Hanging mechanism for garment conveying assembly line

An assembly line and hanging technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as easy shaking and affect work efficiency, reduce friction, increase occlusal area, and reduce the difficulty of hanging and placing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

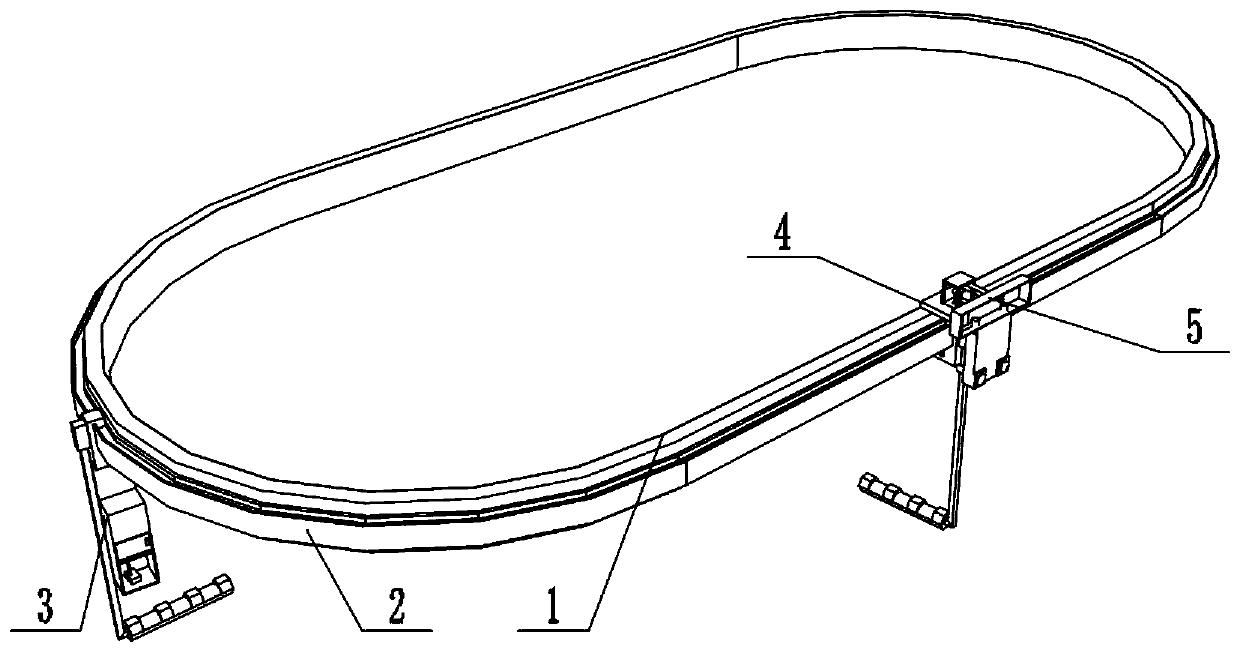

[0030] A hanging mechanism for a clothing transmission line, such as Figure 1-3 As shown, a bracket 1 is included, the side wall of the bracket 1 is provided with an electric slide rail 2, and the outer wall of the electric slide rail 2 is slidably connected with a spreader 3;

