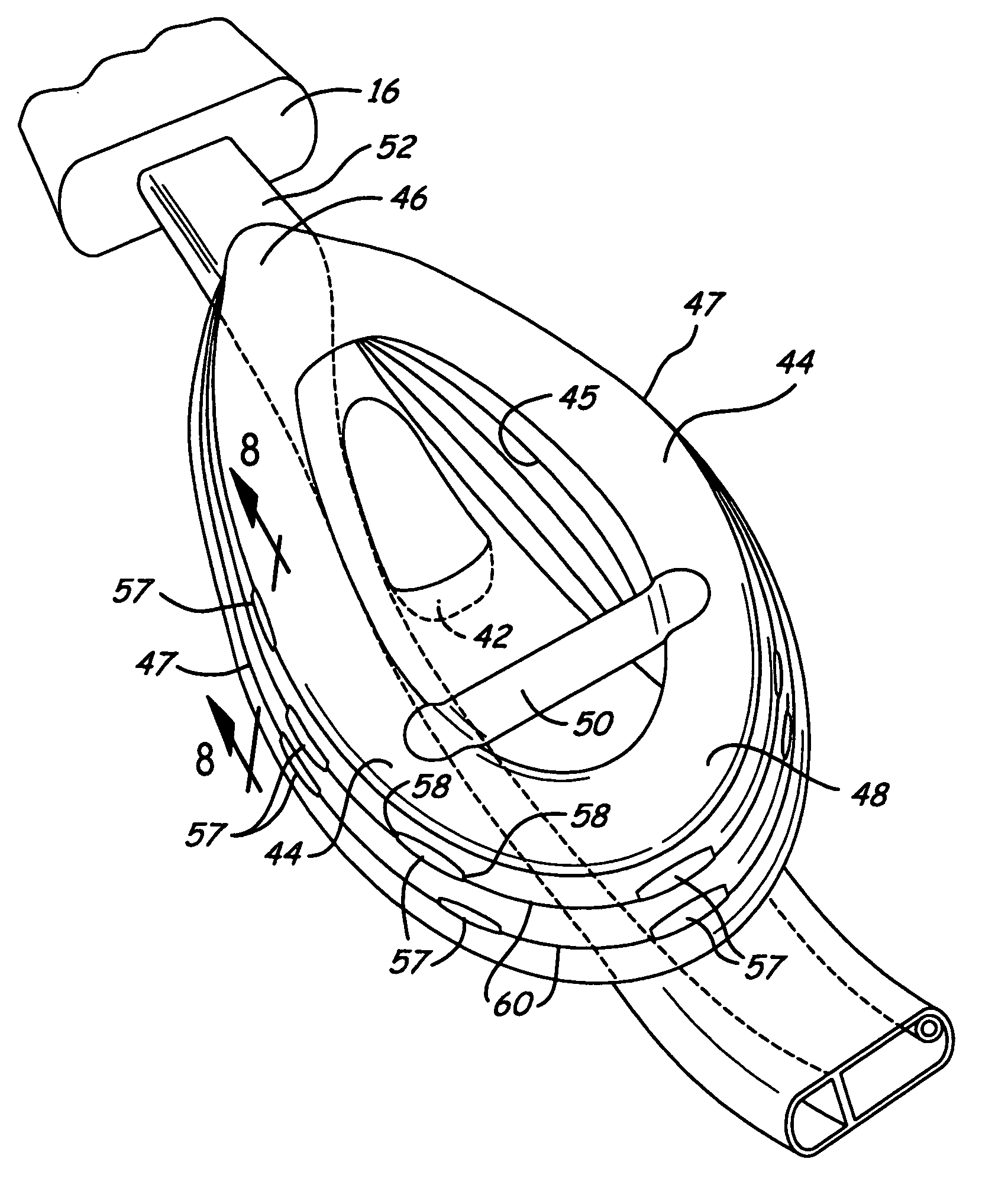

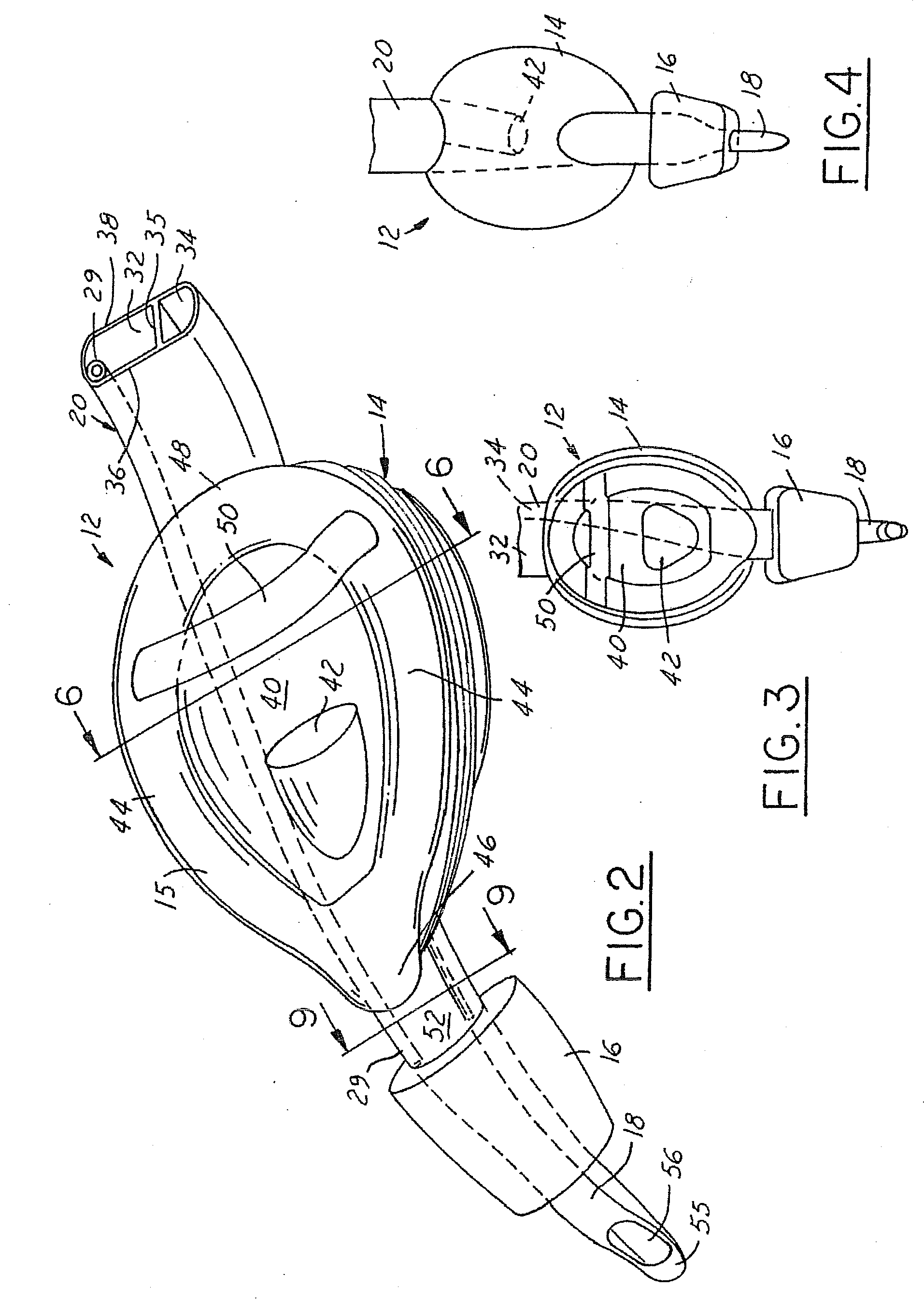

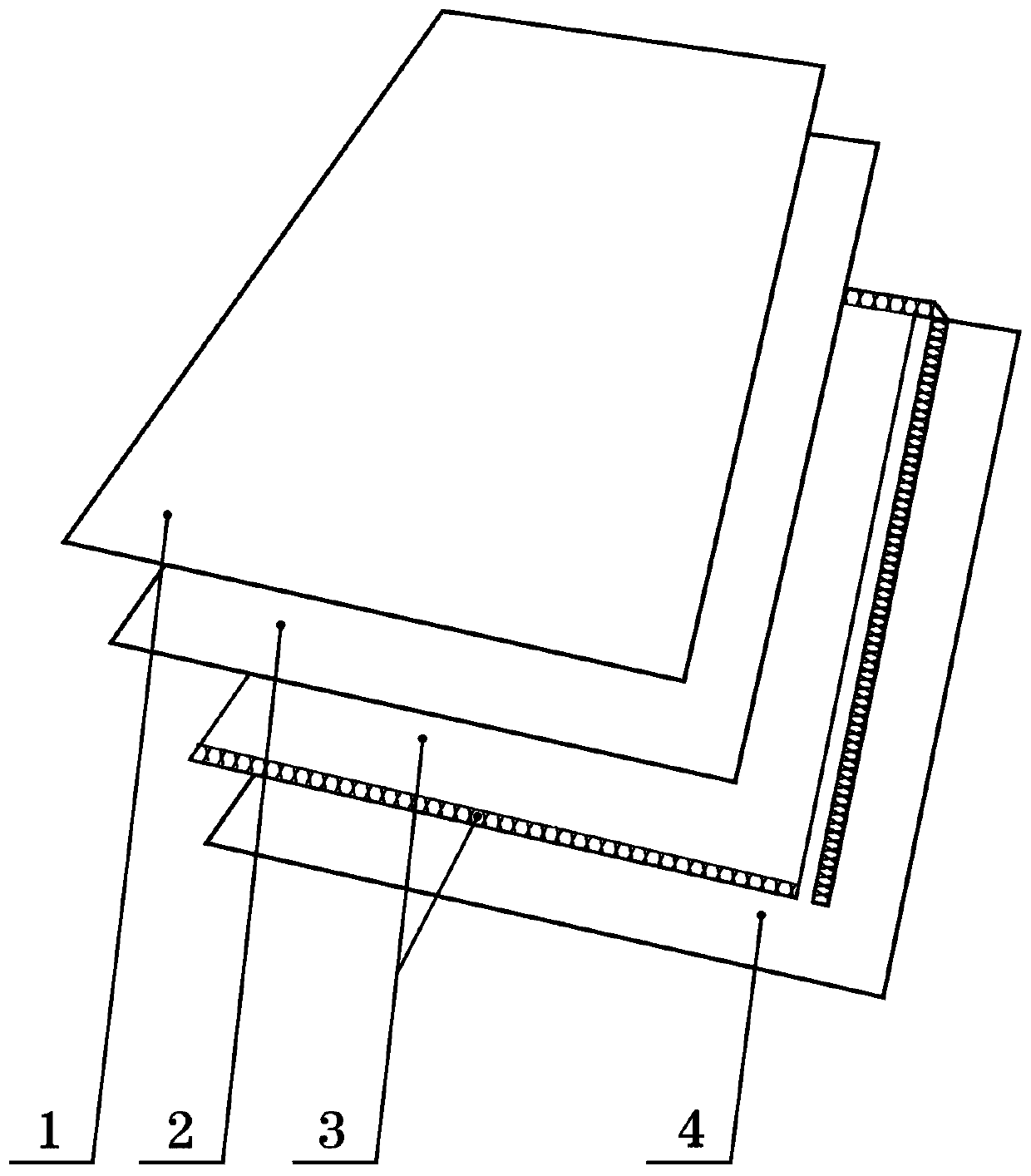

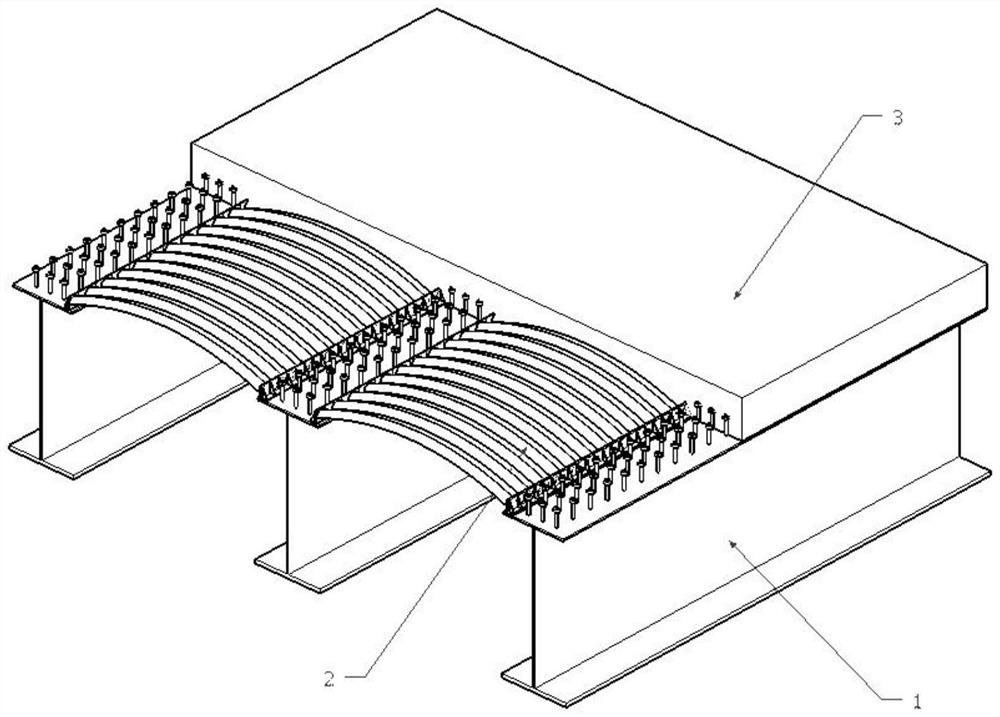

Midsole structure for an athletic shoe

InactiveUS7162815B2Reduce manufacturing costLayout can be facilitatedSolesFasteningsMechanical engineering

A midsole structure for an athletic shoe includes an upper midsole (3) formed of a soft elastic material, a lower midsole (4) disposed under the upper midsole (3) and formed of a soft elastic material, and a wavy plate assembly (5) interposed between the upper midsole (3) and the lower midsole (4). The wavy plate assembly (5) includes a wavy board (50) and a pair of sidewall members (51) provided discretely from the wavy board (50) and disposed on opposite Bides of the wavy board (50). Each of the sidewall members (51) includes a wavy bottom portion (51b) overlapping the wavy board (50) and an upraised portion (51a) extending upwardly from the wavy bottom portion (51b) to face a side surface of the upper midsole (3). Provision of the wavy board (50) and the sidewall members (51) discretely from each other simplifies a layout of a mold for forming the wavy plate assembly (5), thereby reducing a manufacturing cost.

