Cooling mechanism and cooling method for driving element of injection moulding machine

An injection molding machine and injection molding technology, applied in the cooling mechanism and cooling field, can solve the problems of corrosion of cooling fluid flow path, large-scale manufacturing cost of injection molding machine, reduction of rated heat output of electric drive parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

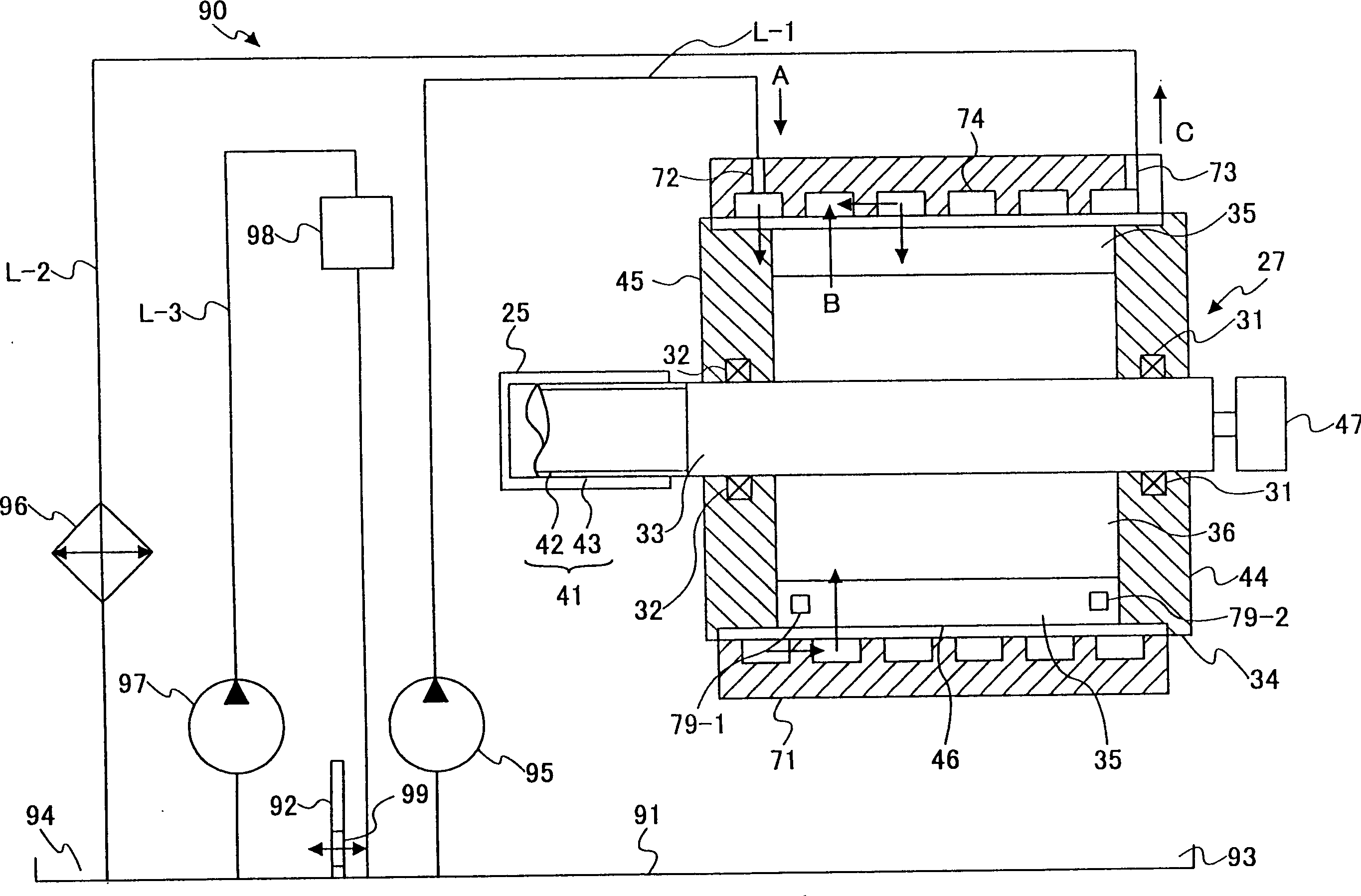

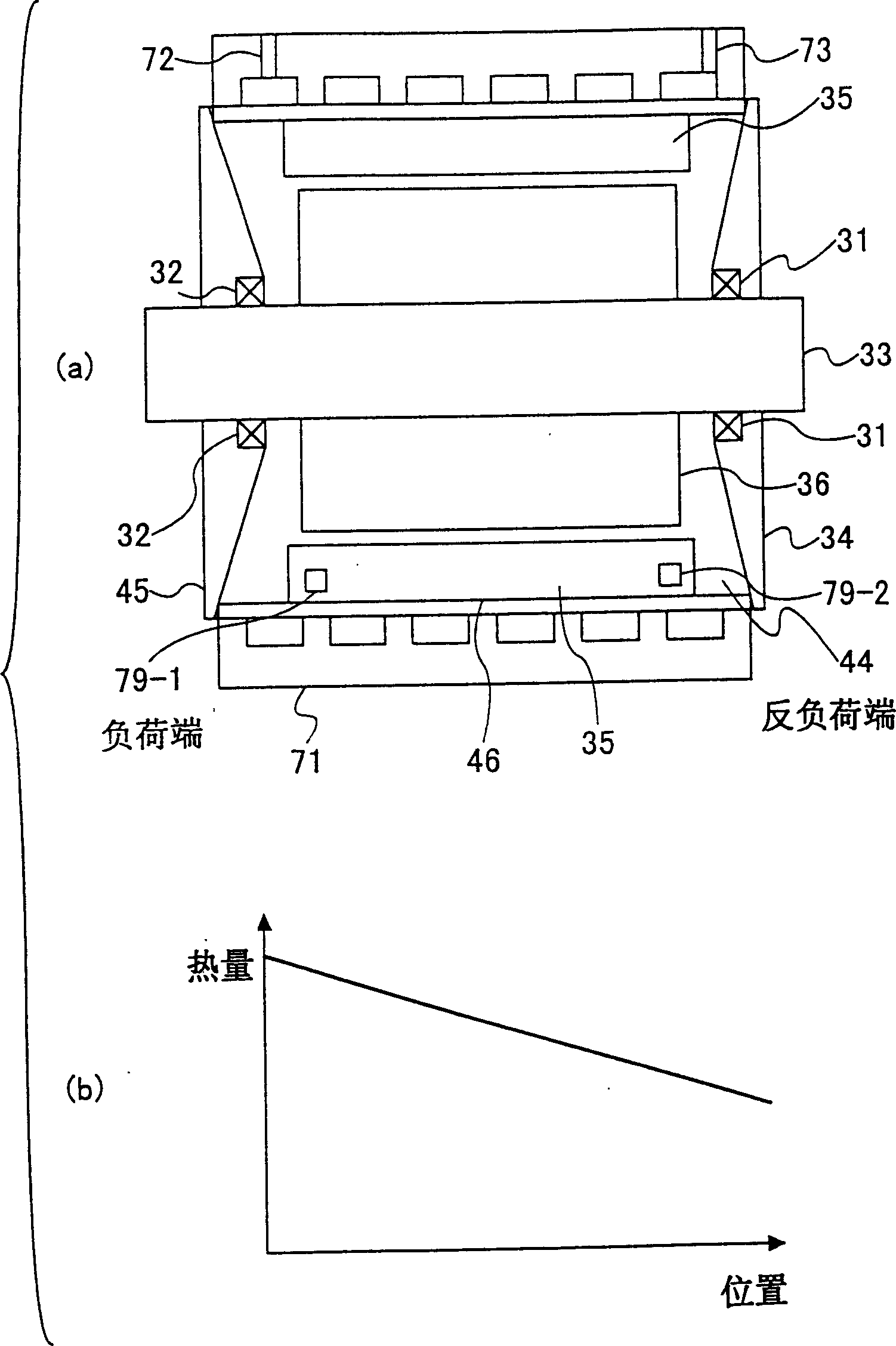

[0018] Refer to the attached below figure 1 To 4 illustrate the embodiments of the present invention.