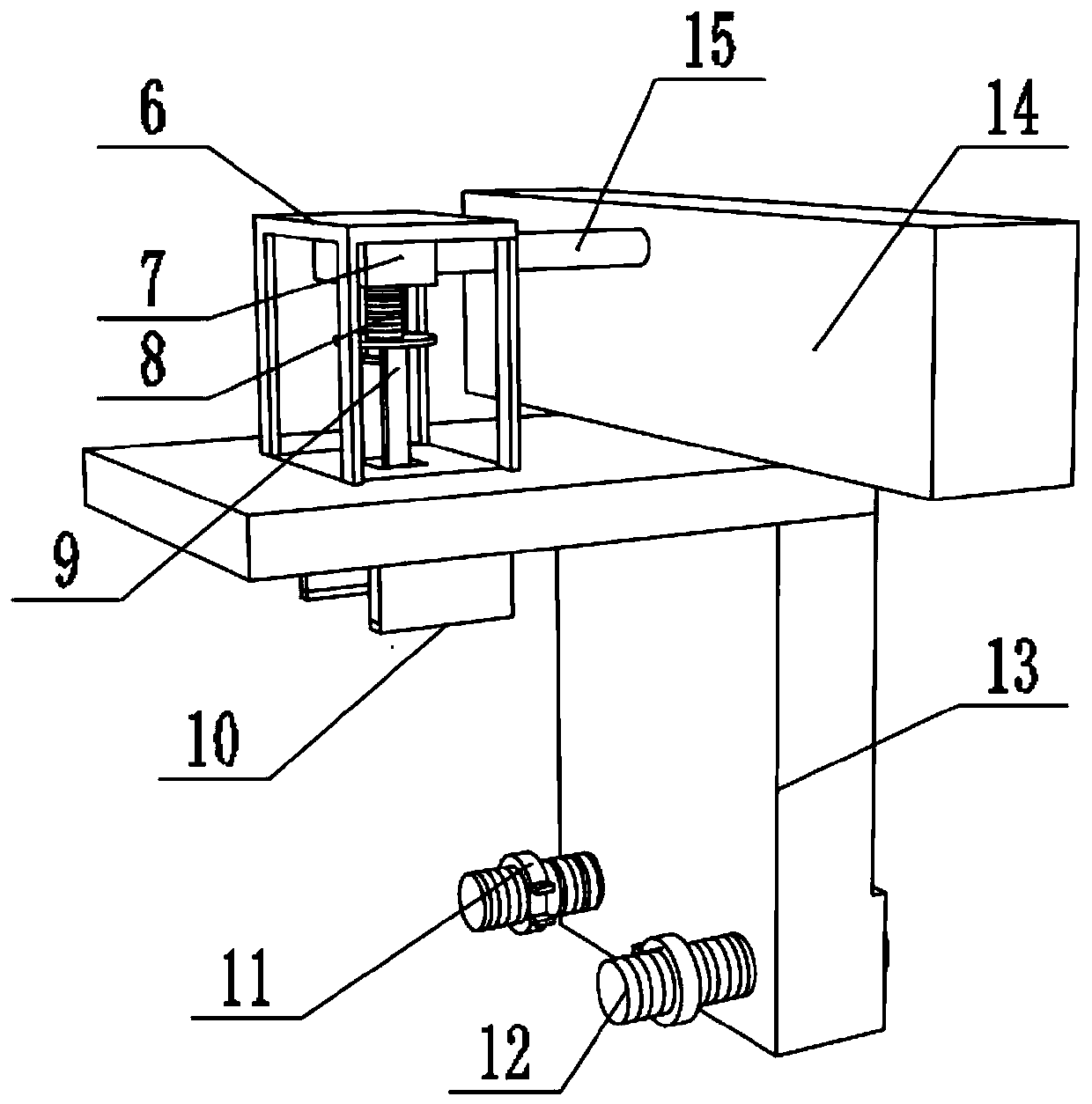

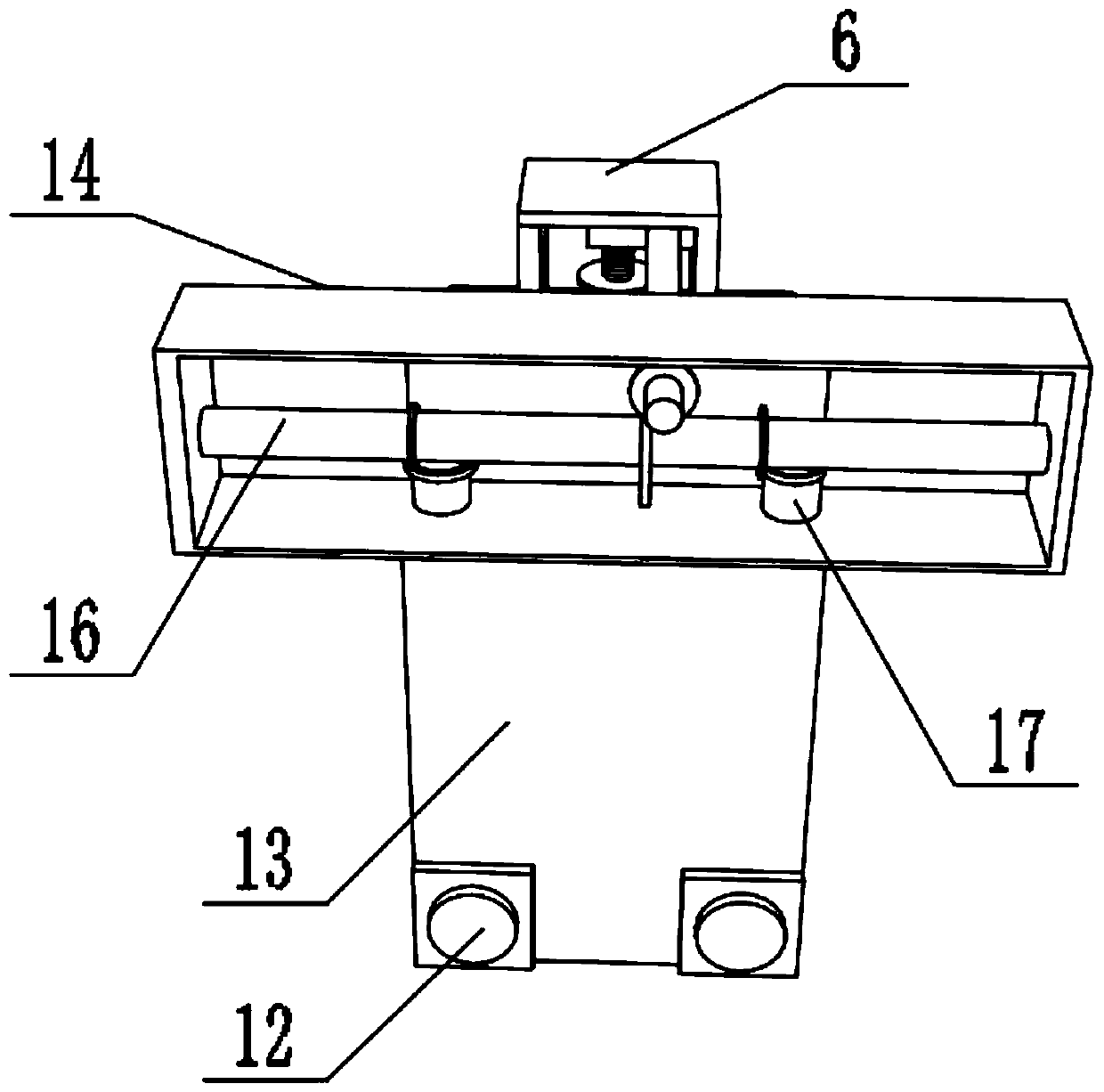

[0031] The top of the support 1 is welded with a fixed plate 4, and one side of the fixed plate 4 is provided with a station holder 5, the station holder 5 includes a fixed frame 6 and a top box 14, and the fixed frame 6 and the top box 14 are all fixed on the top of the fixed plate 4 by screws, the bottom end of the fixed frame 6 is connected with the first block 10 through the drive assembly by screws, the bottom end of the fixed plate 4 is welded with the connecting plate 13, and the connecting plate 13 is a Both ends of the side outer wall are rotatably connected with a second threaded rod 12, and the outer wall of the second threaded rod 12 is threaded with a second stopper 11, and the second thr...

Embodiment 2

[0036]A hanging mechanism for a garment conveying line, as shown in the figure figure 1 , 3 with Figure 4 As shown, in order to solve the problem of the single function of the sling in the garment-making process; this embodiment makes the following improvements on the basis of Embodiment 1: the sling 3 includes a slider 19 and a hanger 28, and the slider 19 The side wall is welded with connecting block 21, and the bottom end of connecting block 21 is welded with connecting rod 22, and the side wall of connecting rod 22 is welded with hanging seat 27, and hanger 28 is welded on the top of hanging seat 27;

[0037] The bottom end of the side wall of described slider 19 is welded with support plate 18, and the bottom end of support plate 18 is welded with storage box 23, and the bottom inner wall of storage box 23 is fixed with fan 26 by screw, and the air outlet end of fan 26 passes through The first connecting pipe 25 communicates with the top of the storage box 23. One side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com