Owner:MIZUNO CORPORATION

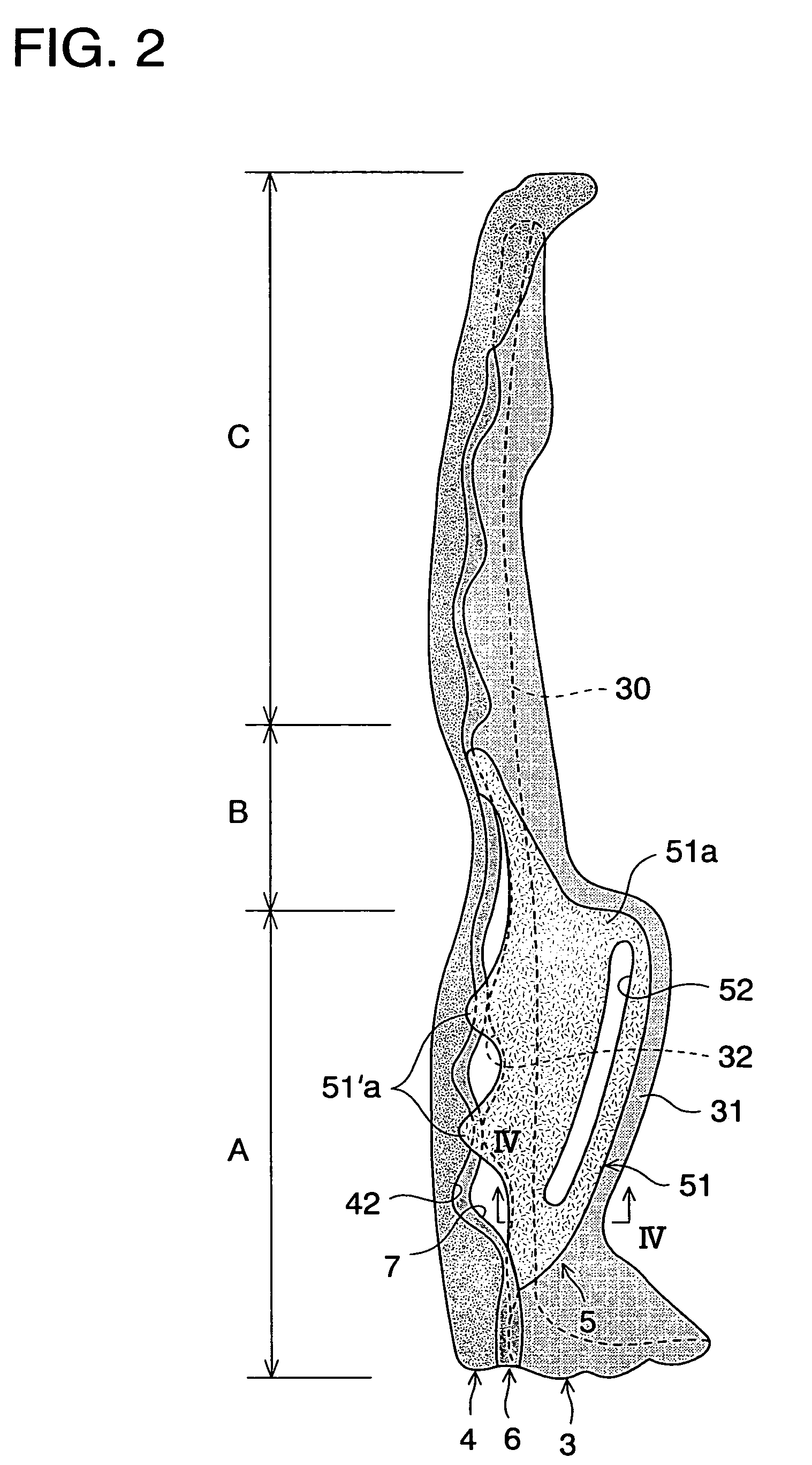

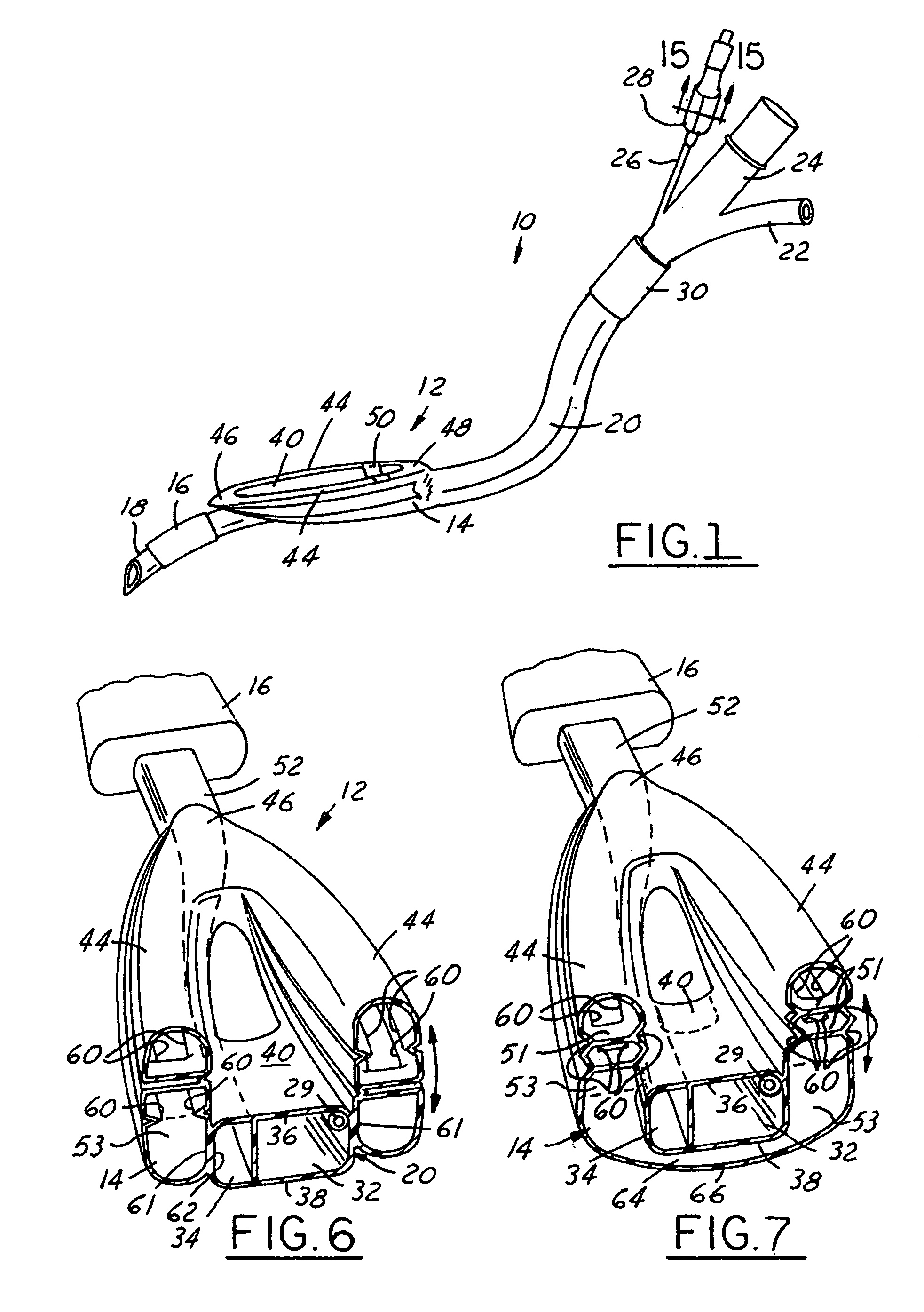

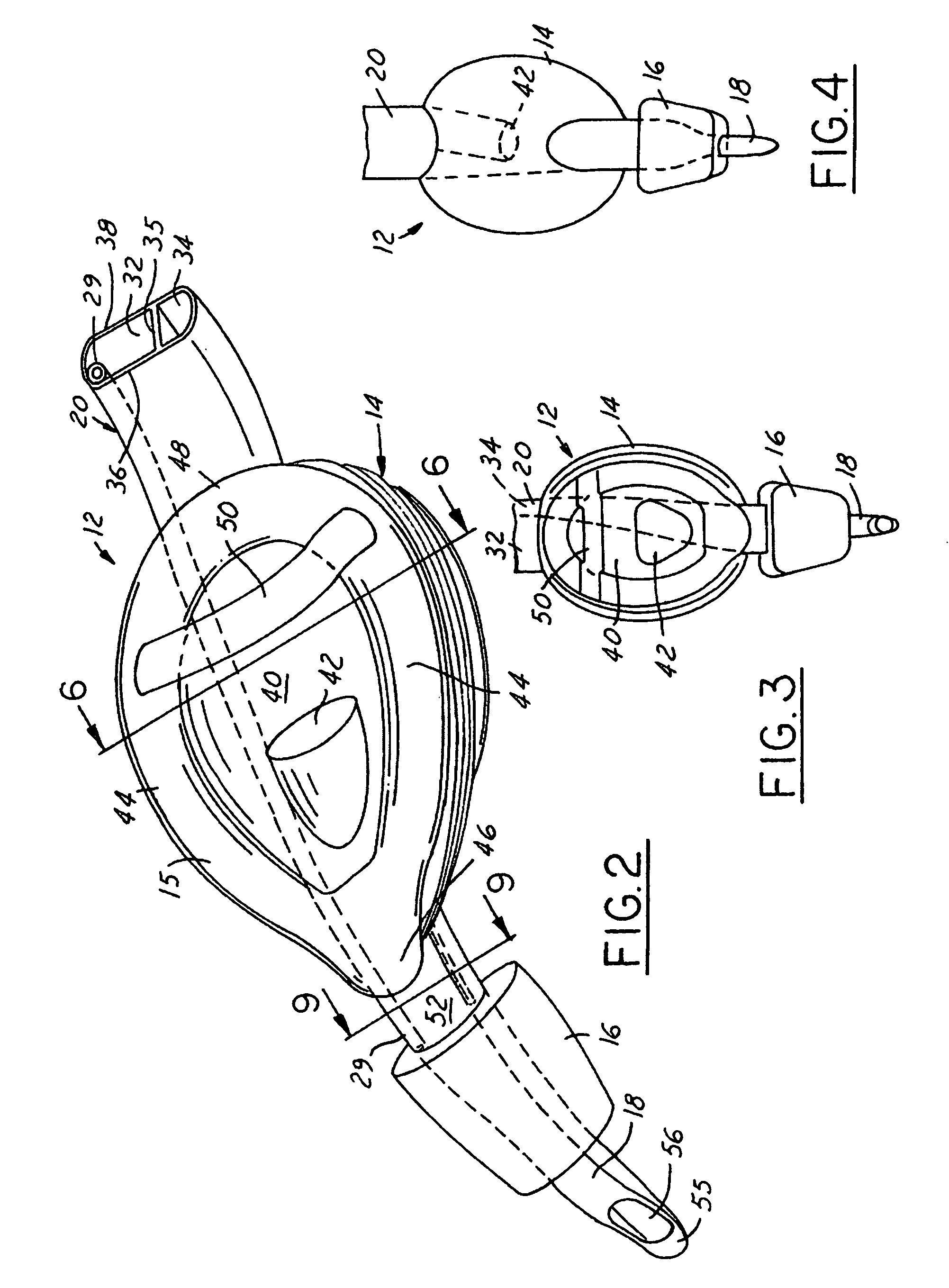

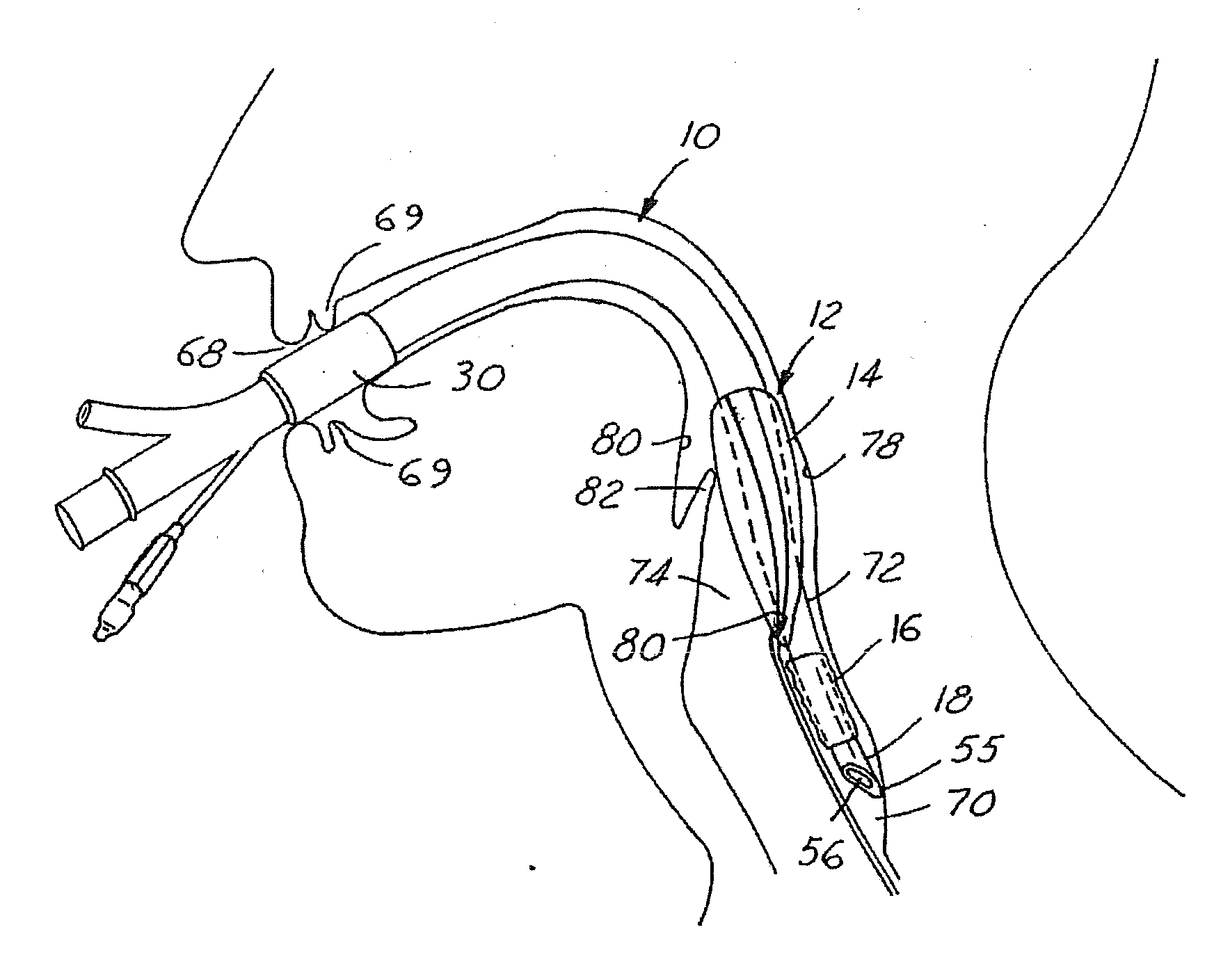

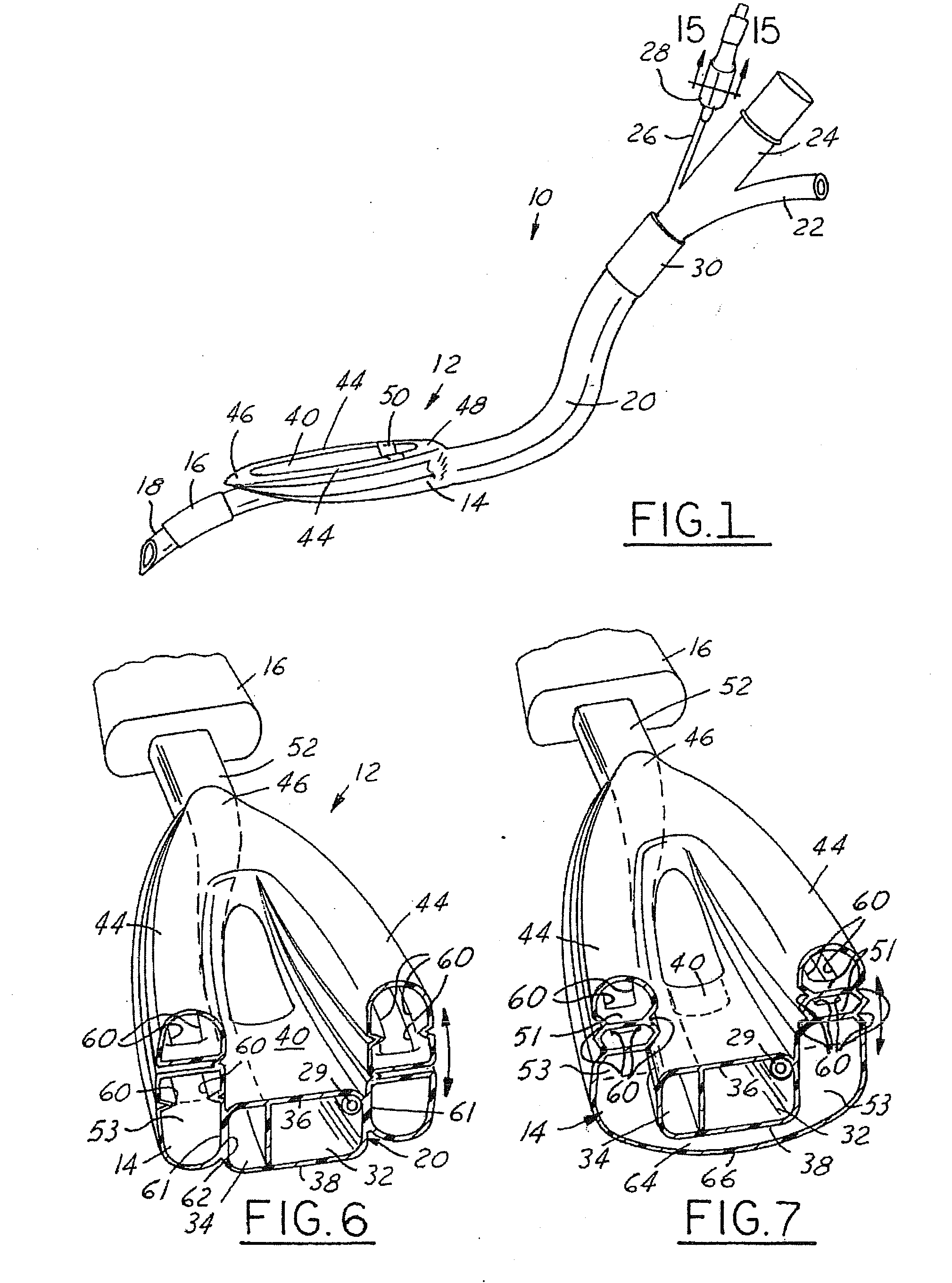

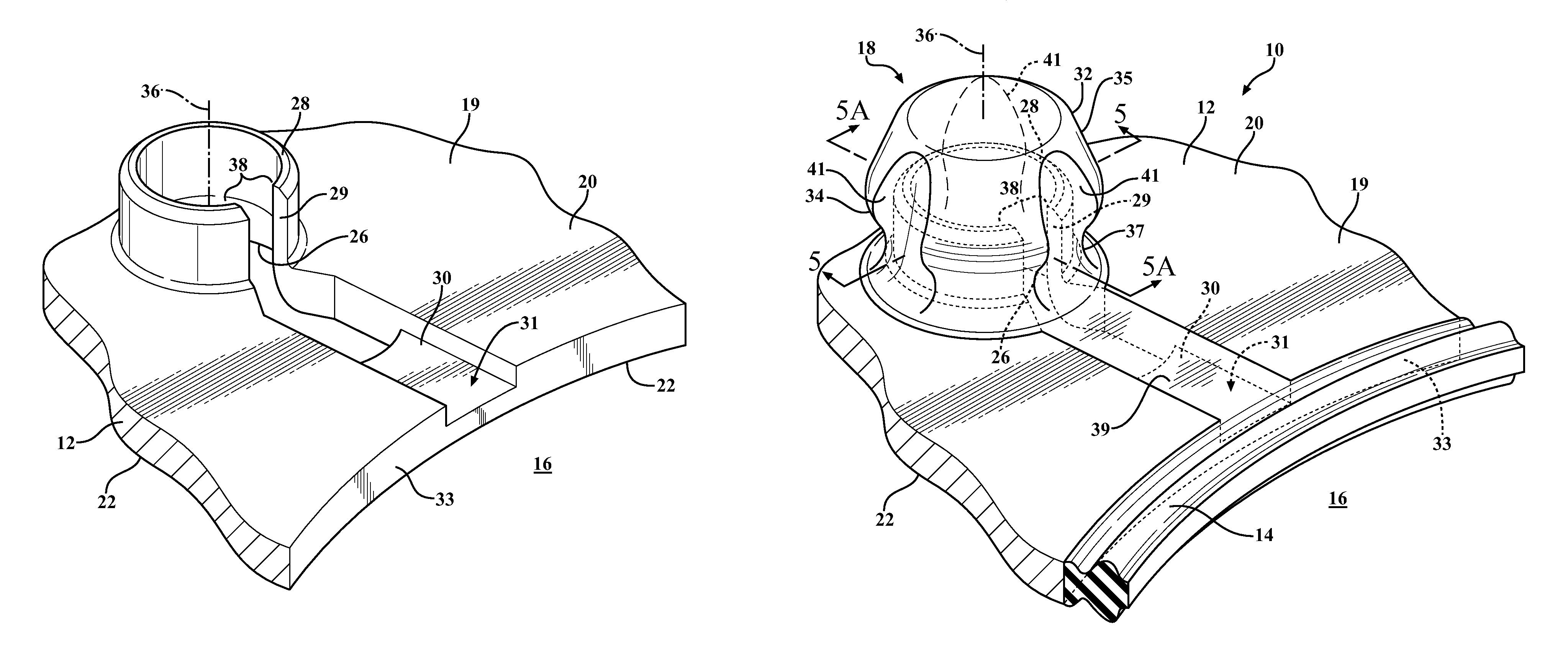

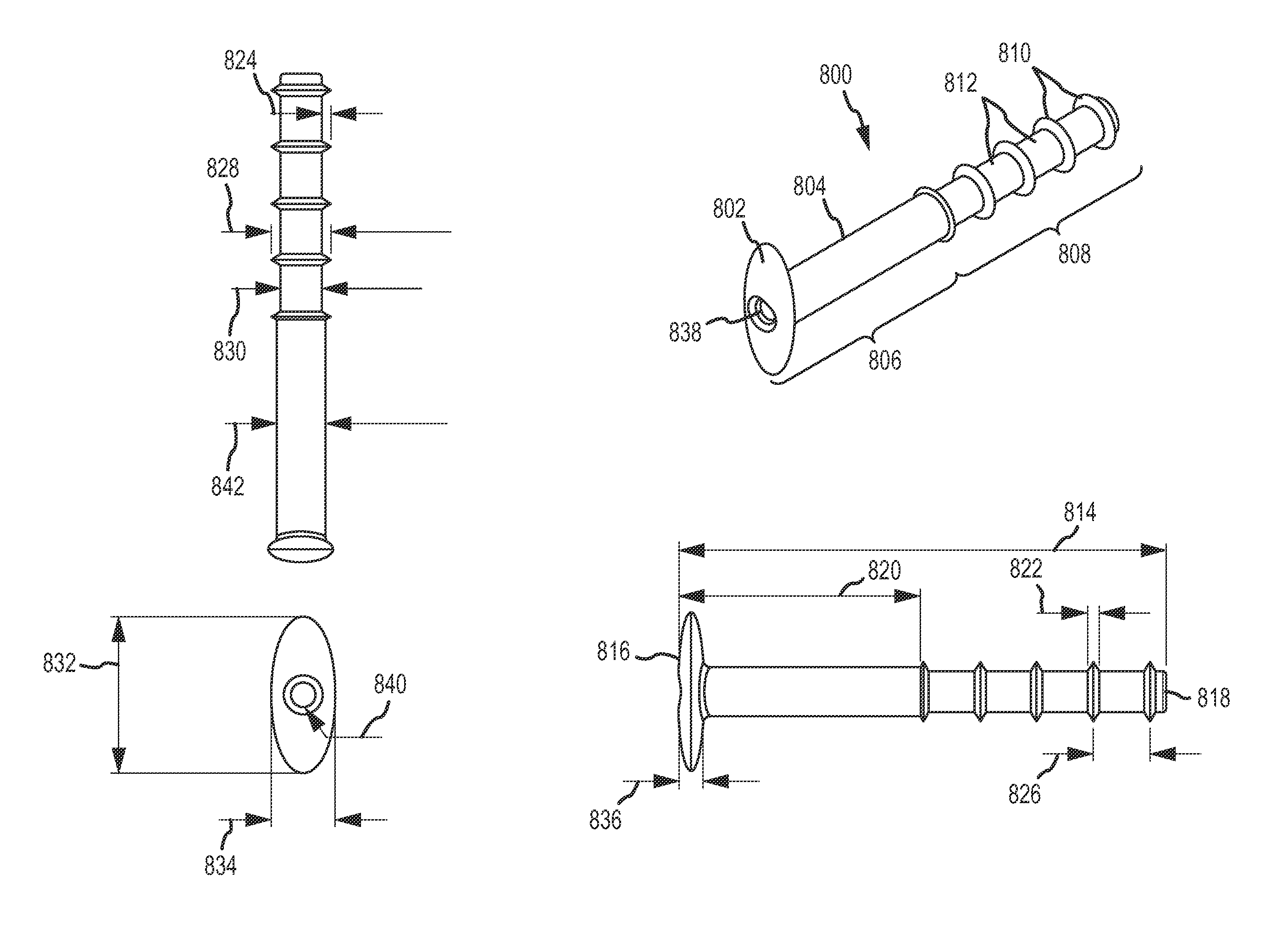

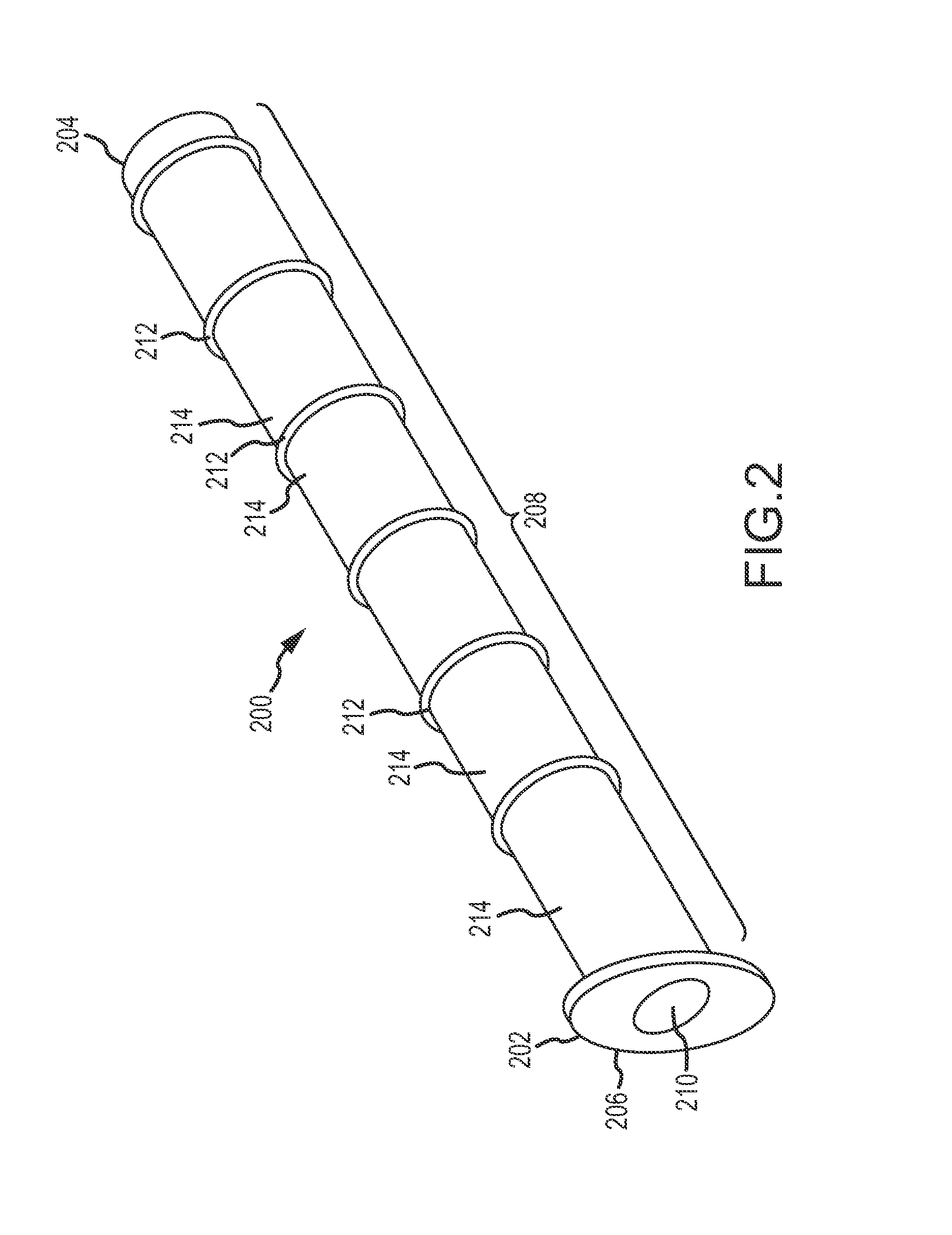

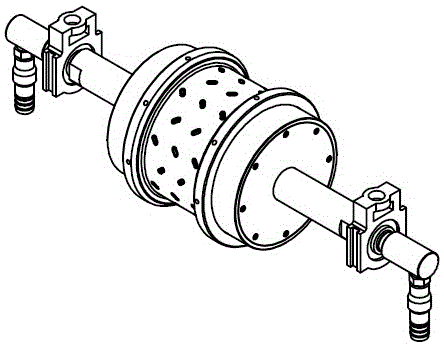

Combination artificial airway device and esophageal obturator

InactiveUS7762261B1Prevent lateral deformationTracheal tubesSurgeryInternal pressureEsophageal obturator

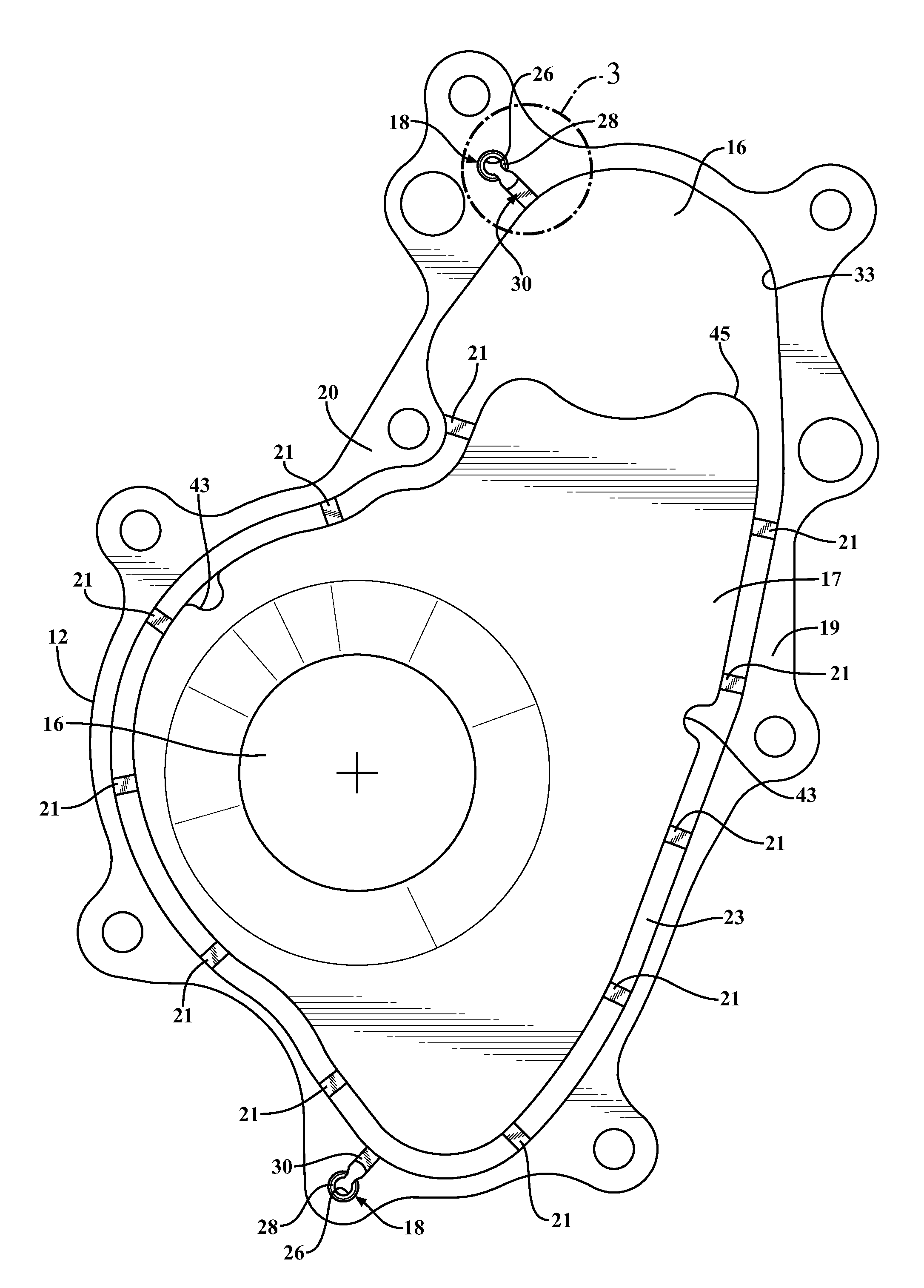

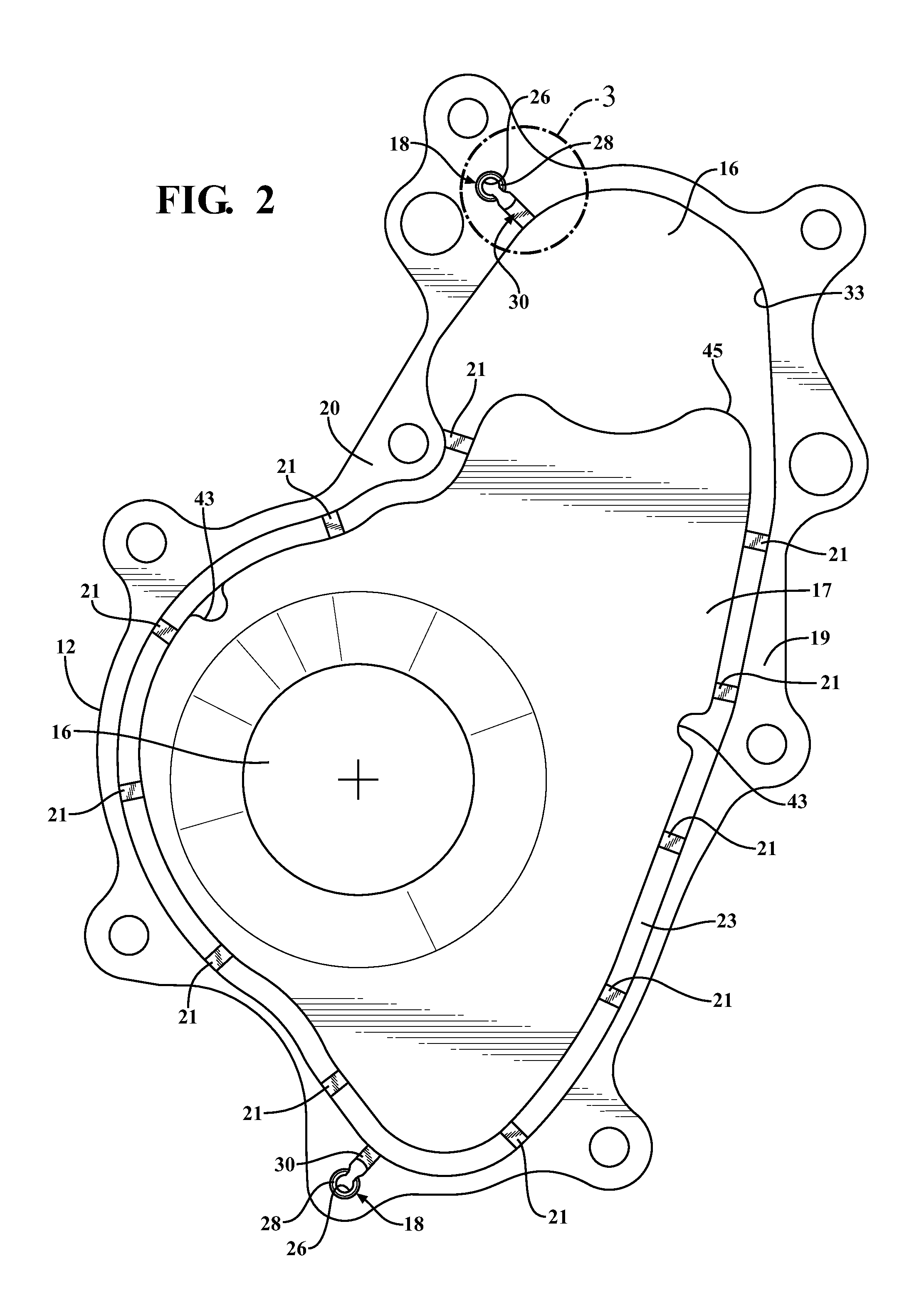

A combination artificial airway device and esophageal obturator (10) includes a esophageal cuff (16) and supraglottic cuff (14) that are inflated in a sequence to provide quick isolation of the esophagus relative to the tracheal air passage. The supraglottic cuff is asymmetrical in shape with a wedge like or cone like shape that is ergonomically shaped for providing less trauma to the pharyngeal tissues. A pressure indicator (25) surrounds a pilot balloon (28) for continuous monitoring of the internal pressure within the cuffs (14&16).

Owner:FORTUNA ANIBAL DE OLIVEIRA

Combination Artificial Airway Device and Esophageal Obturator

InactiveUS20100242957A1Prevent lateral deformationTracheal tubesRespiratory device testingInternal pressureEsophageal obturator

A combination artificial airway device and esophageal obturator (10) includes a pressure indicator (25) surrounding a pilot balloon (28) for continuous monitoring of the internal pressure within the cuffs (14&16).