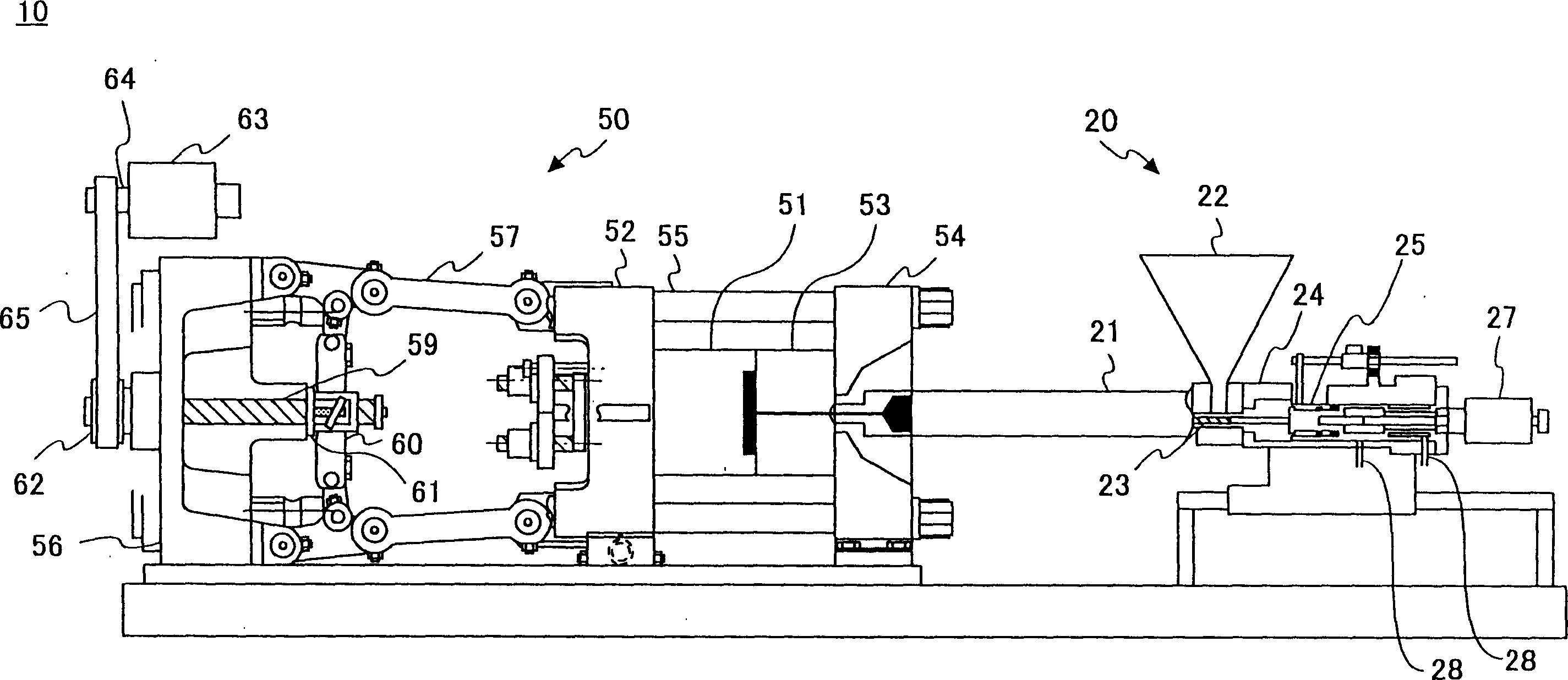

[0019] figure 1 The basic structure of an injection molding machine according to an embodiment of the present invention is shown. See figure 1 The injection molding machine 10 is a hybrid injection molding machine equipped with an electric drive and a work piece that operates by supplying a working fluid.

[0020] The injection molding machine 10 includes an injection device 20 and a mold clamping device 50.

[0021] The injection device 20 includes a heating cylinder 21, and a hopper 22 is arranged at the heating cylinder 21. In addition, the screw rod 23 is arranged in the heating cylinder 21 so as to freely rotate and advance and retreat. An injection cylinder 24 is provided at the rear of the screw rod 23.

[0022] The injection cylinder 24 is provided with an injection plunger 25 that can move linearly. By supplying hydraulic oil from the oil passage 28, the injection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com