A filter press device for nano calcium carbonate production

A technology of nano calcium carbonate and pressing mechanism, applied in the directions of filtration separation, separation method, chemical instrument and method, etc., can solve the problem that the plate frame and filter cloth should not be removed, and achieve the effect of stable efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

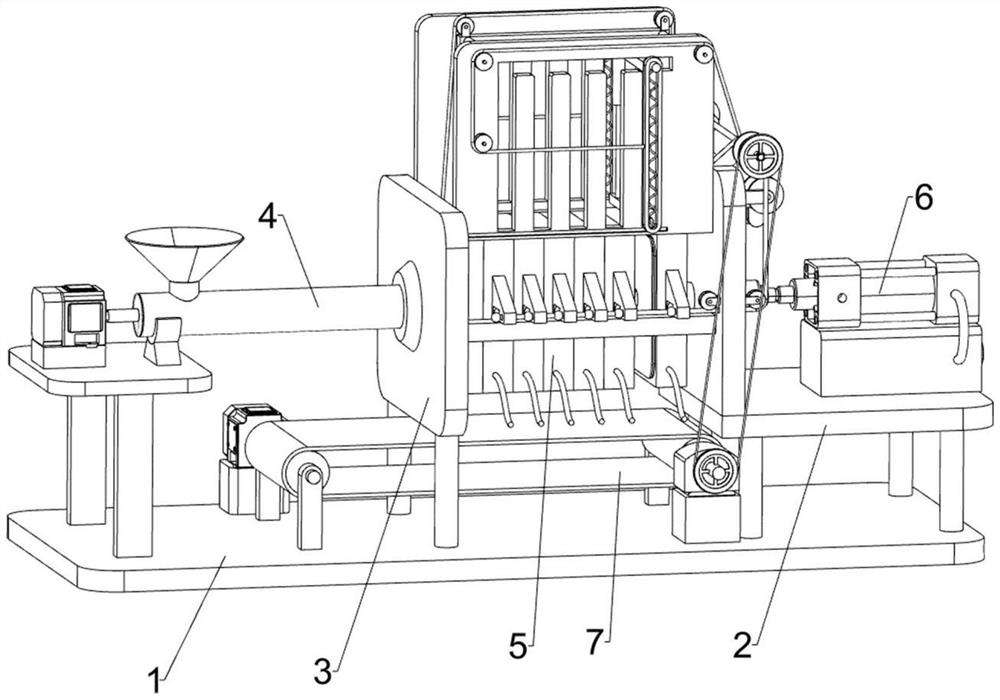

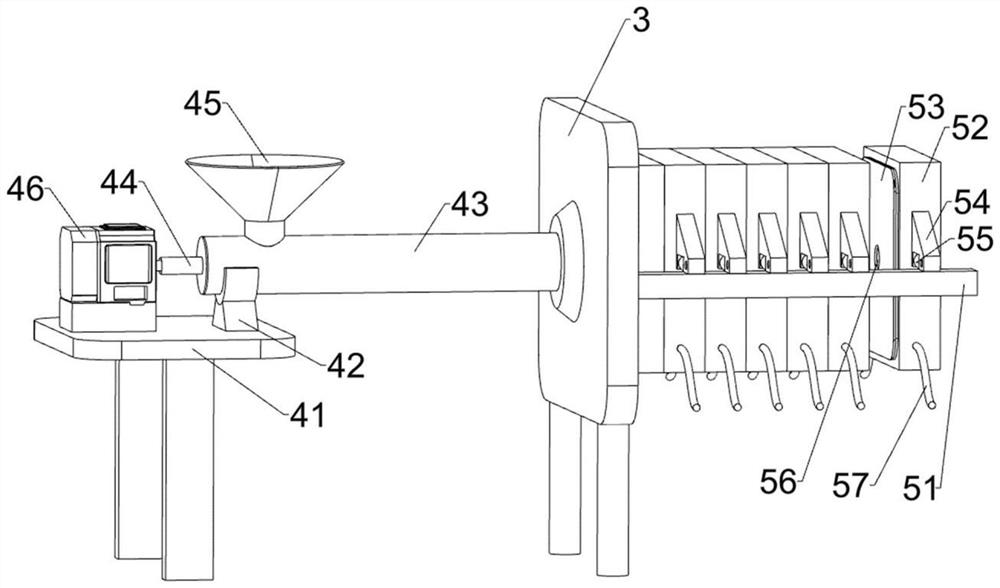

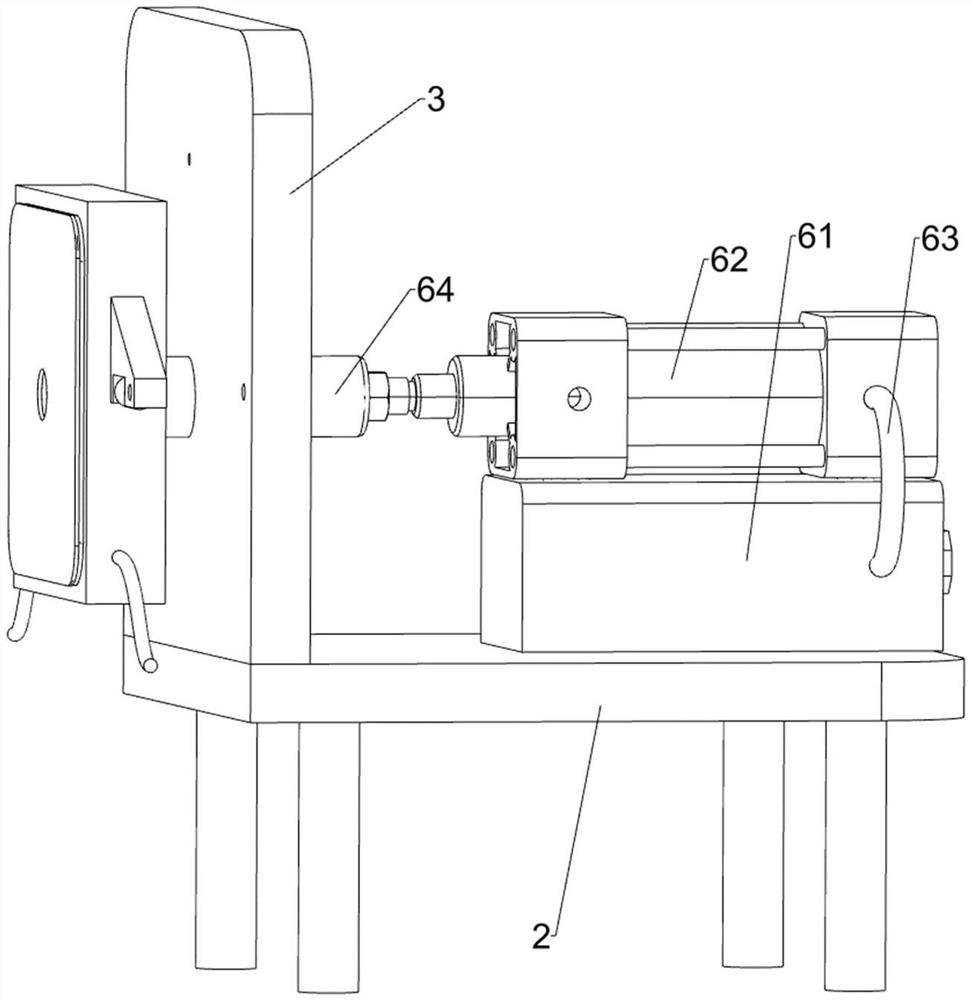

[0028] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a filter press device for producing nano-calcium carbonate includes a bottom plate 1, a first support frame 2, a support plate 3, a feeding mechanism 4, a filtering mechanism 5, a pressing mechanism 6 and a discharging mechanism 7, and the bottom plate 1 A first support frame 2 is arranged on the upper right side, and two support plates 3 are arranged at intervals in the middle of the bottom plate 1. 1 is provided with a feeding mechanism 4 on the side away from the first support frame 2, a filter mechanism 5 is provided between the two support plates 3, a pressing mechanism 6 is provided on the top of the first support frame 2, and an outlet is provided in the upper middle of the bottom plate 1. Feeding mechanism 7.

[0029] The feeding mechanism 4 includes a second supporting frame 41, a fixing frame 42, a cylinder 43, a screw rod 44, a feeding hopper 45 and a first servo motor 46. A second supporting fr...

Embodiment 2

