Surface cross-scale composite micro-modeling tool and preparation method

A micro-modeling and cross-scale technology, applied in the direction of manufacturing tools, cutting tools for lathes, turning equipment, etc., can solve problems such as uneven distribution, affecting the effect of friction reduction, and increased chip curling, and achieves enhanced film-base bonding strength , enhance continuous wettability, and increase the effect of occlusal area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

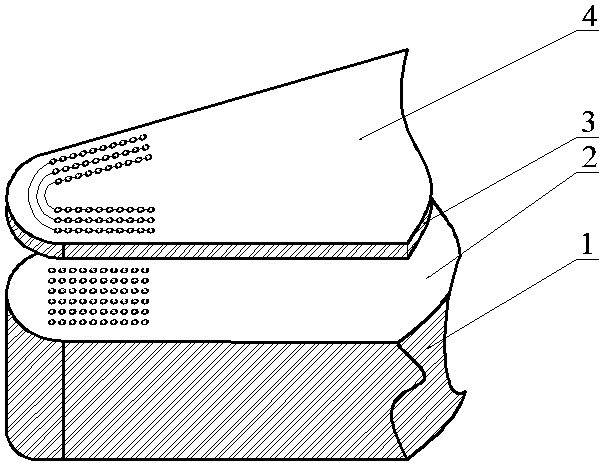

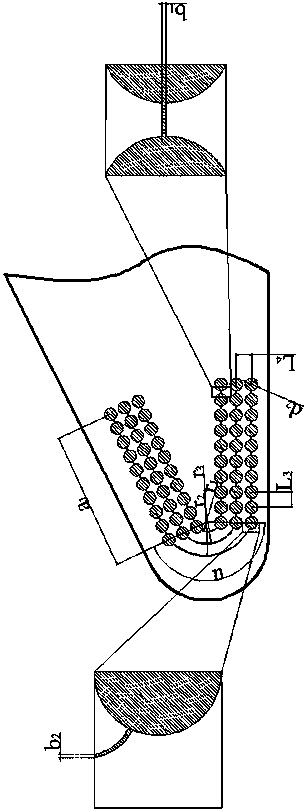

[0036] In conjunction with the accompanying drawings, the implementation examples of the present invention include:

Embodiment

[0037] An embodiment, a surface cross-scale composite micro-shaped tool, the tool material is YG6X hard alloy, the coating is TiAlN hard coating, and the coating method is cathodic arc physical evaporation. The specific steps are:

[0038] (1) Pretreatment: Polish the rake surface of the tool base material to a mirror surface with Ra<0.01, put it in an aqueous solution of 60g / L sodium hydroxide and 75g / L sodium carbonate in sequence, and clean it ultrasonically for 20 minutes at a temperature of 45°C. Remove surface oil and sweat stains, dry fully;

[0039] (2) Laser processing textured tool material surface: Nd:YAG pulsed laser is used to texture the tool material surface, the tool is clamped on the workbench, and the laser is adjusted at a distance of 100 μm from the rake face of the tool to the main cutting edge , from the outside of the blade to the inside of the blade, an array of micro-cavities with a number of columns of 10x10 is processed, and the diameter of the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com