Owner:FORTUNA ANIBAL DE OLIVEIRA

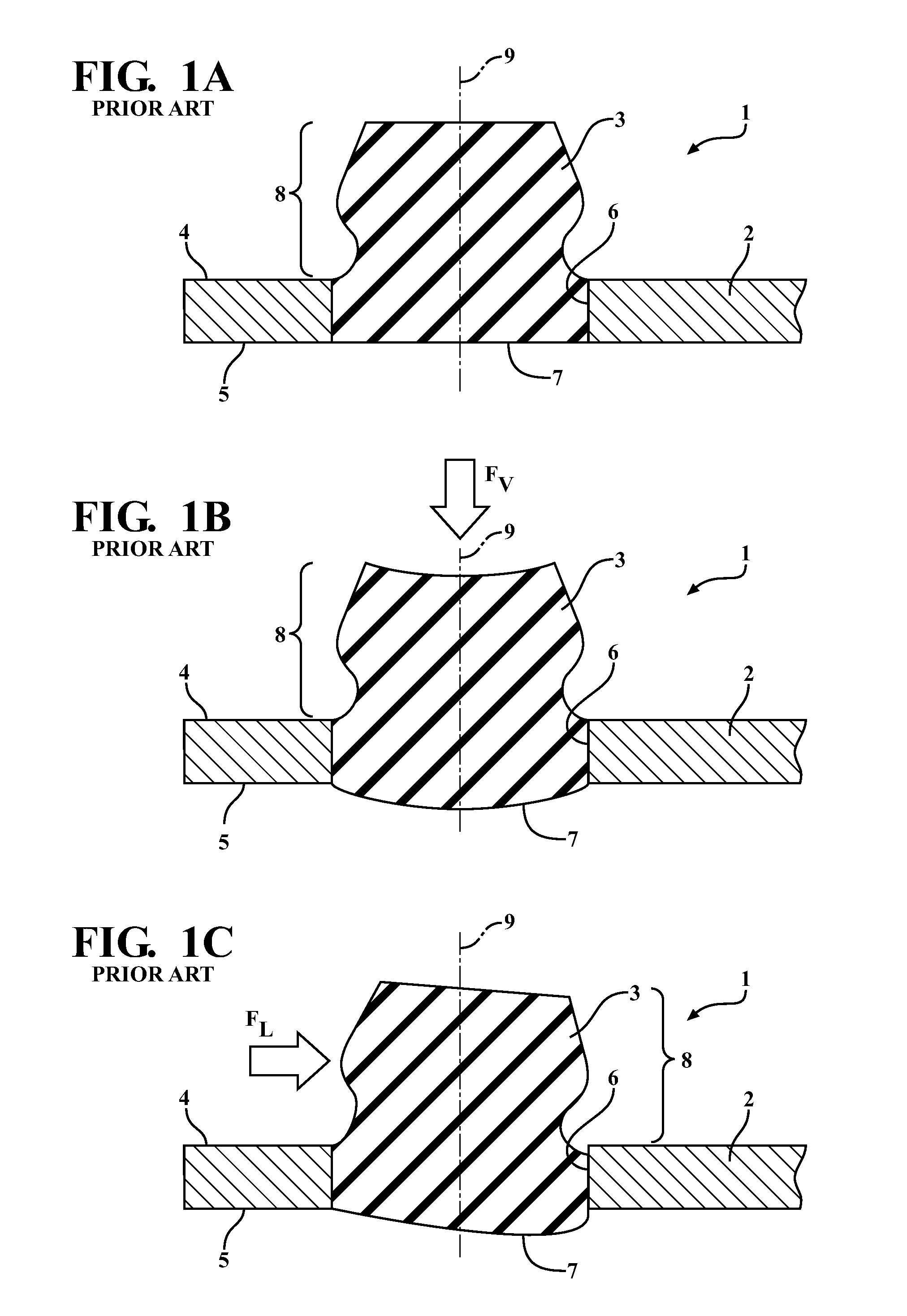

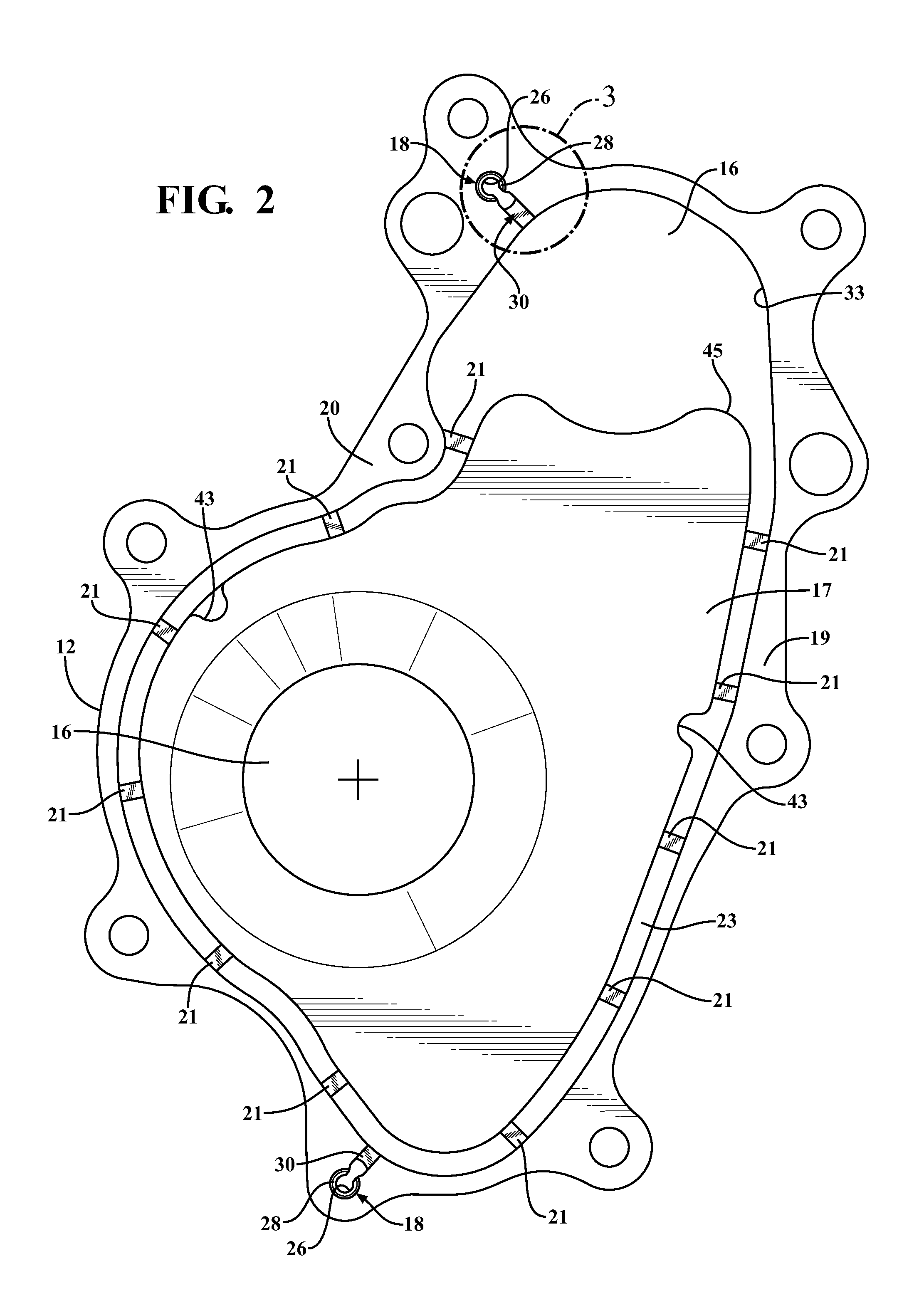

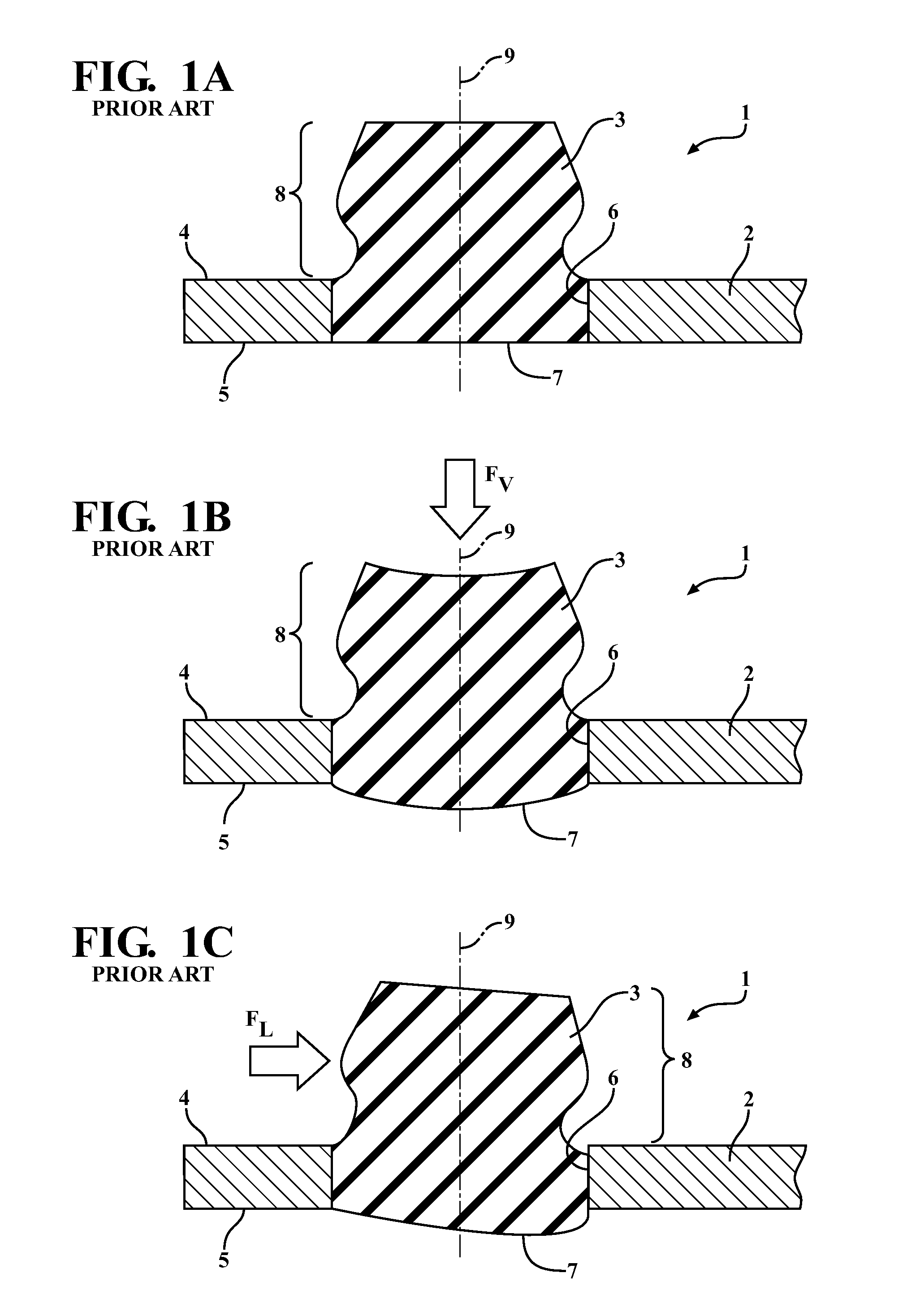

Gasket assembly with improved locating and retention pin and method of construction thereof

A gasket assembly and method of construction is provided. The assembly includes a carrier body having opposite planar surfaces with at least one media-conveying opening extending through the planar surfaces with at least one through opening spaced radially from the at least one media-conveying opening. Further, the carrier body has at least one projection formed of the material of the carrier body. The at least one projection extends from the at least one through opening outwardly from at least one of the planar surfaces. The assembly further includes an elastomeric material encapsulating the projection.

Owner:FEDERAL MOGUL MOTORPARTS LLC

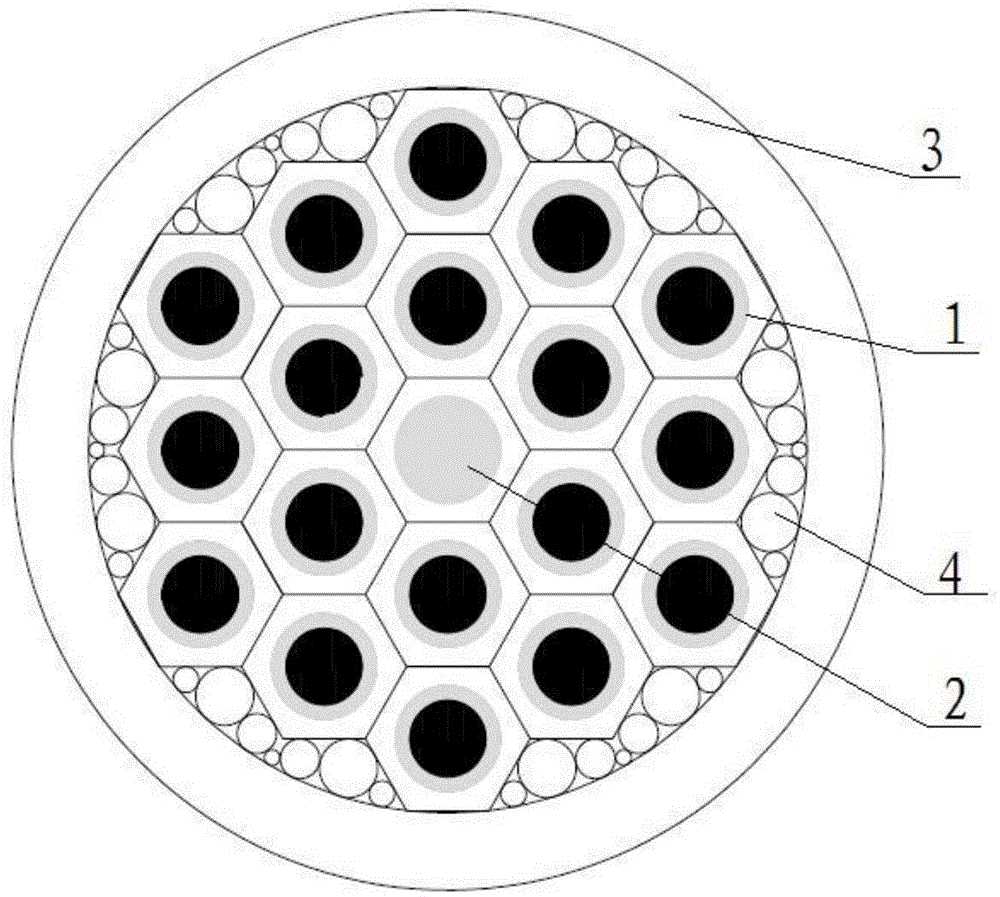

Method for manufacturing multi-core MgB2 superconductive wires through extrusion technology

ActiveCN104091651AImprove compactnessHigh yield strengthCable/conductor manufactureComposite strengthMachining deformation

The invention discloses a method for manufacturing multi-core MgB2 superconductive wires through the extrusion technology. The method includes the steps that first, precursor powder is prepared; second, the precursor powder is installed in a pipe to prepare a primary complex, and single-core wires are obtained through drawing machining; third, the precursor powder is installed in a pipe to prepare a secondary complex; fourth, the secondary complex processed through pre-heating seal welding is extruded, and multi-core rods are obtained; fifth, the multi-core rods are stripped and drawn to obtain multi-core wires, the multi-core wires are subjected to heat treatment, and then the multi-core MgB2 superconductive wires are obtained. According to the method, on the basis of a traditional power pipe-installing technology, a large single-pass machining deformation amount is adopted for manufacturing the multi-core MgB2 superconductive wires, in other words, the extrusion technology is adopted for manufacturing the multi-core MgB2 superconductive wires, because the secondary complex is in a very favorable three-dimensional stress state in extrusion, good metallurgical bonding will be achieved between different metal interfaces in the secondary complex along with the large extrusion deformation amount, the manufactured multi-core rods are high in composite strength, and the compactness and the yield strength of the multi-core MgB2 superconductive wires can be significantly improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

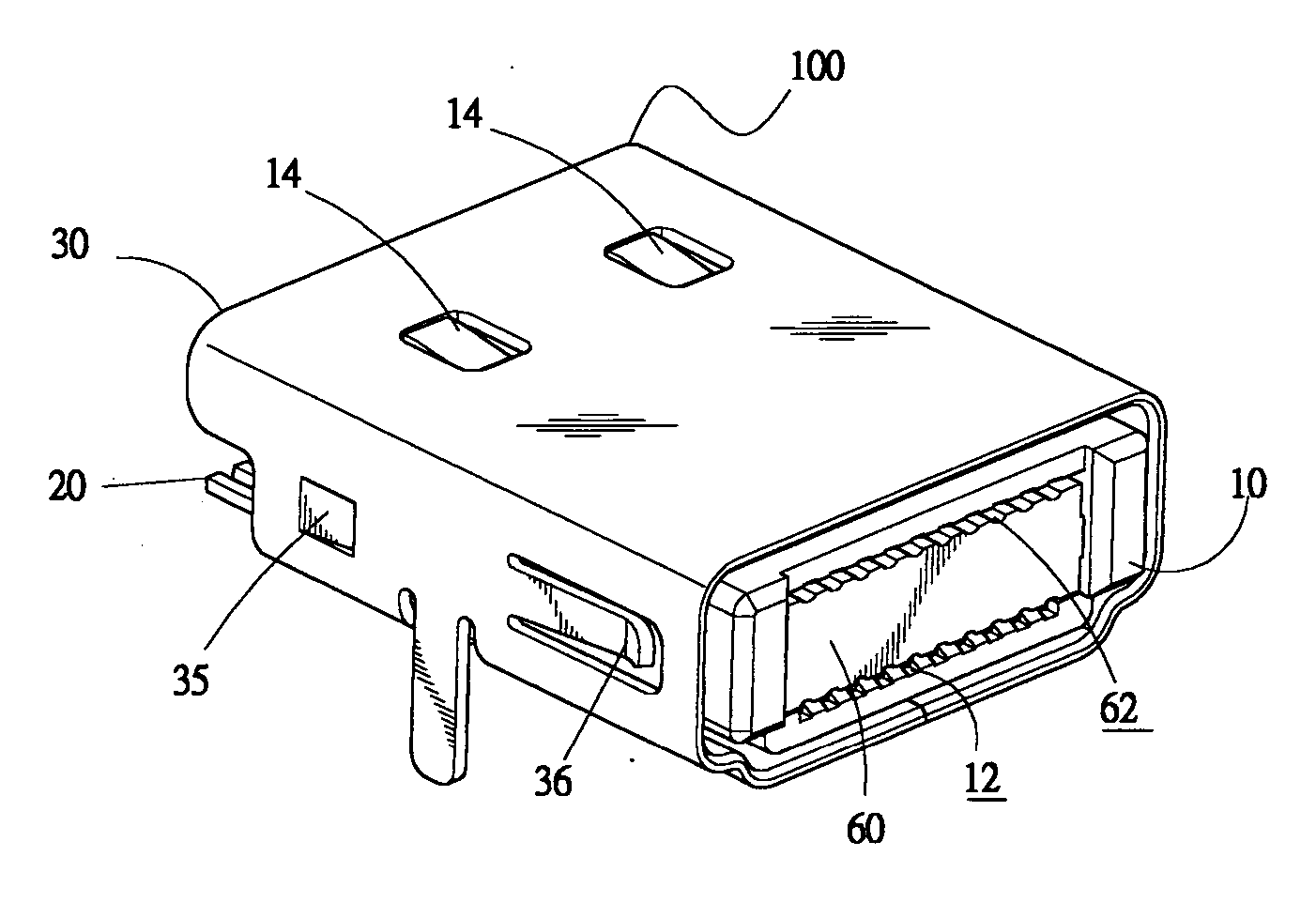

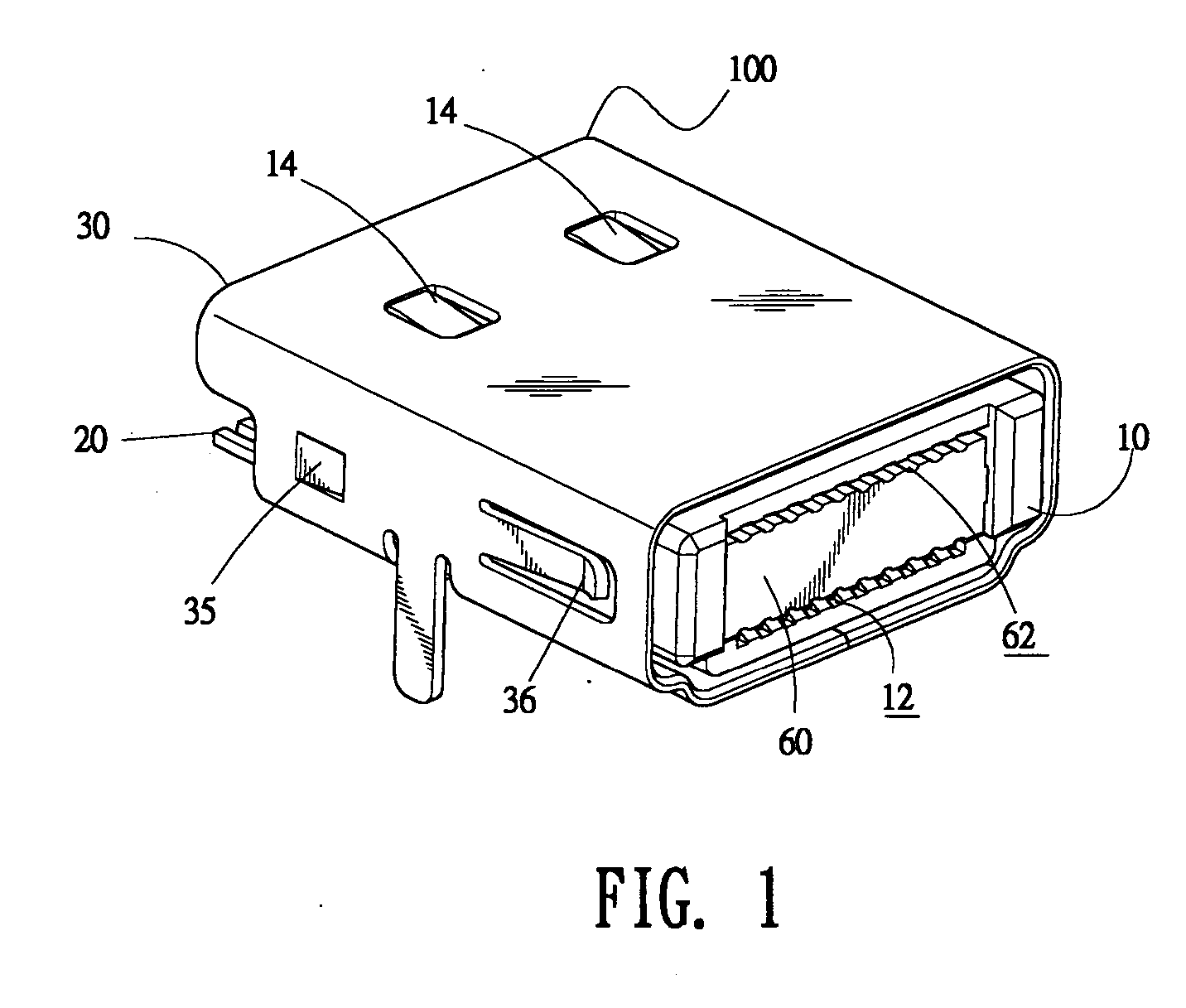

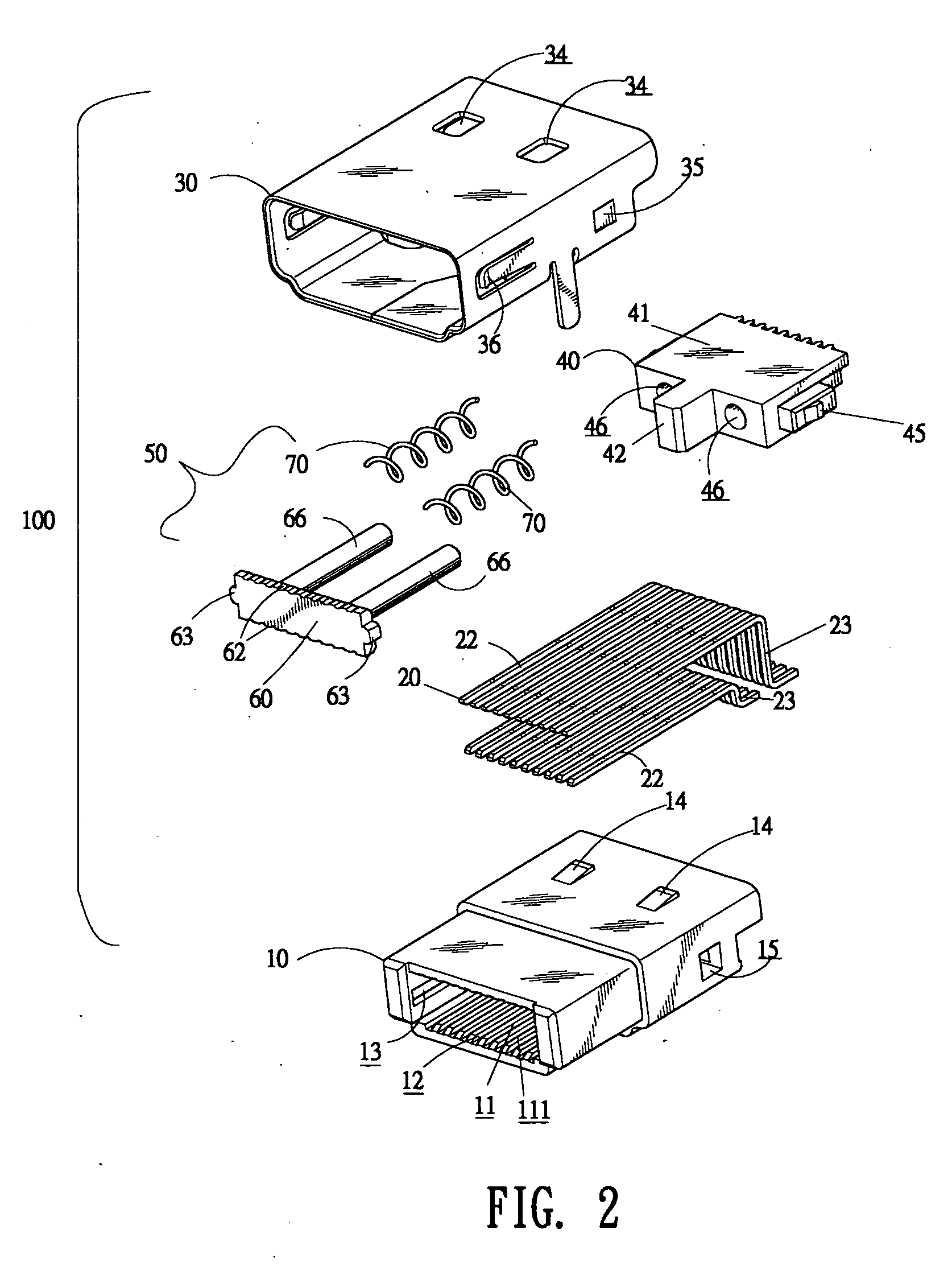

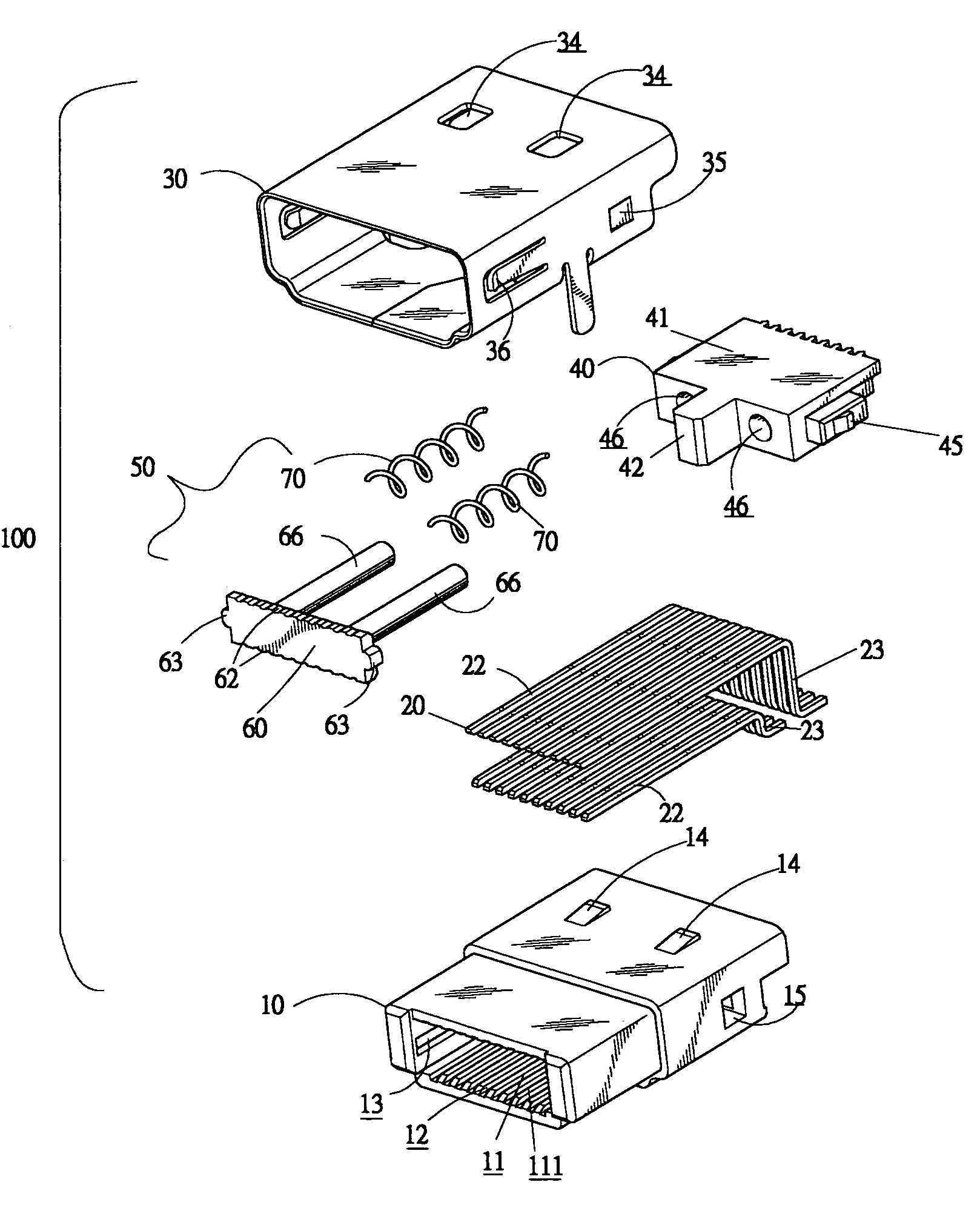

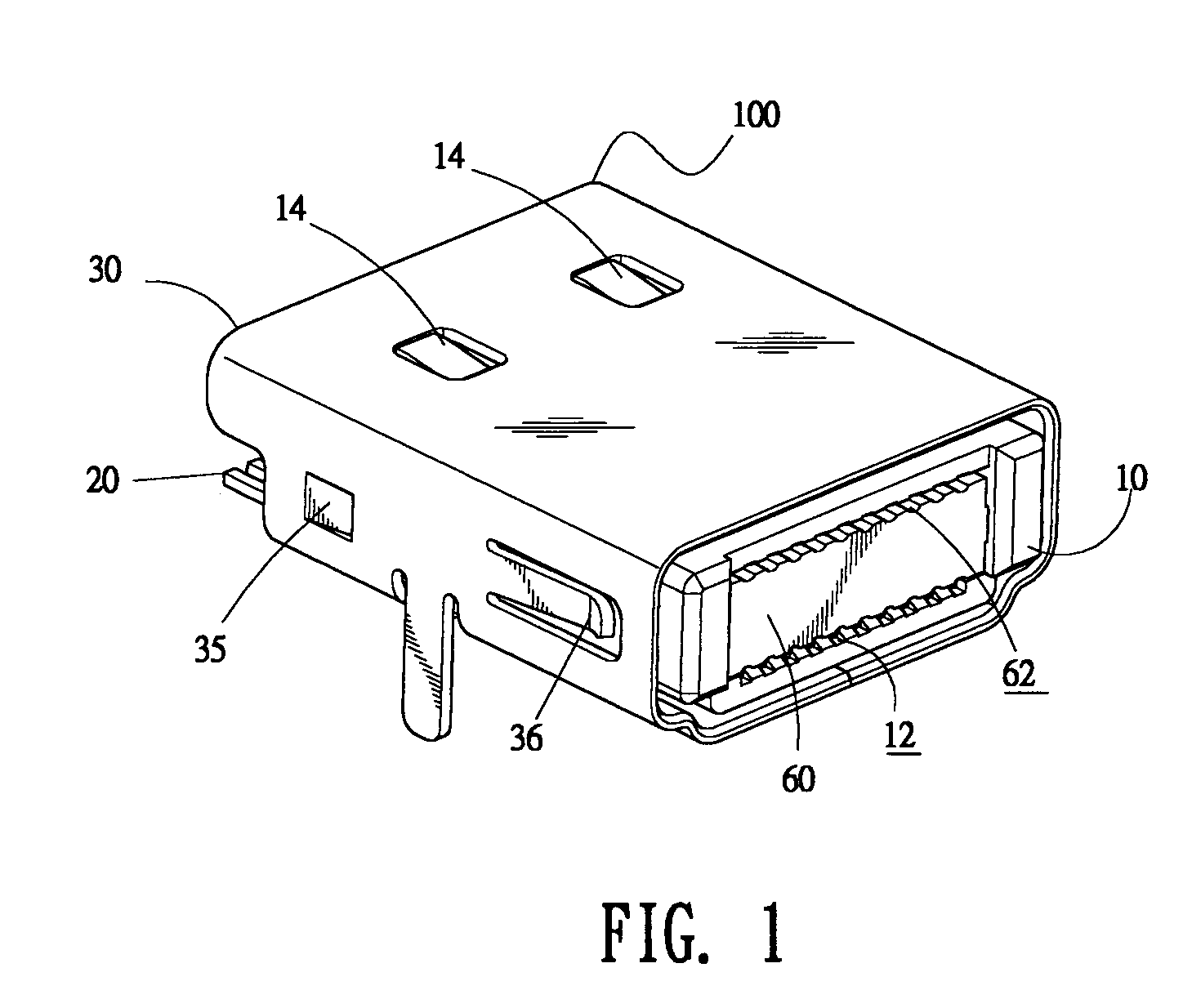

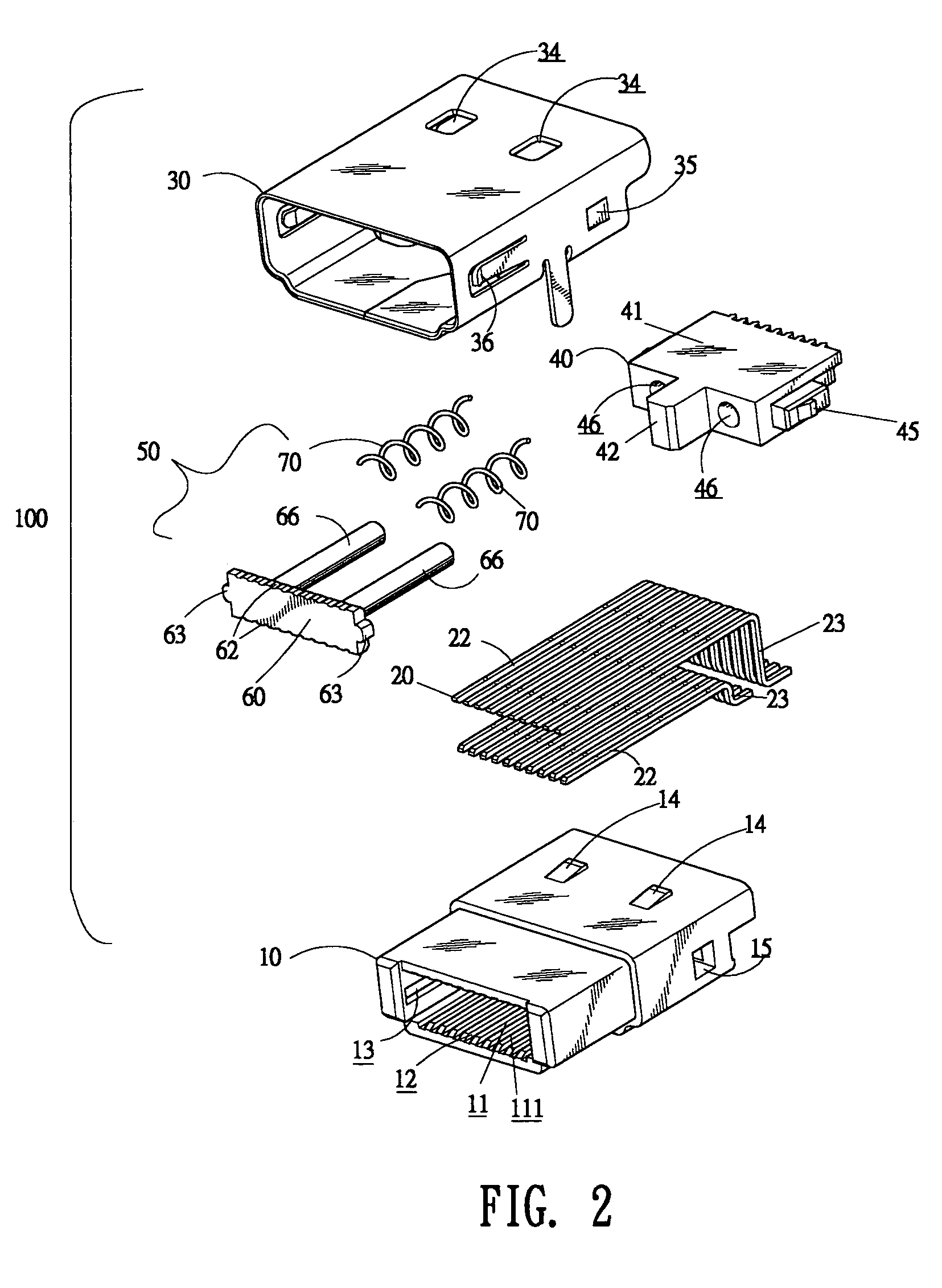

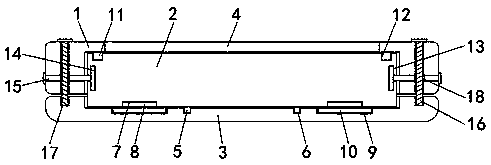

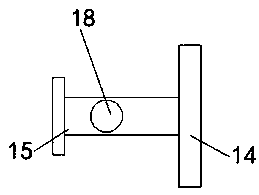

Dustproof receptacle connector

InactiveUS20060270254A1Prevent lateral deformationCouplings bases/casesLive contact access preventionEngineeringMechanical engineering

A dustproof receptacle connector includes a dielectric housing, a plurality of female contacts disposed in the housing, and a slider unit installed in the housing. The housing has a receiving cavity with a front opening defined in a front surface thereof, and a pair of mounting holes defined in a rear wall of the housing communicating with the receiving cavity. The slider unit includes a dustproof cover slidably received in the receiving cavity for sealing the front opening and a pair of springs disposed on the dustproof cover. A pair of longitudinal pillars extending backwards from the dustproof cover, with the free end of each pillar slidably disposed in the corresponding mounting hole of the housing. Each spring is retained on the corresponding longitudinal pillar, with one end thereof abutting against the dustproof cover and the other end thereof abutting against the rear wall of the housing.

