Drainage type fixture and method for plugging bimetal composite pipe piercement under pressure by utilizing drainage type fixture

A bimetallic composite pipe, plugging technology under pressure, applied in the direction of pipe elements, piping systems, pipes/pipe joints/pipe fittings, etc., can solve the problem of only stopping and changing pipes, etc., and achieves the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

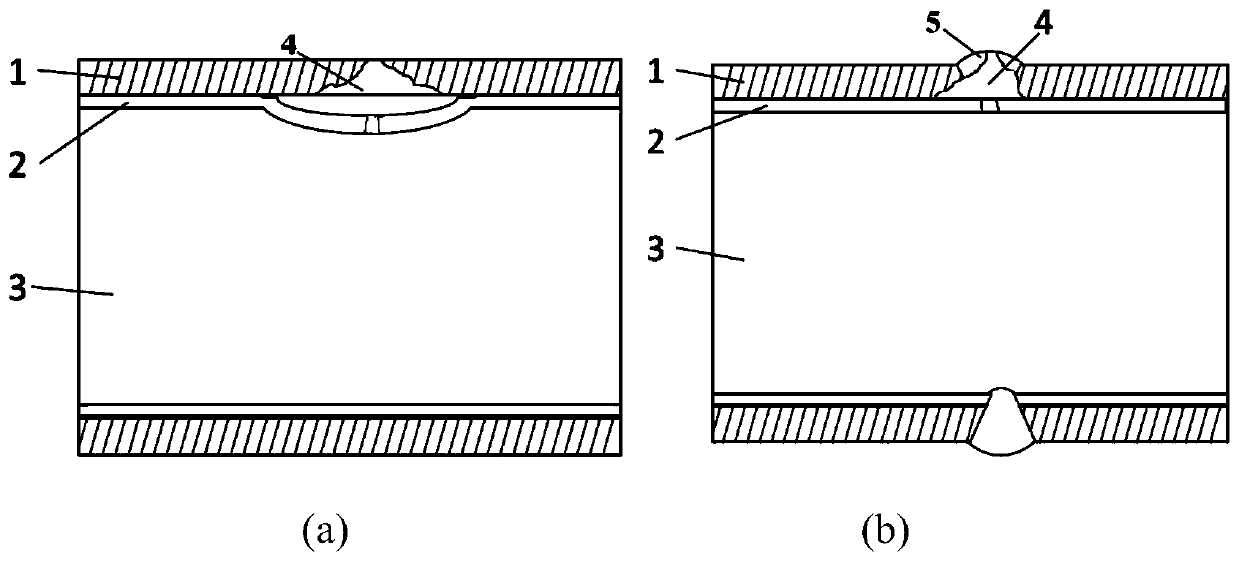

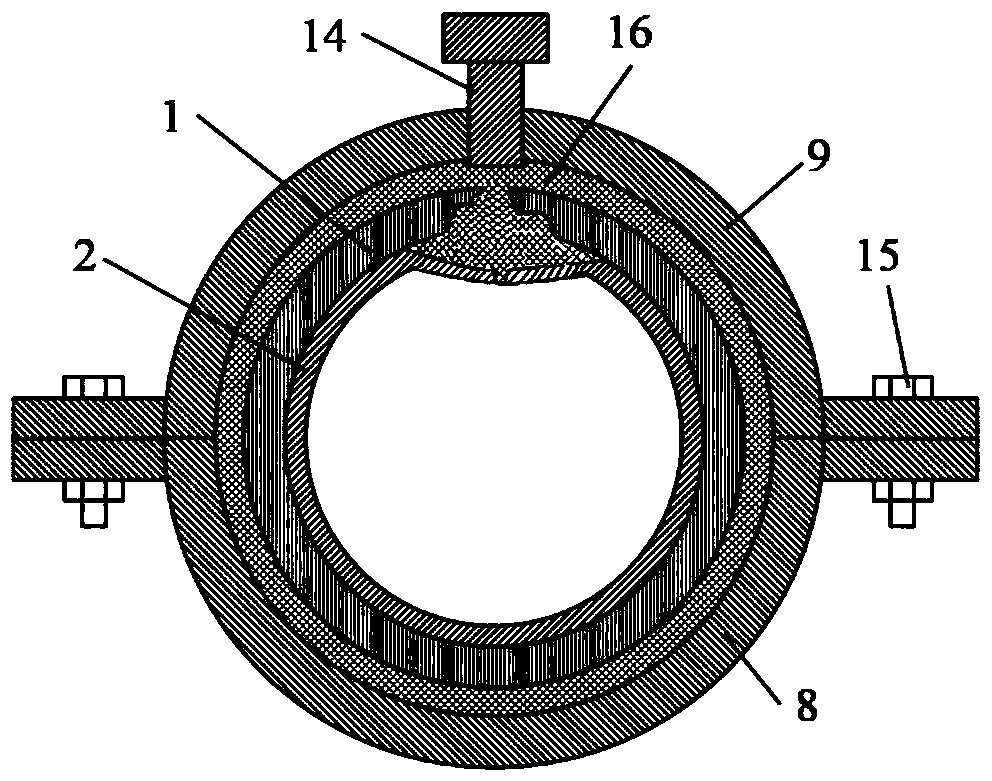

[0069] The pipeline is a 316L bimetal composite pipe, which is composed of a base pipe 1 and a liner 2, wherein the base pipe 1 is L245 steel, the liner 2 is stainless steel, the outer diameter of the pipe is 508mm, and the wall thickness is 14mm; the conveying medium 3 is Crude oil, the pressure is 10MPa; the diameter of the notch on the outer wall of the base pipe 1 is about 3mm.

