Patents

Literature

50results about How to "Prevent excessive bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

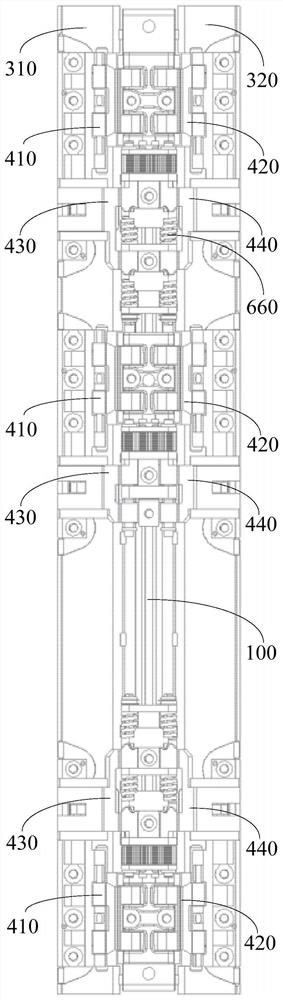

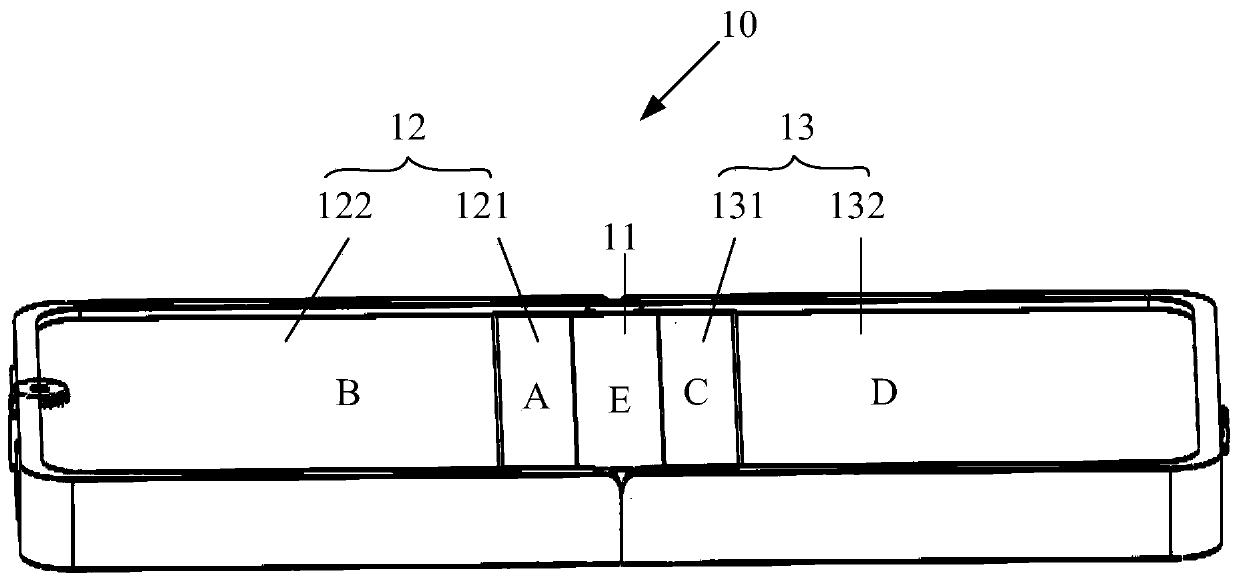

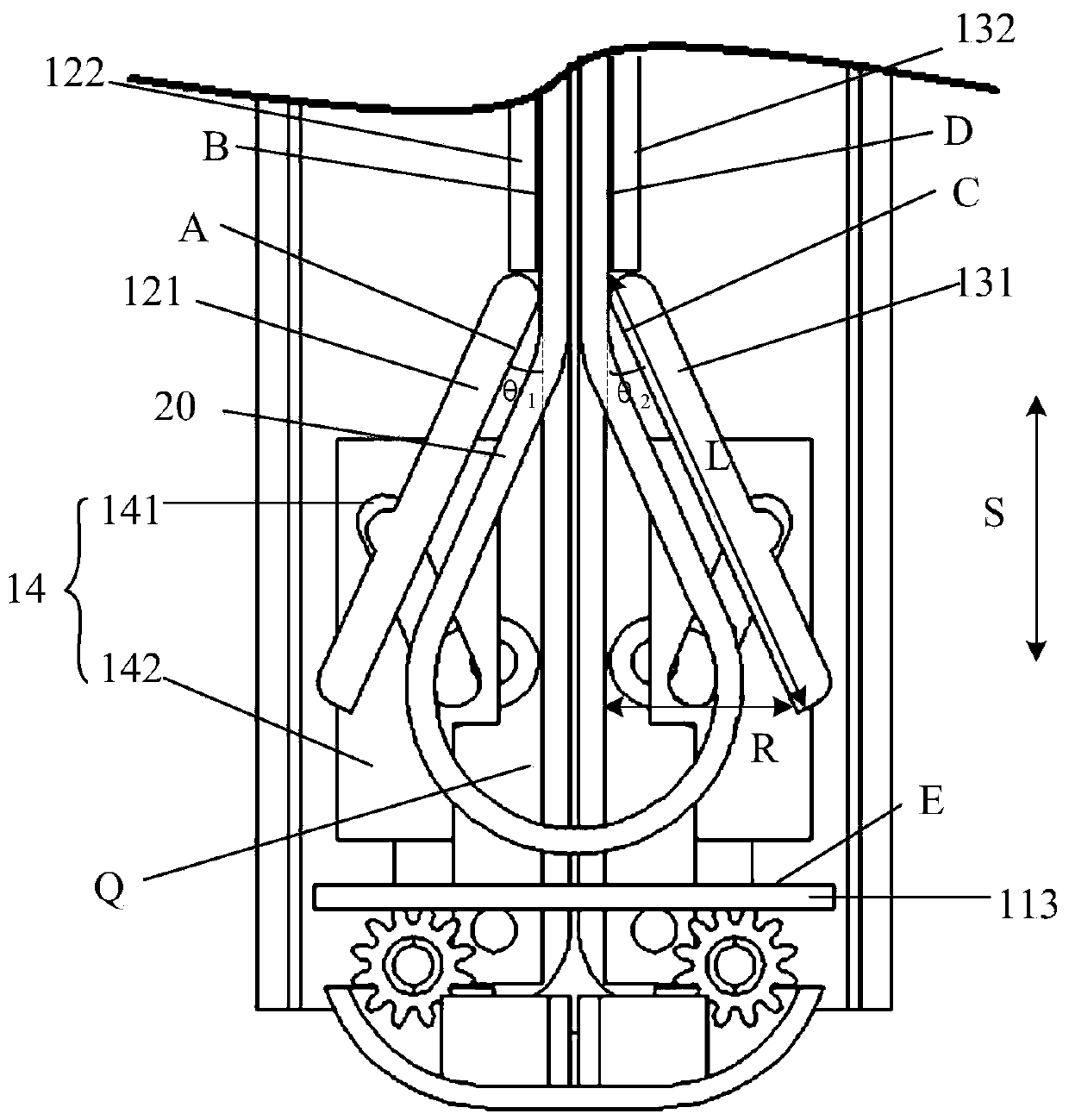

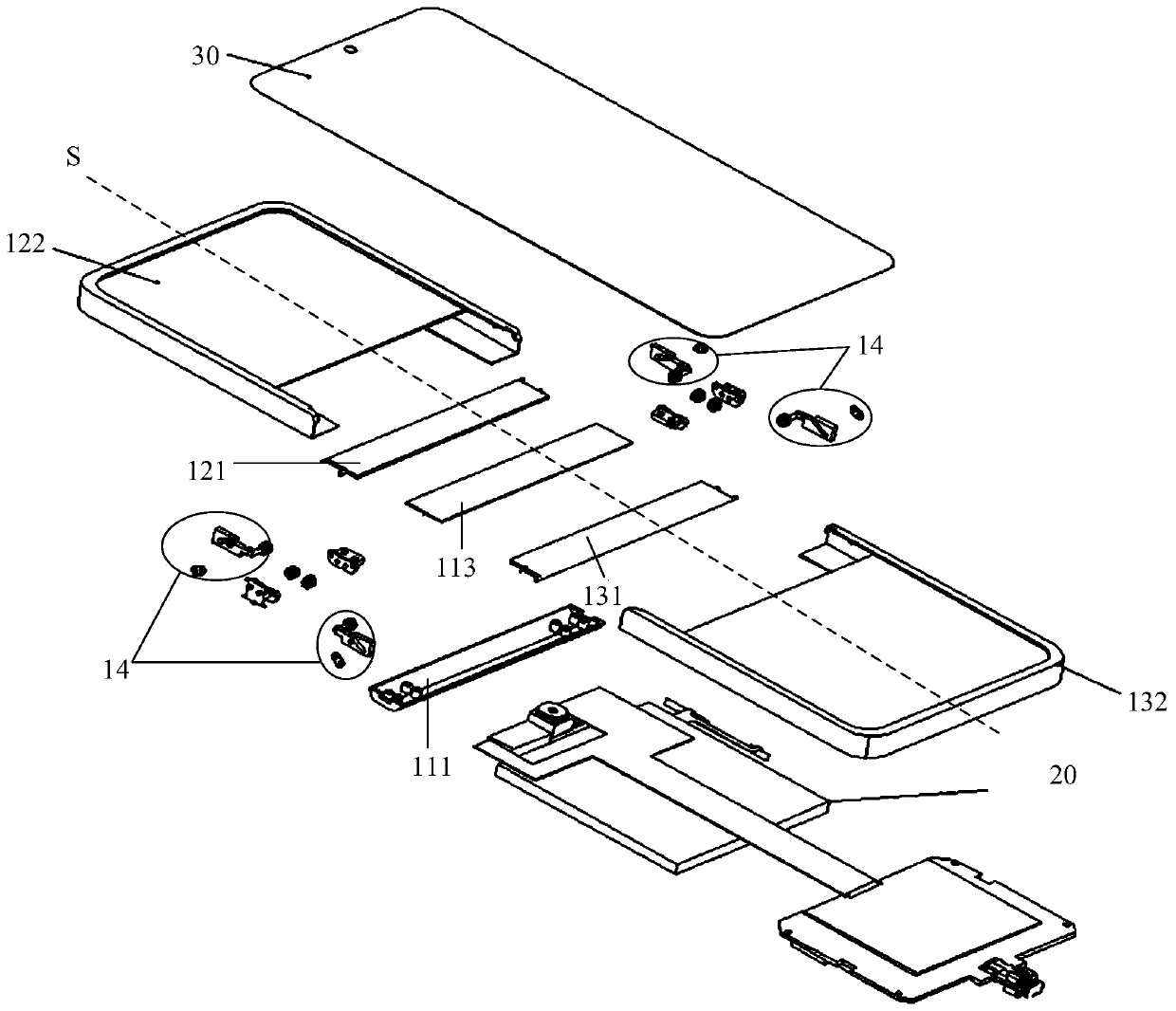

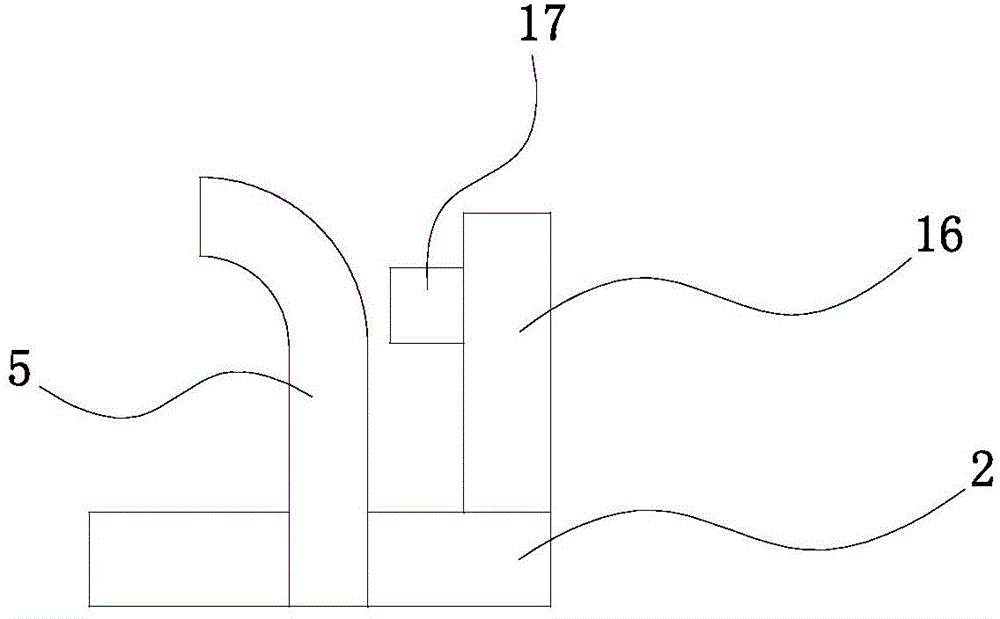

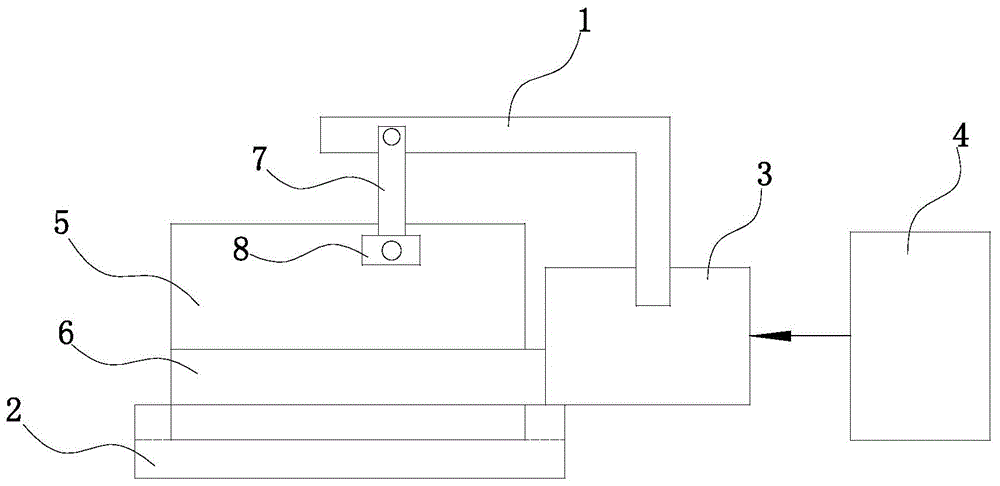

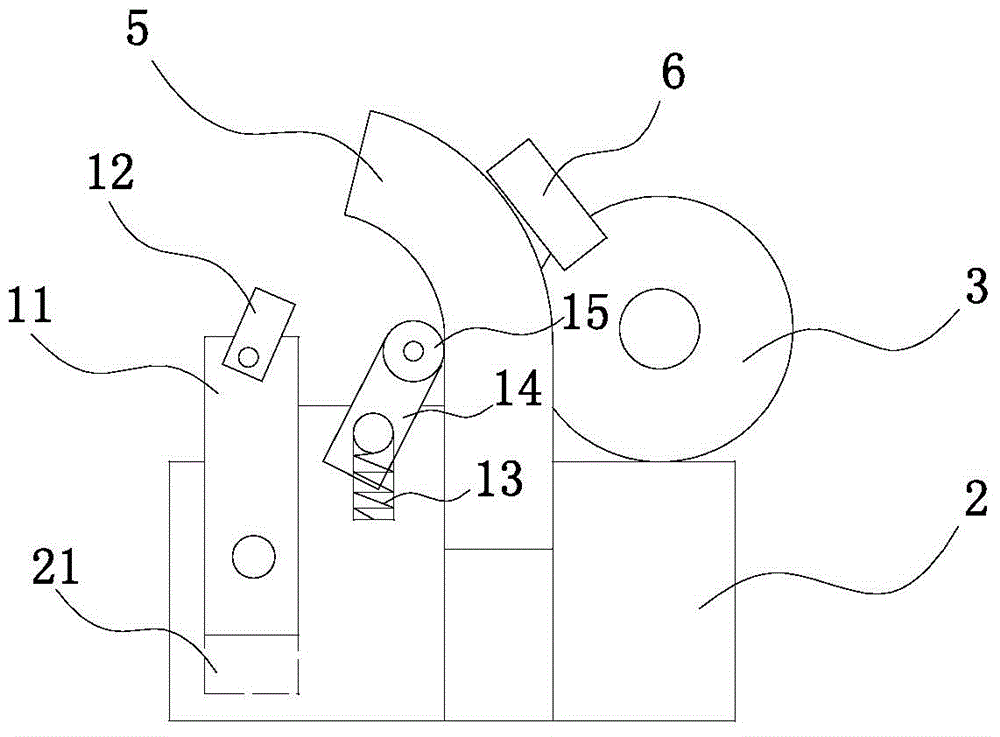

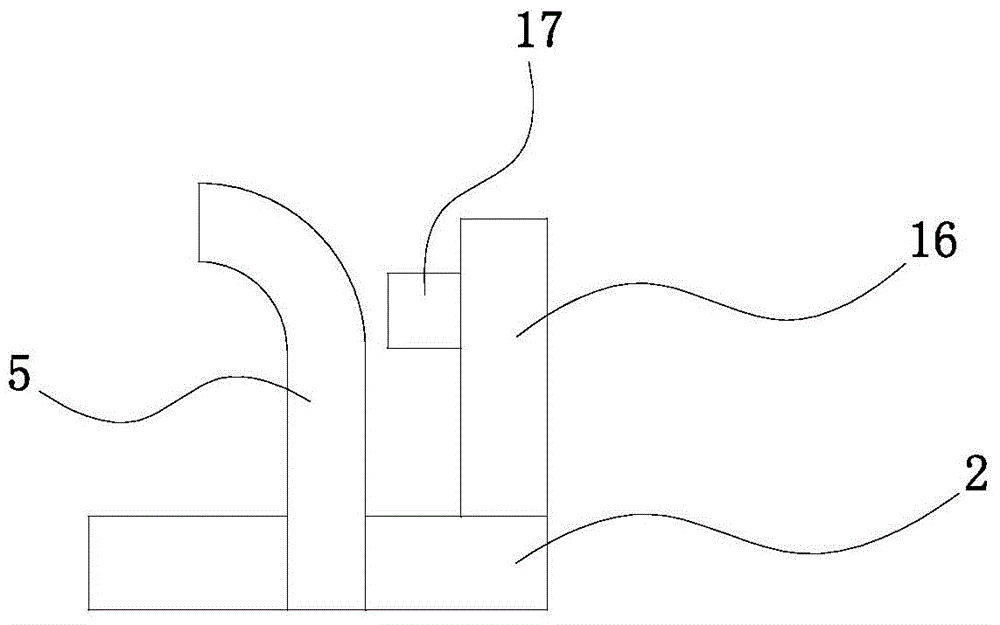

Folding mechanism and electronic equipment

PendingCN113194183APrevent excessive bendingExtended service lifeDetails for portable computersTelephone set constructionsStructural engineeringMechanical engineering

The invention discloses a folding mechanism and electronic equipment, and belongs to the field of communication equipment. The folding mechanism comprises a base part, a first shell base, a second shell base, a first screen supporting plate, a second screen supporting plate and a third screen supporting plate, the first shell base is rotationally arranged on the first screen supporting plate, the second shell base is rotationally arranged on the second screen supporting plate, the third screen supporting plate is movably connected with the base part in the supporting direction of the third screen supporting plate; the first shell base is rotatably connected with the base part through a first swing arm, the second shell base is rotatably connected with the base part through a second swing arm, the first screen supporting plate is slidably and rotatably connected with the base part through a third swing arm, and the second screen supporting plate is slidably and rotatably connected with the base part through a fourth swing arm, the rotating axes of the first swing arm and the third swing arm are arranged at intervals, and the rotating axes of the second swing arm and the fourth swing arm are arranged at intervals. The folding mechanism can prevent the bending part of the flexible screen from being extruded to be excessively bent, and the service life of the flexible screen can be prolonged.

Owner:VIVO MOBILE COMM CO LTD

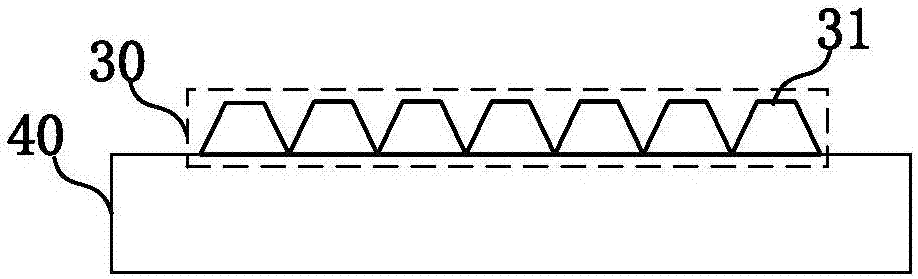

Flexible display device, manufacturing method thereof and electronic device

ActiveCN107067979ALimit bending curvatureImprove bending resistanceIdentification meansShock resistanceFlexible display

The embodiment of the invention discloses a flexible display device, a manufacturing method thereof and an electronic device. The flexible display device comprises a flexible display panel and at least one layer of buffer membrane, wherein the flexible display panel is provided with a first side surface for displaying images and a second side surface opposite to the first side surface; the buffer membrane is at least formed on the second side surface of the flexible display panel and is composed of a second buffer area and a first buffer area surrounding the second buffer area, and the inside of the buffer membrane of the first buffer area is provided with a plurality of hollow structures; when the flexible display panel is in a horizontal state, in a first direction perpendicular to the flexible display panel, the area of the cross section of the hollow structures in a second direction parallel to the flexible display panel increases to a preset area and then gradually decreases. According to the flexible display device, the buffer membrane can avoid collapse or bending of the flexible display panel, limit the bending curvature of the flexible display panel, improve the shock resistance and the shock absorbing capacity of the flexible display panel and achieves a moisture-proof function.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

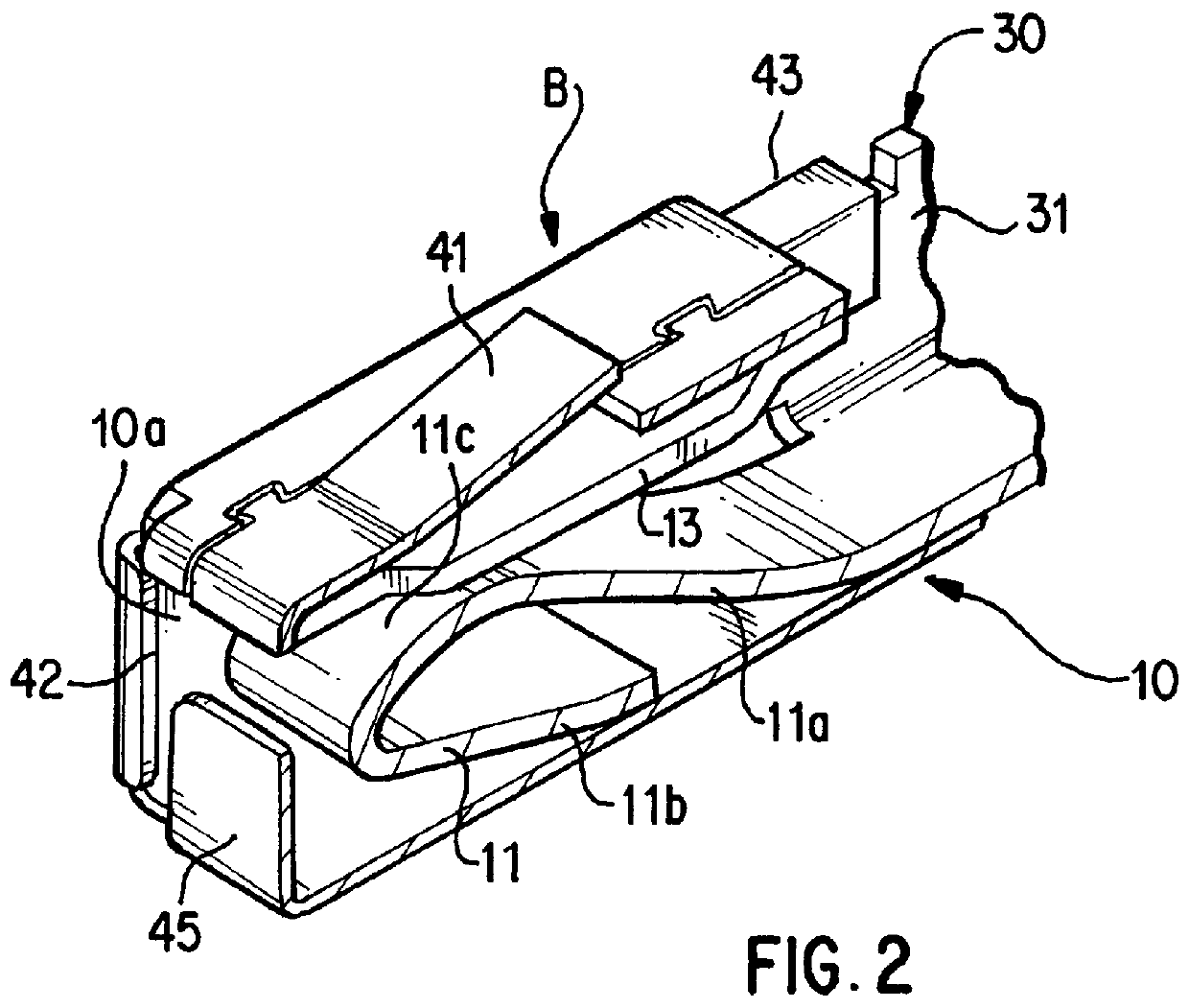

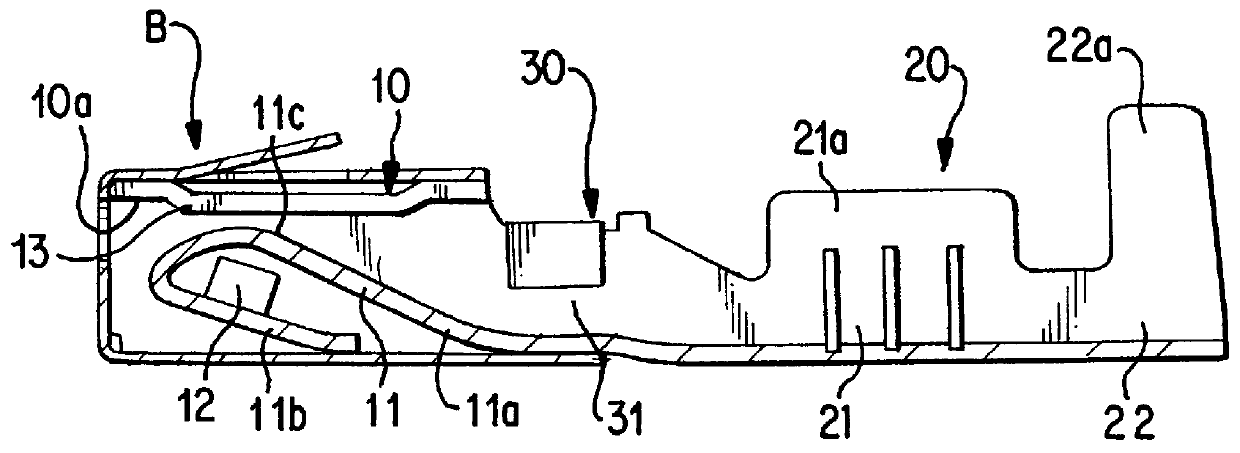

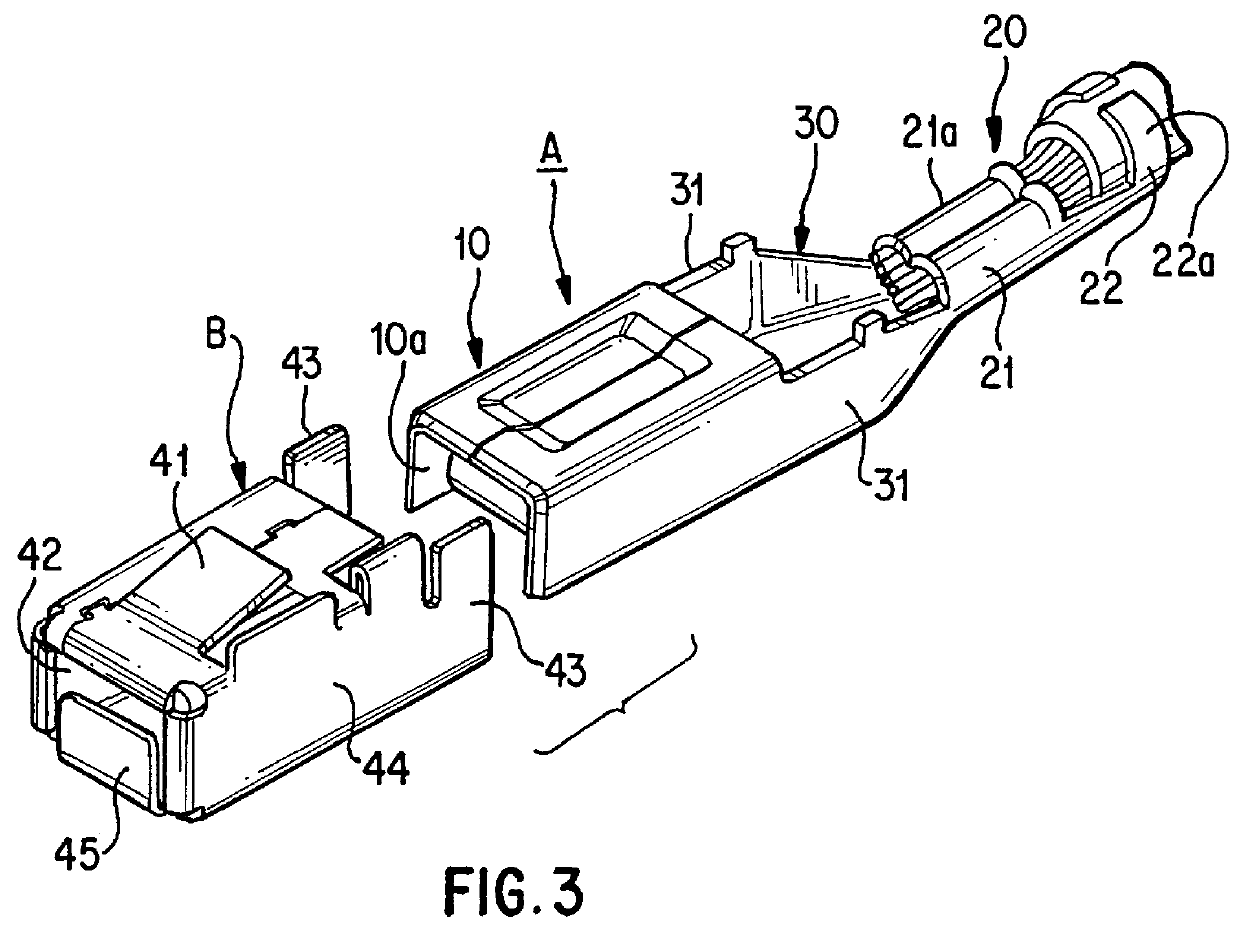

Female terminal fitting

InactiveUS6019646AIncrease engagementPrevent excessive bendingCoupling contact membersElectric connection basesEngineeringMechanical engineering

A resilient contact 11 rise upwards diagonally towards the open end of an electrical terminal. A supporting member 11b is formed by folding an end of the contact 11 downwards and making the end of this folded over portion make contact with the base face of the protecting cover B. By these means, even if the point of contact is set towards the open end, the contact force can be maintained, and the rising member 11a is supported by the supporting member 11b when bending.