Owner:CHENG UEI PRECISION IND CO LTD

Dustproof receptacle connector

InactiveUS7223108B2Prevent lateral deformationCouplings bases/casesLive contact access preventionEngineeringMechanical engineering

A dustproof receptacle connector includes a dielectric housing, a plurality of female contacts disposed in the housing, and a slider unit installed in the housing. The housing has a receiving cavity with a front opening defined in a front surface thereof, and a pair of mounting holes defined in a rear wall of the housing communicating with the receiving cavity. The slider unit includes a dustproof cover slidably received in the receiving cavity for sealing the front opening and a pair of springs disposed on the dustproof cover. A pair of longitudinal pillars extending backwards from the dustproof cover, with the free end of each pillar slidably disposed in the corresponding mounting hole of the housing. Each spring is retained on the corresponding longitudinal pillar, with one end thereof abutting against the dustproof cover and the other end thereof abutting against the rear wall of the housing.

Owner:CHENG UEI PRECISION IND CO LTD

Gasket assembly with improved locating and retention pin and method of construction thereof

A gasket assembly and method of construction is provided. The assembly includes a carrier body having opposite planar surfaces with at least one media-conveying opening extending through the planar surfaces with at least one through opening spaced radially from the at least one media-conveying opening. Further, the carrier body has at least one projection formed of the material of the carrier body. The at least one projection extends from the at least one through opening outwardly from at least one of the planar surfaces. The assembly further includes an elastomeric material encapsulating the projection.

Owner:FEDERAL MOGUL MOTORPARTS LLC

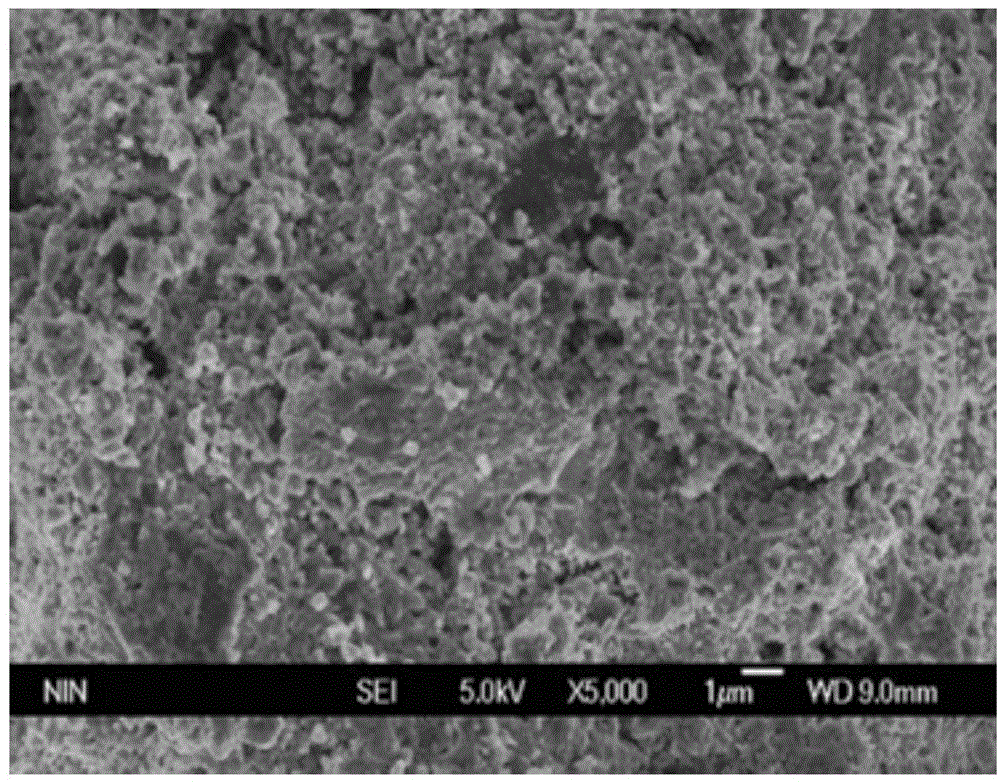

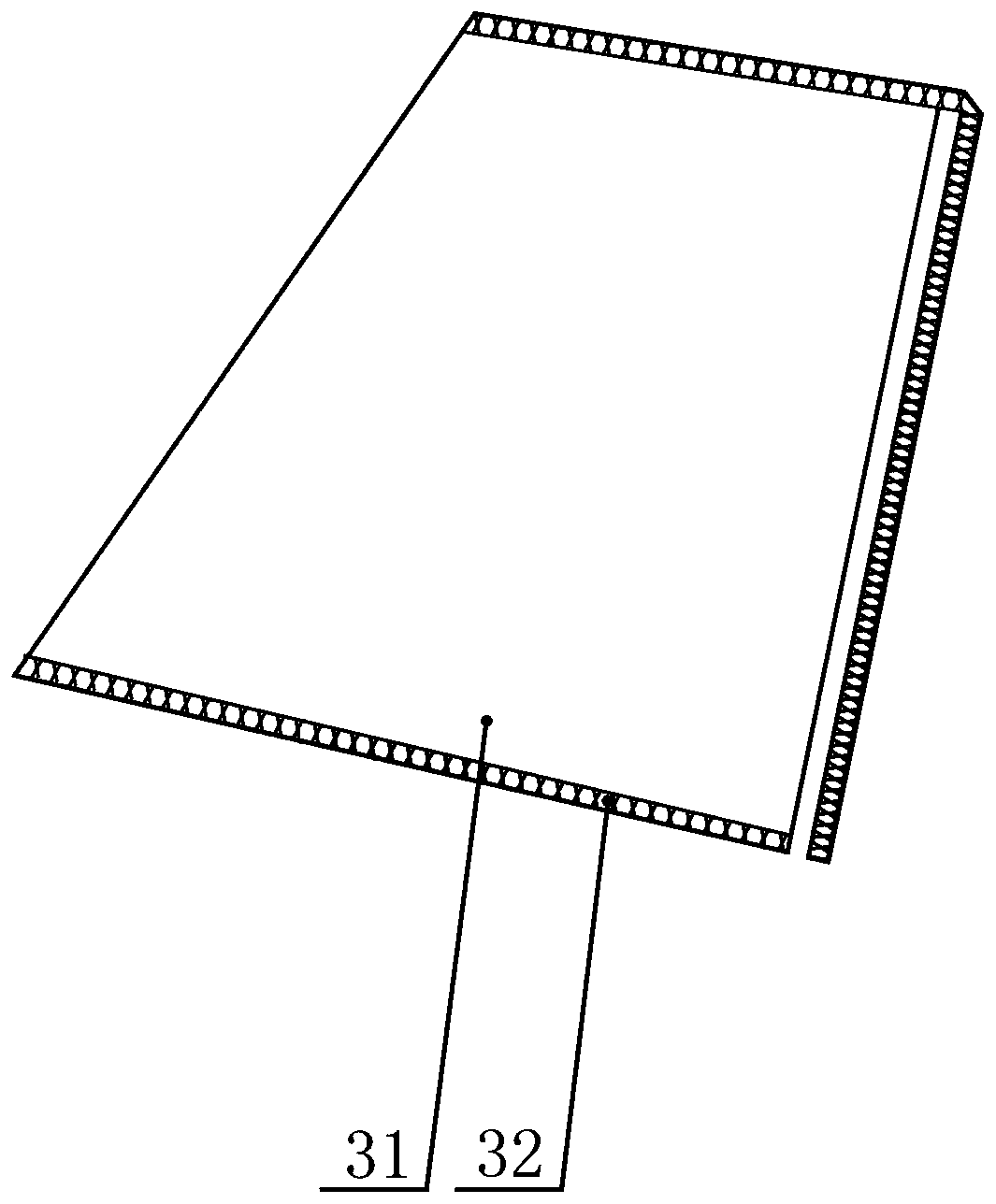

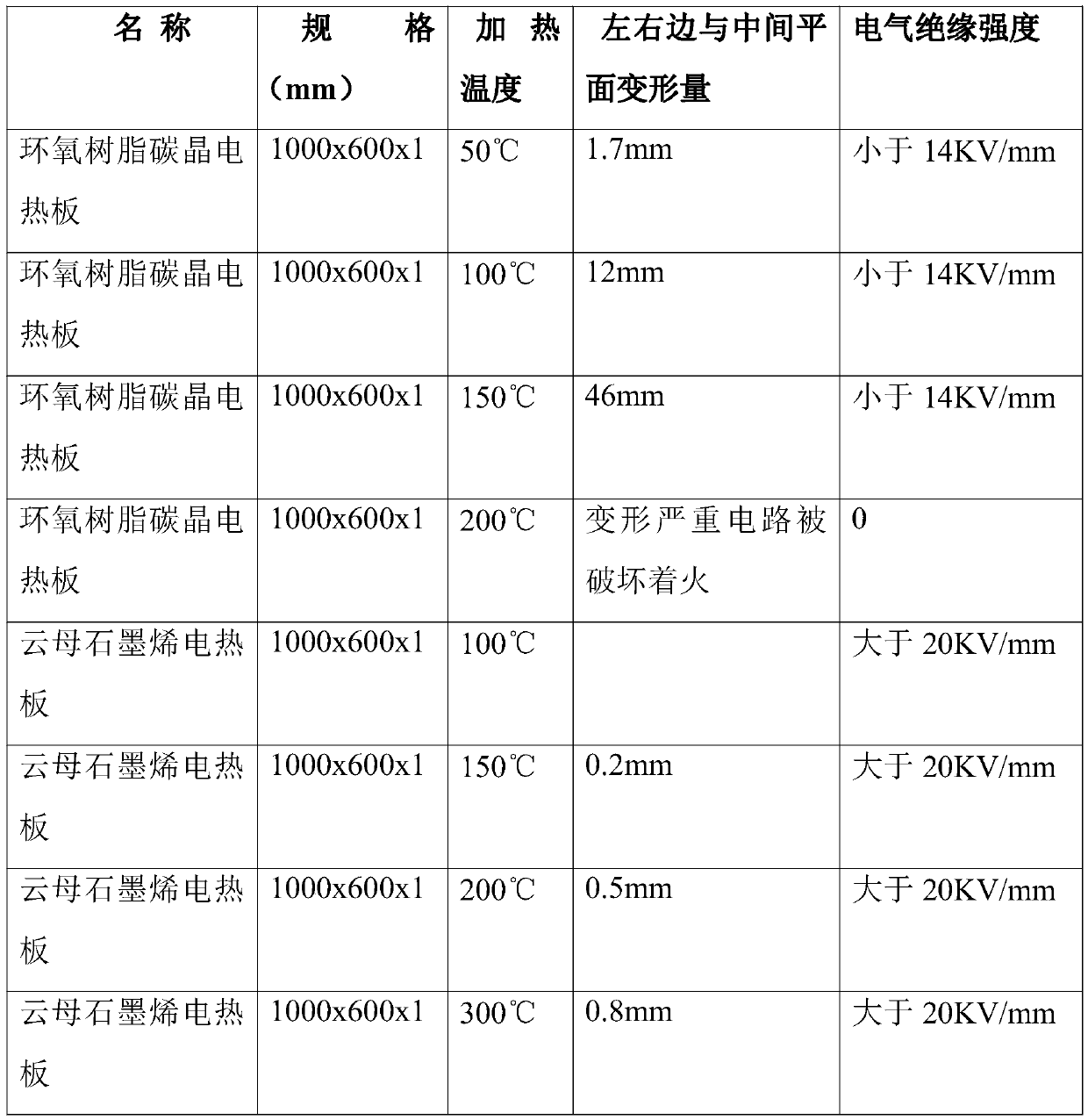

High-temperature resistant graphene mica electrical heating plate and fabrication method thereof

InactiveCN110213845AUniform heatingFast feverChemical industryLaminationHeating filmTemperature resistance

The invention relates to an electrical heating plate and a fabrication method thereof, in particular to a high-temperature resistant graphene mica electrical heating plate and a fabrication method thereof. The high-temperature resistant graphene mica electrical heating plate comprises a surface modification layer, an upper mica insulation layer, a graphene heating layer and a lower mica insulationlayer which are sequentially laminated from top to bottom and are hot-pressed by a hot-press machine. The high-temperature resistant graphene mica electrical heating plate employs graphene conductivepaper as a heating core layer, the mica paper with fireproof class is used as an insulation material, the electrical heating plate is synthesized by hot-pressing of a hot-press machine and by takingorganic silicon as an adhesive has the advantages of fireproof performance, high safety class, high temperature resistance (300 DEG C), high insulativity, high heating efficiency, rapid heating speed,structure stability and long service lifetime and can be used for a long time between 200-300 DEG C, the limitation of an electrical heating film and an epoxy electric coupling plate which are only used within 100 DEG C and a phenomenon that a fire is easily caused are solved, and the electrical heating plate is suitable for promotion and application.

Owner:QINGDAO GRAPHENE CARBON NEW MATERIAL TECH CO LTD

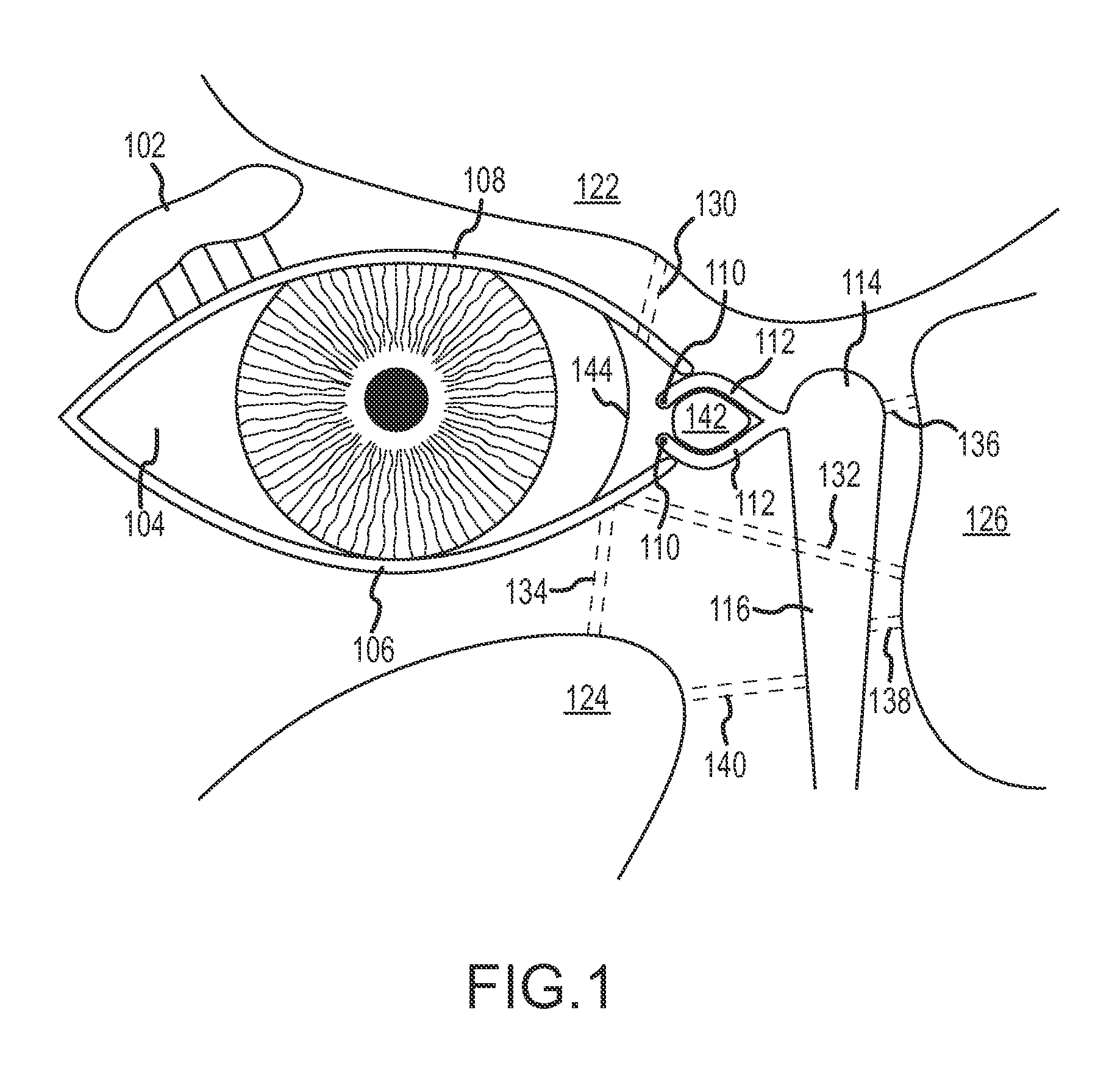

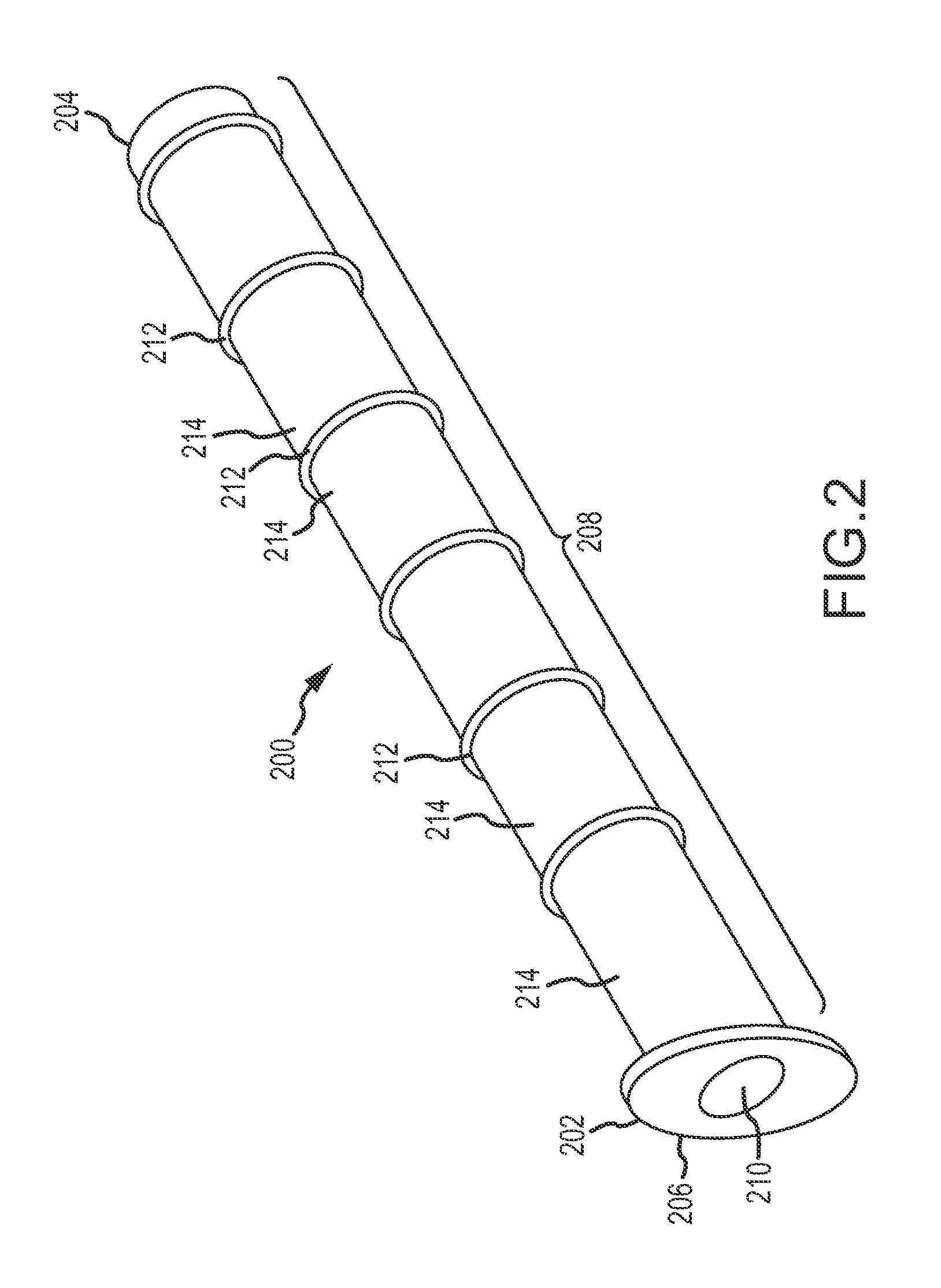

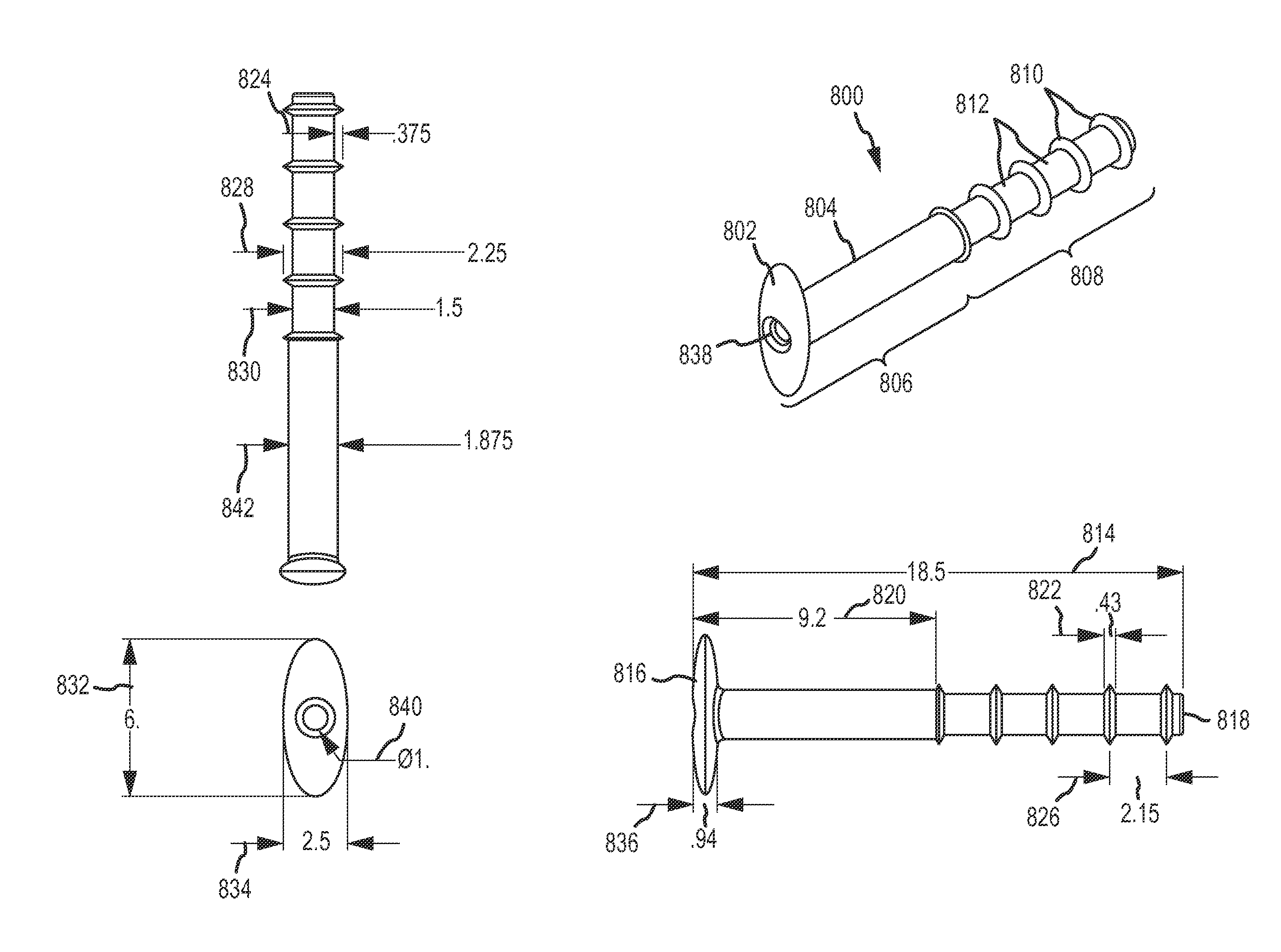

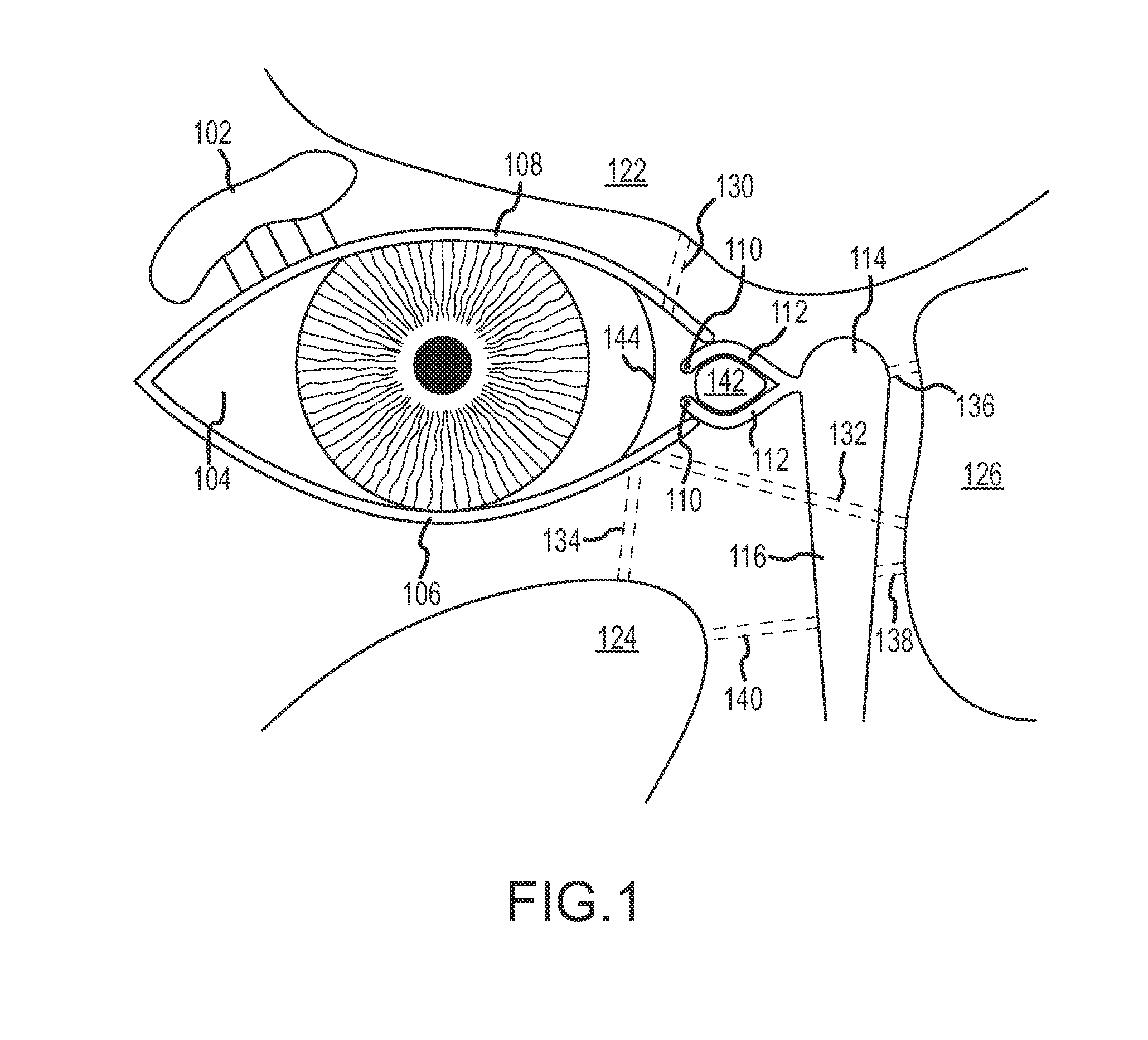

Paranasal sinus access implant devices and related tools, methods and kits

ActiveUS9561350B2Improve mechanical durabilityReduce mechanical damageEye surgerySurgeryNoseImplanted device

A paranasal sinus access implant device to provide an artificial fluid path in fluid communication with the lacrimal apparatus may be implanted through a fistula opening into the lacrimal apparatus. The implant device may have a conduit with a first longitudinal portion having a larger minimum wall thickness than a minimum wall thickness of a second a second longitudinal portion of the conduit located distal of the first longitudinal portion. Various kits may include a paranasal sinus access implant device and one of more other components for a procedure involving implantation. A method involves use of a cutting tool to cut away tissue to prepare a fistula sized for implantation.

