Technology for producing large-size quartz cylinder through continuous melting method, quartz cylinder and application of quartz cylinder

A quartz cylinder, large-scale technology, used in manufacturing tools, glass manufacturing equipment, glass molding, etc., can solve problems such as poor quality, difficult production, and inability to guarantee quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The diameter of the quartz cylinder is 600mm, and the wall thickness is 60mm.

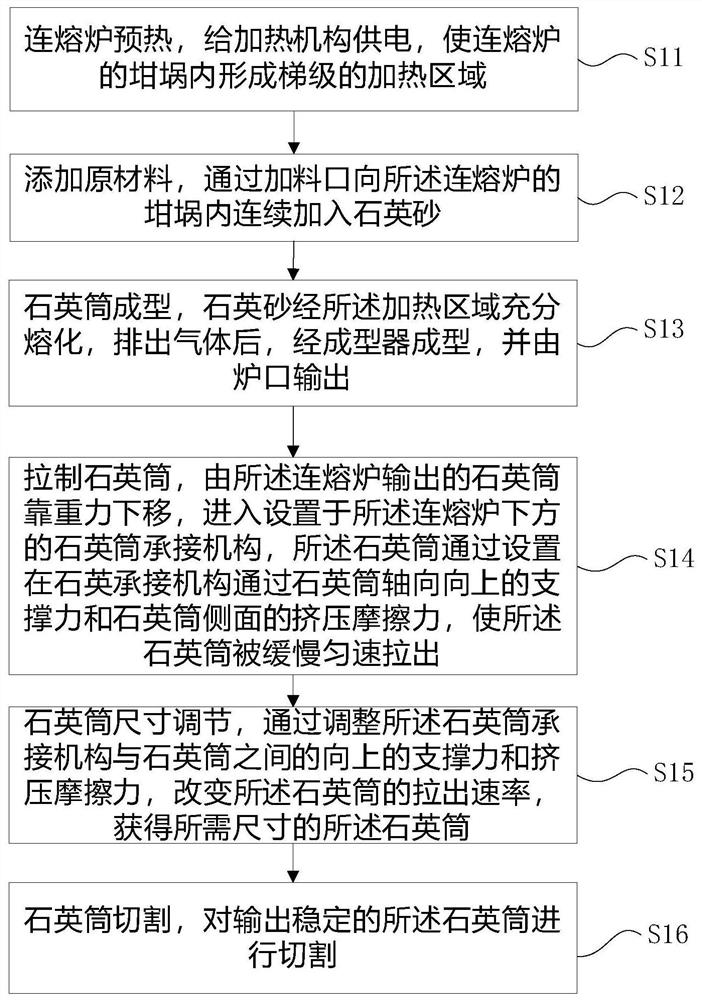

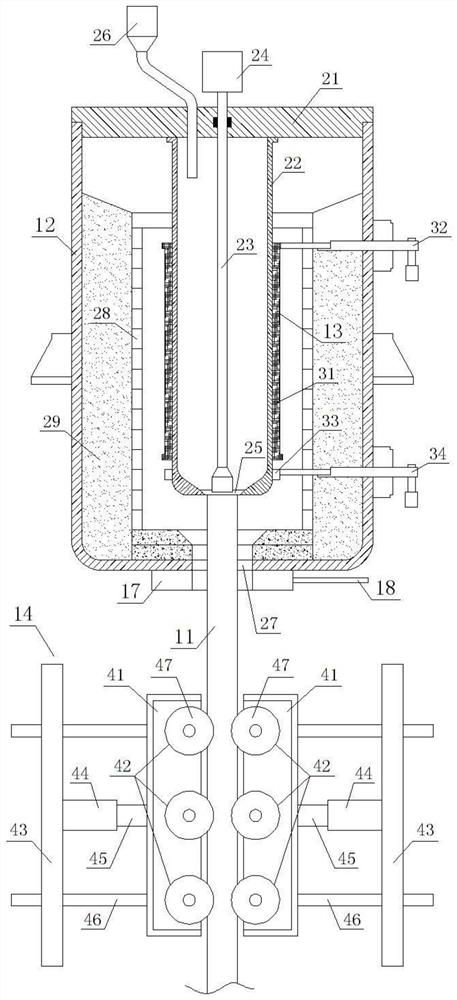

[0060] The step heating area refers to the formation of three areas from top to bottom in the continuous melting furnace, namely the preheating area, the melting area and the forming area. The temperature of the preheating area is 1650 ° C, and the temperature of the melting area is 2200°C, the temperature of the forming zone is 1800°C.

[0061] Choose k=D 2 *S / 1800000=12.

[0062] The moving speed of the quartz cylinder is v=(600 2 -480 2 ) / (12*1800)=6.3 cm / min.

[0063] The above temperature and rate can continuously produce quartz tubes with a diameter of 600mm and a wall thickness of 60mm. The produced quartz cylinder was continuously sampled at 10 cm to take 10 small samples for cross-sectional measurement, and no eccentricity occurred, and the inner diameter and outer diameter of the 10 small samples were compared, and the deviation was within 0.01%.

Embodiment 2

[0065] The diameter of the quartz cylinder is 300mm, and the wall thickness is 30mm.

[0066] The step heating area refers to the formation of three areas from top to bottom in the continuous melting furnace, namely the preheating area, the melting area and the forming area. The temperature of the preheating area is 1720 ° C, and the temperature of the melting area is 2250°C, the temperature of the forming zone is 1780°C.

[0067] K=D 2 *S / 1800000=1

[0068] The rate that described quartz cylinder moves downward is v=(300 2 -260 2 ) / (1*1780)=12.58 cm / min.

[0069] The above temperature and rate can continuously produce quartz tubes with a diameter of 300mm and a wall thickness of 30mm. The produced quartz cylinder was continuously sampled at 10 cm to take 10 small samples for cross-sectional measurement, and no eccentricity occurred, and the inner diameter and outer diameter of the 10 small samples were compared, and the deviation was within 0.01%.

Embodiment 3

[0071] The diameter of the quartz cylinder is 500 mm, and the wall thickness is 60 mm.

[0072] The step heating area refers to the formation of three areas from top to bottom in the continuous melting furnace, namely the preheating area, the melting area and the forming area. The temperature of the preheating area is 1730 ° C, and the temperature of the melting area is 2150°C, the temperature of the forming zone is 1795°C.

[0073] k(mm 2 *min) / (cm*℃)=500 2 *40 / 1800000(cm*mm*℃ / min)=5.55

[0074] The rate that described quartz cylinder moves downwards is v=(500 2 -420 2 ) / (5.55*1795)=7.38 cm / min.

[0075] The above temperature and rate can continuously produce quartz tubes with a diameter of 500mm and a wall thickness of 60mm. The produced quartz cylinder was continuously sampled at 10 cm to take 10 small samples for cross-sectional measurement, and no eccentricity occurred, and the inner diameter and outer diameter of the 10 small samples were compared, and the deviatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com