Trapped vortex combustor head device for preventing main flow from being entrained towards cavity

A combustion chamber and concave cavity technology, applied in the field of trapped vortex combustor head devices, can solve the problems that the concave cavity cannot effectively stabilize the flame, reduce the structural weight of the trapped vortex combustor head, etc., so as to reduce the burden on the head device and reduce the Affecting and inhibiting the effect of entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

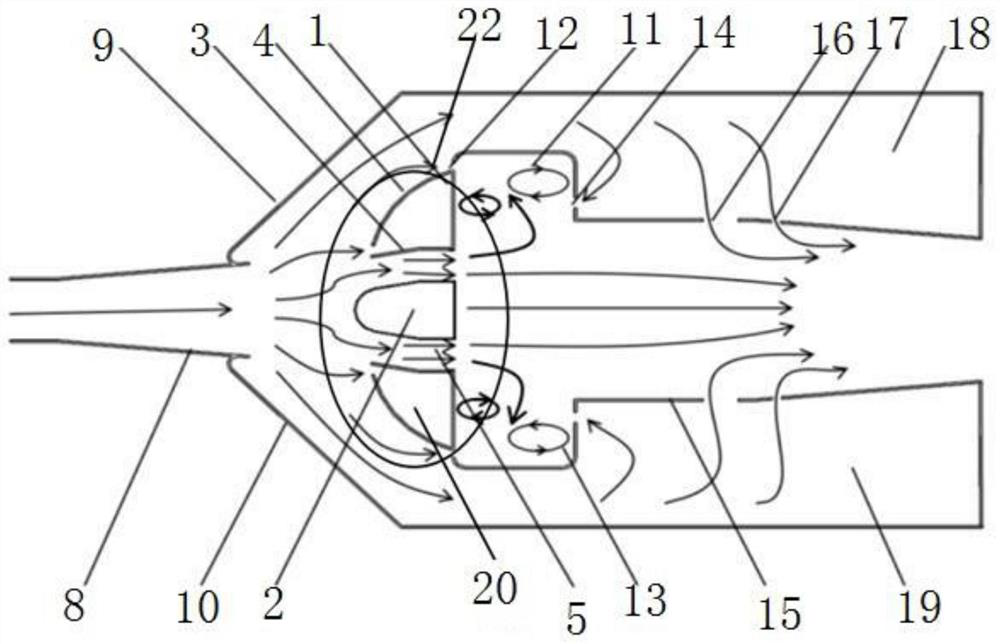

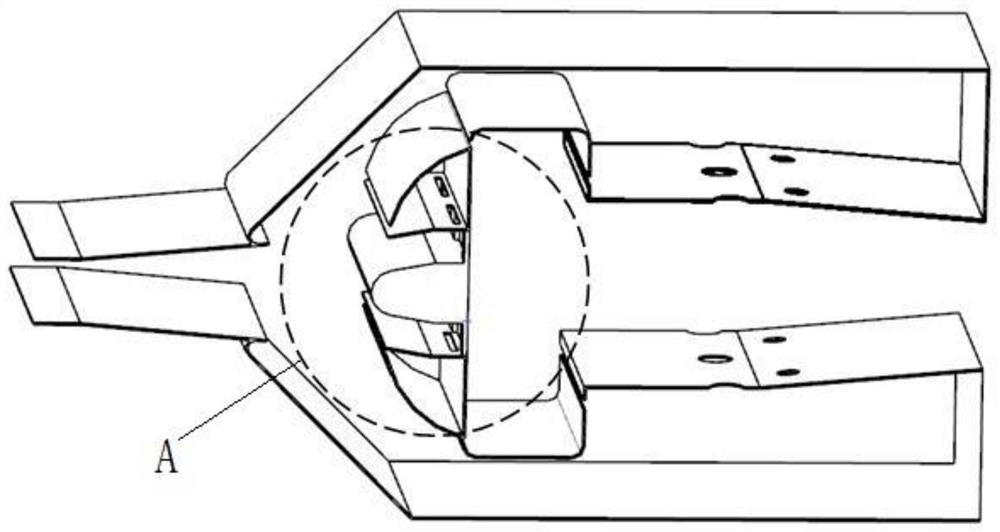

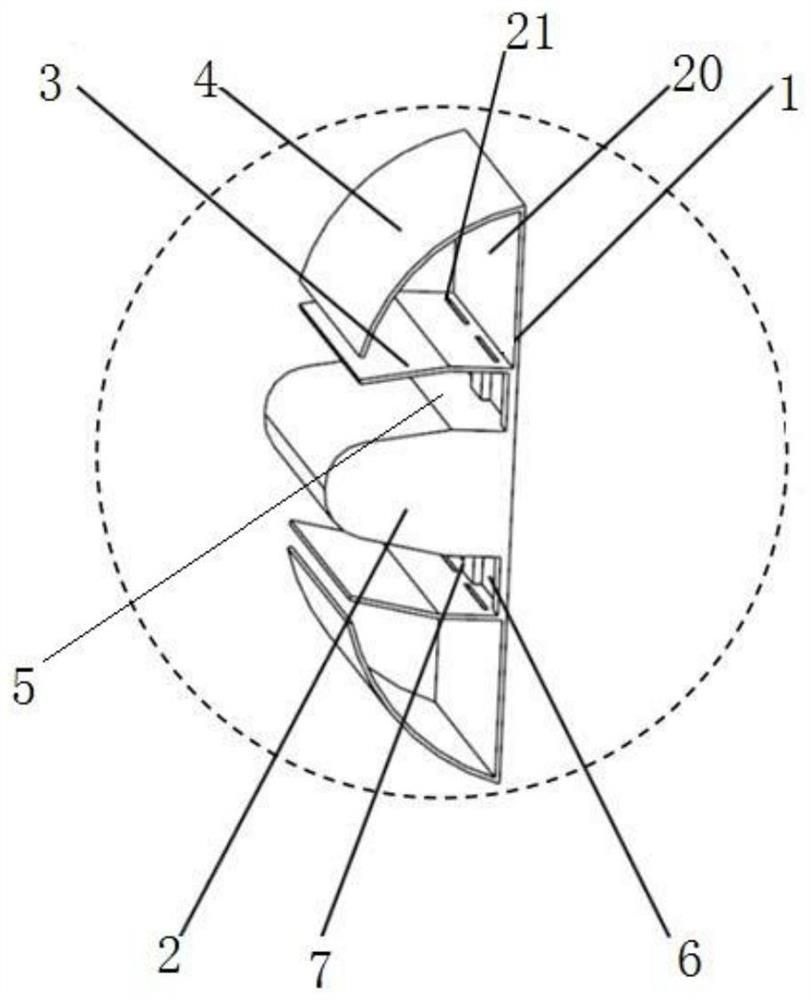

[0020] Such as figure 1 As shown, the existing vortex combustor head device 22 includes a concave cavity front wall 1, a central blunt body 2 is provided in the middle of one side of the concave cavity front wall 1, and the concave cavity front wall on both sides of the central blunt body 2 1 is provided with a deflector 3 and a cap 4 in turn, and there is a gap between the deflector 3 and the cap 4, and the gap introduces air into the space formed by the front wall surface 1 of the concave cavity, the deflector 3 and the cap 4. In the cavity 20 structure; the main flow channel 5 is formed between the deflector 3 and the central blunt body 2, and the front wall 1 of the concave cavity between the deflector 3 and the central blunt body 2 is provided with a main flow opening 6 and a support plate 7 , under the action of the support plate 7, the mainstream oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com