Owner:SINOPSYS SURGICAL

Paranasal sinus access implant devices and related tools, methods and kits

ActiveUS20150231376A1Improve mechanical durabilityReduce mechanical damageEye surgeryWound drainsNoseFistula

A paranasal sinus access implant device to provide an artificial fluid path in fluid communication with the lacrimal apparatus may be implanted through a fistula opening into the lacrimal apparatus. The implant device may have a conduit with a first longitudinal portion having a larger minimum wall thickness than a minimum wall thickness of a second a second longitudinal portion of the conduit located distal of the first longitudinal portion. Various kits may include a paranasal sinus access implant device and one of more other components for a procedure involving implantation. A method involves use of a cutting tool to cut away tissue to prepare a fistula sized for implantation.

Owner:SINOPSYS SURGICAL

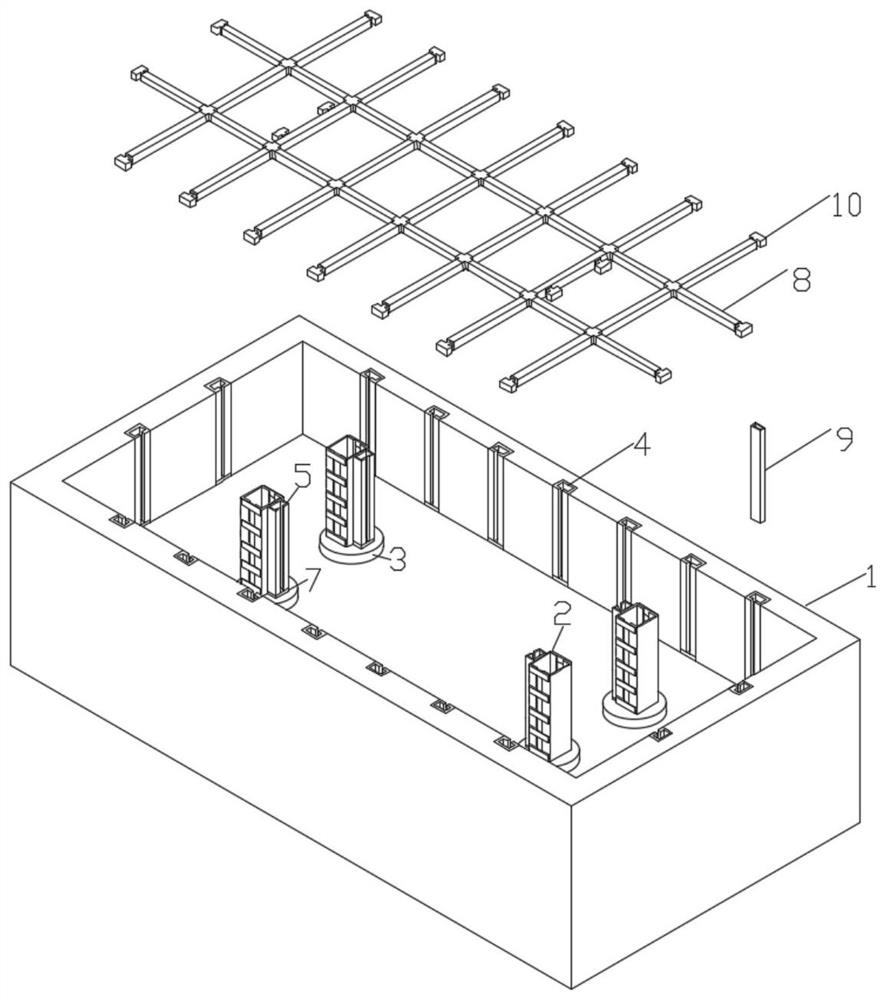

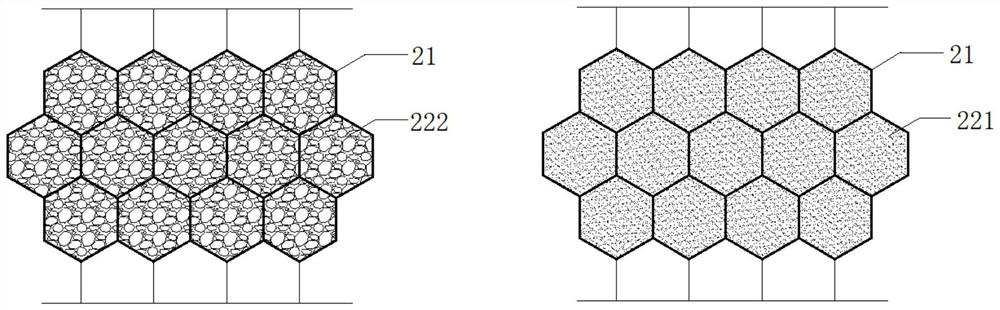

Vertical sliding assembly type foundation pit supporting structure and construction method thereof

InactiveCN112761159AImprove stabilityAvoid technical issues with distortionExcavationsReinforced concreteArchitectural engineering

The invention provides a vertical sliding assembly type foundation pit supporting structure and a construction method thereof. The vertical sliding assembly type foundation pit supporting structure comprises a steel stand column, a first steel sliding rail and a second steel sliding rail. A plurality of first steel slide rails are uniformly embedded in the underground diaphragm wall. The diaphragm wall reinforcing structure reinforcing steel bar mesh is welded to the diaphragm wall reinforcing steel bar mesh, and the diaphragm wall reinforcing steel bar mesh is arranged on the face, away from the first steel sliding rail, of the diaphragm wall. At least two layers of horizontal steel supporting mechanisms are arranged, each layer of horizontal steel supporting mechanism is connected with the first steel sliding rail and the second steel sliding rail in a clamped mode through a T-shaped connector, and the horizontal steel supporting mechanism on the top layer is replaced by a reinforced concrete support. According to the vertical sliding assembly type foundation pit supporting structure and the construction method thereof, supporting is conducted firstly, then excavation is conducted, one-time supporting is conducted in place, the technical problem that in the construction process of excavation while supporting, layered excavation and layered supporting, deformation of a diaphragm wall and a soil body behind the wall occurs is solved, and the overall stability of the structure is improved.

Owner:NANJING GEOTECHNICAL & UNDERGROUND SPACE TECH CO LTD +1

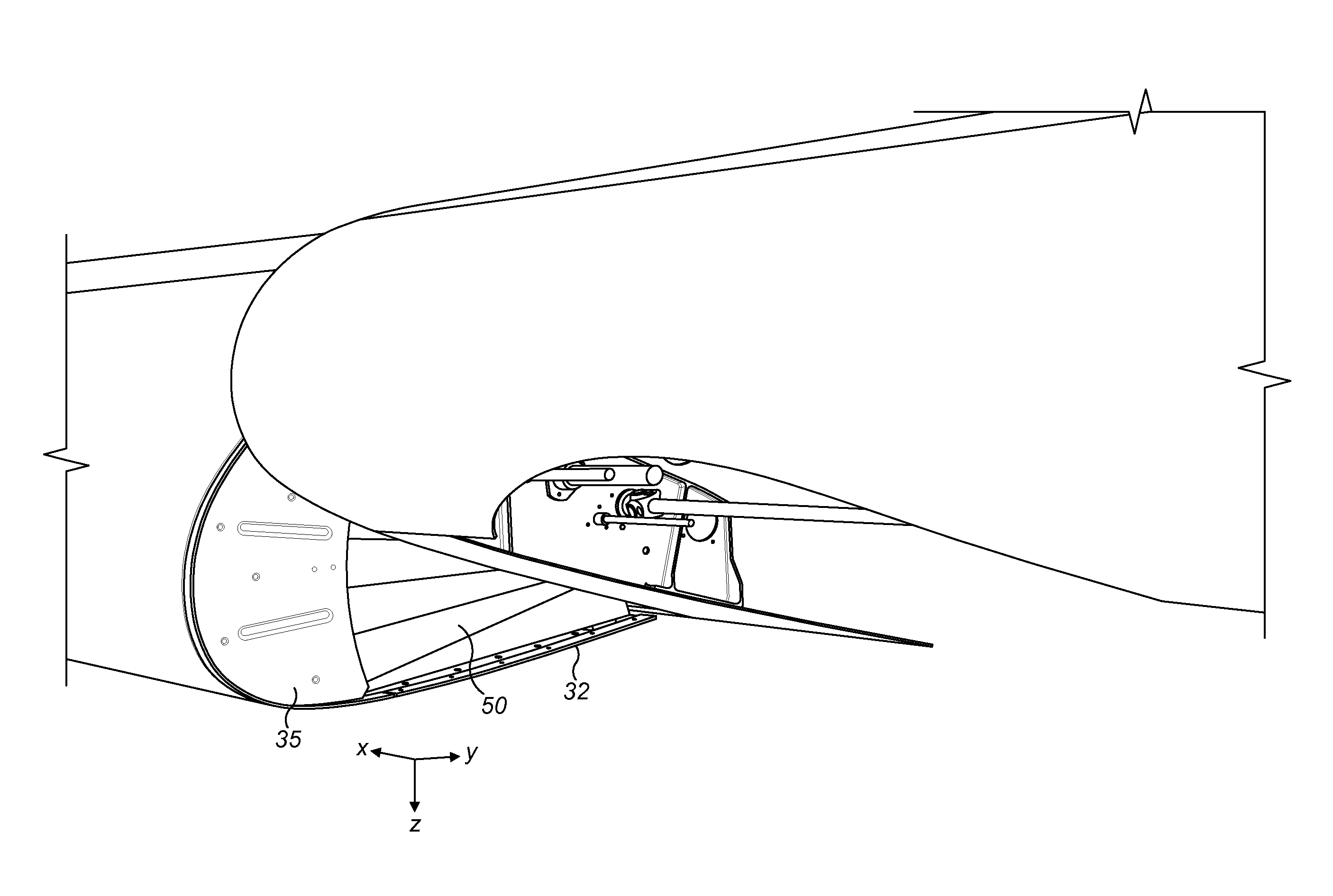

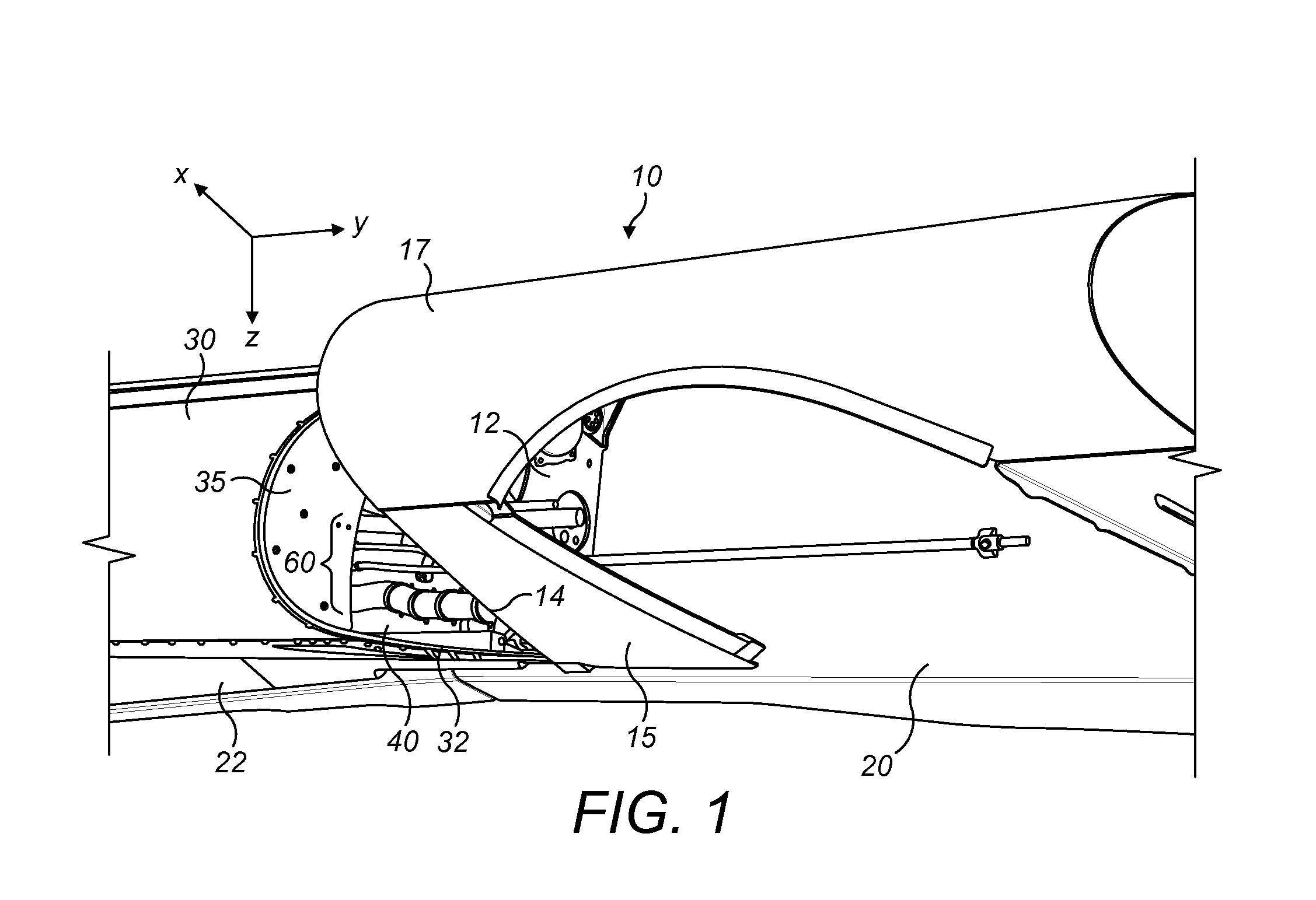

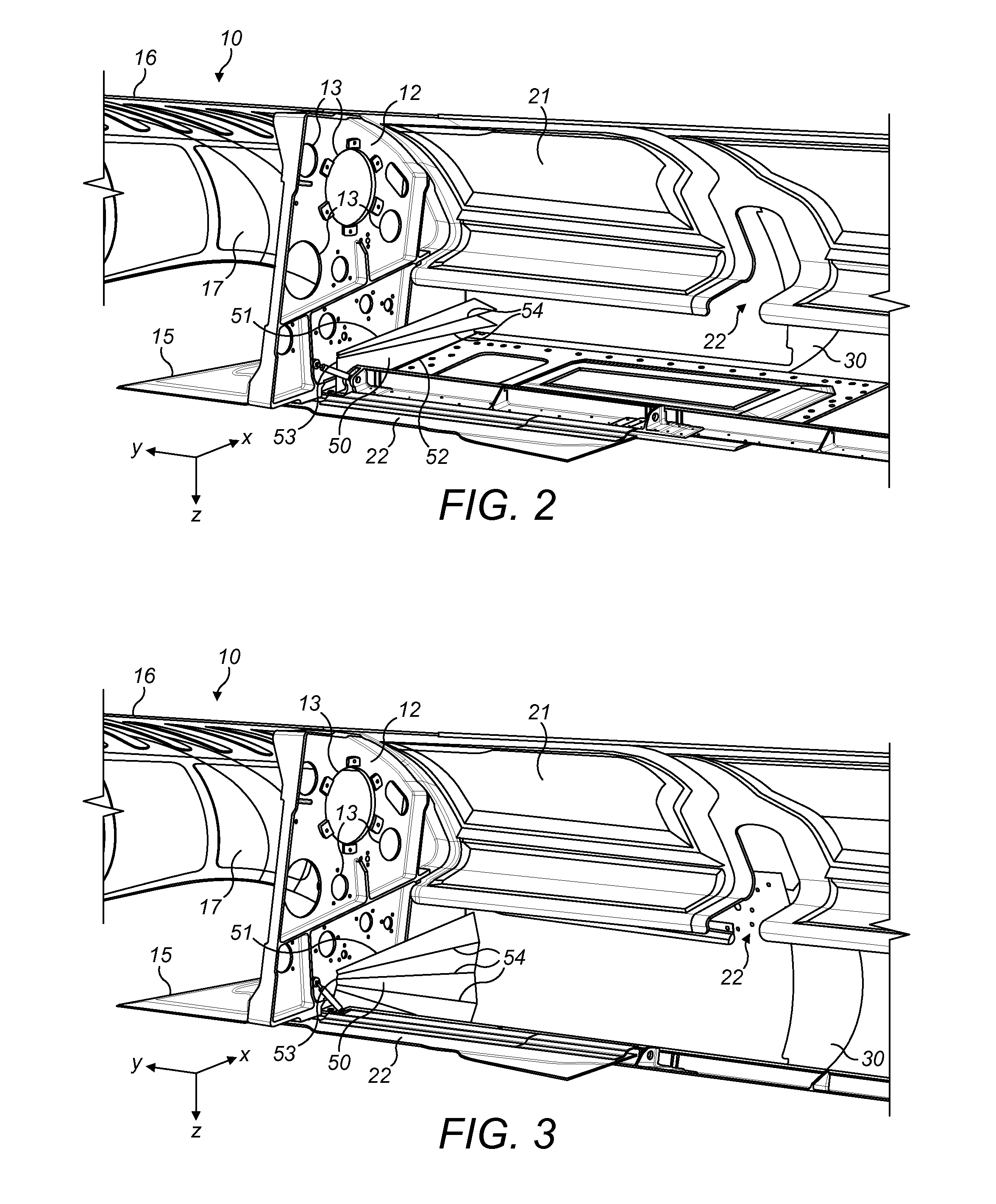

Retractable infill panel for high-lift device

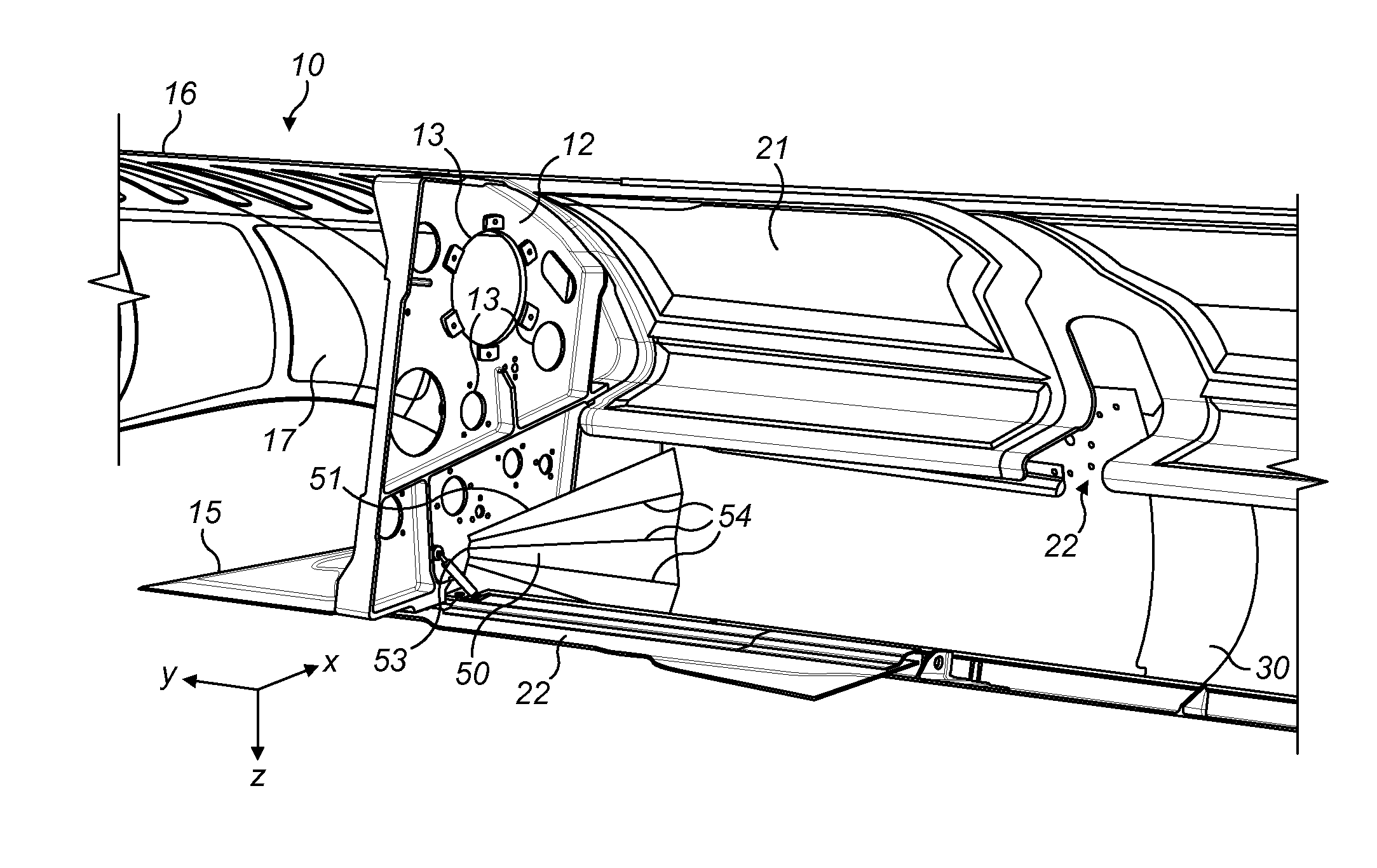

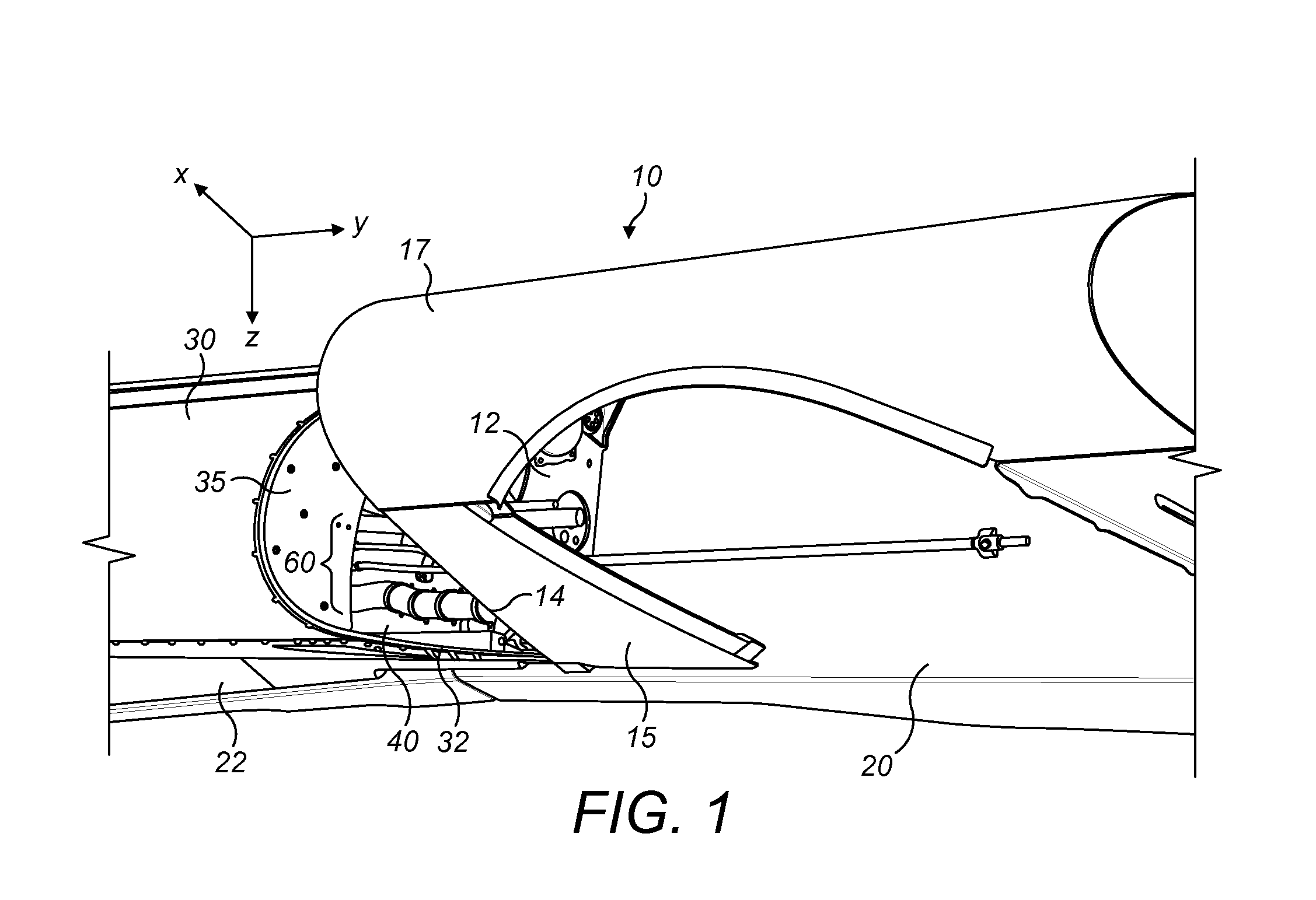

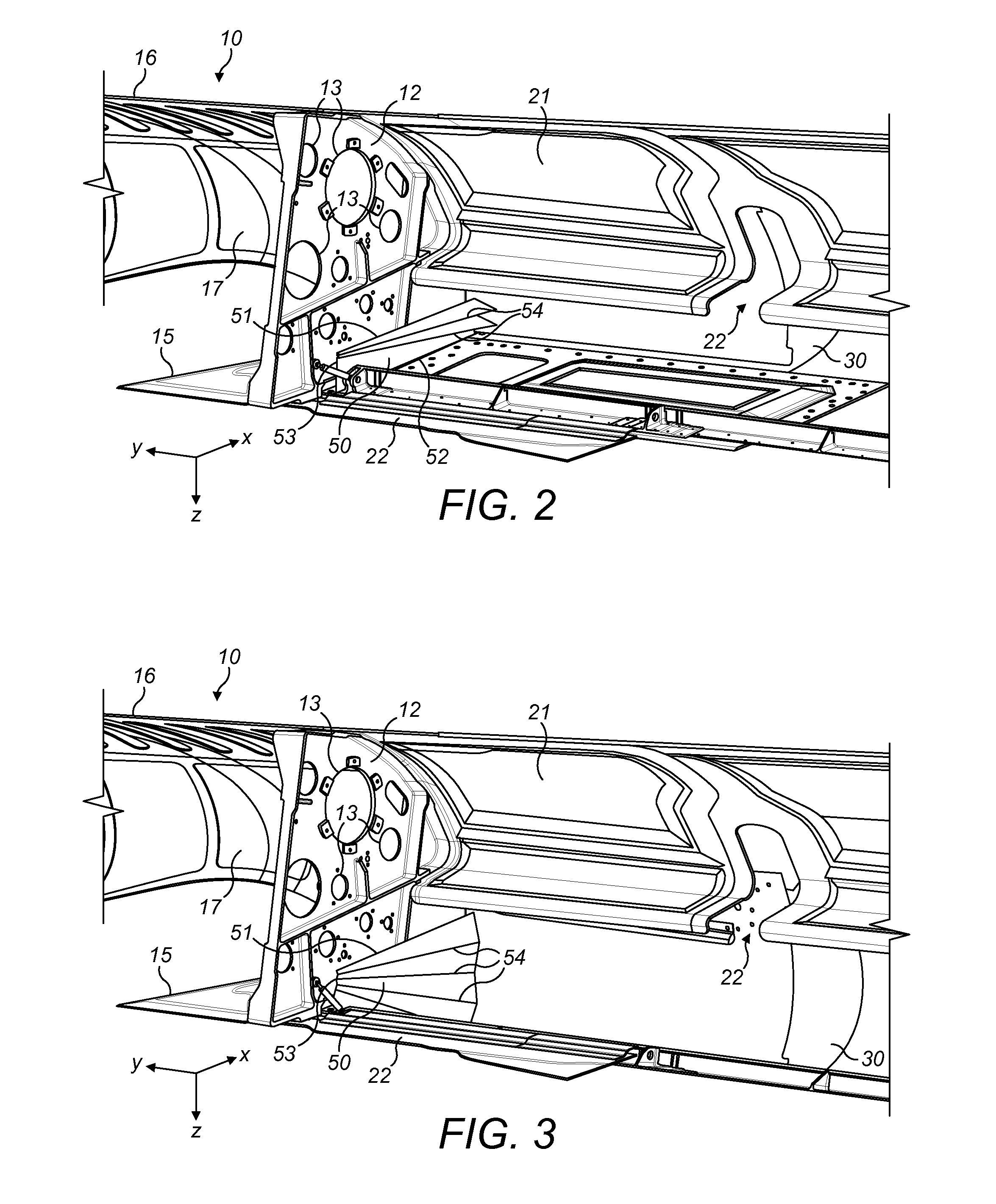

ActiveUS20140138487A1Overall small sizePrevent lateral deformationAircraft controlFuselagesInfillAircraft landing

The present invention provides an aircraft assembly with a fixed structure and a high-lift device. The fixed structure has a spar, a forward part which provides a foremost edge of an aircraft wing, and a lower part which provides a lower surface of the aircraft wing. A high-lift device is downwardly movable relative to the fixed structure from a stowed configuration to a deployed configuration. The high-lift device has a forward part which provides a foremost edge of the aircraft wing and a lower part which provides a lower surface of the aircraft wing. Downward movement of the high-lift device causes progressive opening of a lateral gap between the lower part of the high-lift device and the lower part of the fixed structure. A retractable infill panel is arranged to progressively extend from a retracted configuration to an extended configuration to fill the lateral gap.

