Patents

Literature

213 results about "Collapsed cavity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Backfill repairing method for tunnel collapse cavity

InactiveCN102182472AReduce construction difficultyFast constructionUnderground chambersTunnel liningCollapsed cavityEarth surface

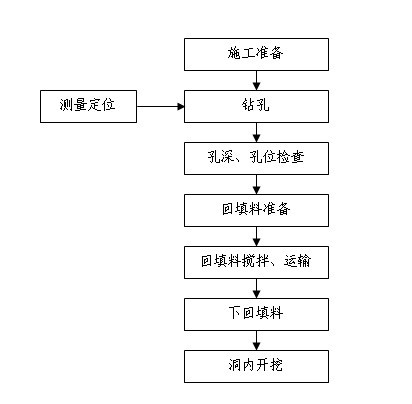

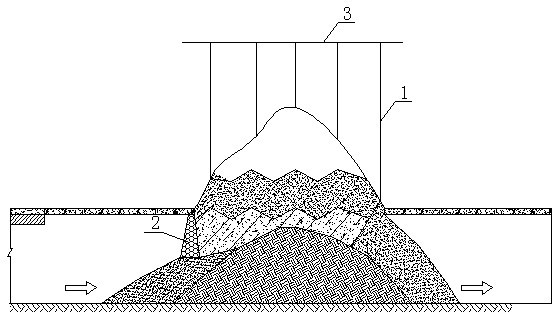

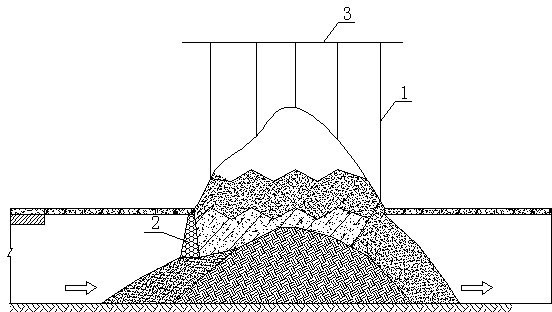

The invention discloses a backfill repairing method for a tunnel collapse cavity, which is a collapse processing method comprising surface drilling and grouting or backfilling. The method comprises the following steps: (1) positioning and drilling; (2) backfilling the cavity; and (3) excavating and cleaning. Through the construction method of drilling and backfilling, the collapse cavity is backfilled with various backfill materials to form a force bearer which bears unstable load of a collapse area so as to prevent further collapse and provide force application point for subsequent support, and then hidden excavation construction is performed; the method reduces the construction difficulty, realizes fast construction, and is equivalent to tunneling in normal geological conditions, and isa very reliable collapse processing method; moreover, the method not only has high safety as the collapse processing staff and machinery carry out construction basically on a safe working surface without potential safety hazards, but also has high construction speed and high operation efficiency.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

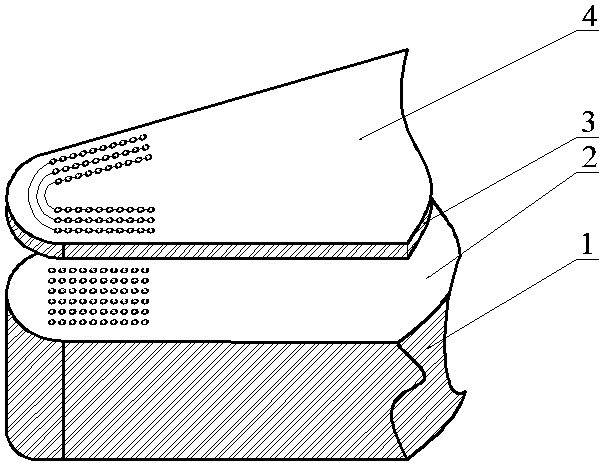

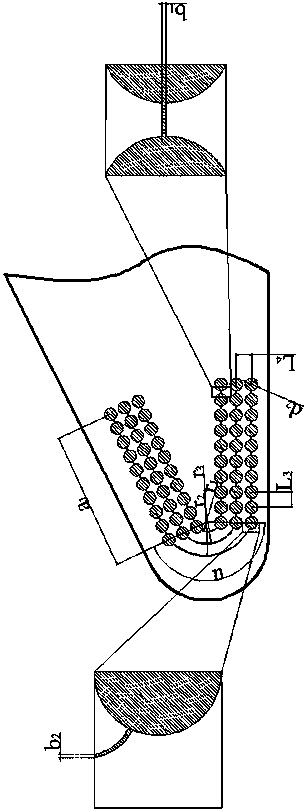

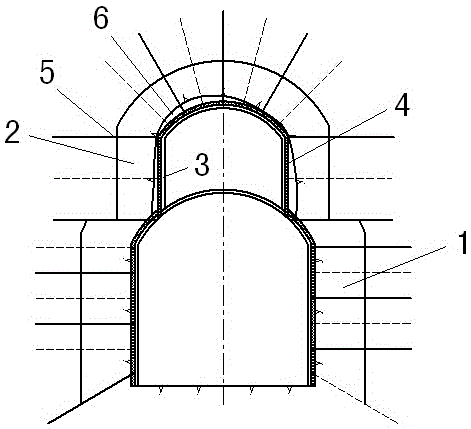

Non-disturbance type supporting structure used for tunnel vault collapsed cavity processing

InactiveCN104975861AAdvanced conceptSimple and fast operationUnderground chambersTunnel liningCollapsed cavityEngineering

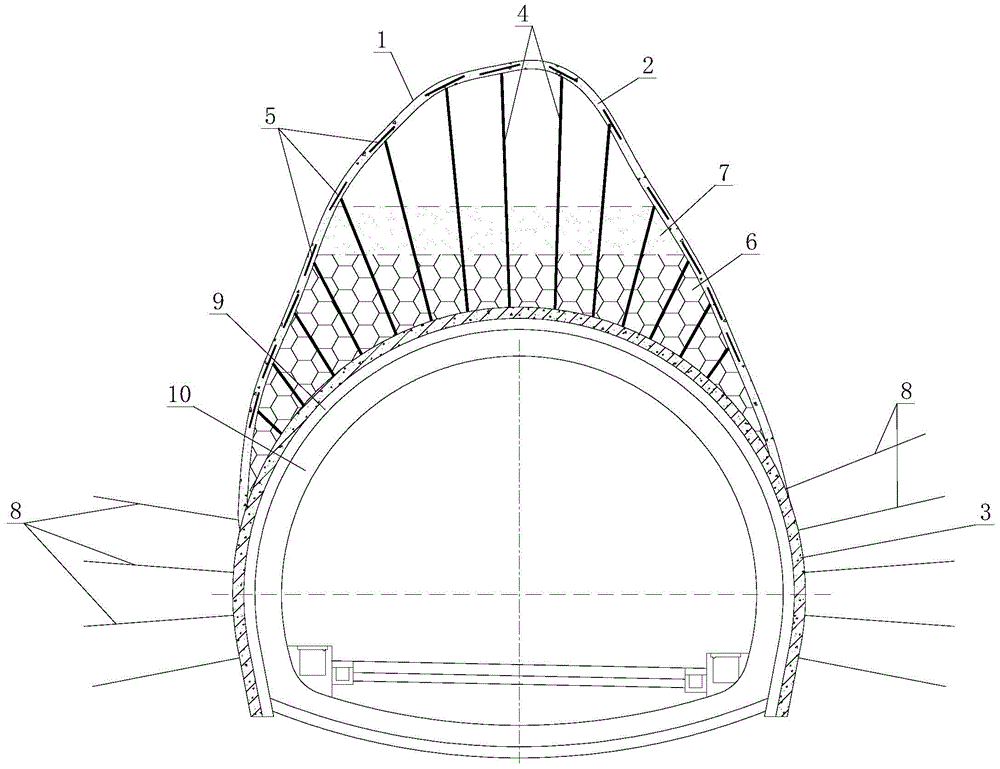

The invention discloses a non-disturbance type supporting structure used for tunnel vault collapsed cavity processing. The supporting structure comprises a concrete reinforcement net layer laid on a wall face of a collapsed cavity and a protection arc erected along the fracture surface of the collapsed cavity. The protection arc is arranged under the concrete reinforcement net layer. Multiple support pieces are arranged between the protection arc and the concrete reinforcement net layer. The space between the arc back of the protection arc and the inner wall of the concrete reinforcement net layer is filled by arch back backfill layers. Compared with the new Austrian tunneling method, the supporting idea is more advanced by following the principle that surrounding racks and lining structures bearing load together, so the lining structures are allowed to actively participate in load bearing to the greatest extent. The wall face of the collapsed cavity will not be nearly disturbed in the implementation process, so construction risks in the collapsed cavity processing process and potential operation risks are reduced.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Method for treating tunnel collapse through dugand covered method

ActiveCN105041333AAvoid security risksEnsure safetyUnderground chambersTunnel liningCollapsed cavitySlag

The invention discloses a method for treating tunnel collapse through a dugand covered method, which relates to the filed of constructional engineering, and substantially aims to solve the problem that existing tunnel collapse is high in construction cost and large in safety risk, wherein segments which are not collapsed are reinforced, tunnel faces are blocked off by utilizing hole slag recovery until to a position of an arch crown, enable stone ballasts which collapse in collapsed cavities in the later stage to fall into positions above the arch crown, backfill holes and overfall holes are obligated when the funnel faces are blocked off, the overfall holes use Phi (Phi) 48mm steel pipes, a pipe head arranged on one end of the steel pipes stretches into the collapsed cavities for certain height, a pipe head arranged on one end of the steel pipes is exposed outside backfill bodies, the positions above the arch crown are filled back by adopting C25 pumped concrete after collapsed segments are sealed, the backfill thickness is 2.5m, and concrete protective layers are formed on the positions above the arch crown. Furthermore, in order to guarantee the whole stability of the pumped concrete, small grouting pipes are added from springing lines of the two sides of tunnels to the positions of haunches after the tunnel faces are backfilled and sealed, and then sealed segments are divisionally excavated, supported and protected after backfilling and grouting. The method for treating tunnel collapse through the dugand covered method has the advantages that the method for treating tunnel collapse through the dugand covered method reduces safety risk and is low in construction cost.

Owner:CHINA RAILWAY 19TH BUREAU GRP SECOND ENG CO LTD

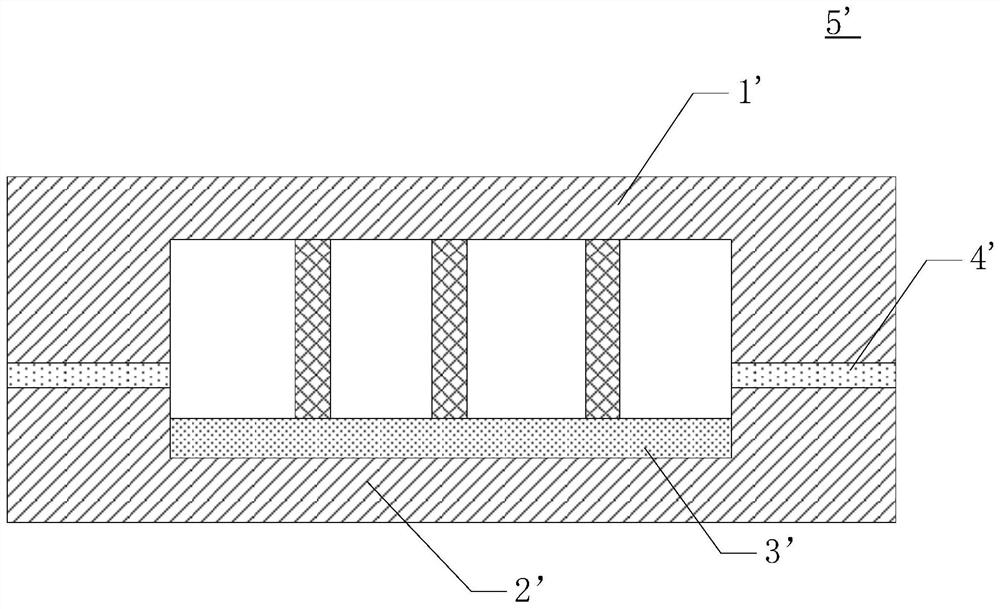

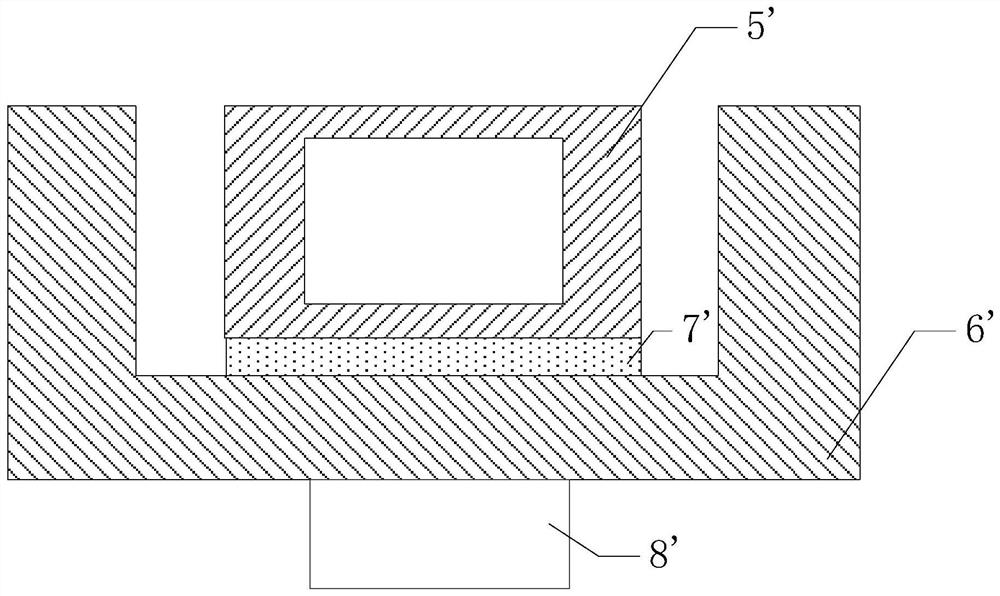

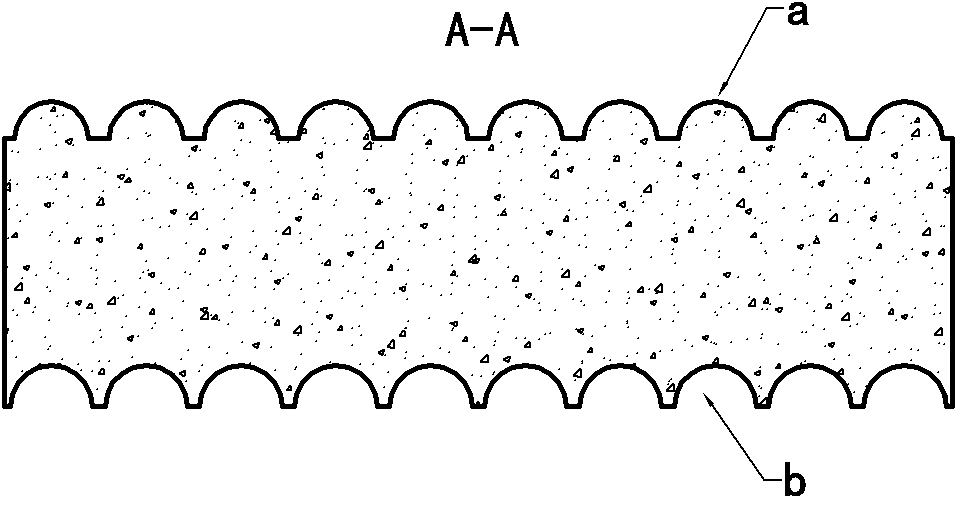

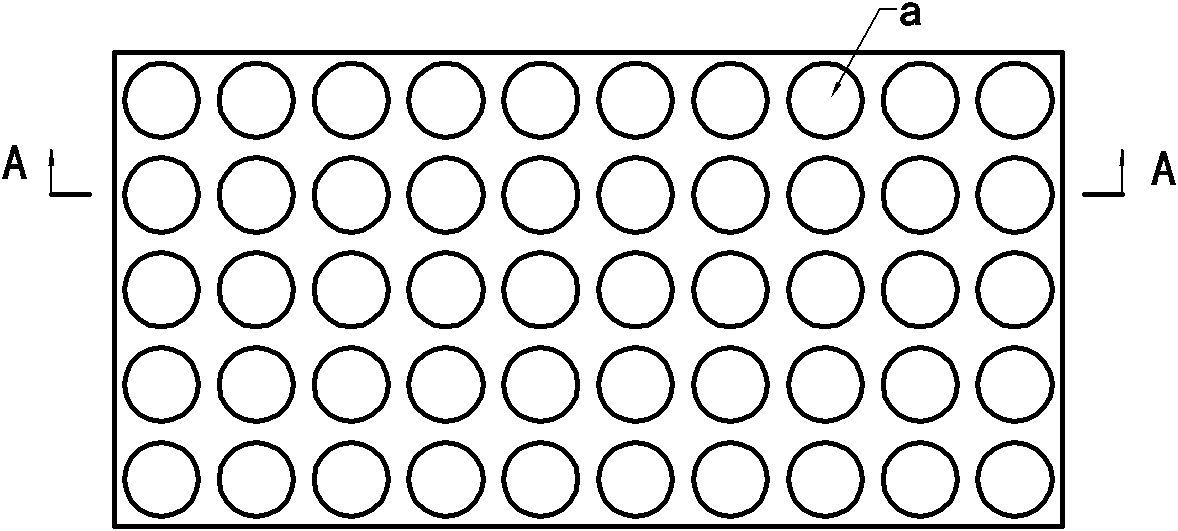

Surface cross-scale composite micro-modeling tool and preparation method

The invention discloses a surface cross-scale composite micro-modeling tool and a preparation method, and belongs to the technical field of machine manufacturing. The surface of a tool material is subjected to micro-modeling treatment of a recessed cavity morphology, a micron-size recessed cavity and a nanoscale groove are machined in a friction and abrasion sensitive area on the surface of a hardcoating, a combined way that the groove communicates with the cavity is adopted for distribution, and the cross-scale composite micro-modeling coating tool is obtained. In this way, the film-base combined strength of the coating tool is improved, and the wettability and lubrication performance of the surface of the coating tool are improved.

Owner:JIANGSU UNIV

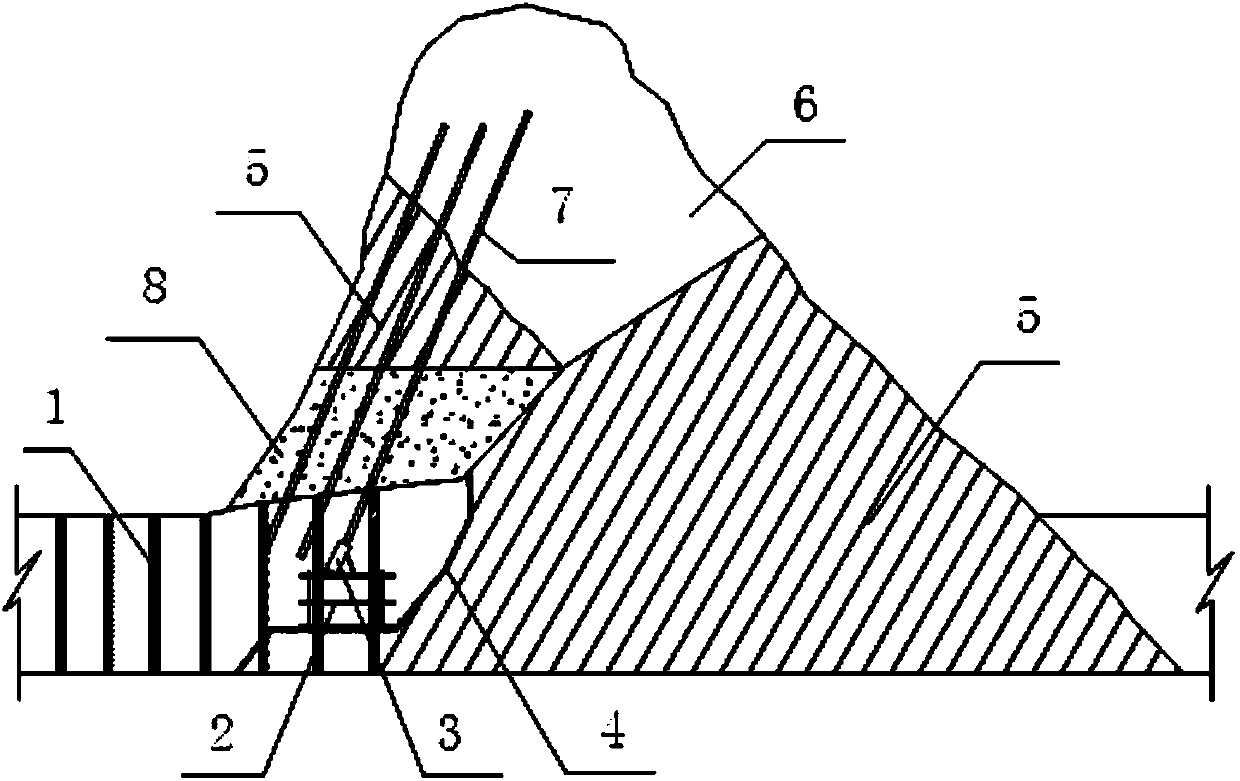

Tunnel collapse handling method for convergent collapse cavity

ActiveCN110656954AEasy to operateImprove project qualityUnderground chambersTunnel/mines ventillationCollapsed cavityLandslide

The invention discloses a tunnel collapse handling method for a convergent collapse cavity, and relates to the field of tunnel engineering. By the adoption of the tunnel collapse handling method for the convergent collapse cavity, the problem that an existing handling method lacks operability, can cause potential safety hazards, and is not economical is solved. According to the technical scheme, the tunnel collapse handling method for the convergent collapse cavity comprises the steps that first, after the tunnel collapse cavity is stabilized, a construction platform is formed by means of collapse residues; second, a landslide-affected section is divided into an excavated landslide-affected section and a non-excavated landslide-affected section which are separately reinforced; third, concrete is sprayed to support the collapse cavity; fourth, a temporary support and a formwork are constructed on a landslide section, a manhole is formed in the portion, in the middle of the landslide section, of a tunnel vault, the collapse cavity is backfilled with concrete, landslide anchoring rods are constructed, reinforcement of the temporary support and the landslide-affected section is removed, and the construction platform is removed through excavation; and finally, a tunnel drain pipe and a waterproof plate are constructed according to original design, and secondary lining concrete is constructed. The tunnel collapse handling method has high practical value in handling convergent tunnel collapse cavities.

Owner:POWERCHINA CHENGDU ENG

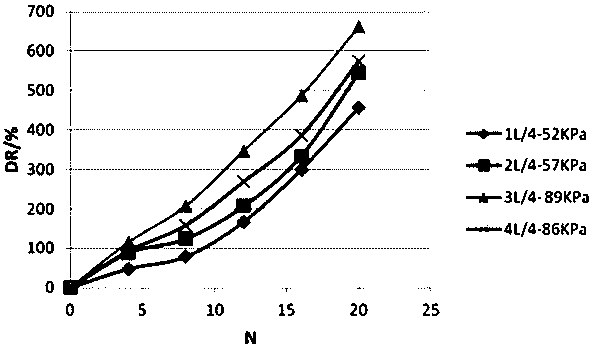

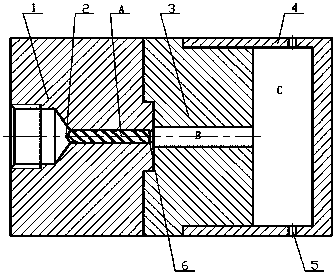

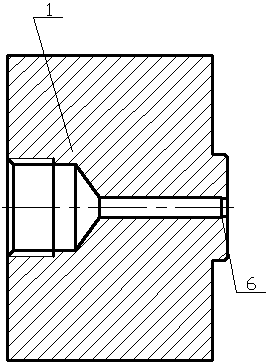

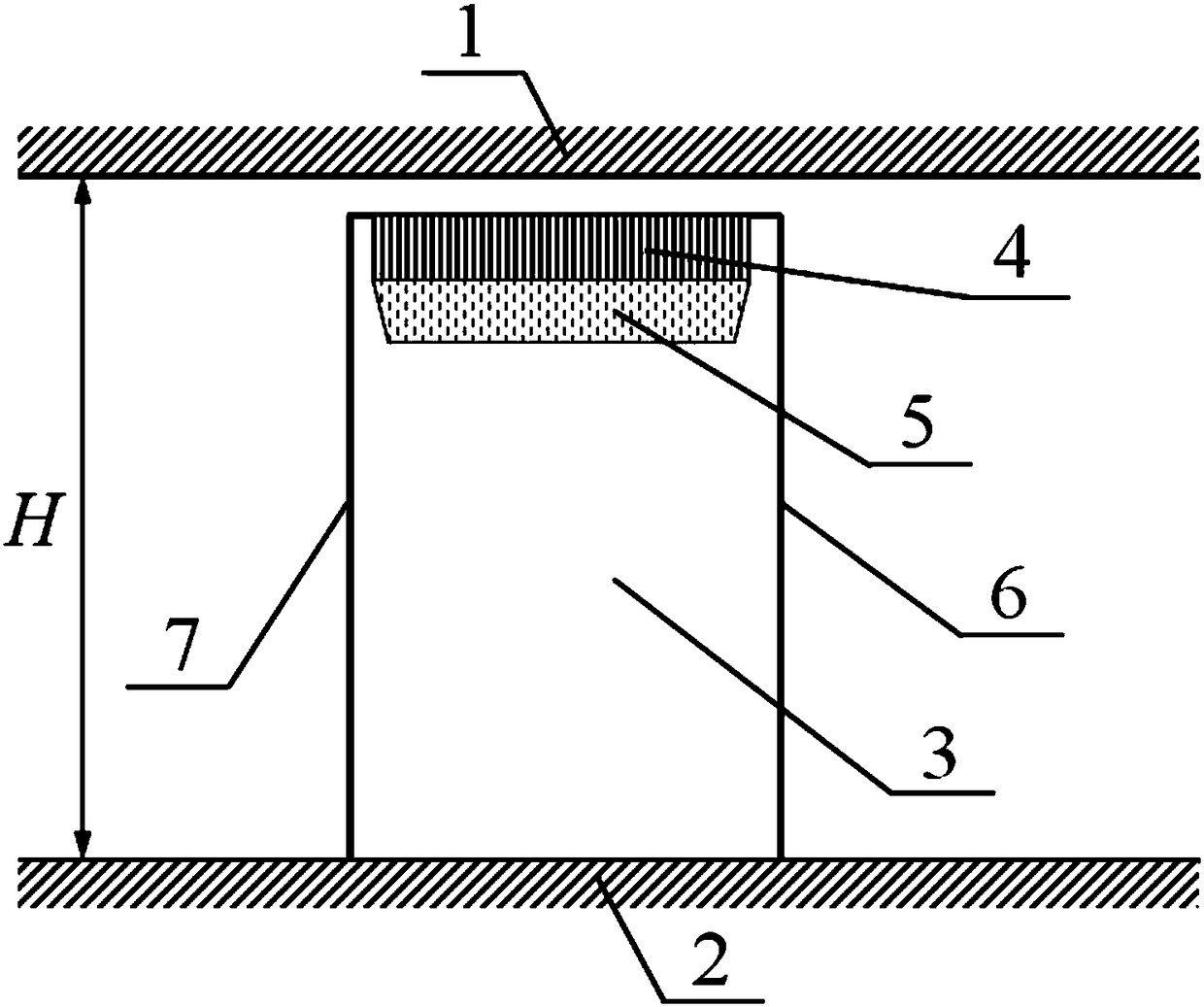

Simulation test method for gas extraction from tectonically-deformed coal seam in-situ by depressurizing horizontal well cavity

ActiveUS20200263511A1Increase the diameterAvoid problemsDrill bitsUnderground miningCoal measuresThermodynamics

A simulation test method for gas extraction from a tectonically-deformed coal seam in-situ by depressurizing a horizontal well cavity. A coal series stratum structure reconstruction and similar material simulation subsystem simulates a tectonically-deformed coal reservoir. A horizontal well drilling and reaming simulation subsystem constructs a U-shaped well in which a horizontal well adjoins a vertical well, and performs a reaming process on a horizontal section thereof. A horizontal well hole-collapse cavity-construction depressurization excitation simulation subsystem performs pressure-pulse excitation and stress release on the horizontal well, and hydraulically displaces a coal-liquid-gas mixture such that the mixture is conveyed towards a vertical well section. A product lifting simulation subsystem further pulverizes the coal and lifts the mixture. A gas-liquid-solid separation simulation subsystem separates the coal, liquid and gas. A monitoring and control subsystem detects and controls the operation and the execution processes of equipment in real time.

