Waterproof construction method for preventing leakage of deformation joint

A construction method and deformation joint technology, which are applied in the field of building leakage control, can solve problems such as uneven material, achieve the effects of avoiding uneven material, improving the anti-leakage effect, and ensuring the quality of waterproof maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

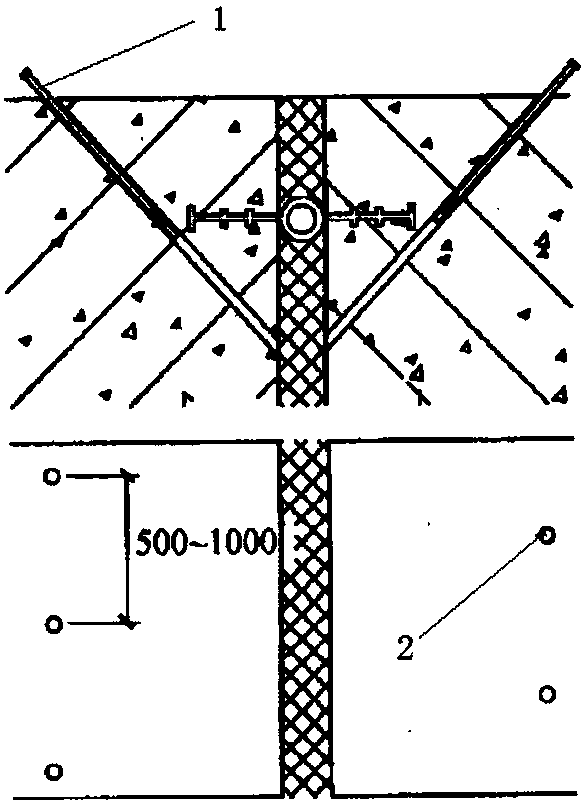

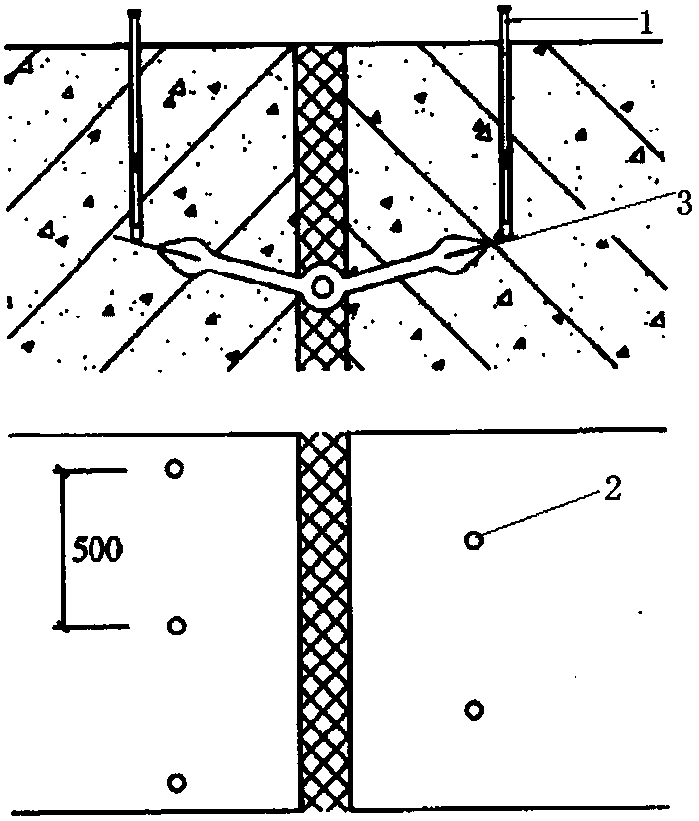

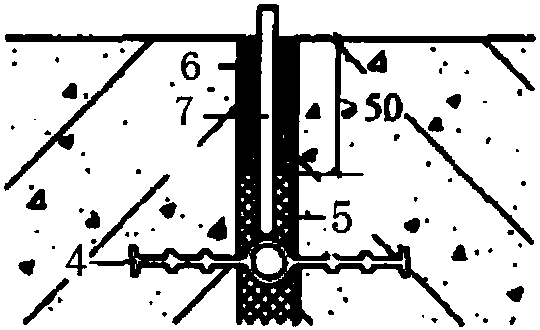

[0080] Figure 5 It shows a schematic diagram of the grouting pipe pre-embedded construction of the deformation joint leakage waterproof construction method according to an embodiment of the present invention, Image 6 A schematic diagram of the construction structure of the construction method for waterproofing of deformation joint leakage according to an embodiment of the present invention is shown.

[0081] like Figure 5 and Image 6 As shown, the embodiment provides a construction method for leakage and waterproofing of deformation joints, in which a buried water stop is provided in the deformation joints, and the construction method includes:

[0082] Step 1: Remove the original external waterstop and metal cover of the deformation joint, remove the original filling in the deformation joint until the buried water stop 18 is exposed, and chisel out the concrete slag inside the deformation joint, and put Clean up the seams;

[0083] Step 2: Arrange arc-shaped support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com