Strain culture device convenient to coat based on enzyme engineering

A technology of bacterial culture and enzyme engineering, applied in the field of enzyme engineering, can solve problems such as easy entry of bacteria into culture dishes and breaking of culture medium, and achieve the effects of being conducive to normal growth and reproduction, preventing bacterial liquid spraying, and preventing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

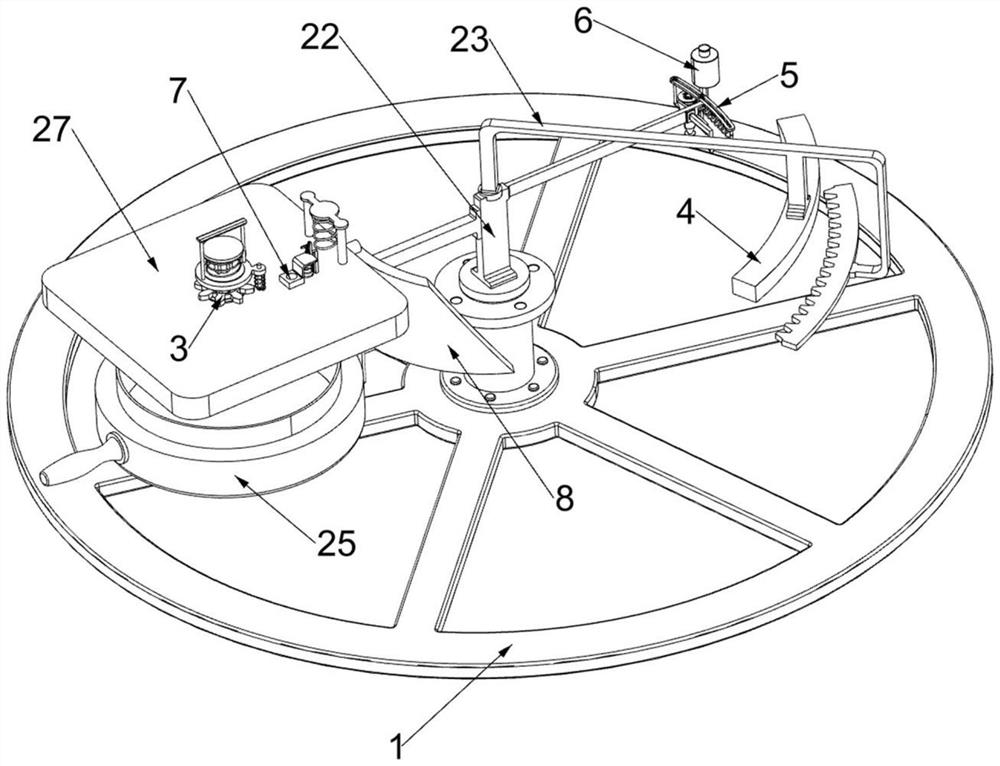

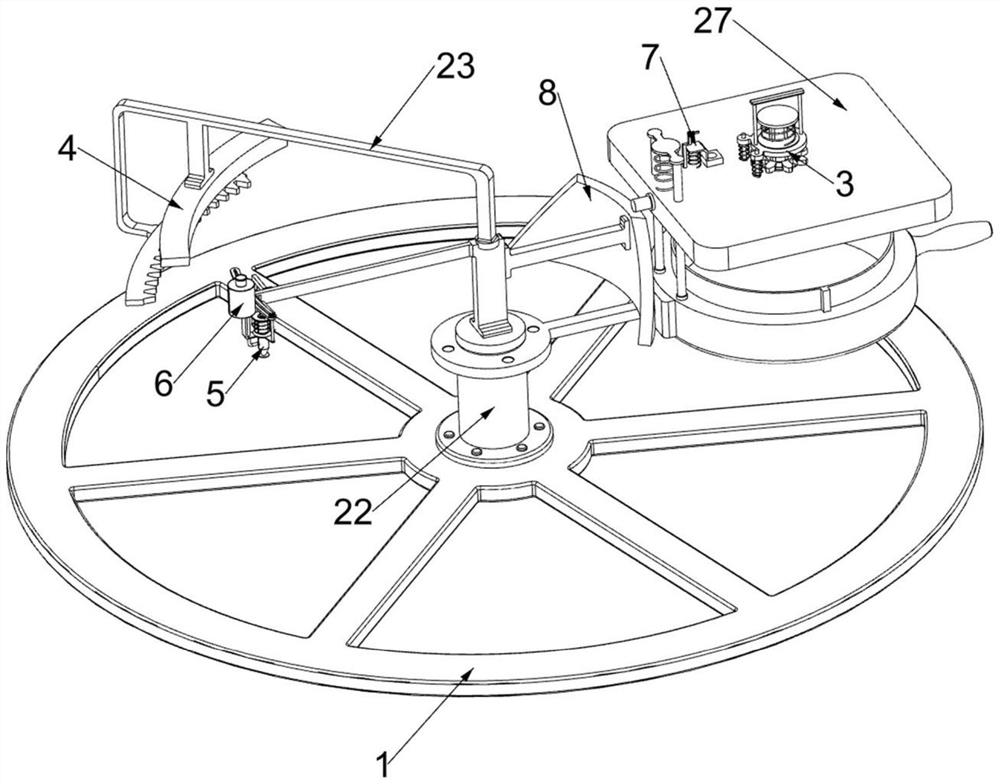

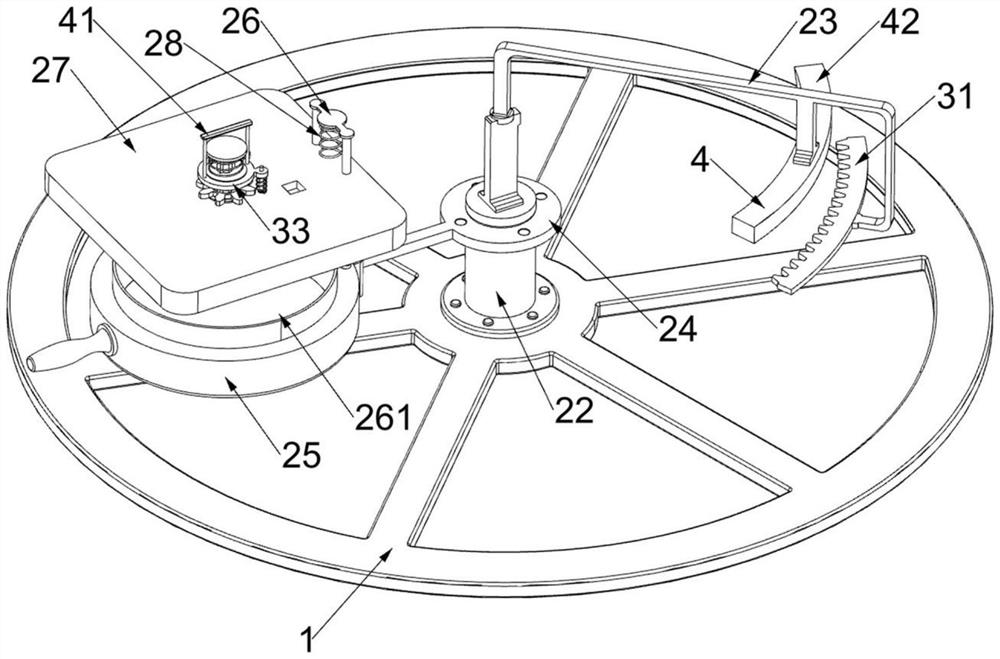

[0046] A strain culture device that is easy to coat based on enzyme engineering, such as Figure 1-5 As shown, it includes a support base 1, a first support frame 22, a second support frame 23, a first turret 24, a placement frame 25, a limit frame 26, a culture dish 261, a support cover plate 27, a first spring 28, The coating component 3 and the close-fitting component 4, the support base 1 has a circular structure, the support base 1 is connected with a first support frame 22 by bolts, the top of the first support frame 22 is connected with a second support frame 23, and the second support frame 23 is an N-shaped structure, the first support frame 22 is rotatably connected with a first turret 24, the first turret 24 is fixedly connected with a placement frame 25, the placement frame 25 adopts a circular structure, and the top of the placement frame 25 is connected with a limited position. Frame 26, the culture dish 261 that is used to cultivate bacterial classification is p...

Embodiment 2