[0035] like Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, on the basis of Embodiment 1, it also includes a reduction box 8, a second bearing seat 10, a second rotating shaft 11, a pulley assembly 12, a first bobbin 13, a first fixed wheel assembly 14, a first The cable 15 and the ball 16, the front end of the first rotating shaft 72 on the right side is provided with a reduction box 8, the input shaft of the reduction box 8 is connected with this wheel 73 and then the output torque is connected, the reduction box 8 is connected with the bottom plate 1, and the support on the right side is The top of the plate 3 is provided with a second bearing seat 10 symmetrically in the front and rear, the second rotating shaft 11 is rotatably mounted on the two second bearing seats 10, the output shaft of the reduction box 8 is connected with the second rotating shaft 11 through the pulley assembly 12, and the second rotating shaft 11 The first bobbins 13 are symmetrically in...

Embodiment 3

[0039] like Figure 8 As shown, on the basis of Embodiment 2, it also includes a pressure rod 28, a second connecting pin 29, a second guide groove 30, a third fixed wheel assembly 31, a third bearing seat 32, a third rotating shaft 33, a third The three bobbins 34, the rotating handle 35 and the third cable 36, the top of the cross bar 24 is provided with a pressing rod 28, the front side of the pressing rod 28 is symmetrically provided with a second connecting pin 29, the rear side of the front side guide groove plate 17 The left and right edges are symmetrically provided with second guide grooves 30 , the pressure rod 28 is slidably connected to the second guide groove 30 through the second connecting pin 29 , and two third fixed wheel assemblies 31 are symmetrically arranged at both ends of the top of the pressure rod 28 . A third bearing seat 32 is arranged on the right side of the right support plate 3 , a third shaft 33 is rotatably mounted on the third bearing seat 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com