Owner:AIRBUS OPERATIONS LTD

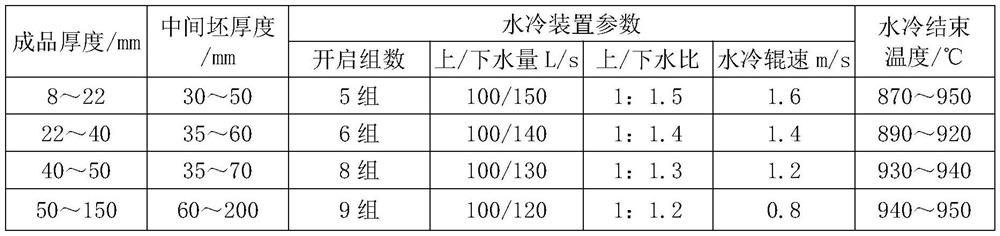

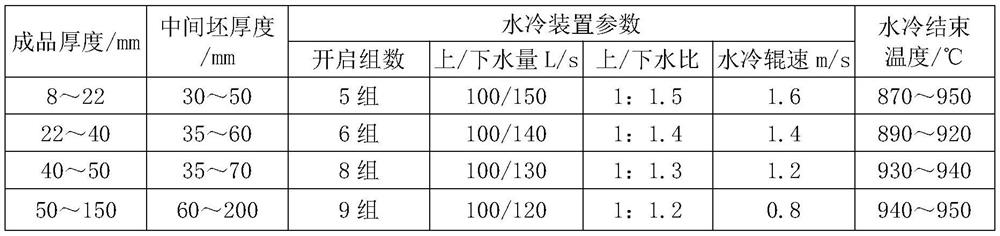

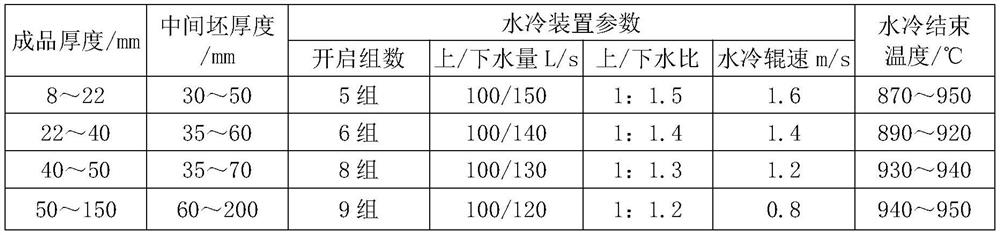

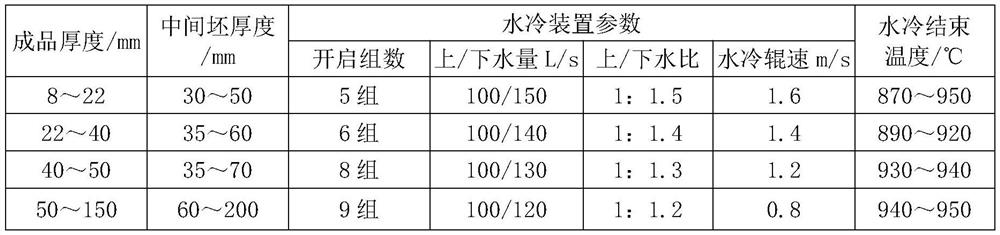

Production method for controlling transverse plate shape of high-quality carbon structural steel plate based on single-rack wide and thick plate rolling line

ActiveCN113210421APrevent lateral deformationProductivity does not affectTemperature control deviceMetal rolling arrangementsTemperature controlThick plate

The invention relates to a production method for controlling the transverse plate shape of a high-quality carbon structural steel plate based on a single-rack wide and thick plate rolling line. The production method comprises the following steps that (1) a plate blank is heated, specifically, the thickness of the plate blank is 200-300mm, and the tapping temperature of the plate blank is controlled to be 1080-1140 DEG C; (2) rolling is conducted, specifically, the initial rolling temperature of the plate blank is 1050-1100 DEG C, the thickness of an intermediate blank is 30-200mm, different amounts of water are used for cooling the intermediate blank with different thicknesses through a water cooling device, the water cooling ending temperature is controlled to be 870-950 DEG C, and the final rolling temperature of the plate blank is 800-880 DEG C; and (3) the straightening and red returning temperature of the steel plate is controlled to be 600-700 DEG C. According to the production method, in the rolling process of the carbon structural steel plate, the low straightening and red returning temperature is obtained by integrating execution of a series of key process temperature point control measures, the high-precision transverse plate shape is obtained, and meanwhile the production efficiency of a rolling mill is not reduced; and by the adoption of the production method, the transverse unevenness of the finally-manufactured steel plate is smaller than or equal to 5mm / plate width size, and the market competitiveness is high.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

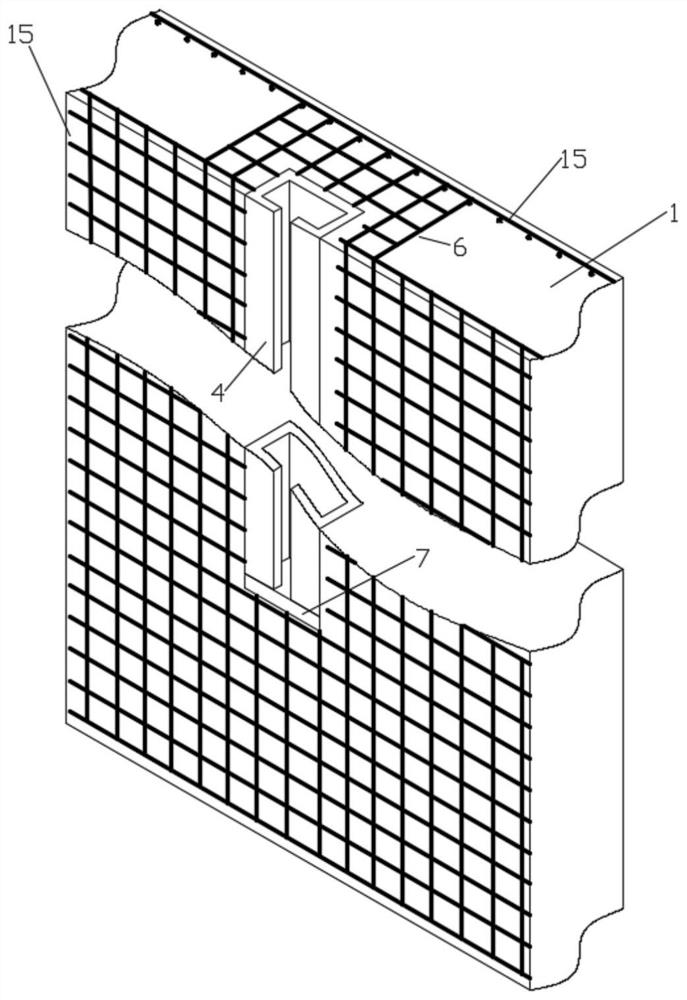

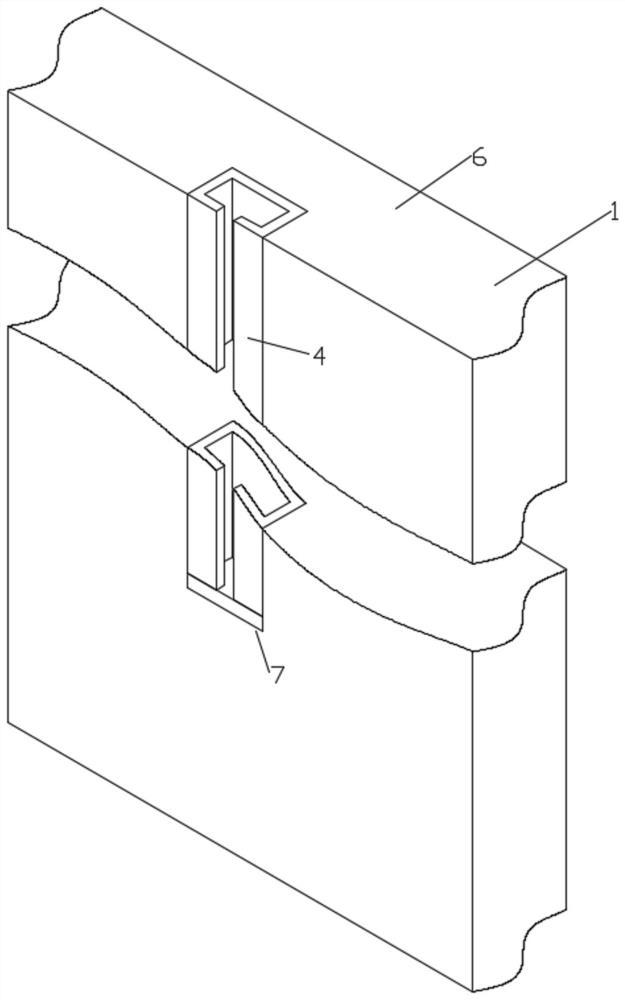

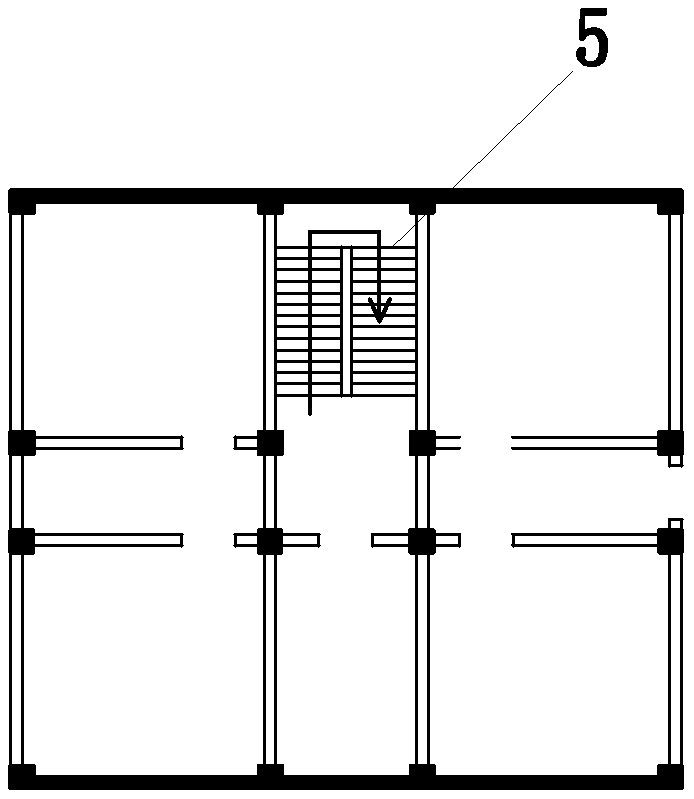

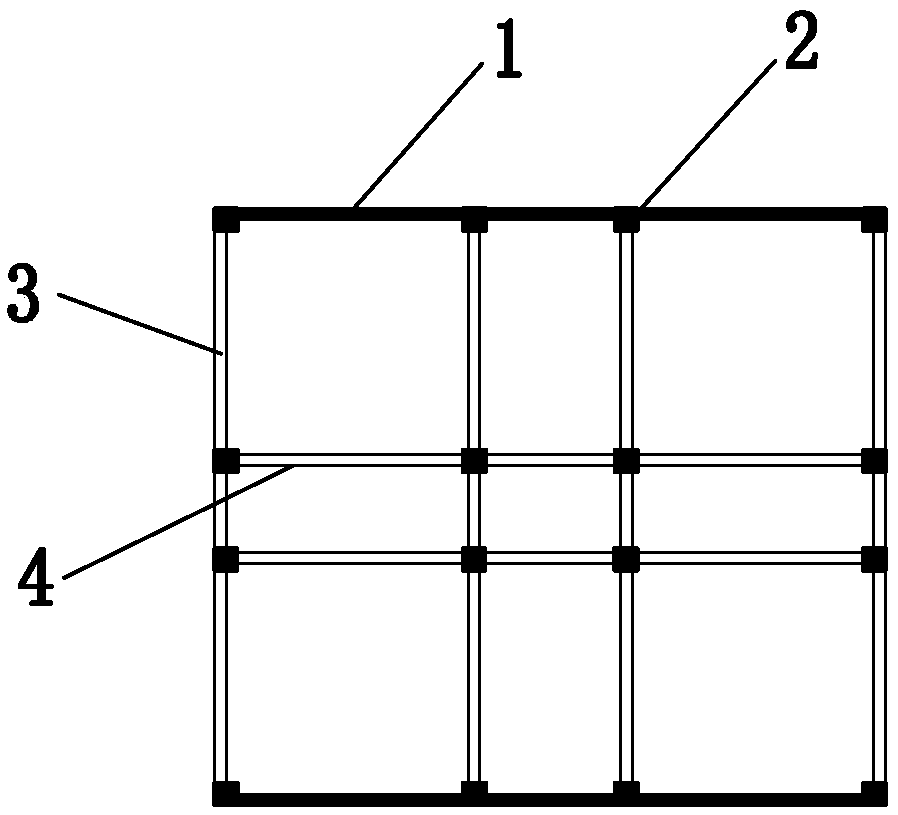

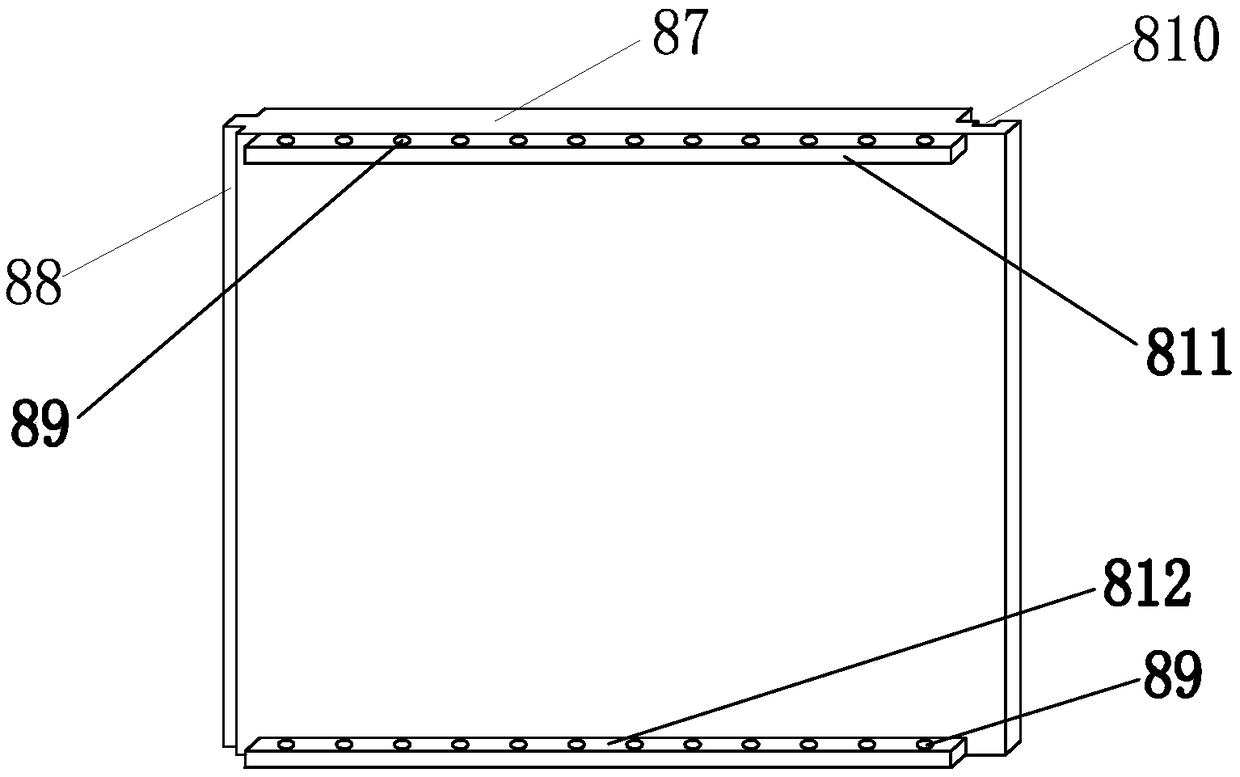

Frame-shear wall structure formwork system and construction method thereof

InactiveCN109339434AQuick stitchingEasy to manufactureForms/shuttering/falseworksBeam shapingShear wall

The invention relates to a frame-shear wall structure formwork system and a construction method thereof. The frame-shear wall structure formwork system comprises symmetrically arranged shear walls which are connected through a plurality of crossbeams, stand columns are arranged at the joint of the shear walls and the crossbeams, longitudinal beams are vertically connected to the crossbeams, standcolumns are arranged at the joint of the crossbeams and longitudinal beams, and stairs are arranged between the shear walls, the longitudinal beams and the two crossbeams located in the middle. The shear walls comprises shear wall shaping formworks. The stand columns comprise frame column shaping formworks. The crossbeams and the longitudinal beams comprise frame beam shaping formworks. The stairscomprise stair shaping formworks. According to the frame-shear wall structure formwork system and the construction method thereof, step splicing holes and stair bottom plate connecting holes are formed in stair prefabricated side formworks; and only stair bottom plate modules and connecting pieces on step formworks need to be inserted into corresponding reserved holes in sequence in the stair formwork erection process, and then the stair bottom plate modules and the connecting pieces on the step formworks are fixed by screws and nuts, so that the frame-shear wall structure formwork system isquickly completed.

Owner:HANGZHOU JIANGRUN TECH LIMITED

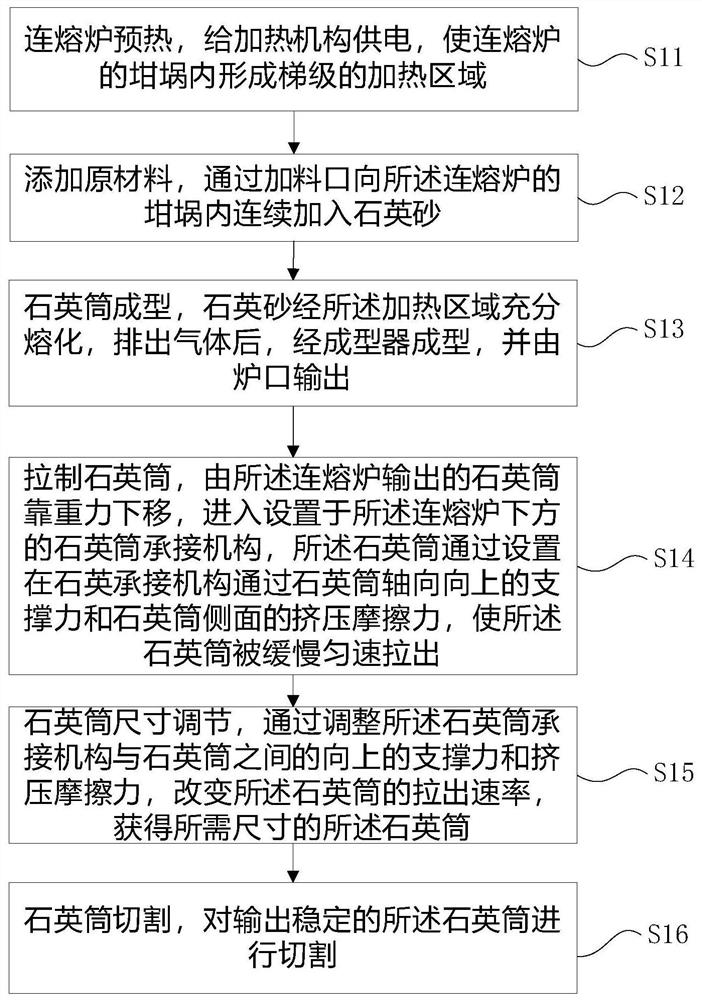

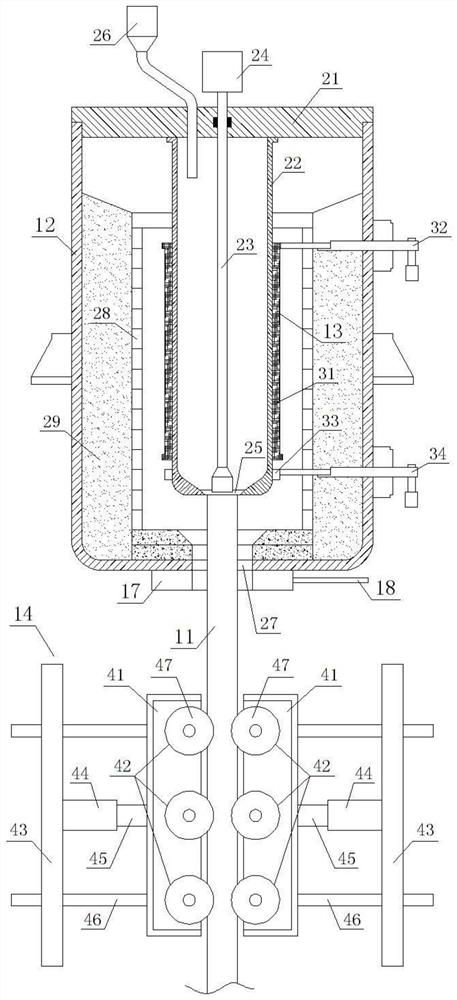

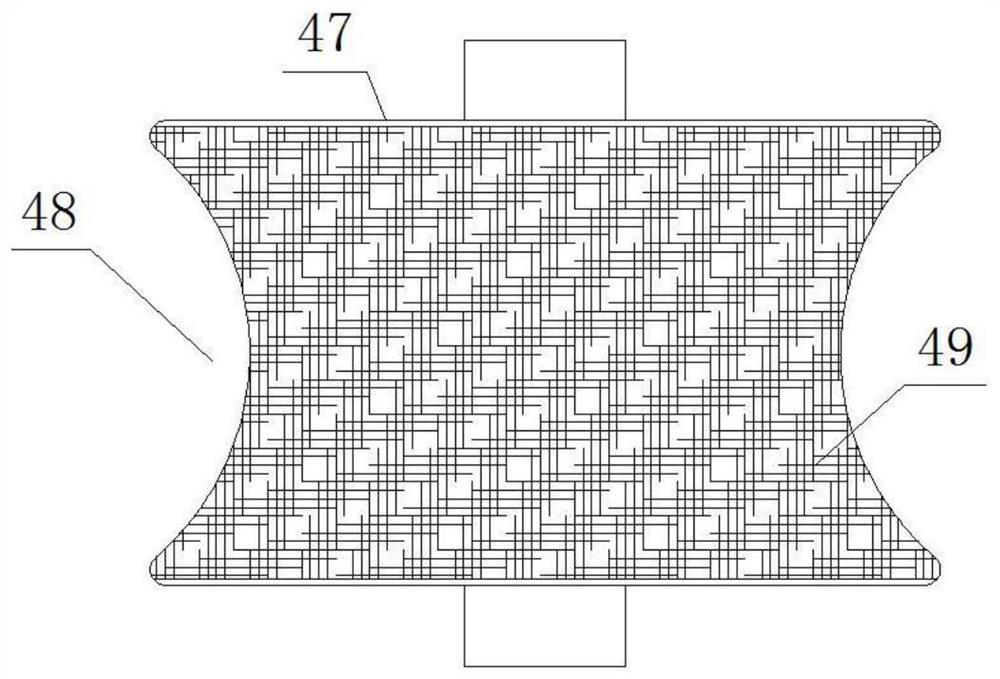

Technology for producing large-size quartz cylinder through continuous melting method, quartz cylinder and application of quartz cylinder

ActiveCN111792821AIncrease productivityReduce manufacturing costGlass shaping apparatusPhysical chemistrySemiconductor

The invention discloses a process for producing a large-size quartz cylinder by a continuous melting method. The technology comprises the following steps: preheating a continuous melting furnace, adding raw materials, molding the quartz cylinder, and drawing the quartz cylinder to ensure that the quartz cylinder is slowly pulled out at a constant speed; adjusting the size of the quartz cylinder, wherein the pull-out rate of the quartz cylinder is changed by adjusting the upward supporting force and extrusion friction force between a quartz cylinder bearing mechanism and the quartz cylinder toobtain the quartz cylinder with the required size, the diameter of the quartz cylinder is 300-600 mm, and the wall thickness of the quartz cylinder is 20-100 mm; and cutting the quartz cylinder, namely cutting the quartz cylinder with stable output. The technology can be applied to semiconductor processing and high-temperature manufacturing fields.

Owner:JIANGSU PACIFIC QUARTZ

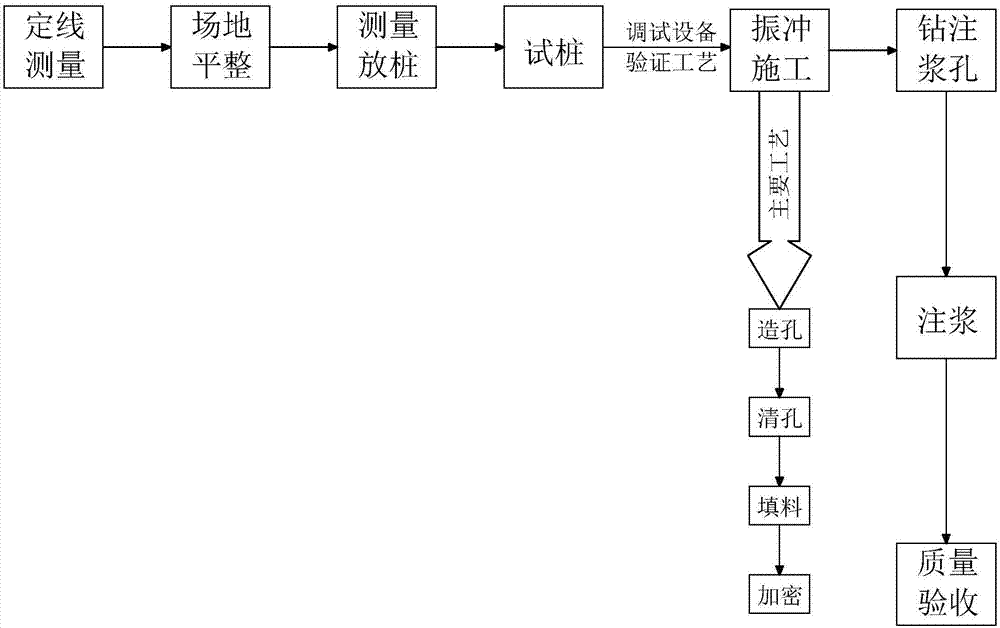

Construction technology for vibrocompaction of gravel pile of sediment storage dam of lower storage reservoir

The invention discloses a construction technology for vibrocompaction of a gravel pile of a sediment storage dam of a lower storage reservoir. On one hand, a center grouting hole and circumferential grouting holes are formed in a gravel pile and the periphery of the gravel pile through a drilling machine correspondingly, and when grout permeates into the peripheral loose soil body through the center grouting hole and the circumferential grouting holes, the soil body can be cemented to be a whole body; after solidification, the whole density degree and the effective stress are greatly improved, the nature of the soil body on the periphery of the pile is improved, and the bearing capacity is improved; on the other hand, when the grout permeates towards the pile side, the influence of a mud cake is eliminated to enable the cementing ability of a pile body and the peripheral soil of the pile is enhanced, so that the frictional force of the pile side is improved; and meanwhile, the pile generates a binding effect on the peripheral soil of the pile and prevents the peripheral soil of the pile from deforming in the side direction.