Owner:CHINA UNIV OF MINING & TECH +4

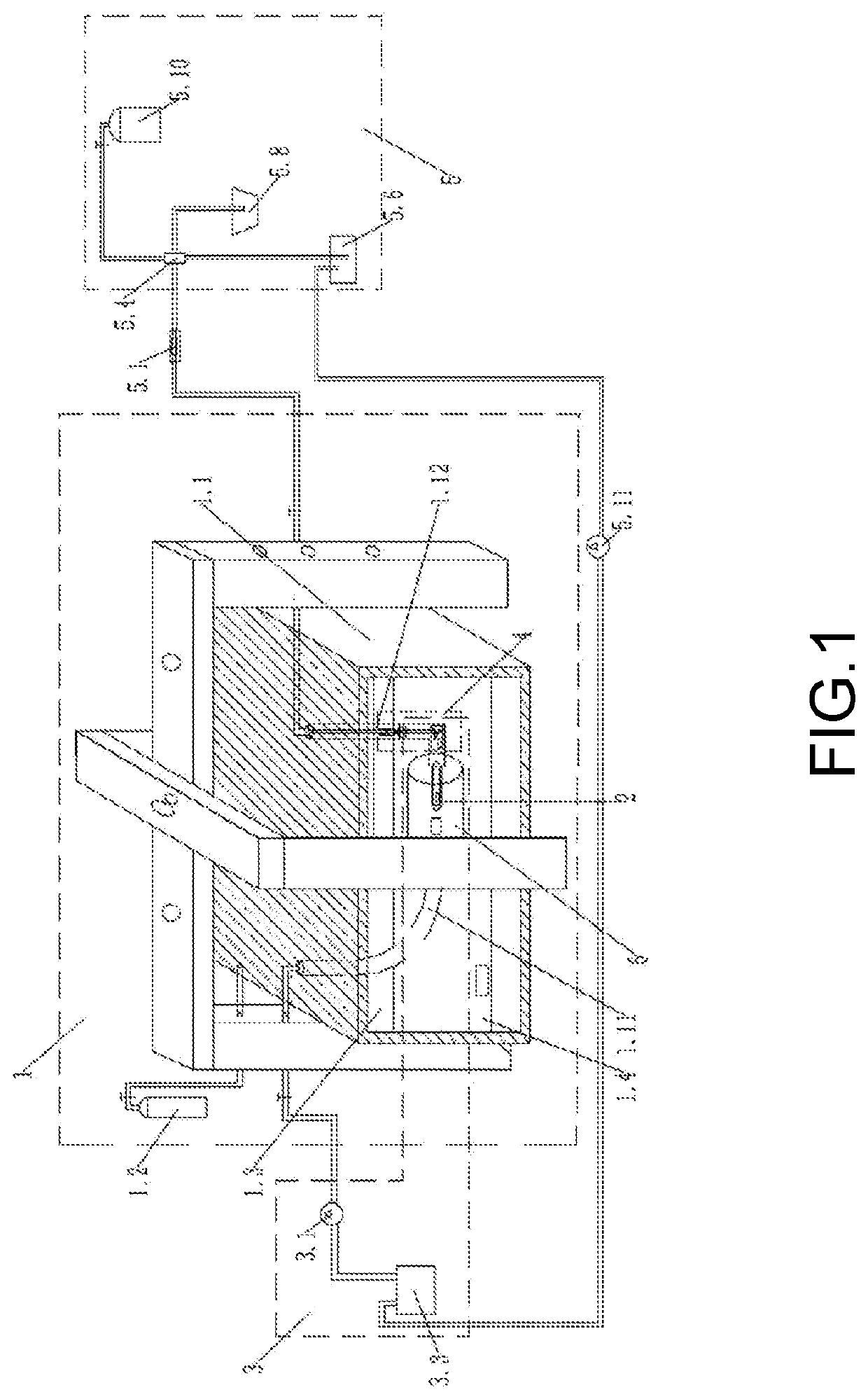

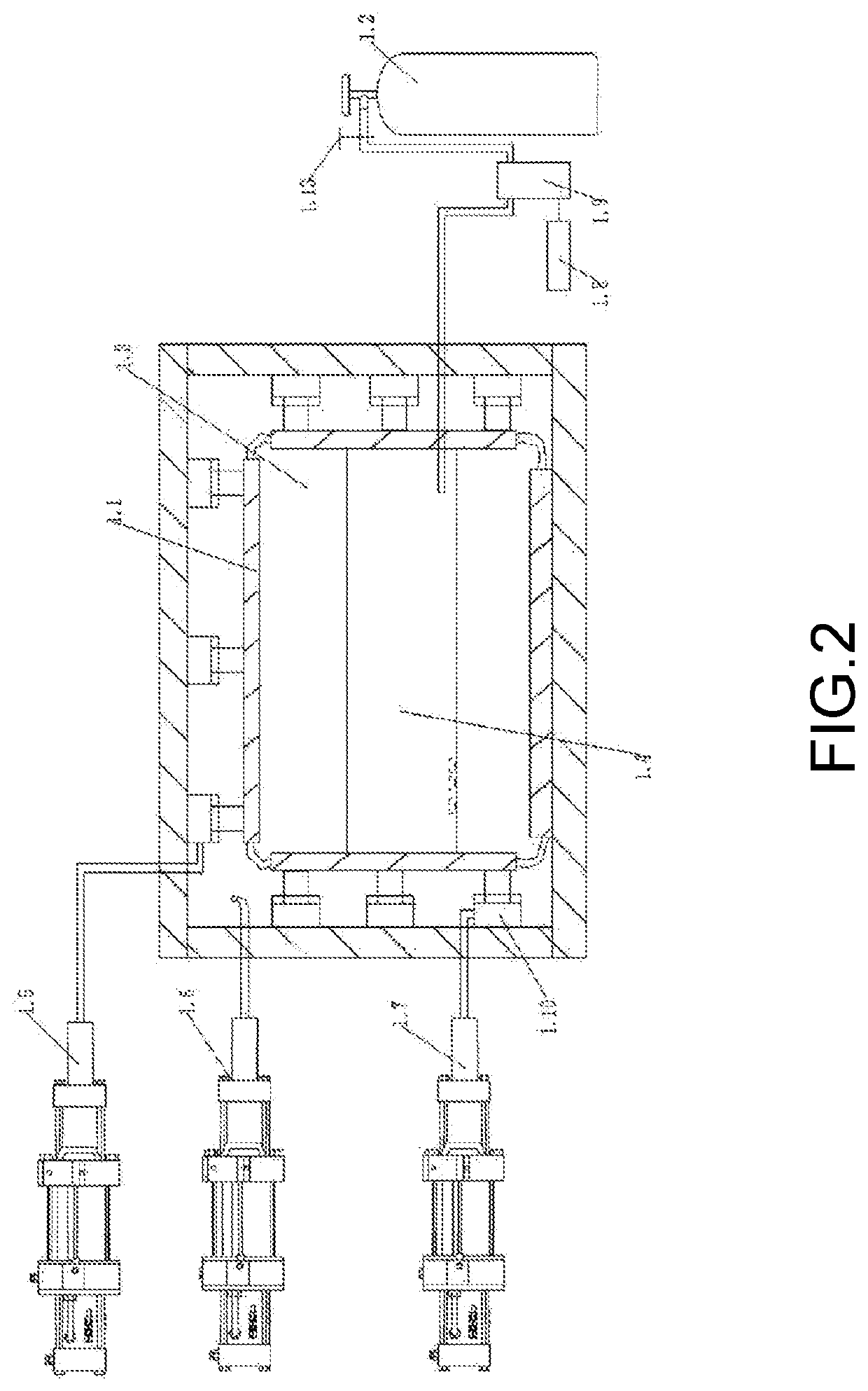

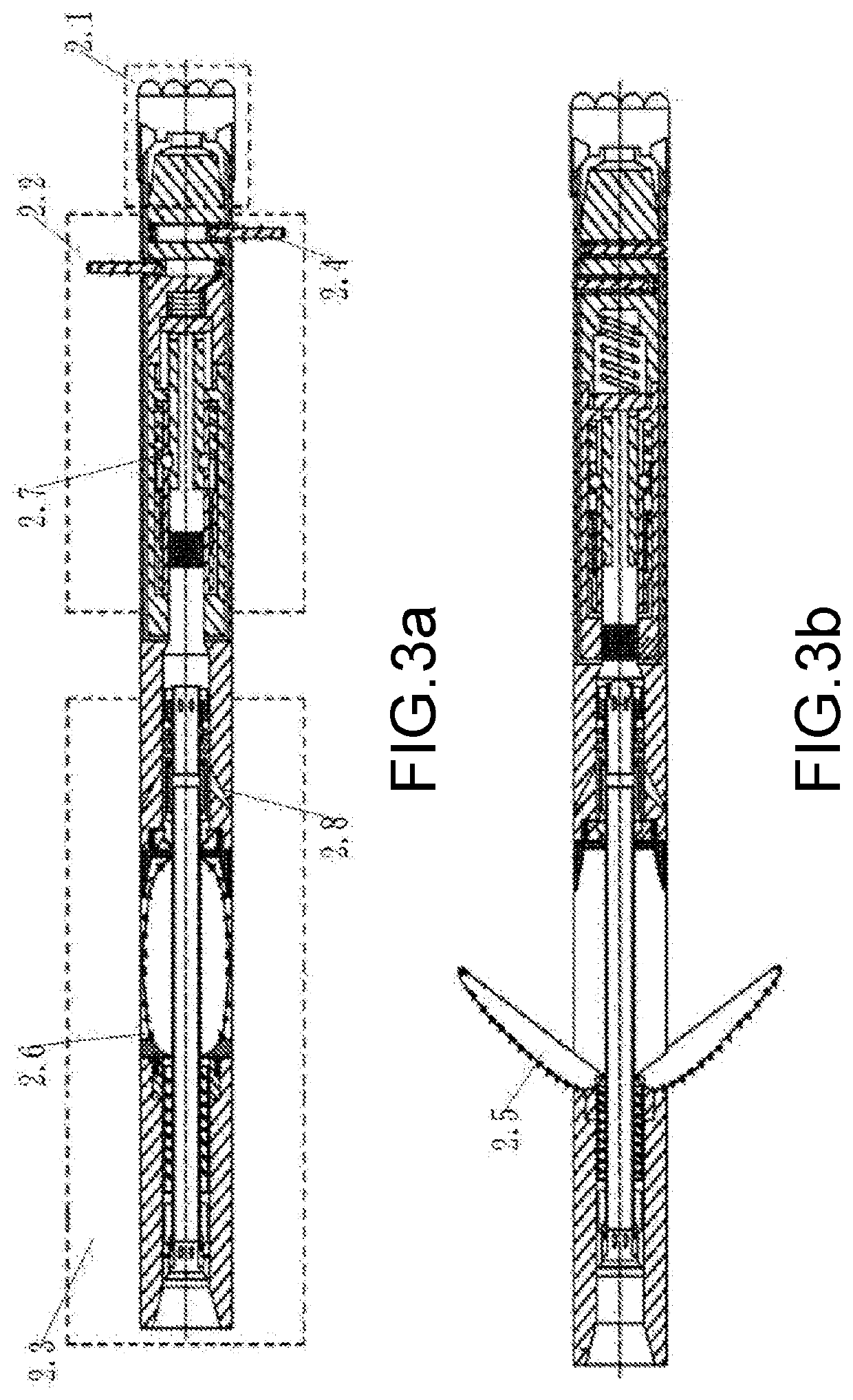

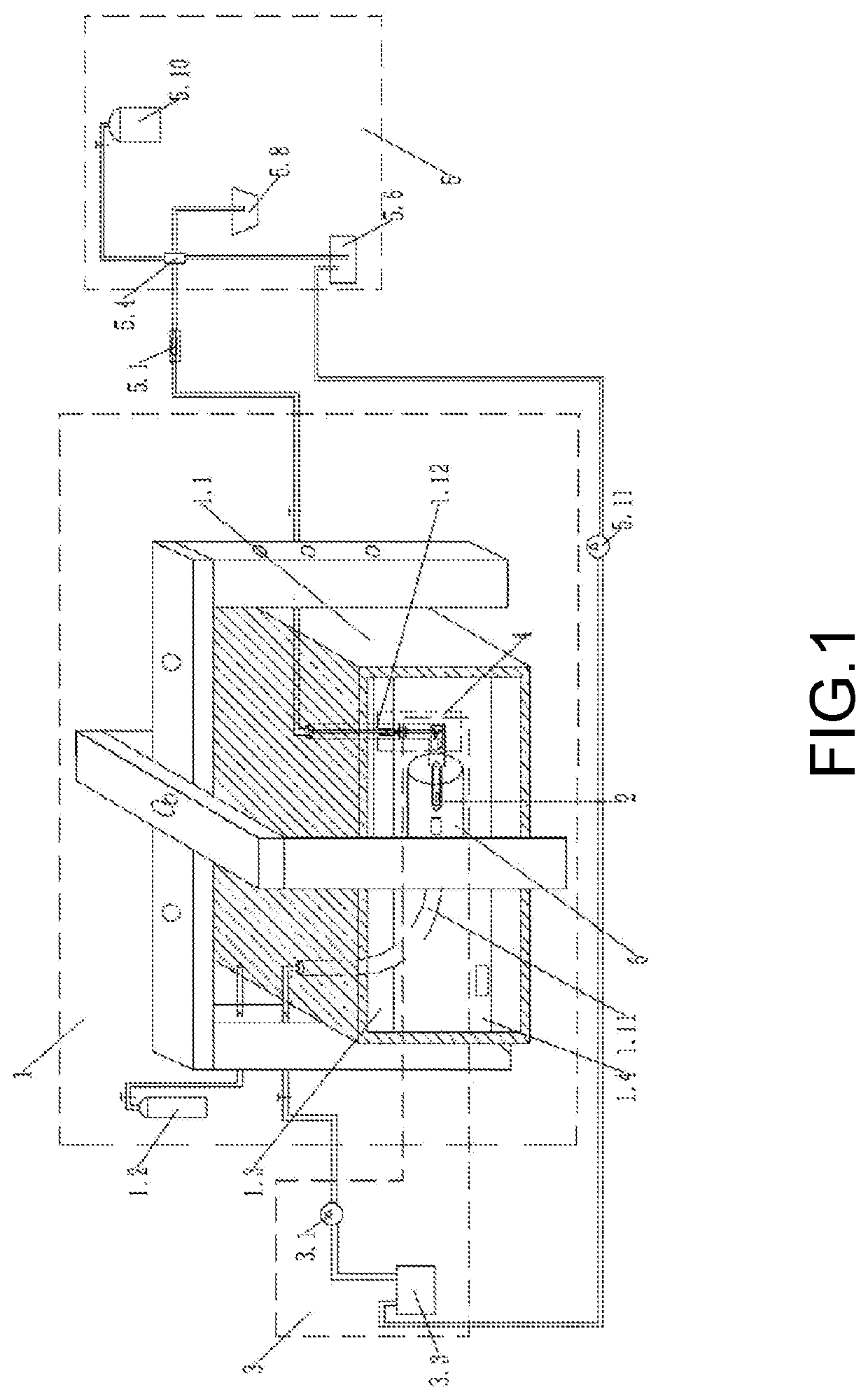

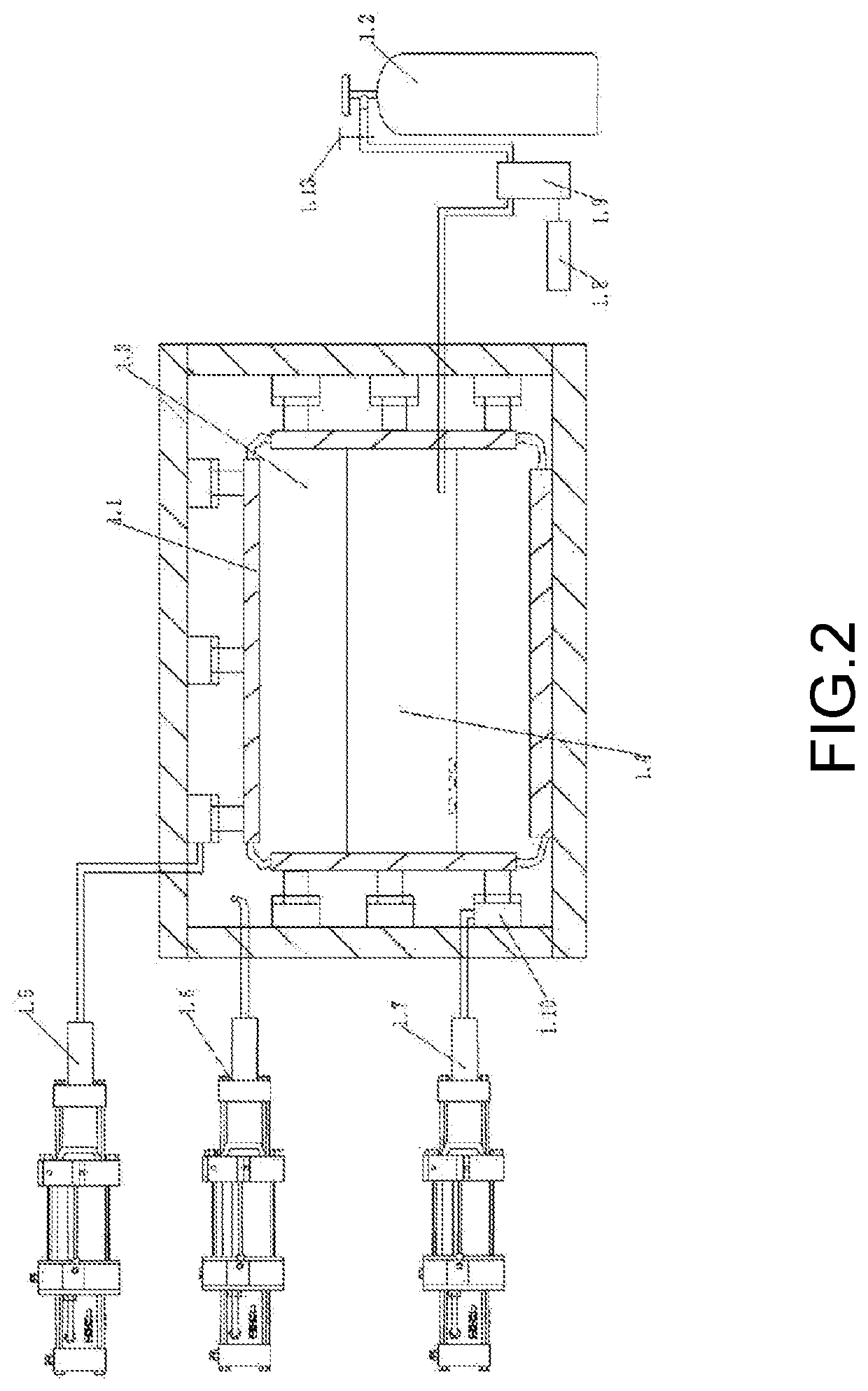

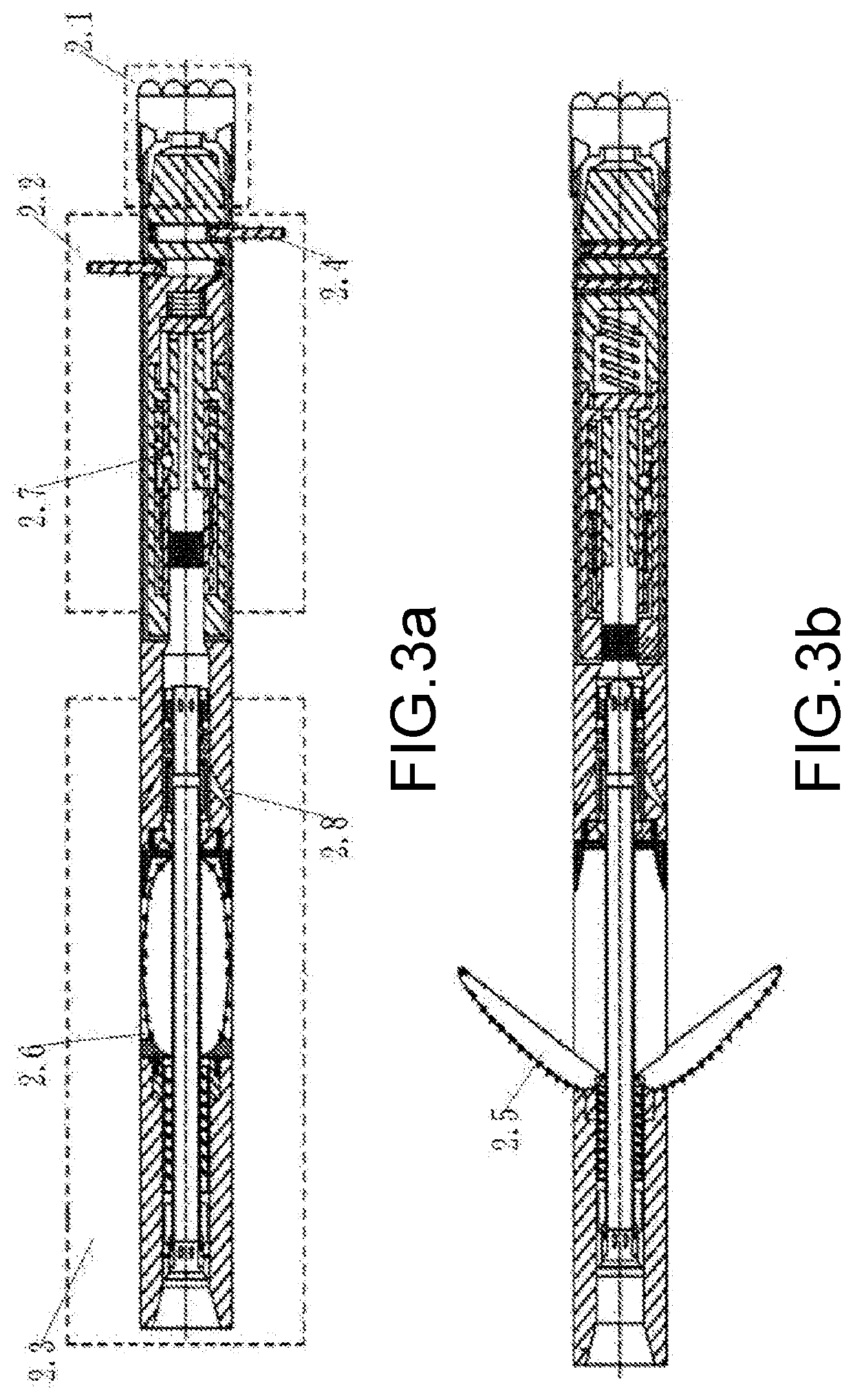

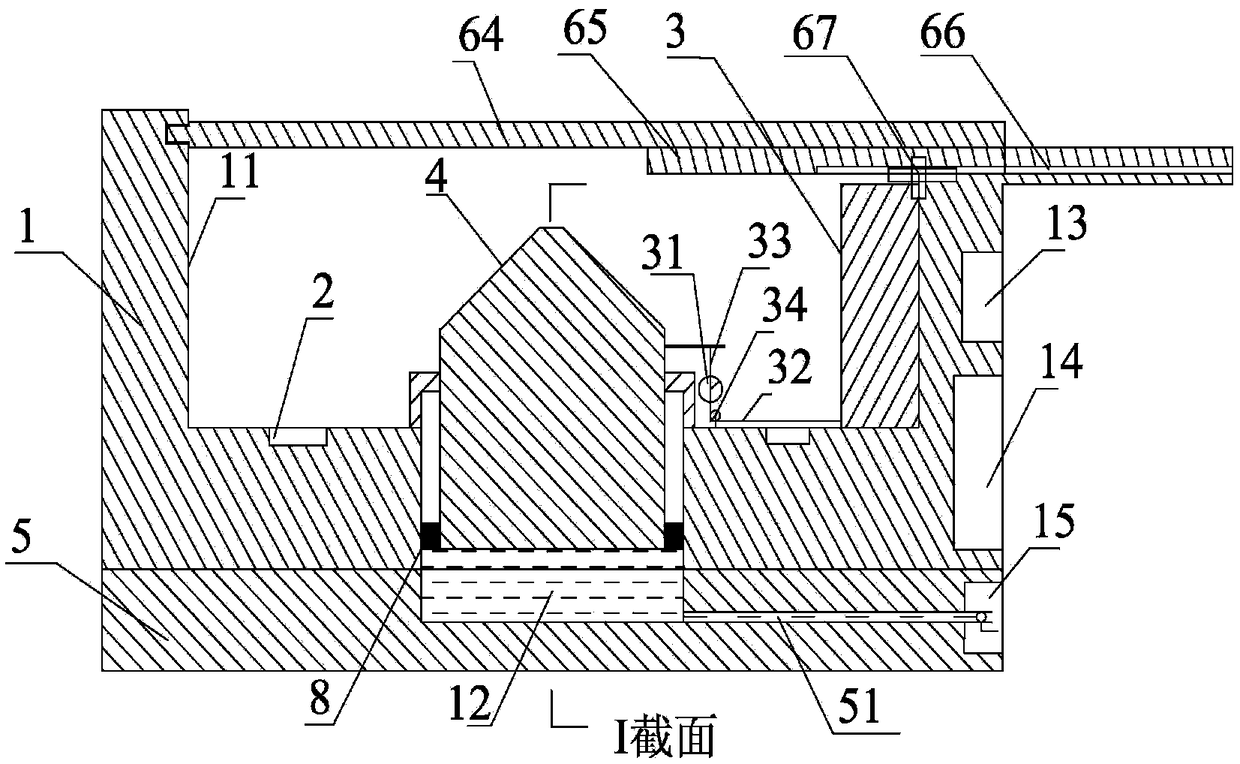

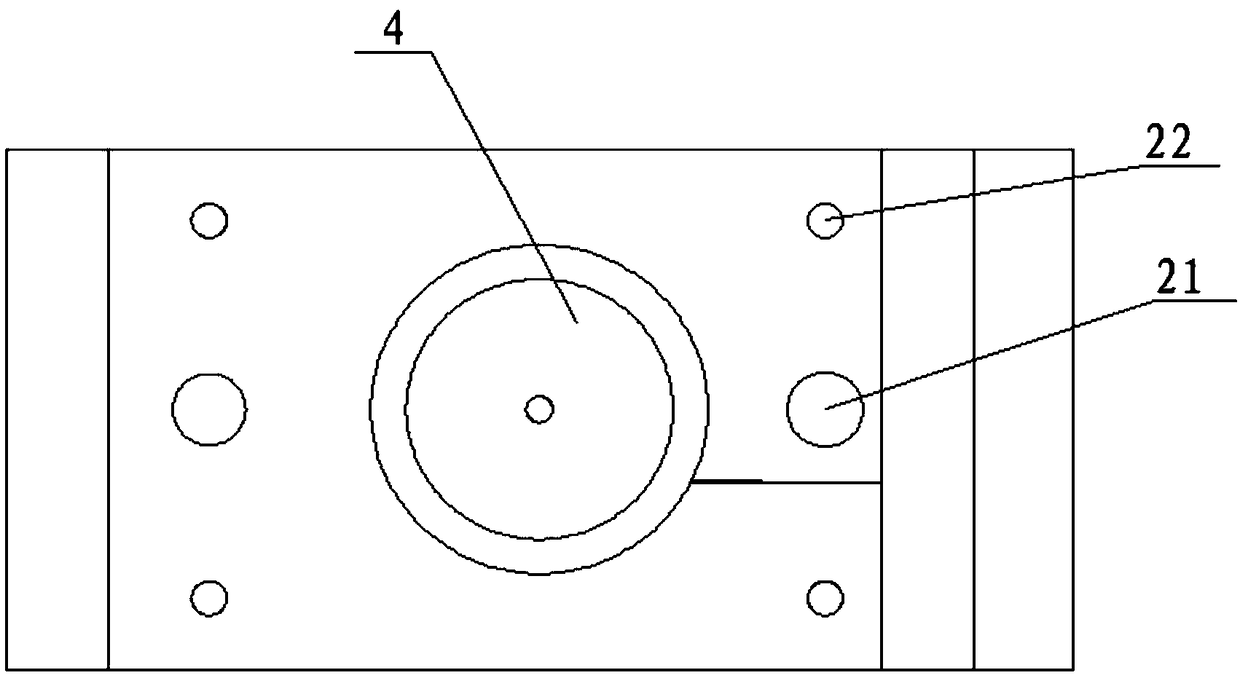

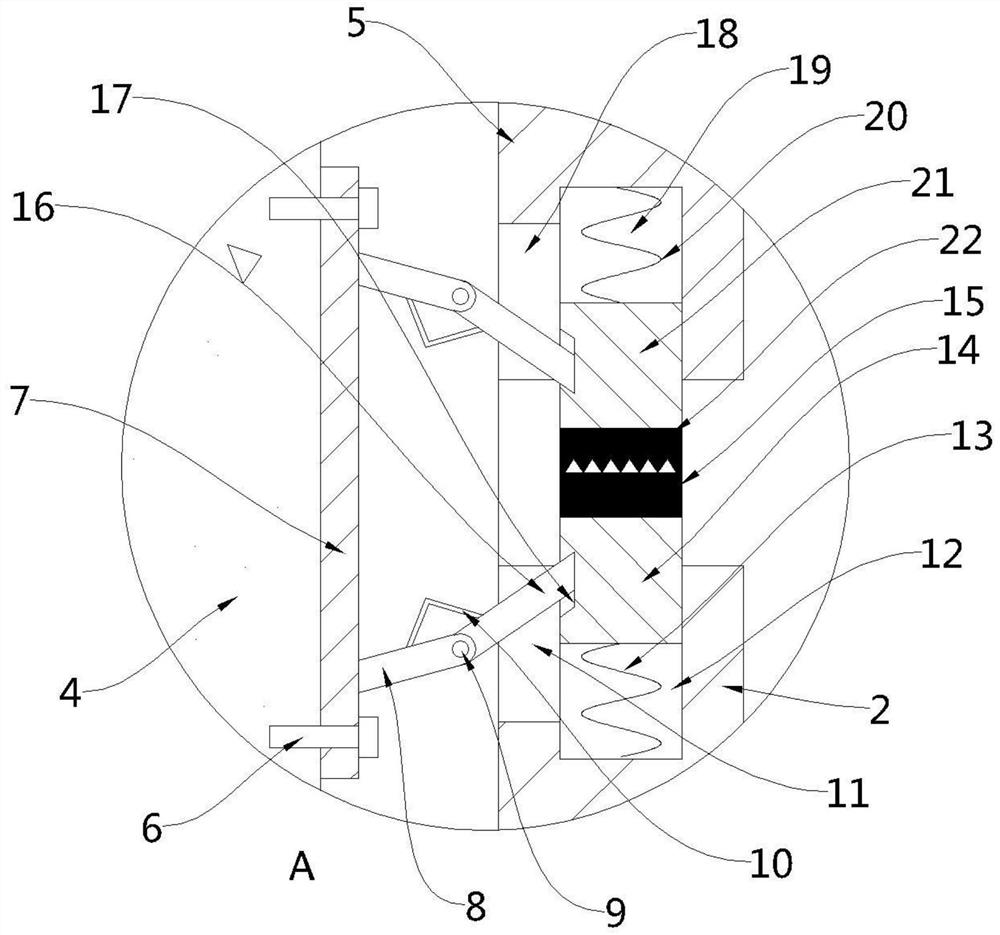

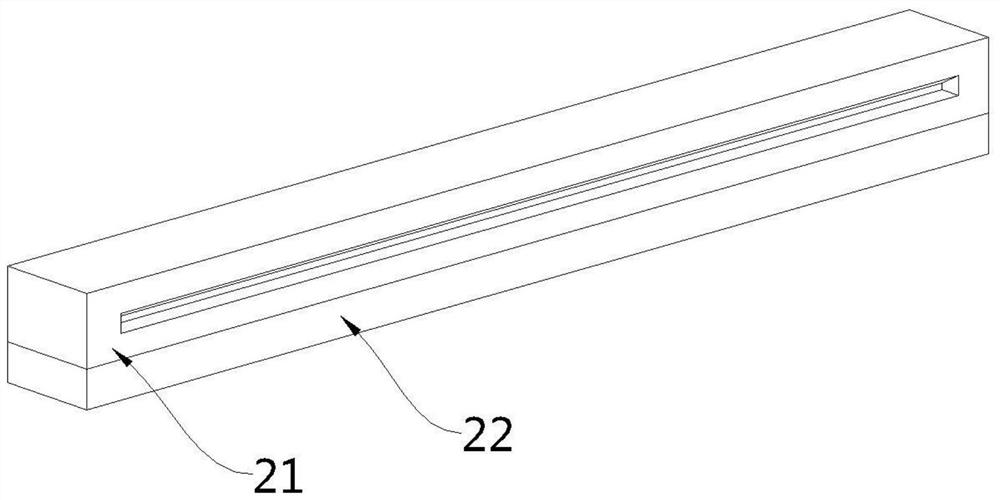

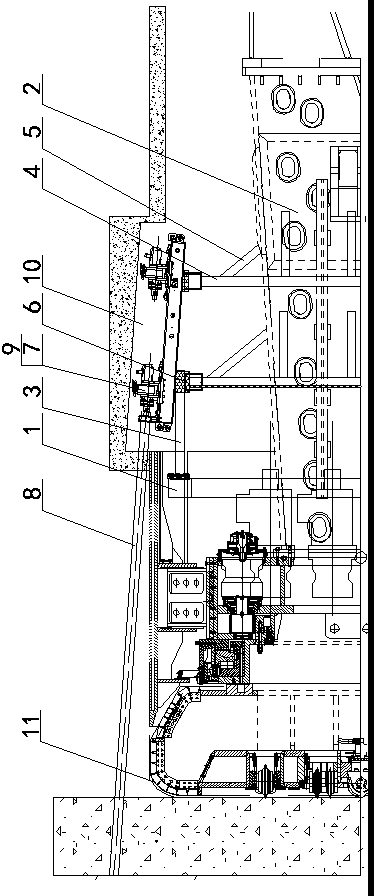

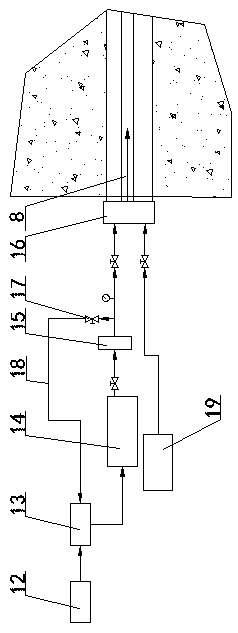

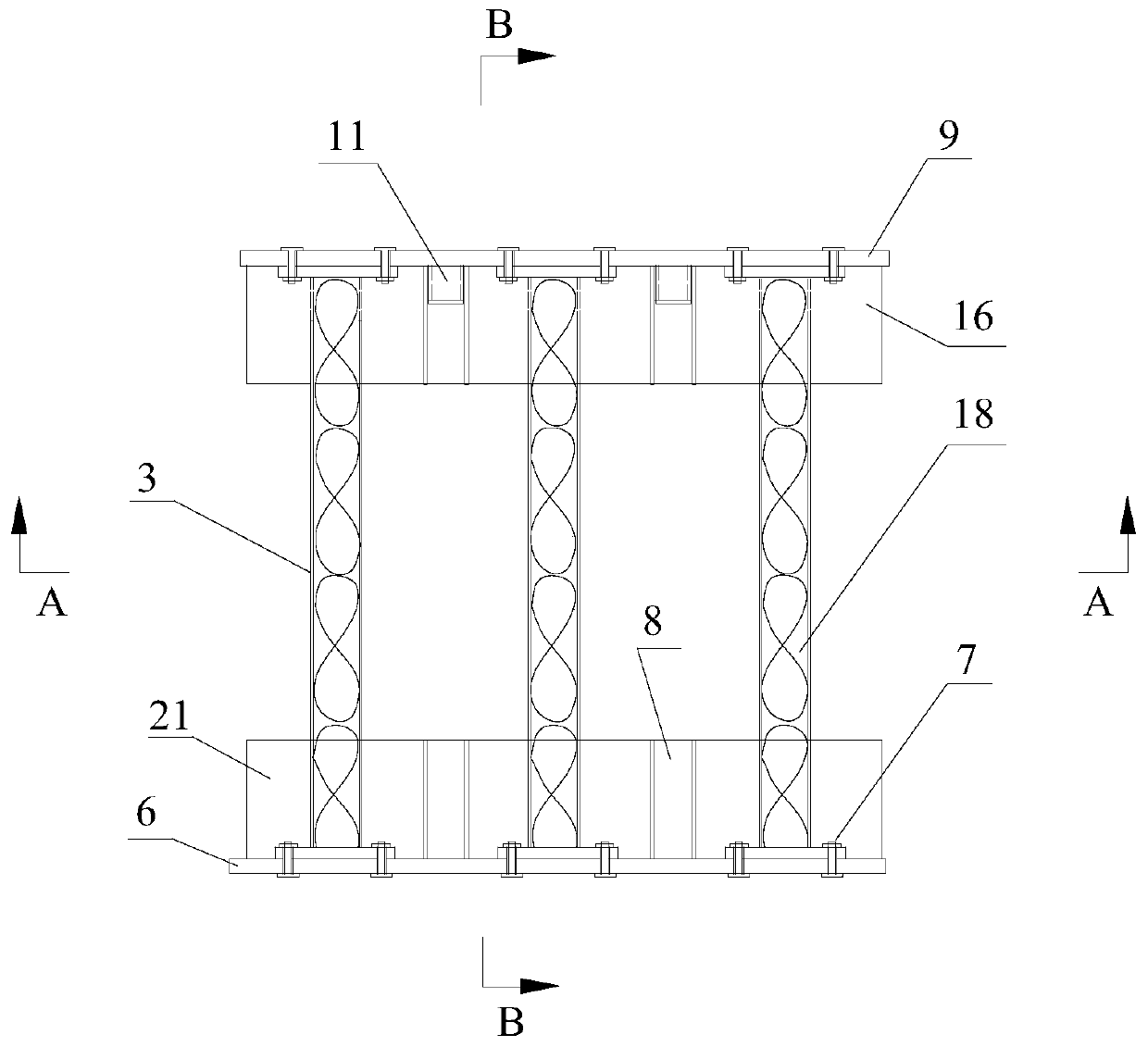

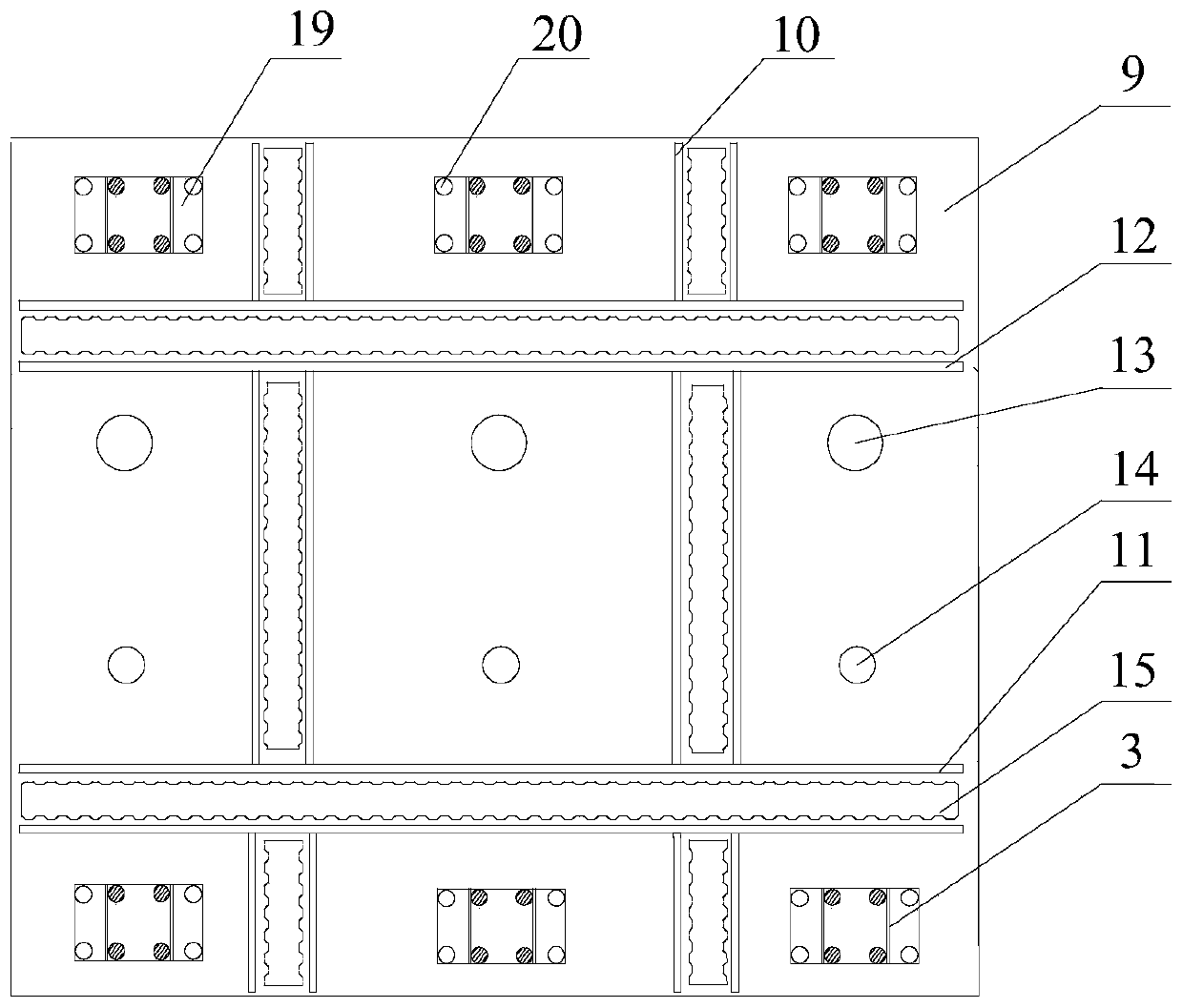

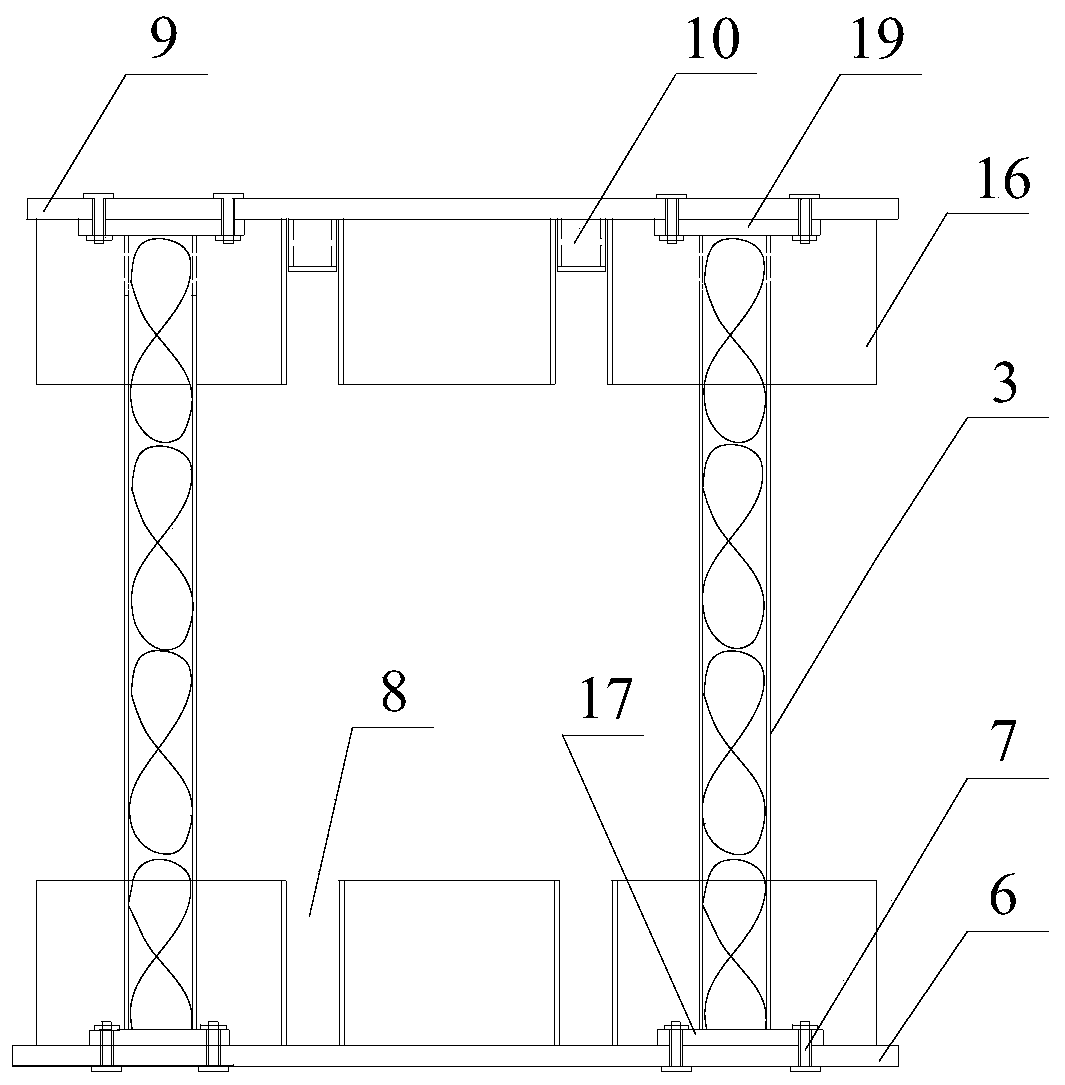

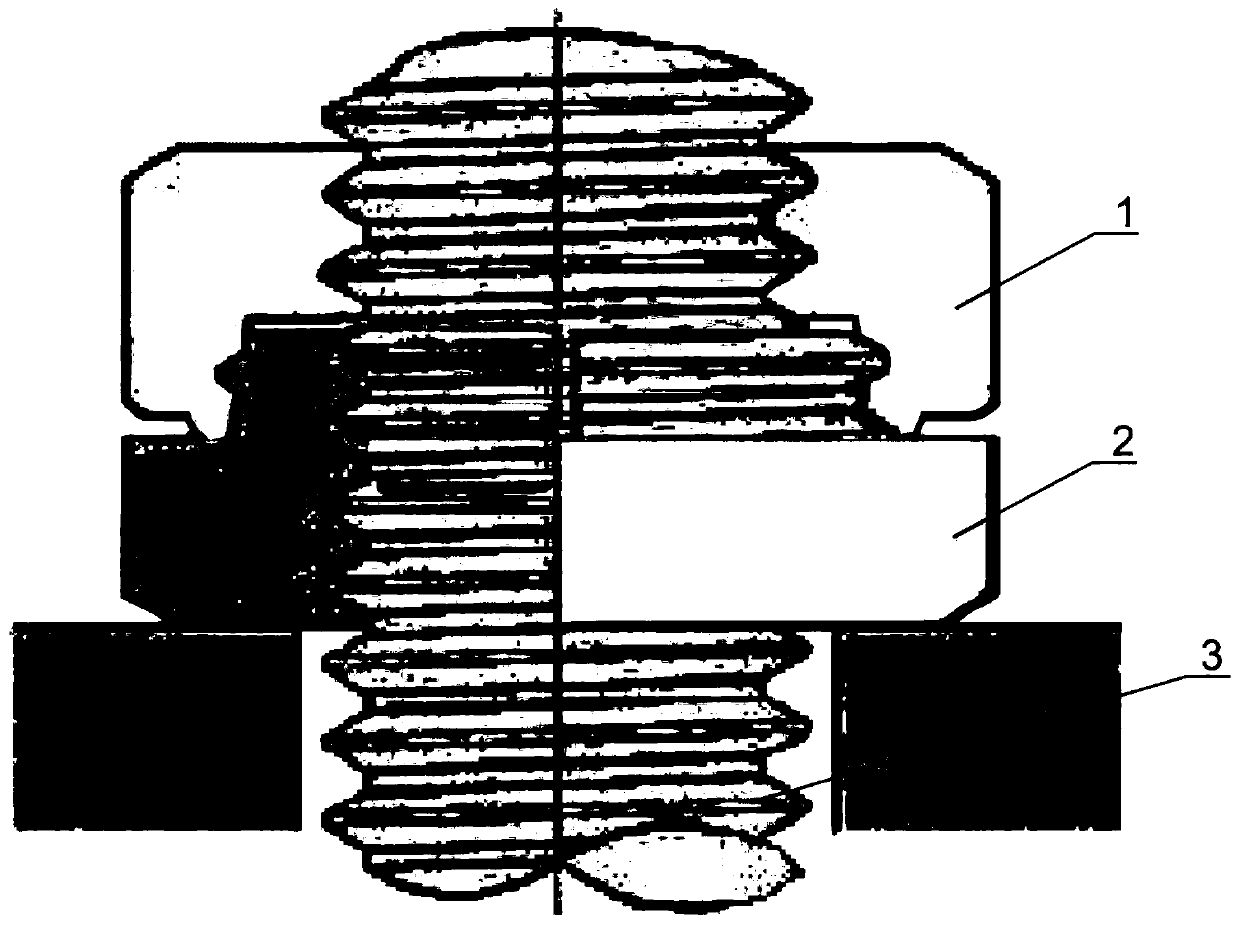

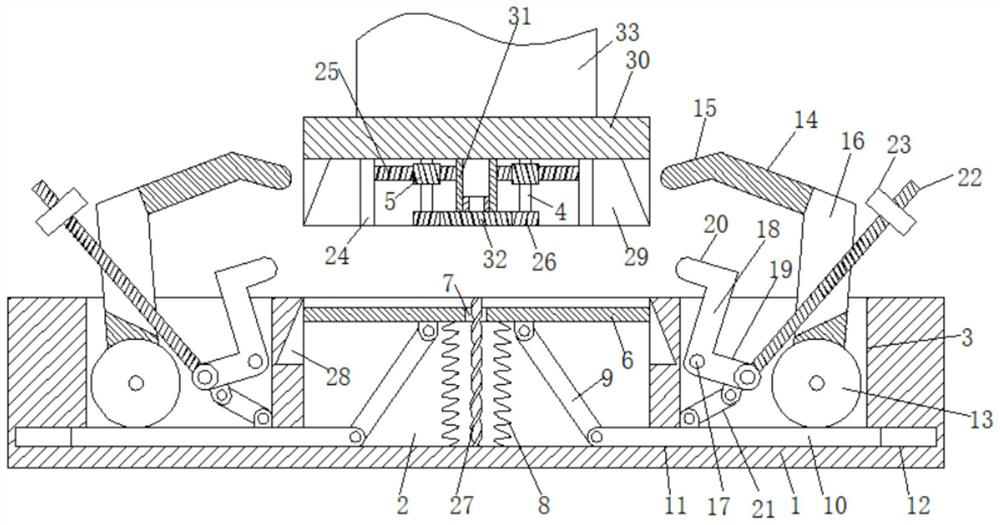

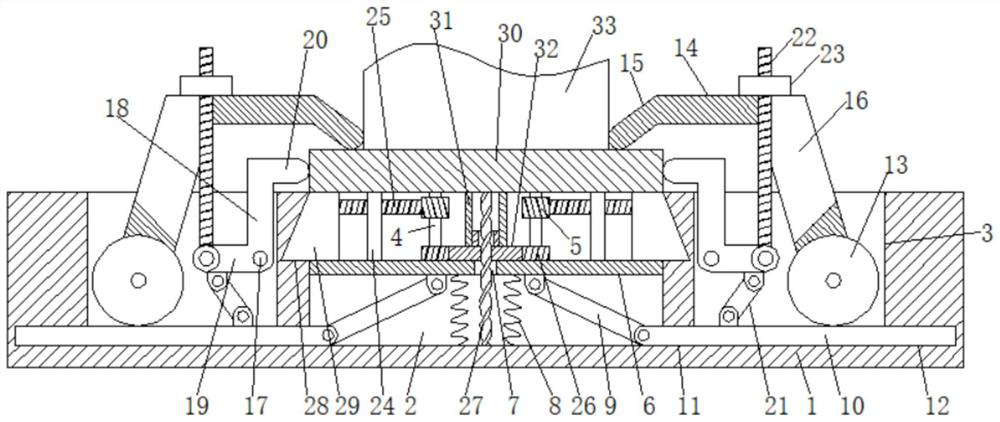

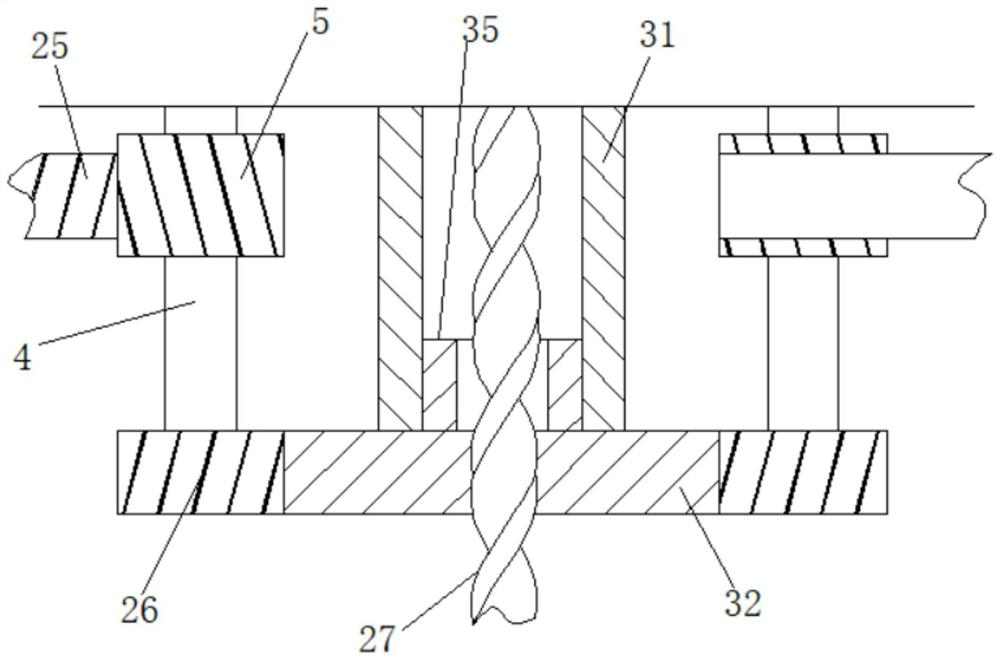

Simulation test system for gas extraction from tectonically-deformed coal seam in-situ by depressurizing horizontal well cavity

ActiveUS20200318476A1Increase the diameterAvoid problemsSurveyMining devicesCoal measuresThermodynamics

A simulation test system for gas extraction from a tectonically-deformed coal seam in-situ by depressurizing a horizontal well cavity. A coal series stratum structure reconstruction and similar material simulation subsystem simulates a tectonically-deformed coal reservoir. A horizontal well drilling and reaming simulation subsystem constructs a U-shaped well in which a horizontal well adjoins a vertical well, and performs a reaming process on a horizontal section thereof. A horizontal well hole-collapse cavity-construction depressurization excitation simulation subsystem performs pressure-pulse excitation and stress release on the horizontal well, and hydraulically displaces a coal-liquid-gas mixture such that the mixture is conveyed towards a vertical well section. A product lifting simulation subsystem further pulverizes the coal and lifts the mixture. A gas-liquid-solid separation simulation subsystem separates the coal, liquid and gas. A monitoring and control subsystem detects and controls the operation and the execution processes of equipment in real time.

