A medium-frequency furnace bottom blowing argon ventilation brick and its preparation method

A gas permeable brick and bottom argon blowing technology, which is applied in the field of high temperature smelting and purification, can solve the problems of low air permeability, inability to solve the problem of permeable brick leakage, and high production cost of permeable bricks, so as to improve the anti-leakage performance and achieve good synchronism Effect, the effect of improving the anti-slag erosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

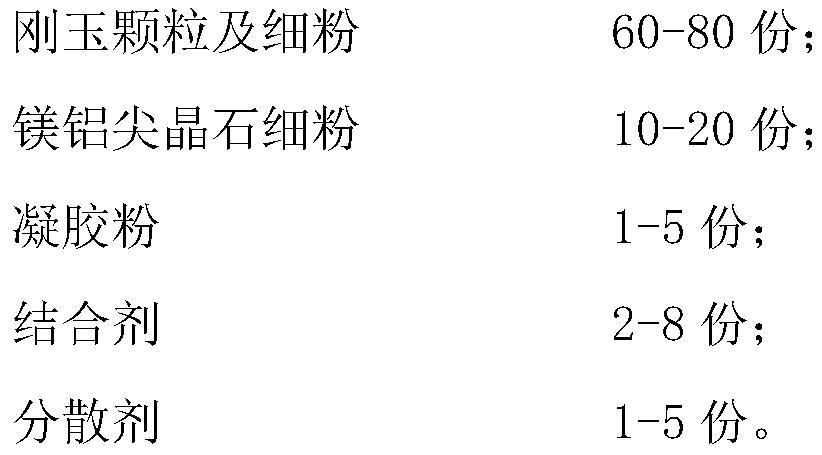

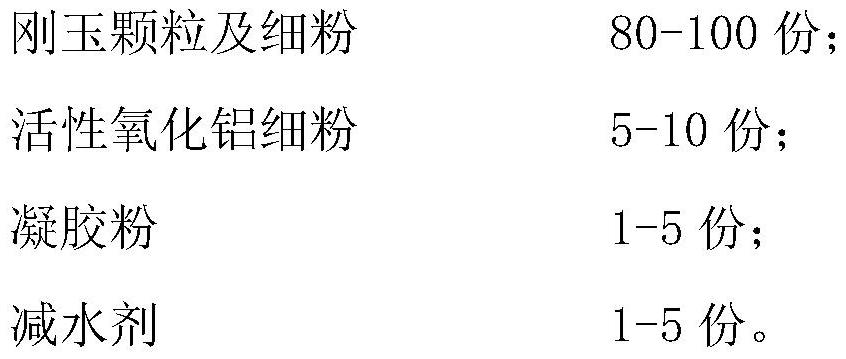

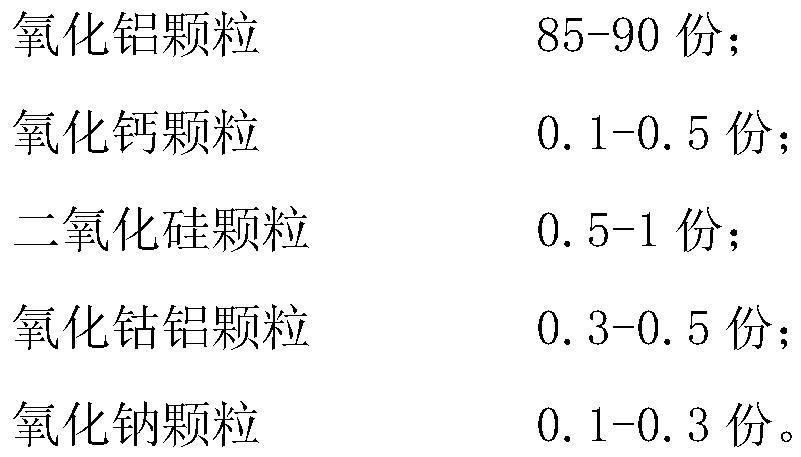

[0039] (1) Classification and preparation: according to the ratio of each component, weigh 60 parts of corundum particles and fine powder, 10 parts of magnesium aluminum spinel fine powder, 1 part of gel powder, 2 parts of binder, dispersant 1 part, and respectively bagged and labeled as raw materials for contacting air-permeable bricks, wherein the binder is formulated according to 85 parts of alumina particles, 0.1 parts of calcium oxide particles, 0.5 parts of silica particles, 0.3 parts of cobalt aluminum oxide particles, and 0.1 parts of sodium oxide particles The dispersant is weighed according to the ratio of 60 parts of sodium tripolyphosphate, 15 parts of sodium hydroxymethanesulfonate, and 10 parts of ammonium polyacrylate; 80 parts of powder, 5 parts of activated alumina fine powder, 1 part of gel powder, and 1 part of water reducer, which are respectively bagged and marked as raw materials for argon-blowing permeable bricks;

[0040] (2) Classified mixing and stirr...

Embodiment 2

[0048](1) Classification and preparation of materials: according to the ratio of each component, weigh 80 parts of corundum particles and fine powder, 20 parts of magnesium aluminum spinel fine powder, 5 parts of gel powder, 8 parts of binder, dispersant 5 parts, and respectively bagged and marked as raw materials for contacting air-permeable bricks, wherein the binder is formulated according to 90 parts of alumina particles, 0.5 parts of calcium oxide particles, 1 part of silica particles, 0.5 parts of cobalt aluminum oxide particles, and 0.3 parts of sodium oxide particles. The dispersant is weighed according to the ratio of 70 parts of sodium tripolyphosphate, 20 parts of sodium hydroxymethanesulfonate, and 15 parts of ammonium polyacrylate; 100 parts of powder, 10 parts of activated alumina fine powder, 5 parts of gel powder, and 5 parts of water reducer, which are respectively bagged and marked as raw materials for argon-blowing permeable bricks;

[0049] (2) Classified m...

Embodiment 3

[0057] (1) Classification and preparation of materials: according to the ratio of each component, weigh 70 parts of corundum particles and fine powder, 15 parts of magnesium aluminum spinel fine powder, 3 parts of gel powder, 5 parts of binder, dispersant 3 parts, and respectively bagged and labeled as raw materials for contacting air-permeable bricks, wherein the binder is formulated according to 87 parts of alumina particles, 0.3 parts of calcium oxide particles, 0.8 parts of silica particles, 0.4 parts of cobalt aluminum oxide particles, and 0.2 parts of sodium oxide particles. The dispersant is weighed according to the ratio of 65 parts of sodium tripolyphosphate, 18 parts of sodium hydroxymethanesulfonate, and 13 parts of ammonium polyacrylate; 90 parts of powder, 8 parts of activated alumina fine powder, 3 parts of gel powder, and 3 parts of water reducer, which are respectively bagged and marked as raw materials for argon-blowing permeable bricks;

[0058] (2) Classifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com