Owner:SUMITOMO WIRING SYST LTD

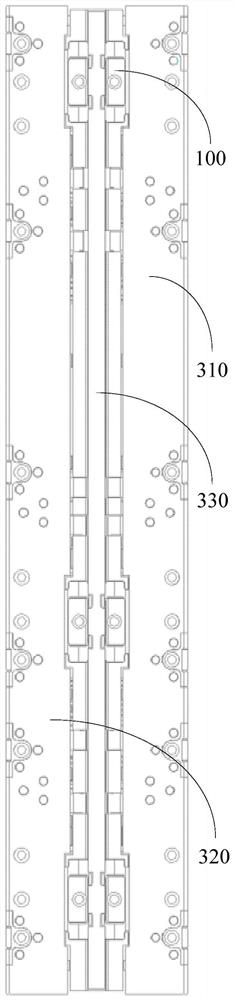

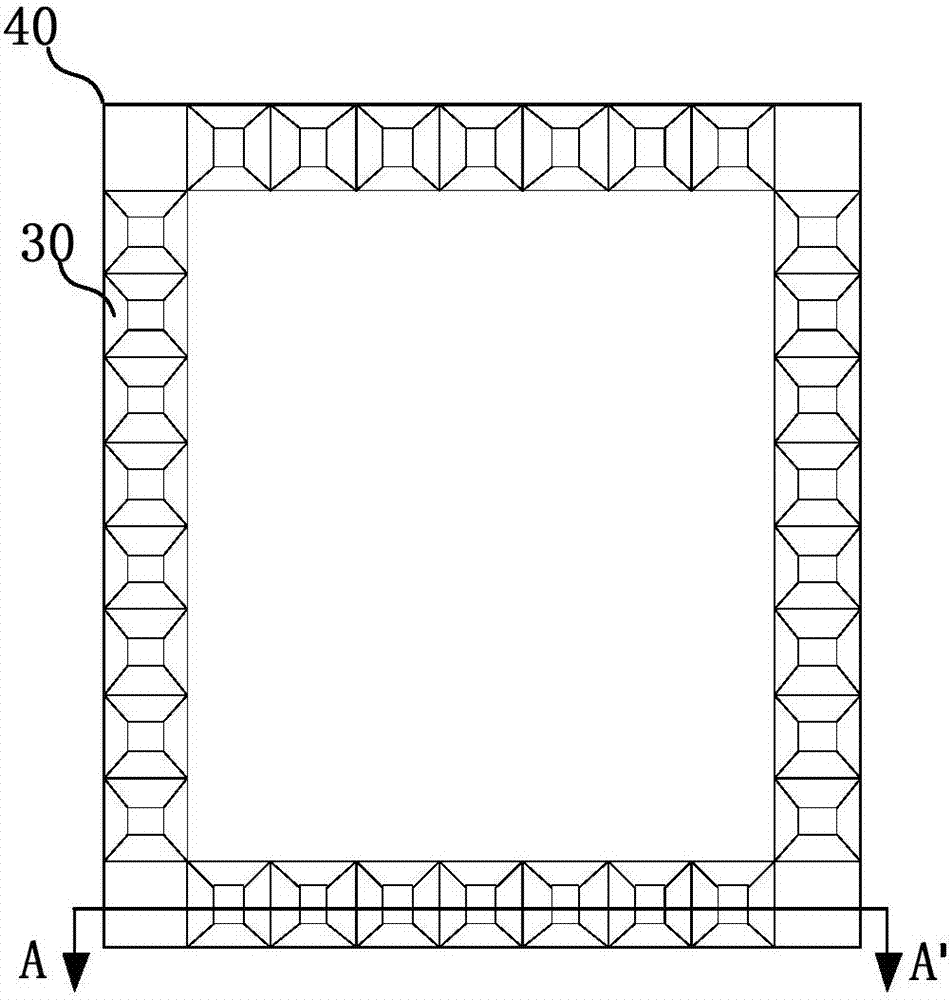

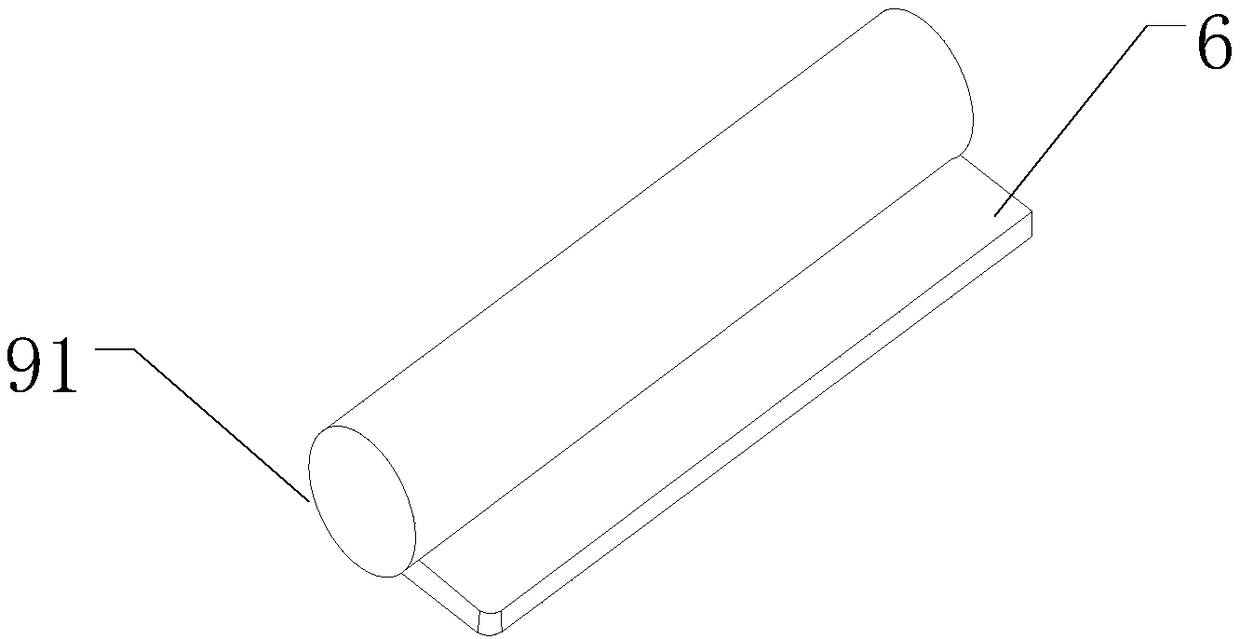

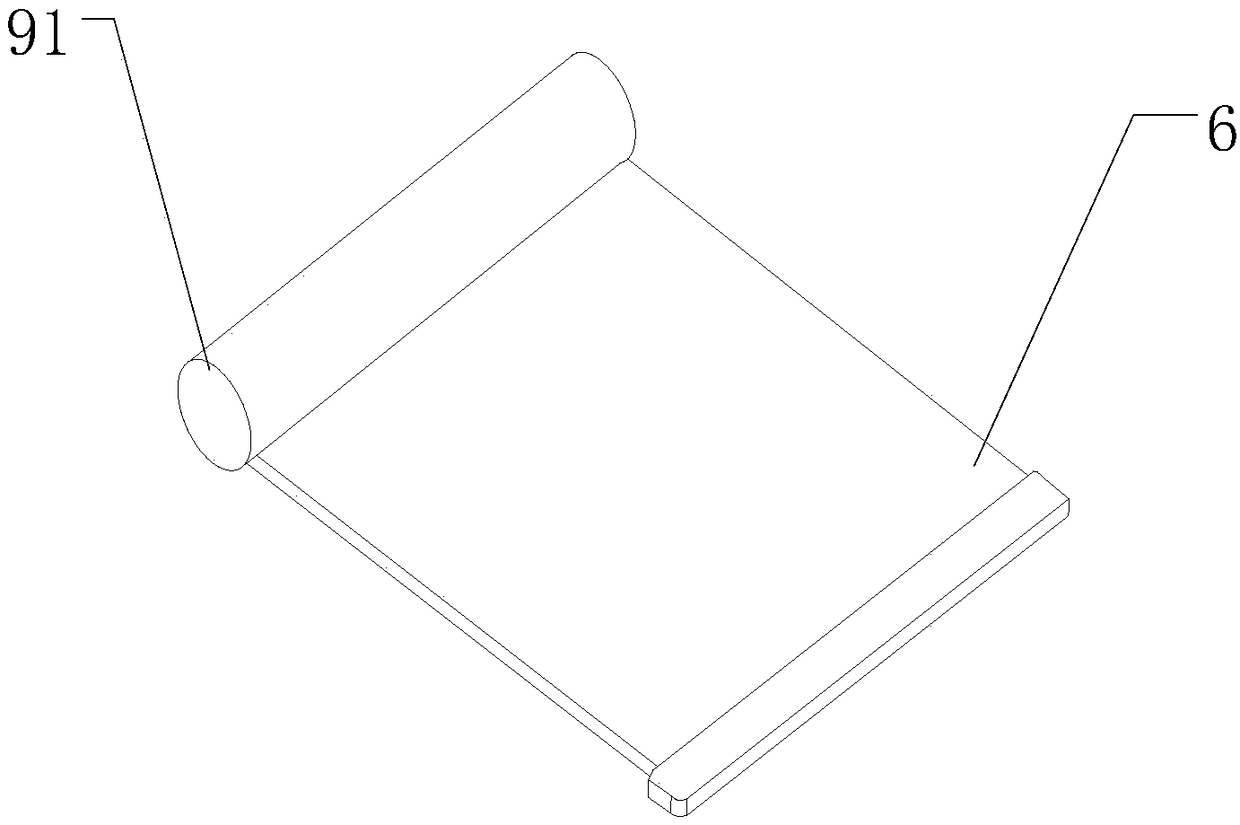

Flexible display equipment supporting component and flexible display equipment

ActiveCN108399861AExtended service lifePrevent excessive bendingIdentification meansEngineeringFlexible display

The invention provides a flexible display equipment supporting component and flexible display equipment. A supporting portion is arranged to support a flexible display screen of the flexible display equipment, a connecting member connecting two supporting members in the supporting portion is arranged to be of an extensible structure, or each of mounting shell components at two ends of the supporting portion are arranged to be of an extensible structure to enable a distance between the mounting shell components to be switched from first preset length to second preset length to provide effectivesupporting when the flexible screen is unfolded so as to avoid the flexible screen being excessively bent under action of external force, so that service life of the flexible display equipment is prolonged.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

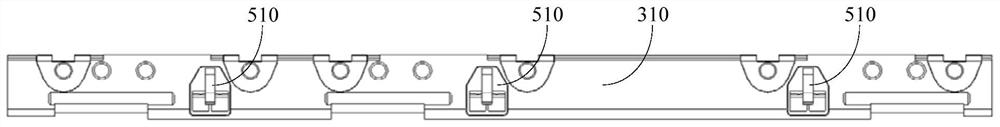

Flexible screen supporting device and flexible screen terminal

ActiveCN111583791APrevent excessive bendingImprove reliabilityCasings/cabinets/drawers detailsDetails for portable computersEngineeringStructural engineering

The invention provides a flexible screen supporting device and a flexible screen infolding terminal. The problem that in the prior art, a flexible screen infolding terminal is prone to being damaged due to excessive bending of a flexible screen is solved. The flexible screen supporting device comprises a first shell and a second shell which are connected through a rotating assembly, and the firstshell and the second shell are in a flattened state and a folded state in a rotating mode; the first shell and the second shell respectively comprise a first part and a second part which are rotatablyconnected, and the first part is located on one side, close to the rotating assembly, of the second part; and in the process of switching from the flattening state to the folding state, the first part rotates around the second part, and the rotating direction of the first part of the first shell is opposite to that of the first part of the second shell, so that a containing space is formed abovethe rotating assembly.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