Owner:浙江华东工程咨询有限公司

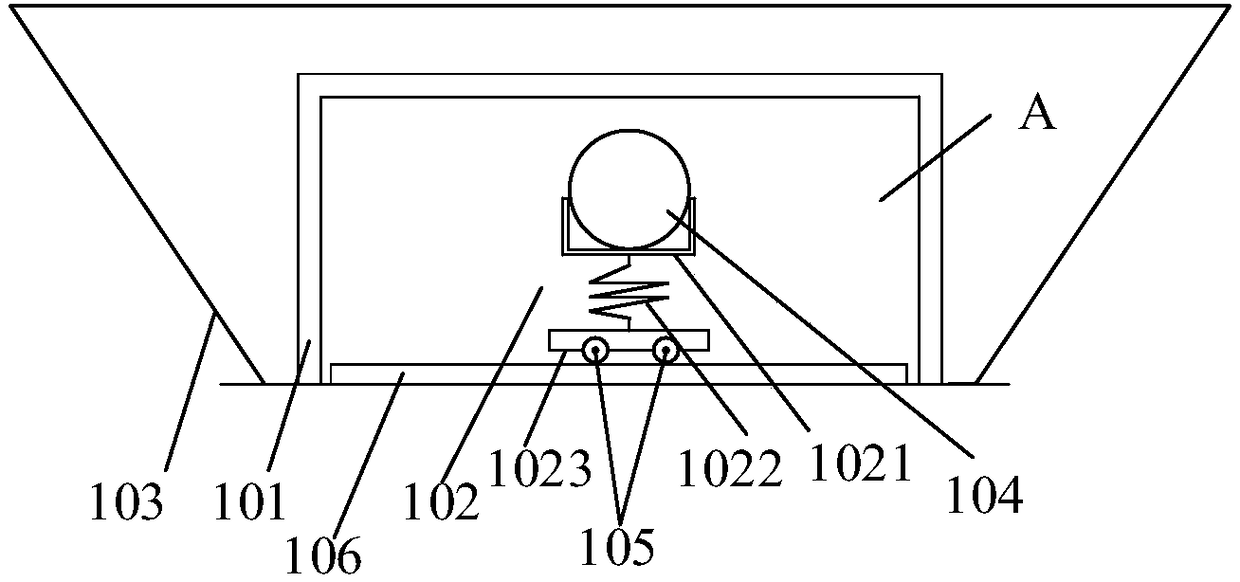

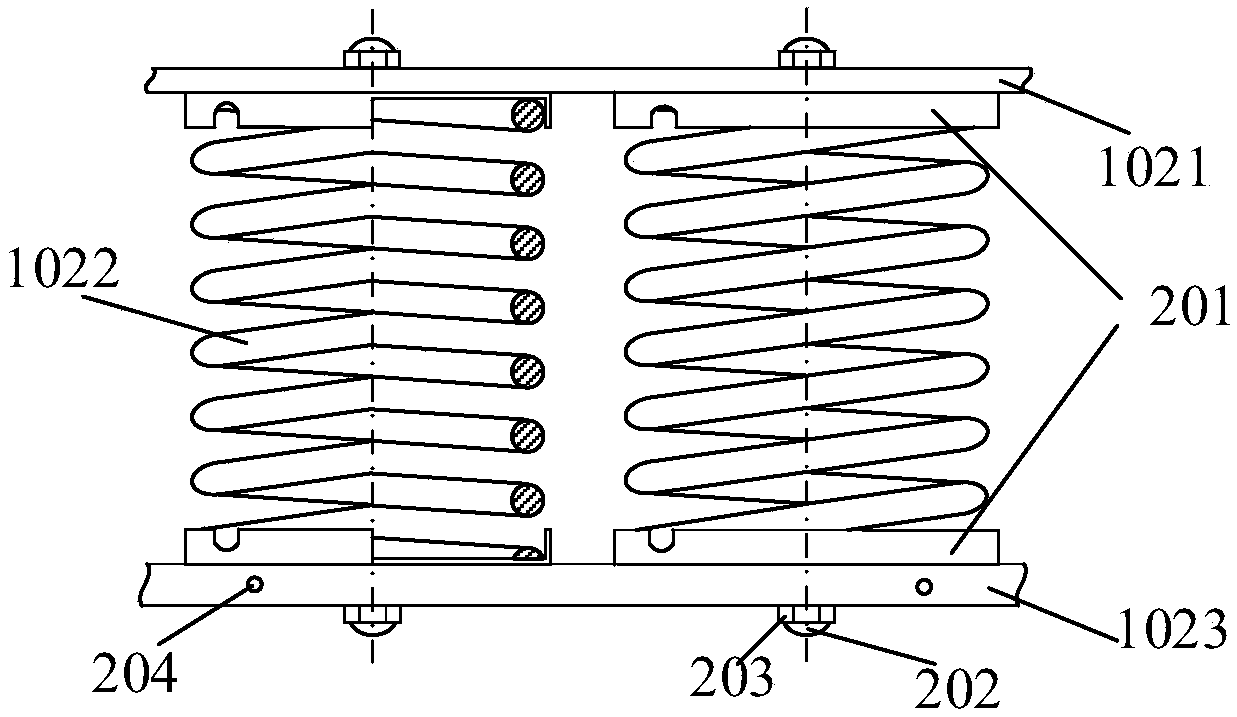

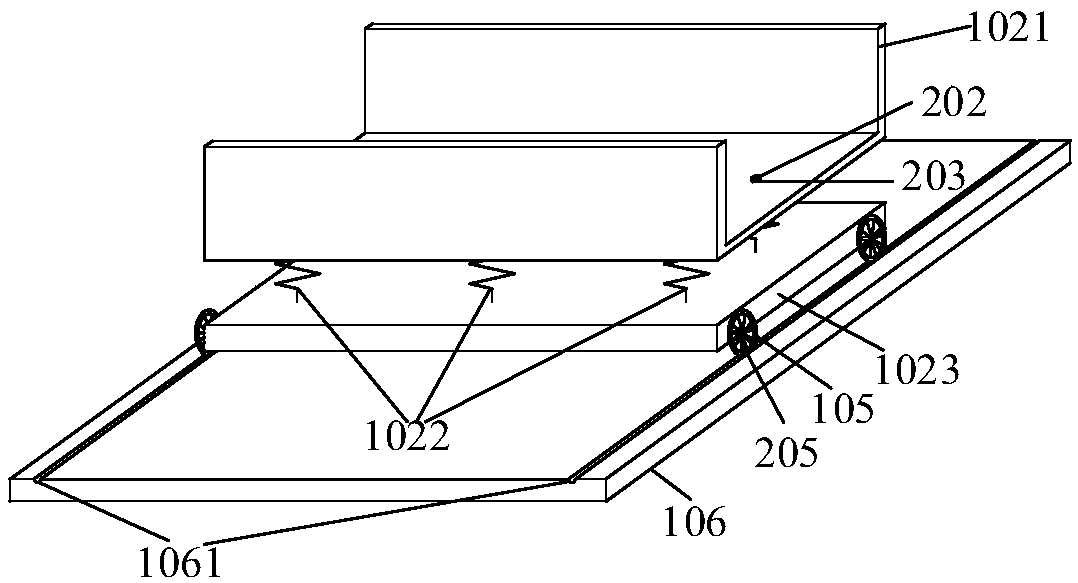

Anti-seismic device and anti-seismic system of buried pipeline

The invention provides an anti-seismic device and an anti-seismic system of a buried pipeline. The device comprises a culvert and a sliding supporting structure. The culvert is buckled in a pipe ditchto form a space structure, and the sliding supporting structure is arranged in the formed space and can laterally slide within a certain range perpendicular to the buried pipeline axis direction. When the earthquake happens, great relative displacement of the surrounding soil body can be generated due to faulting, and within a certain range, the buried pipeline arranged on the sliding supportingstructure can laterally slide along with movement of the soil body. The sliding supporting structure is internally further provided with a spring structure with high elasticity, and deformation of theburied pipeline can be partially absorbed by the spring structure under the earthquake wave motion effect. Thus, according to the provided scheme, within a certain range, lateral deformation generated to the buried pipeline due to faulting can be effectively avoided, and influences on the buried pipeline due to the earthquake wave motion effect can be reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

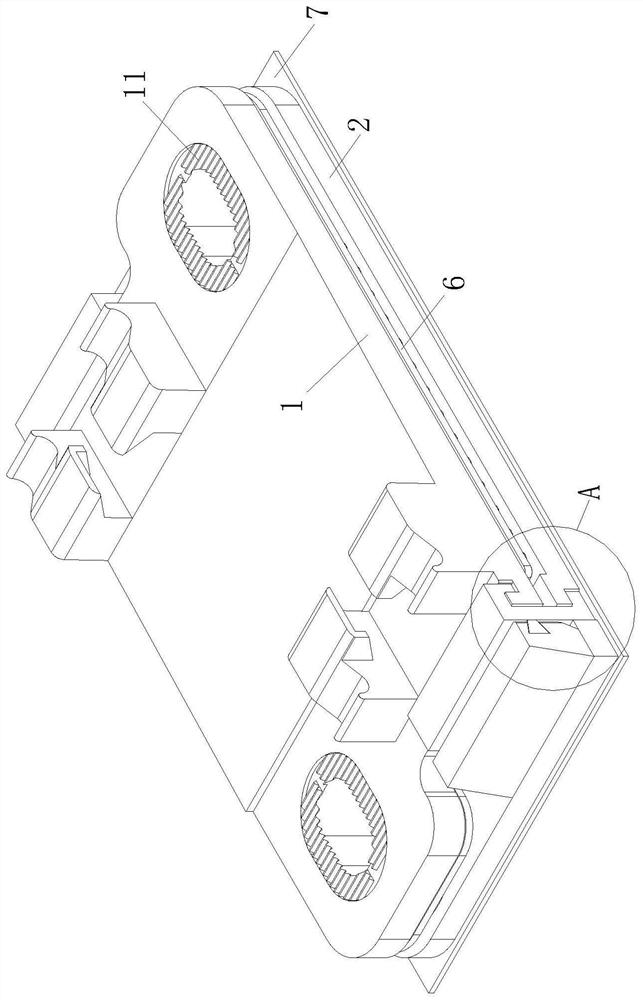

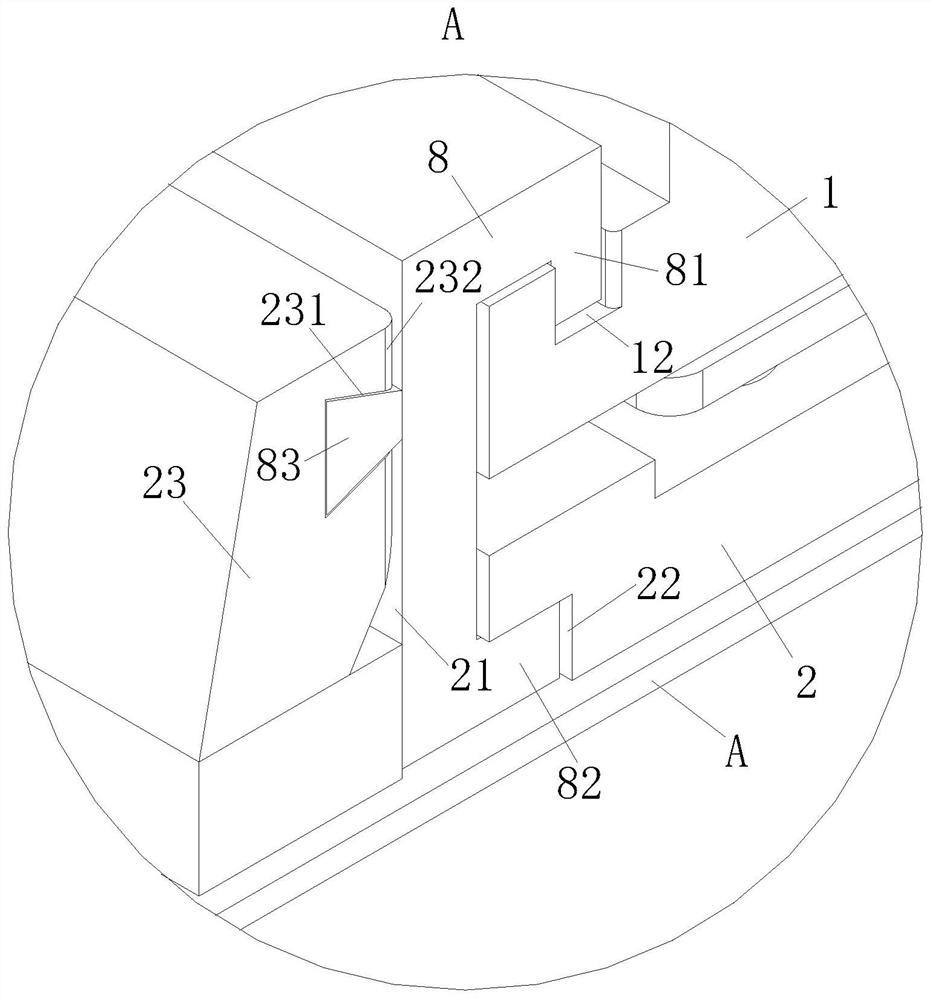

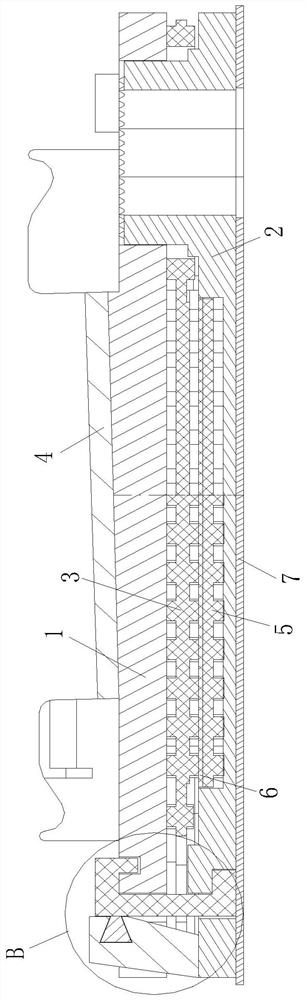

Vibration reduction fastener system

The invention belongs to the technical field of urban rail transit, and particularly relates to a vibration reduction fastener system which comprises an upper iron base plate, a lower bottom plate, a middle vibration reduction pad, an under-rail vibration reduction pad, an under-plate vibration reduction pad, a middle vibration isolation plate, an insulating coupling plate and a self-locking limiting structure. The insulating coupling plate is laid on the ground, and the lower bottom plate is mounted above the insulating coupling plate; a self-locking buckle is arranged and embedded into the mounting groove, so that the lower bottom plate and the upper iron base plate are limited, it is guaranteed that the lower bottom plate, the upper iron base plate and components in the gap between the lower bottom plate and the upper iron base plate are kept stable, and the phenomenon that the vibration reduction fastener moves and is staggered under the vibration effect of passing of a train is avoided; and through the series connection effect of the middle anti-vibration pad, the under-rail anti-vibration pad and the under-plate anti-vibration pad, the overall rigidity of the fastener is effectively reduced, meanwhile, excessive deformation of the anti-vibration pads is prevented, and therefore it is guaranteed that the fastener system can normally play a vibration reduction role.

Owner:河北中烁轨道科技有限公司

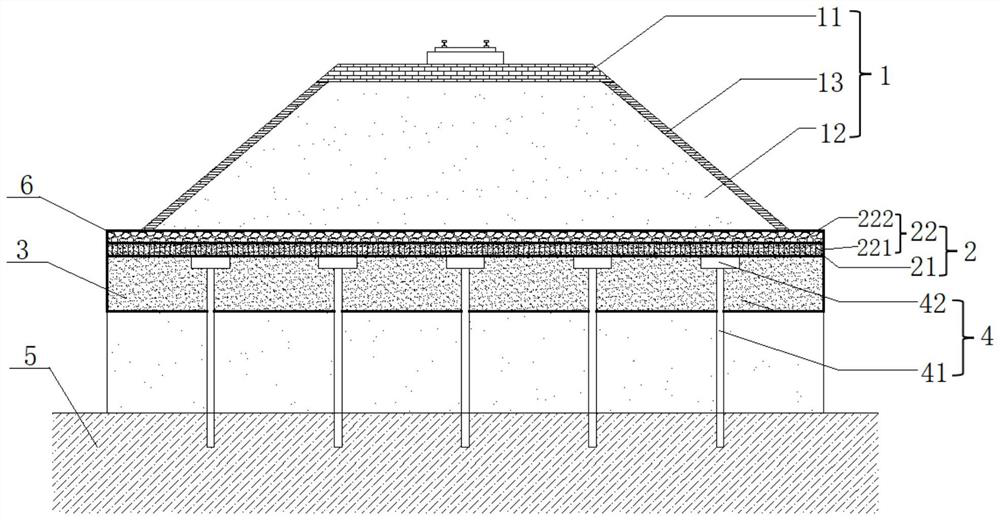

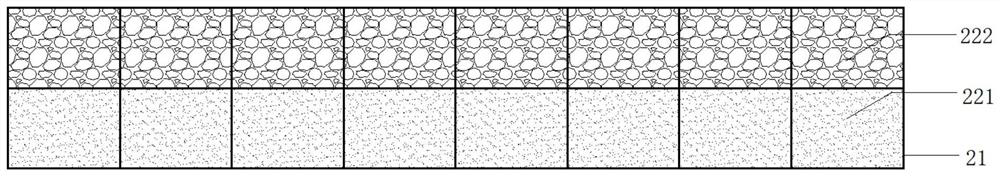

Pile-supported soft soil roadbed reinforcing structure and reinforcing method

PendingCN114508011AImprove bearing capacityControl for settlement differencesRoadwaysSoil preservationSoil scienceMagnesium phosphate

The invention discloses a pile-supported soft soil roadbed reinforcing structure and a reinforcing method. The pile-supported soft soil roadbed reinforcing structure comprises a solidified sludge filling embankment layer, a pile-supported soft soil roadbed reinforcing layer, a pile-supported soft soil roadbed reinforcing layer and a pile-supported soft soil roadbed reinforcing layer which are sequentially arranged from top to bottom, the three-dimensional geocell reinforced cushion layer is formed by filling a three-dimensional geocell with potassium magnesium phosphate cement solidified sludge; the shallow soft soil solidification layer is formed by in-situ stirring and solidification of soft soil through a soil solidifying agent; a pile bearing structure of a cement mixing pile group; and a bearing layer; the upper end of the pile bearing structure of the cement mixing pile group extends into the shallow soft soil solidification layer, and the lower end of the pile bearing structure of the cement mixing pile group extends into the bearing layer. On the basis of the concept of using local materials and treating waste with waste, an environment-friendly sludge curing technology is introduced, and in-situ curing of soil between shallow piles is conducted, a cement mixing pile group serves as a pile bearing structure, a three-dimensional geocell replaces a two-dimensional geogrid, and sludge solidified soil serves as a reinforced cushion layer filling material and roadbed filler; the method has the outstanding advantages of improving the rib-soil interface friction force, controlling differential settlement, preventing lateral deformation and the like.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

Retractable infill panel for high-lift device

ActiveUS9254927B2Overall small sizePrevent lateral deformationAircraft controlAircraft indicatorsInfillAircraft landing

Owner:AIRBUS OPERATIONS LTD

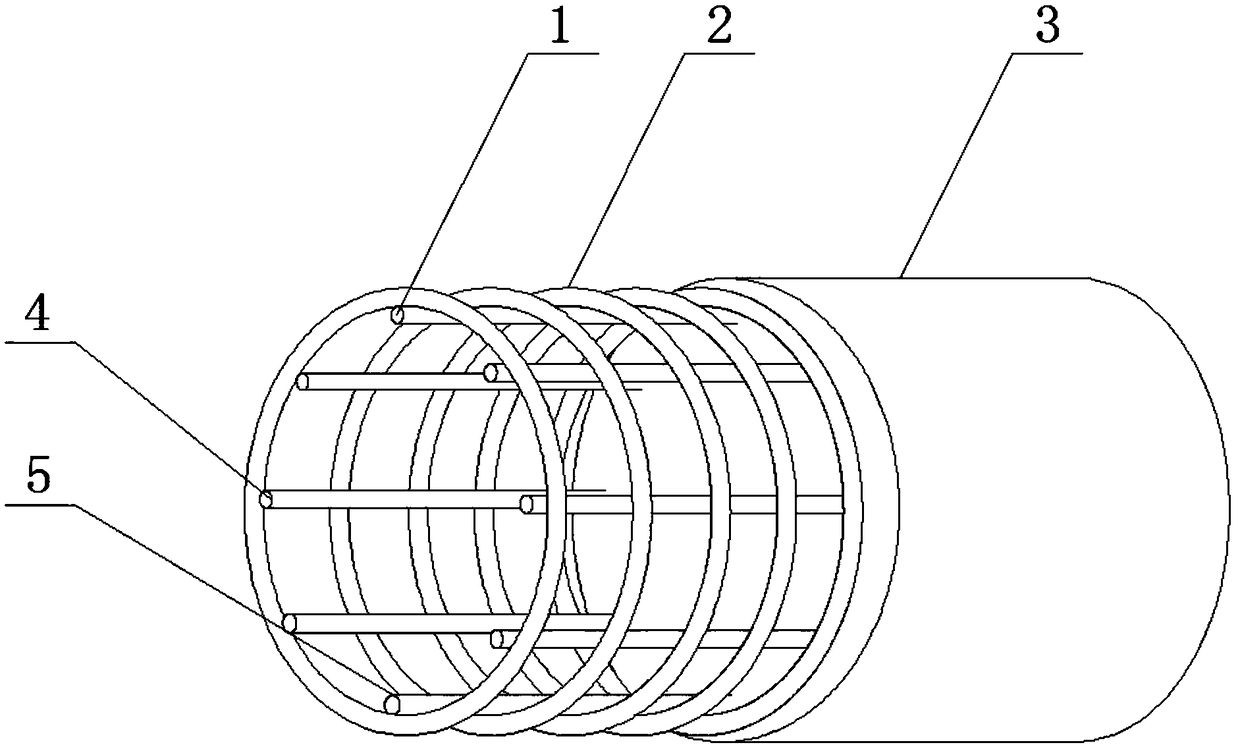

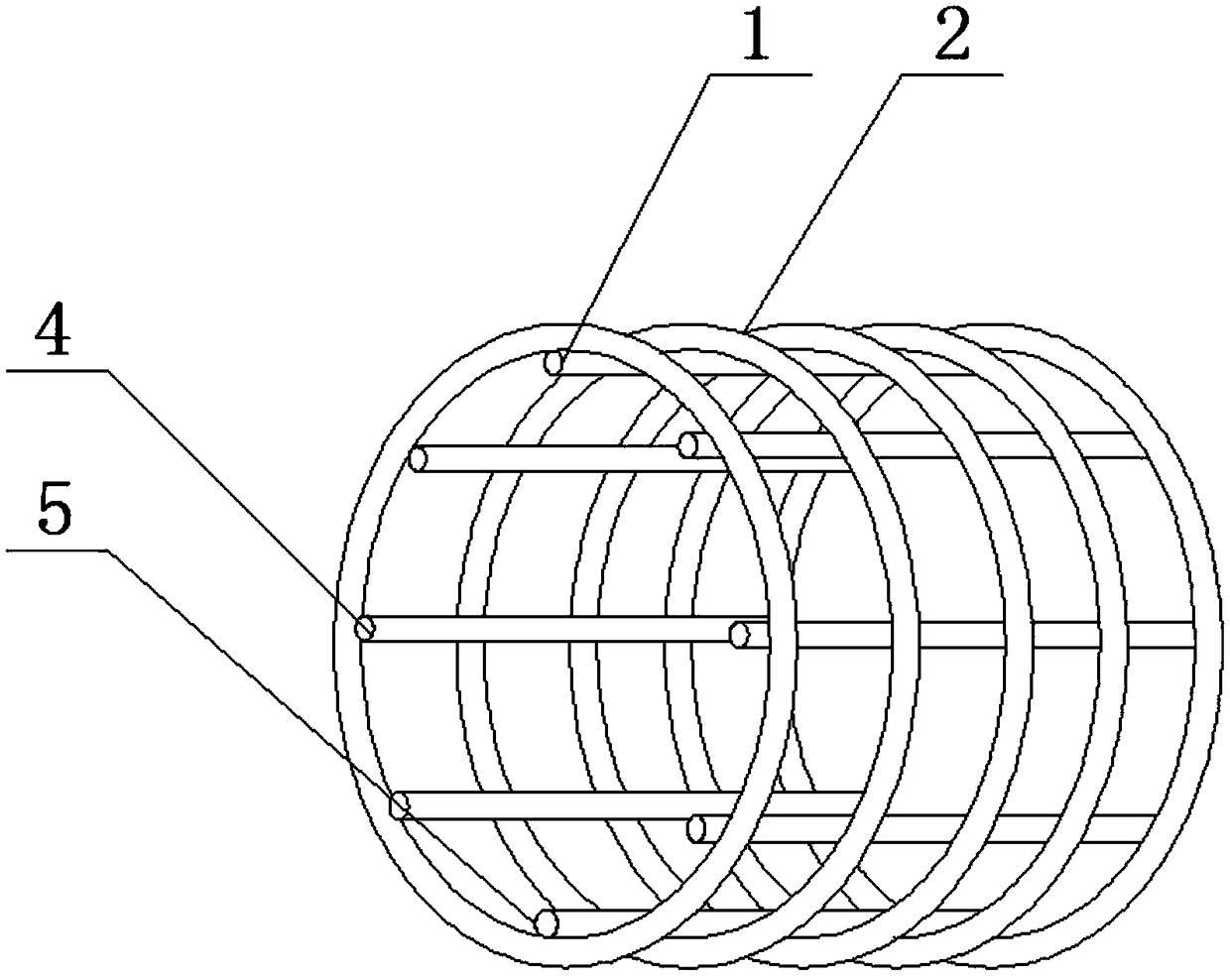

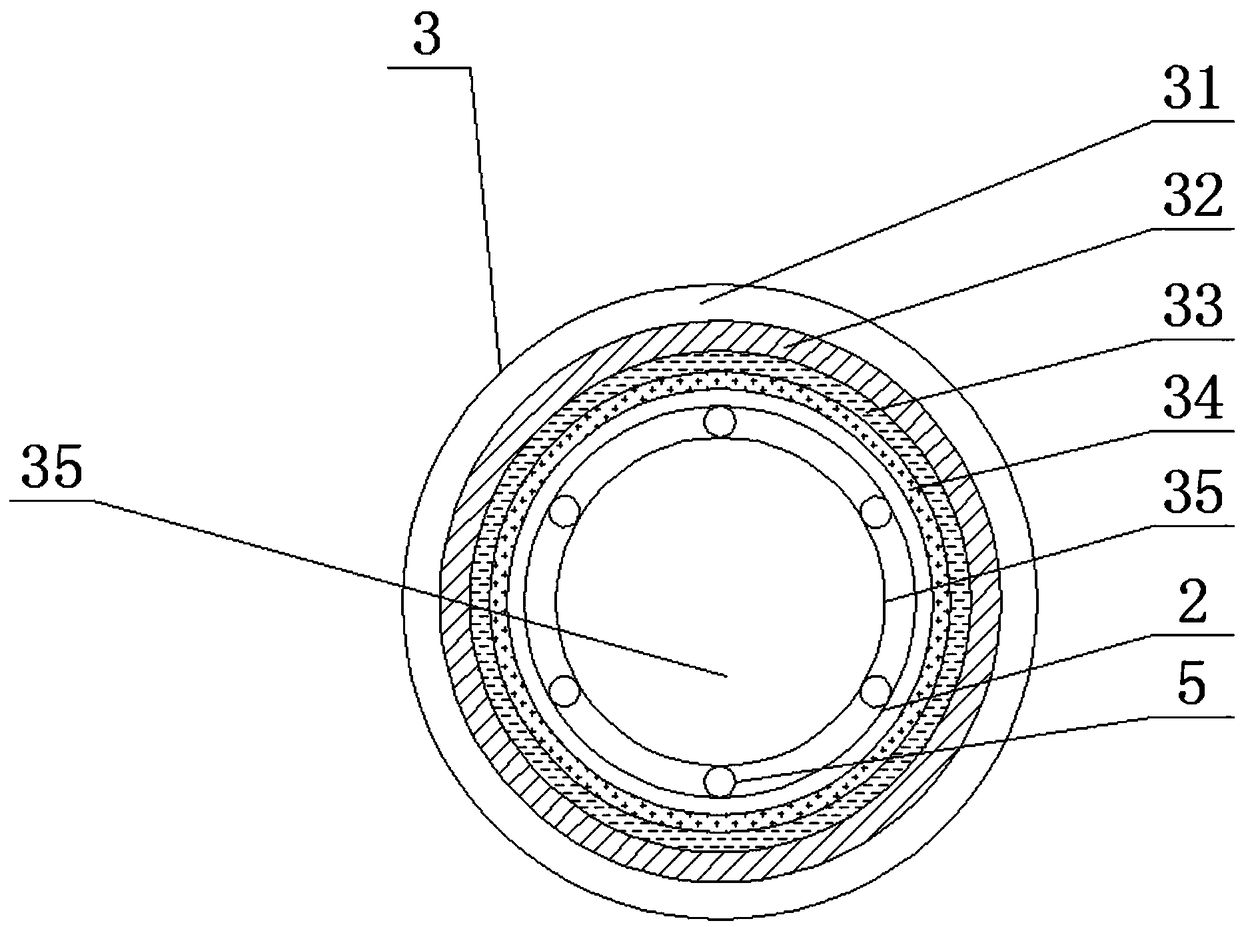

Novel flexible permeable hose with full-plastic framework

InactiveCN108869900AEasy maintenancePrevent lateral deformationFlexible pipesArchitectural engineeringSewage

The invention discloses a novel flexible permeable hose with a full-plastic framework. The novel flexible permeable hose with the full-plastic framework comprises an upper horizontal reinforcing steelbar and a modified plastic framework, wherein the modified plastic framework is connected to the outer side of the upper horizontal reinforcing steel bar; a hose shell is arranged on an outer ring ofthe right side of the modified plastic framework; a middle horizontal reinforcing steel bar is connected to the middle of an inner ring of the modified plastic framework; and a bottom horizontal reinforcing steel bar is arranged on the lower part of the middle horizontal reinforcing steel bar. Even if the hose shell is broken, sewage and dirty water directly contact the plastic framework, the plastic framework cannot be corroded due to the characteristics of corrosion prevention and acidproofness of plastics, so that the hose can be easy to maintain by a maintenance worker; the horizontal reinforcing steel bar is additionally arranged on the full-plastic framework, so that the inside plastic framework can be fixed without being deformed laterally; and a connector between pipe bodies and the plastic framework are hot-melting type welded so as to form seamless joint between flexible permeable hoses, so that water is permeated smoothly and discharged smoothly.

