Invisible door cover, invisible door system and installation method of invisible door system

An installation method and invisible door technology, applied in the direction of window/door frame, frame fixing, etc., can solve the problems of inaccurate determination of the installation level of the main door cover, low installation efficiency, damage to the main door cover, etc., and improve the invisible vision. effect, improve construction efficiency, and improve the effect of force strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

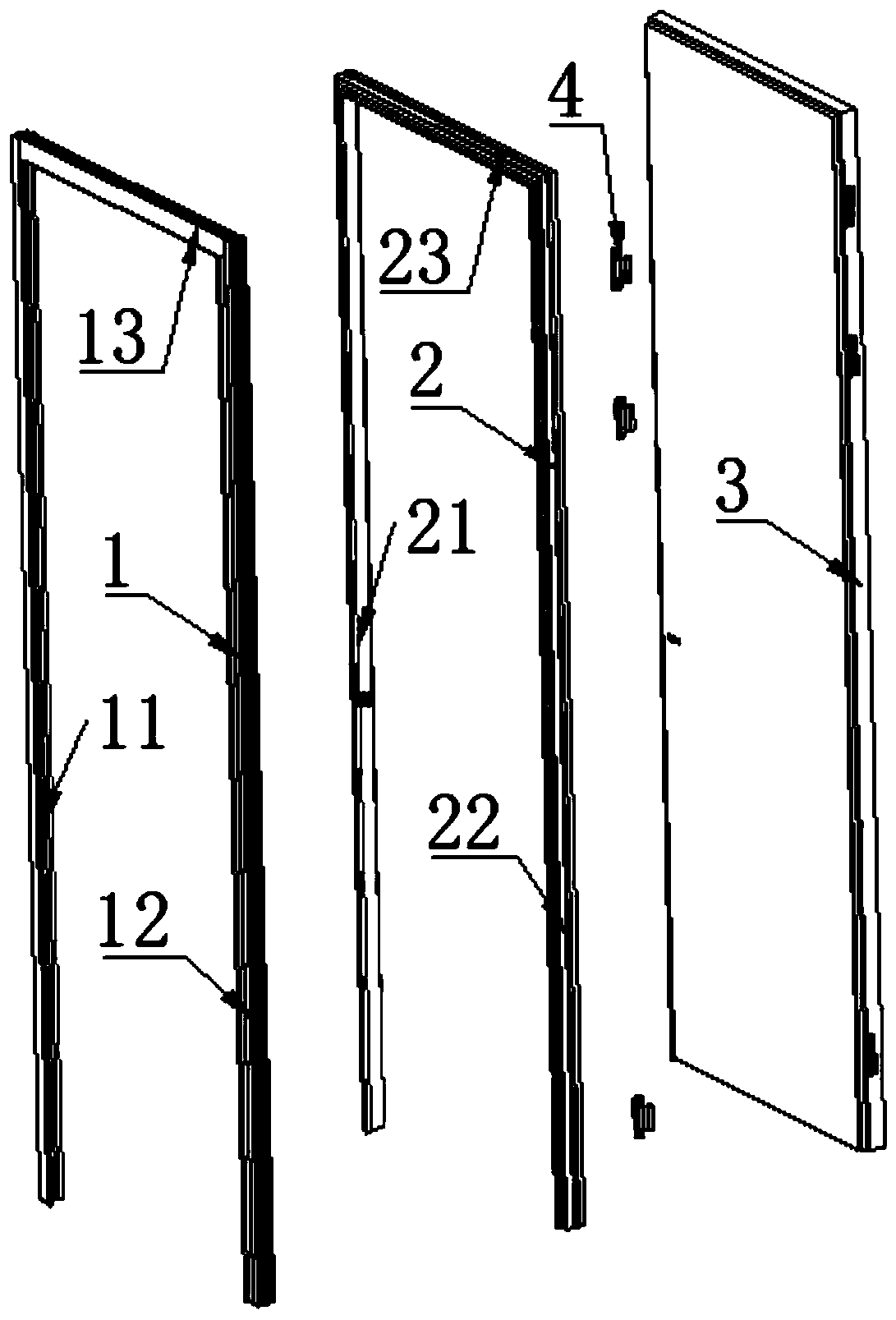

[0063] like figure 1 As shown, the invisible door system includes a hidden door cover and a door leaf 3, wherein the invisible door cover includes a hidden secondary cover 1 and a main door cover 2, and the hidden secondary cover 1 includes a left secondary cover 11 and a right secondary cover 12, and is connected by fastening screws The top secondary cover 13 of the left and right secondary cover, the left and right secondary cover and the top secondary cover all adopt the hidden secondary cover profiles with the same structure.