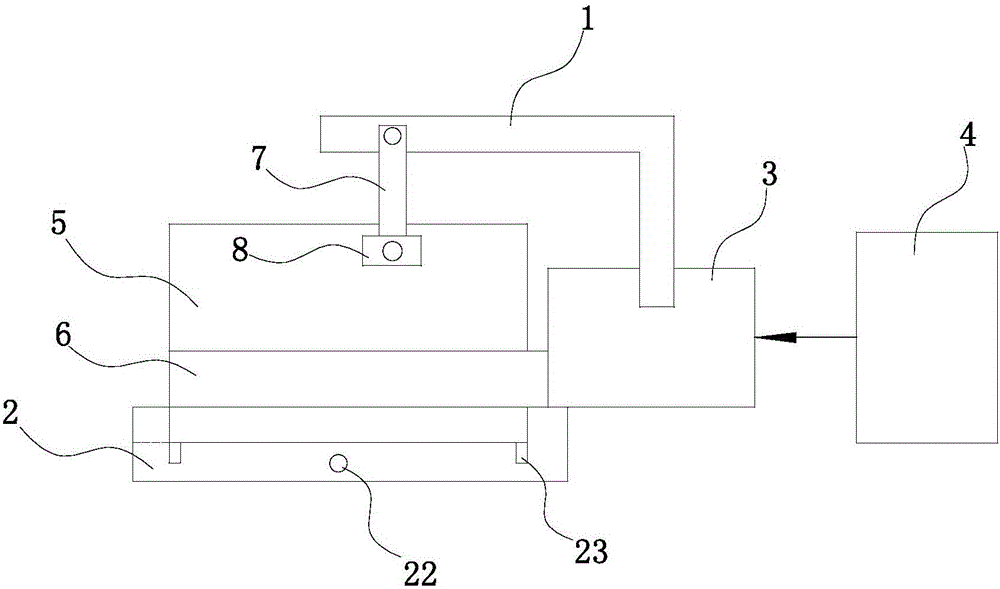

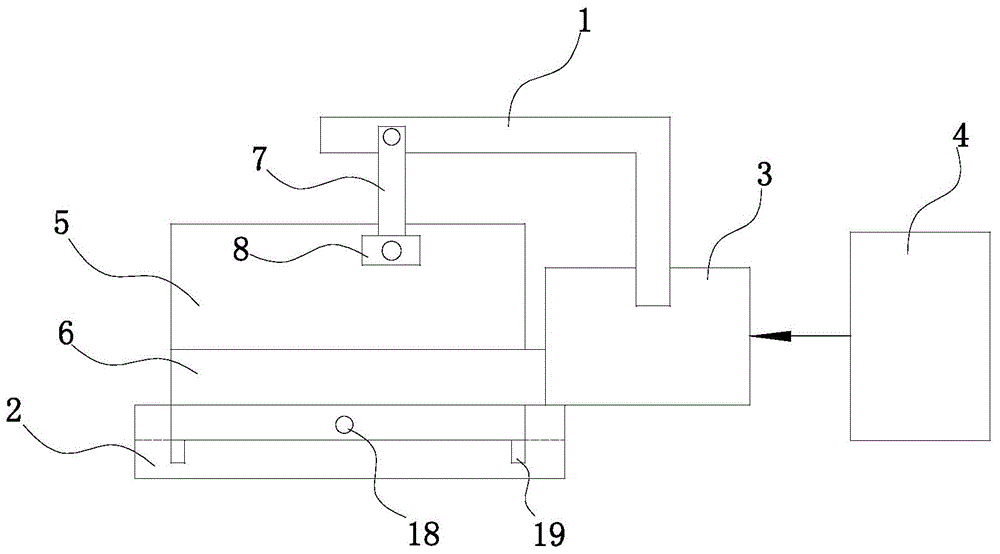

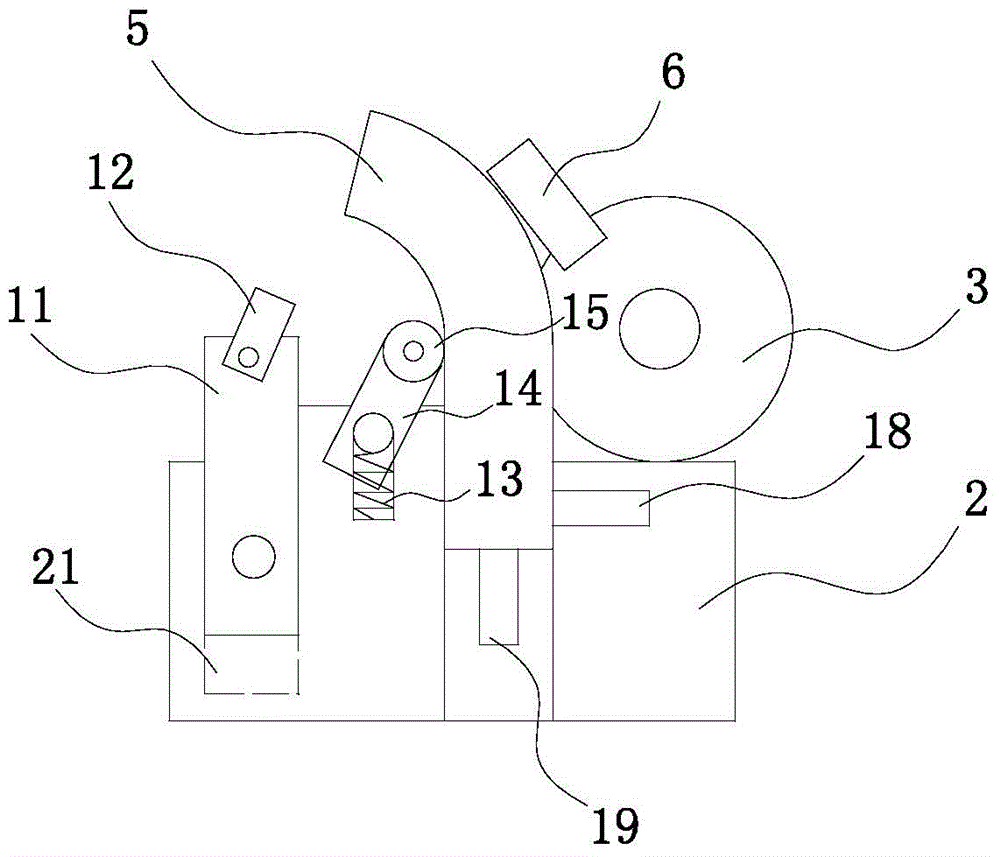

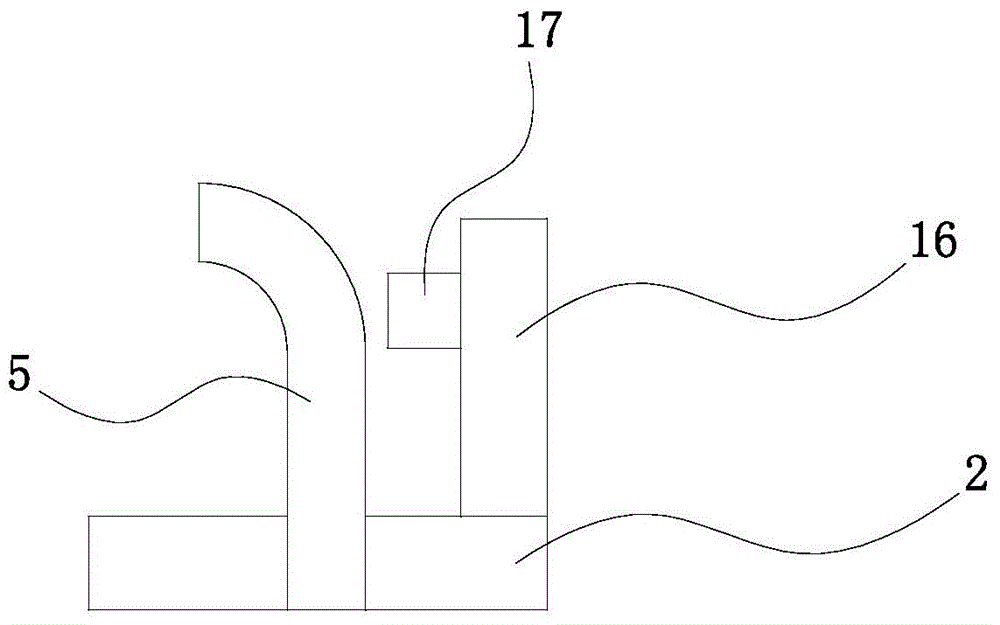

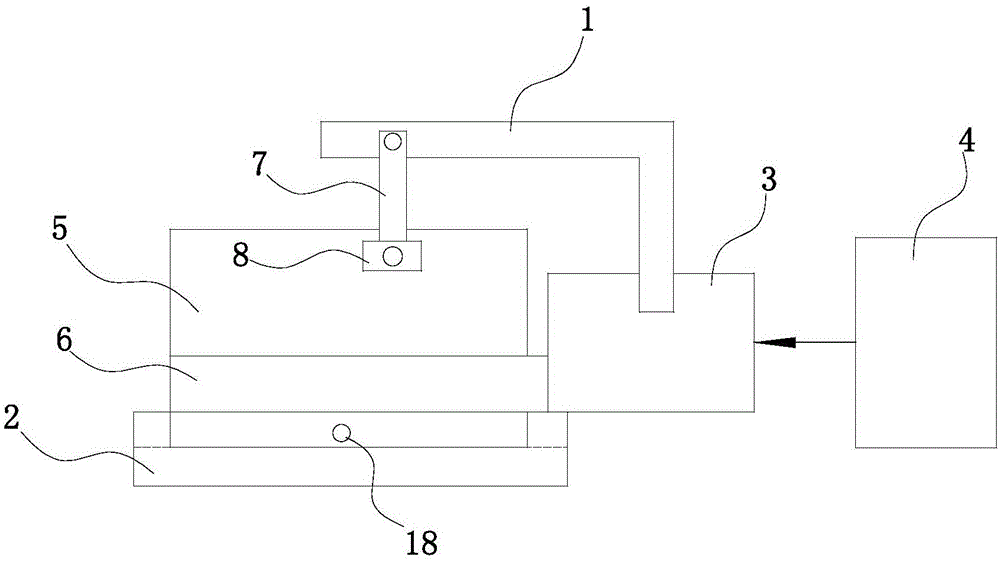

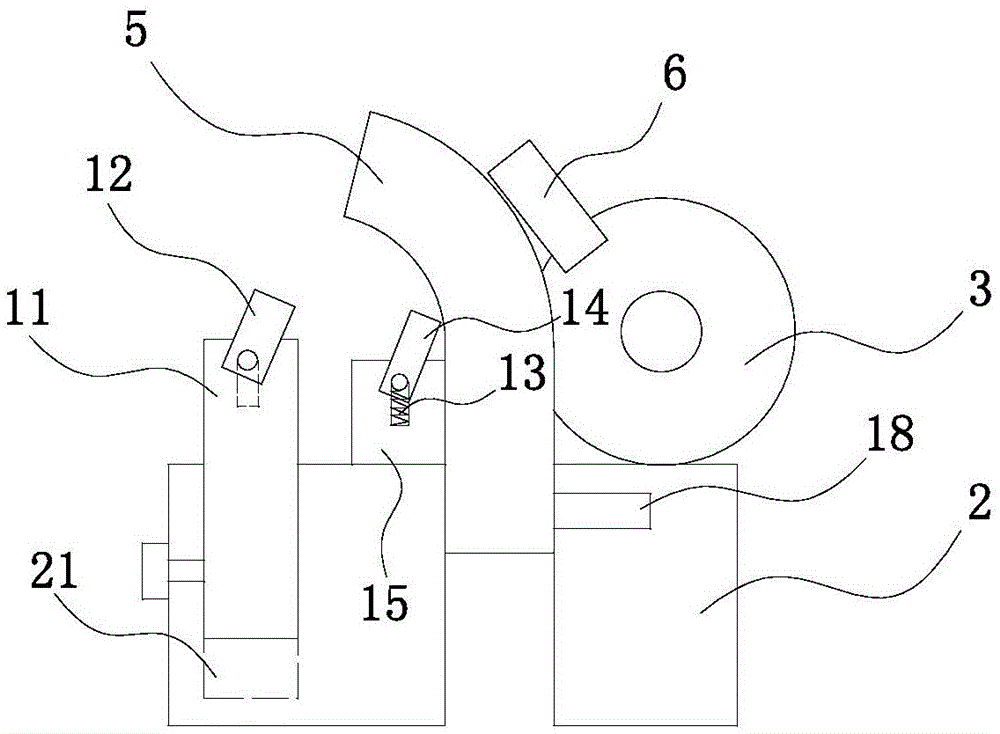

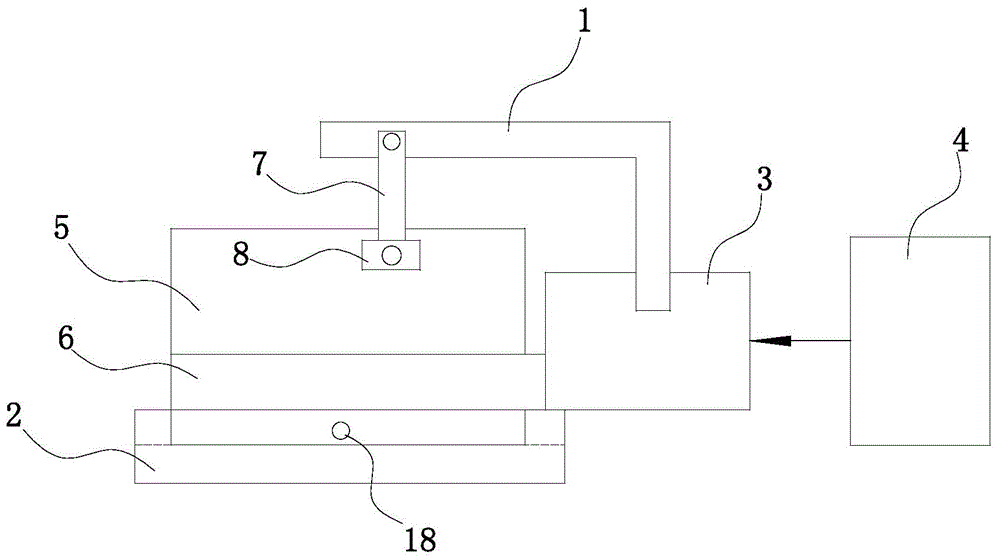

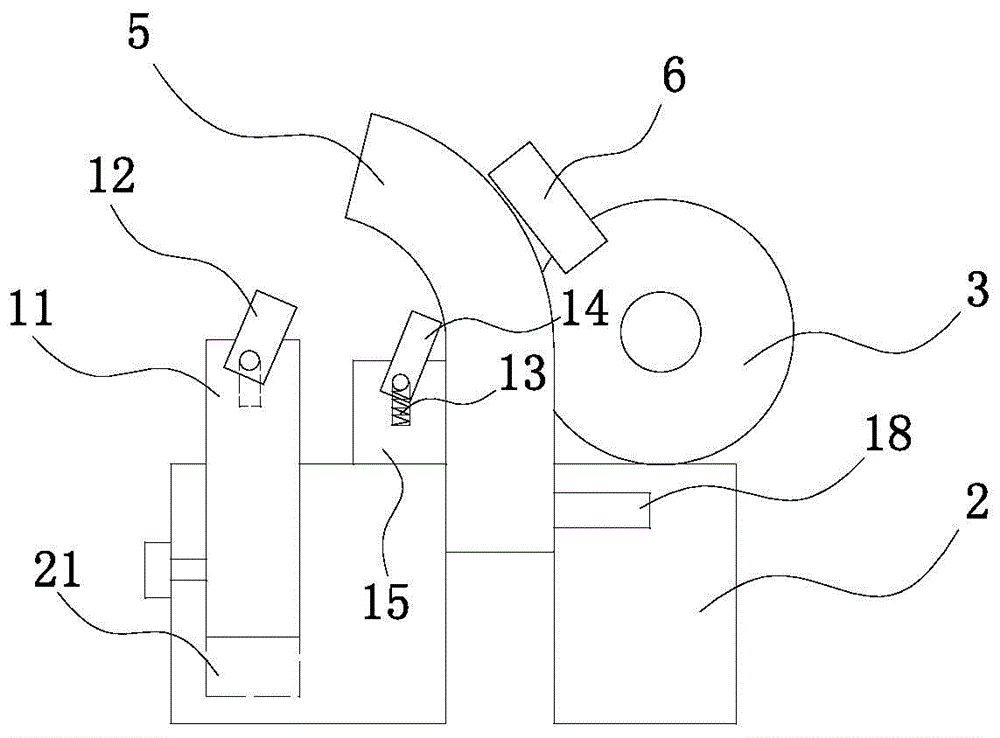

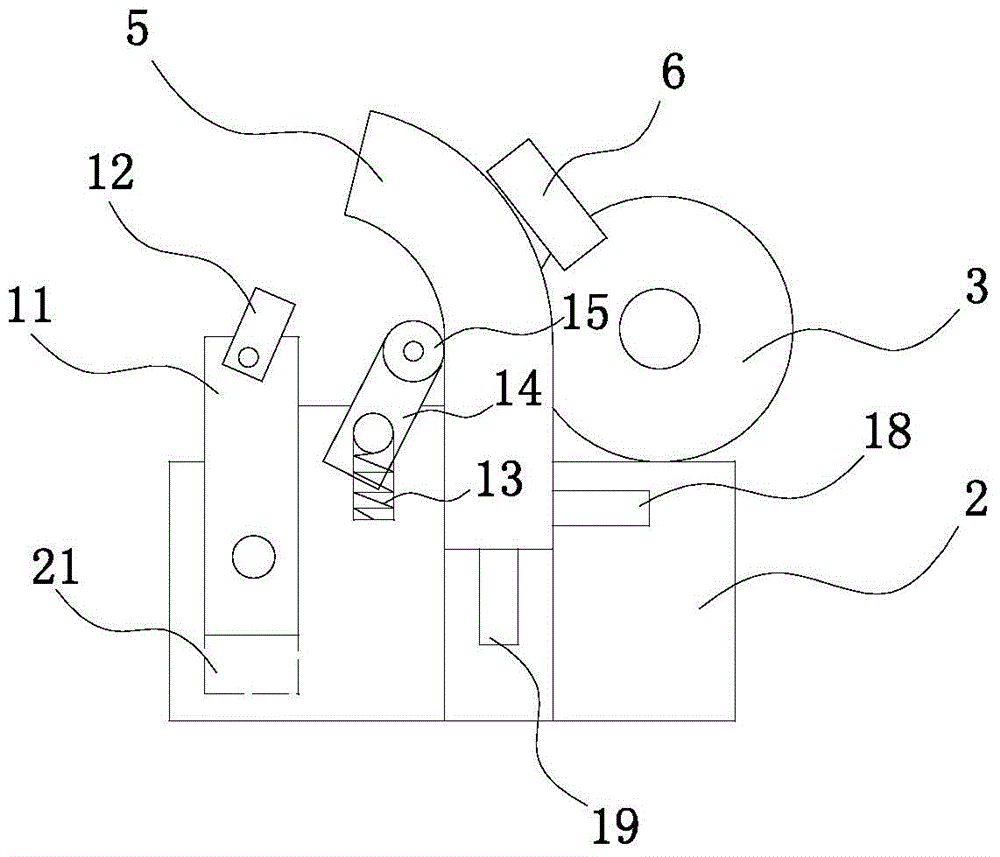

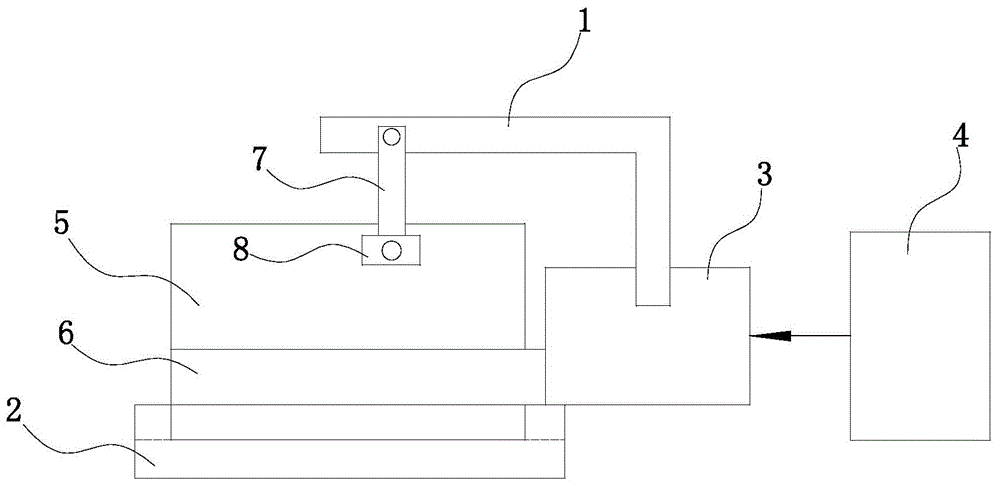

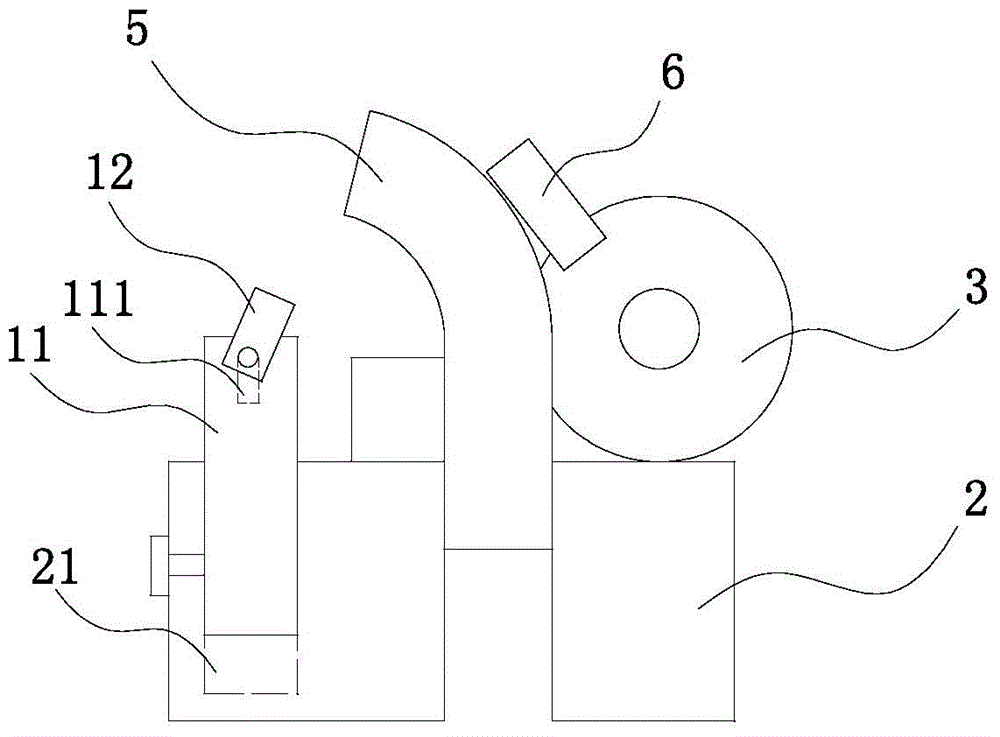

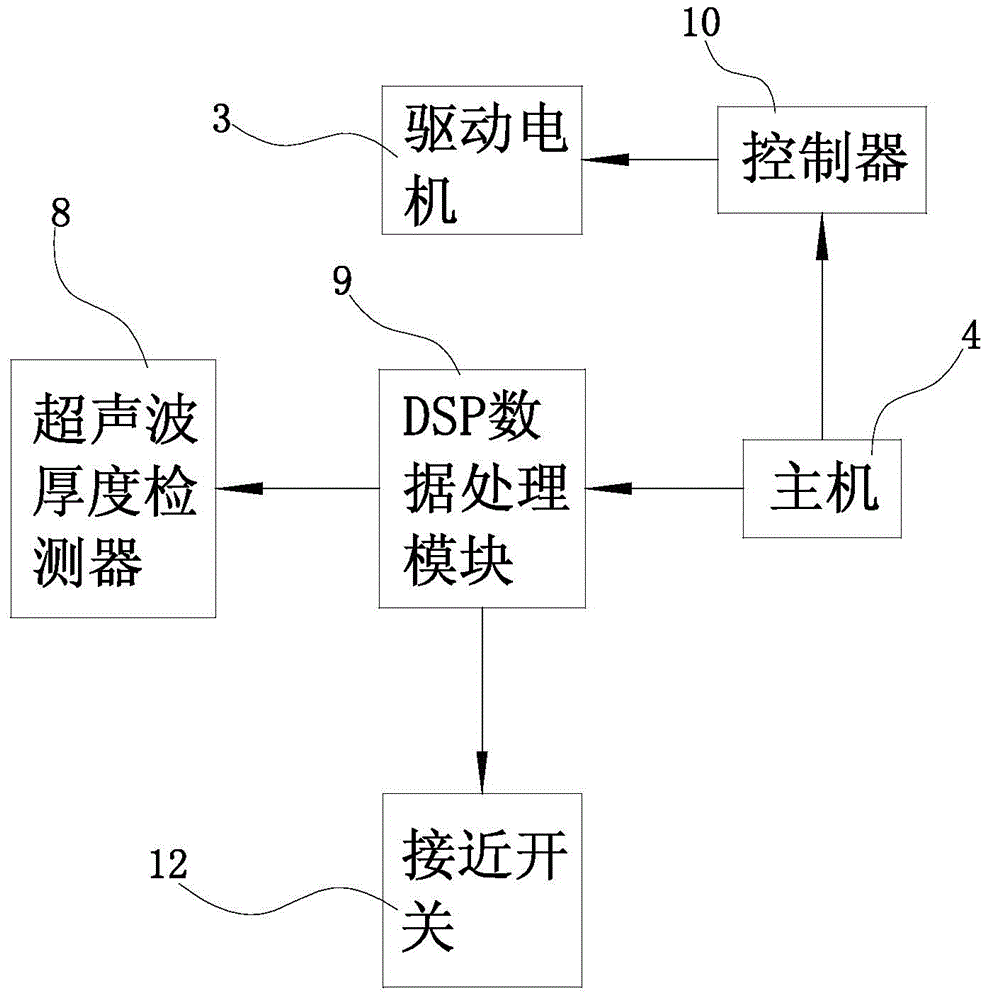

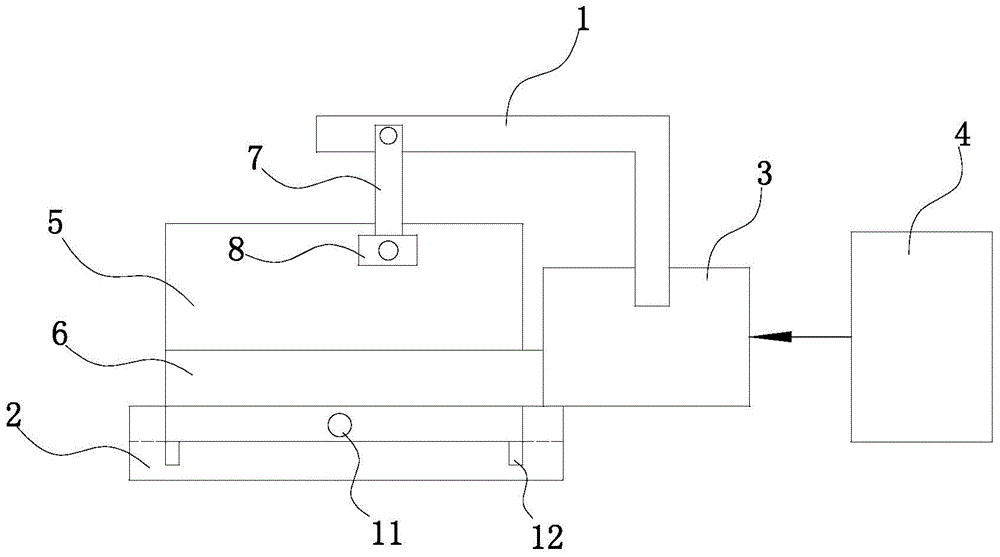

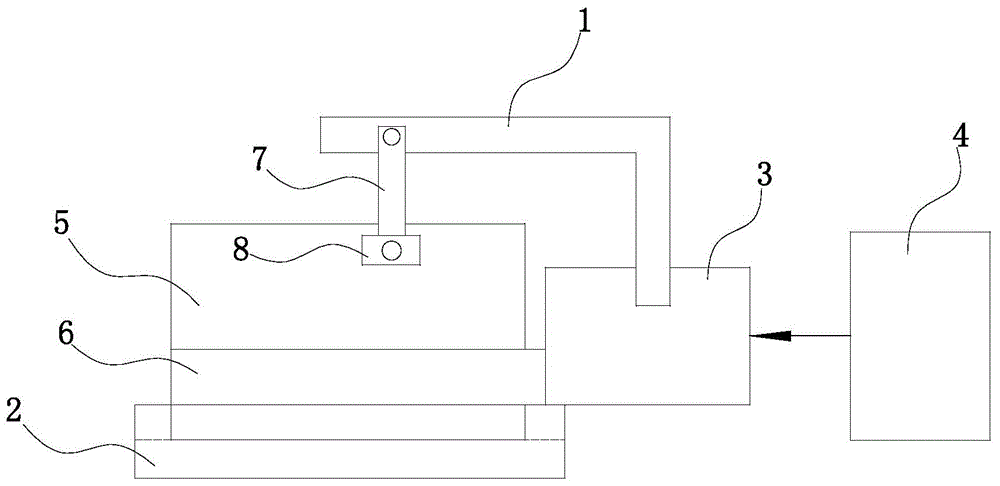

Feedback torque adjustment and metal plate bending system

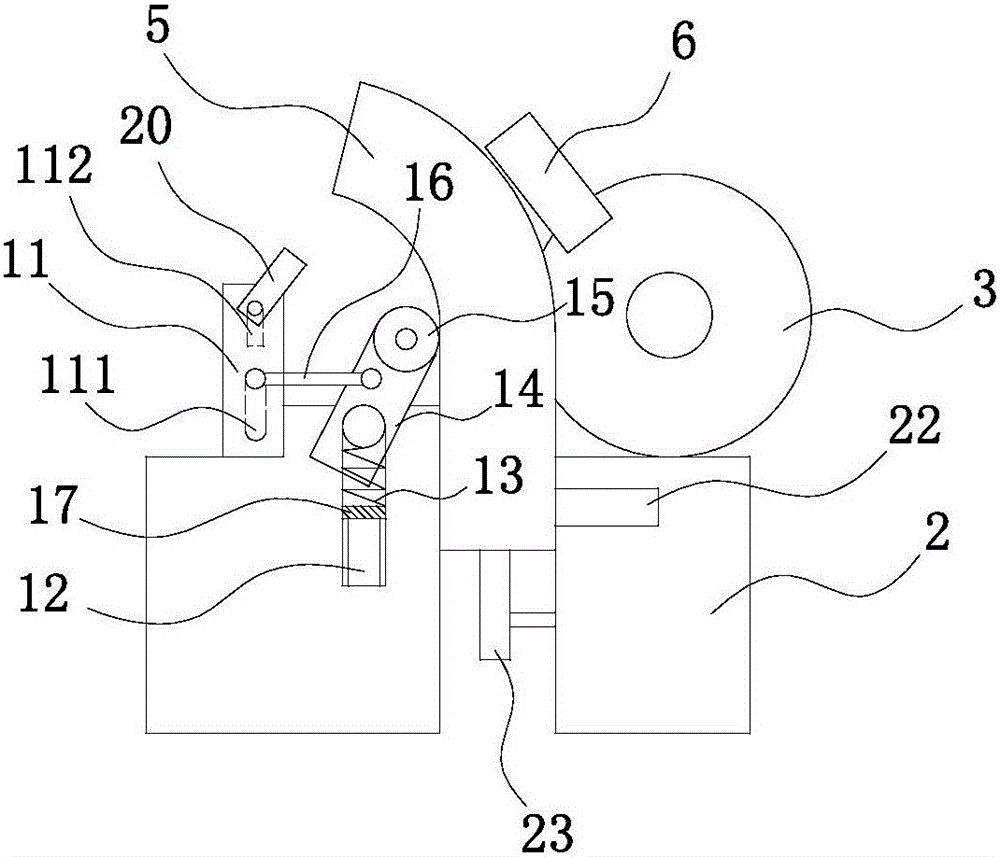

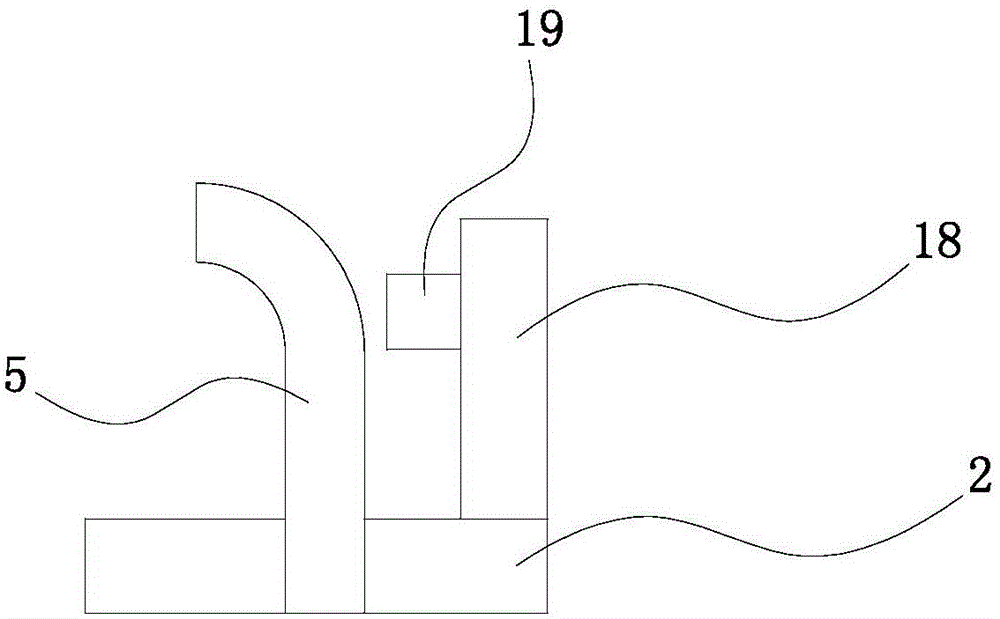

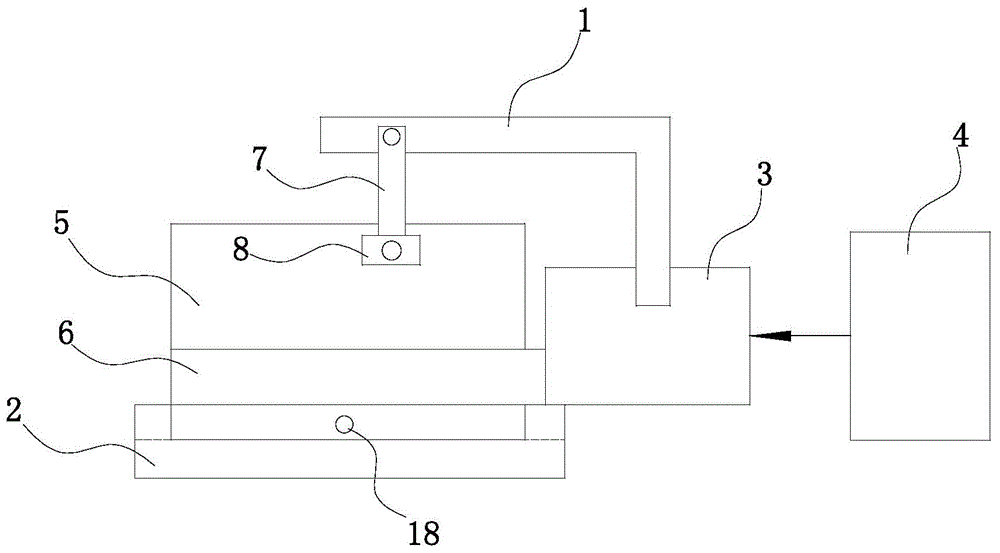

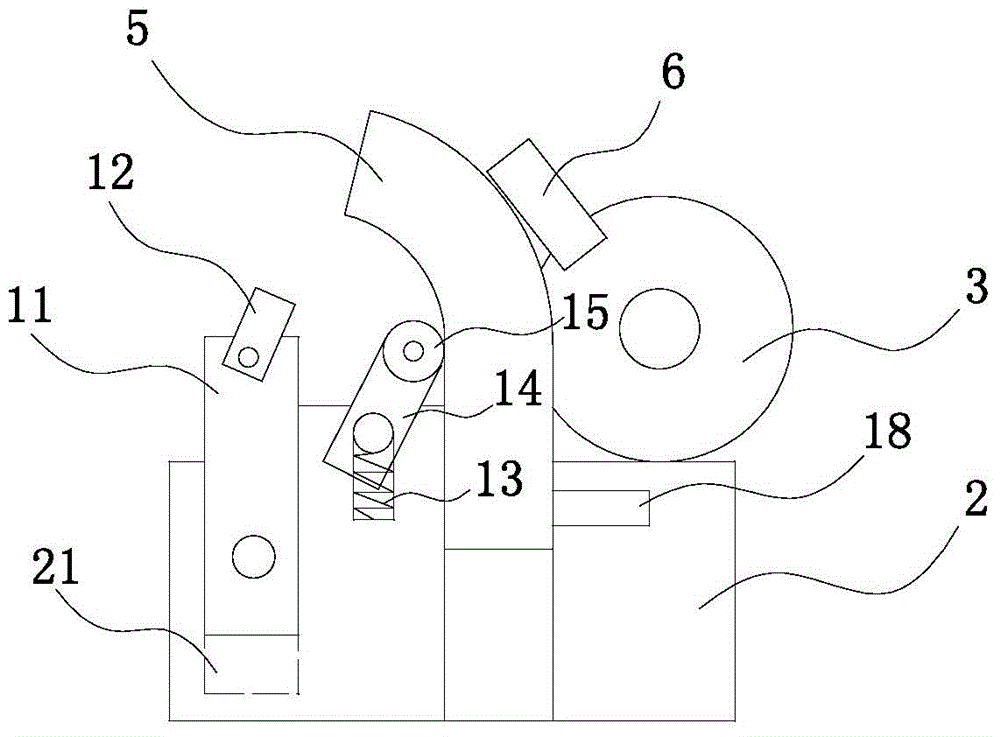

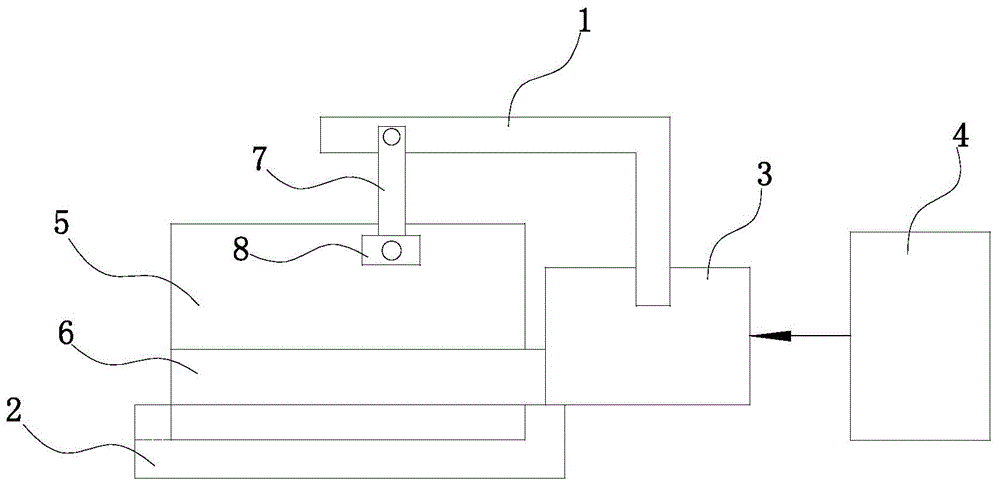

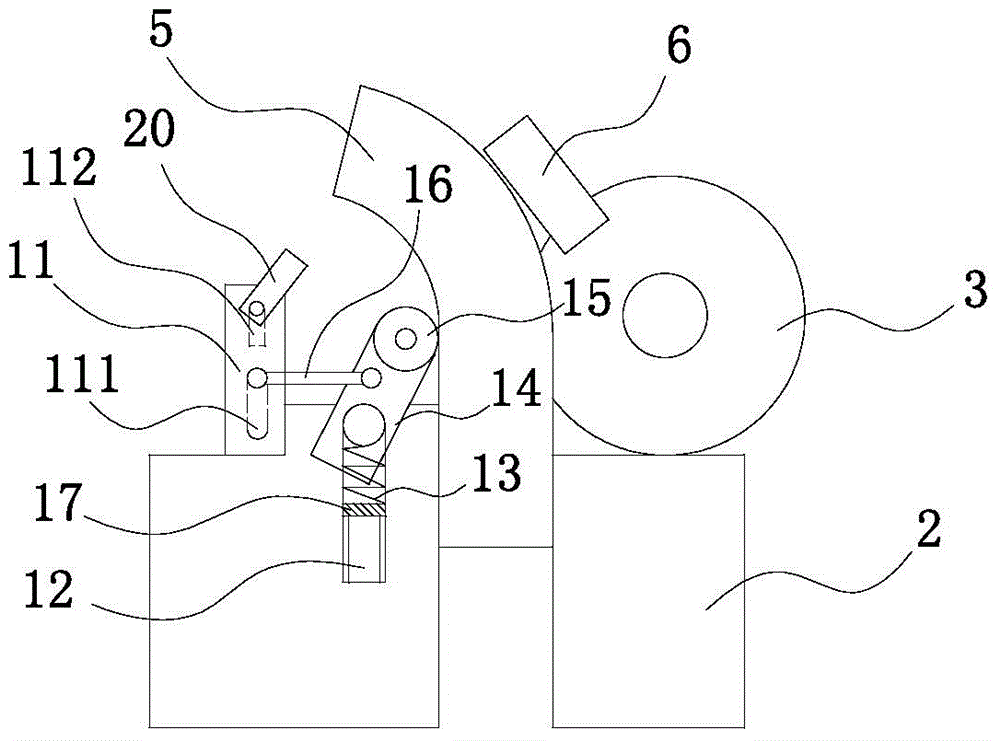

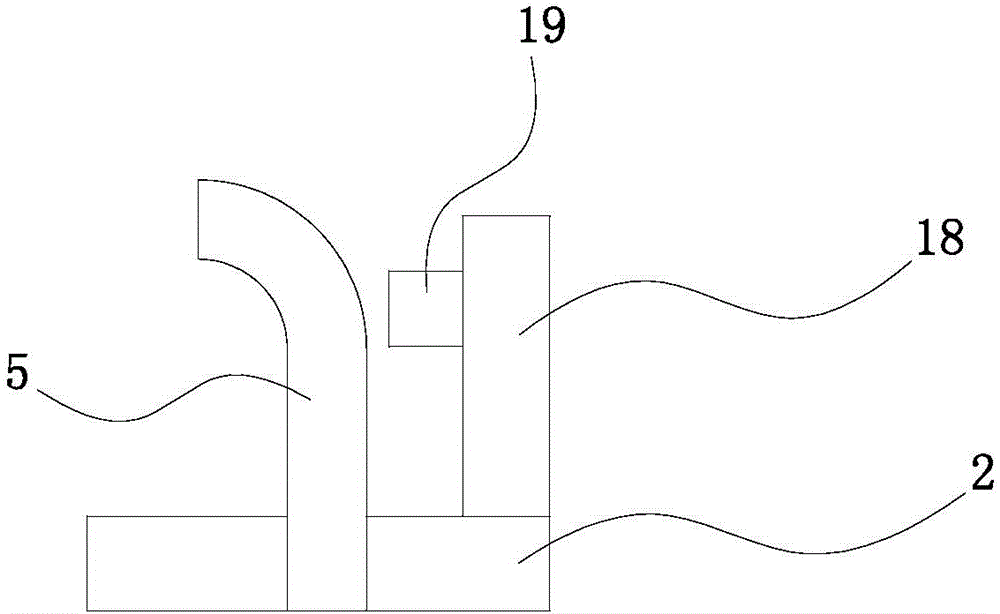

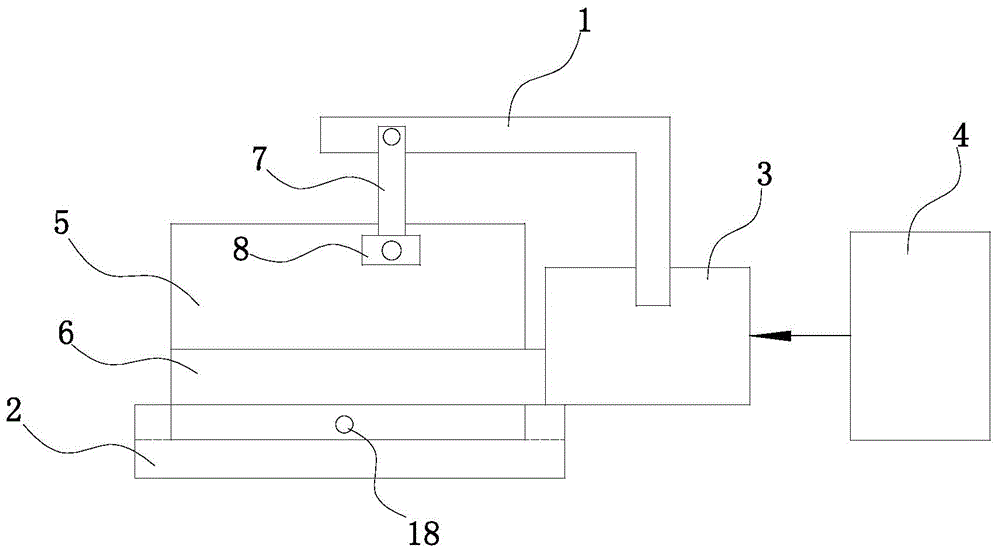

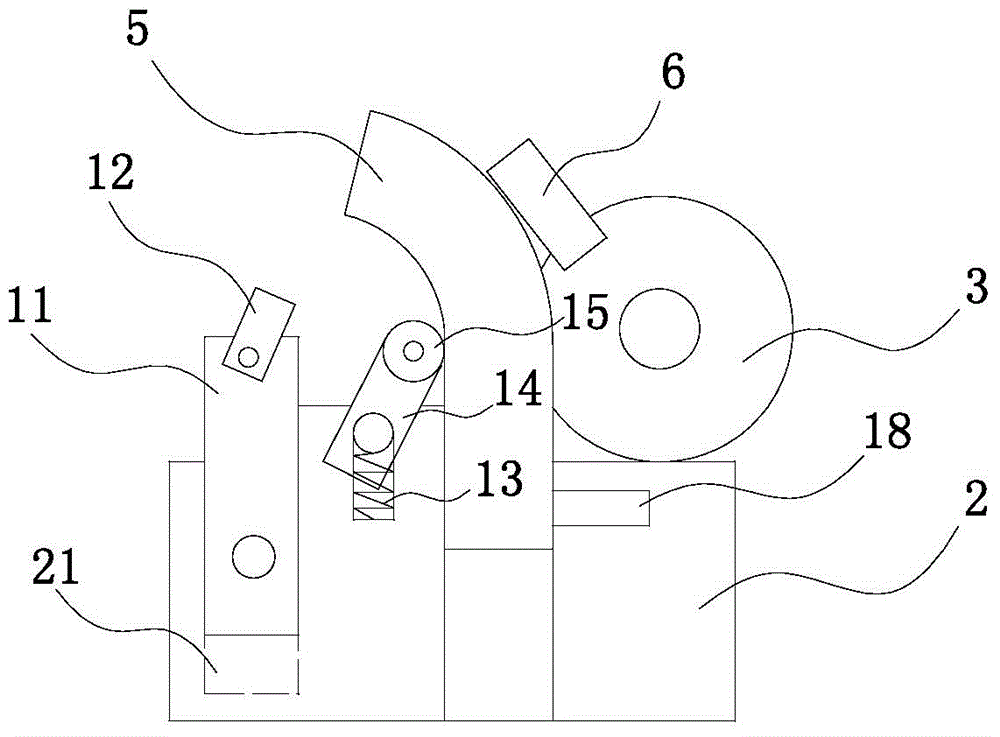

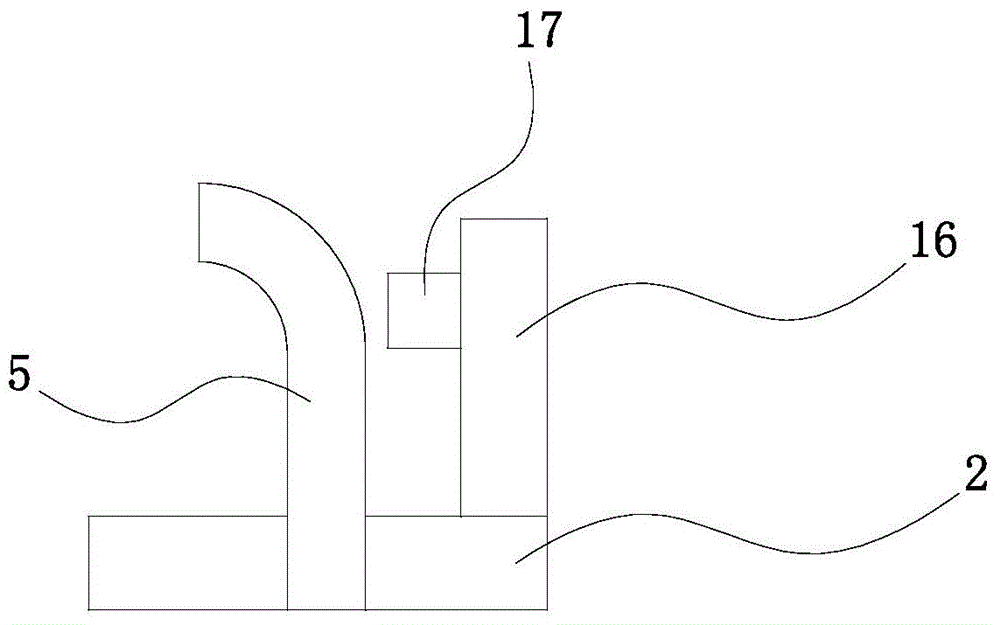

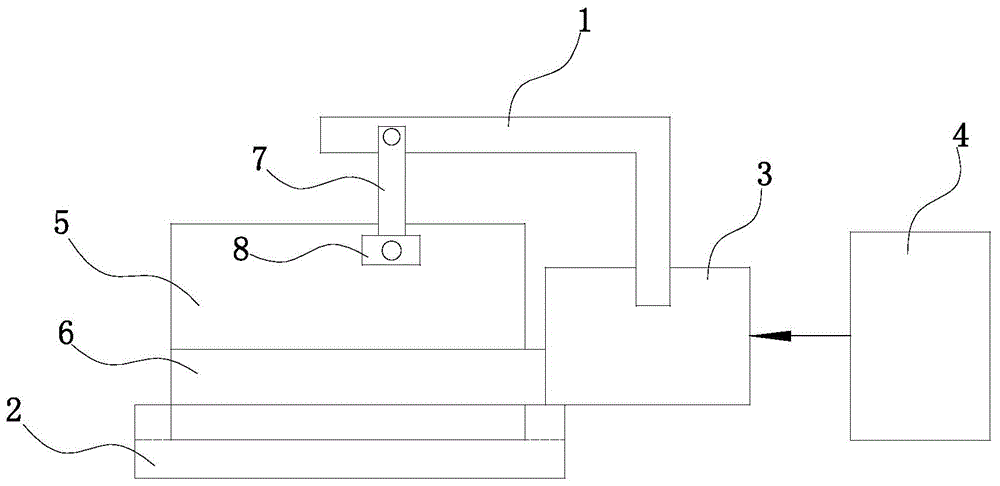

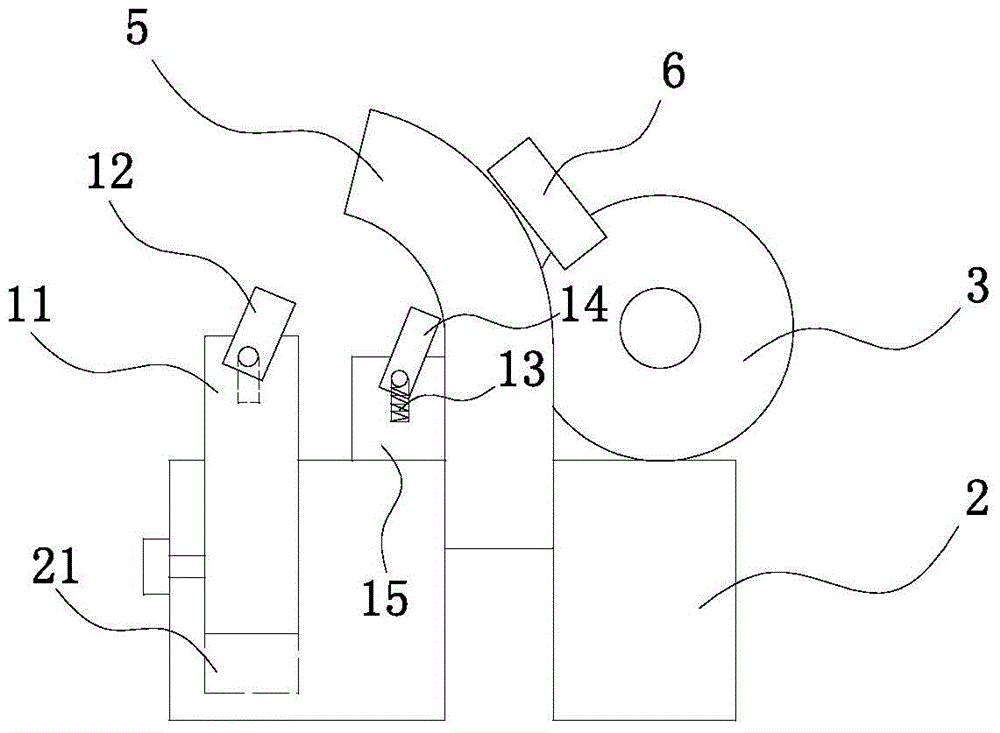

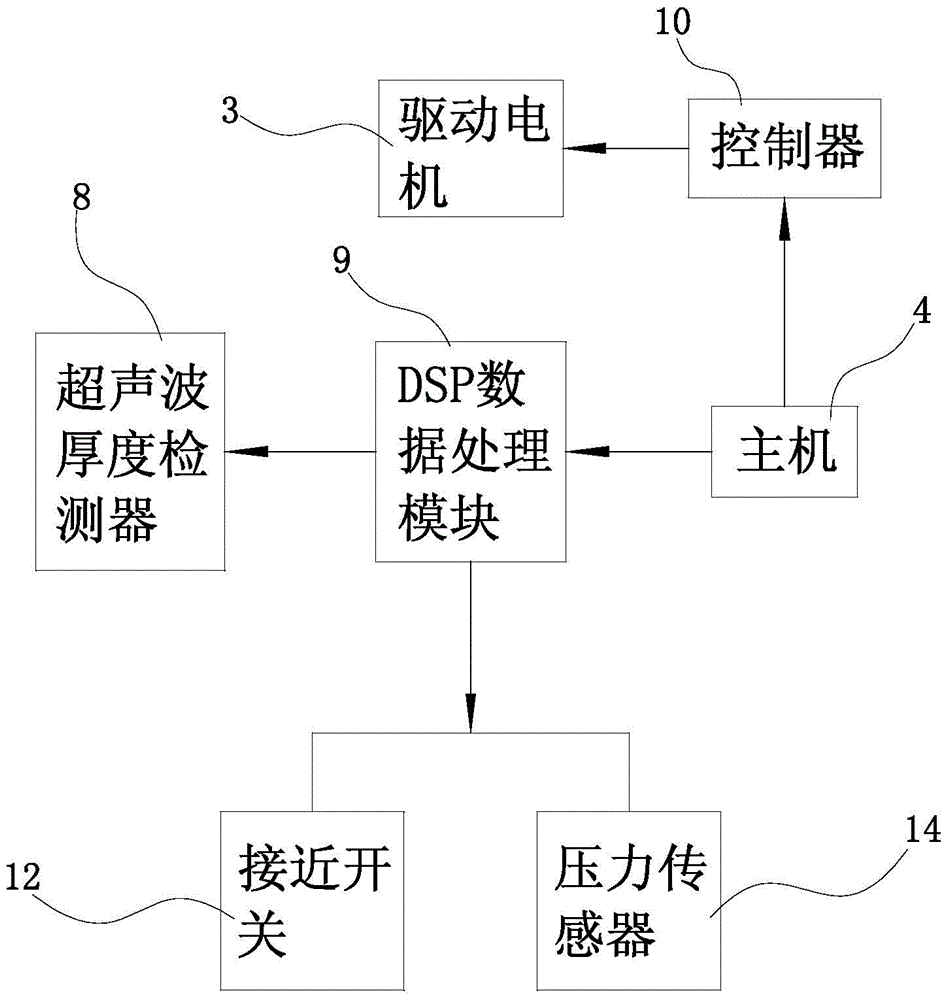

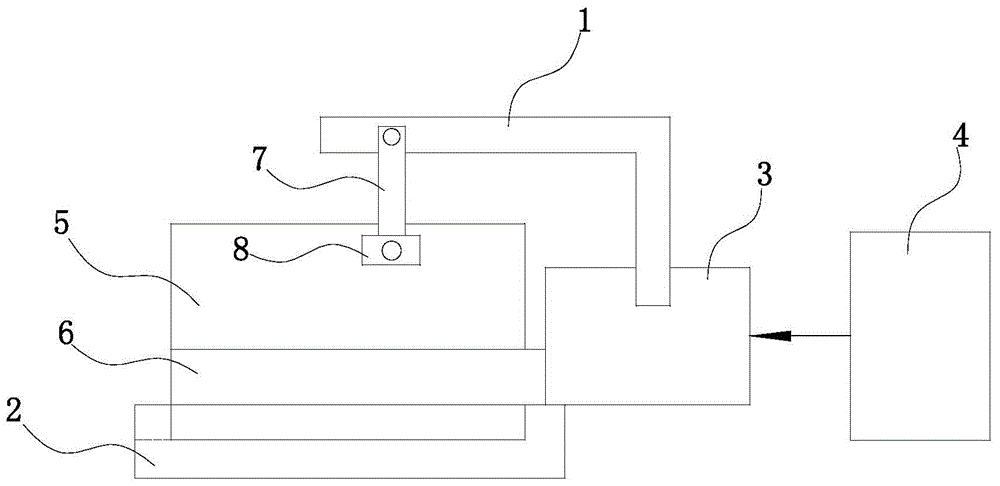

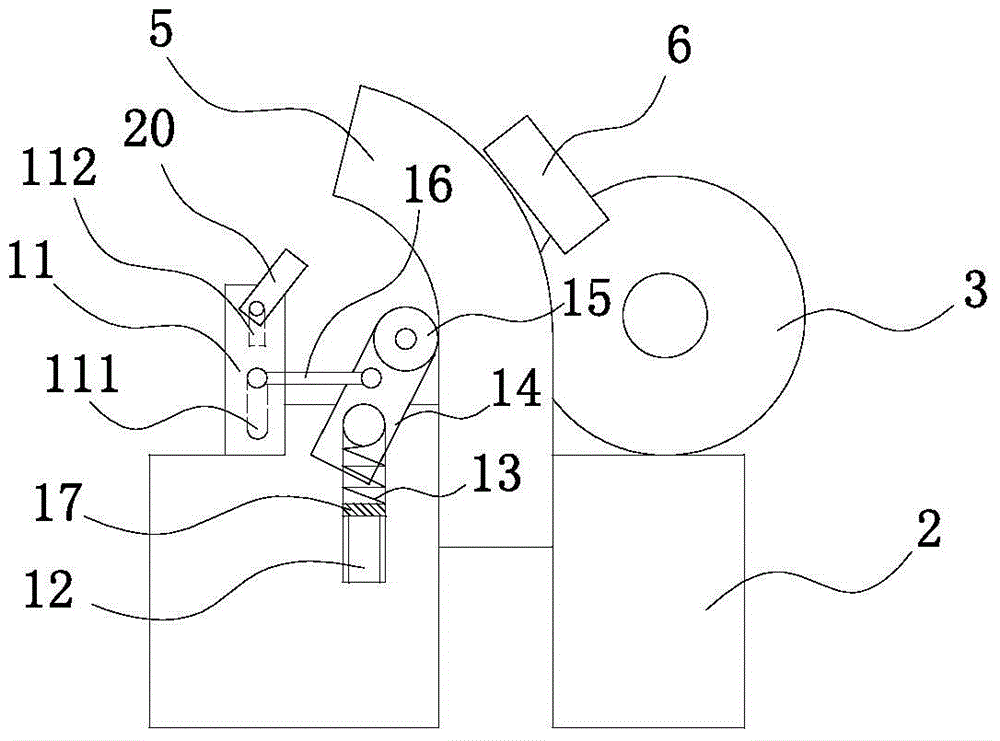

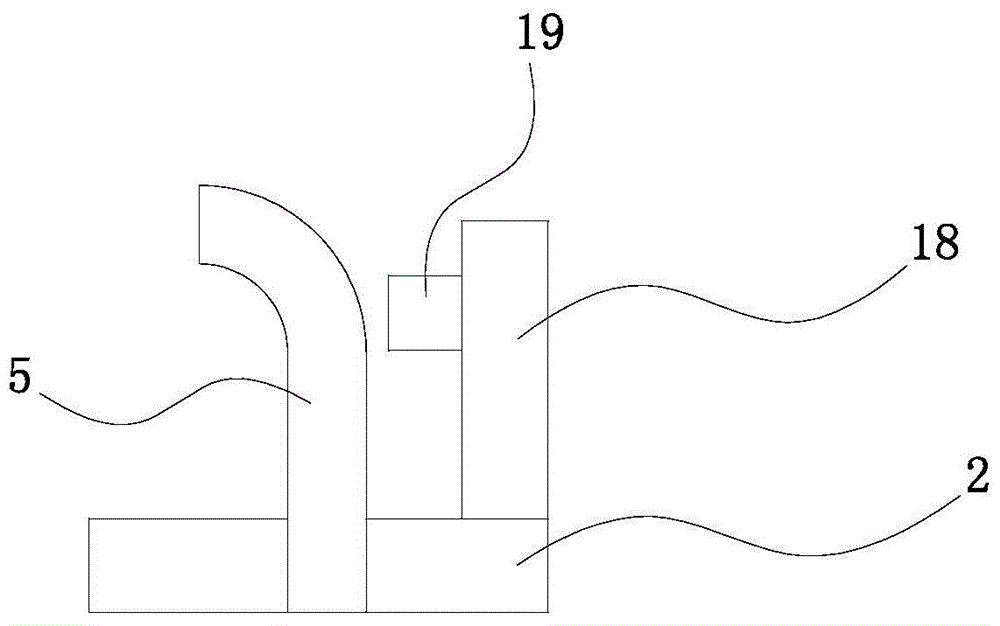

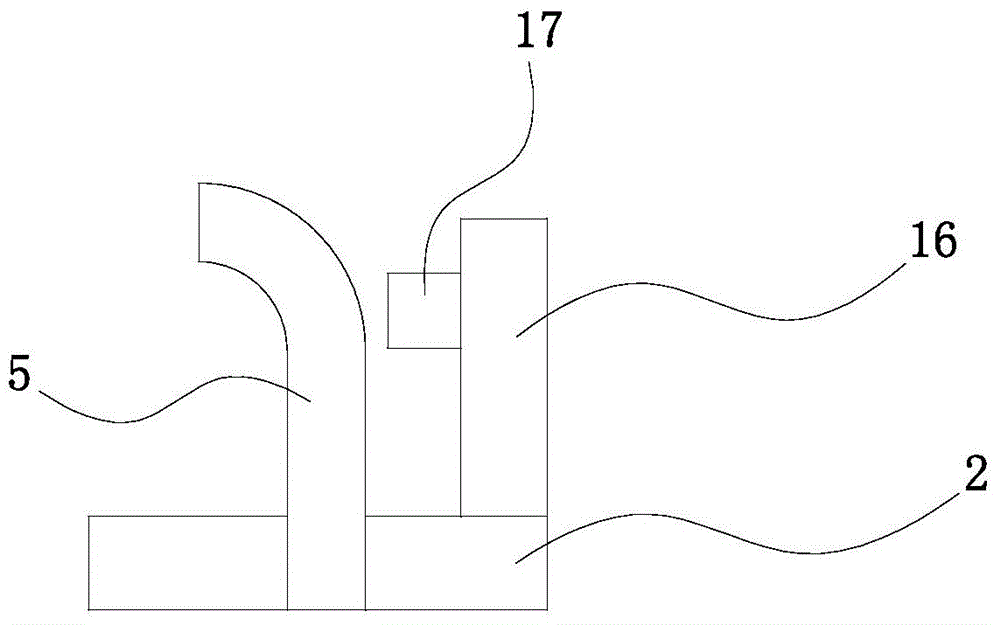

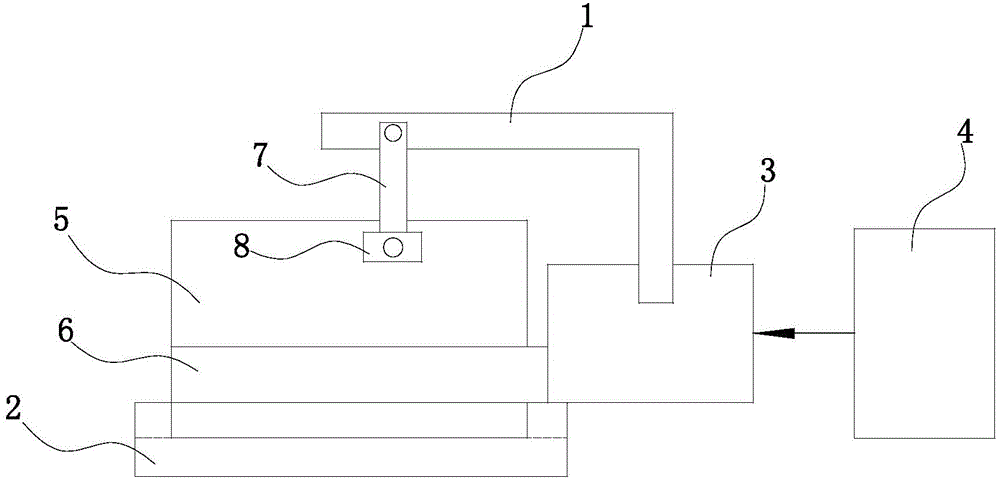

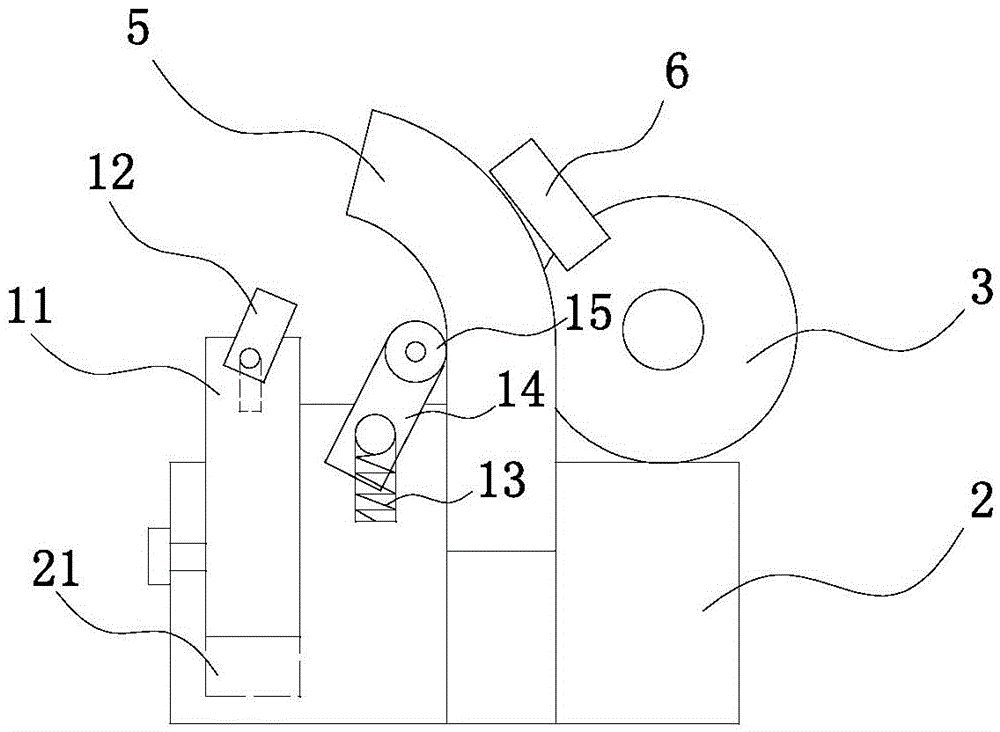

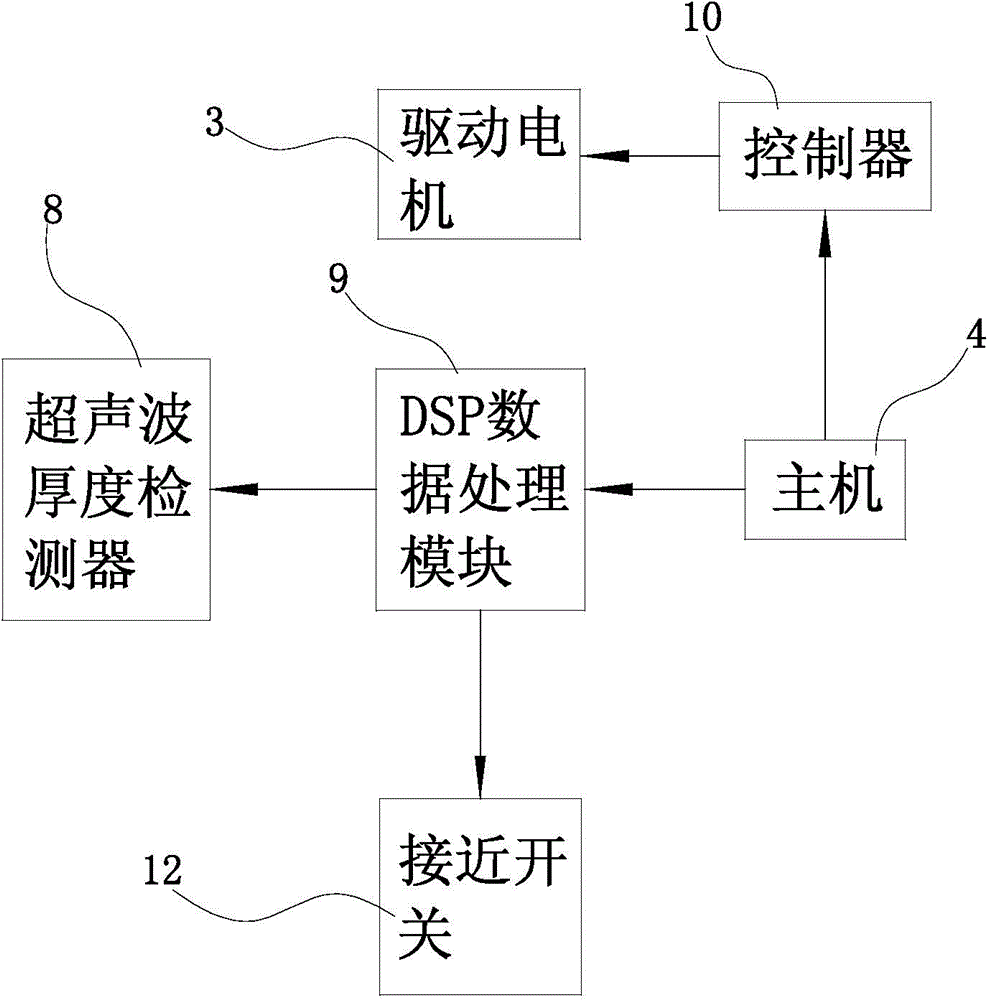

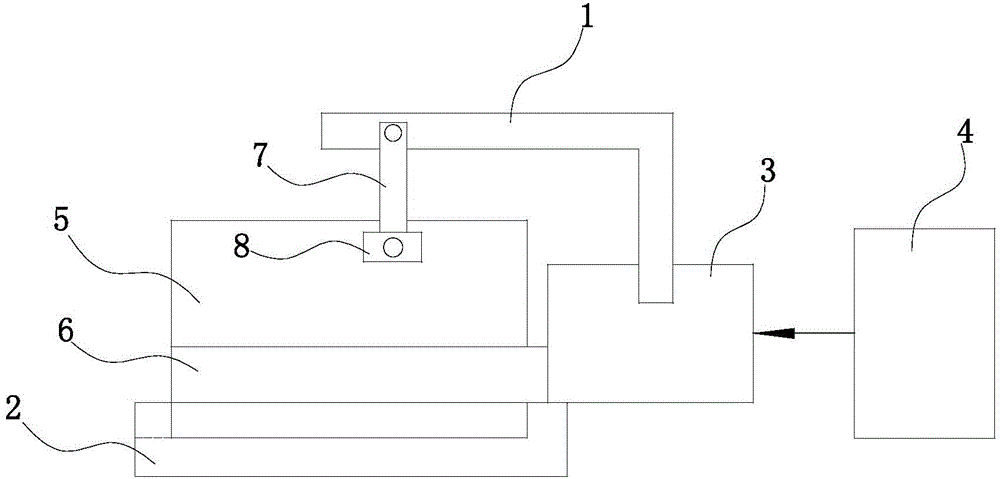

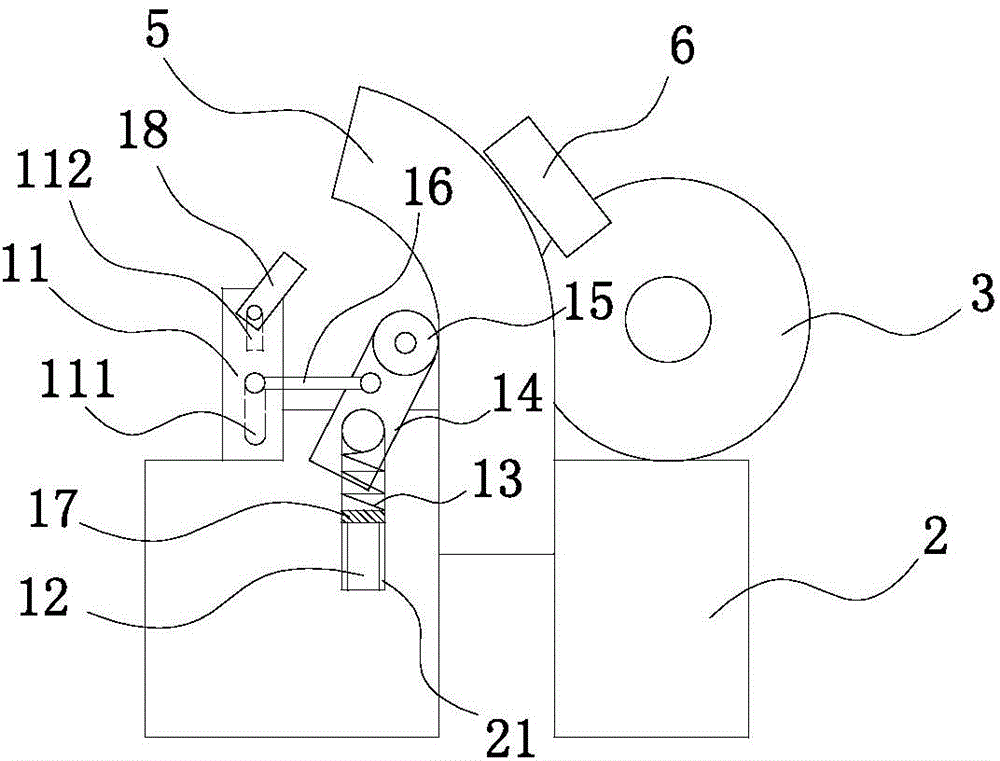

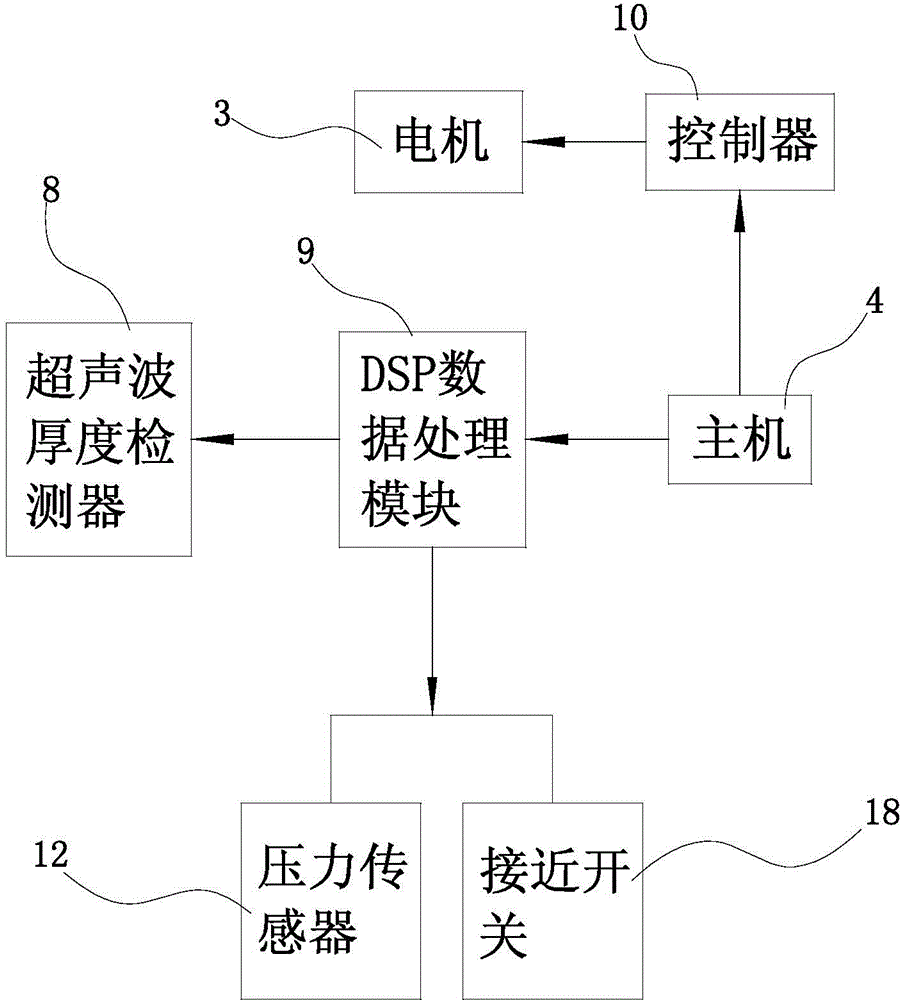

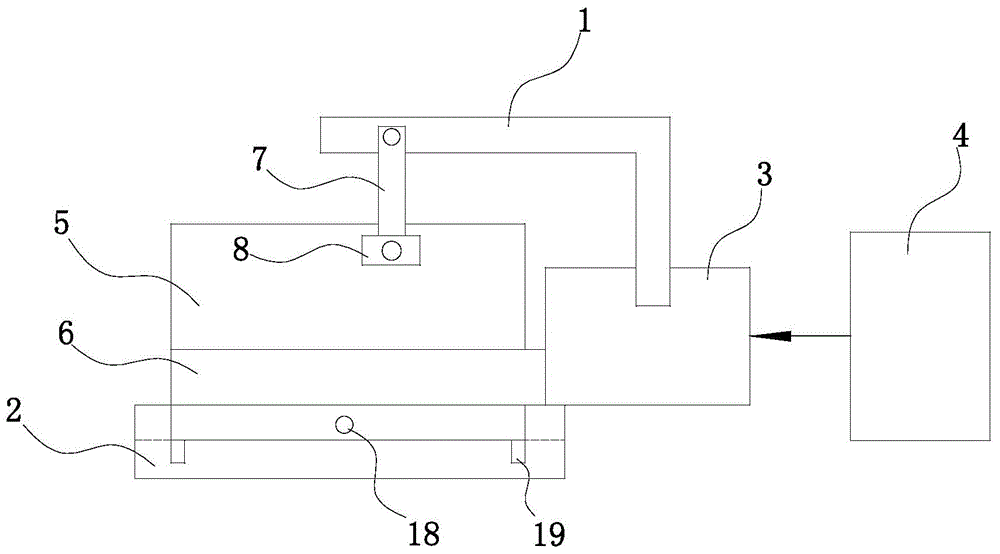

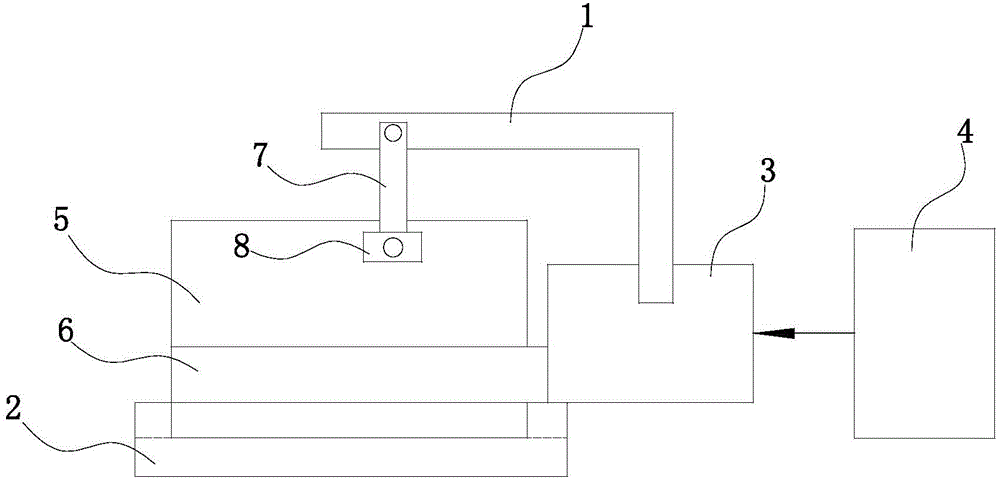

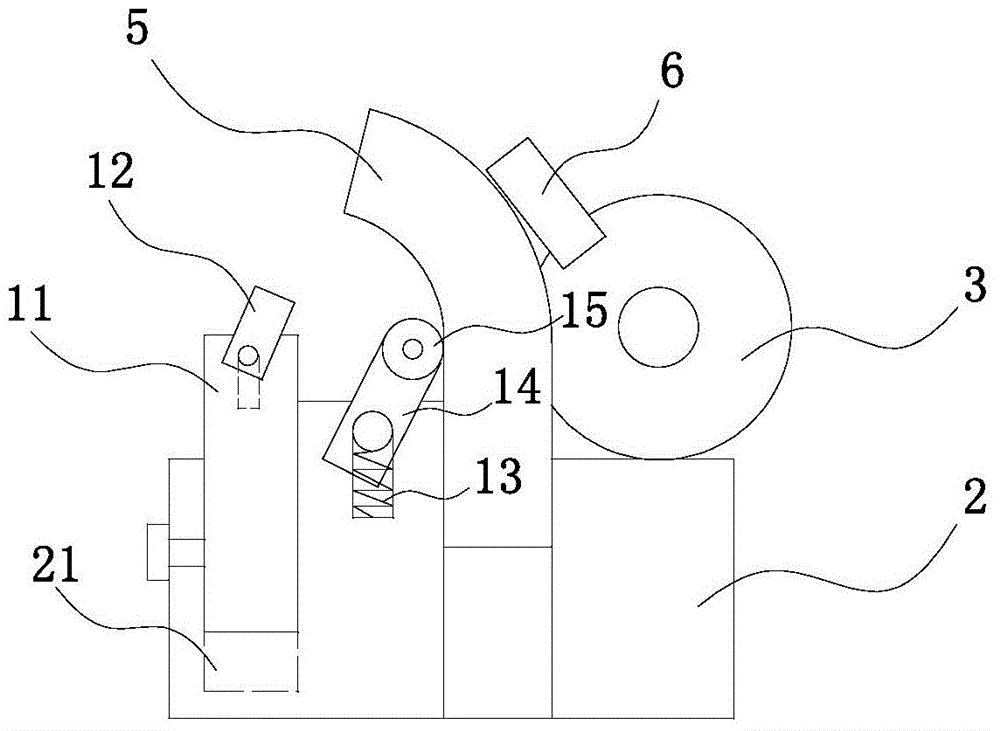

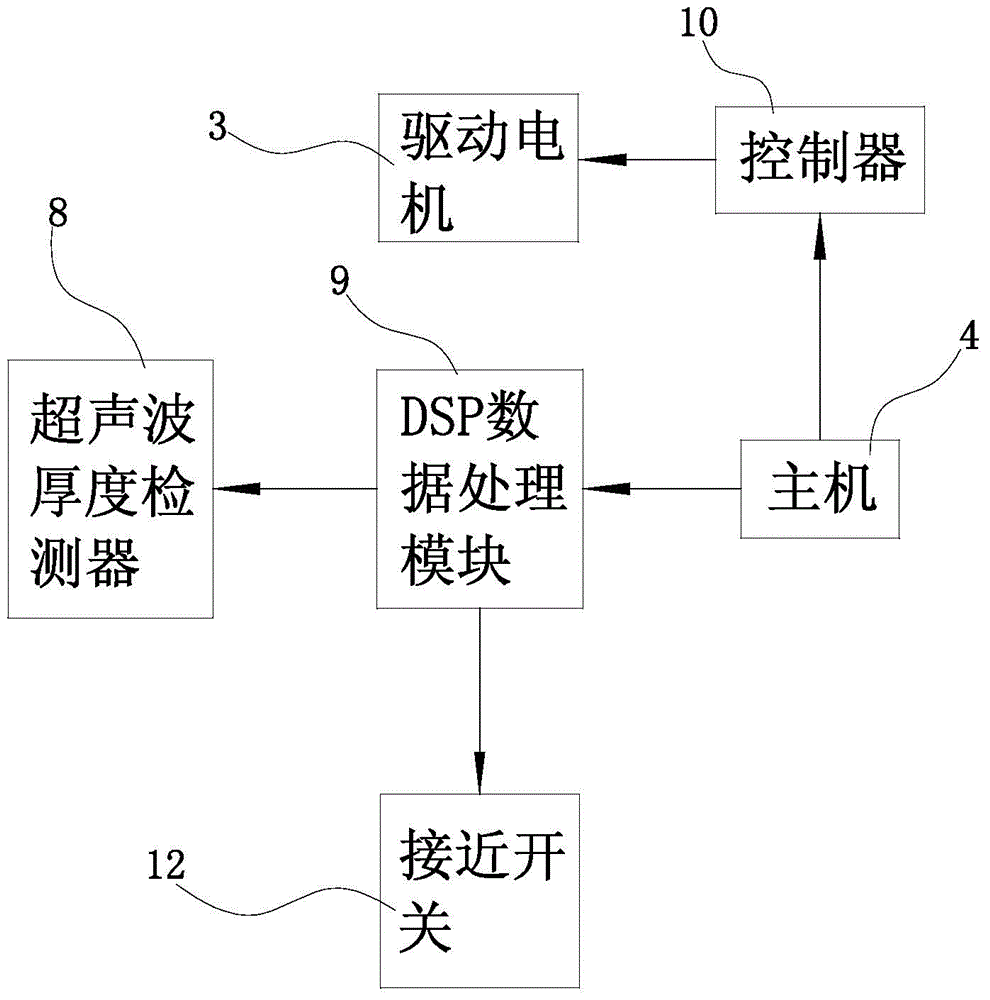

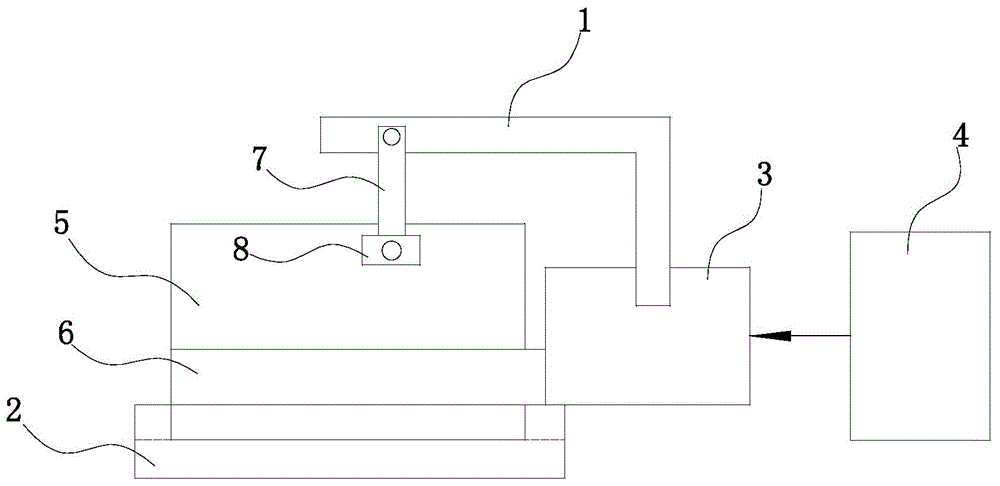

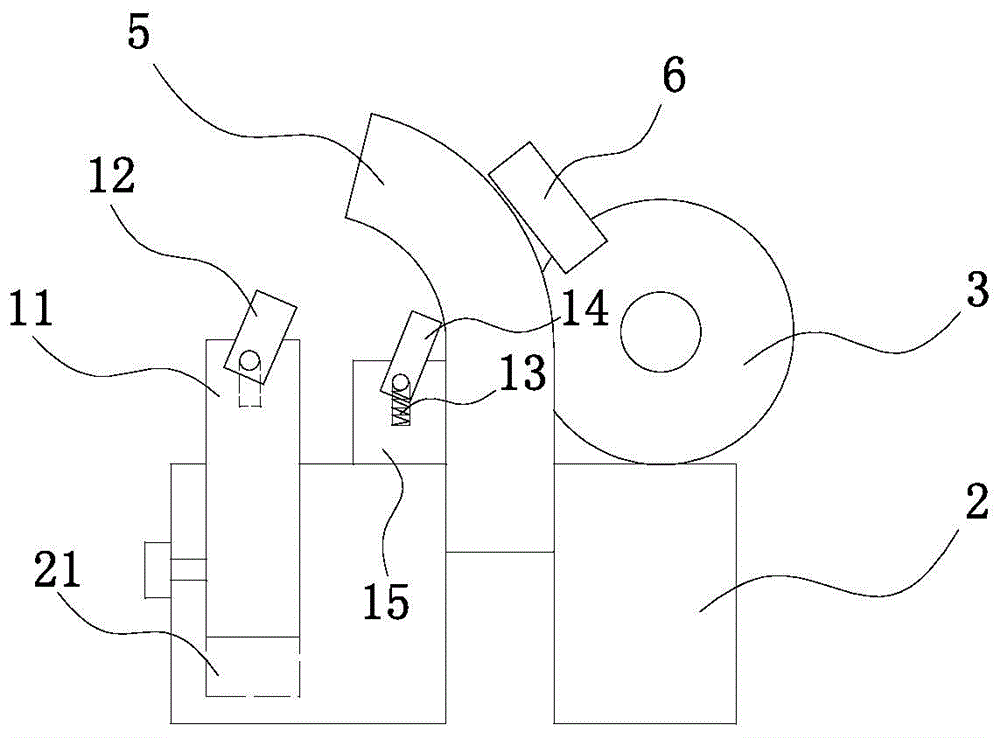

InactiveCN104959410AIncreased process reliabilityImprove processing qualityMetal-working feeding devicesMetal working apparatusDrive motorData treatment

