Backfill repairing method for tunnel collapse cavity

A repair method and cavity technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., to achieve the effects of low risk, high operating efficiency, and reduced construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

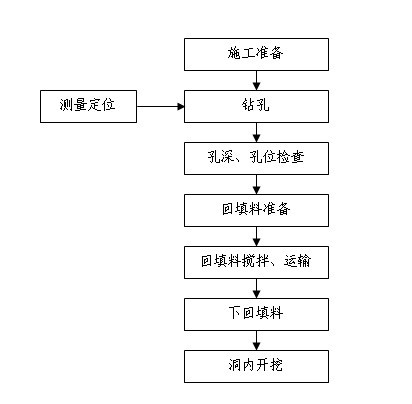

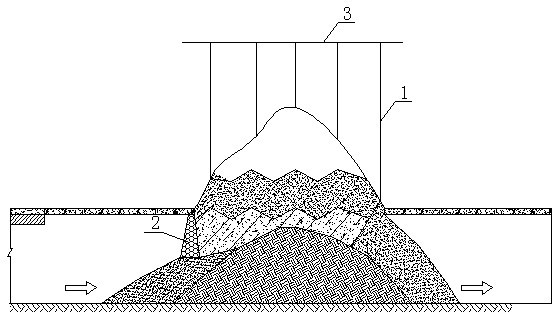

[0024] figure 1 It is a process flow diagram of the present invention; figure 2 It is a construction schematic diagram of the present invention.

[0025] As shown in the figure: the method for backfilling and repairing the tunnel collapse cavity of the present invention includes the following construction procedures:

[0026] First, positioning drilling: use a total station to assist positioning, and then use a drilling rig to drill holes on the surface 3 above the cavity to form a plurality of through holes 1 connecting the cavity and the surface;

[0027] Second, cavity backfill:

[0028] a. Bottom backfill: choose sand, stone, sandstone cement mixture or cement mortar to backfill the part below the vault;

[0029] b. Backfilling of the landslide cavity: choose materials with cohesive force and certain strength to backfill the landslide cavity;

[0030] Third, excavation and cleaning: after the backfill material in the cavity of the collapse is condensed and stabilized,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Drilling aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com