Pile-supported soft soil roadbed reinforcing structure and reinforcing method

A soft soil roadbed and reinforcement structure technology, applied in infrastructure engineering, roads, roads, etc., can solve the problems of huge building material resources, uneven settlement, and environmental pollution occupying land resources, so as to save land resources and control settlement differences , to avoid the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

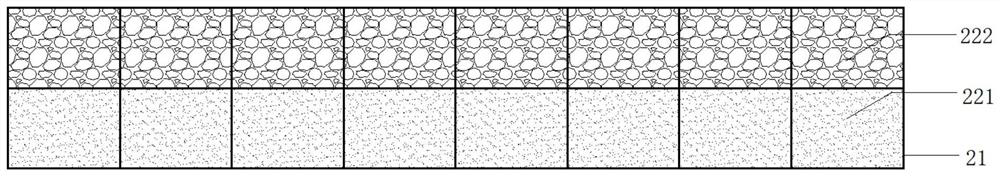

[0063] As a preferred embodiment, the three-dimensional geocell reinforced cushion 2 includes:

[0064] Three-dimensional geocell 21;

[0065] And the filling layer 22 filled in the three-dimensional geocell: comprising a potassium magnesium phosphate cement solidified mud layer filled in the lower layer of the three-dimensional geocell, and a gravel cushion layer filled in the upper layer of the three-dimensional geocell.

[0066] The lower layer of the three-dimensional geocell in the present invention is filled with potassium magnesium phosphate cement to solidify the silt, and the upper layer is filled with crushed stones to bear and transfer the upper load, and provide a construction platform, water storage space and drainage channels.

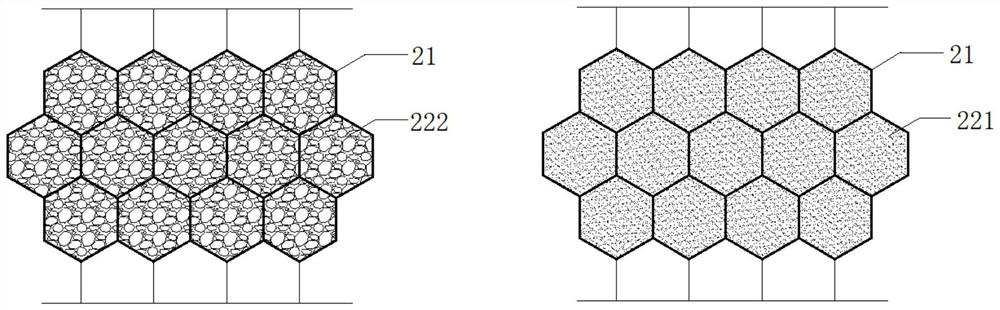

[0067] The reinforced material of the present invention adopts three-dimensional geocells 21 of HDPE or polypropylene (PP), and the sheet height is 20 cm. The meshes of the geocells are honeycomb-shaped, and the mesh size is 30-40 mm.

...

Embodiment 1

[0088] A pile-supported soft soil subgrade reinforcement structure and reinforcement method of the present application will be described in detail below in conjunction with the accompanying drawings. Embodiment 1. A pile-supported soft soil subgrade reinforcement structure and its preparation method

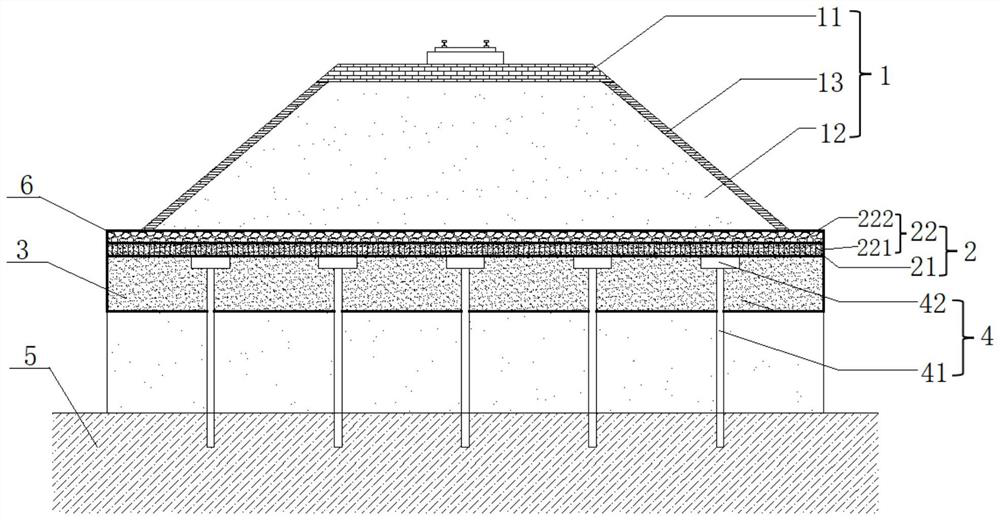

[0089] One, a pile-supported soft soil subgrade reinforcement structure, such as figure 1 shown, including:

[0090] The embankment layer 1 filled with solidified silt comprises a solidified silt filled embankment 12 and a bed surface 11 positioned on the solidified silted filled embankment; bed surface layer 11; the solidified silt filling roadbed 12 is formed by filling in layers;

[0091] The three-dimensional geocell reinforced cushion 2 is formed by filling the three-dimensional geocell with the solidified silt of potassium magnesium phosphate cement, including: the three-dimensional geocell 21; and the filling layer 22 filled in the three-dimensional geocell: including fi...

Embodiment 2

[0122] In the embodiment of the present invention, the soil solidifying agent comprises in terms of mass fraction: potassium magnesium phosphate cement 90%, fly ash 5% and silica fume 5%, and the mixing amount of the soil stabilizing agent in the in-situ solidification Be 5wt%; Other structures and steps are all the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com