The invention relates to a feedback torque adjustment and metal plate bending system. The feedback torque adjustment and metal plate bending system comprises a driving motor arranged on a machine frame, a clamping fixing seat and a mainframe, wherein a bending shaft is installed on the driving motor, and a machined part is arranged on the clamping fixing seat. The feedback torque adjustment and metal plate bending system further comprises an ultrasonic thickness detector, an ultrasonic crack detector, pressure sensors, a rolling shaft, a proximity switch and a controller connected with the mainframe, wherein the ultrasonic thickness detector, the ultrasonic crack detector, the pressure sensors, the rolling shaft and the proximity switch are installed on the machine frame. The ultrasonic thickness detector, the ultrasonic crack detector, the pressure sensors and the proximity switch are respectively connected with the mainframe through a DSP data processing module. Staged bending and feedback control are combined, so that crack amount is greatly decreased. The arranged rolling shaft is used for conducting extrusion and friction on the inwards concave face of the machined part, and protruding burrs and cracks are effectively removed. A bending angle is controlled through the proximity switch so as to prevent excessive bending. A clamping pressure and positioning are controlled through the pressure sensors, plate deformation or drop is avoided, and machining reliability is improved.

Owner:SUZHOU BIANTONG SENSING TECH

Metal plate bending machining system with feedback detection and clamping control

InactiveCN104959412APrevent looseningReduce crackingMetal-working feeding devicesMetal working apparatusCapacitanceAutomatic control

The invention relates to a metal plate bending machining system with feedback detection and clamping control. The metal plate bending machining system comprises a drive motor, a clamping fixed seat and a main engine which are installed on a rack, the drive motor is provided with a bending shaft, and a machined workpiece is arranged on the clamping fixed seat; the metal plate bending machining system further comprises a capacitive sensing thickness detector, a roller, a proximity switch, a pressure sensor, a detection feedback device and a controller; the roller and the proximity switch are installed on the