Head injector of low-thrust engine for electric discharge and ignition by utilizing nozzle clearance

A small thrust, engine technology, applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems of discharge ignition failure, increase in engine structure and weight, and increase in structure size, so as to reduce structural weight and structure. Quality, failure avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

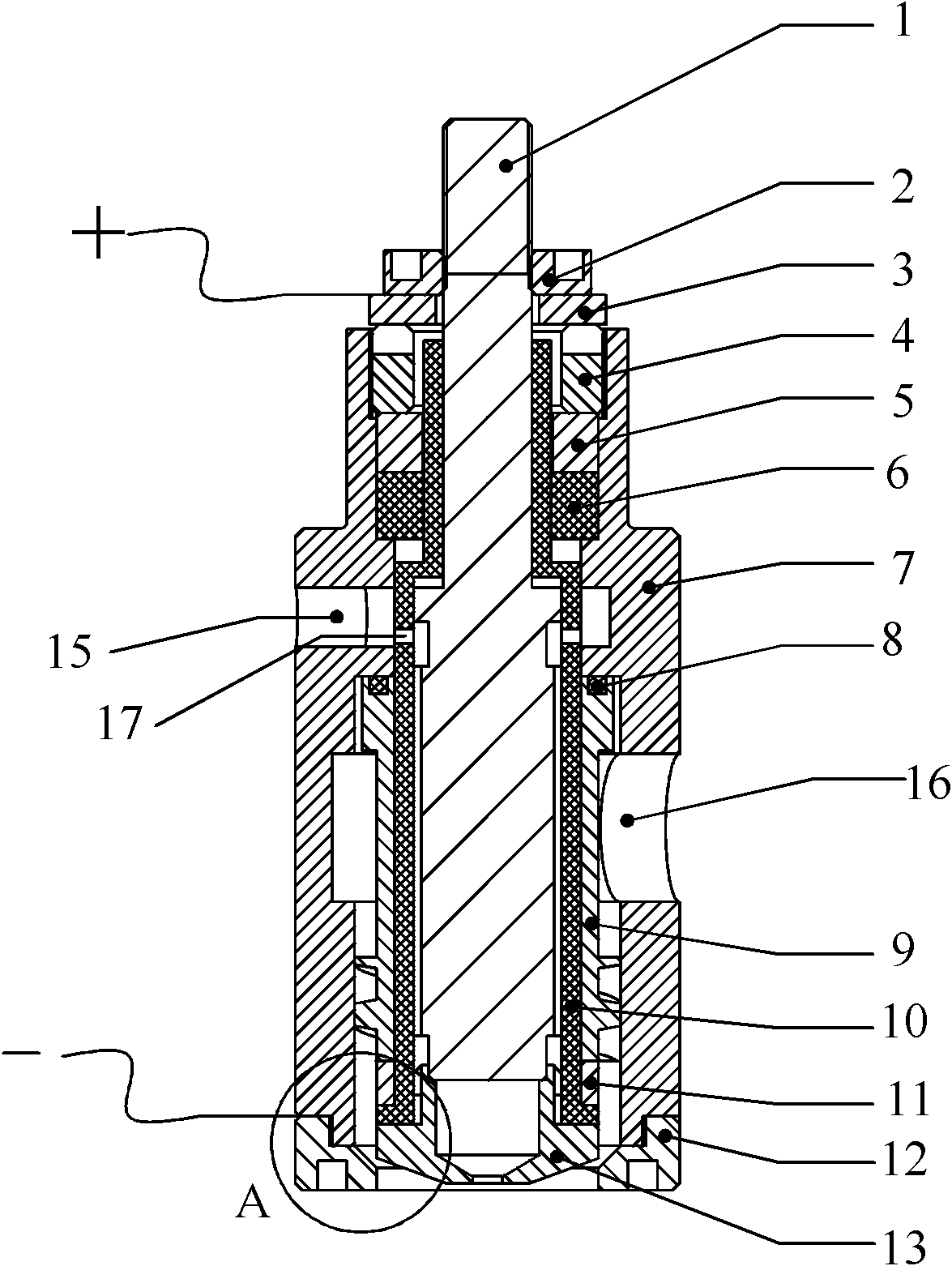

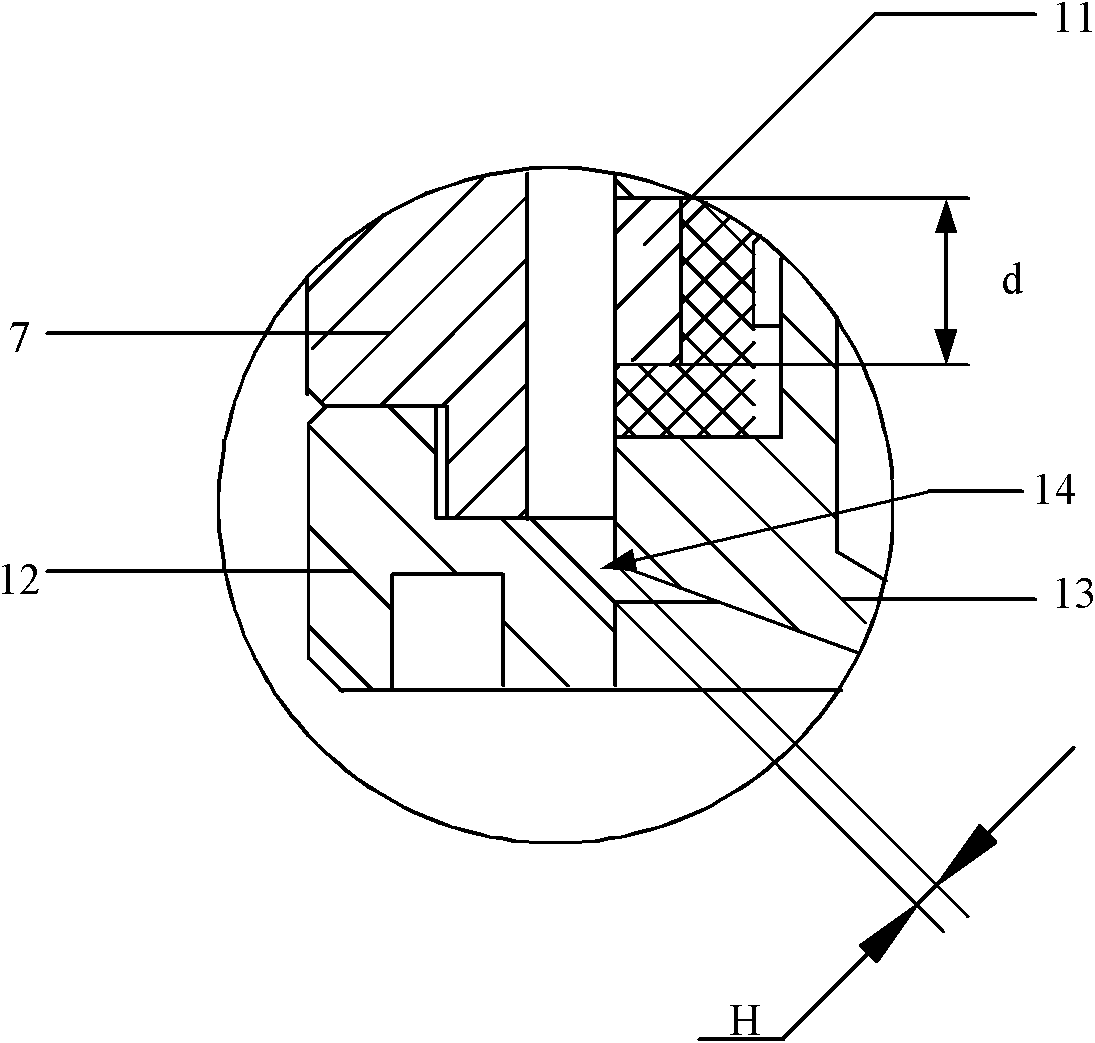