Owner:CHINA UNIV OF MINING & TECH +4

Low type bidirectional pressure regulating tower

ActiveCN101037870ALower the altitudeLow costPipe elementsService pipe systemsPressure risePressboard

The invention discloses a low type bidirectional pressure regulating tower which comprises an upper case body and a lower case body with a seal ring, the lower case body is provided with a movement control assembly and a fixing tower ring with a seal ring, the movement control assembly is composed of a diaphragm pressboard, a control diaphragm, a guide piston, a spring, a piston rod and a one-way seal board. The control diaphragm is tightly pressed on the guide piston by the diaphragm pressboard, and the peripheral edge of the control diaphragm is tightly pressed on the lower case body by the upper case body, the one-way seal board is fixedly coupled with the piston rod integrally, and the lower end surface of the one-way seal board pressed on the seal valve seat of the guide piston by a spring baffle and the spring, while the upper end surface of the one-way seal board is pressed on the fixing tower ring. By arranging the guide piston, the invention can greatly lower the height of the bidirectional pressure regulating tower which must be arranged according to the height of the water line, save the engineering cost, lower or eliminate the water hammer pressure rising in the pipe, thereby preventing the pressure pipe from damage caused by bearing overhigh water pressure, or supplementing the collapsing cavity possibly generated by negative pressure to prevent the possible water hammer due to cavity collapsing.

Owner:杨硕

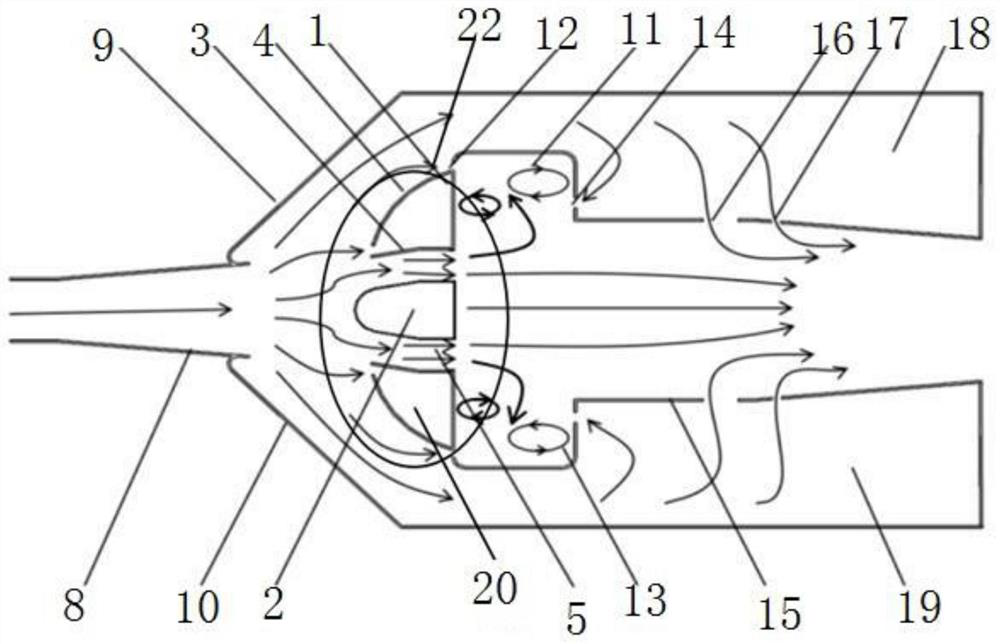

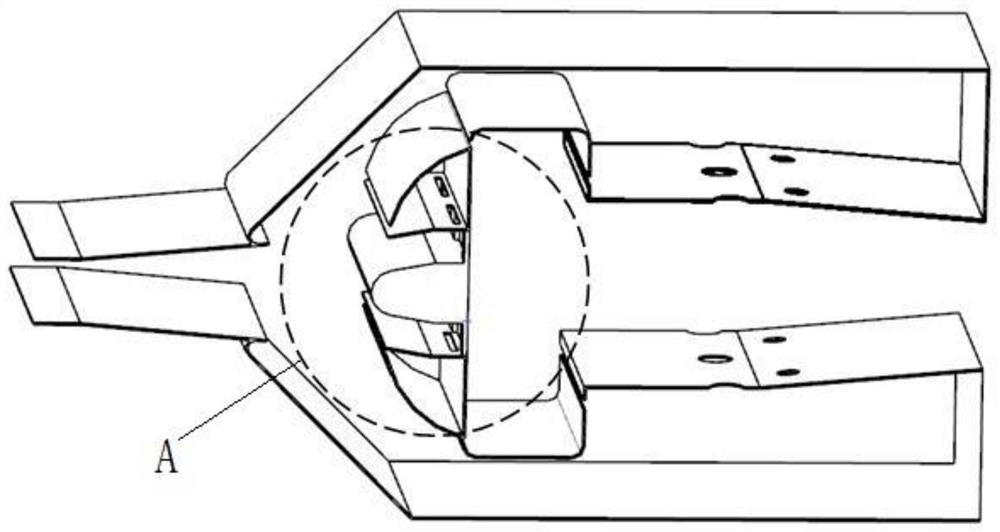

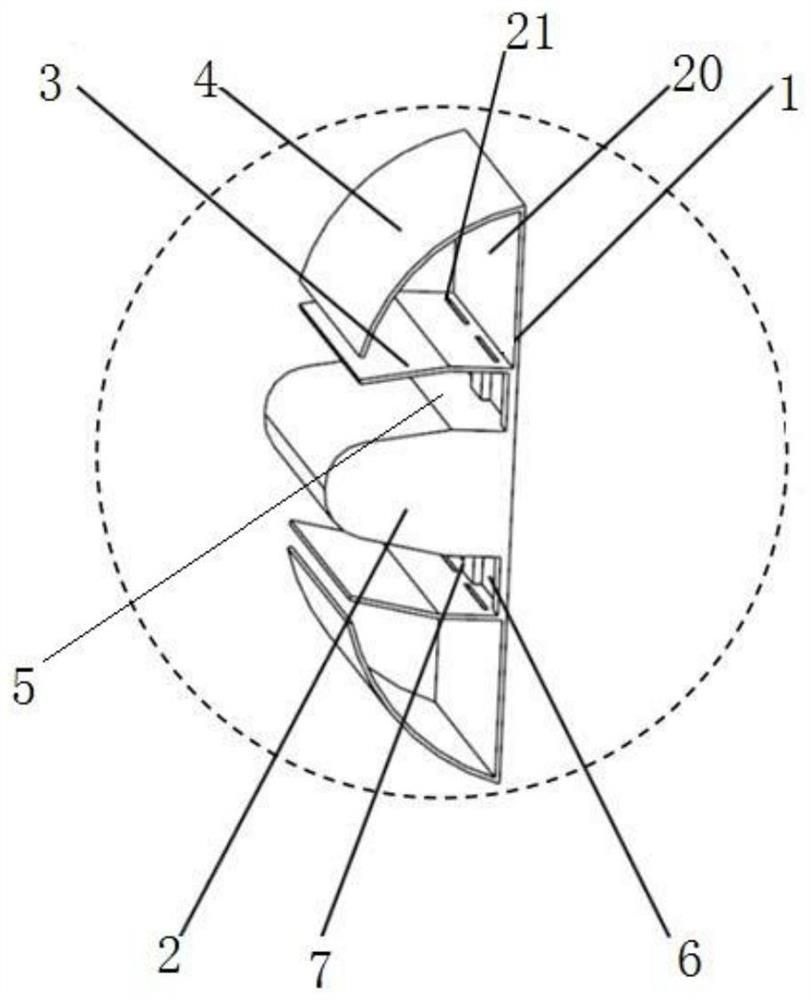

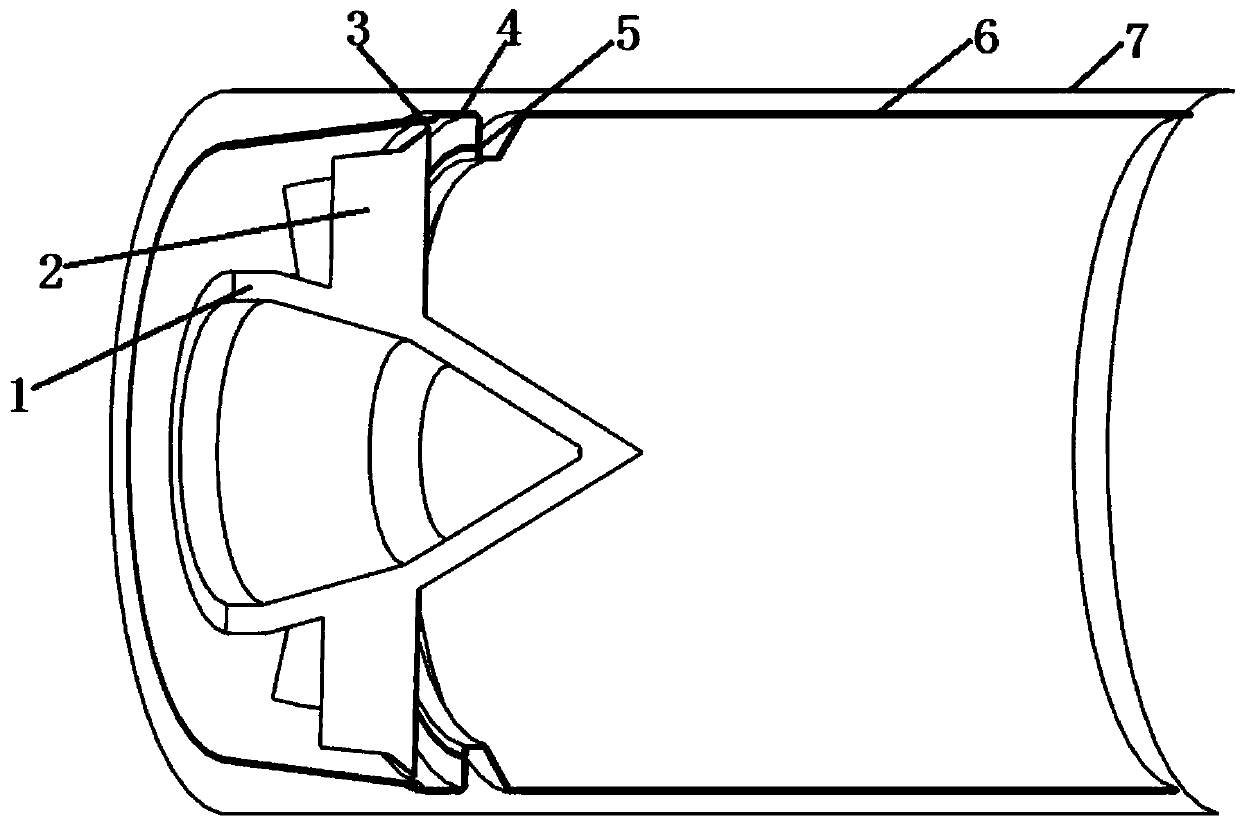

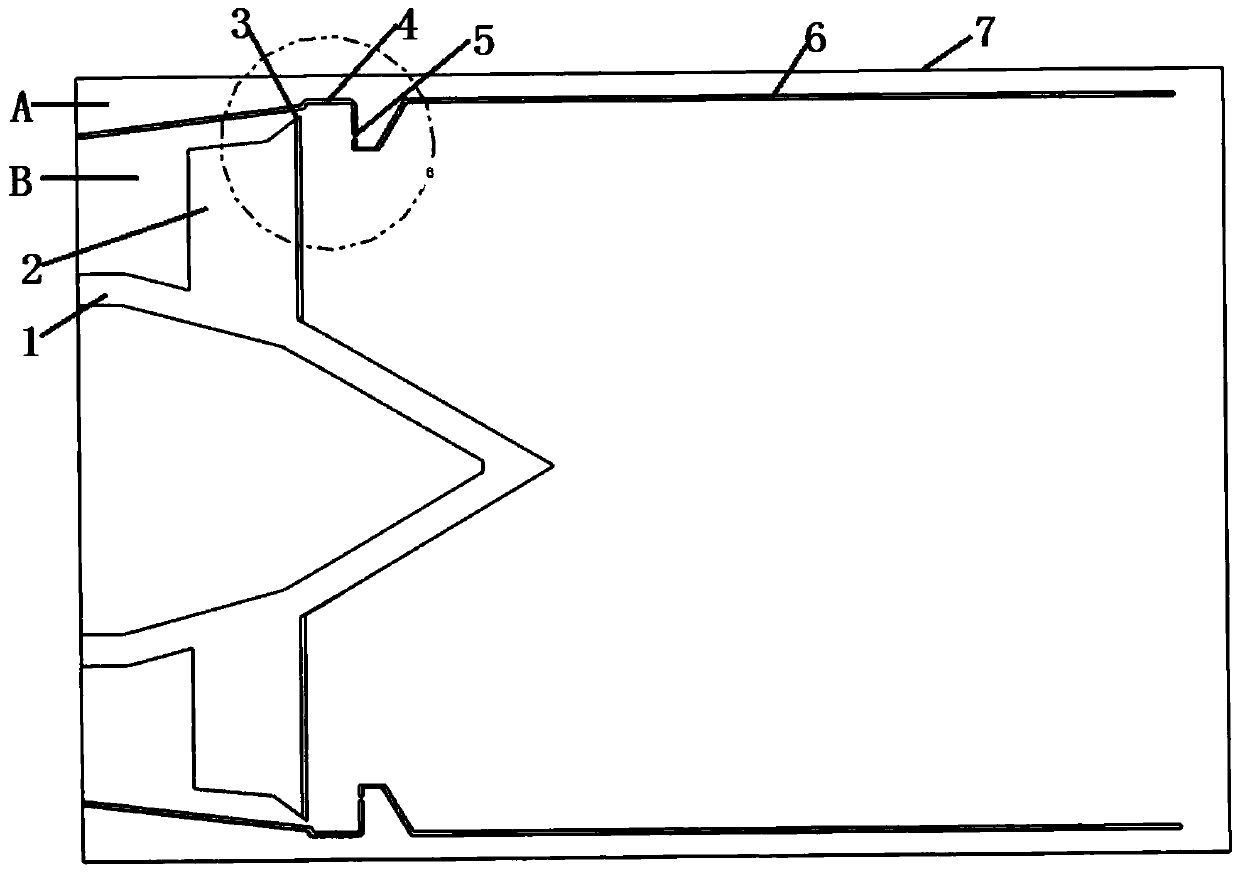

Trapped vortex combustor head device for preventing main flow from being entrained towards cavity

ActiveCN112610982AReduce structural weightSuppressed forced entrainmentContinuous combustion chamberCombustorCollapsed cavity

The invention discloses a trapped vortex combustor head device for preventing main flow from being entrained towards a cavity. The front wall face of the cavity in the device, a central bluff body, a flow guide plate, a supporting plate and a cap form an integrated structure; the front wall face of the cavity, the flow guide plate and the cap form a cavity structure; an air inlet seam for making the cavity structure communicate with a main flow channel is formed in the flow guide plate; and air in the cavity structure is jetted by the air inlet seam into the main flow channel in the direction perpendicular to the main flow channel. By reasonably designing and arranging the air inlet seam of the flow guide plate, the entrainment, caused by the supporting plate, of partial air towards the cavity can be effectively prevented, the influence of entrainment air on the flow field in the cavity is further reduced, and the cavity can stabilize flame at a higher main flow rate. Meanwhile, the burden of the head device can be reduced, and therefore, the structural weight of the whole combustor is reduced.

Owner:JIANGSU UNIV OF SCI & TECH +1

Cavity trapped vortex and rectifying support plate combined type integrated afterburner

InactiveCN109539309AStable reflux strengthShorten the lengthContinuous combustion chamberCombustion chamberEngineering

The invention provides a cavity trapped vortex and rectifying support plate combined type integrated afterburner. The ignition stability can be improved effectively, and the swirling intensity of a backflow area and the fuel atomization effect are improved, so that the combustion efficiency and stability are improved. A rectifying support plate flame stabilizer is combined with cavity trapped vortex; on one hand, air flow of inner and outer ducts enters a cavity from different positions, and a trapped vortex area is formed; duty-level flame is generated, so that mixed gas of a main flow area is ignited; on the other hand, a stable main backflow area with a certain gas backflow amount and in an appropriate size is formed downstream; and ignited high-temperature air and air in the outer ductare promoted to mix, and play a role in rectification and stabilization of combustion. The integrated afterburner has the advantages that the structural design of a cavity duty stabilizer is added atthe rear edge of the rectifying support plate flame stabilizer on the original basis of the integrated afterburner, and the ignition ability under the rich oil and high altitude conditions can be improved effectively; and the high combustion stability and efficiency are ensured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