bending side of the machined workpiece; the detection feedback device comprises an ultrasonic crack detector which is installed on the clamping fixed seat; the capacitive sensing thickness detector, the proximity switch, the pressure sensor and the ultrasonic crack detector are connected with the main engine through DSP date process modules respectively. Bending is conducted through combination of crack detection and roller extrusion friction, the number of cracks is greatly reduced, and the machining quality is improved; the bending angle is automatically controlled by arranging of the proximity switch, and excessive bending is prevented; by means of the pressure sensor, the clamping pressure is controlled, and a metal plate is prevented from being deformed or loosened.

Owner:SUZHOU BIANTONG SENSING TECH

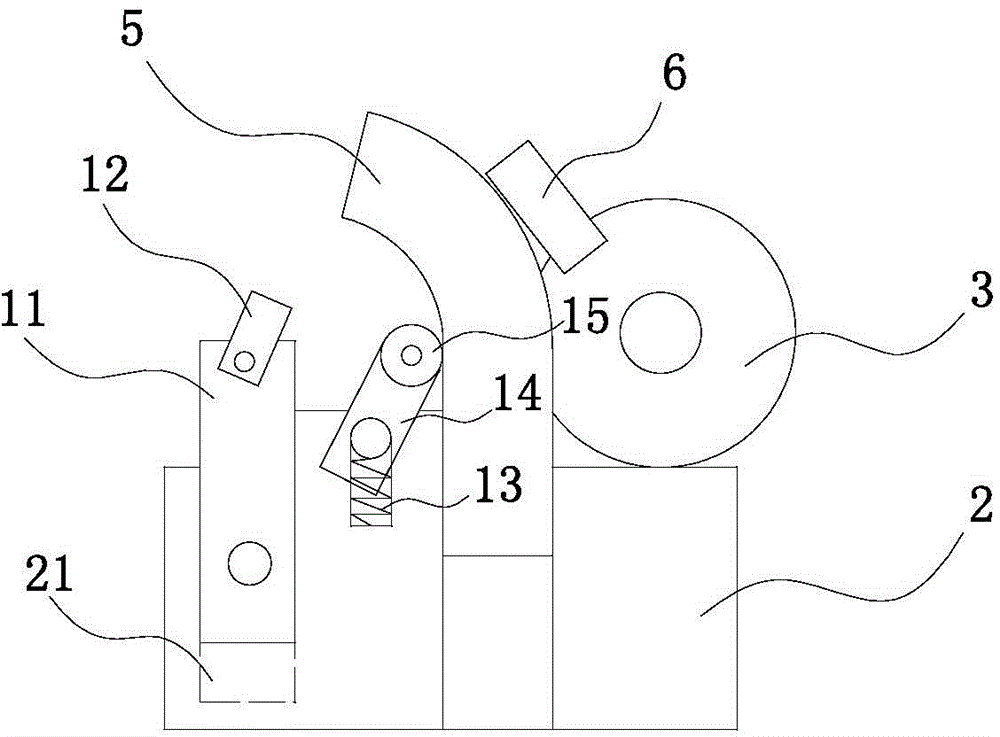

Sheet metal bending device based on feedback detection and rolling bending

InactiveCN104942059AAvoid influencePrevent excessive bendingMetal working apparatusAutomatic controlDrive motor

The invention relates to a sheet metal bending device based on feedback detection and rolling bending. The device comprises a drive motor on a rack, a clamping and fixing base and a main machine. A bending shaft is installed on the drive motor, and the clamping and fixing base is provided with a machined part. The device further comprises a capacitance induction thickness detector, a rolling shaft, a proximity switch, a detection feedback device and a controller. The rolling shaft and the proximity switch are arranged on the bending side of the machined part. The detection feedback device comprises an ultrasonic crack detector arranged on the clamping and fixing base. The capacitance induction thickness detector, the proximity switch, the pressure sensor and the ultrasonic crack detector are connected with the main machine through a DSP data processing module. Crack detection and rolling shaft extrusion and friction are combined for bending, the quantity of cracks is greatly reduced, and machining quality is improved. The proximity switch is arranged to automatically control the bending angle, and excessive bending is prevented.

