Positive pole piece of winding lithium-manganese battery

A technology of lithium manganese battery and positive electrode sheet is applied in the field of positive electrode sheet of wound lithium manganese battery, which can solve the difficulty of electrolyte penetration into the middle section of the positive electrode sheet, the limitation of high current pulse discharge performance of the battery, and the limitation of the continuous discharge time of the battery, etc. problems, to achieve the effect of improving ion conduction efficiency, increasing ion conduction speed, and increasing the number of high current pulses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

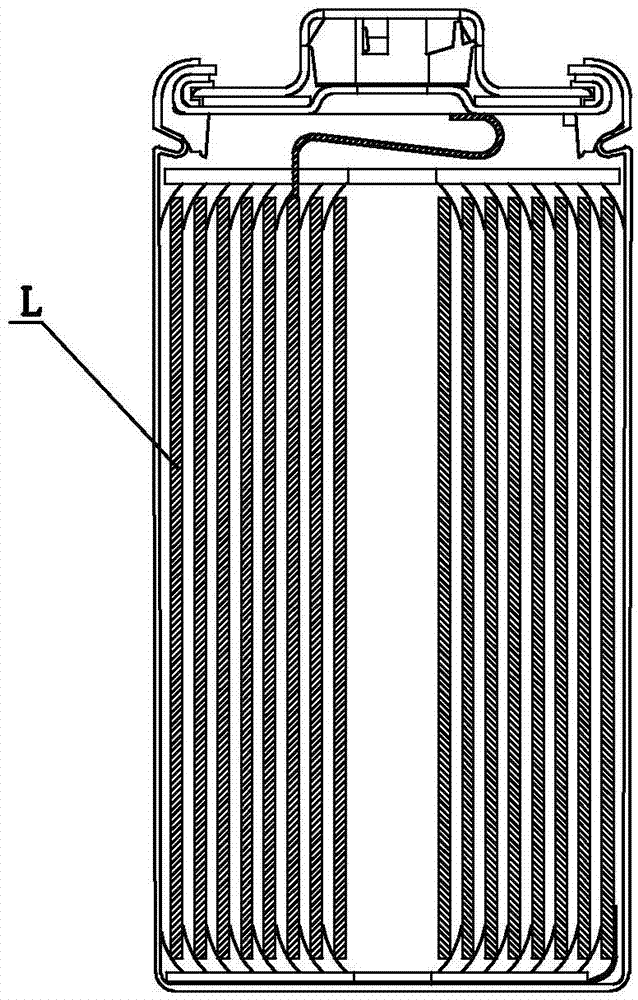

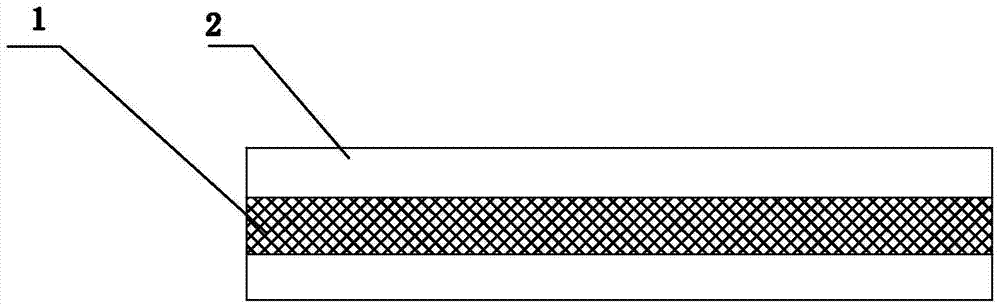

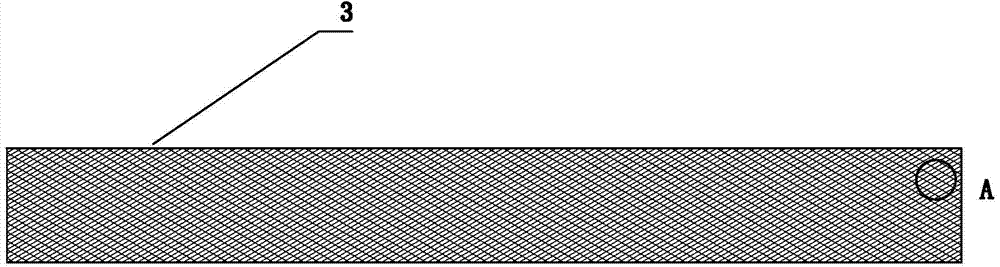

[0022] Example 1: figure 1 Shown in is the position of the positive electrode sheet L in the battery; a winding type lithium manganese battery positive electrode sheet, including a positive electrode current collector 1 and an active material layer 2 coated on both sides of the positive electrode current collector 1, and the active material layer 2 The upper surface is provided with mesh grooves 3 communicating with each other.

[0023] The depth of the mesh groove 3 accounts for 1 / 2 of the thickness of the active material layer 2.

[0024] The positive electrode current collector 1 is a metal mesh, and the active material layer 2 is a manganese dioxide layer.

[0025] The thickness of the metal mesh 1 is 100 μm, and the thickness of the manganese dioxide layer 2 is 50 μm.

[0026] The mesh groove 3 is composed of a plurality of first grooves 31 parallel to each other and the same interval, and a plurality of second grooves 32 parallel to each other and the same interval. The first ...

Embodiment 2

[0029] Embodiment 2: A wound type lithium manganese battery positive sheet, comprising a positive current collector 1 and an active material layer 2 coated on both sides of the positive current collector 1. The upper surface of the active material layer 2 is provided with interconnected meshes Slot 3.

[0030] The depth of the mesh groove 3 accounts for 3 / 4 of the thickness of the active material layer 2.

[0031] The positive electrode current collector 1 is a metal mesh, and the active material layer 2 is a manganese dioxide layer.

[0032] The thickness of the metal mesh 1 is 300 μm, and the thickness of the manganese dioxide layer 2 is 300 μm.

[0033] The mesh groove 3 is composed of a plurality of first grooves 31 parallel to each other and the same interval, and a plurality of second grooves 32 parallel to each other and the same interval. The first groove 31 and the second groove 32 intersect and communicate with each other.

[0034] The structure of the first groove 31 is the...

Embodiment 3

[0036] Embodiment 3: A wound type lithium manganese battery positive sheet, comprising a positive current collector 1 and an active material layer 2 coated on both sides of the positive current collector 1. The upper surface of the active material layer 2 is provided with interconnected meshes Slot 3.

[0037] The depth of the mesh groove 3 accounts for 2 / 3 of the thickness of the active material layer 2.

[0038] The positive electrode current collector 1 is a metal mesh, and the active material layer 2 is a manganese dioxide layer.

[0039] The thickness of the metal mesh 1 is 200 μm, and the thickness of the manganese dioxide layer 2 is 150 μm.

[0040] The mesh groove 3 is composed of a plurality of first grooves 31 parallel to each other and the same interval, and a plurality of second grooves 32 parallel to each other and the same interval. The first groove 31 and the second groove 32 intersect and communicate with each other.

[0041] The structure of the first groove 31 is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com