[0064] The main door cover 2 is installed on the main door cover installation surface of the hidden auxiliary cover 1, and the door leaf 3 is installed on the main door cover 2 through the hinge 4. The main door cover 2 includes the left main door cover 21 and the right main door cover 22 using the same profile. And the top main door pocket 23 that connects left and right main door pockets.

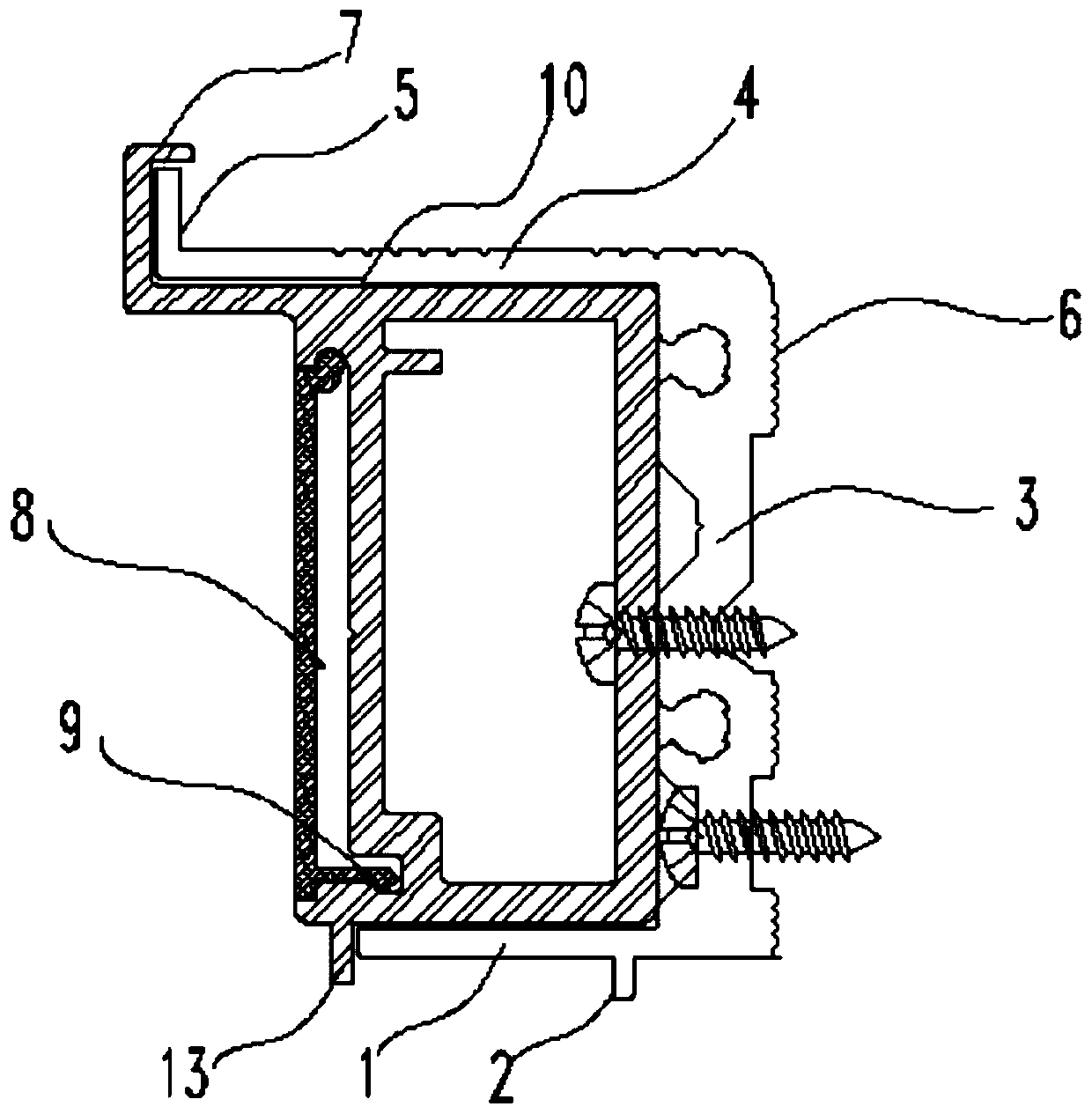

[0065] like Figure 2-3 As shown in the figure, the hid...

Embodiment 2

[0072] like Figure 4 As shown in the figure, there is a structural schematic diagram of the installed invisible door system described in Embodiment 1. The bending structure 7 of the main door cover in the invisible door cover visually hides the limit rib 5 of the hidden secondary cover, and the usual process seam of a few millimeters between the main and secondary cover can be eliminated, and the invisible effect of the entire door cover is better .