Owner:SUZHOU BIANTONG SENSING TECH

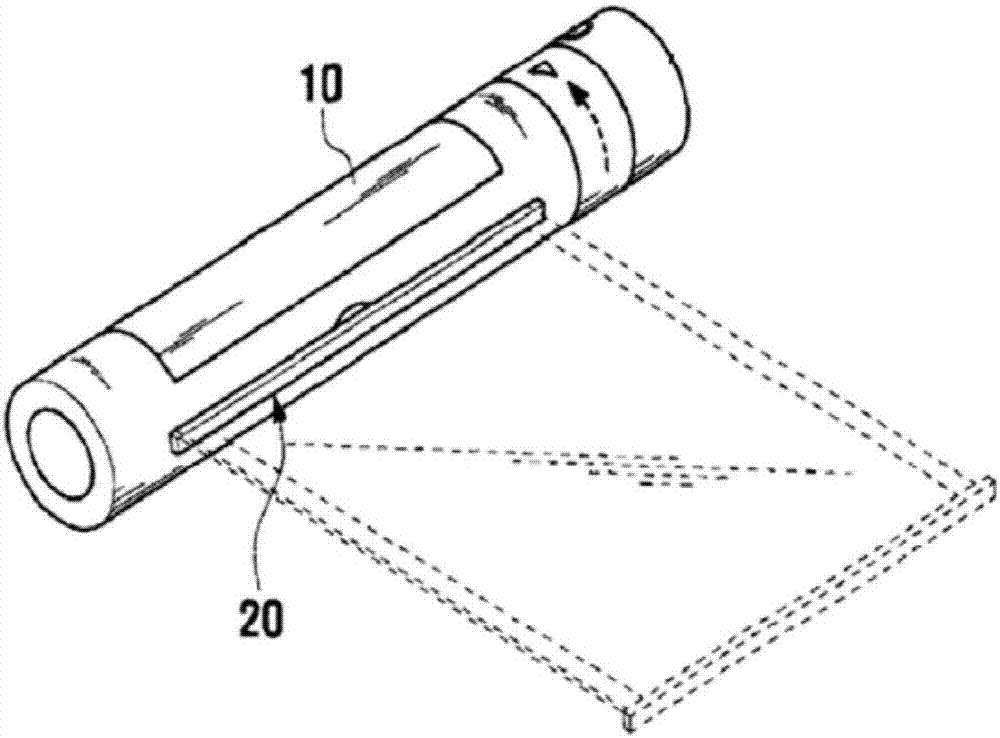

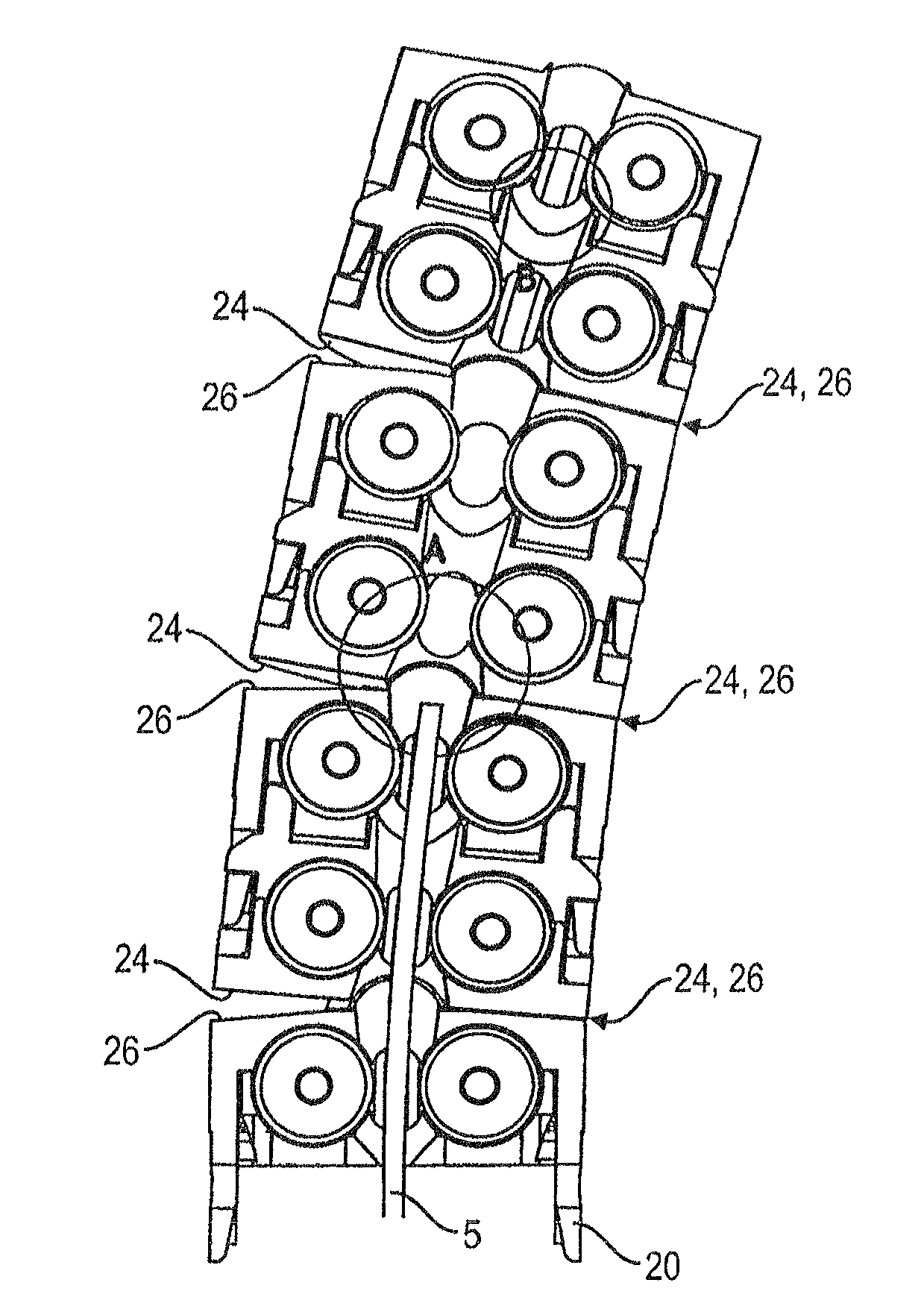

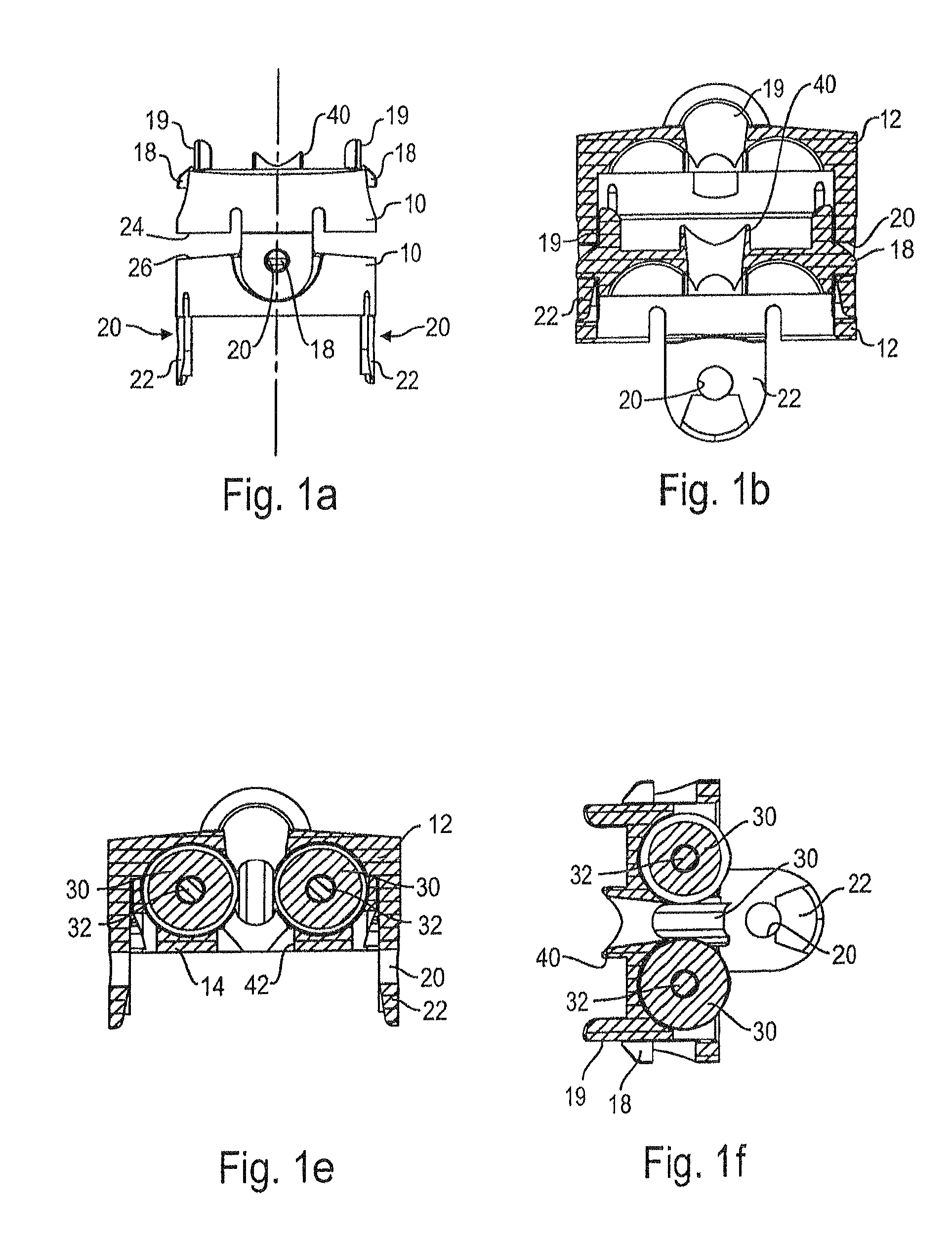

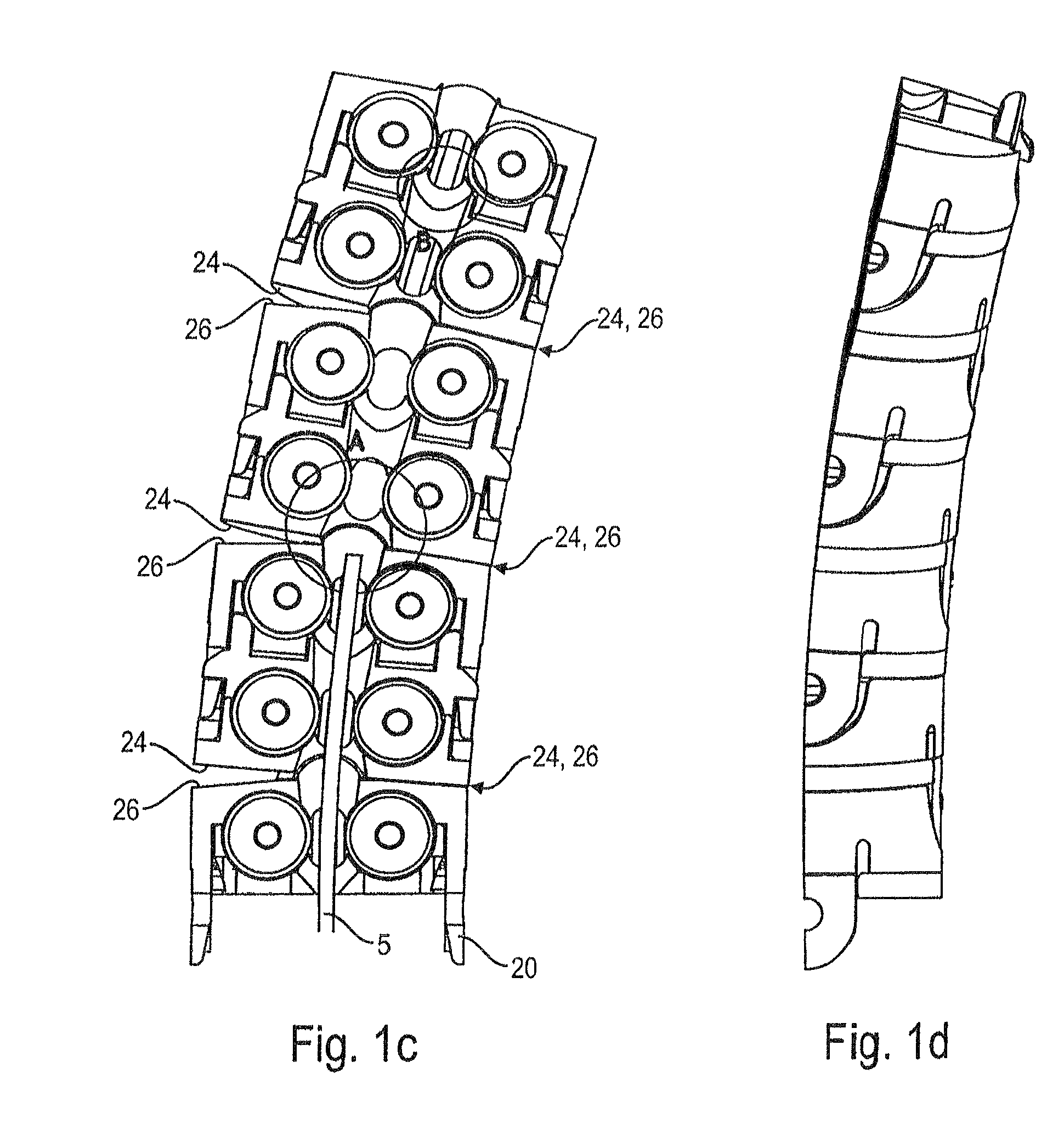

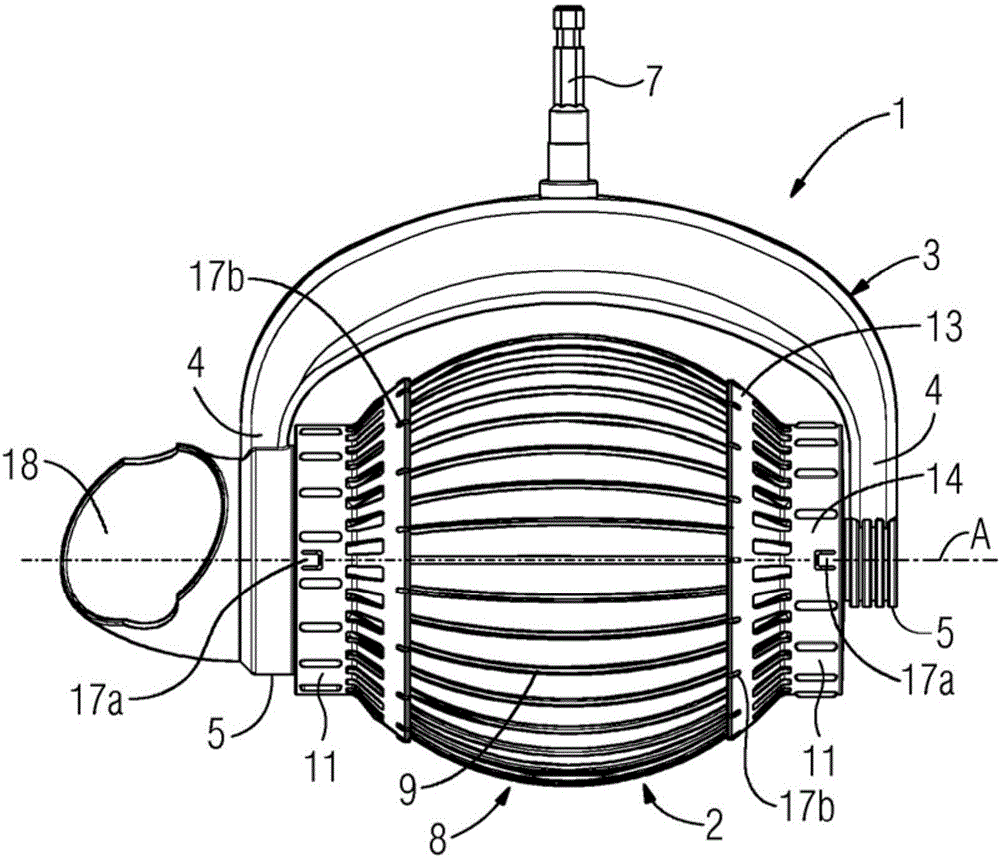

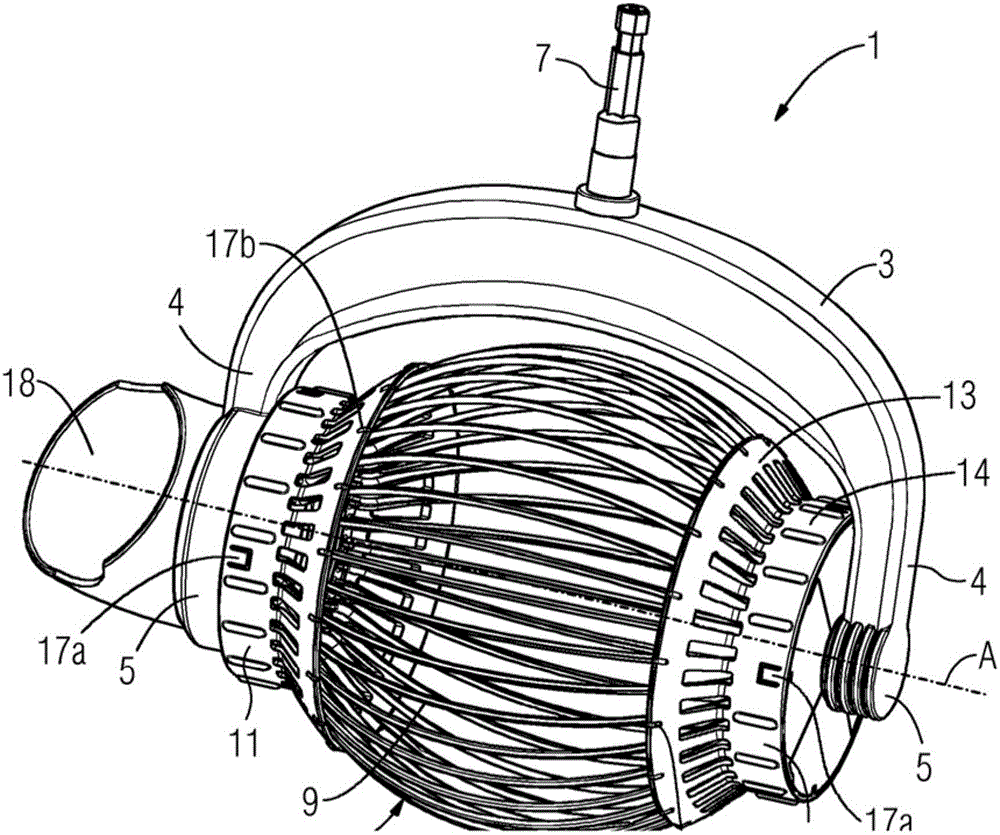

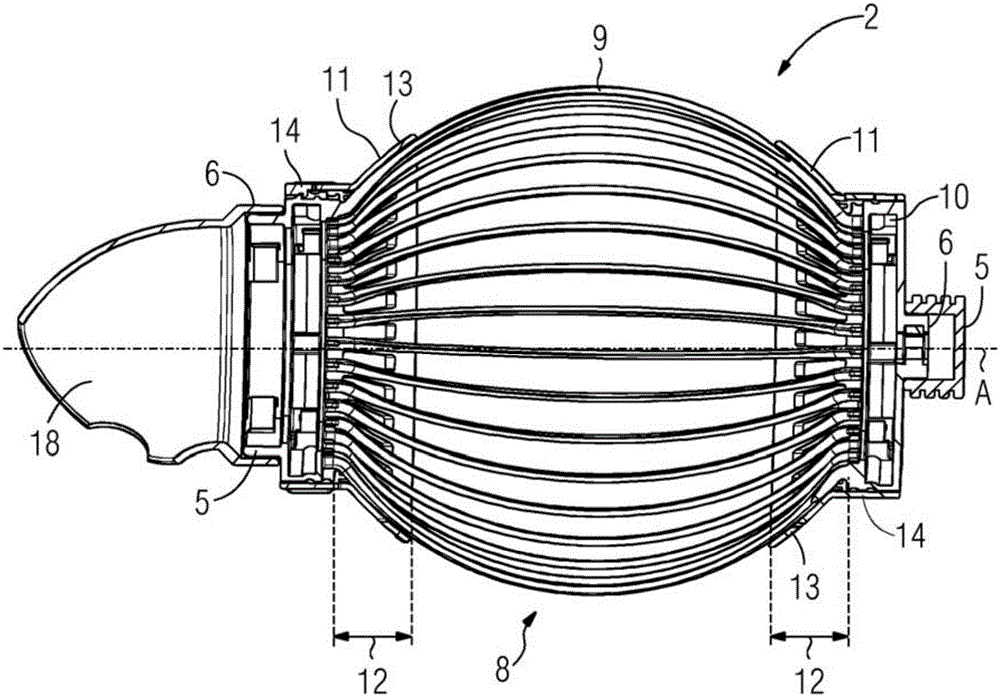

Wire guiding system

ActiveUS8453960B2Reduce frictionReduce manufacturing costElectrical apparatusProjector film strip handlingEngineeringMechanical engineering

A wire guiding liner, in particular welding wire liner, has a plurality of roll holders which are displaceable with respect to each other, each roll holder holding a plurality of rolls. The angular displaceability of a roll holder with respect to the adjacent roll holder is limited such that when the wire is fed through the liner, it always touches exclusively on the rolls even when the liner is bent to its maximum curve, such that the wire while being inserted always hits the next roll at an angle that will push it towards and maintain it guided at the center of the liner.

Owner:AWDS TECH

Bending device based on positioning and clamping control and feedback control

InactiveCN104942056APrevent looseningPrevent excessive bendingMetal-working feeding devicesMetal working apparatusCapacitanceMachine parts

The invention relates to a bending device based on positioning and clamping control and feedback control. The device comprises a drive motor on a rack, a clamping and fixing base and a main machine. A bending shaft is installed on the drive motor, and a machined part is arranged on the clamping and fixing base. The device further comprises a capacitance induction thickness detector, a rolling shaft, a proximity switch, a pressure sensor, a detection feedback device and a controller, and the rolling shaft and the proximity switch are arranged on the bending side of the machined part. The detection feedback device comprises an ultrasonic crack detector arranged on the clamping and fixing base. The capacitance induction thickness detector, the proximity switch, the pressure sensor and the ultrasonic crack detector are connected with the main machine. Crack detection and rolling shaft extrusion and friction are combined for bending, the quantity of cracks is greatly reduced, and machining quality is improved. The proximity switch is arranged to automatically control the bending angle, and excessive bending is prevented. The pressure sensor is adopted to control clamping pressure and positioning, plates are prevented from deforming or disengaging, and machining reliability is improved.

Owner:SUZHOU BIANTONG SENSING TECH

Bending processing system and method based on crack detection feedback and clamping control

InactiveCN104998931APrevent looseningReduce the proportion of cracksMetal working apparatusCapacitanceCapacitive sensing

The invention relates to a bending processing system and method based on crack detection feedback and clamping control. The bending processing system comprises a drive motor which is arranged on a rack, a clamping fixing base and a main engine, wherein a bending shaft is arranged on the drive motor; a processed workpiece is arranged on the clamping fixing base. The bending processing system further comprises a capacitive sensing thickness detector, pressure sensors, a proximity switch, a detection feedback device and a control, wherein a first pressure sensor and the proximity switch are arranged at the bent part of the processed workpiece; the detection feedback device comprises an ultrasonic crack detector which is arranged on the clamping fixing base; the capacitive sensing thickness detector, the pressure sensors, the proximity switch and the ultrasonic crack detector are separately connected to the main engine through a DSP (Digital signal Processor) module. According to the bending processing system and method disclosed by the invention, a second pressure sensor is used for controlling clamping force, and the proportion of cracks is greatly reduced through crack detection and multi-stage bending, so that the processing quality is improved; and excessive bending is avoided by controlling the bending angle, so that the use safety of the equipment is improved.

Owner:SUZHOU BIANTONG SENSING TECH

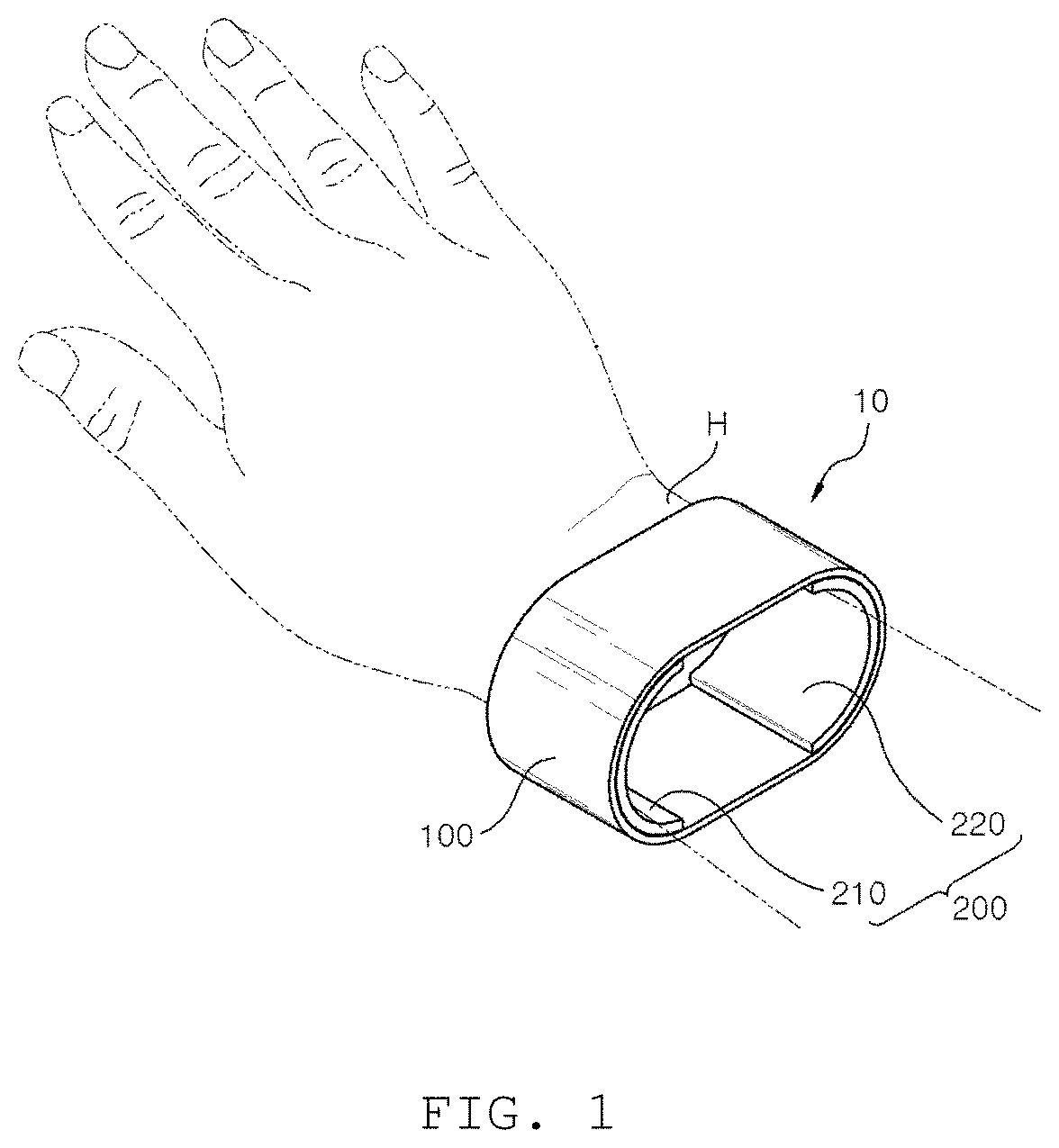

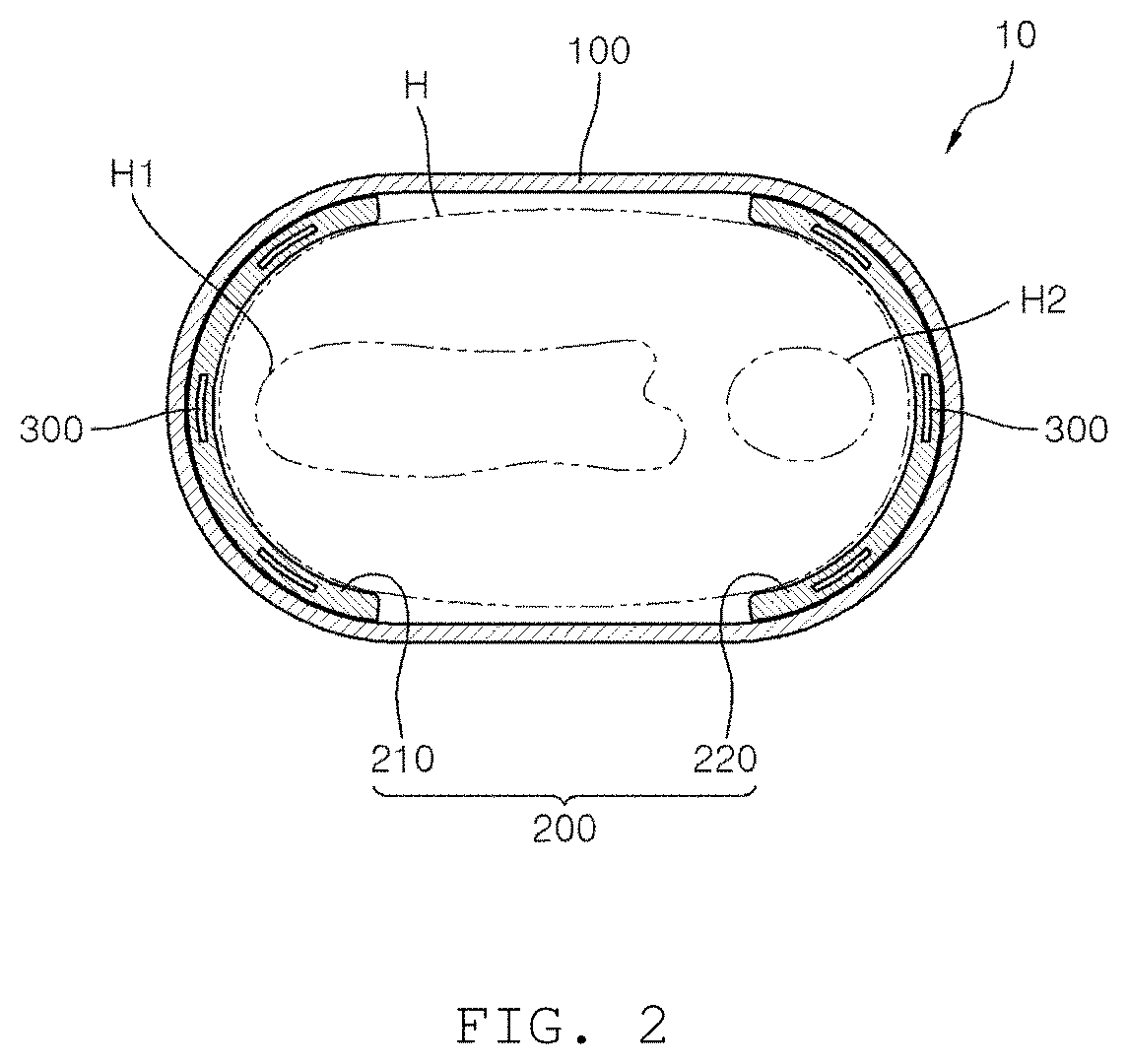

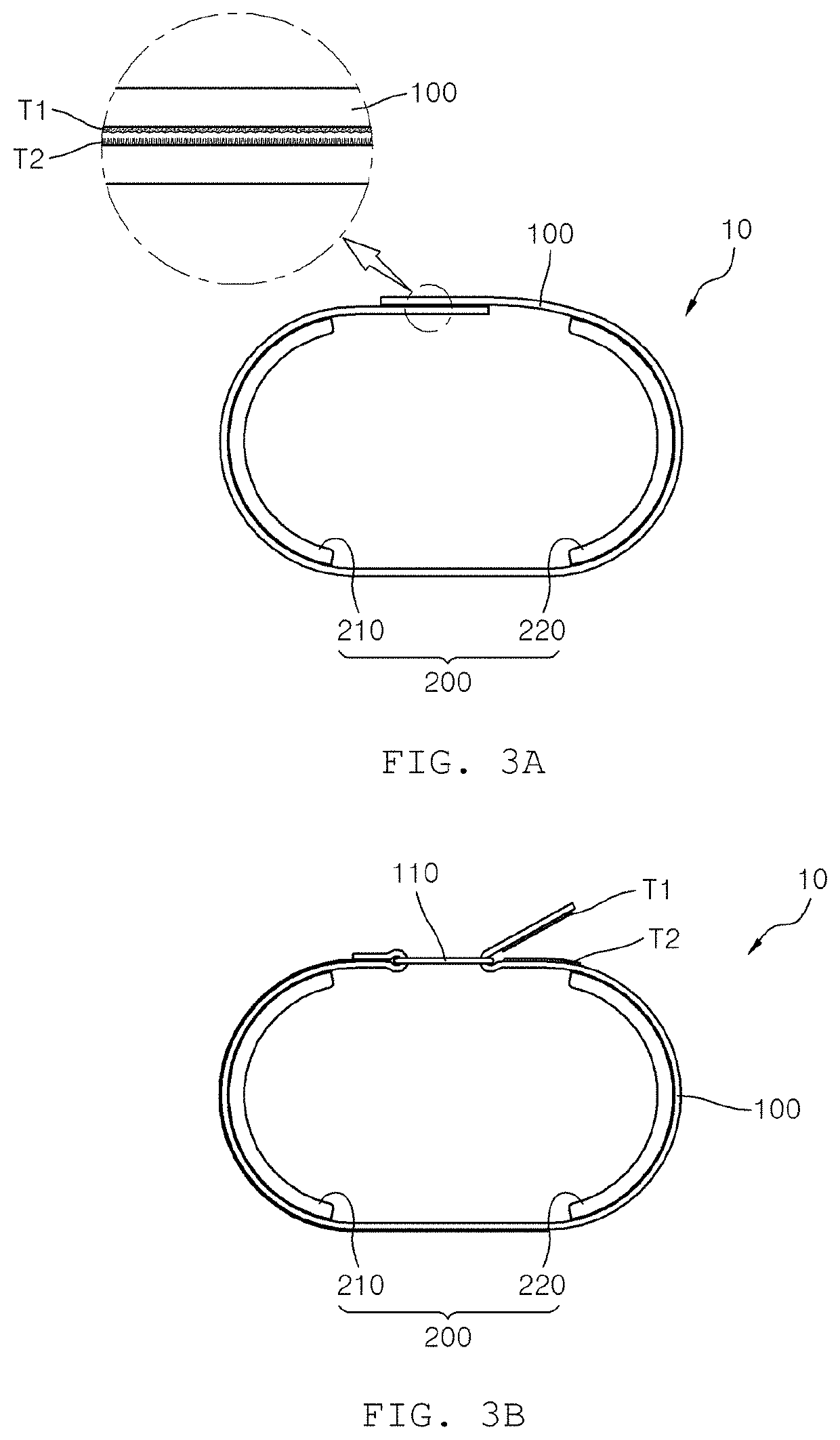

Wrist guard

ActiveUS20190364991A1Improve usabilityAvoid it happening againGarment special featuresWristbandsSide effectEntire wrist

The present invention relates to a wrist guard and provides a wrist guard that does not pressurize the entire wrist portion but allows for pressurizing only the radius portion and the ulna portion, thereby not only performing a wrist protection function in a stable manner, but also not hindering blood circulation since other portions of the wrist are not pressurized, and thus may be conveniently used since side-effects such as hand numbness or hand swelling do not occur even when wearing same for a long period, and the position and thickness of a pressurizing pad for pressurizing the radius portion and the ulna portion of the wrist may be adjusted according to the needs of a user, and thus the wrist guard may be more conveniently used since same may be altered into an optimal state according to physical conditions of the user or environmental conditions.

