High-temperature resistant graphene mica electrical heating plate and fabrication method thereof

A technology of graphene and high temperature resistance, applied in the field of graphene high temperature resistant mica electric heating plate and its preparation, can solve the problems of low temperature resistance coefficient of electric heating plate, large deformation of electric heating plate, large safety hazard, etc., and achieves good cost performance and uniform heating , the effect of improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

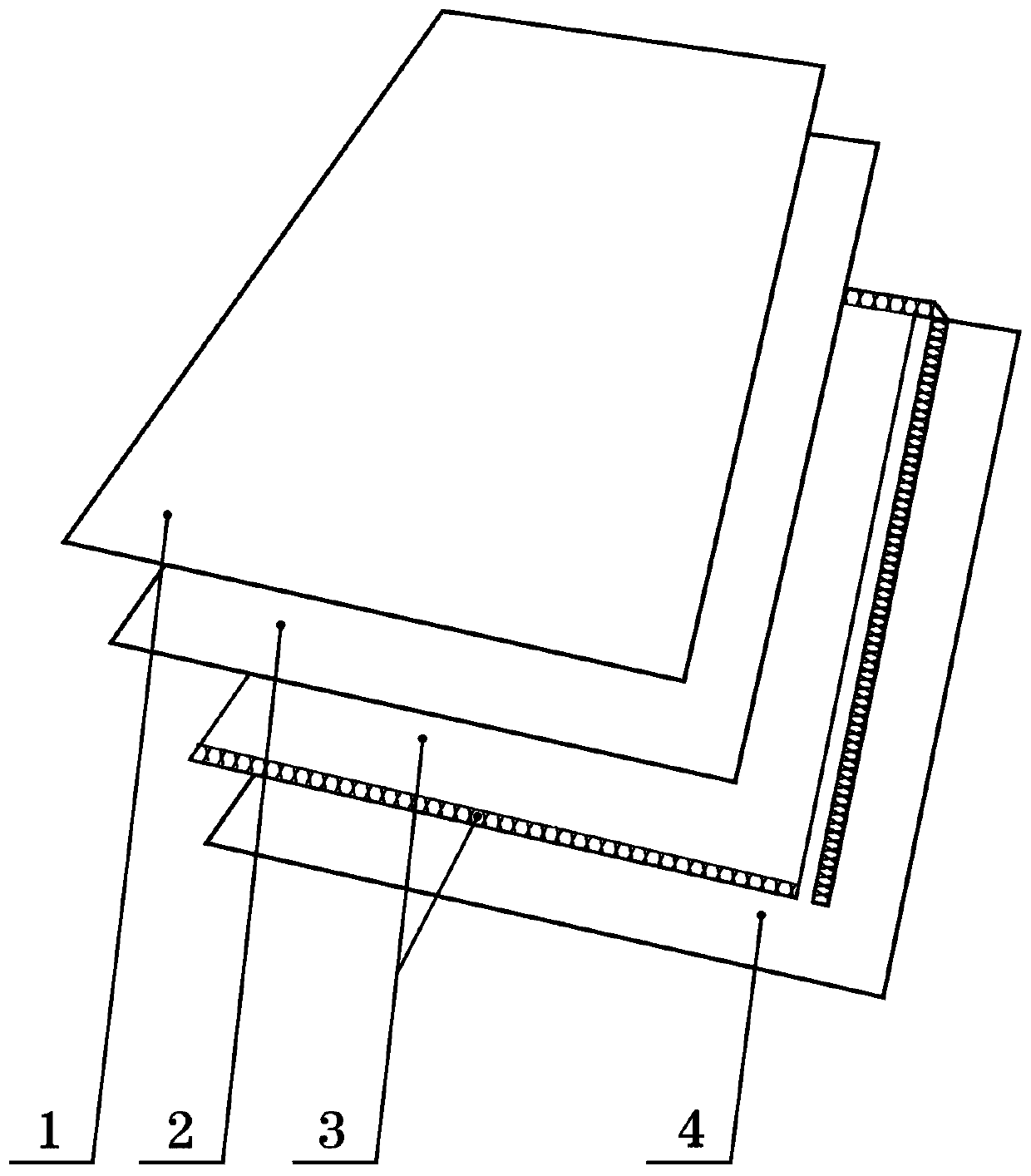

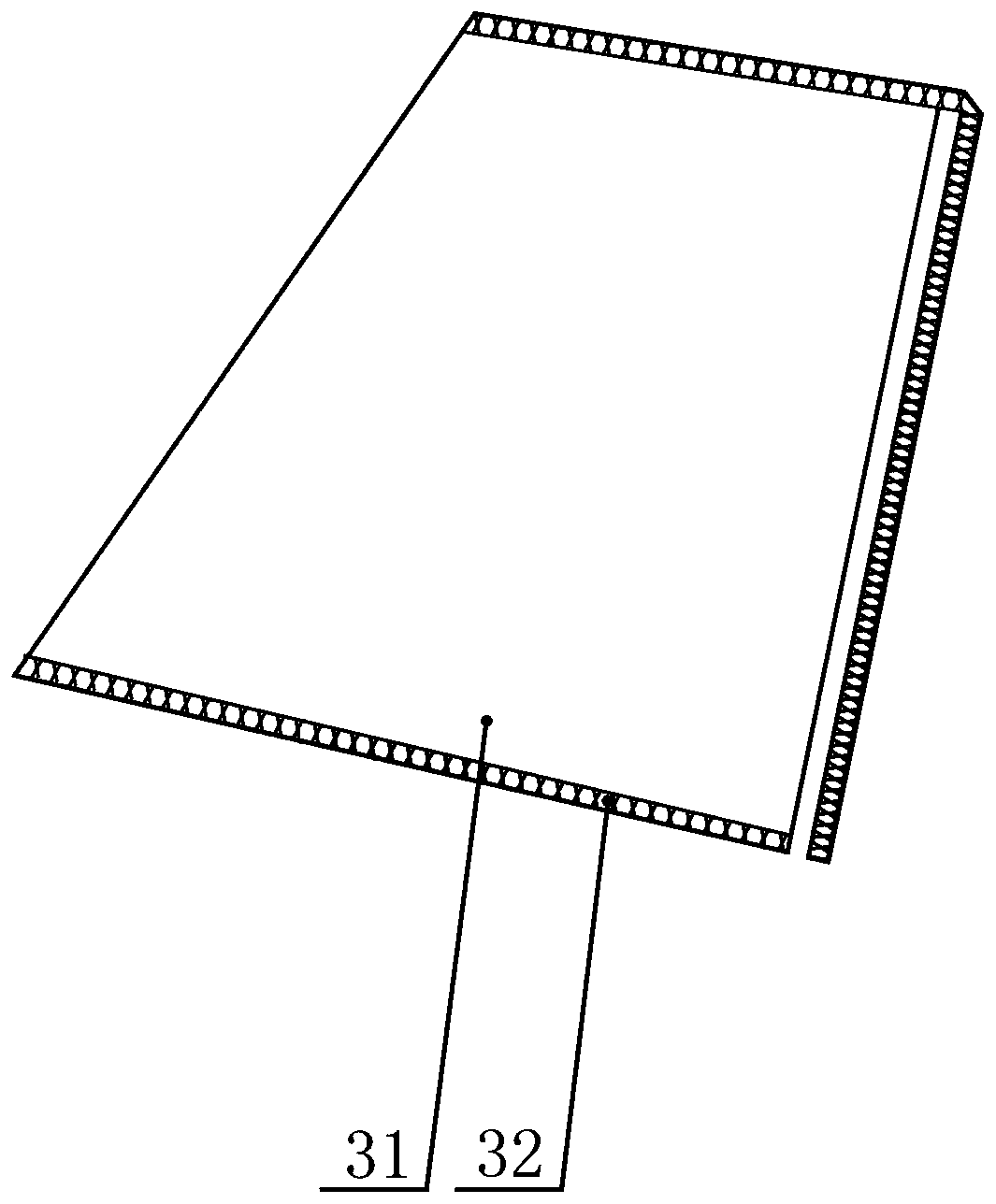

[0033] Such as figure 1 with 2 As shown, a graphene high temperature resistant mica electric heating plate includes a surface decoration layer 1, an upper mica insulating layer 2, a graphene heating layer 3 and a lower mica insulating layer 4 fixedly connected by an adhesive from top to bottom. The surface decoration layer 1 is set as a PET heat transfer film or a UV color printing decoration layer, and the PET heat transfer film is selected in this embodiment. The upper mica insulating layer 2 and the lower mica insulating layer 4 respectively include several layers of mica insulating paper.

[0034] The graphene heating layer 3 includes a graphene conductive paper 31 and a copper tape 32 fixed on the graphene conductive paper 31 and arranged around the graphene conductive paper. The copper tape 32 is fixed on the periphery of the graphene conductive paper 31 by graphene conductive glue. The top and bottom of the graphene heating layer 3 are coated with silicone resin glue...