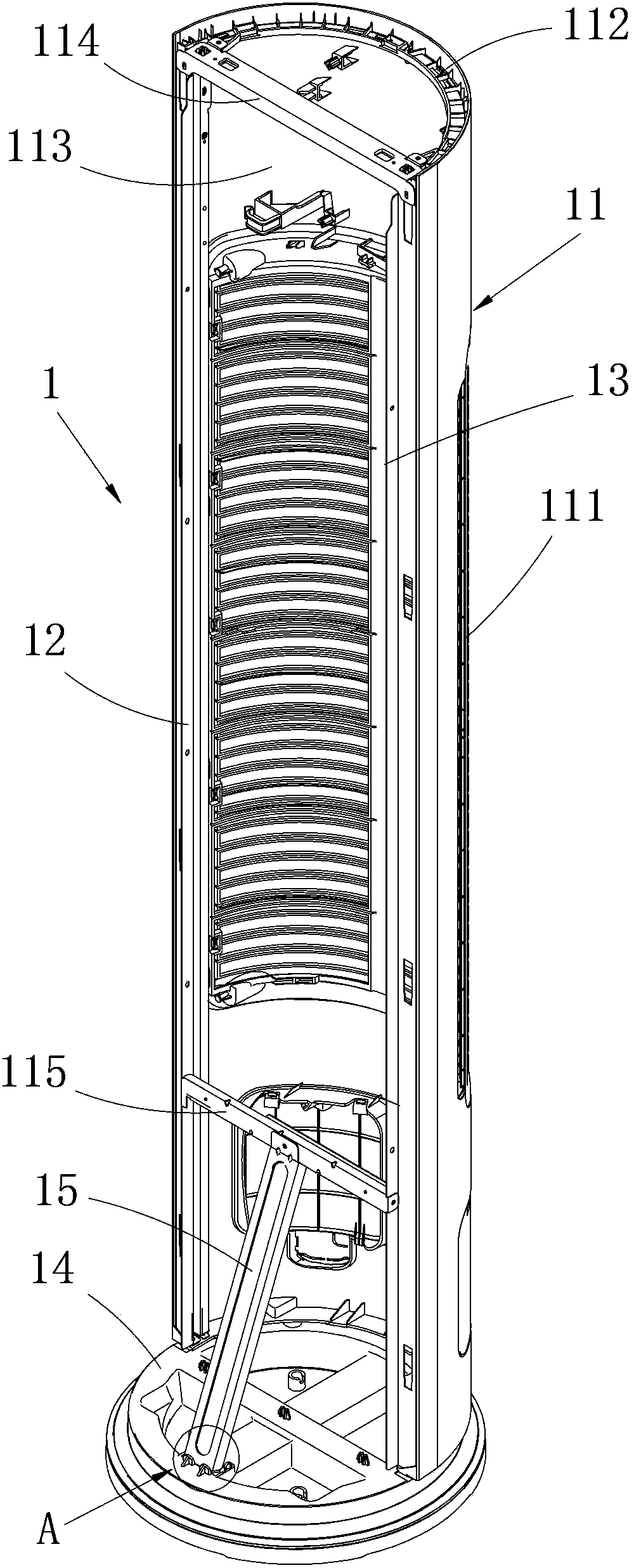

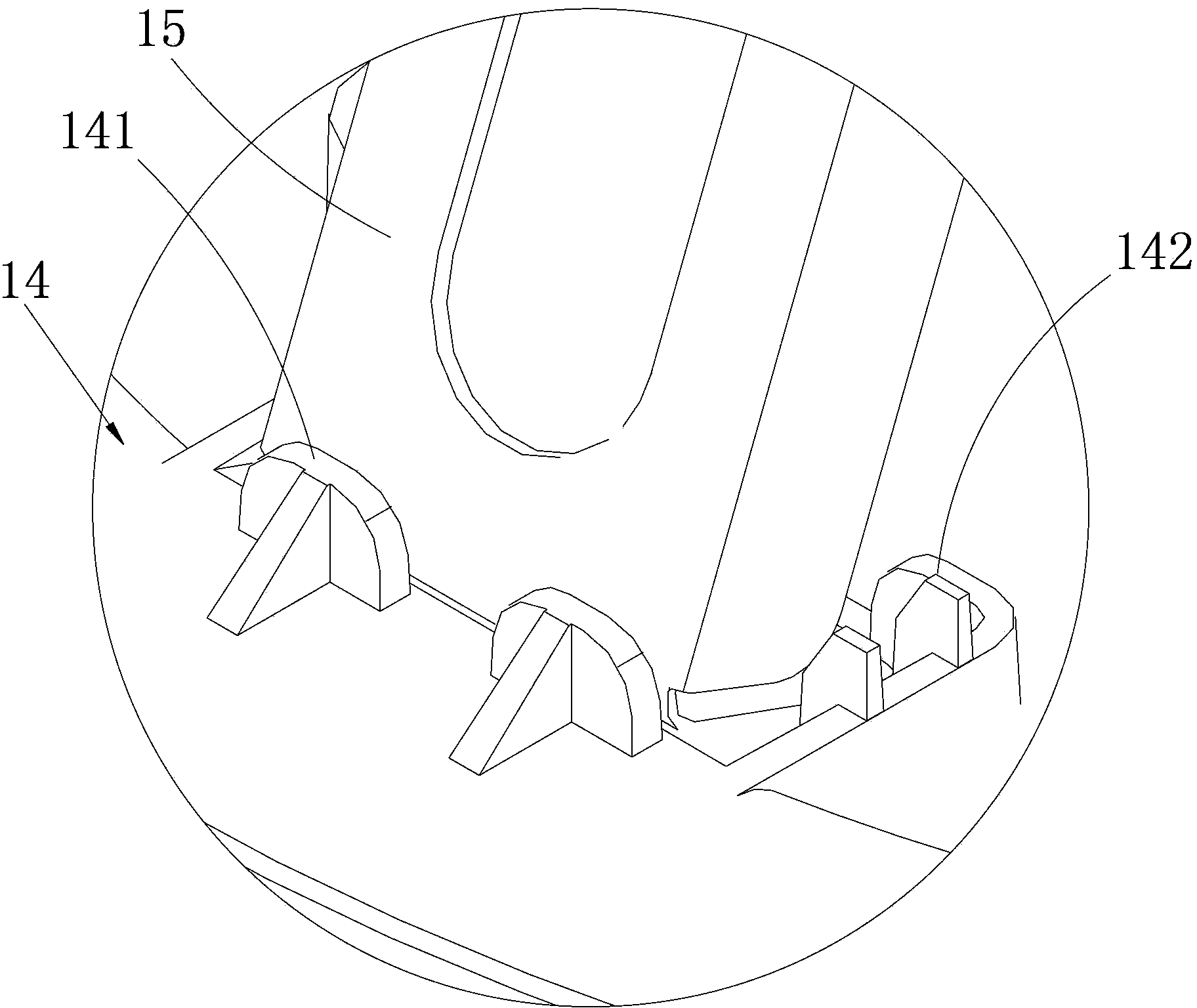

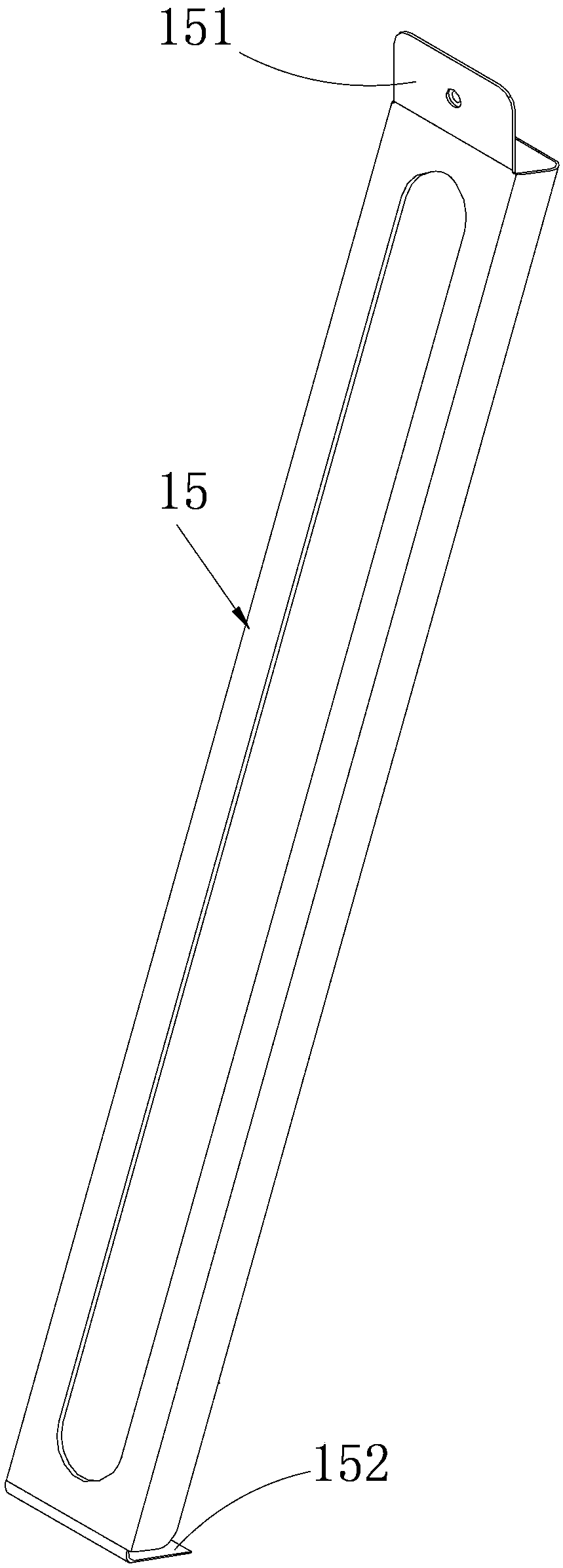

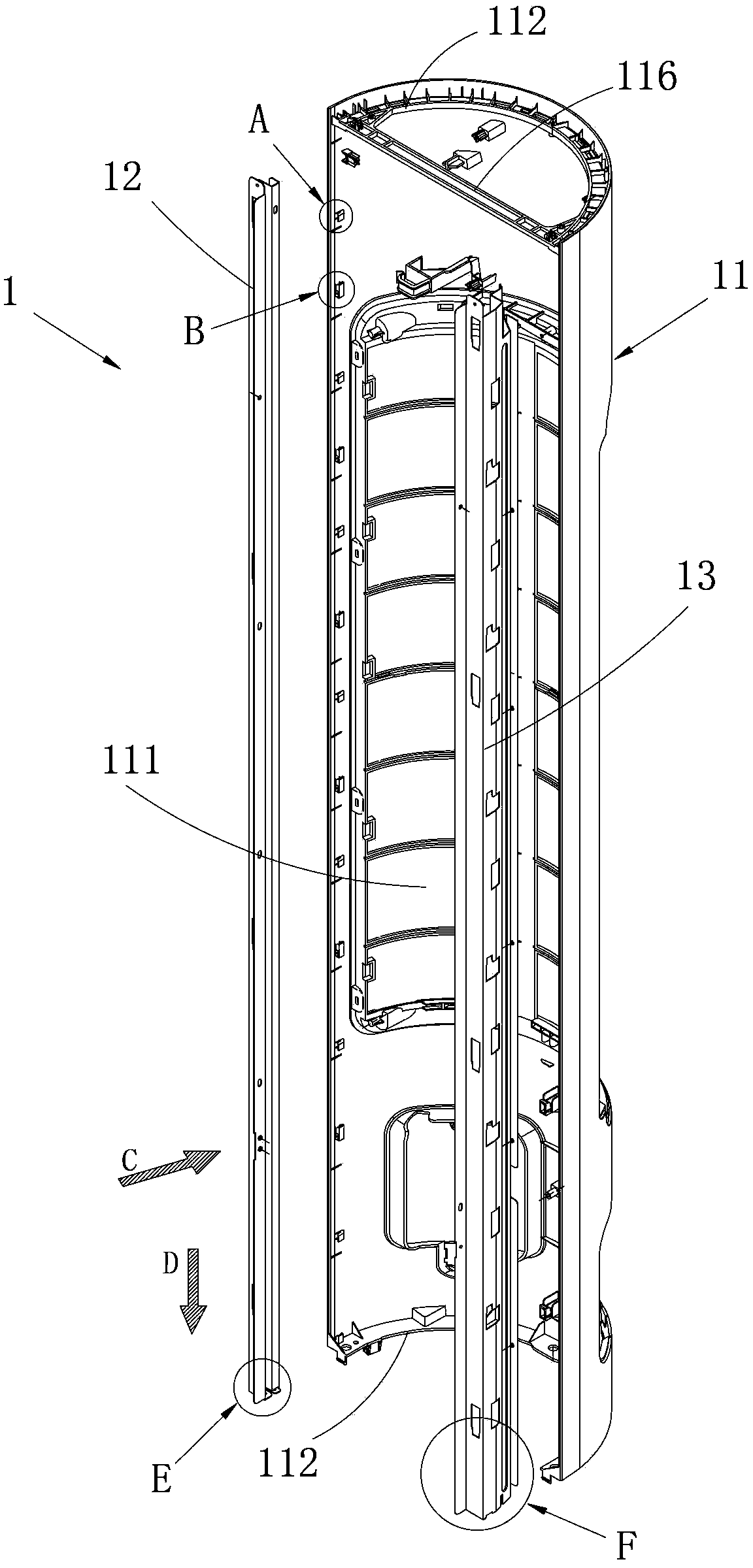

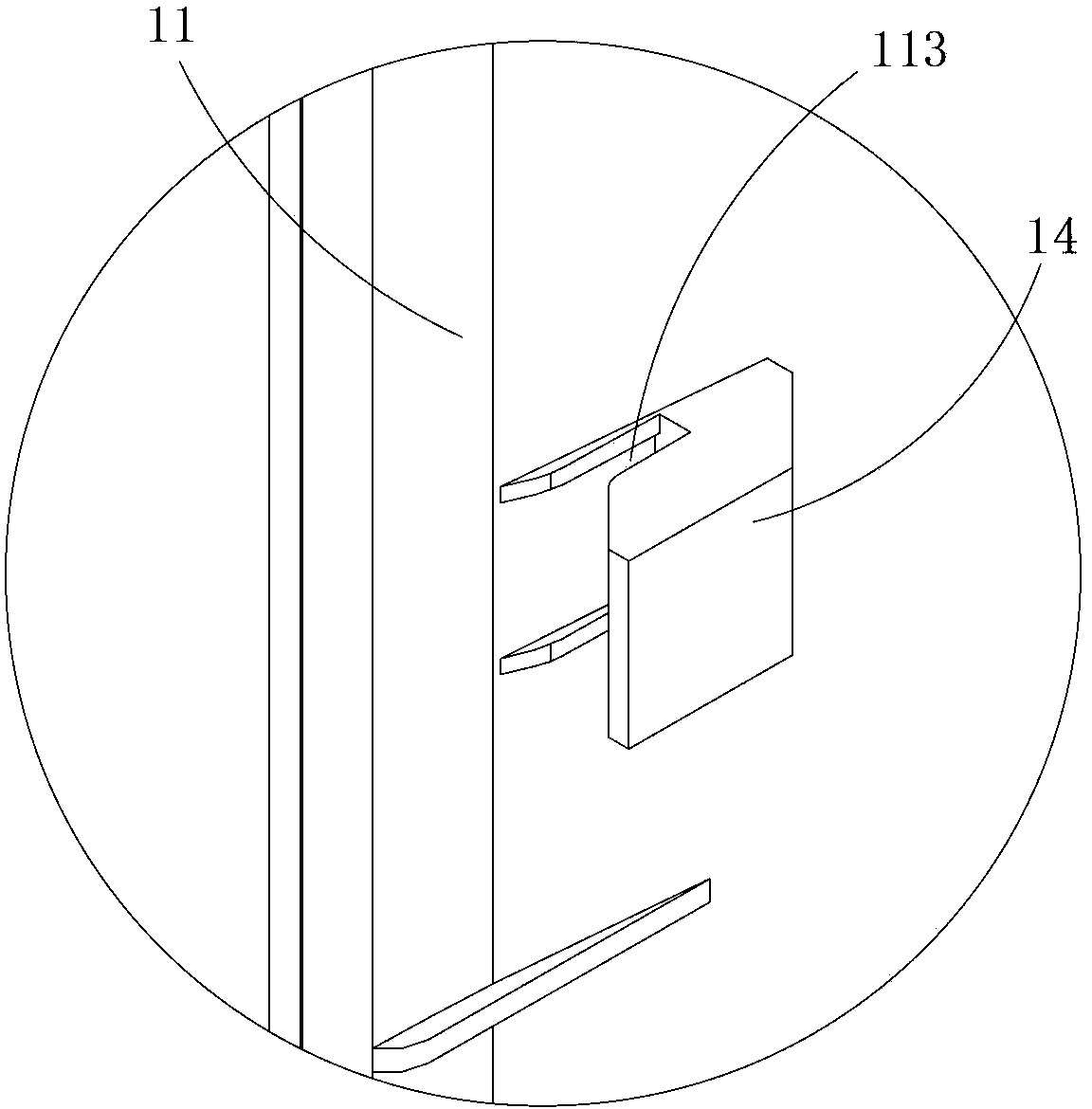

Anti-tipping floor type tank and air conditioner

ActiveCN103375903AStable positionAvoid shakingHeating and ventilation casings/coversGravity centerFloor type

The invention relates to the technical field of air conditioner manufacture, and discloses an anti-tipping floor type tank and an air conditioner comprising the same. The tank comprises a rear tank shell and a base plate, the lower end of the rear tank shell is connected to the base plate, the front end of the rear tank shell is provided with a cavity with an opening, the opening of the cavity is provided with a lower connecting strip and a supporting component, two ends of the lower connecting strip are connected to two sides of the opening of the cavity respectively, the upper end of the supporting component is connected to the lower connecting strip, the lower end of the supporting component is inclined forwards, and the supporting component is positioned below the gravity center of the tank. As the supporting component is arranged at the opening of the cavity of the rear tank shell of the floor type tank, when pushing force is externally acted on the tank, the horizontal component of supporting force generated by the supporting component can offset the pushing force, the direction of the vertical component of the supporting force is consistent with that of the gravity of the tank, shake and even tipping of the tank are avoided, and the tank has an anti-tipping performance. The tank is applied to the air conditioner, the tank can be prevented from shaking or tipping and the like when a user touches a touch screen with a hand, and the air conditioner can be stably placed.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

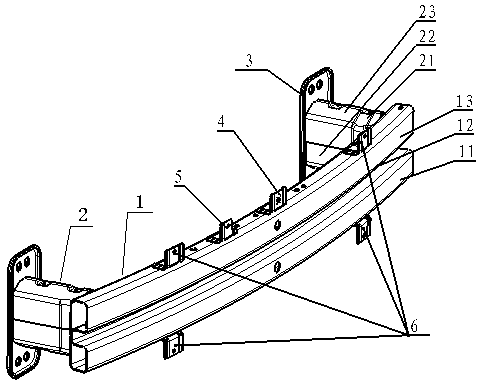

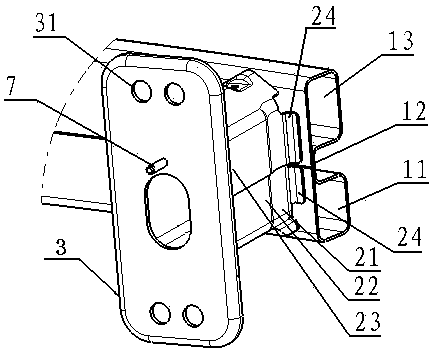

Automobile front anti-collision beam structure

InactiveCN104249695AReduce the degree of lossImprove buffering effectBumpersCollapsed cavityEngineering

The invention discloses an automobile front anti-collision beam structure. The automobile front anti-collision beam structure comprises a cross beam, energy absorbing boxes and a bracket plate, wherein two energy absorbing boxes are provided, and are respectively positioned at the two ends of the cross beam; one ends of the energy absorbing boxes are in positioned connection with the cross beam, and the other ends of the energy absorbing boxes are in positioned connection with one side of the bracket plate; the other side of the bracket plate is in positioned connection with a longitudinal beam; the cross beam is a pipe-shaped structure; the middle part of the outer side of the cross beam is inwards recessed to form a joint surface; and the joint surface is contacted with the side wall of the inner side of the cross beam, so that the cross beam becomes two collapse cavities vertically arranged. The automobile front anti-collision beam structure can effectively protect an automobile to reduce the damage degree in the automobile collision, can achieve the protection effect on pedestrians, and reduces the arrangement pressure of an engine cabin space.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Floor type rear box structure and air conditioner

ActiveCN103375902AGuaranteed StrengthEasy to manufactureHeating and ventilation casings/coversEngineeringUltimate tensile strength

The invention relates to the technical field of manufacture of air conditioners, and discloses a floor type rear box structure and an air conditioner. The rear box structure comprises a box shell, an opening cavity is formed in the rear end of the box shell, the inner sides of two side walls of an opening of the cavity are respectively connected with stiffeners completely extending along the height direction of the box shell, the stiffeners are connected onto the side walls of the box shell through fastening structures for limiting the stiffeners in front, back, left and right movement relative to the box shell, the upper ends and the lower ends of the stiffeners extend to the upper end and the lower end of the box shell respectively and are fixedly connected with the upper end and the lower end of the box shell respectively, and the stiffeners completely and fixedly cling to the box shell. Therefore, the overall strength of the box shell is ensured, a complicated supporting structure arranged in the cavity is omitted, the rear box structure is simple to manufacture and assemble, and cost is greatly reduced. Besides, deformation of the side walls of the opening of the cavity can be corrected.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

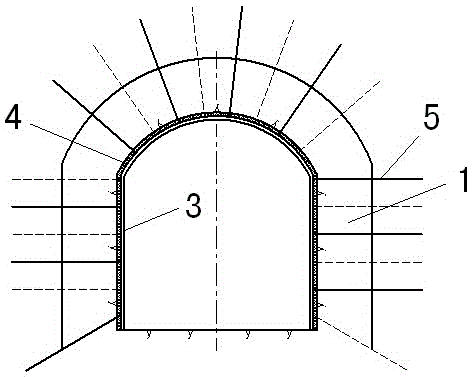

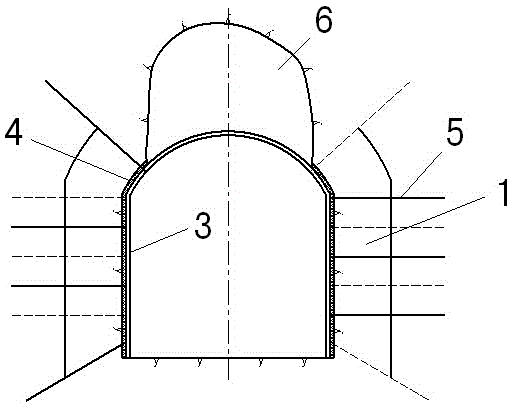

Tunnel collapse disposing method and tunnel collapse support structure

InactiveCN105065038ASolve the problem of further expansion of the collapse trendMeet the needs of the projectUnderground chambersTunnel liningCollapsed cavityArchitectural engineering

The invention discloses a tunnel collapse disposing method and a tunnel collapse support structure. The method is characterized in that an arch-on-arch structure corresponding to the shape and the range of a collapse cavity is arranged on the top of a steel arch frame of a primary support; the collapse cavity is supported through the arch-on-arch structure; and meanwhile, network concrete and anchor rods are used in an auxiliary way, so that the further enlargement of the collapse is prevented. Through the arrangement of the arch-on-arch structure on the top of the steel arch frame, the problems that the collapse cavity stress continuously changes and the collapse cavity trend is further enlarged are effectively solved; through engineering measures, the engineering requirements are met; the engineering investment is reduced; and the engineering construction period is shortened.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

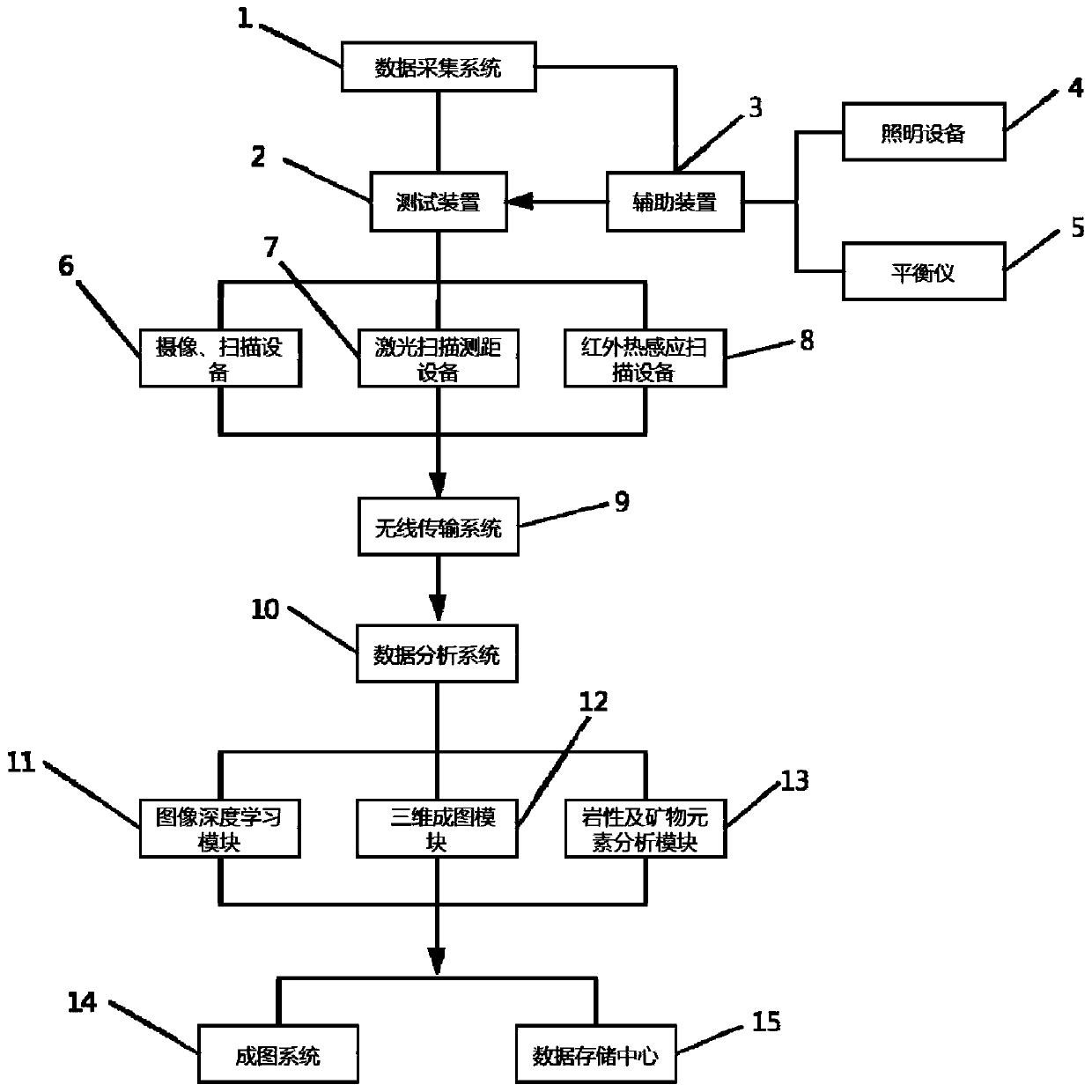

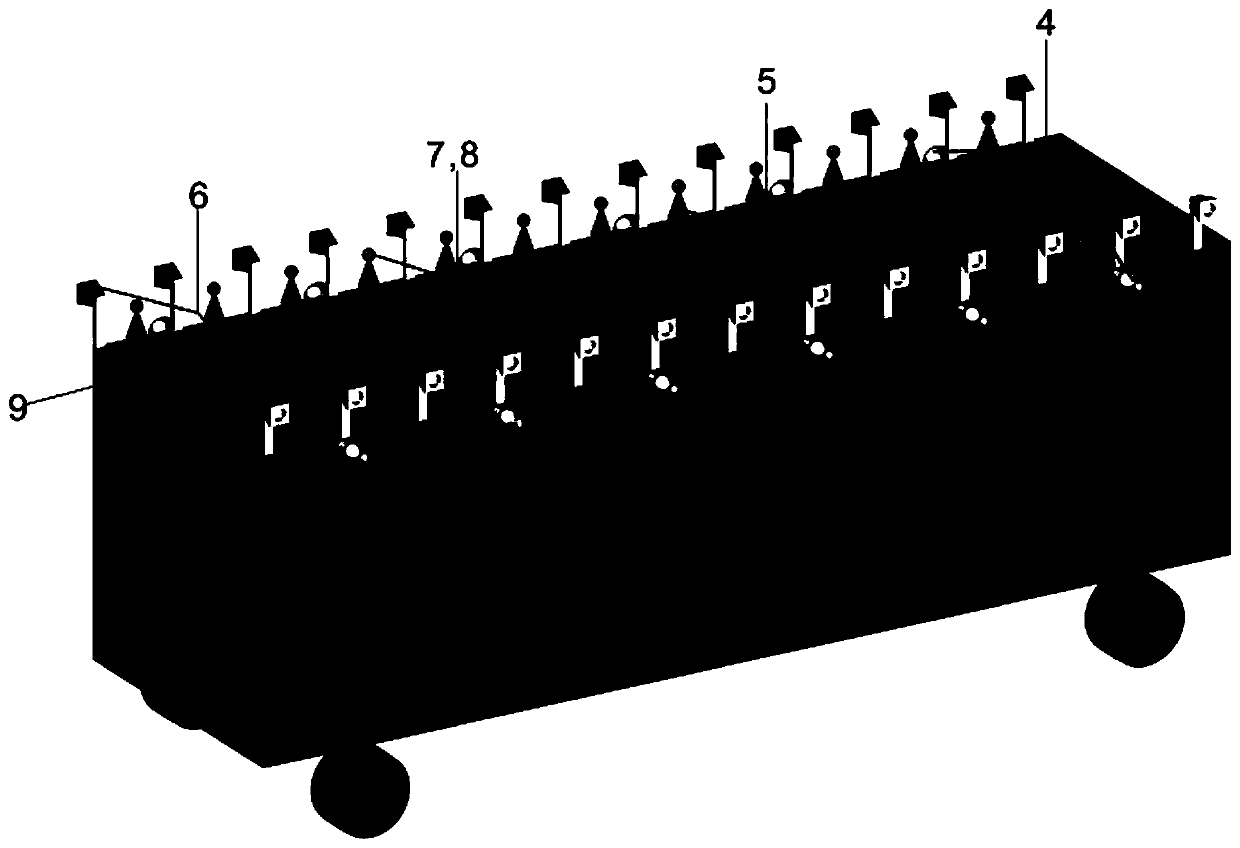

Vehicle-mounted tunnel geological sketch device and application method thereof

PendingCN110850435ATake advantage ofLabor savingImage enhancementTelevision system detailsLithologyCollapsed cavity

The invention provides a vehicle-mounted tunnel geological sketch device and an application method thereof. The vehicle-mounted tunnel geological sketch device comprises a data acquisition unit, wherein the data acquisition unit is arranged on a rail car in a tunnel and comprises shooting and scanning equipment, laser scanning distance-measurement equipment and infrared thermal-induction scanningequipment, the shooting and scanning equipment is arranged at two sides of the rail car and is configured to acquire an inner hole wall image of the tunnel, the shooting and scanning equipment at a single side covers the whole side wall from a vault intermediate line to one corresponding side, the laser scanning distance-measurement equipment is used for acquiring a distance from the laser scanning distance-measurement equipment to a tunnel wall, the infrared thermal-induction equipment is used for acquiring a temperature of a tunnel wall stratum, the data acquisition unit is used for transmitting the temperature to a data analysis system by a wireless transmission system, and the data analysis system is configured to analyze joint position and size and positions and sizes of a collapse cavity region and a block falling region according to a distance, acquired by the laser distance-measurement equipment, from the rail car to the tunnel wall, provide the whole three-dimensional space diagram of a tunnel, identify tunnel lithology by a trained model according to image characteristic and judge basic lithology of the stratum in the image.