Owner:LEE SANG JIN

Sheet metal bending device based on bending angle control and feedback torque adjustment

InactiveCN104942069AEfficient removalReduce the amount of cracksMetal working apparatusComputer moduleDrive motor

The invention relates to a sheet metal bending device based on bending angle control and feedback torque adjustment. The sheet metal bending device based on bending angle control and feedback torque adjustment comprises a drive motor, a clamping fixing base and a host which are arranged on a machine frame; a bending shaft is installed on the drive motor; the clamping fixing base is provided with a processed workpiece. The sheet metal bending device based on bending angle control and feedback torque adjustment further comprises an ultrasonic thickness detector, an ultrasonic crack detector, a pressure sensor, a roller, a proximity switch and a controller connected with the host, wherein the ultrasonic thickness detector, the ultrasonic crack detector, the pressure sensor and the roller are installed on the machine frame; the ultrasonic thickness detector, the ultrasonic crack detector, the pressure sensor and the proximity switch are connected with the host through a DSP data processing module. Through combination of staged type bending and feedback control, the crack quantity is greatly reduced, and the processing quality is improved; the arranged roller carries out extrusion and friction on the concave surface of the processed workpiece, effectively removes protrusive burrs and cracks and omits the subsequent processing process; the proximity switch controls the bending angle, so that excessive bending is prevented, and the processing safety is improved.

Owner:SUZHOU BIANTONG SENSING TECH

Sheet metal bending system and method with detection feedback function and clamping control function

InactiveCN104942073APrevent looseningAvoid influenceMetal working apparatusCapacitanceAutomatic control

The invention relates to a sheet metal bending system and method with the detection feedback function and the clamping control function. The system comprises a driving motor arranged on a rack, a clamping and fixing base and a main machine. A bending shaft is installed on the driving motor. A machined workpiece is installed on the clamping and fixing base. The system further comprises a capacitance induction thickness detector, a rolling shaft, a proximity switch, a pressure sensor, a detection feedback device and a controller. The rolling shaft and the proximity switch are installed on the bending side of the machined workpiece. The detection feedback device comprises an ultrasonic crack detector installed on the clamping and fixing base. The capacitance induction thickness detector, the proximity switch, the pressure sensor and ultrasonic crack detector are all connected with the main machine through a DSP data processing module. According to the system, bending is performed through combination of crack detection and extrusion and friction of the rolling shaft, the quantity of cracks is greatly reduced, and machining quality is improved. The proximity switch is arranged to automatically control the bending angle, and excessive bending is prevented. The pressure sensor is used for controlling clamping pressure, and a plate is prevented from deforming or getting loose.

Owner:SUZHOU BIANTONG SENSING TECH

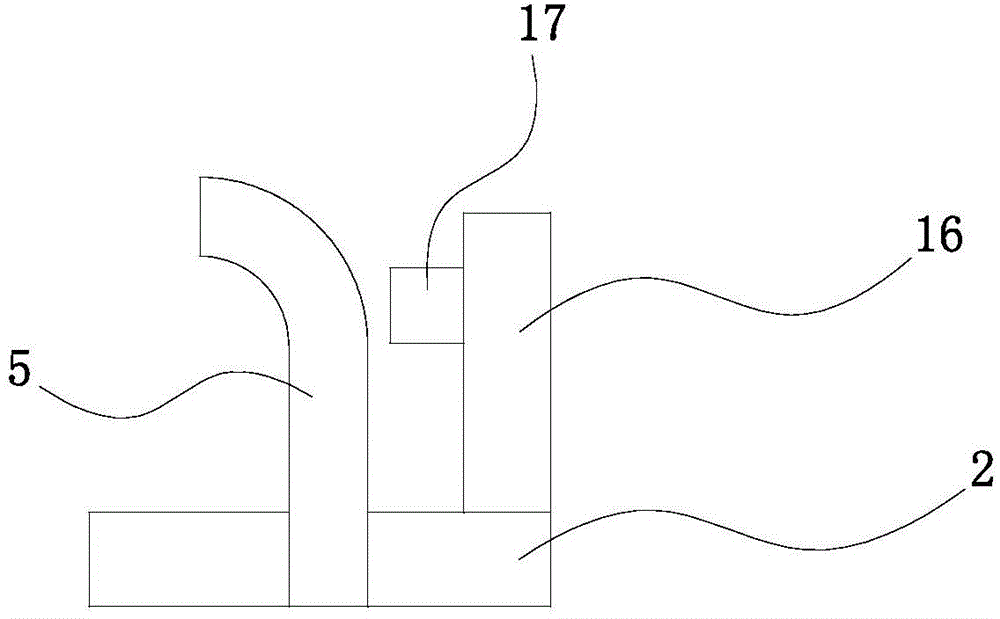

Stage-type bending device

InactiveCN104942063AReduce the proportion of cracksImprove processing qualityMetal working apparatusAutomatic controlComputer module

The invention relates to a stage-type bending device. The stage-type bending device comprises a drive motor arranged on a rack, a clamping fixed seat, a main engine, an ultrasonic thickness detector, a support rod installed on the clamping fixed seat, a pressure sensor and a controller connected with the main engine. A bending shaft is installed on the drive motor. A workpiece to be processed is arranged on the clamping fixed seat. The upper end of the support rod is connected with a proximity switch. The pressure sensor is arranged on an installing groove of a stop dog through a spring device. The ultrasonic thickness detector, the pressure sensor and the proximity switch are connected with the main engine through a DSP date processing module respectively. According to the stage-type bending device, through staged bending, the crack proportion is reduced greatly, and the processing quality is improved; the proximity switch is arranged to control a bending angle automatically, excessive bending is prevented, the proximity switch can adjust the height and angle conveniently, and the stage-type bending device is suitable for multi-size and multi-angel stamping part bending.

Owner:SUZHOU BIANTONG SENSING TECH

Object collector device, object collector container, object collector grid protector

ActiveCN107438361AAvoid plastic deformationAvoid damageHarvestersBall sportsCollector deviceEngineering

The underlying invention is directed to devices for collecting objects, such as fruits, from the ground. In particular, an object collector grid protector (11) is provided, which is configured for use with a collector grid basket (8) of an object collector device. A corresponding basket (8) comprises an object penetrable grid comprising a plurality of mutually spaced resilient grid bars (9) supported by and extending off a basket base (10). The object collector grid protector (11) comprises at least one annular protector shell (13) with a predefined lateral width (W) overlapping, when properly applied to the grid basket (8), with a predefined grid basket section located adjacent to the basket base (10), to thereby disable in the overlapping region a passage of objects into the grid basket (8).

Owner:HUSQVARNA AB

Metal plate bending device and method based on bending angle control and feedback torque regulation

InactiveCN104959418AAvoid influenceEfficient removalMetal working apparatusEngineeringTorque regulation

The invention relates to a metal plate bending device and method based on bending angle control and feedback torque regulation. The device comprises a driving motor arranged on a machine frame, a clamping and fixing base, and a main unit, wherein a bending shaft is installed on the driving motor, and a part to be machined is arranged on the clamping and fixing base. The device further comprises an ultrasonic thickness detector installed on the machine frame, an ultrasonic crack detector, a pressure sensor, a roller, a proximity switch, and a controller connected with the main unit, wherein the ultrasonic thickness detector, the ultrasonic crack detector, the pressure sensor and the proximity switch are all connected with the main unit through a DSP data processing module. By combining staged bending with feedback control, the number of cracks is reduced greatly, and machining quality is improved. The roller is arranged for extrusion friction of the inward-concave surface of the part to be machined, protruding burrs and cracks are effectively removed, and subsequent processing is omitted. Bending angle is controlled through the proximity switch, excessive bending is prevented, and machining safety is improved.

Owner:SUZHOU BIANTONG SENSING TECH

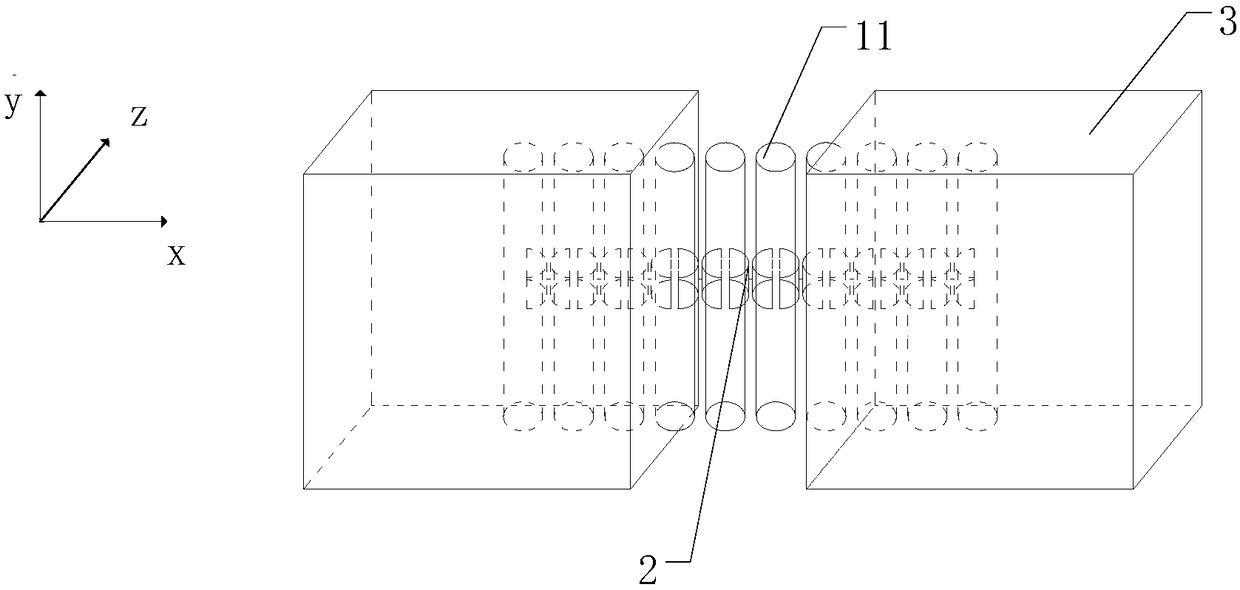

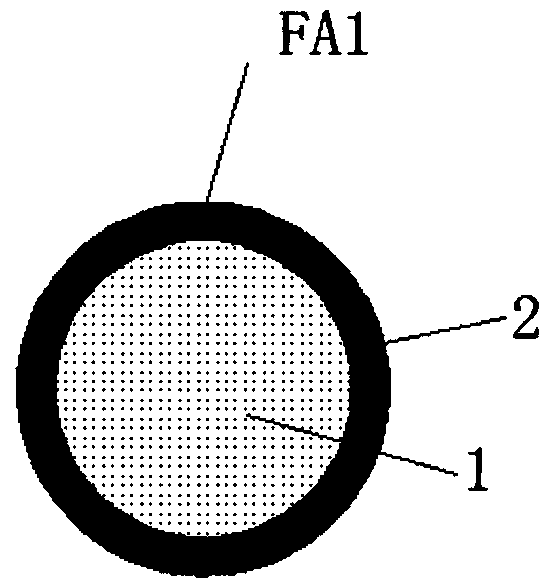

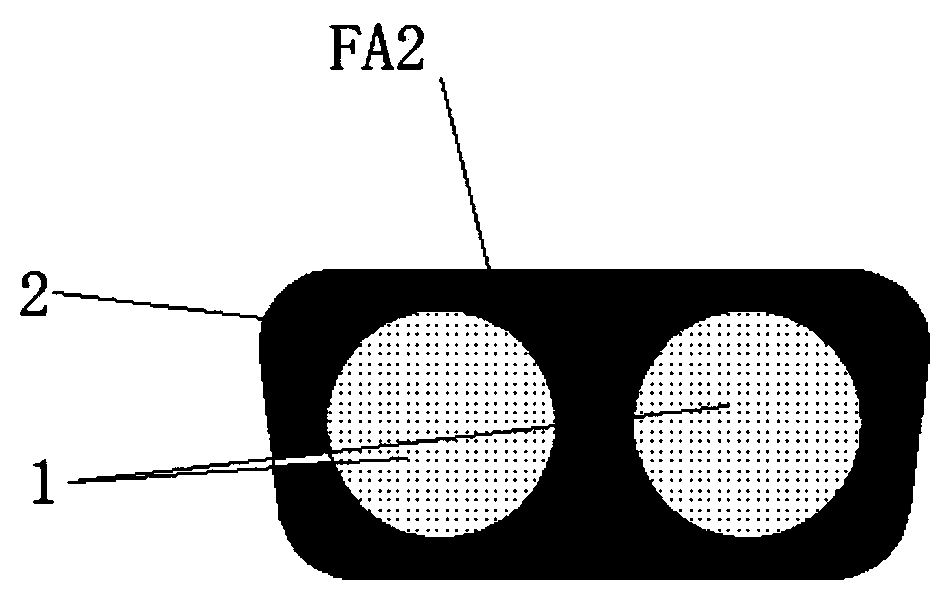

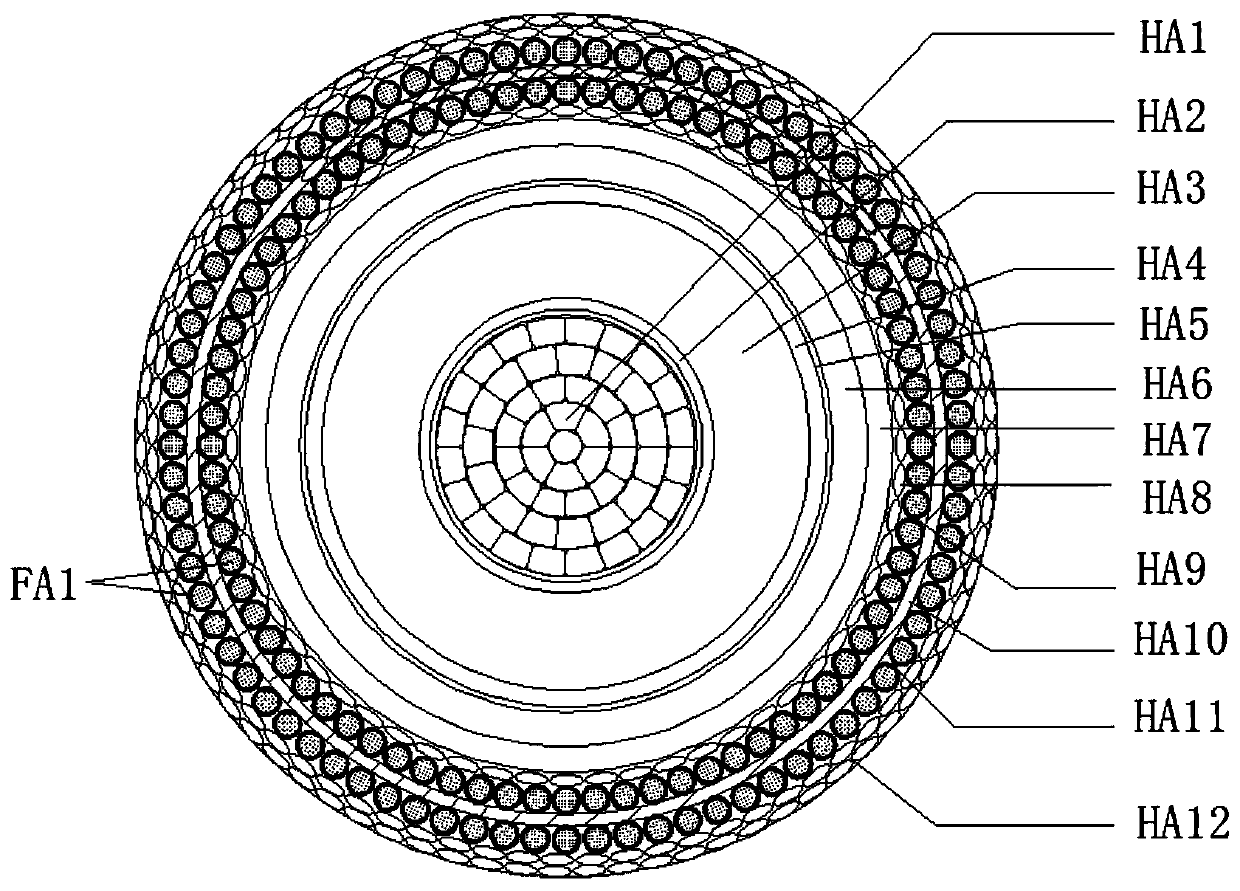

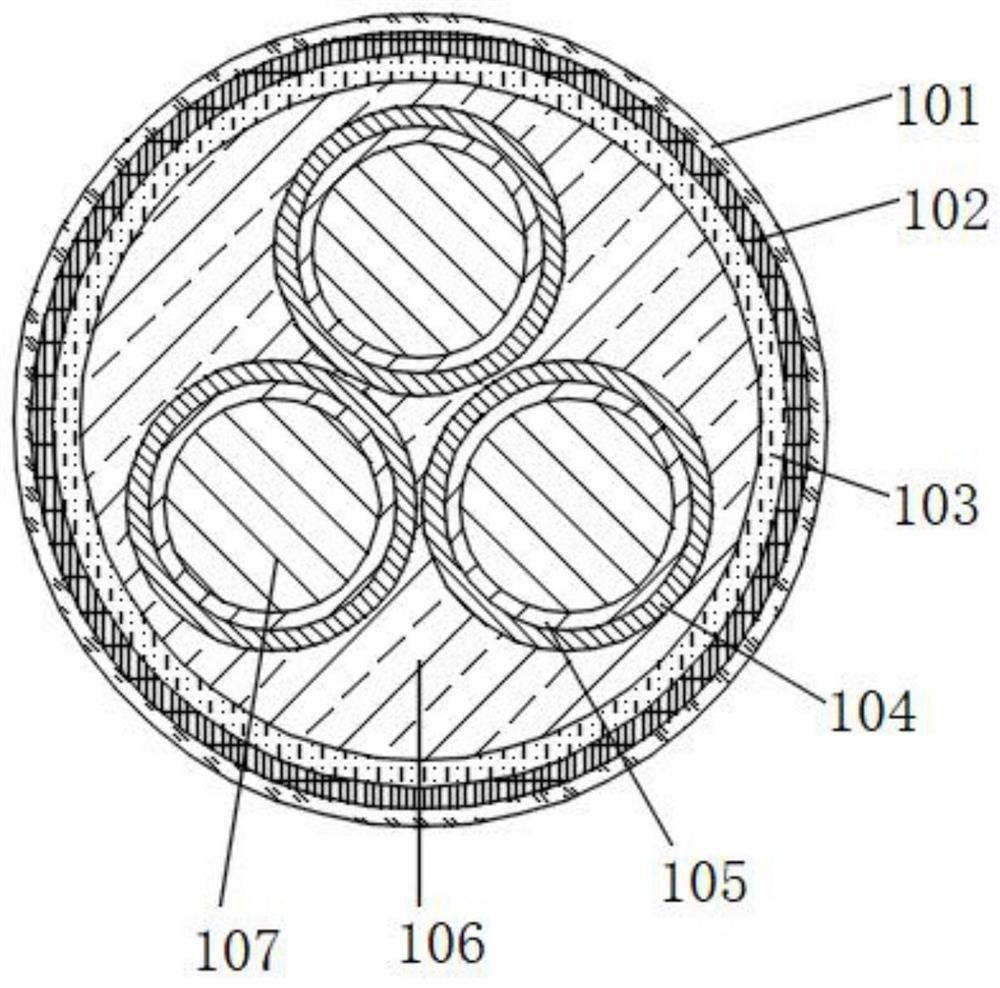

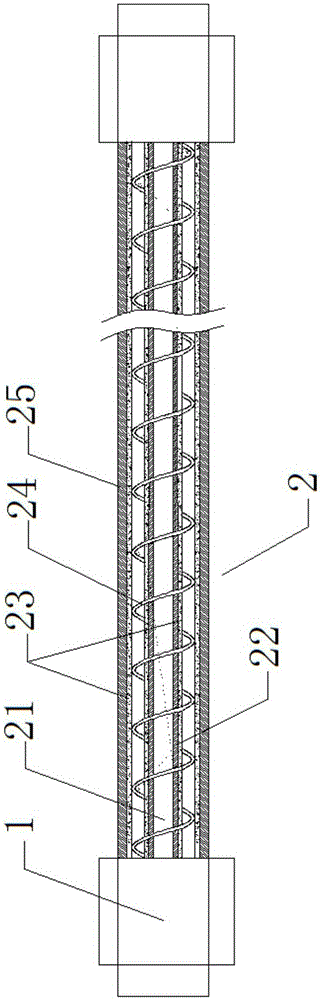

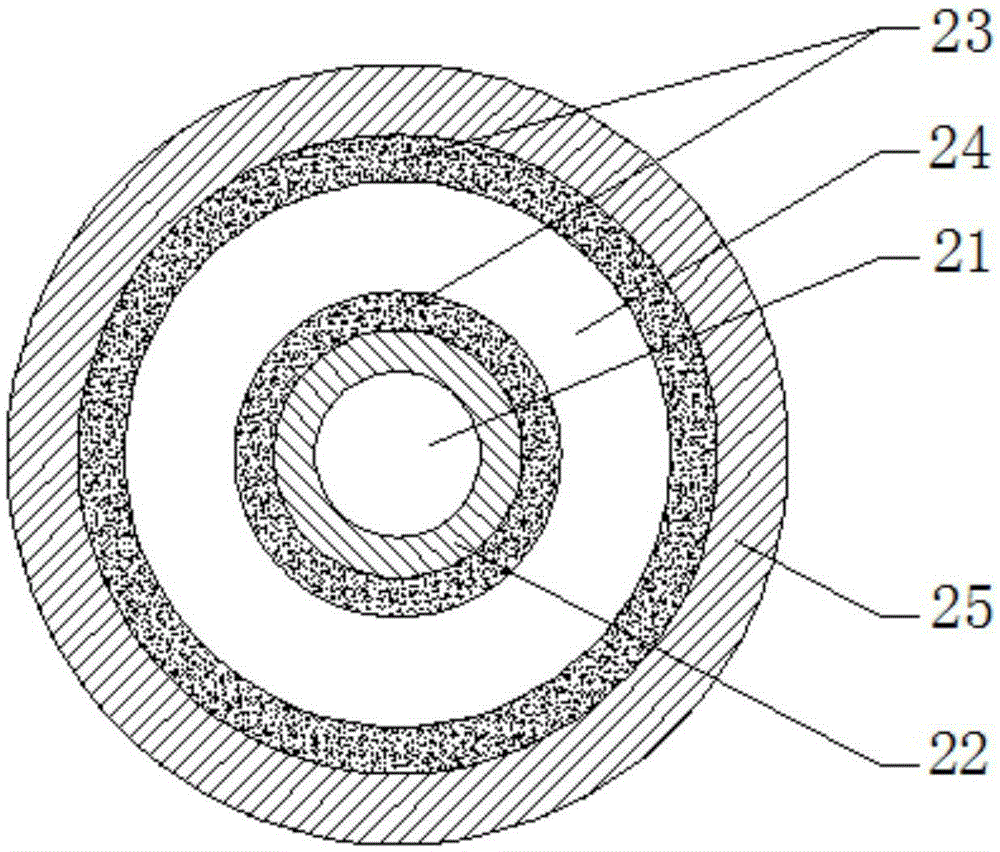

Light non-metal armored submarine cable

ActiveCN111292883ALow costImprove water resistanceClimate change adaptationSubmarine cablesMarine engineeringStructural engineering

The invention discloses a light non-metal armored submarine cable. The submarine cable comprises a central cable composed of one or more electric units, an armor layer and an outer coating layer, wherein the armor layer is twisted outside the central cable; the armor layer is sleeved with the outer coating layer; the armor layer is formed by twisting a plurality of circular or flat nonmetal armored elements and / or a plurality of armor metal wires; when the non-metal armored element is circular, the non-metal armored element is composed of a non-metal rod and an outer sheath extruded outside the non-metal rod, or is composed of a central rod body composed of a plurality of non-metal rods which are stacked in a tangent manner, and an outer sheath extruded outside the central rod body; and when the non-metal armored element is flat, the non-metal armored element is composed of a plurality of non-metal rods and an outer sheath extruded outside the non-metal rods. According to the invention, the problems of large submarine cable weight and large vertical laying installation stress under the condition of large water depth are solved, lighter submarine cable weight is achieved while the mechanical performance of the deep submarine cable is ensured, and the laying construction and the operation safety of the submarine cable are ensured.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

Bending processing system based on crack detection and feedback and clamping control

InactiveCN104942057APrevent looseningReduce the proportion of cracksMetal-working feeding devicesMetal working apparatusCapacitanceEngineering

The invention relates to a bending processing system based on crack detection and feedback and clamping control. The bending processing system based on crack detection and feedback and clamping control comprises a drive motor, a clamping fixing base and a host which are arranged on a machine frame; a bending shaft is installed on the drive motor; the clamping fixing base is provided with a processed workpiece. The bending processing system based on crack detection and feedback and clamping control further comprises a capacitive sensing thickness detector, a pressure sensor, a proximity switch, a detection feedback device and a controller, wherein the pressure sensor and the proximity switch are arranged at the bent position of the processed workpiece; the detection feedback device comprises an ultrasonic crack detector arranged on the clamping fixing base; the capacitive sensing thickness detector, the pressure sensor, the proximity switch and the ultrasonic crack detector are connected with the host through a DSP data processing module. The clamping force is controlled by the pressure sensor, and through crack detection and staged type bending, the crack ratio is greatly reduced and the processing quality is improved; as the bending angle is controlled, excessive bending is prevented and the use safety of equipment is improved.

Owner:SUZHOU BIANTONG SENSING TECH

Metal plate bending device with torque regulation and roll bending

InactiveCN104959405AAvoid influenceReduce the proportion of cracksShaping toolsMetal-working feeding devicesAutomatic controlEngineering

The invention relates to a metal plate bending device with torque regulation and roll bending. The metal plate bending device comprises a drive motor, a clamping fixed seat and a main engine which are installed on a rack, a motor shaft of the drive motor is provided with a bending shaft, and a machined workpiece is arranged on the clamping fixed seat; the metal plate bending system further comprises an ultrasonic thickness detector, a support rod, a roller and a controller, wherein the ultrasonic thickness detector is installed on the rack with the help of a support, the support rod is installed in a clamping groove of the clamping fixed seat, the roller is installed on the clamping fixed seat and is located on the concave surface side of the machined workpiece, and the controller is connected with the main engine, the upper end of the support rod is connected with a proximity switch, the roller is connected to the upper end face of an adjustment plate in a rotating mode, and the lower end face of the adjustment plate is installed in an installing groove of the clamping fixed seat with the help of a rotary shaft and a spring. Bending is conducted by using the most suitable torque, and the machining quality is improved; by means of the proximity switch, the bending angles are automatically controlled, and excessive bending is prevented; by means of the roller, friction and extrusion are carried out on the face, recessed inwards, of the machined workpiece, and cracks and burrs on the concave surface are effectively reduced.

Owner:SUZHOU BIANTONG SENSING TECH

Metal plate bending machining device and method

InactiveCN104942080AEfficient removalReduce the amount of cracksMetal-working feeding devicesMetal working apparatusDrive motorMachining process

The invention relates to a metal plate bending machining device and method. The metal plate bending machining device comprises a driving motor arranged on a rack, a clamping fixing base and a main machine; a bending shaft is installed on the driving motor, and a machined piece is arranged on the clamping fixing base; the device further comprises an ultrasonic wave thickness detecting device installed on the rack depending on a support, a pressure sensor installed on the clamping fixing base, a proximity switch, a rolling shaft and a controller connected with the main machine; the ultrasonic wave thickness detecting device, the pressure sensor and the proximity switch are each connected with the main machine through a DSP data processing module. According to the metal plate bending machining device and method, staged bending is achieved, so that the crack number is greatly decreased, and the machining quality is improved; the rolling shaft is arranged to extrude and rub the internal concave face of the machined piece, so that protruding burrs and cracks are effectively removed, the follow-up machining process is saved, and the machining period is shortened; the proximity switch for controlling the bending angle is arranged, so that excessive bending is prevented.

Owner:SUZHOU BIANTONG SENSING TECH

Bending device and method based on positioning clamping control and feedback control

The invention relates to a bending device and method based on positioning clamping control and feedback control. The device comprises a driving motor arranged on a machine frame, a clamping and fixing base and a main unit, wherein a bending shaft is installed on the driving motor, and a part to be machined is arranged on the clamping and fixing base. The device further comprises a capacitive sensing thickness detector, a roller, a proximity switch, a pressure sensor, a detection feedback device and a controller, wherein the roller and the proximity switch are arranged on the bent side of the part to be machined, the detection feedback device comprises an ultrasonic crack detector arranged on the clamping and fixing base, and the capacitive sensing thickness detector, the proximity switch, the pressure sensor and the ultrasonic crack detector are all connected with the main unit. By combining crack detection with roller extrusion friction for bending, the number of cracks is reduced greatly, and machining quality is improved; the proximity switch is arranged to automatically control bending angle, so that excessive bending is prevented; the pressure sensor is adopted for controlling clamping pressure and positioning, so that a metal plate is prevented from deformation or disengagement and machining reliability is improved.