[0051] On the basis of Example 1, such as Figure 5-10 As shown, an anti-splash assembly 5 is also included, and the anti-splash assembly 5 used to prevent the splashing of the bacterial liquid during the injection process is arranged on the first support frame 22, and the anti-splash assembly 5 includes a third support frame 51. Push plate 52, fourth spring 53, support rod 54, arc-shaped slotted support plate 55, limit slide frame 56, slide support frame 57, fifth spring 571, one-way guide tube 58, arc-shaped extrusion plate 59 , the sixth spring 510 and the reset frame 511, the top of the support cover plate 27 is connected with the third support frame 51, the third support frame 51 is slidably connected with the push plate 52, and the push plate 52 is connected with the third support frame 51 The fourth spring 53, the first support frame 22 is connected with a support rod 54, and one end of the support rod 54 is connected with an arc-shaped slotted support plate 55, and the...

Embodiment 3

[0054] On the basis of Example 2, such as Figure 9-12 As shown, it also includes an extrusion assembly 6, which is used to extrude the bacterial liquid inside the one-way introduction pipe 58 to the surface of the agar medium. The extrusion assembly 6 is arranged on the splash prevention assembly 5, and the extrusion assembly 6 includes the first Four bracing frame 61, push plate frame 62, the 7th spring 63, the 5th bracing frame 64, liquid storage frame 65, screw cap 66, one-way guide pipe 67 and wedge-shaped extruding piece 68, sliding bracing frame 57 tops are connected with the 6th Four bracing frames 61, sliding bracing frame 57 internal sliding type is connected with push pedal frame 62, and the bottom of push pedal frame 62 is disc-shaped, is connected with the 7th spring 63 between push pedal frame 62 and the 4th bracing frame 61, position-limiting The sliding frame 56 is connected with a fifth support frame 64, the top of the fifth support frame 64 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com