Assembly vehicle for ironing plate of paver

A technology for screeds and assembling vehicles, which is applied in the directions of roads, road repairs, roads, etc., and can solve problems such as affecting the construction progress and difficulty in alignment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

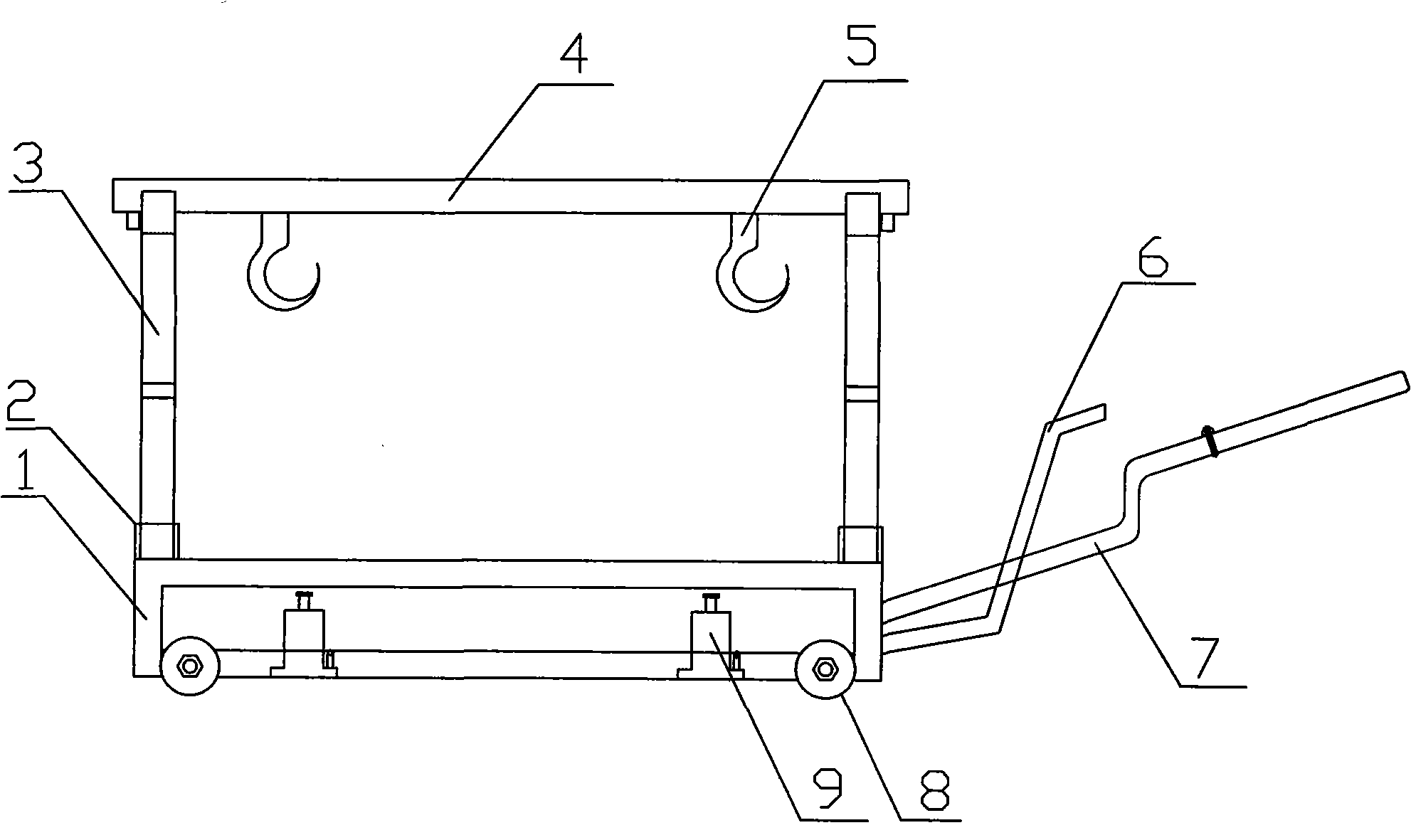

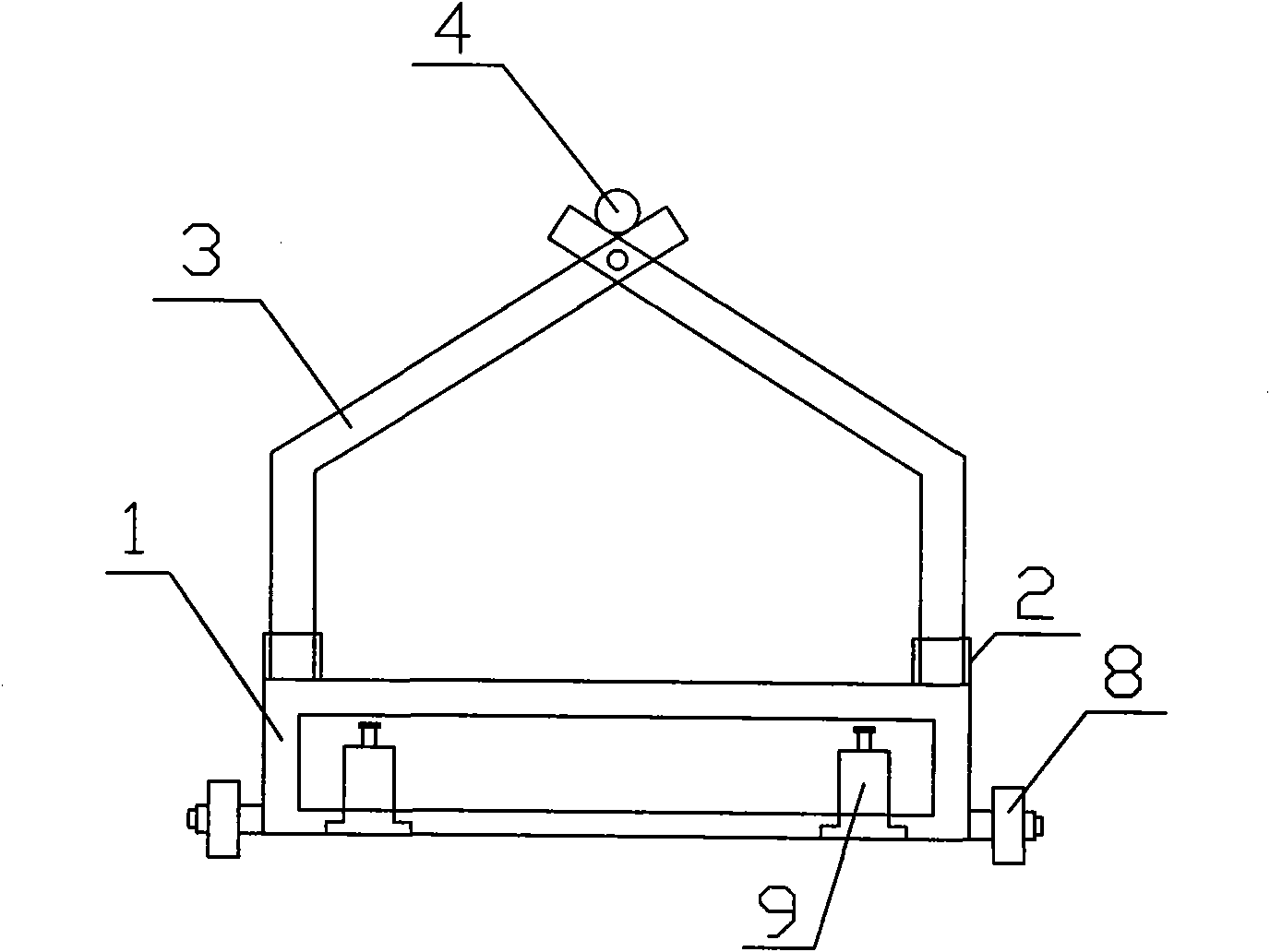

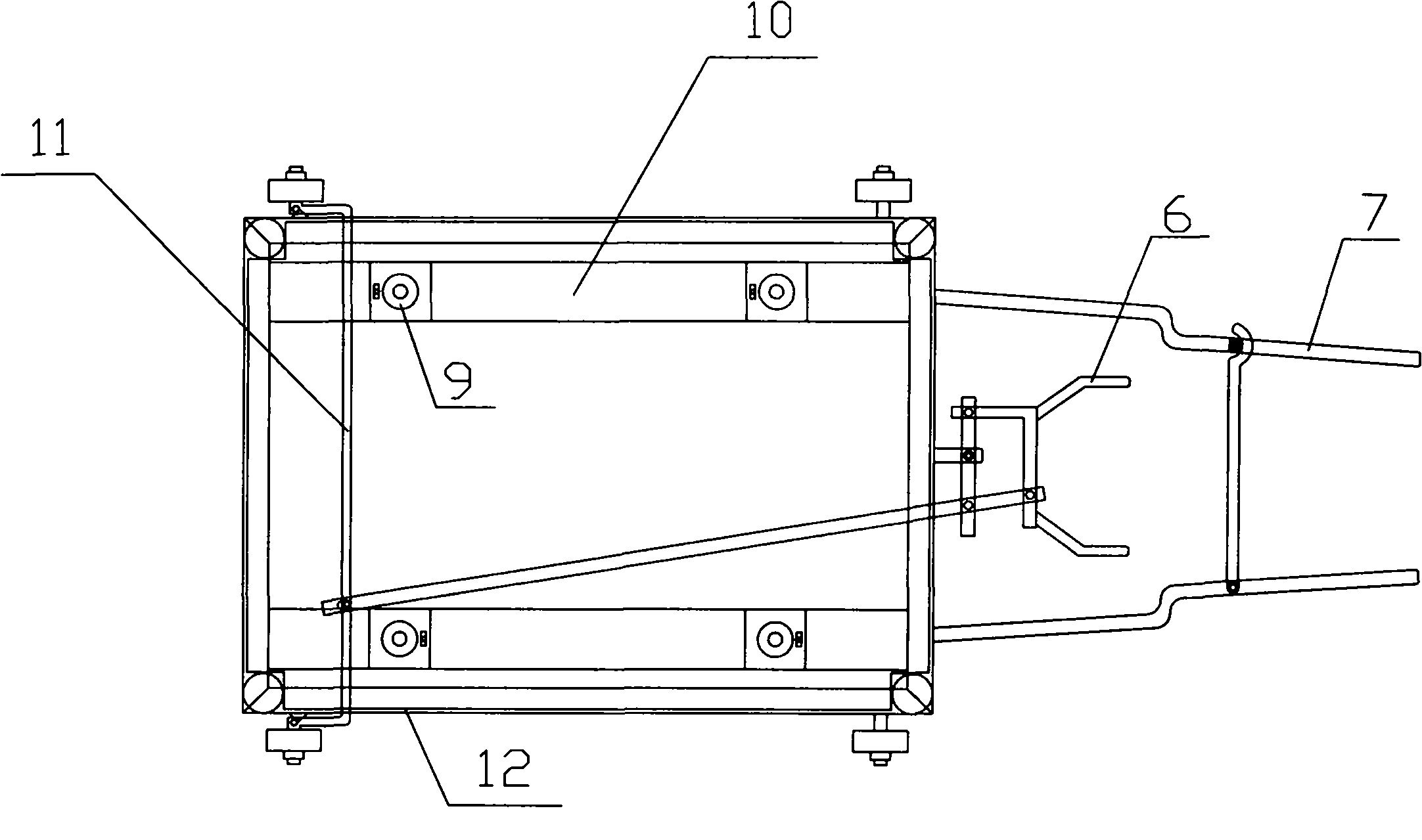

[0016] see figure 1 , figure 2 , image 3 The vehicle frame 1 of the paver screed assembly vehicle described in this embodiment is a frame structure, and hydraulic jacks 8 that can be placed close to the four corners of the vehicle frame 1 are placed in the vehicle frame 1 .

[0017] In this embodiment, in the vehicle frame 1 of the frame structure, a hydraulic jack slideway 10 consistent with the length direction of the screed is installed on both sides of the vehicle frame 1, and each hydraulic jack slideway 10 is respectively placed Two hydraulic jacks 9, each hydraulic jack 9 can approach the four corners of the vehicle frame 1. Four hydraulic jacks 9 tops are placed with an assembling platform 12, and the four corner positions of vehicle frame 1 top are respectively fixed with the installation seat 2 of hoisting frame, and hoisting frame is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com