Owner:安徽合创新型合成材料有限公司

Application of top-down construction method to structural construction of underground substation

ActiveCN102561390AEmission reductionEffective control of deformationArtificial islandsExcavationsSlurry wallBasement

The invention relates to application of a top-down construction method to structural construction of an underground substation, which includes the steps: firstly, applying a combined channeling technique of lifting and milling for an underground diaphragm wall in a soft soil area; secondly, using an independently researched intelligent one-column one-pile verticality adjustment device; thirdly, applying an H-shaped steel joint to the ultra-deep underground diaphragm wall, and applying corresponding overflow and detour flow preventions to the top, the bottom and two sides of each H-shaped steel; fourthly, digging a basement to a certain depth; fifthly, mastering pumping parameters and reasonably distributing unwatering and relief wells inside and outside a pit; and sixthly, using a high-power centrifugal fan, an infrared automatic control flushing system and a construction lifter applicable to underground building top-down construction. Compared with the prior art, the application has the advantages that land resources are saved, brace blasting is reduced, formation of a deep foundation pit is controlled effectively, emission of flying dust, noise and waste is low, efficiency and accuracy are high, and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

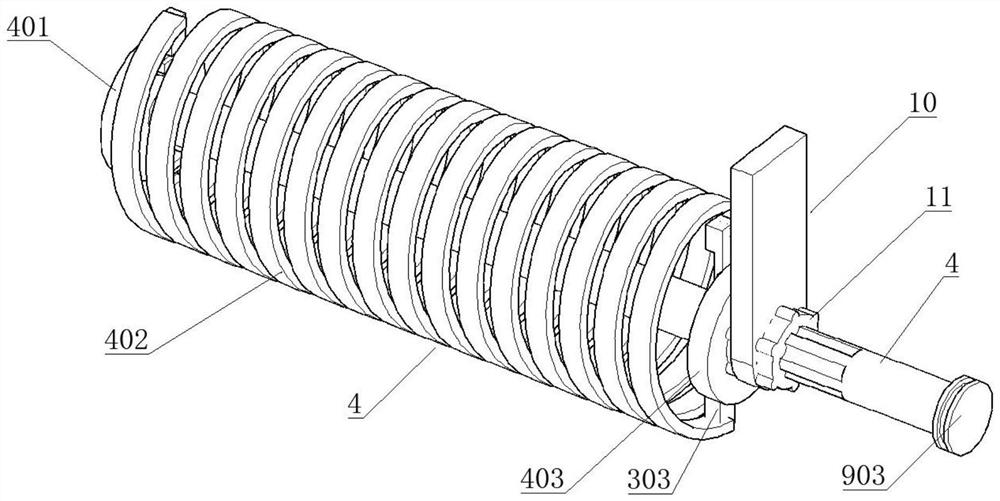

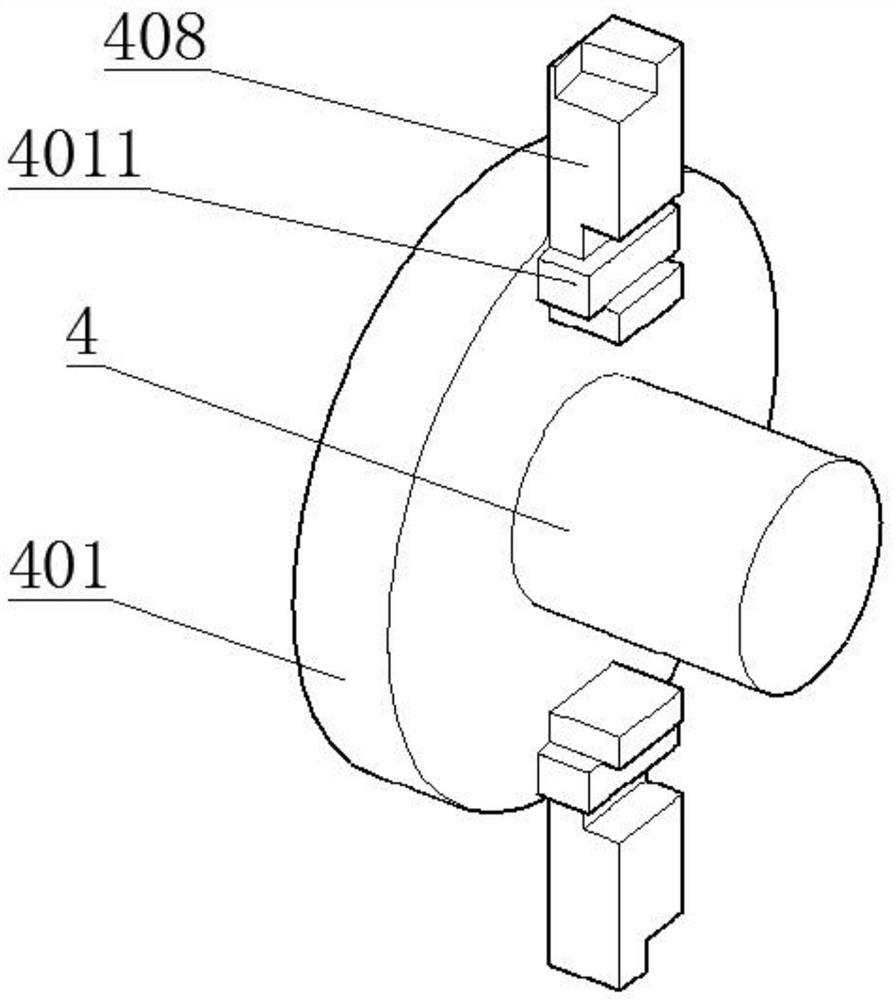

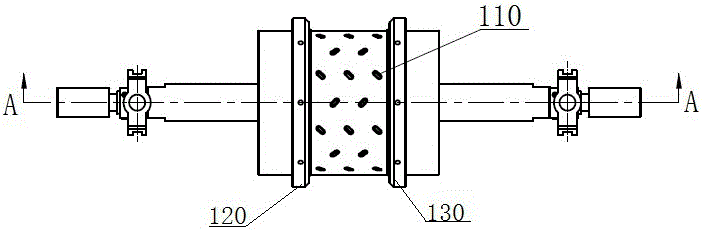

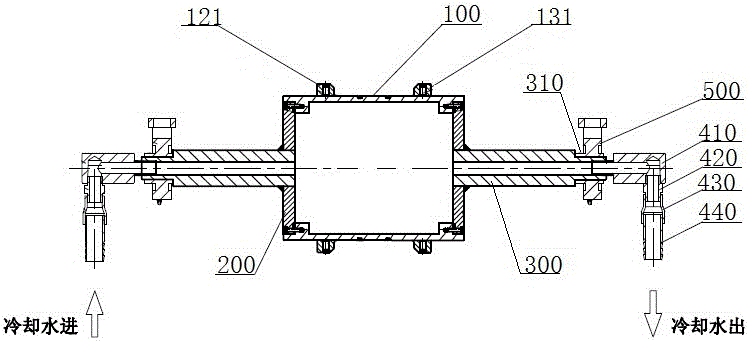

An adjustable winding device and adjustment method for flexible glass winding

Owner:泉州台商投资区飞翔机械设计服务中心

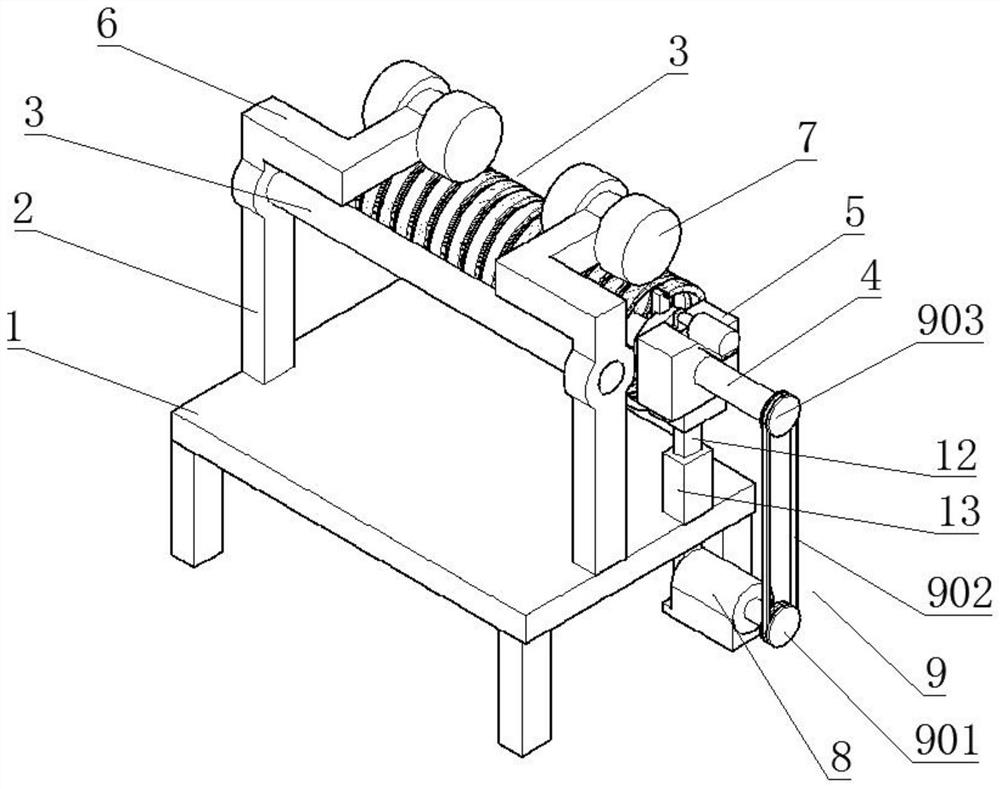

Mariculture net cage pedal antiskid salient point forming roller

InactiveCN105965870AWon't go off trackPrevent lateral deformationClimate change adaptationPisciculture and aquariaMaricultureMachining

The invention relates to the technical field of forming machining equipment and specifically discloses a mariculture net cage pedal antiskid salient point forming roller. The mariculture net cage pedal antiskid salient point forming roller is used for pressing to form an antiskid structure on the surface of a sectional material and comprises a hollow roller main body taking the shape of a cylinder, and a concave pit is arranged on the circumferential surface of the hollow roller main body; two ends of the hollow roller main body are connected with flanges; a support shaft is arranged on the flanges; a passage is formed in the support shaft to communicate with the inner cavity of the hollow roller main body; a water supply joint is connected with the end part of the support shaft. The mariculture net cage pedal antiskid salient point forming roller, disclosed by the invention, can press to form antiskid salient points on the surface of the sectional material to prevent people from slipping.

Owner:HESHAN LESSO IND DEV

Application of Inverse Method Technology in Construction of Underground Substation Structure

ActiveCN102561390BEmission reductionEffective control of deformationArtificial islandsExcavationsSlurry wallInfrared

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Damping pad limiting mechanism for experimental equipment

InactiveCN108775364AAchieve fixationEasy to useSpringsSprings/dampers design characteristicsEngineering

Owner:雀来宝科技江苏有限公司

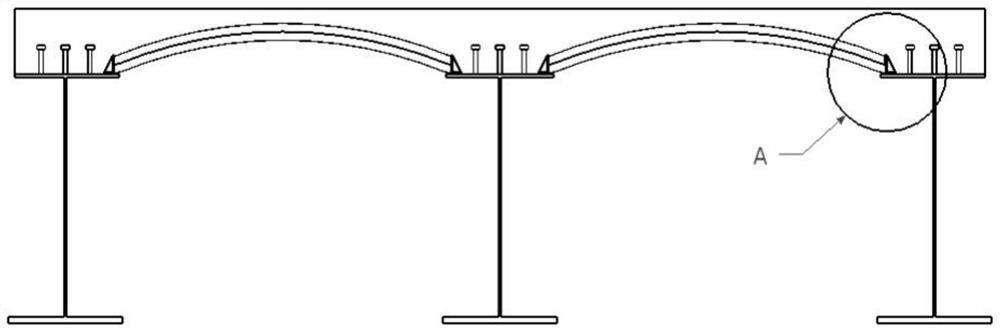

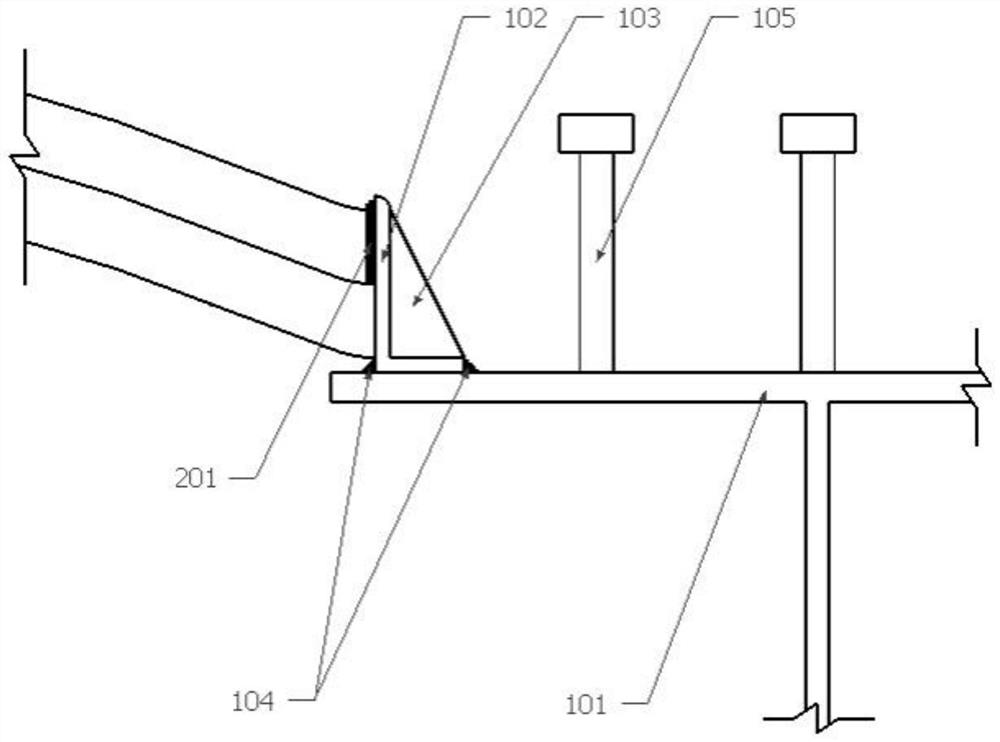

Construction technology of a connection structure between corrugated arched steel plates and steel beams

ActiveCN111424551BFast constructionPrevent leakageBridge structural detailsBridge erection/assemblyRebarFlange

The invention discloses a construction process of a connection structure between a corrugated arched steel plate and a steel beam, comprising the following steps: welding a triangular steel plate with the same inner contour size as the angle steel to the angle steel to form a component with a plurality of transverse stiffeners ; Weld the studs and the member to the upper flange of the steel beam; make the corrugated arched steel plate span across two adjacent steel beams, and the two ends of each corrugated arched steel plate are connected to the upper flange of the steel beam Maintain horizontal contact and maintain vertical contact with the vertical limb of the angle steel; paste rubber sealing strips on the upper surface of the corrugated arched steel plate at the gap in contact with the angle steel; Reinforcement is placed and tied according to size, and then concrete is poured. Compared with the prior art, the invention can prevent grout leakage at the end of the corrugated arched steel plate and slippage in the transverse bridge direction during concrete pouring, and has simple construction, easy quality assurance and fast construction speed.

Owner:JIANGXI PROVINCIAL EXPRESSWAY INVESTMENT GRP CO LTD

A production method for controlling the transverse shape of high-quality carbon structural steel plate

ActiveCN113210421BPrevent lateral deformationProductivity does not affectTemperature control deviceMetal rolling arrangementsTemperature controlThick plate

The invention relates to a production method for controlling the transverse shape of a high-quality carbon structural steel plate based on a single-stand wide and thick plate rolling line. 1080~1140℃, (2) Rolling: the slab rolling temperature is 1050~1100℃, the thickness of the intermediate billet is 30~200mm, and the water cooling device is used to cool the different thickness of the intermediate billet with different amounts of water, and the temperature at the end of the water cooling is controlled at In the range of 870-950°C, the final rolling temperature of the slab is 800-880°C; (3) the steel plate straightening and reddening temperature is controlled in the range of 600-700°C; the method of the present invention is that during the rolling process of the carbon structural steel plate, by collecting A series of key process temperature point control measures are implemented to obtain a lower straightening and reddening temperature, and to obtain a high-precision transverse plate shape without reducing the production efficiency of the rolling mill. By using the method of the present invention, the transverse unevenness of the final steel plate is less than or equal to 5mm. / Board width size, strong market competitiveness.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

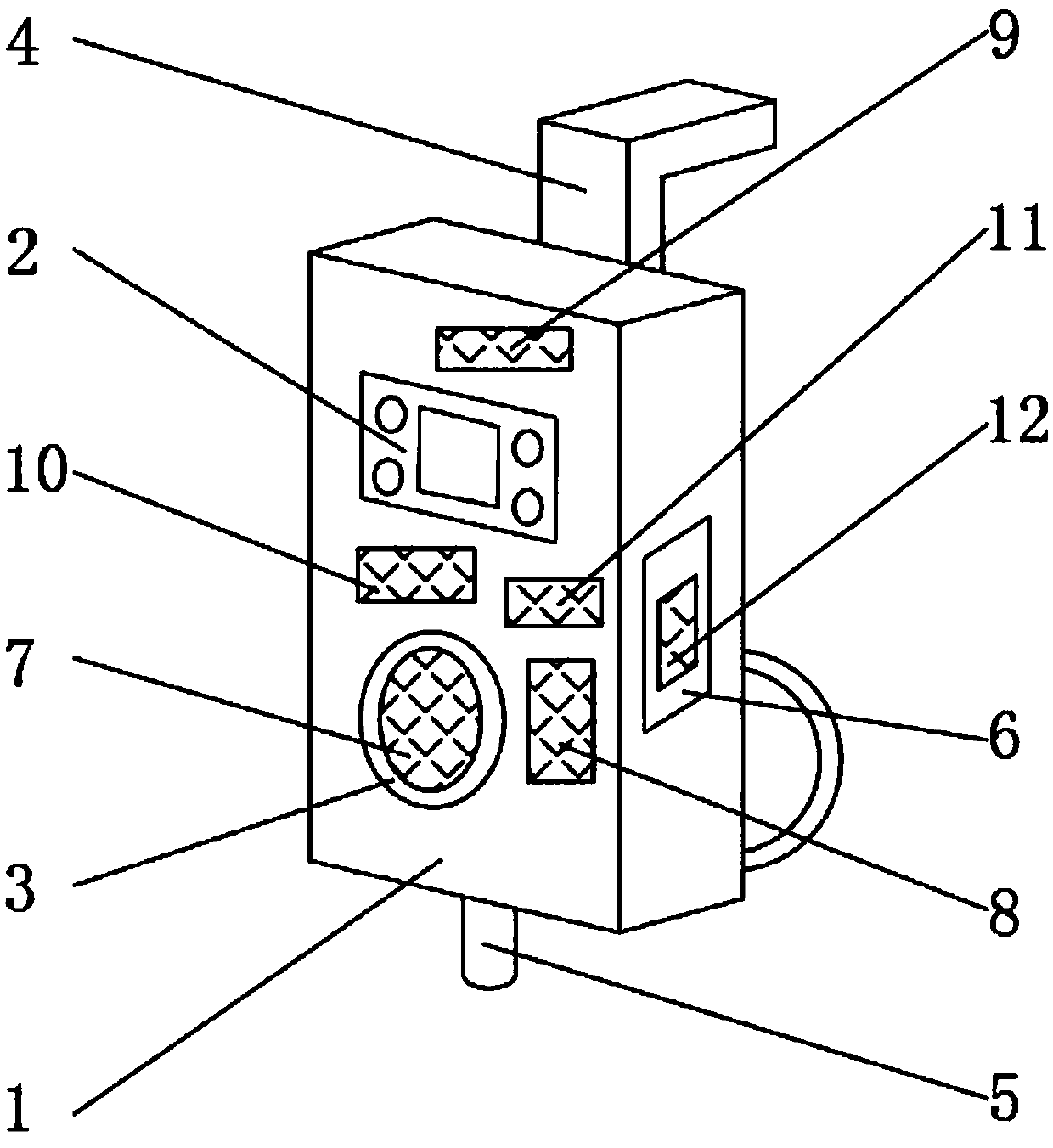

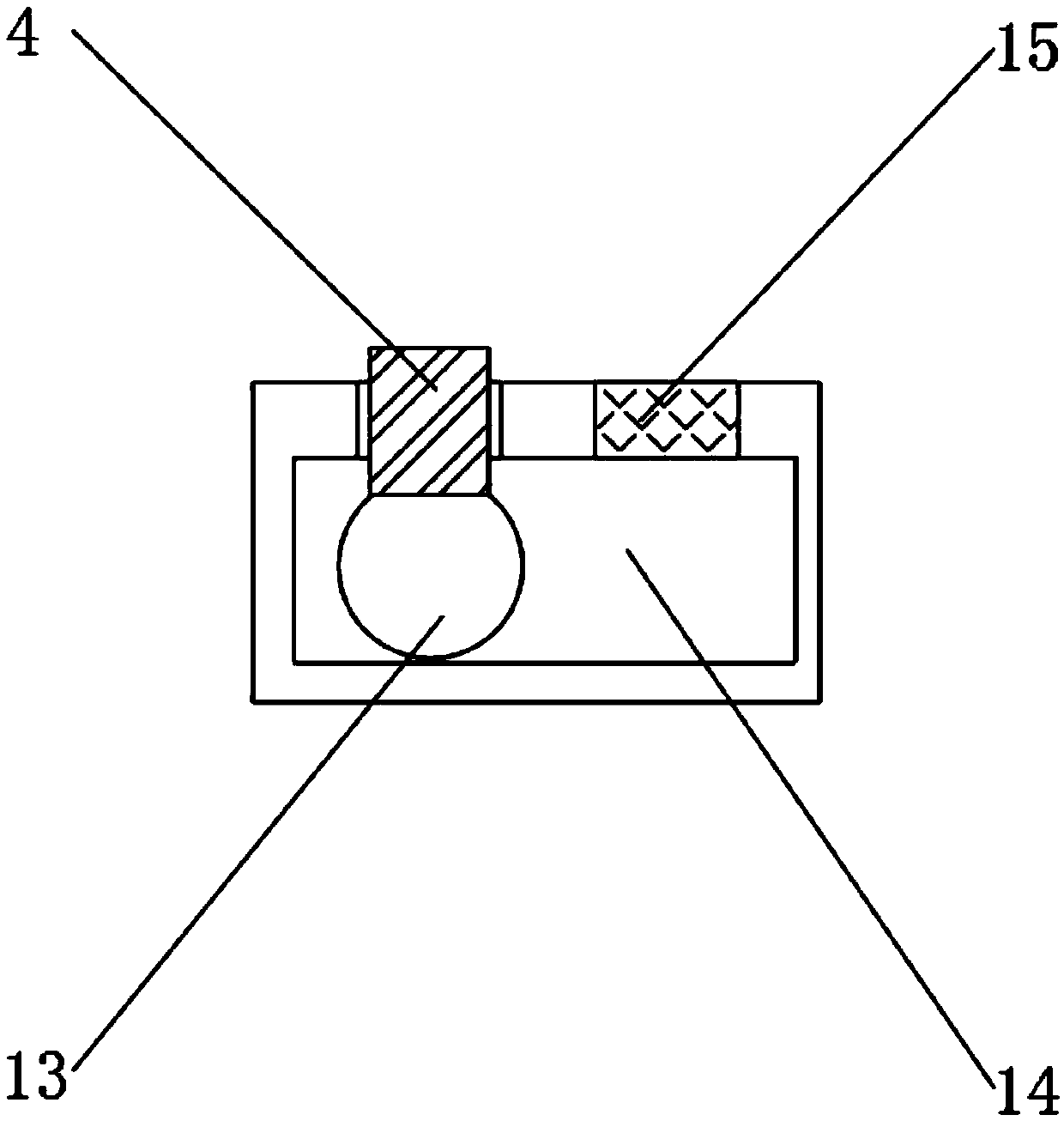

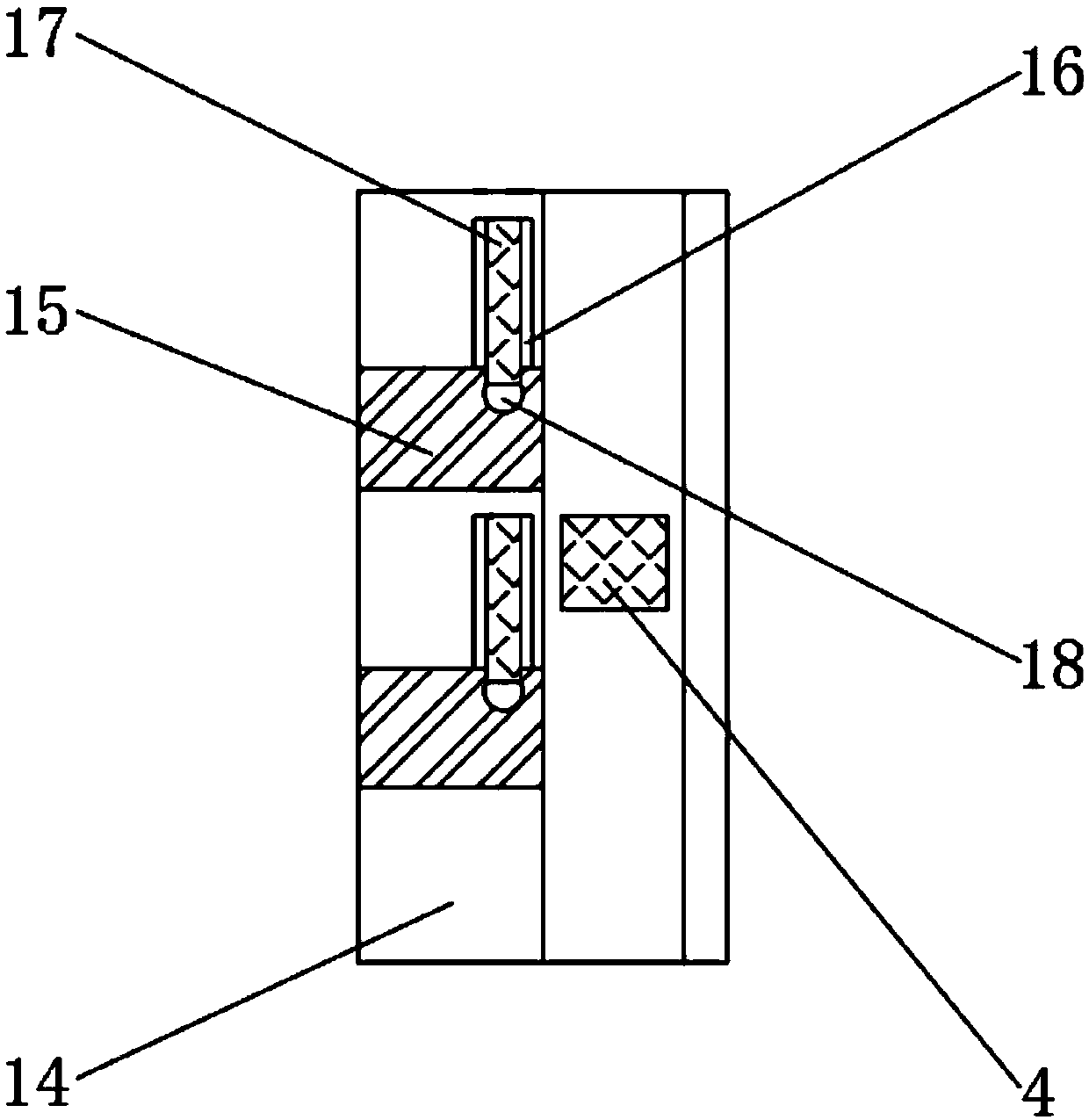

Novel electric cabinet dehumidifying device easy to install

InactiveCN109687305AEasy to installEasy to moveSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringHeat sink

The invention discloses a novel electric cabinet dehumidifying device easy to install. The dehumidifying device comprises a casing. The outer surface at the front end of the casing is fixedly providedwith an operation panel, an air outlet is arranged below the operation panel, the outer surface at the rear end of the casing is fixedly provided with a connecting rod, and a drain pipe is disposed on the outer surface at the lower end of the casing. A heat dissipation port is disposed in the outer surface at one end of the casing, and a fan is fixedly mounted in the casing at the position closeto an air outlet. A condensation module is fixedly mounted on one side of the fan, and a control module is fixedly mounted above the fan. A heater is fixedly mounted between the fan and the control module, and a temperature and humidity sensor is fixedly mounted on one side of the heater. A heat sink is fixedly mounted inside the casing at the position close to the heat dissipation port. By meansof a series of structures, the dehumidifying device achieves the advantages of safe water guiding, convenient installation and movement during use, and the use process is optimized.

Owner:江苏成华能源化工设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com