Construction method for assisting small-diameter open type TBM tunneling for bad geological hole section pipe shed

A construction method and open technology, which is applied in the field of tunneling with small diameter open TBM assisted by tube sheds in unfavorable geological tunnels, can solve the problems of poor fast passage, fast support, impact on construction efficiency, low construction efficiency, etc. The effect of enhancing the self-stabilizing ability of the surrounding rock, reducing the workload of cleaning slag, and improving the strength of the surrounding rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

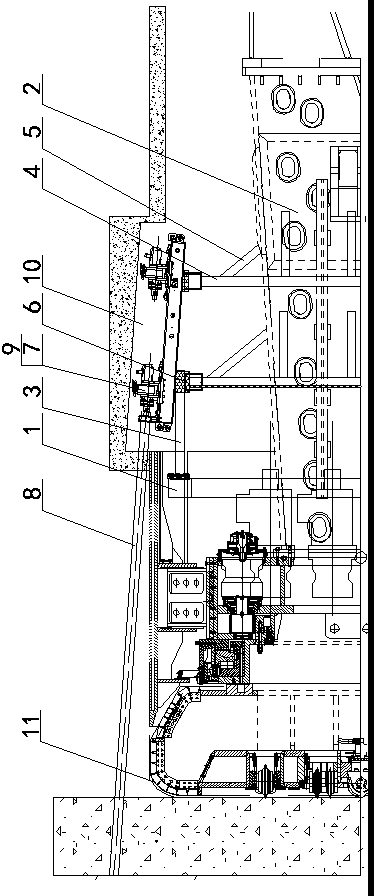

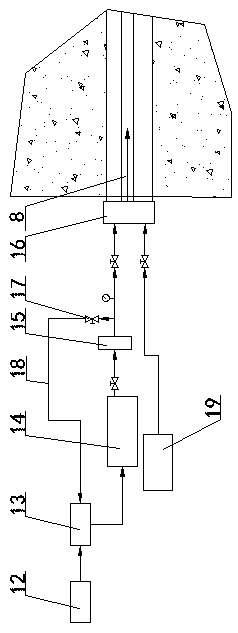

[0018] Embodiment 1: as figure 1 , 2 As shown, a construction method for small open TBM excavation assisted by a pipe shed in an unfavorable geological cave section, the method includes the following steps: 1) Construction preparation for the unfavorable geological cave section; 2) Reinforcing the surrounding rock and applying temporary support; 3) Expansion and excavation of the pipe shed workshop; 4) Installation of the anchor drilling rig and construction of the upper drainage hole of the shield; 5) Consolidation of the shield and the upper part of the cutter head; 6) Remove the anchor rig and install the pipe shed drilling rig; 7) Drilling and grouting of open holes; 8) Drilling and grouting of pipe sheds; 9) Backfilling of expanded excavation sections; 10) TBM tunneling.

[0019] Among them, in the step 2), the drilling rig equipped with TBM is used to lay out self-propelled bolts according to the design requirements, and inject grout to consolidate the surrounding rock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com