Owner:SHANDONG UNIV

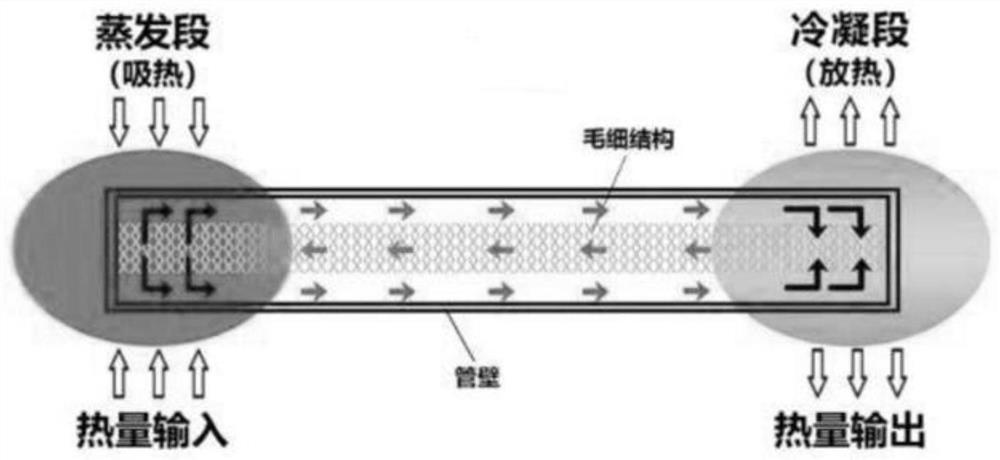

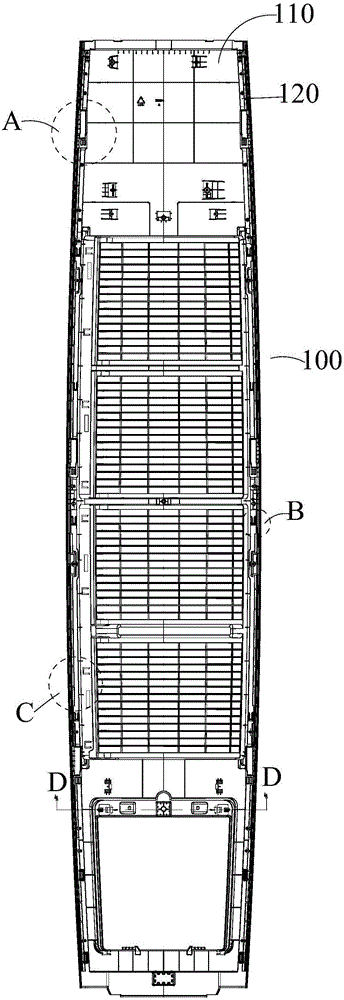

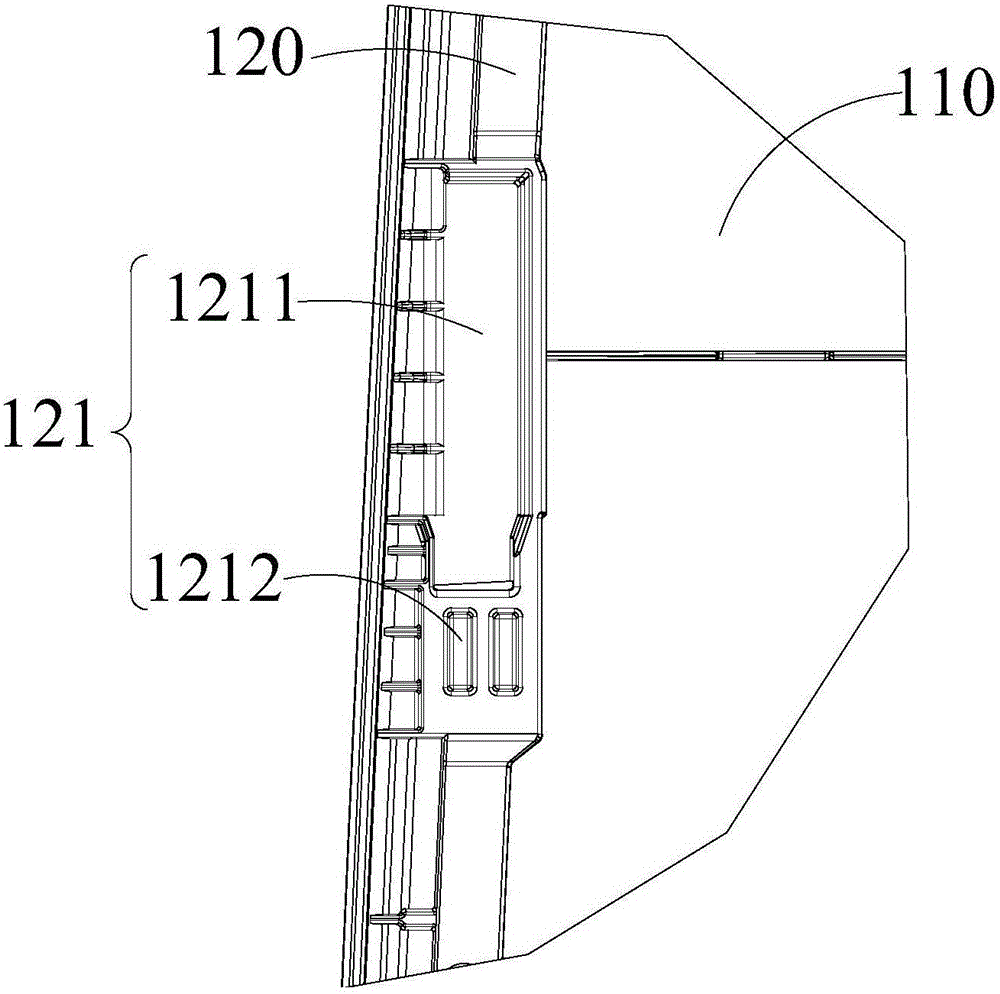

Terminal middle plate, middle frame and terminal

InactiveCN111770222AReduce thicknessReduce heat dissipationModifications using liquid coolingTelephone set constructionsCollapsed cavityEngineering

The invention provides a terminal middle plate, a middle frame and a terminal. In some embodiments, the terminal middle plate comprises a middle plate body, and, wherein a concave cavity is formed ina first surface of the middle plate body; the a sealing cover which covers the opening of the concave cavity so as to seal the concave cavity; the a capillary structure which is arranged in the concave cavity; and thea heat transfer medium which is arranged in the concave cavity, and wherein the interior of the concave cavity is in a vacuum state. According to the terminal middle plate provided bythe embodiment of the invention, the thickness of the terminal middle plate can be reduced while the heat dissipation effect is not reduced.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

Air conditioner, housing assembly and back cover thereof

InactiveCN105805920ASimple structureSimple structural designHeating and ventilation casings/coversEngineeringMechanical engineering

The invention provides a back cover. The back cover and a front cover are mounted in a matched manner to form a housing assembly. The back cover comprises a back cover body and a supporting structure, wherein an opened cavity is formed on the back cover body, and the supporting structure is arranged on the inner wall, close to the back cover body, of a periphery and extends along the edge direction of the opened cavity of the back cover body; a mounting part is arranged on the supporting structure, the back cover is matched with the front cover, and the mounting part is in contact with the front cover to fix the front cover. The back cover is matched with the back cover through the mounting part, so that the mounting part can directly connect and fix the back cover and the front cover, the phenomenon that the back cover and the front cover are connected through other parts expect the back cover is avoided, and the quantity of parts for assembling the front cover and the back cover is reduced; therefore, the structure of the housing assembly is simple, so that the assembling step of the housing assembly is further reduced, and the production efficiency is improved. The invention provides an air conditioner and the housing assembly thereof.

Owner:GREE ELECTRIC APPLIANCES INC

Method for processing tunnel collapse by using roof-contacted shield bracket

ActiveCN111365044AReduced chance of collapseStable supportUnderground chambersMine roof capsCollapsed cavityArchitectural engineering

The invention discloses a method for processing tunnel collapse by using a roof-contacted shield bracket, and relates to the technical field of tunnel engineering. The roof-contacted shield bracket isused for construction, and can adapt to depths of different collapse cavities. The method comprises the steps that a shield, stand columns and supporting columns are mounted to form a combined bracket which is moved to a construction platform, the combined bracket is jacked through an individual hydraulic supporting column installed and placed below the combined bracket, and the height of a beamis larger than the height of an outer contour of a primary branch arch. Fixed supporting columns are initiatively in touch with the surfaces of the collapse cavities and bear the surfaces of the collapse cavities, and then movable supporting columns are lifted to the tops of the collapse cavities and bear the tops of the collapse cavities. The primary branch arch, a welding primary branch arch andthe supporting columns are mounted. The supporting columns invading into the primary branch arch are cut off, and the individual hydraulic supporting column is withdrawn after shield loads are switched to stress of a primary branch canopy frame. Exhaust pipes and filling material pumping pipes are mounted, and filling materials are pumped to the space of the collapse cavities. The method has theadvantages of high level of mechanization, large bracket bearing capacity, safe and efficient construction and the like.

Owner:SHANDONG UNIV OF SCI & TECH +4

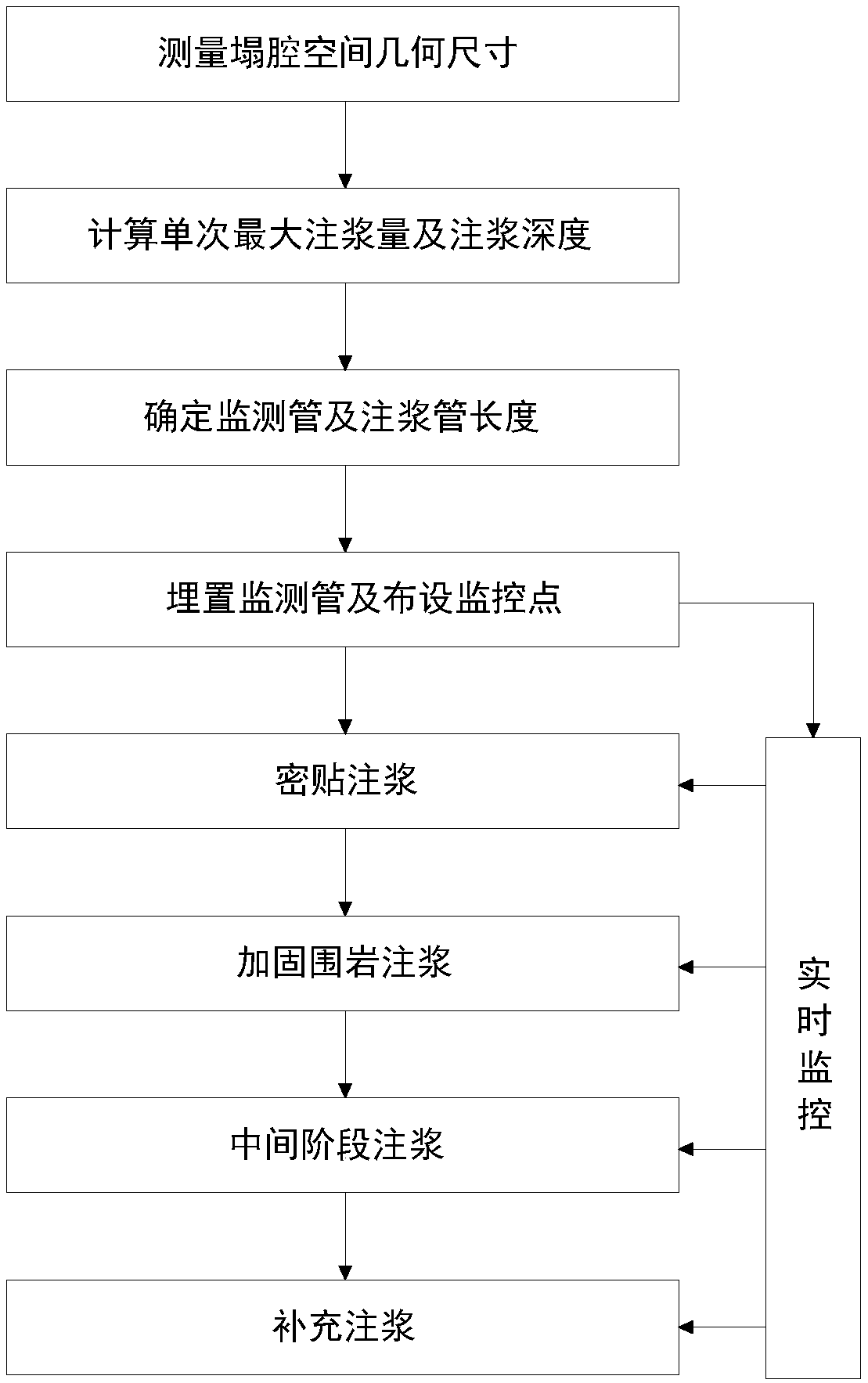

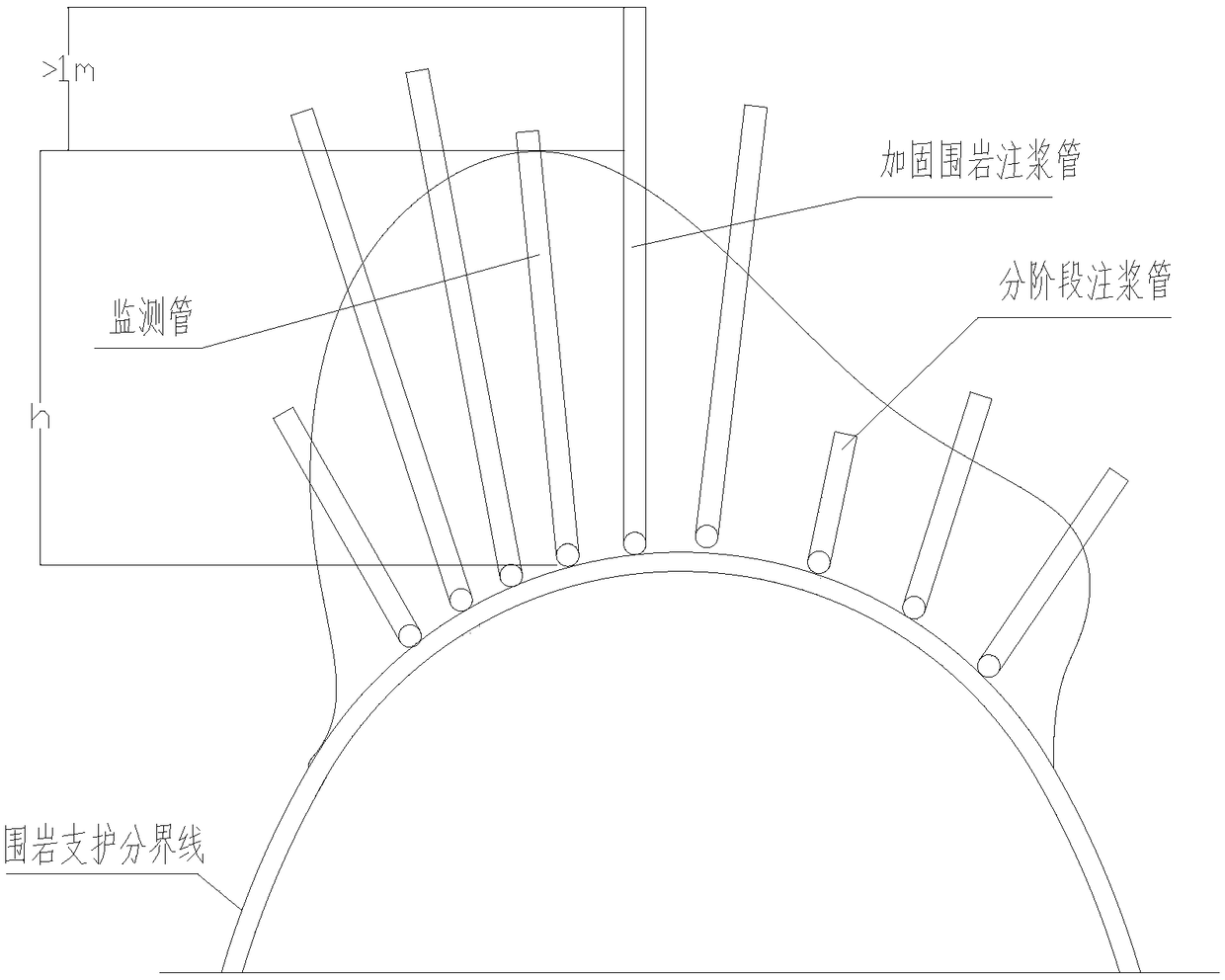

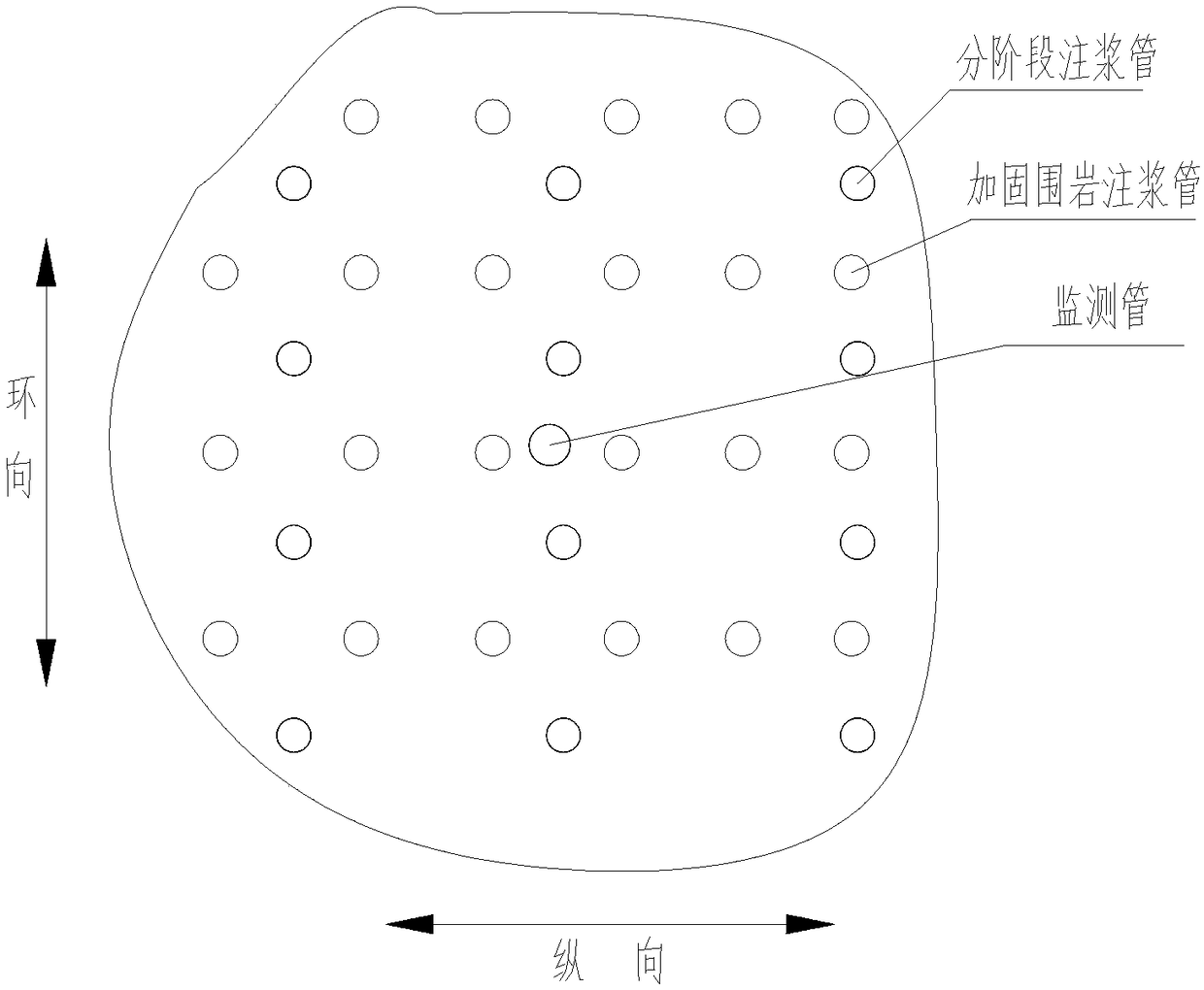

Collapse cavity compact filling method

ActiveCN108843344ASolve the problem of the size of a grouting volumeSolve the problem of grouting sequenceUnderground chambersTunnel liningCollapsed cavityIntermediate stage

The invention discloses a collapse cavity compact filling method which comprises the following steps: I, measuring the geometry size of a collapse cavity space; II, calculating the single maximal grouting amount and grouting depth; III, determining lengths of a monitoring pipe and a grouting pipe; IV, embedding the monitoring pipe and arranging monitoring points; V, performing close contact grouting; VI, performing grouting with surrounding rock reinforcement; VII, performing intermediate stage grouting; VIII, supplementation grouting; and IX performing real-time monitoring. The collapse cavity compact filling method aims at providing a novel collapse cavity compact filling method behind lining after tunnel collapse aiming to the usually caused problem of continuous deformation of primarysupport in the existing collapse cavity compact filling method. The filling method utilizes the monitoring pipe to perform real-time monitoring to deformation of primary support, and stops grouting when a primary support standard prewarning value is reached.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

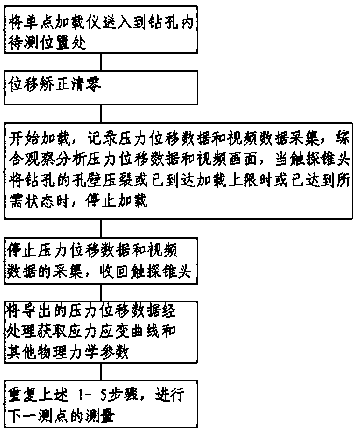

Borehole in-situ test sounding loading device and using method

PendingCN108612526AEasy to testThe testing process is simpleSurveyConstructionsSingle pointEnvironmental geology

The invention discloses a borehole in-situ test sounding loading device and a using method. The borehole in-situ test sounding loading device comprises a single-point loader, a video acquisition unit,a displacement measuring unit, a sounding cone head and a pressure-bearing base. A concave cavity is formed in the upper portion of the single-point loader, a pressure chamber is arranged on the lower potion of the single-point loader, and the bottom of the sounding cone head penetrates through the concave cavity and then extends into the pressure chamber. A wire interface, a push rod interface and an oil way interface are further sequentially arranged on the side face of the single-point loader, the wire interface is connected with an external controller, the push rod interface is connectedwith an external power propulsion system, and the oil way interface is connected with an external hydraulic loading system. The borehole in-situ test sounding loading device is light and convenient, the test process is simple and easy, a test position can be selected flexibly, the physical and mechanical parameters of rock mass can be obtained intuitively and accurately, and the mechanical properties of the rock mass are reflected better.

Owner:SHANDONG UNIV OF SCI & TECH

Down-the-hole drill follow-pipe hole-forming backfill concrete stable free face collapse processing construction method

ActiveCN103775102ASimple construction processReduce security risksUnderground chambersTunnel liningFalseworkShotcrete

The invention relates to a down-the-hole drill follow-pipe hole-forming backfill concrete stable free face collapse processing construction method which comprises the following steps: spraying concrete into a collapsed cavity to carry out sealing; drawing a platform inside an erected steel arch at the bottom of a backfill concrete layer, erecting a construction platform on the platform by utilizing a scaffold and installing a down-the-hole drill on the construction platform; when the down-the-hole drill drills to the collapsed cavity from the backfill concrete layer through collapsed slag bodies, enabling the down-the-hole drill to exit a drilling tool and enabling a steel pipe to be left inside the backfill concrete layer, the collapsed slag bodies and the collapsed cavity; communicating one end of the bottom of the steel pipe with a pump pipe of a concrete delivery pump and spraying the concrete into the steel pipe until the collapsed cavity is full filled with the concrete. The down-the-hole drill follow-pipe hole-forming backfill concrete stable free face collapse processing construction method disclosed by the invention has the superior effects of simple construction process, low safety risk, high construction efficiency, low cost, wide application range and excellent effects.

Owner:SINOHYDRO BUREAU 5

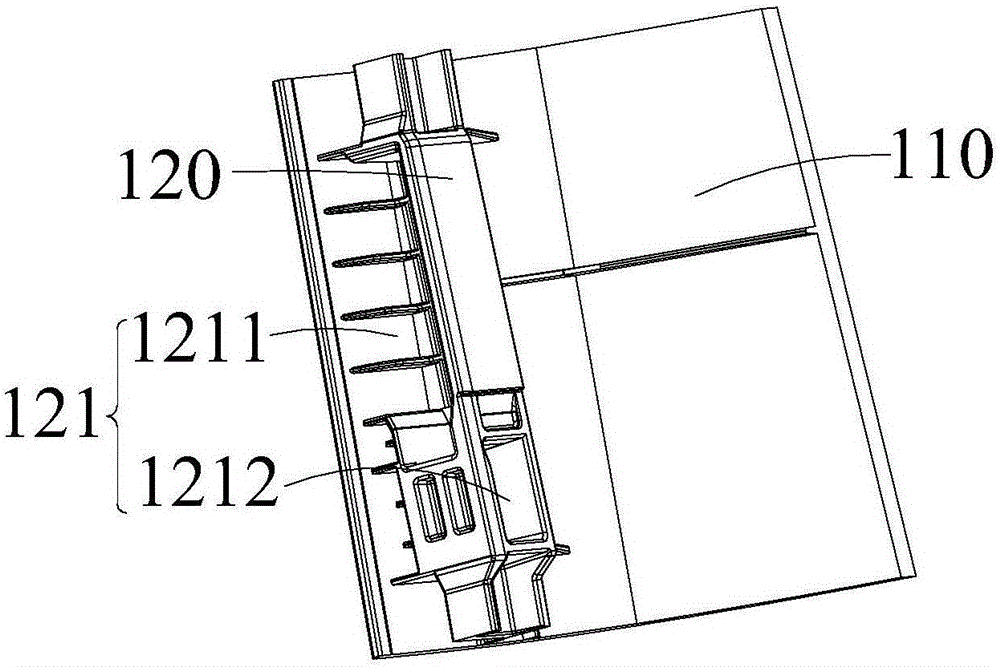

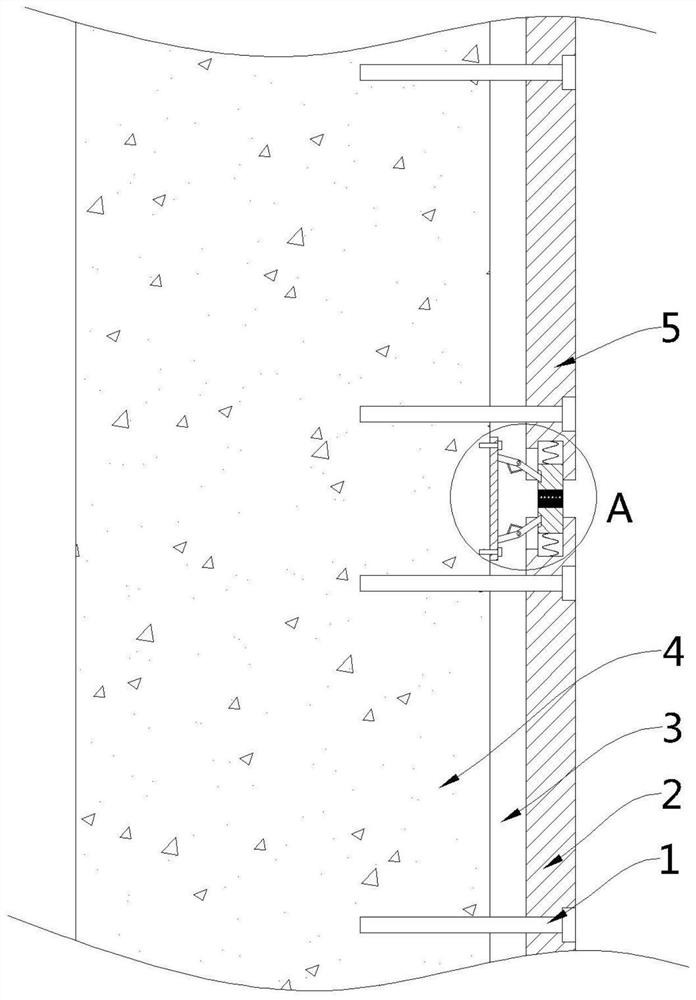

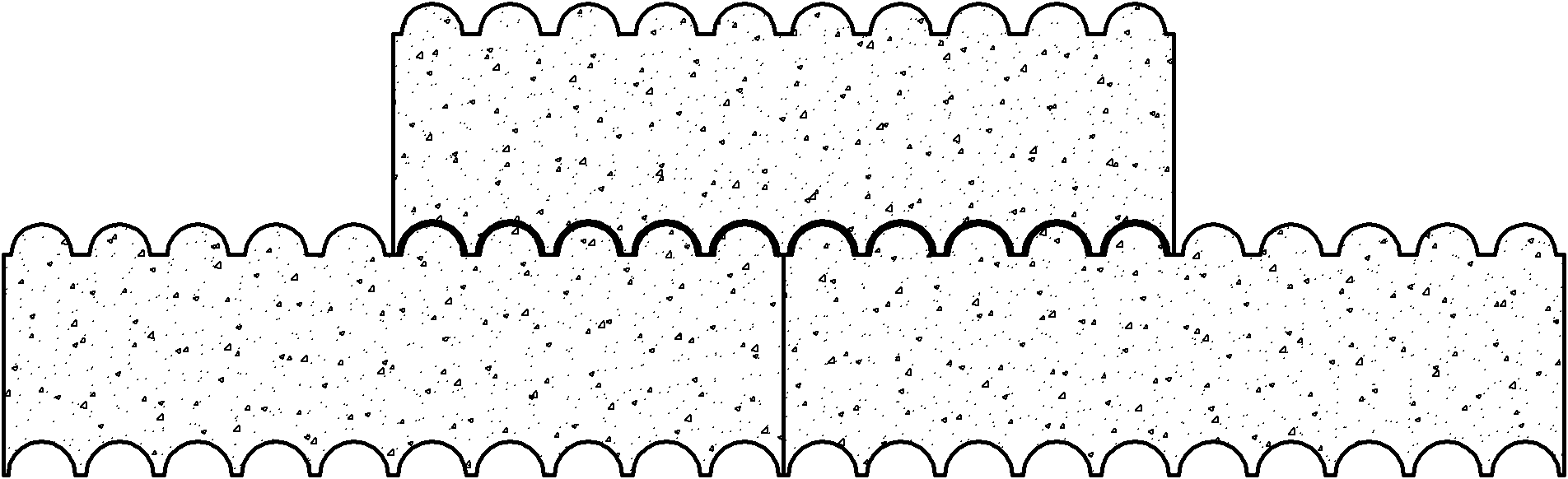

Fabricated building external wall heat preservation device

The invention provides a fabricated building external wall heat preservation device, and belongs to the technical field of building external wall heat preservation. The fabricated building external wall heat preservation device comprises a wall body, a second heat preservation wall plate and a first heat preservation wall plate, wherein the second heat preservation wall plate and the first heat preservation wall plate are connected to the side wall of the wall body through first bolts and distributed up and down; a first sealing assembly is movably mounted on the side, facing the second heat preservation wall plate, of the first heat preservation wall plate, and a second sealing assembly is movably mounted on the side, facing the first heat preservation wall plate, of the second heat preservation wall plate; and the first sealing assembly comprises a first concave cavity formed in the side wall of the first heat preservation wall plate and a first supporting plate connected into the first concave cavity through a first elastic body, and one end of the first supporting plate extends to the exterior of the first heat preservation wall plate and is fixedly provided with a first sealing layer. The fabricated building external wall heat preservation device has the advantages of convenient mounting and good heat preservation effect, compared with the prior art, a gap between the adjacent heat preservation wall plates can be reduced to a great extent, and thus the situation that heat in a building body is lost from the position between the two adjacent sets of heat preservation wall plates is avoided.