Embodiment 2

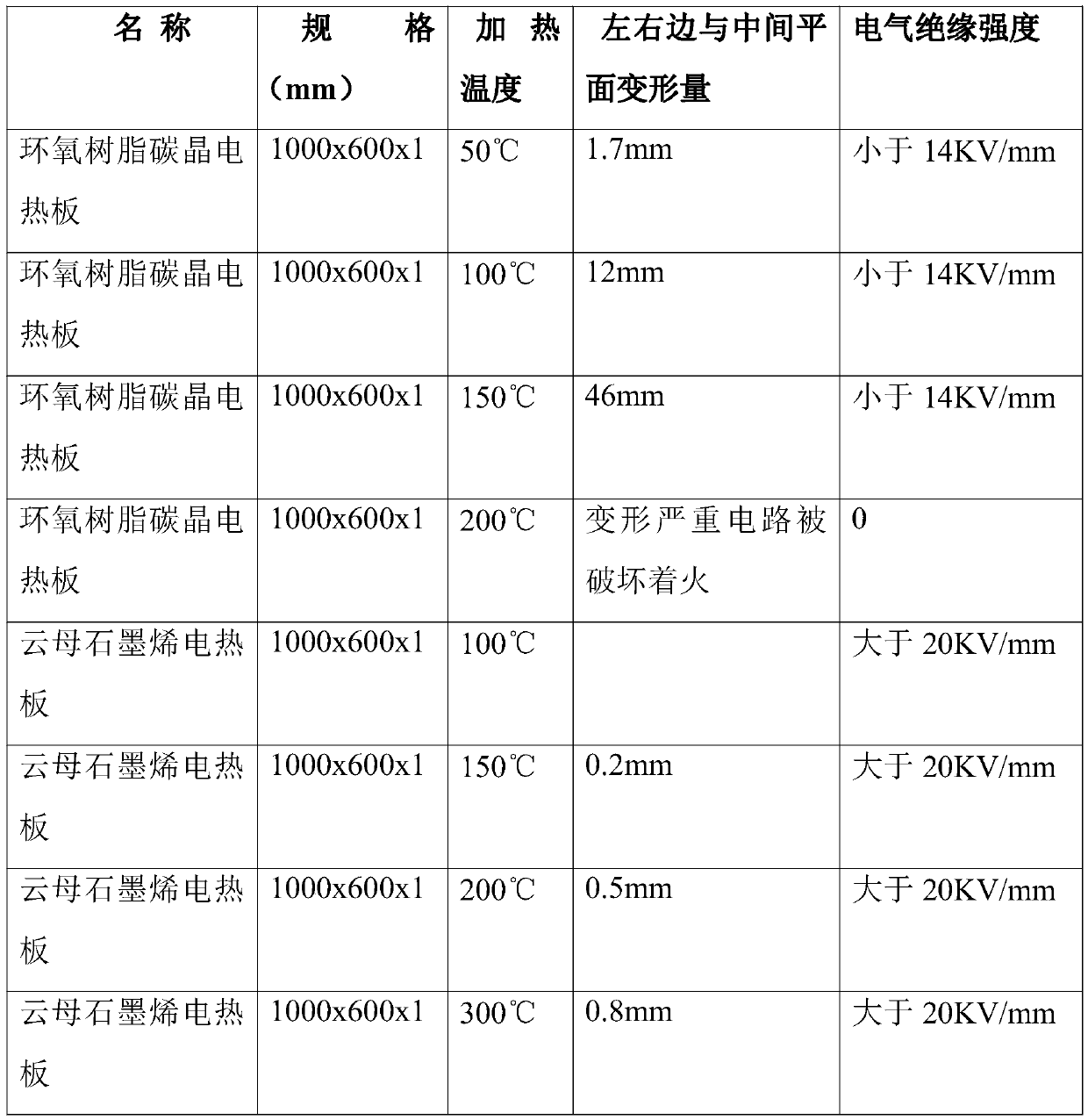

[0049] Graphene high temperature resistant mica electric heating plate and epoxy resin electric heating plate are resistant to temperature and insulation electrical strength characterization data table 1 in embodiment 1 as shown:

[0050] Table 1 Example 1 Graphene high temperature resistant mica electric heating plate and epoxy resin electric heating plate are resistant to temperature and insulation electrical strength characterization data

[0051]

[0052] As shown in Table 1, the deformation of the epoxy carbon crystal electric heating plate is not large when the temperature is within 50°C, but the deformation is already large when the temperature is 100°C, which may cause the internal circuit to be damaged. When the temperature is 200°C, the carbon crystal of the circuit is destroyed and catches fire. Therefore, the epoxy resin carbon crystal electric heating plate is suitable for heating at a temperature of less than 50°C because of its low temperature resistance, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com