Light type rapid splicing warm box

A technology of rapid splicing and incubator, applied in the field of heat preservation, can solve the problems of high cost of use, complicated operation, cumbersome and complicated process, etc., and achieve the effect of ensuring stability and bearing capacity, simple processing method, and expanding the range of material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

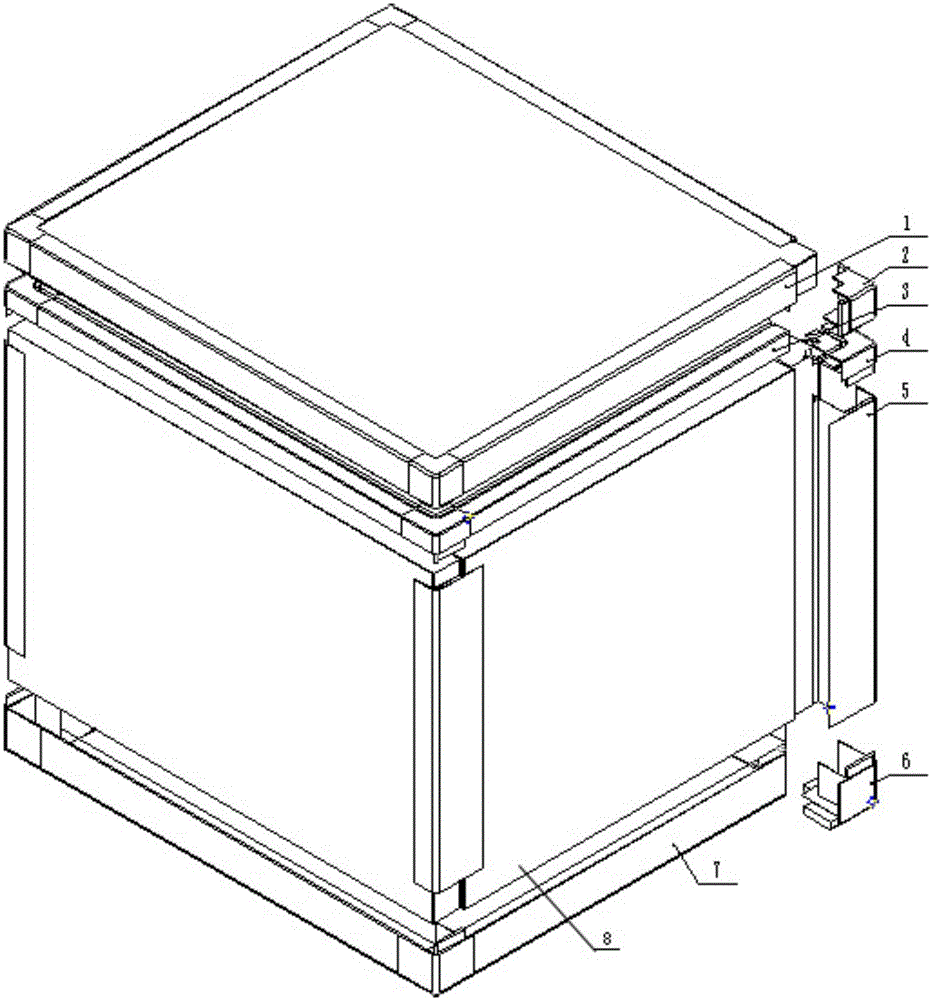

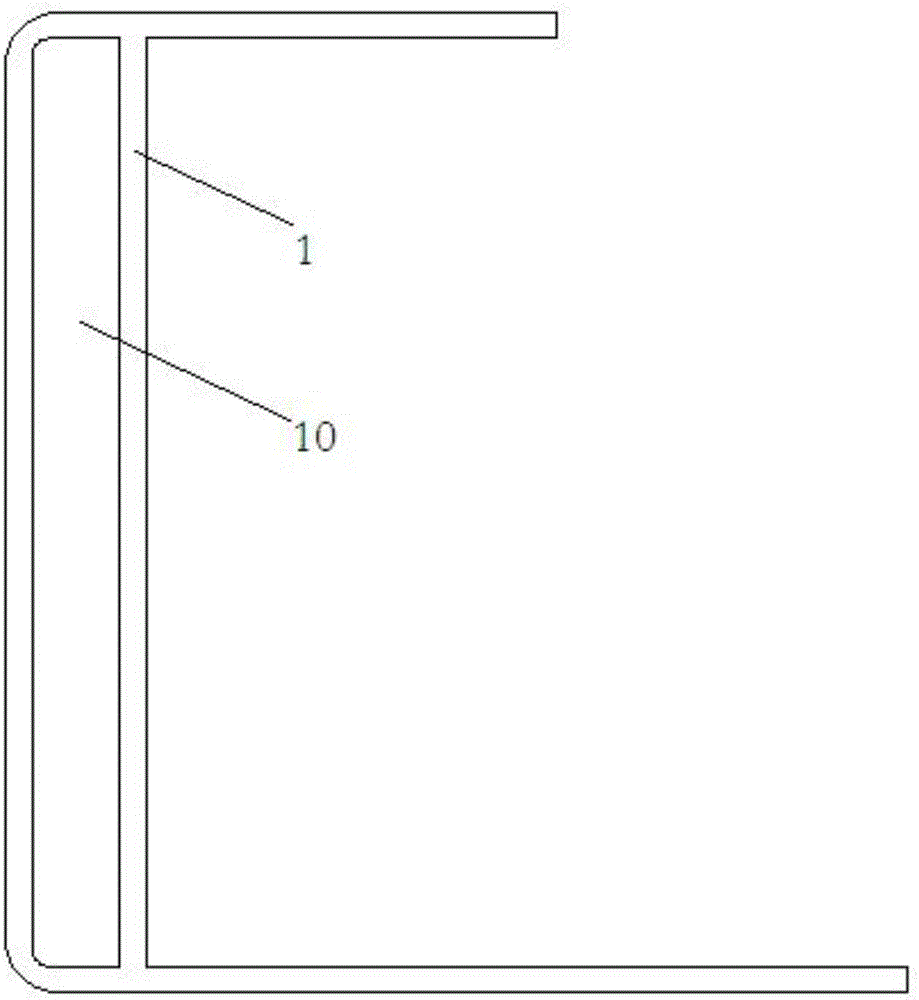

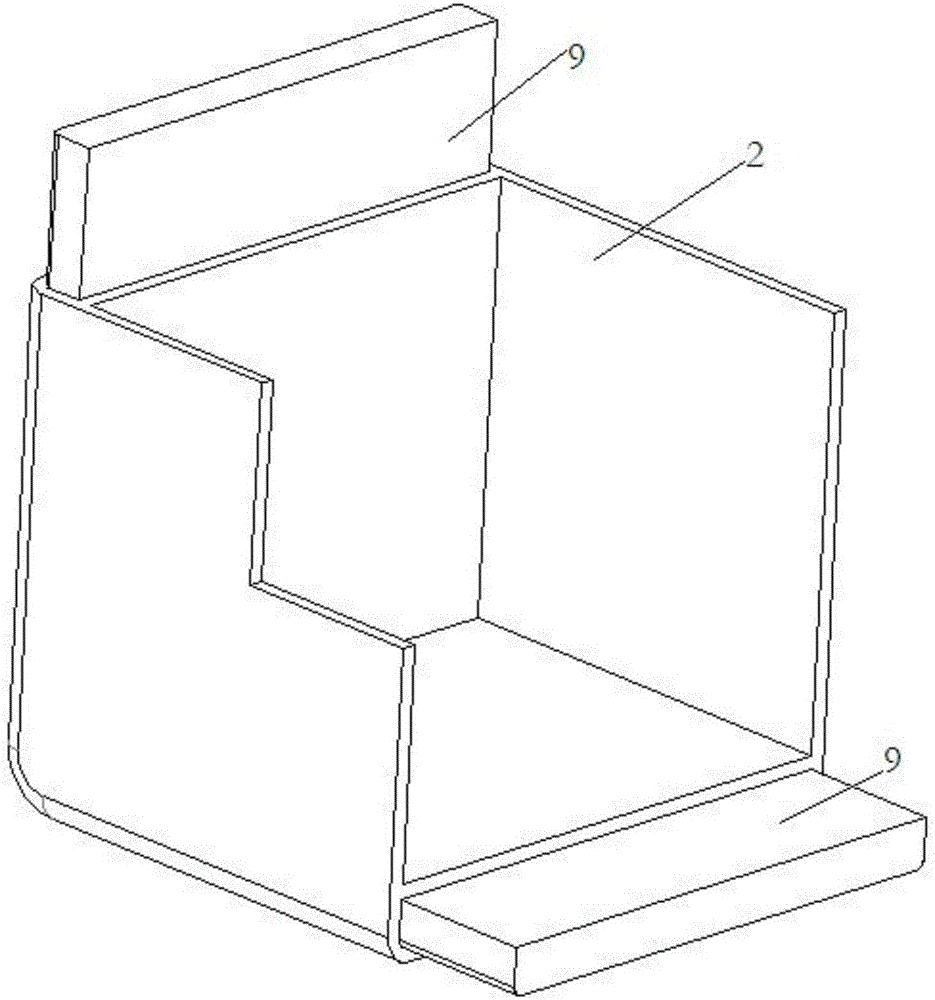

[0031] Such as figure 1 and Figure 12 As shown, a portable quick splicing incubator includes six-sided insulation boards 8, four box cover corners 2, four box mouth corners 4, four box bottom corners 6, and four box cover edge strips 1, four box mouth side strips 3, four vertical side strips 5 and four box bottom side strips 7.

[0032] Such as figure 1 and Figure 12 As shown, the four case cover edge strips 1 are respectively wrapped on the four sides of the top surface insulation board 8, and the four case cover corners 2 are respectively wrapped on the four corners of the top surface insulation board 8 and are connected with the adjacent two case cover sides. The strips 1 are plugged together to form a box cover.

[0033] Such as figure 1 and Figure 12 As shown, four box bottom edge strips 7 and four box bottom corners 6 are inserted altern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com