Mechanical, electrical and heating integrated electronic enclosure

A chassis, electromechanical technology, applied in the direction of electrical equipment casing/cabinet/drawer, electrical components, magnetic field/electric field shielding, etc., can solve the problems of untested electromagnetic compatibility and thermal control, unpublished circuit board installation and vibration reduction, No problems such as vibration reduction design, to achieve the effect of reducing the number and structural weight, saving installation space, and good vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

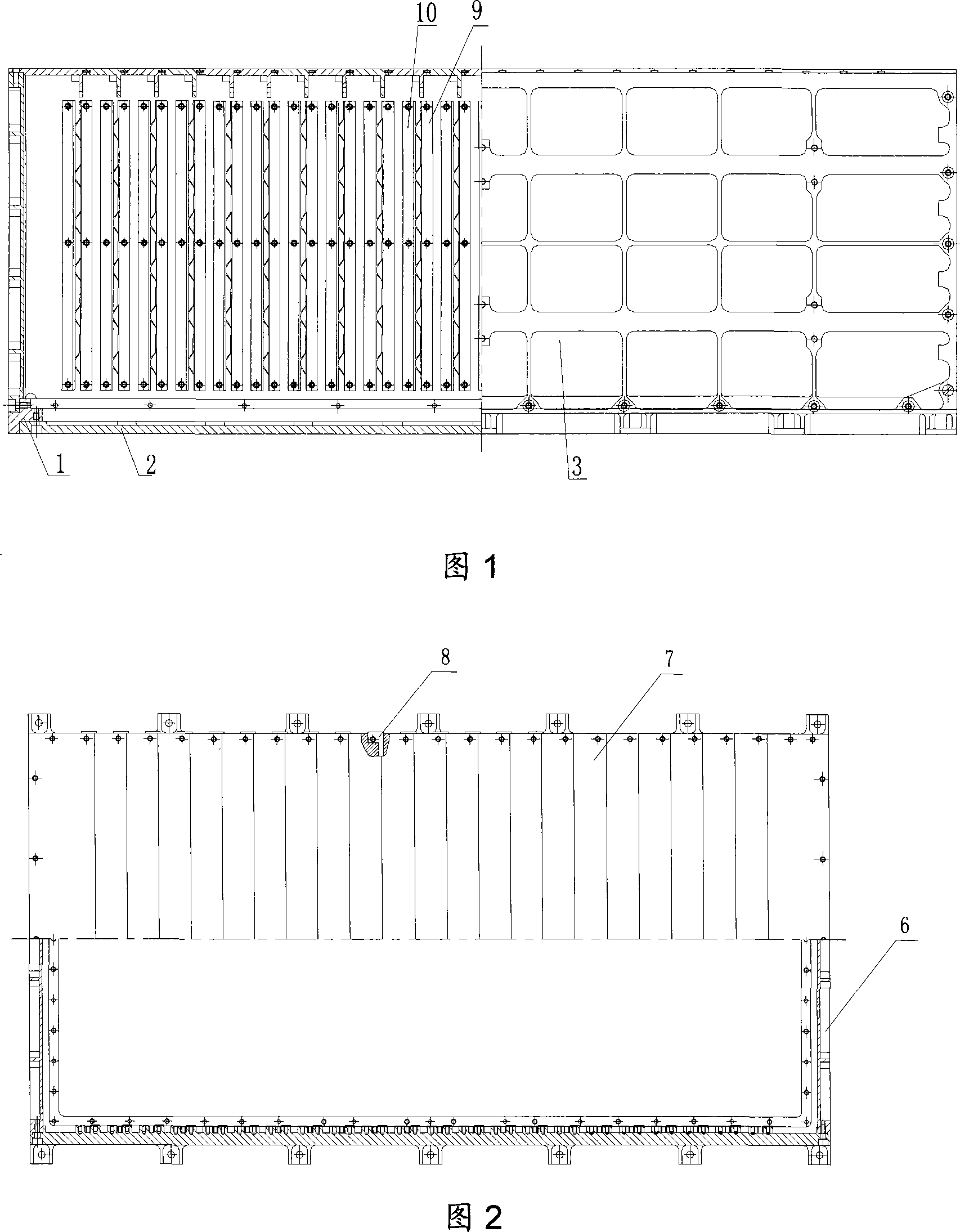

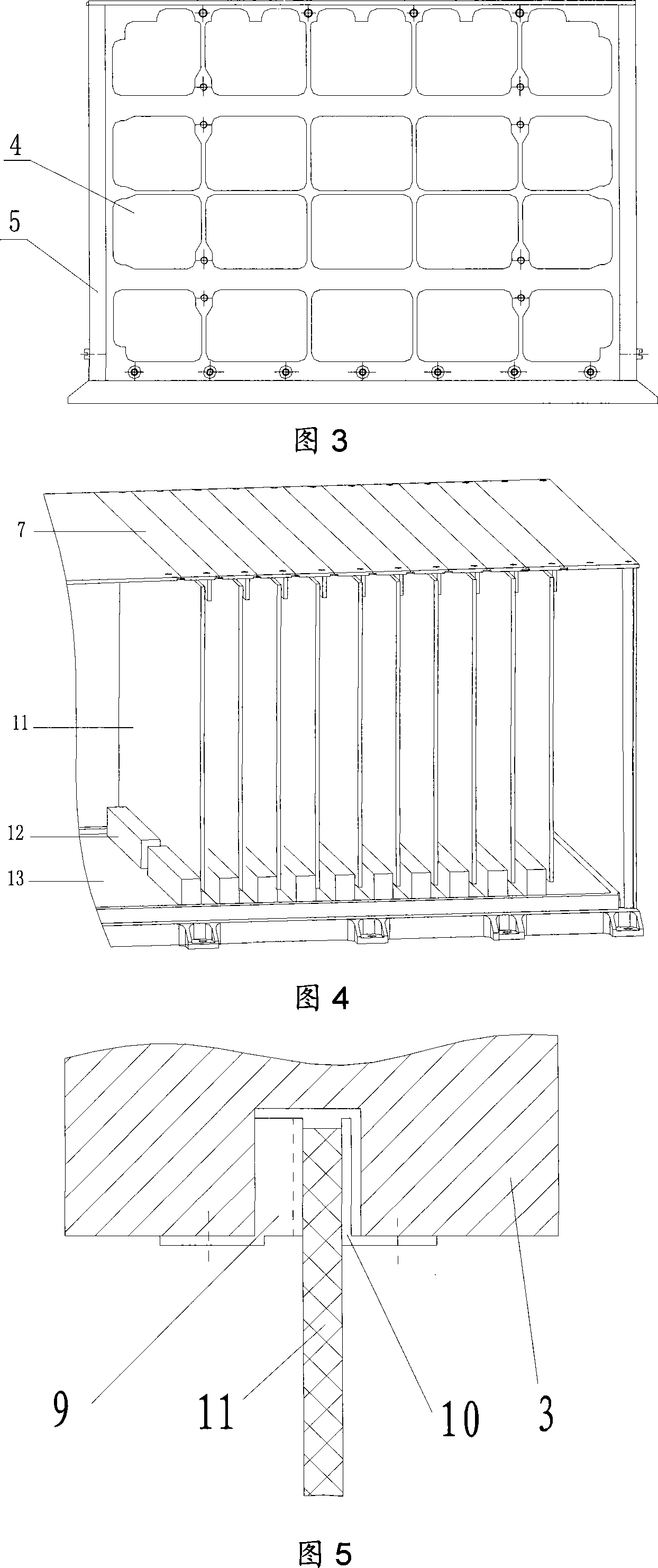

[0027] As shown in Figures 1 to 3, the chassis structure consists of a chassis 1, a bottom cover 2, a front panel 3, a left panel 4, a rear panel 5, a right panel 6, corner strips 7, insert strips 8, spring sheets 9, Corner pad 10 composition. The front panel 3, rear panel 5, left side panel 4, right side panel 6, and bottom cover 2 of the chassis are all made of 1.8mm thick aluminum alloy thin plate reinforced structure, and the chassis is light in weight and high in rigidity. The front plate 3, rear plate 5, left side plate 4, and right side plate 6 of the chassis can be equipped with micro heat pipes, which can make the temperature of the entire chassis uniform. If it is determined through thermal analysis that other thermal control measures can meet the temperature range, micro Heat pipe.

[0028] Electromagnetic compatibility is considered in the design of the chassis. The front panel, rear panel, left side panel, right side panel, top corner strip, bottom cover, and cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com