[0073] After passing the third installation side of the hidden secondary cover through the corrugated plate 13 and fixing it on the wall with fastening screws, with the limit rib 5 and the positioning bar 13 as the boundary, the first installation side and the second installation side are connected to the wall surface. Fan dust on the associated part of the wall surface, and then carry out wallpaper 14 decoration on the fan dust surface 12; wherein the wallpaper 14 bypasses the limit strip 14 and performs closing limit on the s...

Embodiment 3

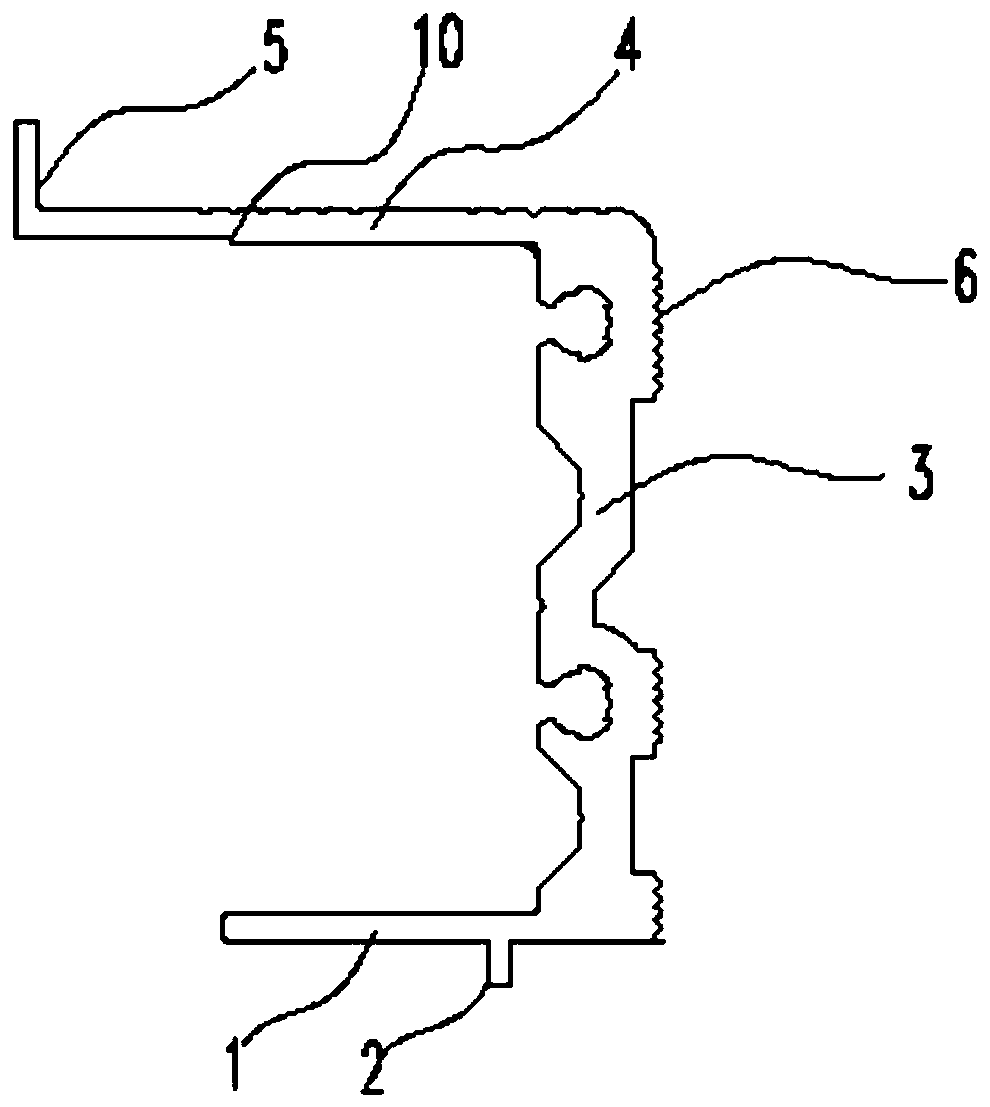

[0077] Different from the installation structure of the concealed auxiliary cover described in Embodiment 2, Embodiment 3 provides another structural schematic diagram of the installed invisible door system described in Embodiment 1. like Figure 5 As shown, the bending structure 7 of the main door cover in the invisible door cover hides the limit rib 5 of the hidden secondary cover visually, and the process seam of several millimeters between the main and secondary cover can be eliminated in the past, and the invisible of the whole door cover Better results.

[0078] In this embodiment, after the third installation edge of the concealed auxiliary cover is staggered with the wall surface, the first installation edge and the wall surface and the decorative closing position defined by the positioning strip 13 and the limit strip 2 are directly used. The panel 15 is decorated.

[0079] The invisible door cover and the invisible door system provided by the present invention can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com