Owner:SUZHOU BIANTONG SENSING TECH

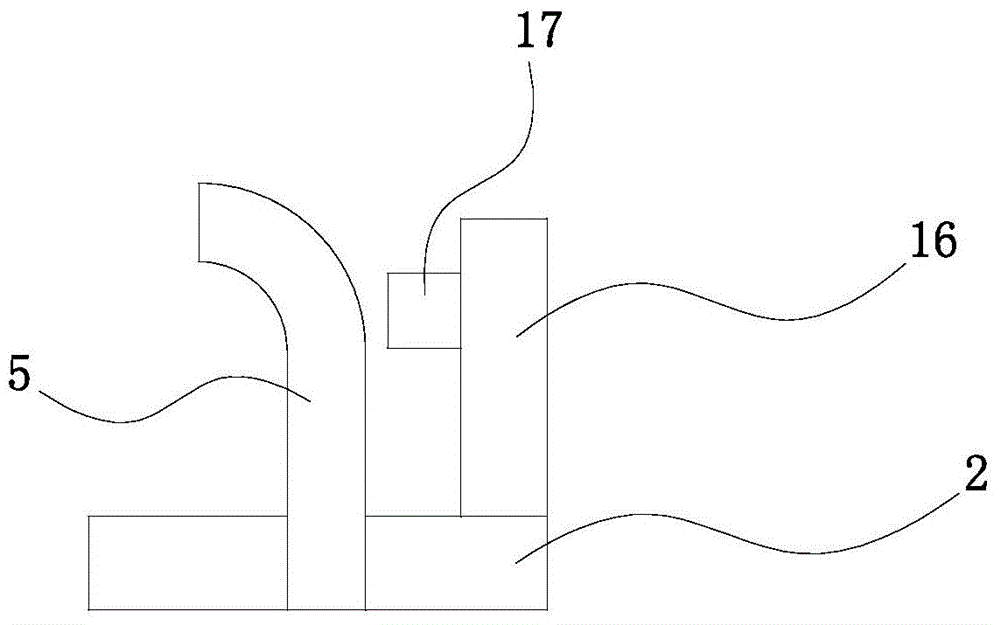

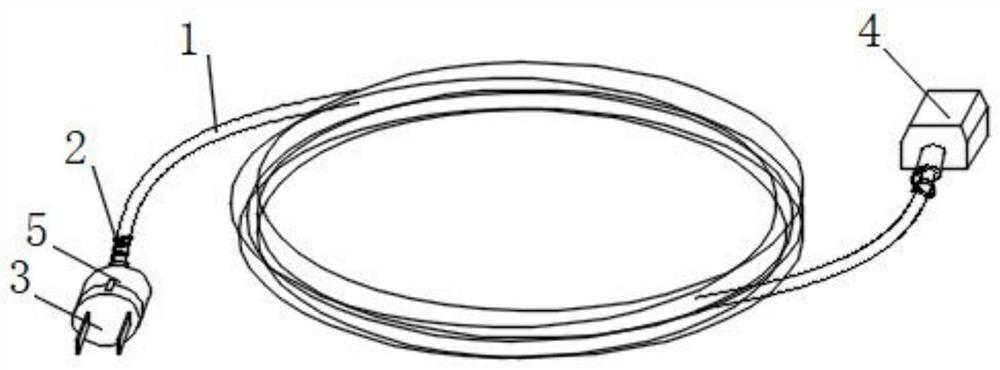

A carbon fiber anti-electromagnetic interference power cord assembly

ActiveCN112582835BAvoid damage and rupturePrevent excessive bendingLive contact access preventionFiberCarbon fibers

The invention discloses a carbon fiber anti-electromagnetic interference power cord assembly, which comprises a main body of a power cord. One end of the main body of the power cord is provided with a three-hole plug, the three-hole plug is covered with an adapter, and the other end of the main body of the power cord is provided with For the safety connector, the two ends of the main body of the power cord are provided with anti-breakage devices near the three-hole plug and the safety joint, and the anti-breakage devices are engaged with the two ends of the main body of the power cord. A carbon fiber anti-electromagnetic interference power cord assembly according to the present invention belongs to the field of power cords, which can prevent the main body of the power cord from being damaged and broken during use, and can prevent the end of the main body of the power cord from being bent too much through the spiral ring. Turn the live wire and neutral wire of the three-hole jack into a two-hole plug, so that the plug can be mated with different jacks or plug-in boards, and the moving sleeve protects the mating jack to avoid touching it when inserting the safety connector. Pin word plug and then cause electric shock, it is safer.

Owner:WEIHAI HONGLIN ELECTRIC POWER TECH CO LTD

Bending device based on intelligent adjustment and control

InactiveCN104942067AAvoid influenceReduce the proportion of cracksMetal working apparatusAutomatic controlComputer module

The invention relates to a bending device based on intelligent adjustment and control. The bending device based on intelligent adjustment and control comprises a drive motor, a clamping fixing base and a host which are arranged on a machine frame; the host controls the drive motor; a bending shaft is installed on a motor shaft of the drive motor; the clamping fixing base is provided with a processed workpiece. The bending device based on intelligent adjustment and control further comprises an ultrasonic thickness detector installed on the machine frame through a support, a supporting rod installed in a clamping groove of the clamping fixing base and a controller connected with the host, wherein the upper end of the supporting rod is connected with a proximity switch; the ultrasonic thickness detector and the proximity switch are connected with the host through a DSP data processing module. Bending is conducted with the most proper torque by detecting the thickness of the processed workpiece, the influence on the processed workpiece from too large or too small torque is avoided, the crack ratio is reduced, and the processing quality is improved. The proximity switch is arranged to automatically control the bending angle and prevents excessive bending. Meanwhile, the proximity switch can adjust the height and angle conveniently and adapt to bending of sheet metal of multiple dimensions and multiple angles.

Owner:SUZHOU BIANTONG SENSING TECH

Metal plate bending device and method based on feedback detection and rolling bending

InactiveCN104959419APrevent excessive bendingEasy to adjust height and angleMetal-working feeding devicesMetal working apparatusAutomatic controlDrive motor

The invention relates to a metal plate bending device and method based on feedback detection and rolling bending. The device comprises a driving motor arranged on a machine frame, a clamping and fixing base and a main unit, wherein a bending shaft is installed on the driving motor, and a part to be machined is arranged on the clamping and fixing base. The device further comprises a capacitive sensing thickness detector, a roller, a proximity switch, a detection feedback device and a controller, wherein the roller and the proximity switch are arranged on the bent side of the part to be machined, the detection feedback device comprises an ultrasonic crack detector arranged on the clamping and fixing base, and the capacitive sensing thickness detector, the proximity switch and the ultrasonic crack detector are all connected with the main unit through a DSP data processing module. By combining crack detection with roller extrusion friction for bending, the number of cracks is reduced greatly, and machining quality is improved; the proximity switch is arranged to automatically control bending angle, so that excessive bending is prevented.

Owner:SUZHOU BIANTONG SENSING TECH

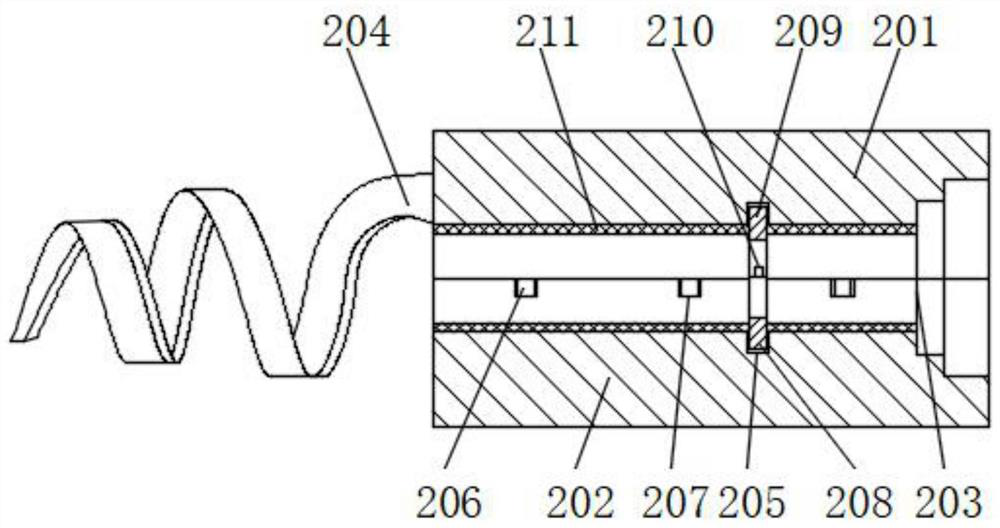

Optical fiber jumper with spring protection layer

InactiveCN105301719AImprove stress resistancePrevent excessive bendingFibre mechanical structuresEngineeringElectrical and Electronics engineering

The invention discloses an optical fiber jumper with a spring protection layer, comprising an optical cable and connectors arranged at the two ends of the optical cable. The optical cable comprises an external protection layer and an internal glass fiber core for light propagation. The external protection layer comprises a glass sealing sleeve and an insulating rubber layer from inside to outside, and a spring protection layer is arranged between the glass sealing sleeve and the insulating rubber layer. The gap between the spring protection layer and the glass sealing sleeve and the gap between the spring protection layer and the insulating rubber layer are filled with sponge. The two ends of a spring in the spring protection layer are respectively fixed to the two connectors. By arranging the spring protection layer in the external protection layer of the glass fiber core, the radial compressive ability of the jumper is improved, the glass fiber core is prevented from being bent too much and damaged, and the overall strength of the jumper is greatly improved.

Owner:上海顺簿贸易经营服务部

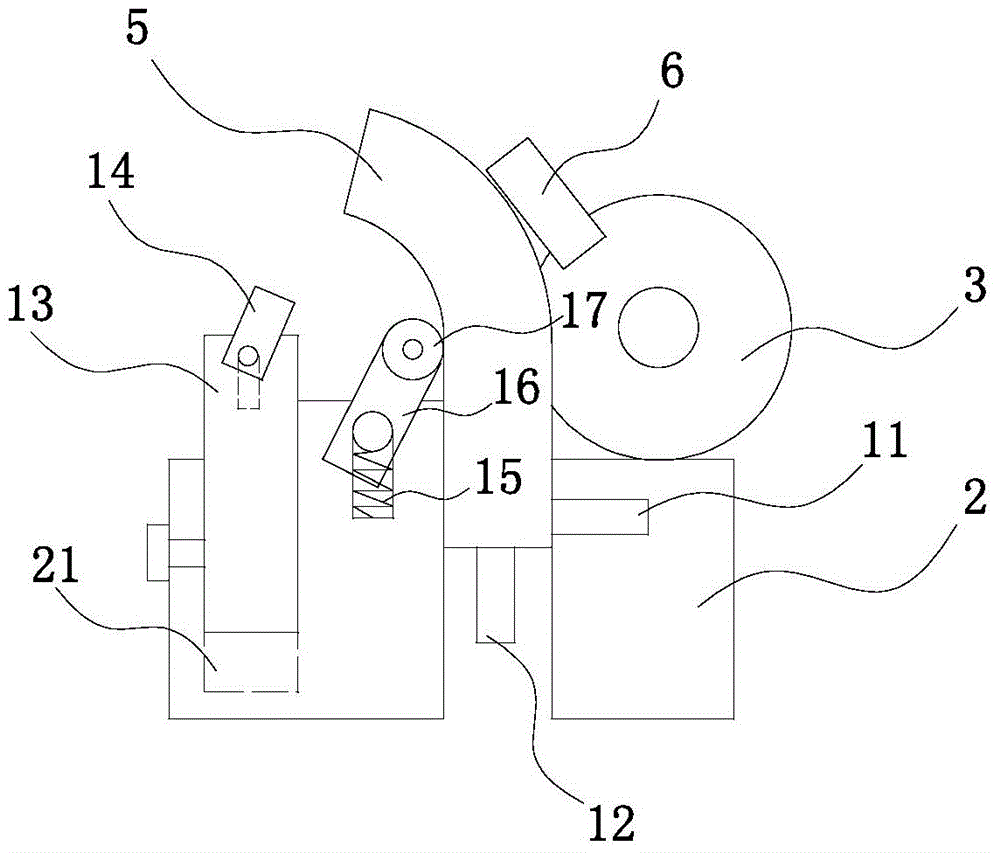

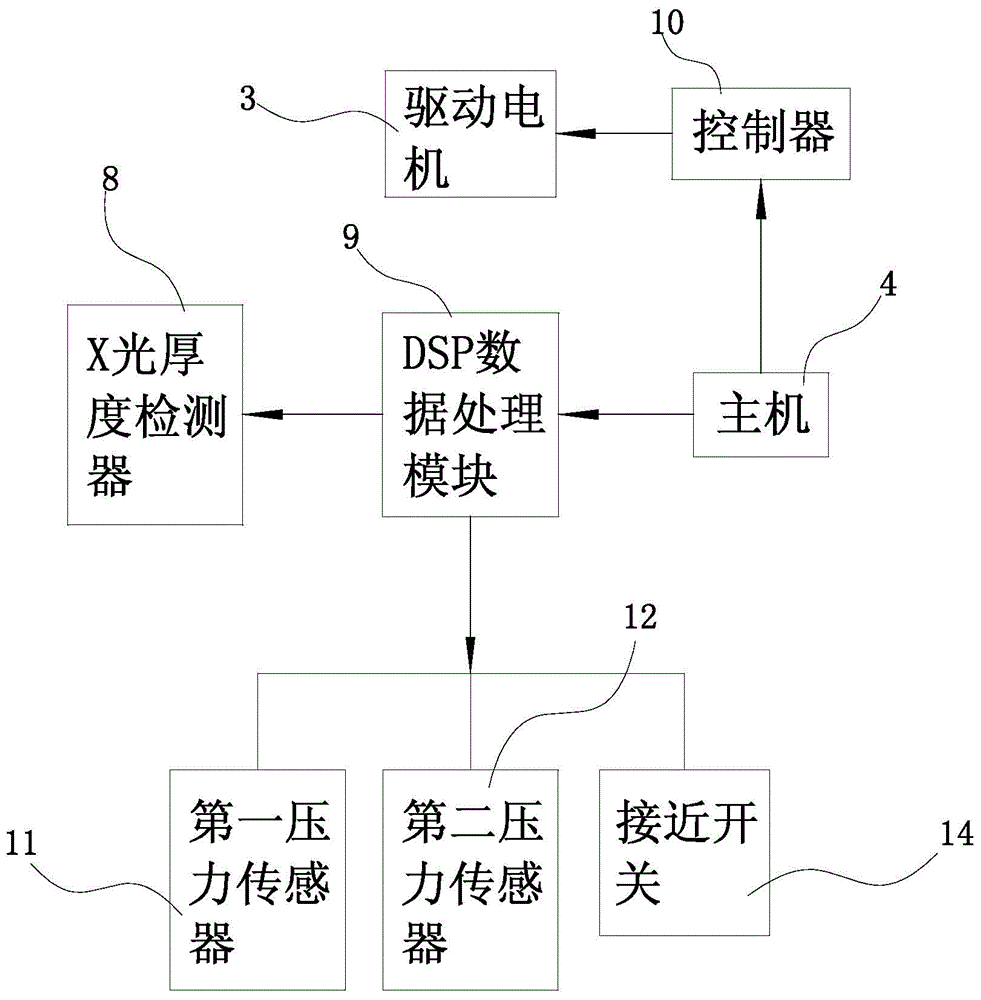

Bending device based on rolling bending and torque control

The invention relates to a bending device based on rolling bending and torque control. The device comprises a drive motor on a rack, a clamping and fixing base and a main machine. A bending shaft is installed on the drive motor, and a machined part is arranged on the clamping and fixing base. The device further comprises an X-ray thickness detector, a proximity switch, a first pressure sensor, a second pressure sensor and a rolling shaft, wherein the X-ray thickness detector is installed on the rack through a support, the proximity switch is installed on the clamping and fixing base, the first pressure sensor and the second pressure sensor are located on the side face and the bottom face of the machined part respectively, and the rolling shaft is arranged on the concave face side of the machined part. Clamping force is controlled through the pressure sensors, and excessive deformation and loosening of plates are avoided. Bending at the most proper torque is carried out, and machining quality is improved. The proximity switch is arranged to automatically control the bending angle, and excessive bending is prevented. The inner concave face of the machined part is rolled through the rolling shaft, and cracks and burrs on the concave face are reduced.

Owner:SUZHOU BIANTONG SENSING TECH

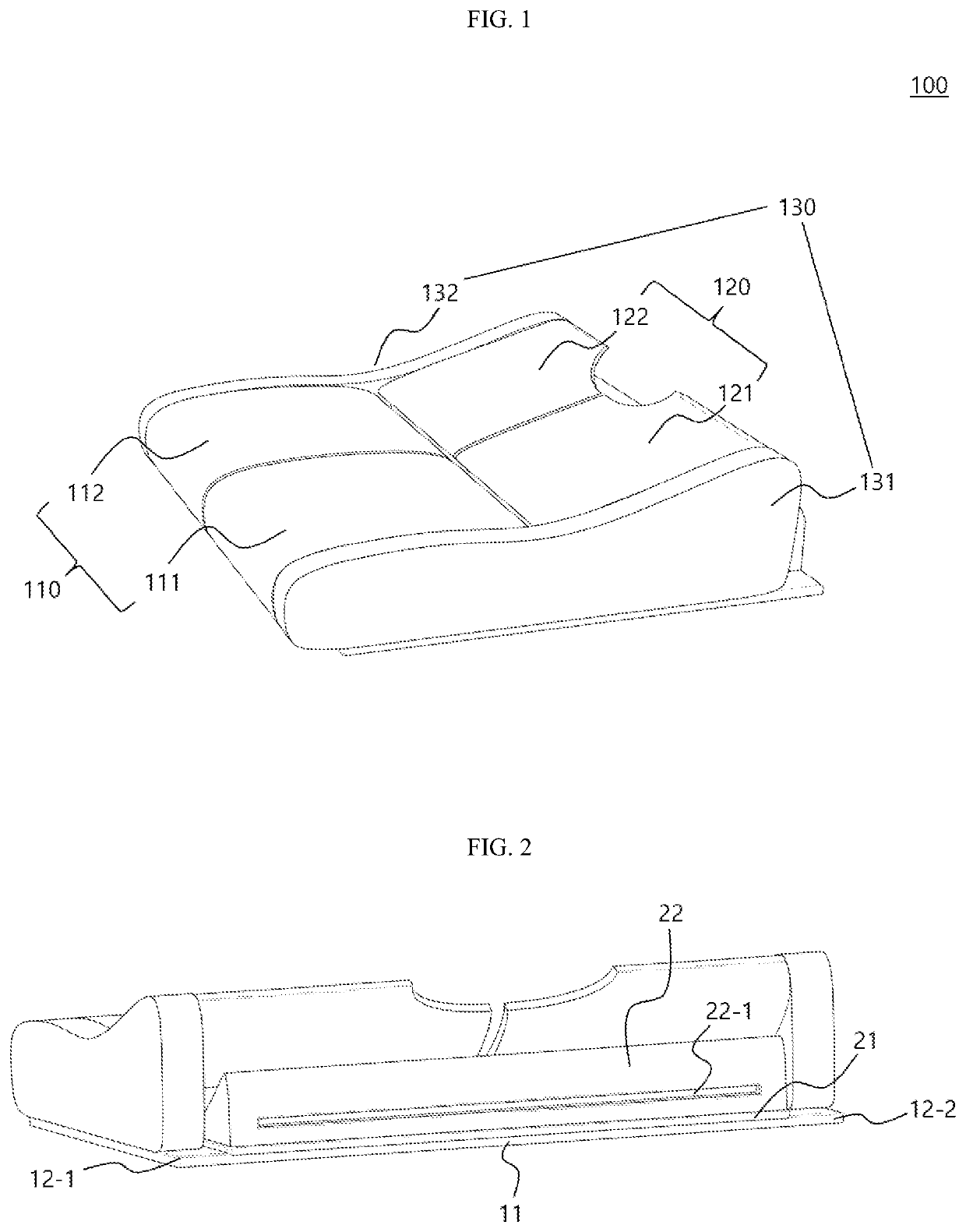

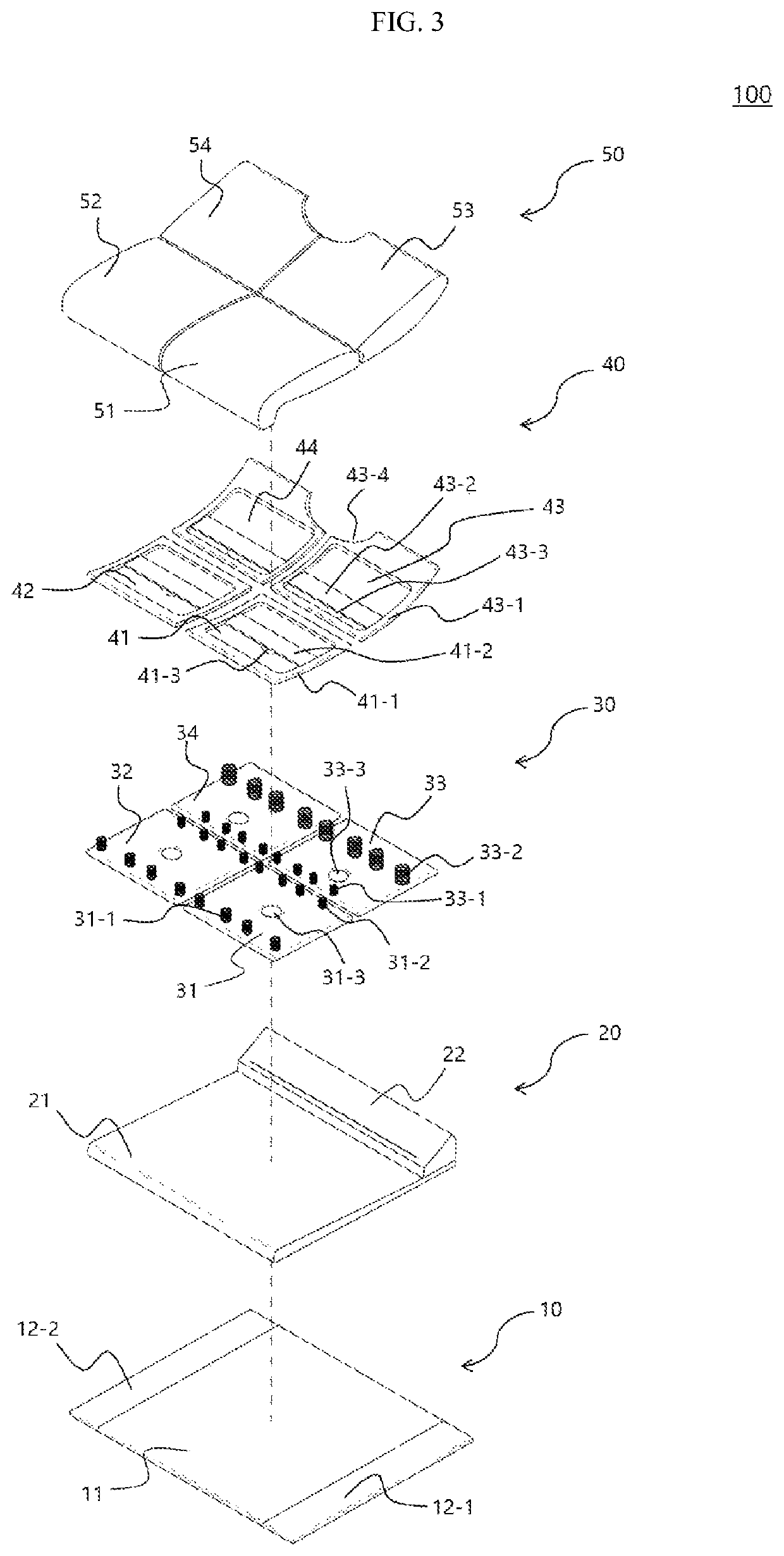

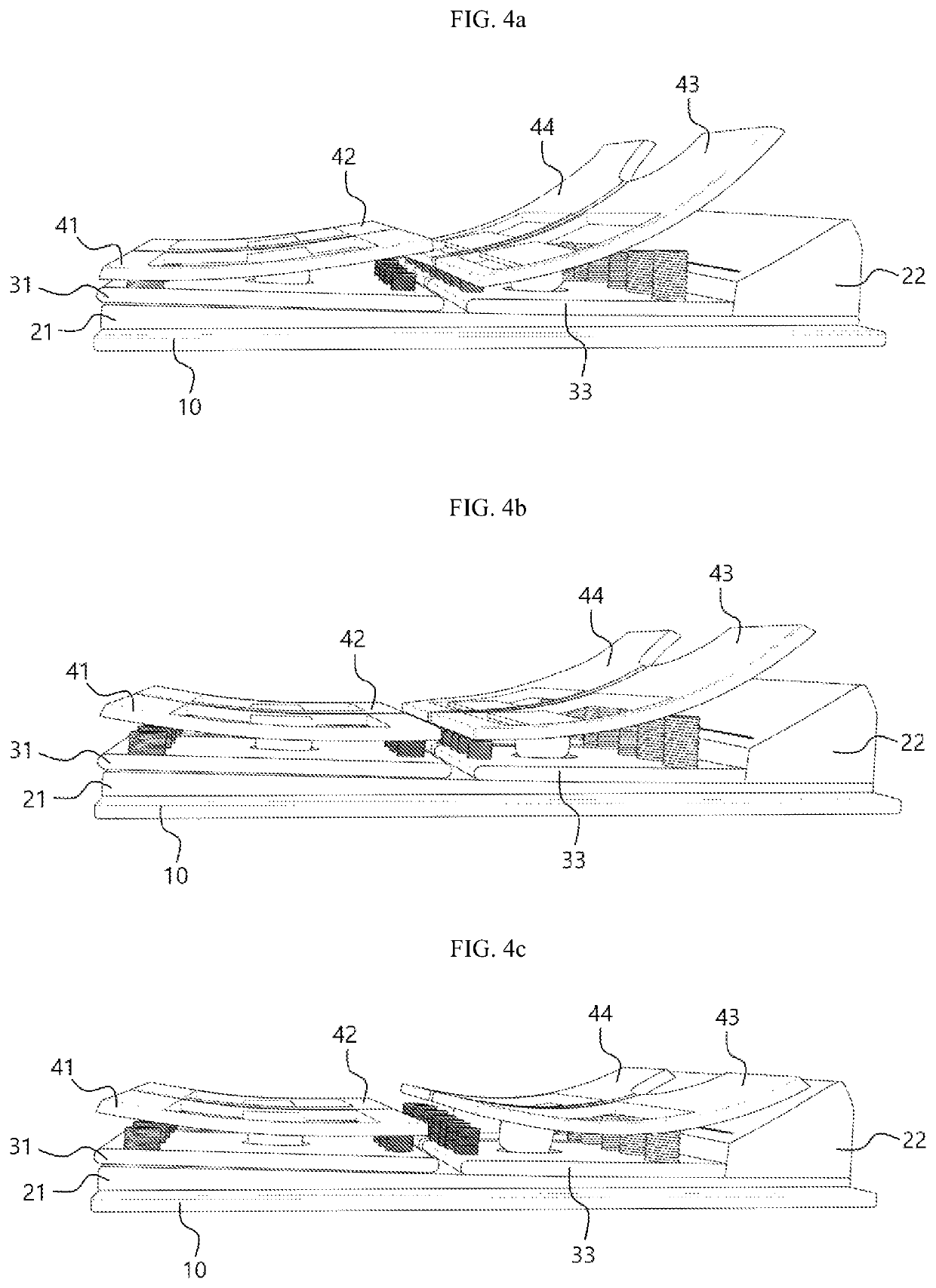

Chair seat board and chair including same

ActiveUS10945528B1Reduce the burden onPrevent excessive bendingStoolsChairsPhysical medicine and rehabilitationMedicine

Disclosed is a chair seat board (100) and a chair (1000) to which a chair backboard (200) is coupled. The chair seat board (100) may comprise: a frame unit 40 having a plurality of frames (41, 42, 43, 44) configured in a hollow shape, respectively, and implemented to allow independent movement; and a support unit configured to support the frame unit 40 while being coupled to the frame unit (40) on a lower side of the frame unit (40).

Owner:PARK CHAN WOOK

Sheet metal bending device and method with torque regulating function and rolling bending function

InactiveCN104942074AReduce the proportion of cracksImprove processing qualityMetal working apparatusAutomatic controlDrive motor

The invention relates to a sheet metal bending device and method with the torque regulating function and the rolling bending function. The device comprises a driving motor arranged on a rack, a clamping and fixing base and a main machine. A bending shaft is installed on a motor shaft of the driving motor. A machined workpiece is installed on the clamping and fixing base. The device further comprises an ultrasonic thickness detector installed on the rack through a support, a supporting rod installed in a clamping groove of the clamping and fixing base, a rolling shaft installed on the clamping and fixing base and located on the concave face side of the machined workpiece, and a controller connected with the main machine. The upper end of the supporting rod is connected with a proximity switch. The rolling shaft is rotationally connected to the upper end face of an adjusting plate, and the lower end face of the adjusting plate is installed in an installing groove of the clamping and fixing base through a rotating shaft and a spring. According to the device, bending is performed at the optimum torque, and machining quality is improved. The proximity switch is arranged to automatically control the bending angle so that excessive bending can be prevented. The rolling shaft is used for performing friction and extrusion on the inwards-concave face of the machined workpiece, and cracks and burrs on the concave face are effectively reduced.

Owner:SUZHOU BIANTONG SENSING TECH

Bending system and method with detection feedback function and phased bending function

InactiveCN104942078AAvoid influenceReduce the proportion of cracksMetal working apparatusCapacitanceAutomatic control

The invention relates to a bending system and method with the detection feedback function and the phased bending function. The system comprises a driving motor arranged on a rack, a clamping and fixing base and a main machine. A bending shaft is installed on the driving motor. A machined workpiece is installed on the clamping and fixing base. The system further comprises a capacitance induction thickness detector, a pressure sensor, a proximity switch, a detection feedback device and a controller. The pressure sensor and the proximity switch are installed on the bending side of the machined workpiece. The detection feedback device comprises an ultrasonic crack detector installed on the clamping and fixing base. The capacitance induction thickness detector, the pressure sensor, the proximity switch and the ultrasonic crack detector are all connected with the main machine through a DSP data processing module. According to the system, the crack proportion is greatly reduced due to crack detection and phased bending, and machining quality is improved. The proximity switch is arranged to automatically control the bending angle so that excessive bending can be prevented, besides, the height and the angle can be conveniently adjusted due to the proximity switch, and the system can adapt to bending of multi-size and multi-angle sheet metal.

Owner:SUZHOU BIANTONG SENSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com