Owner:湖北信德建设集团有限公司

Construction method for assisting small-diameter open type TBM tunneling for bad geological hole section pipe shed

InactiveCN111335901AContinuous passEasy and quick passUnderground chambersTunnel liningCollapsed cavityMining engineering

The invention discloses a construction method for assisting small-diameter open type TBM tunneling for a bad geological hole section pipe shed. The method comprises the following steps: 1) making badgeological hole section construction preparation; 2) reinforcing surrounding rocks as temporary support; 3) expanding and extracting a pipe shed workshop; 4) mounting an anchor rod drilling machine, and performing upper water drainage hole construction on a shield; 5) grouting and solidifying the shield and the upper part of a cutter disc; 6) dismounting the anchor rod drilling machine, and mounting a pipe shed drilling machine; 7) performing open hole drilling and grouting; 8) performing pipe shed drilling and grouting; 9) backfilling an expanding and extracting section; and 10) performing TBM tunneling. The construction method can effectively improve strength of surrounding rocks in front of a TBM cutter disc, strengthens surrounding rock self-stabilizing ability, effectively controls height and the range of a collapse cavity above the shield after open type TBM tunneling, achieves less arch-top slagging, greatly reduces slag clearing workload under bad geological conditions, and realizes that TBM continuously and quickly passes through bad geology.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

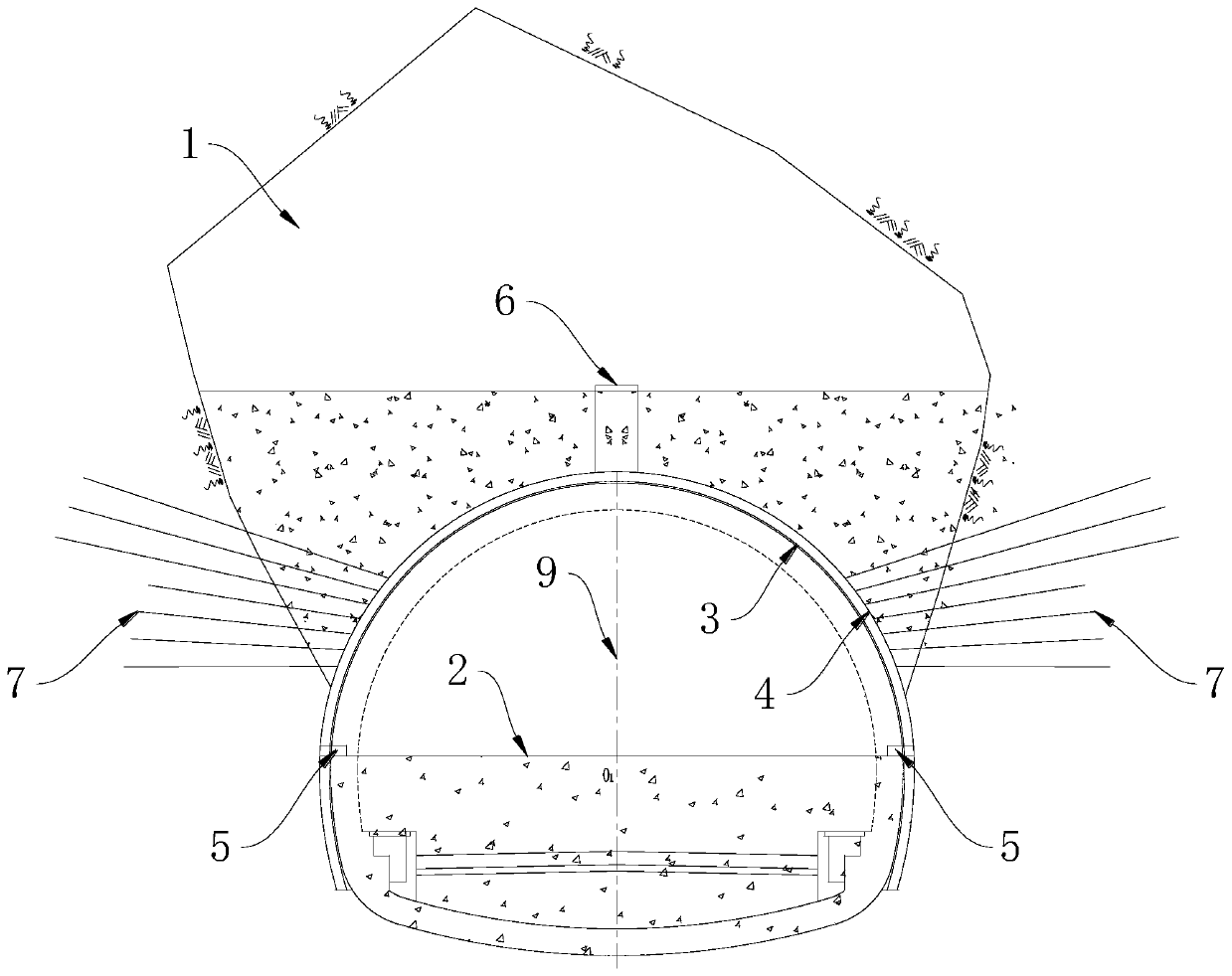

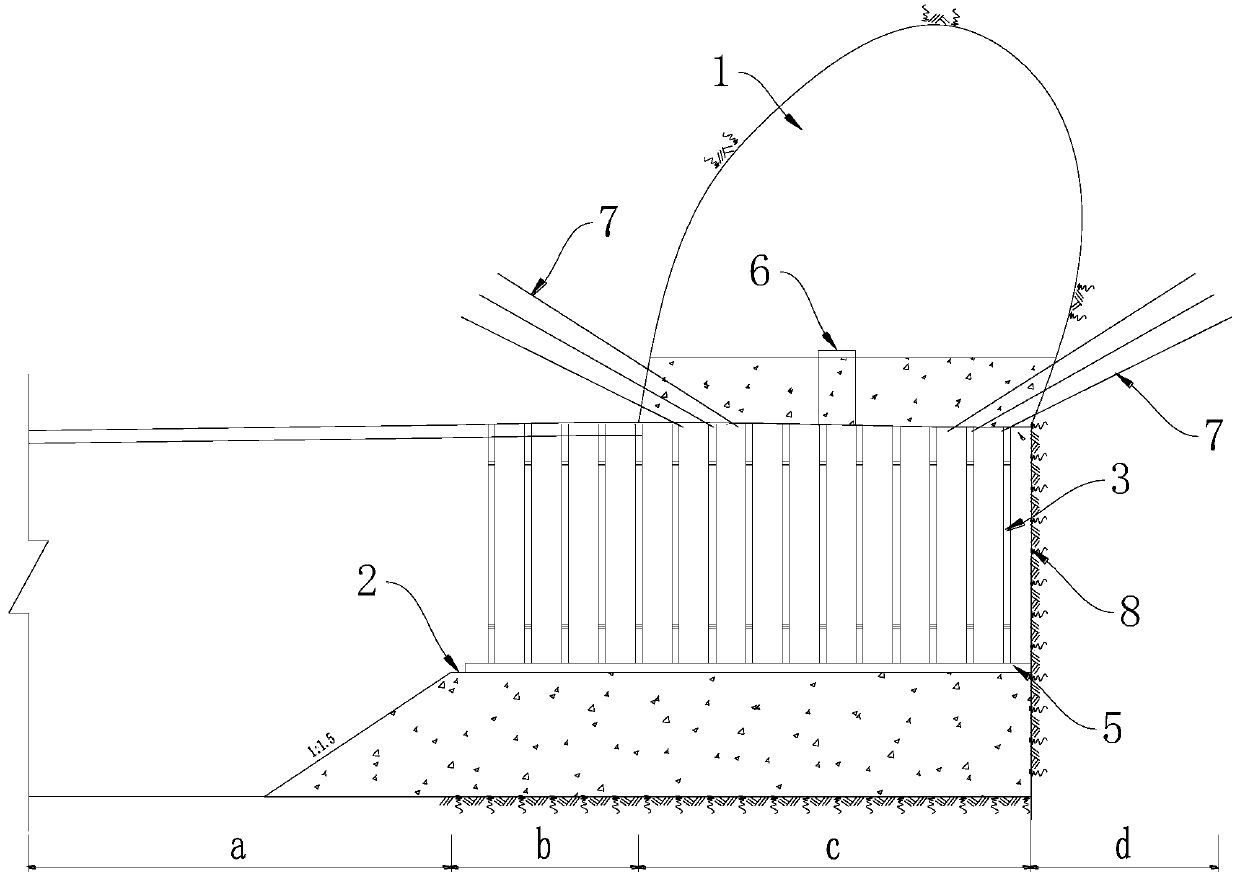

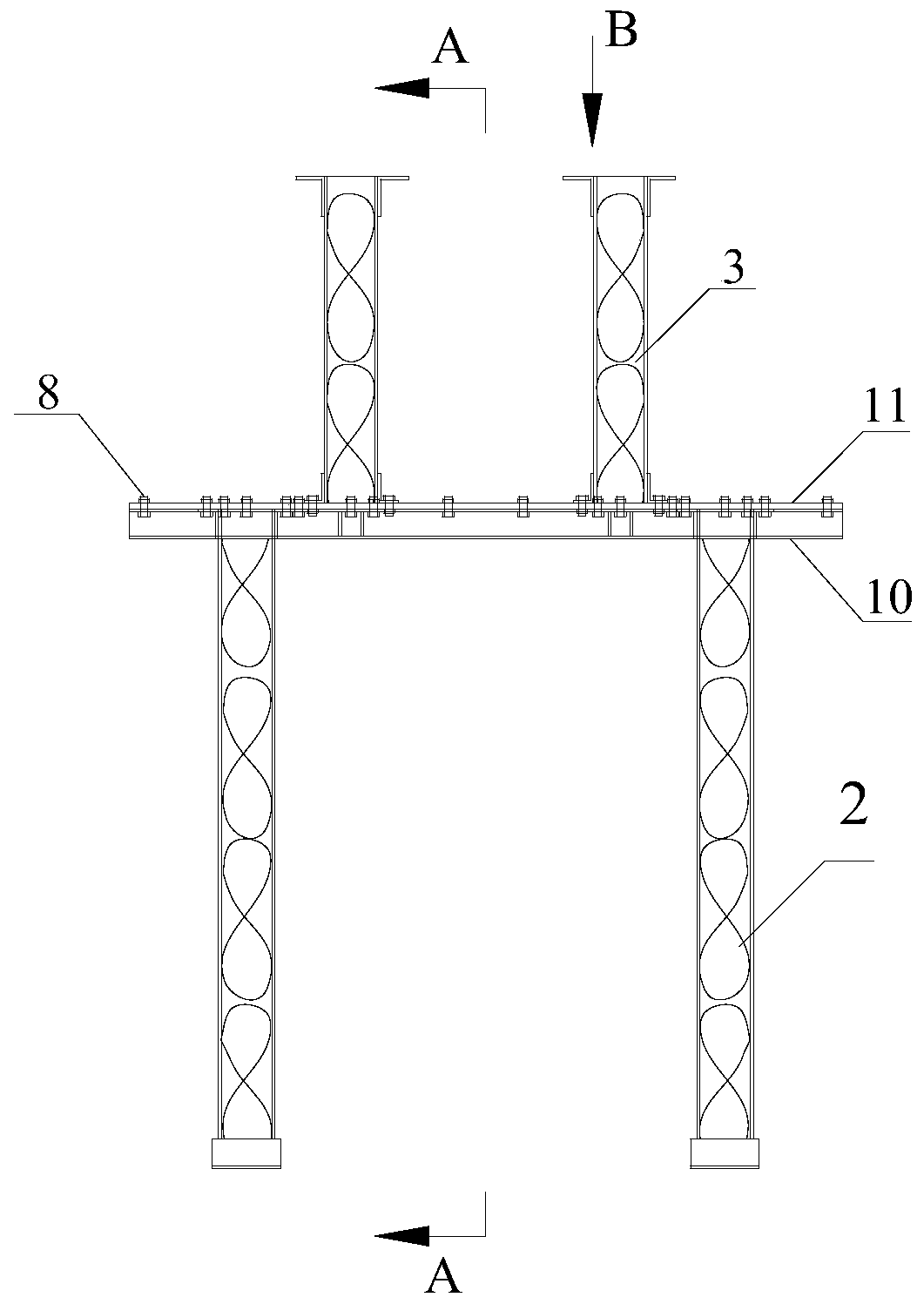

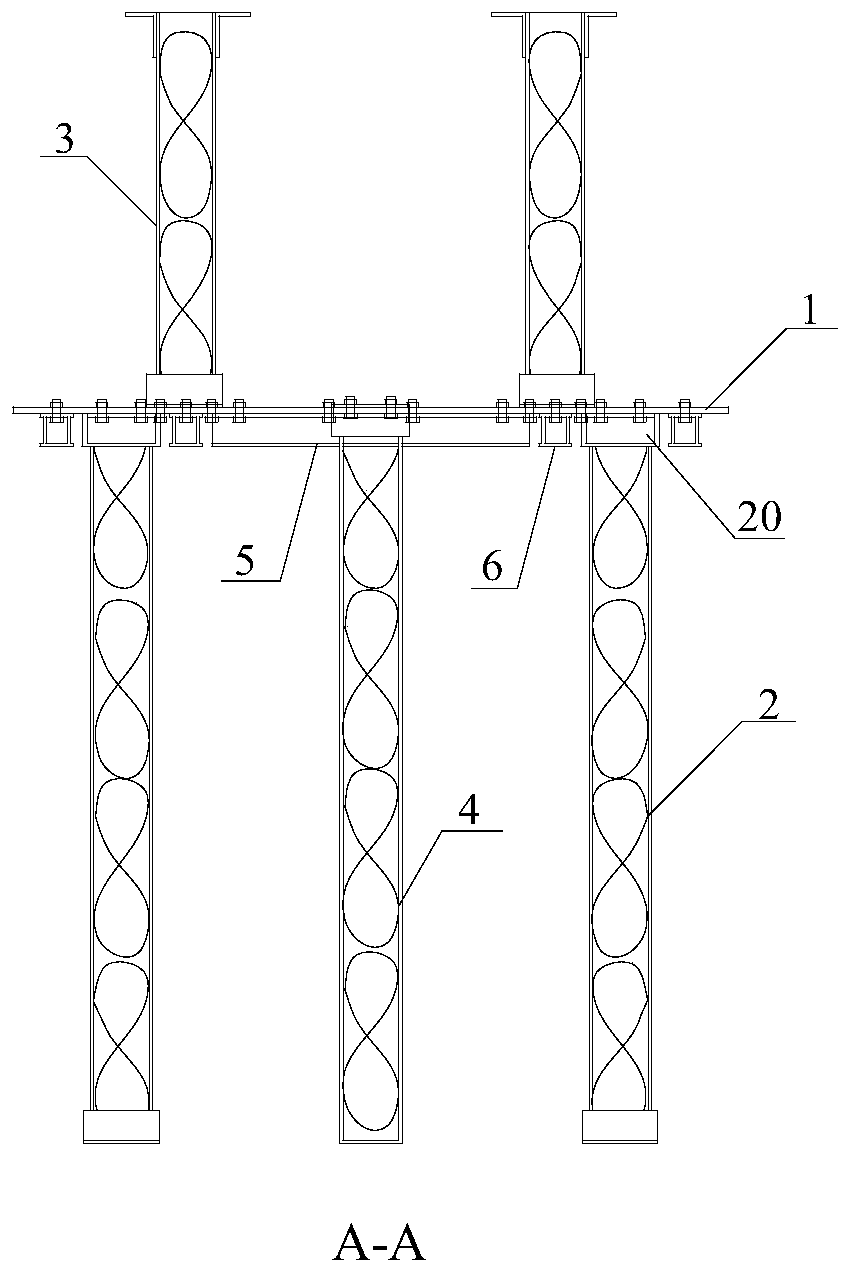

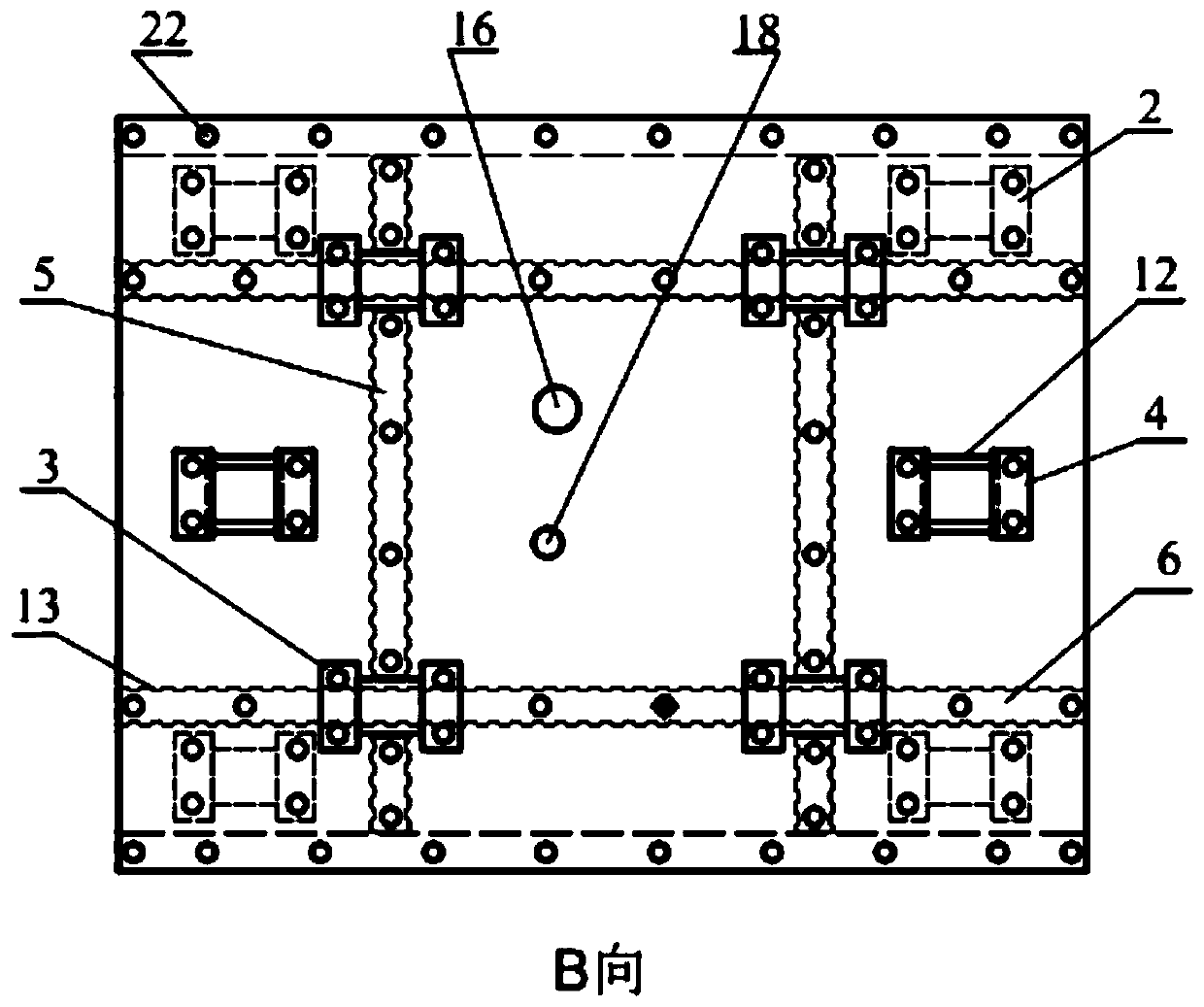

Method for treating tunnel collapse using pavilion-type bracket

ActiveCN111365043ASimple structureEasy to assembleUnderground chambersMine roof capsCollapsed cavityArchitectural engineering

The invention provides a method for treating the tunnel collapse using a pavilion-type bracket, and relates to the technical field of tunnels and underground engineering. The method for treating the tunnel collapse using the pavilion-type bracket is suitable for the case where a collapse cavity is relatively stable and the collapse cavity has the relatively high height and is not prone to contacting the roof. The method for treating the tunnel collapse using the pavilion-type bracket comprises the steps that a collapsed body is leveled, and the pavilion-type bracket is moved to the lower partof the collapse cavity, a hydraulic prop is used for jacking a shield plate to the lower edge of the shield plate beyond the outer contour line of a tunnel primary support arch, a bottom column is connected to the lower part of a stand column, and a base plate is inserted. If the hydraulic prop retracts, the stand column, the bottom column, the base plate and the hydraulic prop jointly bear the load transmitted by the shield plate. The primary support arch is installed and connected under the protection of the shield plate, the intersection of the stand column and the adjacent primary supportarch is welded, and the stand column in the primary support arch is cut off. After the single hydraulic prop is withdrawn, the load of the shield plate is smoothly transferred from the pavilion-type bracket to an initial support scaffold, and the quick-setting concrete is sprayed to a grid arch to form a closed shell, and a filling material is pumped to fill the space of the collapse cavity. Thismethod has the advantages of low requirements for the jacking height of the hydraulic prop, safe construction and the like.

Owner:SHANDONG UNIV OF SCI & TECH +4

Simple and convenient locknut

The invention discloses a simple and convenient locknut. The locknut comprises a concave cavity nut in an inner cone shape and a boss nut in an outer cone shape and matched with the concave cavity nut, conical parts of the matched nuts are provided with matched spiral progressive type locking structures, an opening type through groove is formed in a boss part of the outer cone-shaped nut, and by means of a formed intermittent annular progressive locking structure, the boss part of the nut can be deformed along with the locking action of the concave cavity nut to lock a bolt, or can lock tightly to form an intermittent engagement shape with teeth of the bolt to enhance the locking efficiency of the bolt. According to the locknut, the integral efficiency reliability is guaranteed by multipleuniform stress of the two nuts and the conical annular progressive locking structure, and the expected goal that that nut locks without looseness is achieved without impairing the normal characteristics of the bolt.

Owner:叶春林

Oiling machine installation equipment and using method thereof

The invention relates to the field of oiling machines, in particular to oiling machine installation equipment and a using method thereof. The oiling machine installation equipment comprises a base and an oiling machine body, a concave cavity is formed in the center of the upper surface of the base, a lifting mechanism is arranged inside the concave cavity, a bottom plate is fixed to the bottom of the oiling machine body, an inner clamping mechanism is arranged on the bottom face of the bottom plate, the inner clamping mechanism is used for fixing the bottom plate in the interior of the concave cavity, the inner clamping mechanism can make abutting contact with the lifting mechanism, the lifting mechanism can be fixedly connected with the inner clamping mechanism, an outer clamping mechanism is arranged on the upper surface of the base, the outer clamping mechanism is used for fixing the bottom plate to the base, and the lifting mechanism is in transmission connection with the outer clamping mechanism. According to the oiling machine installation equipment and the using method thereof, the oiling machine body can be conveniently mounted and dismounted, the working procedures are simplified, the operation is easy and convenient, and the labor intensity is greatly reduced.