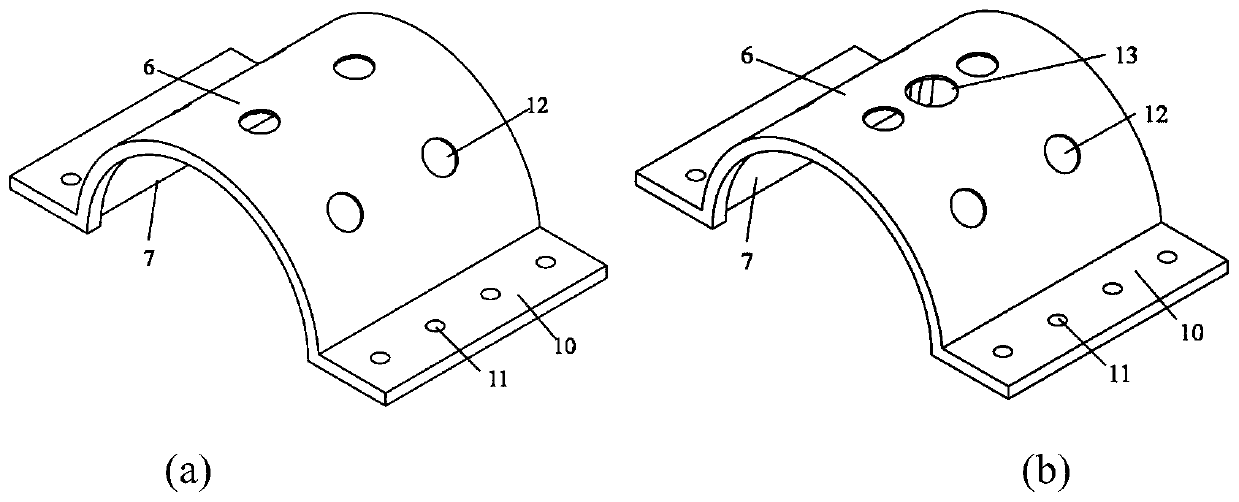

[0070] see Figure 4 , Figure 4 It is a schematic diagram of the split fixture in Example 1. The material of the drainage fixture is 16Mn, and the first shell 8 and the second shell 9 are connected through the side shaft 18 to form a movable part that can be snapped open and closed; the first shell The length of the body 8 and the second shell 9 is 500mm, and the thickness is 18mm; the inner diameter of the filling section 6 of the first shell and the second shell is 508mm, the depth of the shallow groove 7 is 5mm, and the front and rear edges of the shallow groove 7 The distance to both ends o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com