Superjunction device and method of manufacturing the same

A super-junction device and charge technology, applied in the field of semiconductor integrated circuit manufacturing, can solve problems such as poor softness factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example approach

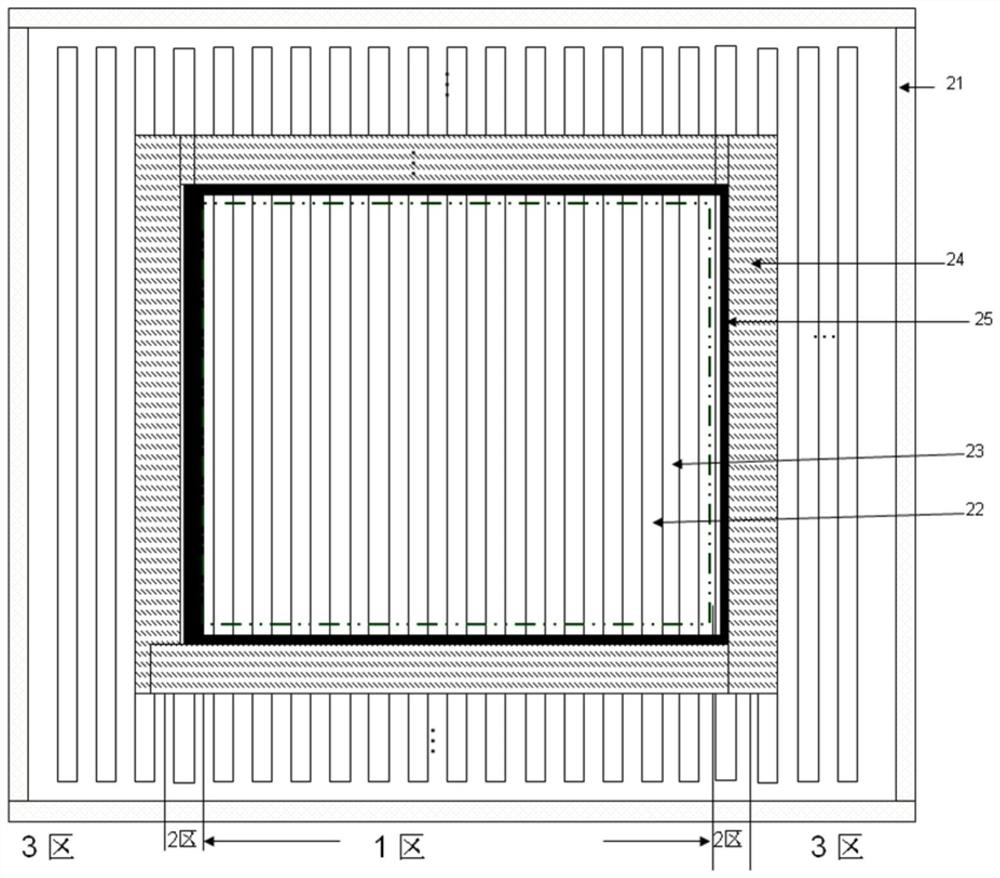

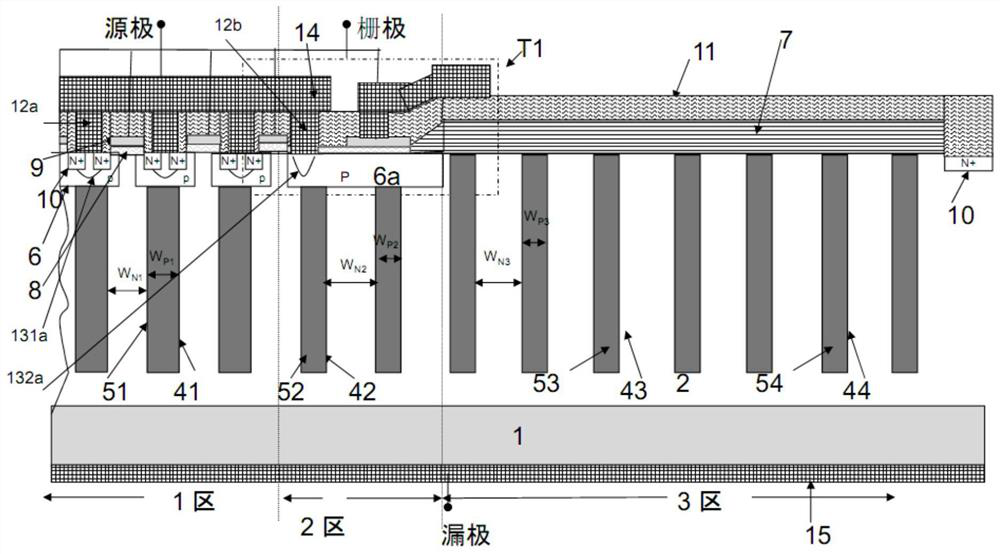

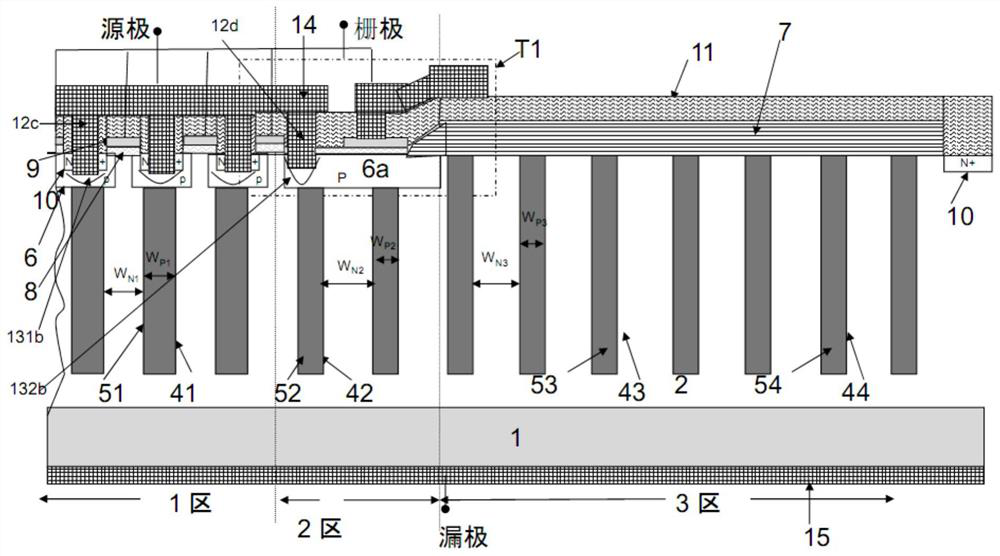

[0118] The manufacturing method of the super junction device according to the first embodiment of the present invention is to manufacture such as Figure 4 The superjunction device of the first embodiment of the present invention is shown as an example for description, as Figure 8A to Figure 8H Shown is a schematic cross-sectional view of the device in each step of the manufacturing method of the super-junction device in the first embodiment of the present invention; in the manufacturing method of the super-junction device in the embodiment of the present invention, the middle region of the super-junction device is the charge flow region, that is, region 1, Termination zone, that is, zone 3, surrounds the periphery of the charge flow region, and transition zone, that is, zone 2, is located between the charge flow zone and the terminal zone; the structure of the top view of the superjunction device can also refer to figure 1 shown. The method of the first embodiment of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com