Frame-shear wall structure formwork system and construction method thereof

A technology of formwork system and frame-shear structure, which is applied in the field of concrete construction, can solve the problems of difficult demoulding, complex construction of wooden formwork, and less number of times a single wooden formwork can be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

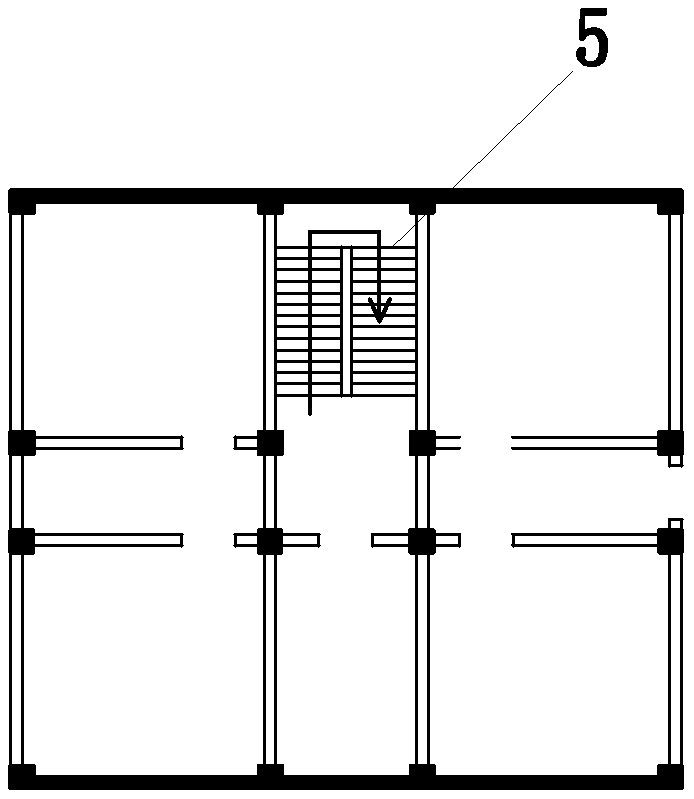

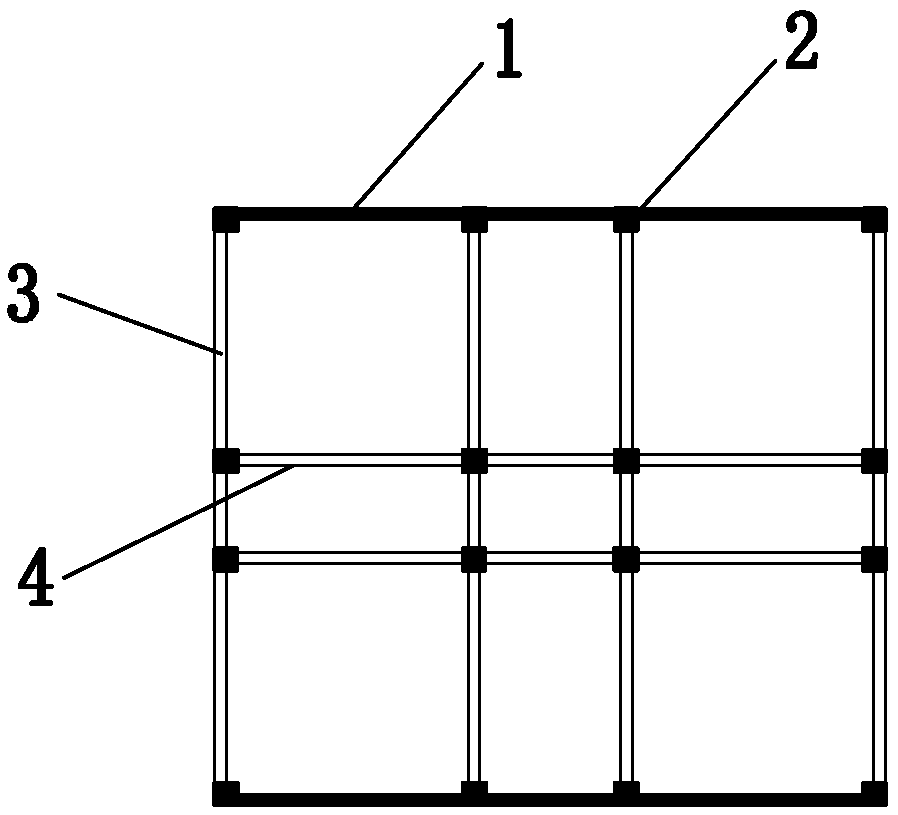

[0072] Example: such as Figure 1-2 As shown, the formwork system of the frame-shear structure includes symmetrically arranged shear walls 1, and the relatively symmetrical shear walls 1 are connected by several beams 3. Columns 2 are arranged at the joints between the shear walls 1 and the beams 3, and several beams 3 are vertically connected to each other. There are longitudinal beams 4, columns 2 are arranged at the connection between the beams 3 and the longitudinal beams 4, and a staircase 5 is arranged between the shear wall 1, the longitudinal beams 4 and the two beams 3 in the middle; the shear wall 1 includes the shear wall stereotypes The column 2 includes a shaped template for the frame column; the beam 3 and the longitudinal beam 4 include a shaped template for the frame beam; the staircase 5 includes a shaped template for the staircase.

