Intelligent robot warehouse

A robot intelligence, six-axis robot technology, applied in the field of packaging, can solve the problems of large footprint, high cost, and many automation systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

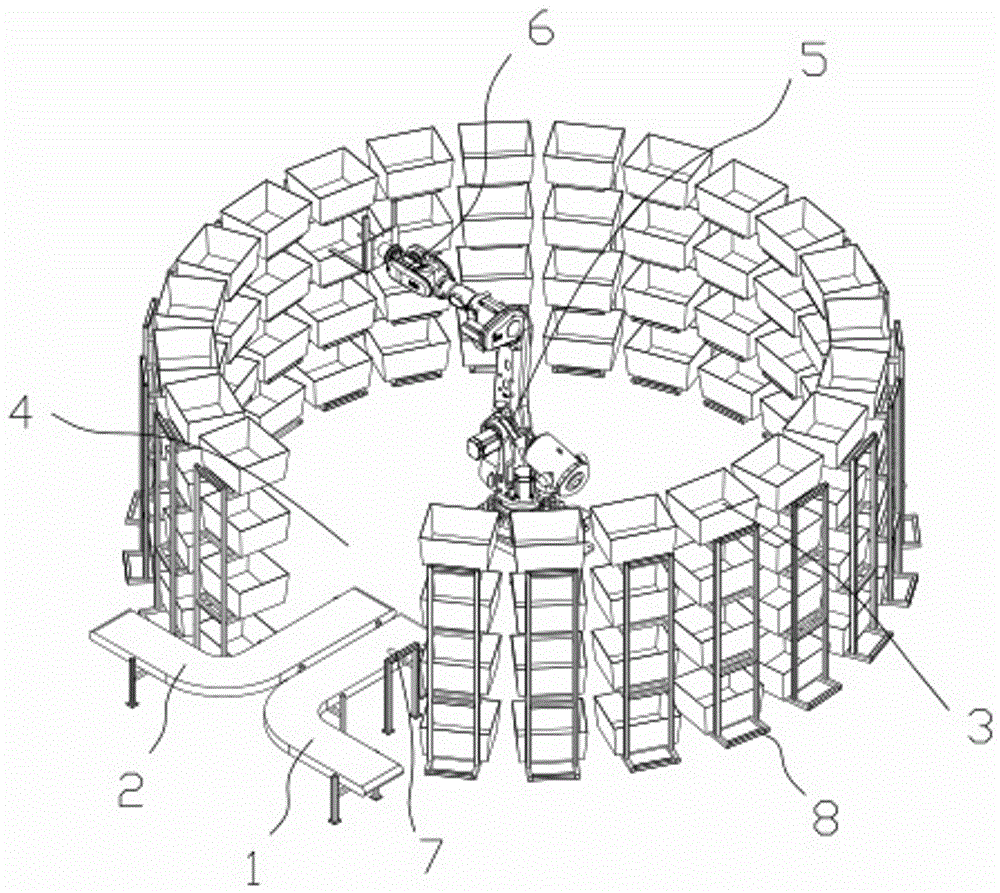

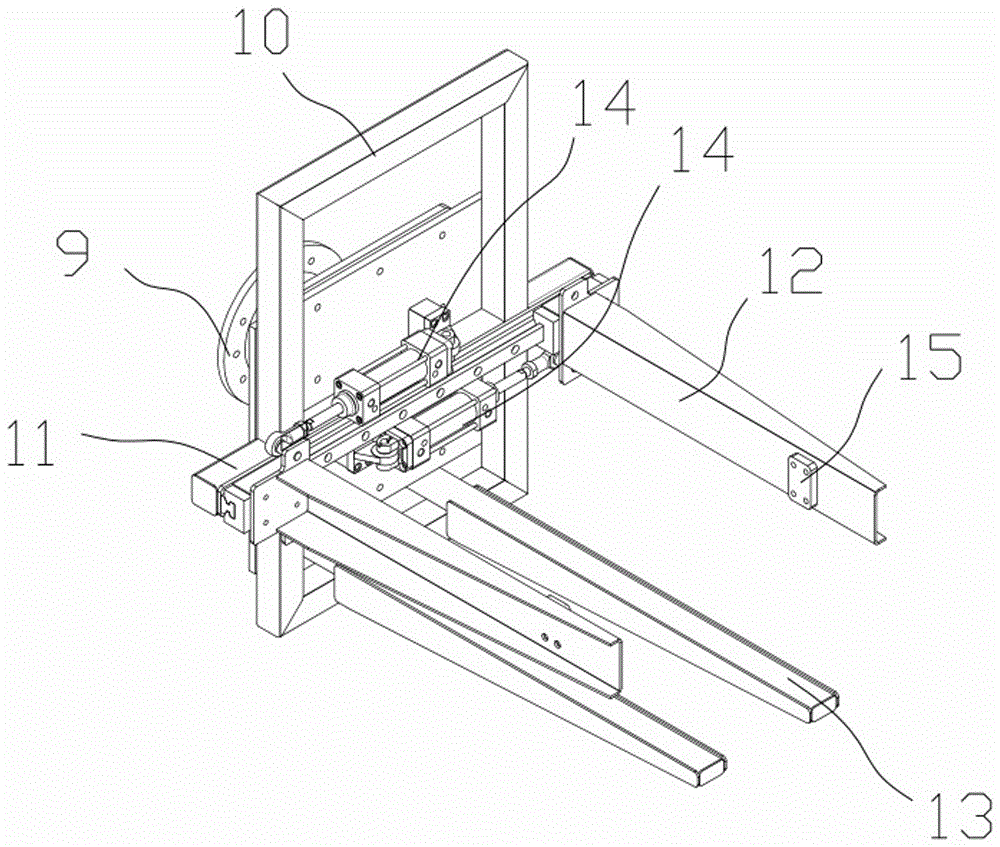

[0008] A robotic intelligent warehouse, such as figure 1 and figure 2 As shown, it includes a feed conveyor belt 1 and a discharge conveyor belt 2, and also includes a circular shelf on which a plurality of turnover boxes 3 with barcode information are placed, and a gap 4 is opened on the circular shelf , the feed conveyor belt 1 and the discharge conveyor belt 2 are arranged at the gap 4, a six-axis robot 5 is arranged at the center of the circular shelf, and the forearm 6 of the six-axis robot 5 is equipped with a grasping turnover frame. Fixtures, the feed conveyor belt 1 is equipped with a code scanner 7 that scans the barcode information on the turnover frame 3 . The code scanner 7 and the six-axis robot 5 are available on the market.

[0009] The radius of the circular shelf is 3 meters to 4 meters, such as 3 meters, 3.1 meters, 3.2 meters, 3.3 meters, 3.4 meters, 3.5 meters, 3.6 meters, 3.7 meters, 3.8 meters or 4 meters, etc., preferably 3.5 meters, Under the premi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com