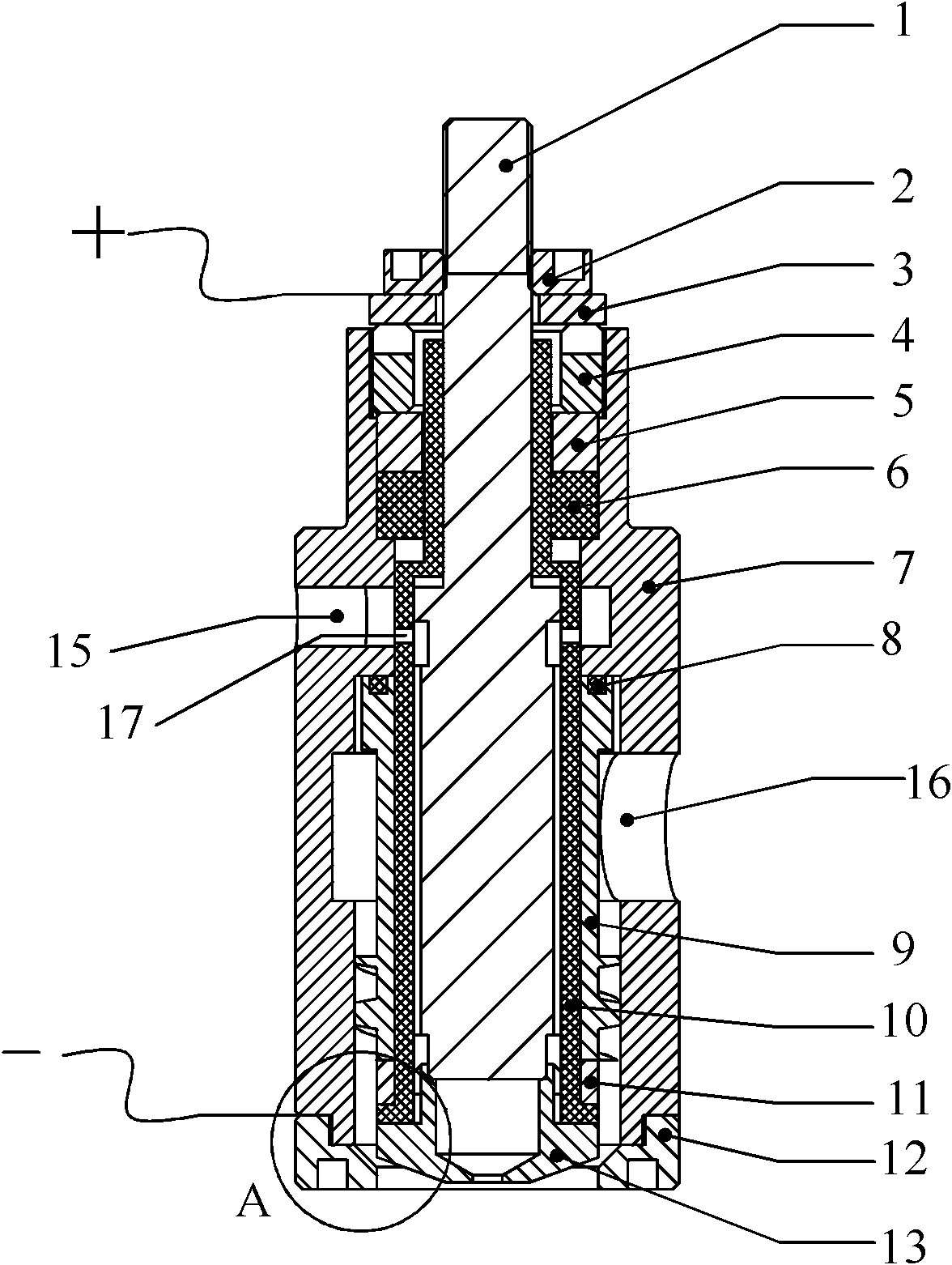

[0025] The present invention proposes a small-thrust engine head injector that utilizes nozzle gap discharge ignition, such as figure 1 As shown, it includes high-voltage positive electrode copper rod 1, positive electrode connection nut 2, positive electrode insulating gasket 3, sealing lock nut 4, sealing extrusion ring 5, sealing gasket 6, housing 7, sealing ring 8, oxidant vortex device 9, Positive electrode insulating sleeve 10 , discharge annular seam adjustment pad 11 , oxidant nozzle outlet end cover 12 , and fuel centrifugal nozzle 13 .

[0026] Such as figure 1 As shown, the bottom of the high-voltage positive copper rod 1 is connected to a fuel centrifugal nozzle 13 , and the top of the high-voltage positive copper rod 1 is connected to a positive terminal nut 2 and a positive insulating gasket 3 in sequence. The high-voltage positive electrode c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com