Thin film electrode and preparation method thereof

A thin-film electrode and thin-film technology, applied in the field of thin-film electrodes and preparation, can solve the problems of poor flexibility of boron-doped diamond electrodes and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

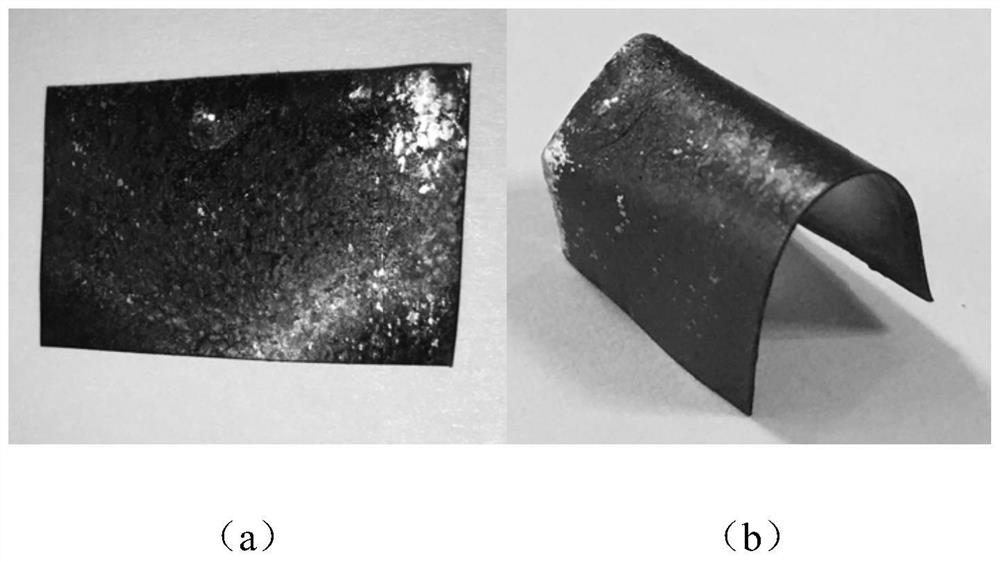

[0020] On the one hand, an embodiment of the present invention provides a method for preparing a thin film electrode, comprising the following steps:

[0021] S01: providing a flexible substrate, placing the flexible substrate in a nanodiamond suspension, and performing adsorption treatment to obtain a flexible substrate with a single layer of nanodiamond particles adsorbed on its surface;

[0022] S02: performing boron doping treatment on the single-layer nano-diamond particles adsorbed on the surface of the flexible substrate to obtain a first boron-doped diamond film;

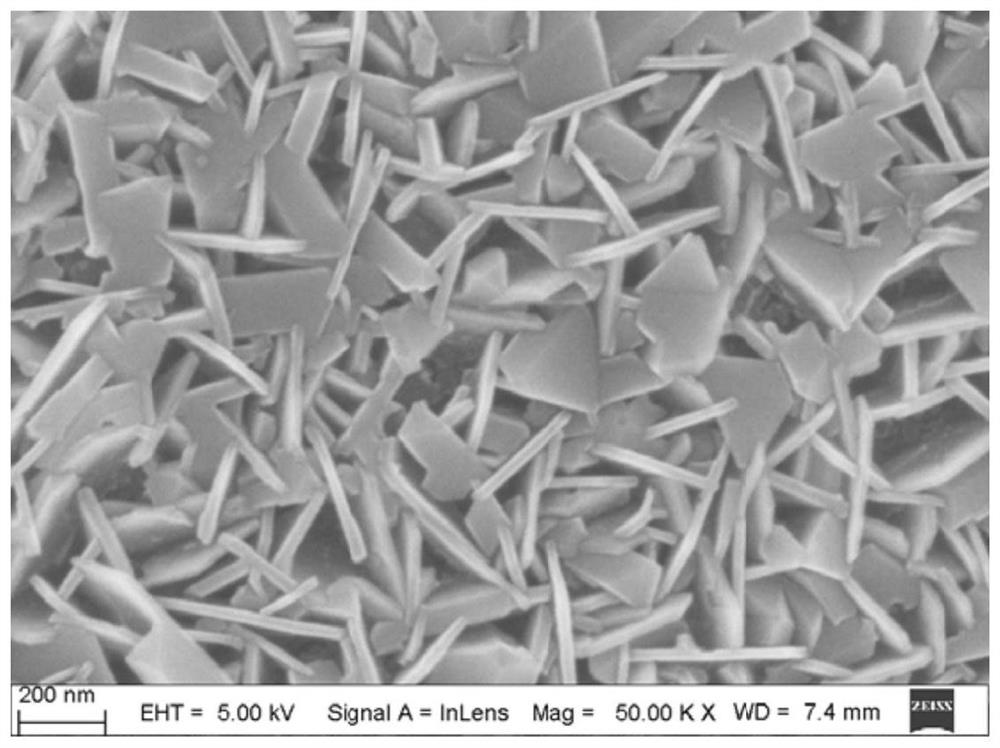

[0023] S03: growing a porous sheet-shaped boron-doped diamond film on the first boron-doped diamond film to form a second boron-doped diamond film to obtain a film electrode;

[0024] Wherein, the first boron-doped diamond film and the second boron-doped diamond film constitute the film electrode.

[0025] The preparation method of the thin film electrode provided by the embodiment of the present invention ...

Embodiment 1

[0052] A method for preparing a thin film electrode, comprising the steps of:

[0053] Step 1, the flexible substrate (aluminum flake) was ultrasonically cleaned in ethanol solution for 10 min, then ultrasonically cleaned in deionized water for 5 min, and finally washed with N 2 blow dry.

[0054] Step 2, preparing nano-diamond suspension (pH is 3) is crystal planting solution: adopt behenic acid amidopropyl dimethyl dihydroxypropyl ammonium chloride as dispersant, deionized water as solvent, dispersant The concentration is 10 -7 mol / L, and then add the detonation nano-diamond powder to the dispersant solution, the mass concentration of nano-diamond is 0.005%wt.%. The nano-diamond suspension is ultrasonically oscillated for 15min to fully disperse the diamond nanoparticles.

[0055] Step 3: Take the crystal-planting solution in step 3, put the flexible substrate into the crystal-planting solution, and perform ultrasonic treatment for 30 minutes, so that the nano-diamond part...

Embodiment 2

[0060] A method for preparing a thin film electrode, comprising the steps of:

[0061] Step 1, the flexible substrate (copper sheet) was ultrasonically cleaned in ethanol solution for 10 min, then ultrasonically cleaned in deionized water for 5 min, and finally cleaned with N 2 blow dry.

[0062] Step 2, the preparation of nano-diamond suspension (pH is 3) is the crystal planting solution: using 3-chloro-2-hydroxypropyltrimethylammonium chloride as the dispersant, deionized water as the solvent, the concentration of the dispersant for 10 -7 mol / L, and then add the detonation nano-diamond powder to the dispersant solution, the mass concentration of nano-diamond is 0.005%wt.%. The nano-diamond suspension is ultrasonically oscillated for 15min to fully disperse the diamond nanoparticles.

[0063] Step 3: Take the above-mentioned crystal-planting solution, put the flexible substrate into the crystal-planting solution, and perform ultrasonic treatment for 30 minutes, so that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com