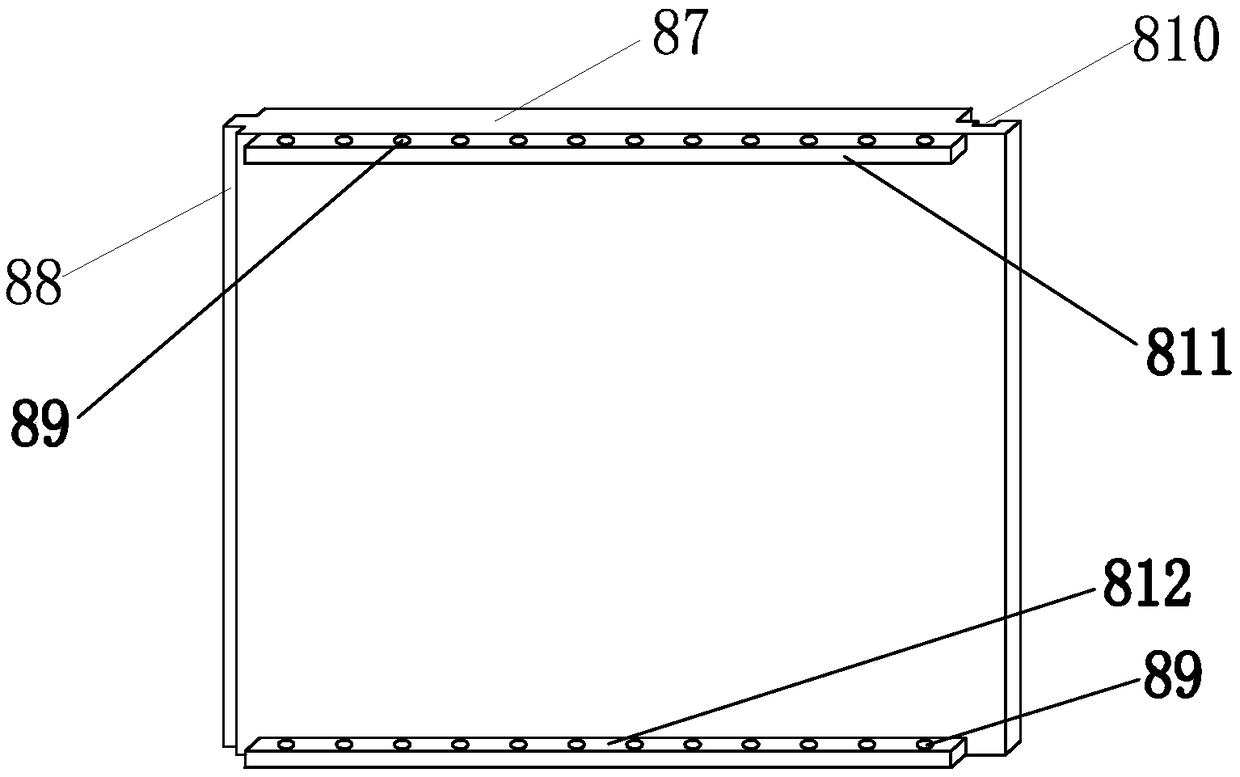

[0073] The finalized formwork for the shear wall, the finalized formwork for the frame column, the finalized template for the f...

specific Embodiment approach

[0097] The specific embodiment of the present invention comprises the following steps:

[0098] Step 1, splicing the side formwork, splicing the two beam side formworks left and right, and the bolt holes on the connecting plate must be strictly aligned. Then pass the screws through the two aligned bolt holes, and fix them with nuts, so that the two adjacent side forms are connected together.

[0099] Step 2, Bottom template splicing; there is a bottom connection bump on the side template, place the bottom template on the rear of the bump, make the bolt holes on the bottom template align with the bolt holes on the bump on the side template, and then use Drill the bolt into the hole, because the hole does not penetrate, so it needs to be screwed in with the threaded bolt to fix it, and then insert another bottom template on the protrusion of the bottom template, so that the groove on the bottom template Insert into the bump to splice the two templates together, and then splice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com