Owner:李佳佳

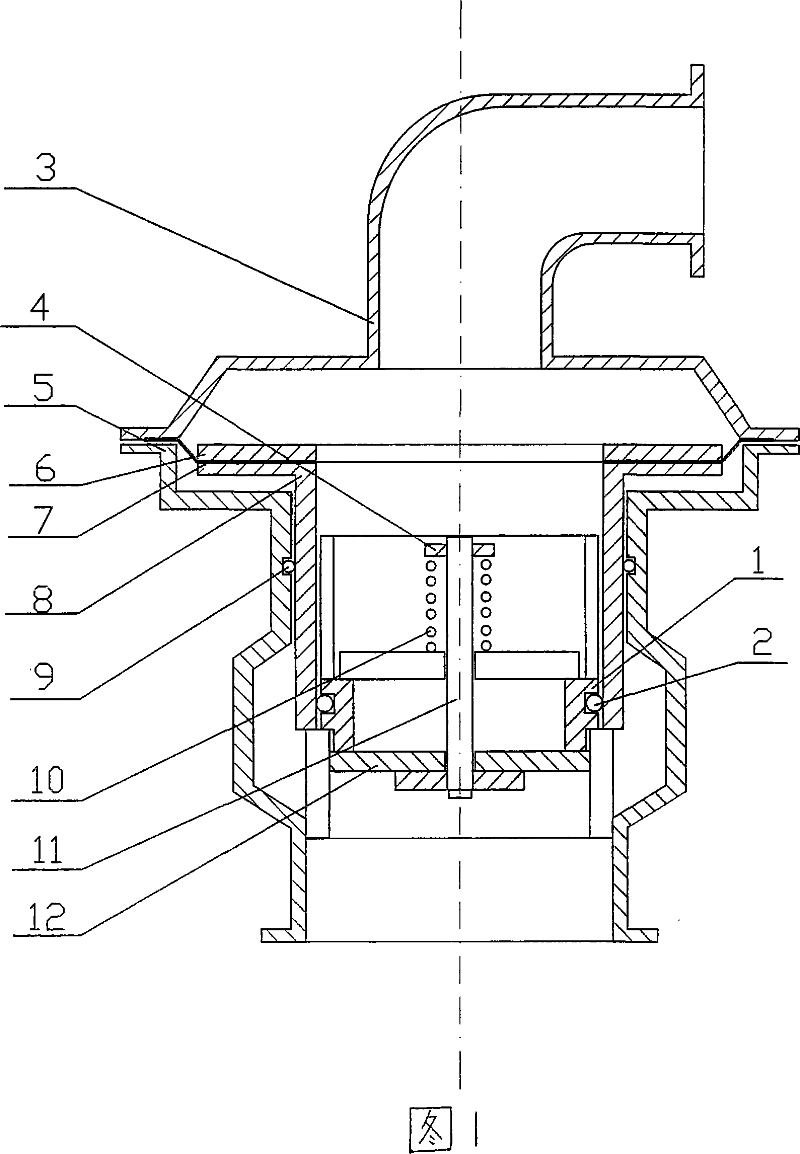

Spiral-flow type jammed cavitation device for breaking excess sludge

ActiveCN105668973ASimple structureEffective collapseSludge treatment by oxidationWater/sewage treatment apparatusSludgeCollapsed cavity

The invention relates to a hydrodynamic cavitation sludge breaking device. A spiral-flow type jammed cavitation device for breaking excess sludge is characterized by comprising a spiral-flow body, a spiral-flow core, a jammed body and a backpressure cover. The spiral-flow body and the spiral-flow core are matched to form a spiral-flow nozzle. A through hole in the jammed body forms a jammed pipe. The jammed body and the backpressure cover are matched to form a collapse cavity. A backpressure hole is formed in the backpressure cover in the radial direction. After fluid enters the spiral-flow nozzle through the spiral-flow body, flows along a spiral channel to possess the tangential speed and the radial speed, and forms rotating jet flow when being ejected through an outlet end, the rotating jet flow is induced on the upstream of the jammed pipe to generate a large number of cavitation bubbles and an acute shear effect, cavitation bubbles carried by the fluid collapse when the fluid passes through the jammed section on the downstream of the jammed pipe to form jammed cavitation, and when the cavitation bubbles collapse, the mechanical effect of formed micro jet and the like effectively promotes breaking of the excess sludge. Compared with the prior art, the spiral-flow type jammed cavitation device is simple in structure, high in cavitaion strength, strong in mechanical shear force action, high in excess sludge breaking rate and the like.

Owner:安徽明亮面业股份有限公司

High-thermal-shock-resistant fire-resistant and thermal-insulating interlocking dry-code special material and preparation method thereof

ActiveCN101955365AImprove the ecological environmentSolve the real problemTunnel kilnEnvironmental resource management

The invention relates to a high-thermal-shock-resistant fire-resistant and thermal-insulating interlocking dry-code special material prepared by utilizing waste firebricks and a method thereof. The high-thermal-shock-resistant fire-resistant and thermal-insulating interlocking dry-code special material comprises the following materials: a bone material, a composite matrix material, a waste born-out additive, a nucleating agent, an adhesive, a plastifying agent and water; the interlocking dry-code special material is a rectangular brick on which is provided with a clamping convex matrix, and a concave cavity matrix is arranged below the brick and is in convex-concave match with a clamping convex matrix of another brick. When in masonry, the bricks are not adhered with fireproof slurry, the whole structure is firm, and the problem existing in a traditional kiln car base can be fully solved. Meanwhile, the invention is also suitable for use by a preheating zone and a cooling zone of a tunnel kiln, can greatly lighten the weight of a kiln car, prevents heat loss, reduce energy consumption, prolongs the service life for durable use, hardly needs repairing and is not only suitable for a newly-built kiln, but also suitable for modifying an old kiln. The invention brings the social benefits of comprehensively utilizing waste resources, improving the ecological environment, saving energy and reducing consumption for the society.

Owner:GUANGDONG REJINBAO NEW MATERIAL TECH +2

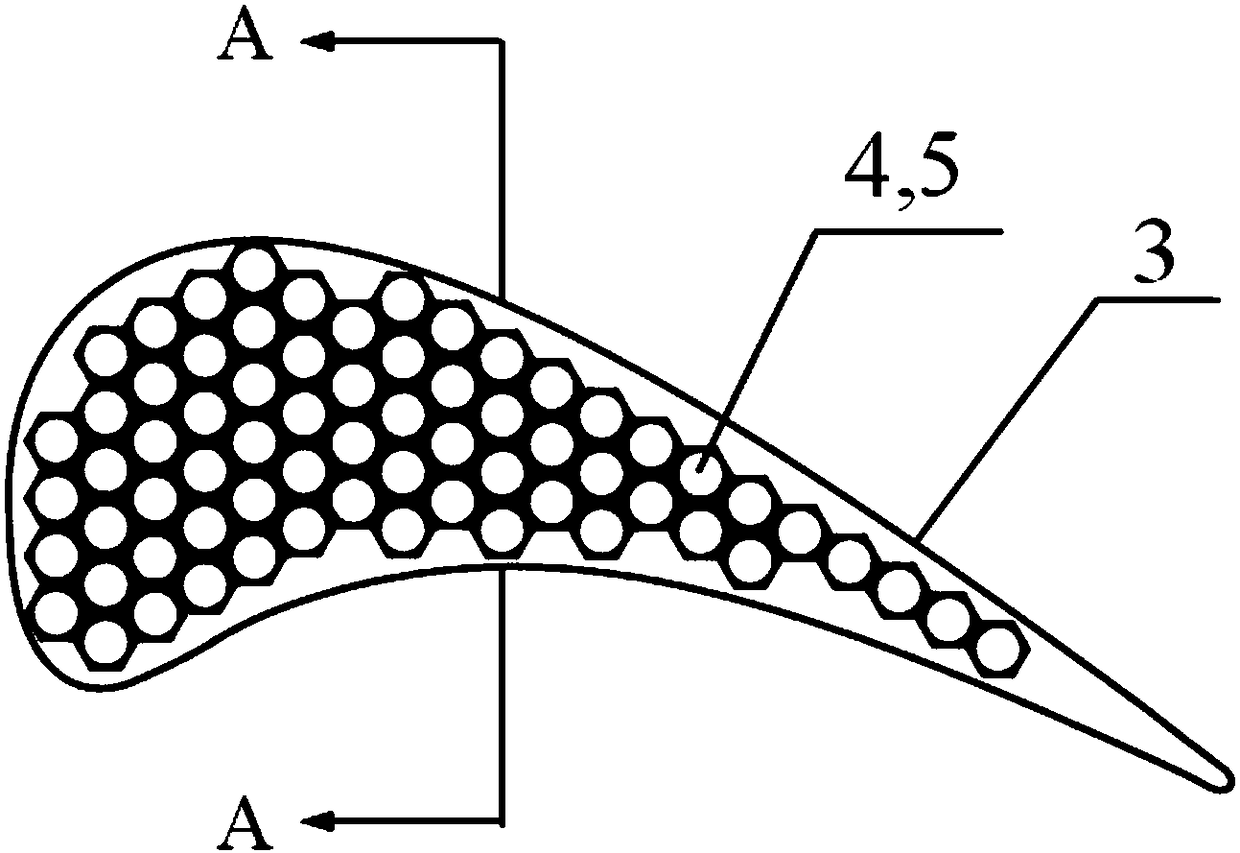

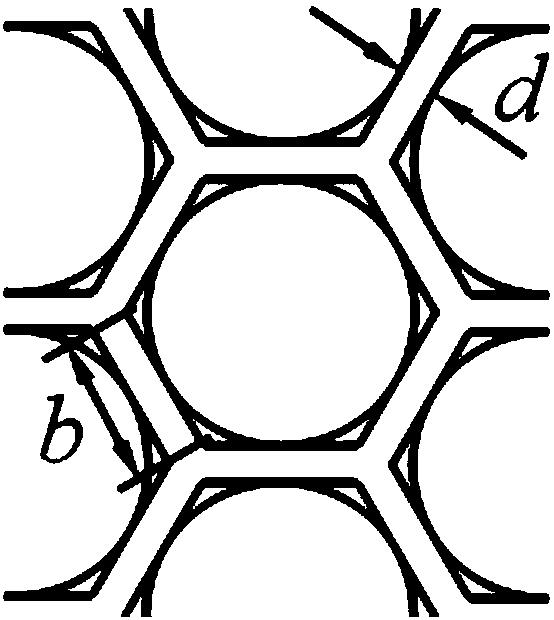

Ball bottom prism and recessed cavity blade tip capable of inhibiting turbine tip leakage flow

InactiveCN108506049ALayout Method AdvantagesReduce leakageBlade accessoriesLeakage preventionPneumatic barrierEngineering

The invention provides a ball bottom prism and recessed cavity blade tip capable of inhibiting a turbine tip leakage flow. A plurality of prism type recessed cavities are formed in a blade tip of a turbine moving blade from the front edge to the rear edge of the turbine moving blade; a ball bottom structure of which the circular section is internally tangent with the lower bottom surface of the corresponding prism type recessed cavity is assembled at the bottom surface of each prism type recessed cavity; and a ratio of the maximum height of the prism type recessed cavity to the blade height is0.5-4%. A vortex structure is formed in each single recessed cavity and develops to a gap in the single recessed cavity, so that gap kinetic energy is dissipated, at the same time small-size pneumatic barriers are formed, and the leakage flow resistance is increased. Ball bottom prism and recessed cavity assembled structures allow fluid in recessed cavities to act on the ball bottom wall surfacesalong tangent lines basically, and due to smooth arc-shaped transition of the ball bottom structures, the vortex development resistance is reduced, so that vortexes formed in the cavities develop more completely and have larger sizes, the inhibition effect on the flow in the gaps is improved, and a better effect of controlling the tip leakage flow can be further achieved.

Owner:HARBIN INST OF TECH

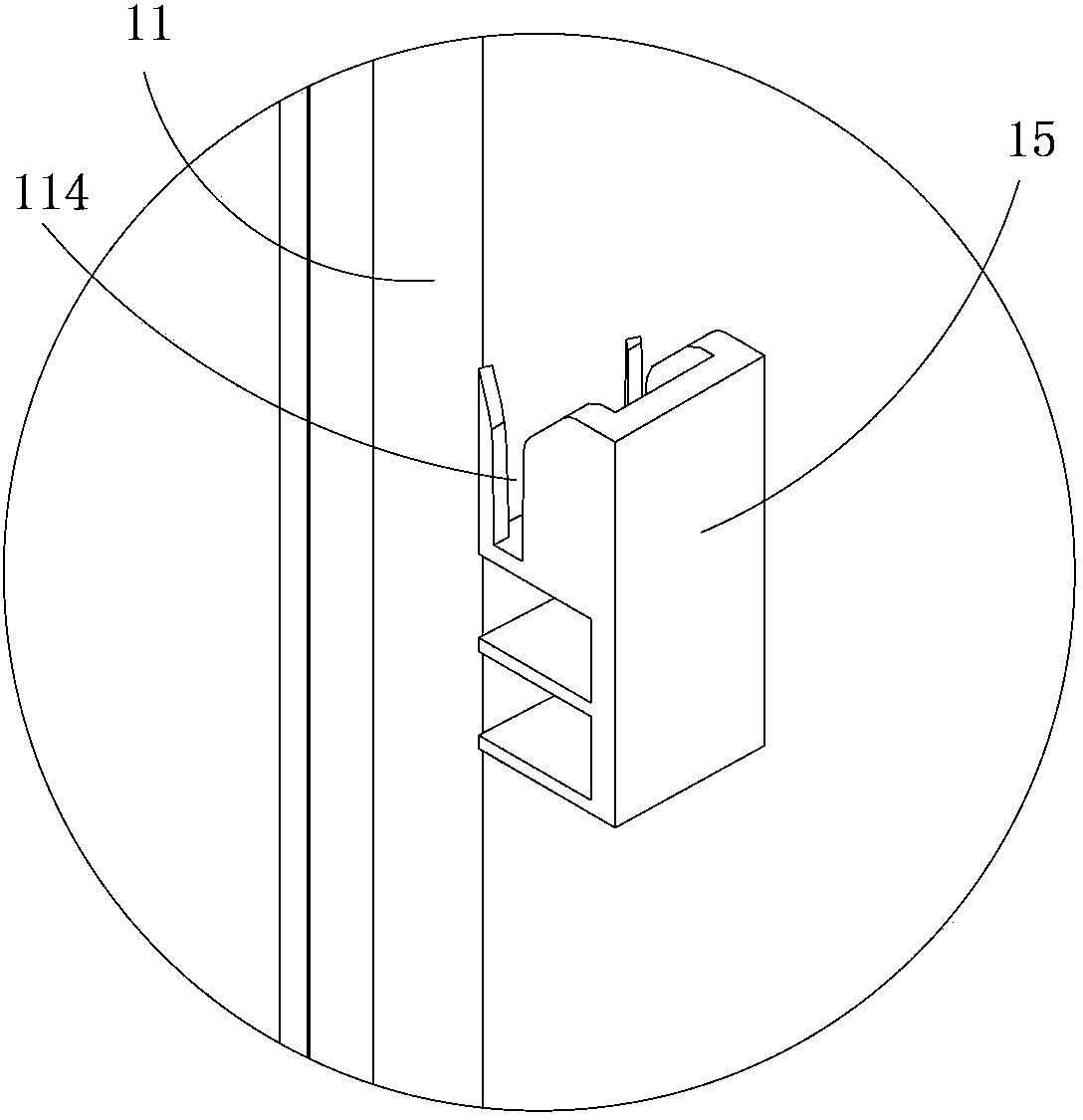

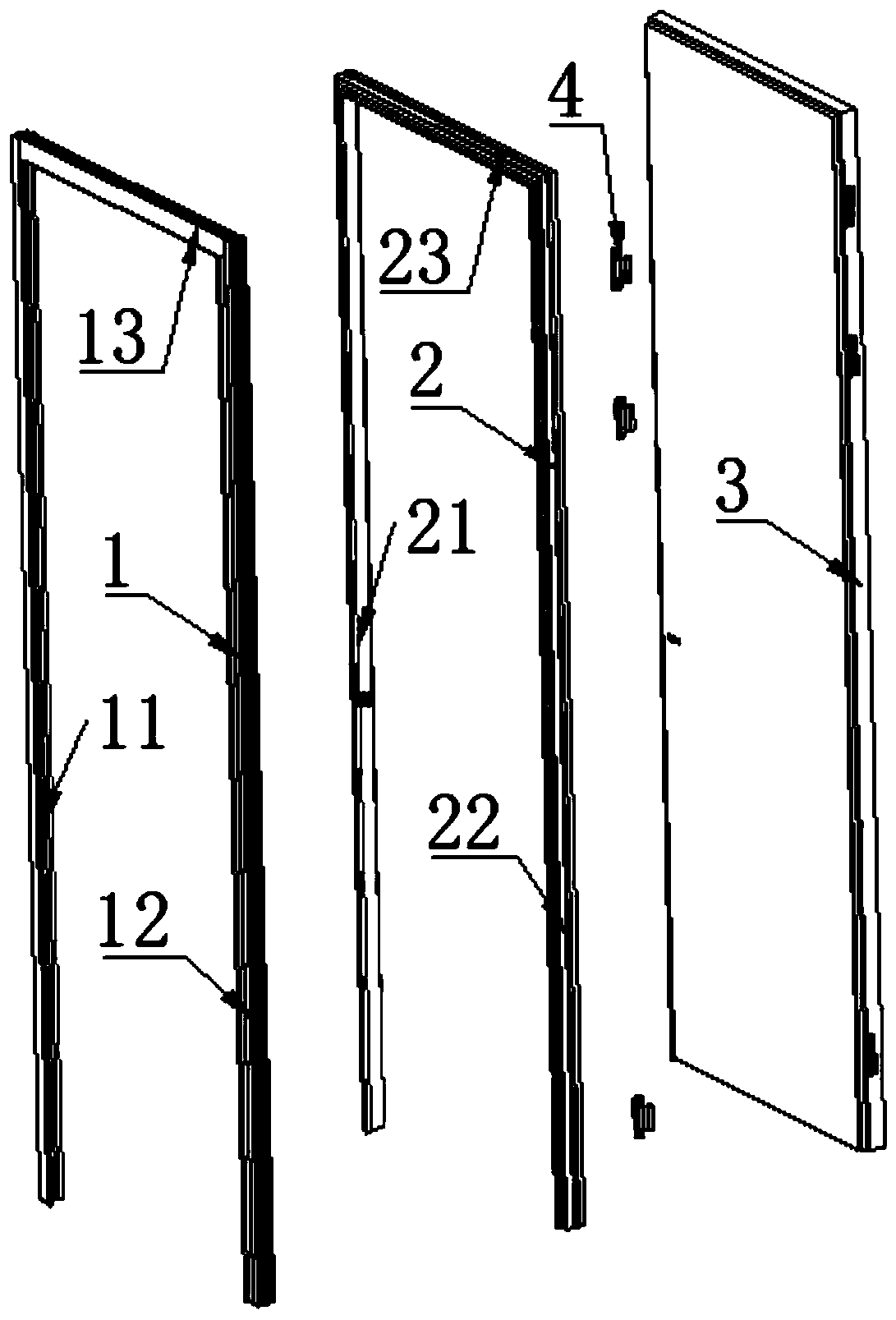

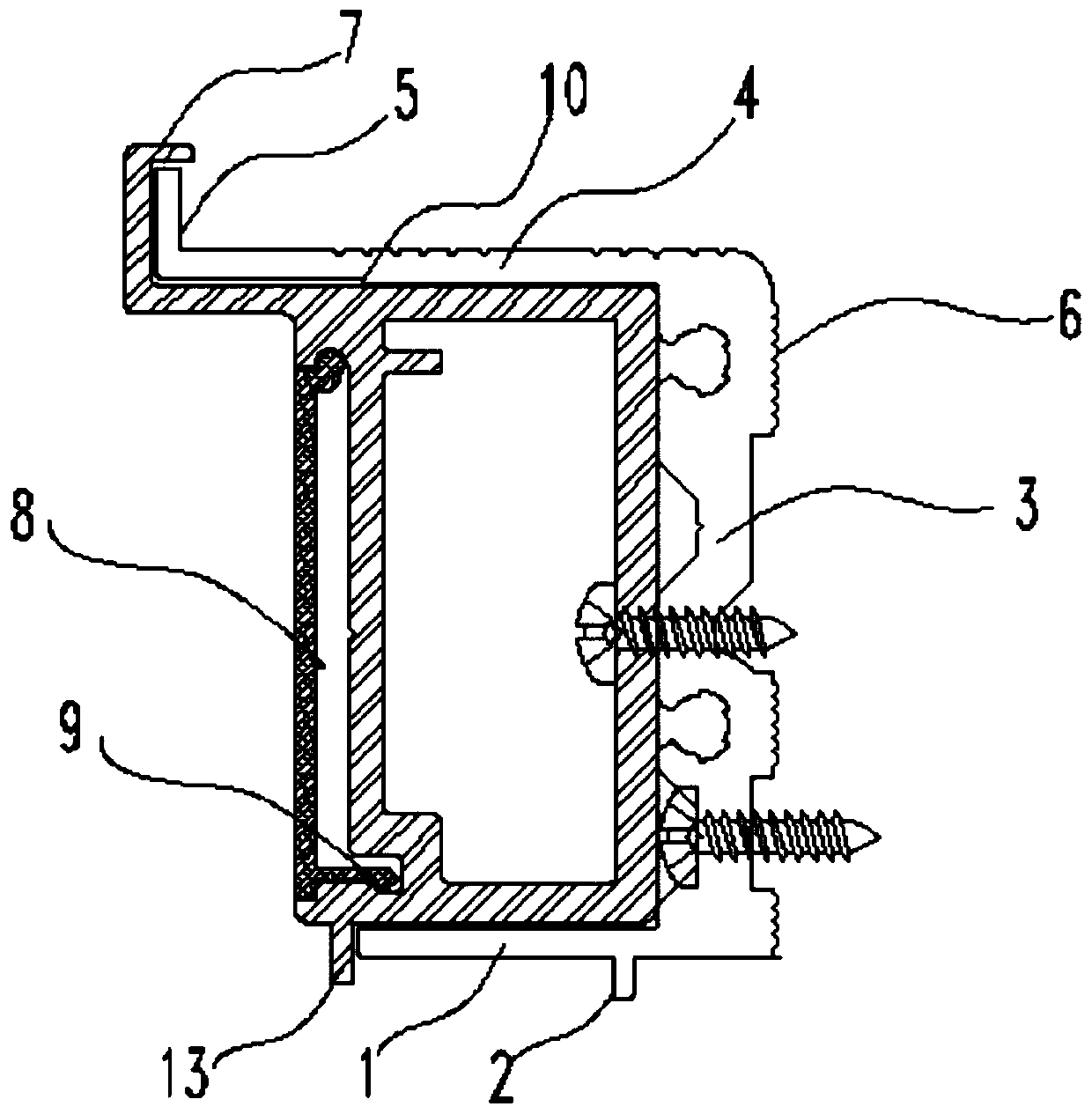

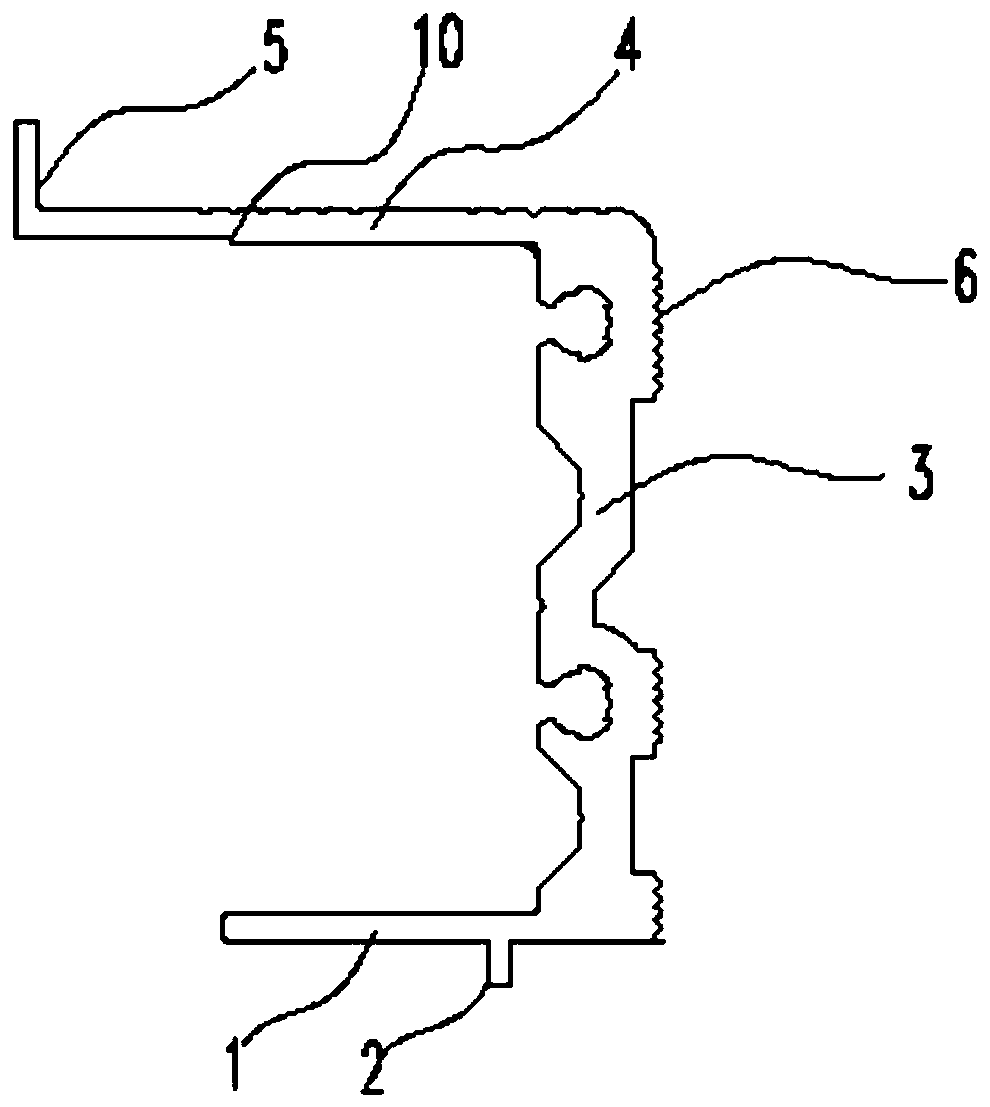

Invisible door cover, invisible door system and installation method of invisible door system

PendingCN109882028AEasy to install in installmentsEasy to installFrame fasteningWindow/door framesInterior spaceEngineering

The invention discloses an invisible door cover, an invisible door system and an installation method of the invisible door system. The invisible door system comprises a hidden auxiliary sleeve composed of a hidden auxiliary sleeve body and a main door sleeve and a door leaf; a profile of the hidden auxiliary sleeve comprises a first mounting edge, a second mounting edge and a third mounting edge,wherein the first mounting edge and the second mounting edge are opposite to each other and the third mounting edge is connected with the same side end parts of the two mounting edges, and an internalspace is limited by the first mounting edge, the second mounting edge and the third mounting edge; the other end of the first mounting edge extends to the outer space to form a limited stop edge; a main door sleeve mounting surface is limited by the first mounting edge, the second mounting edge, the third mounting edge and the limiting stop edge define; a decorative close surface is limited by the limit stop edge and the first mounting edge; a concave cavity is formed by extending the profile of the main door sleeve, and the limit stop edge is hid in the concave cavity. The invisible door system can be installed in stages, namely, the hidden auxiliary sleeve is embedded in a door hole first, then the wall surface decoration construction is carried out, and the main door sleeve and the door leaf are installed after the main body decoration engineering is completed, so that the construction period is shortened, problems such as material installation errors are not needed to be worried,the cost is reduced, and the economic benefit is improved.

Owner:廖丹霞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com