Light non-metal armored submarine cable

A non-metallic and armored technology, applied in the direction of submarine cables, cables, insulated cables, etc., can solve the problems that the strength of non-metallic materials is difficult to be guaranteed, the elastic stress of multi-layer armored wires, and the weight of submarine cables increase. Achieve good radial lateral compression resistance and axial tensile strength, high modulus, and reduce material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

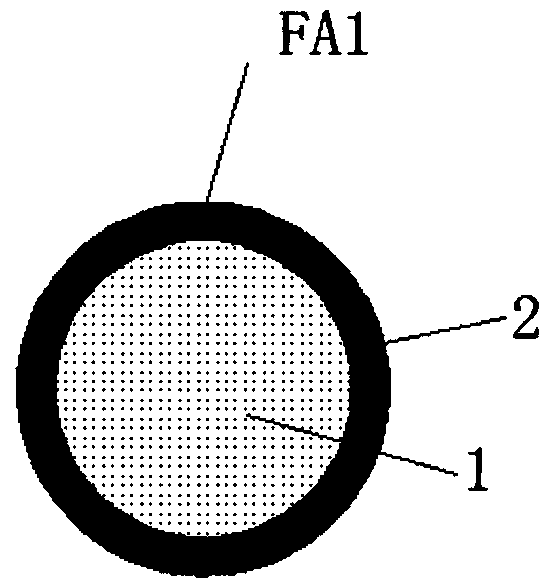

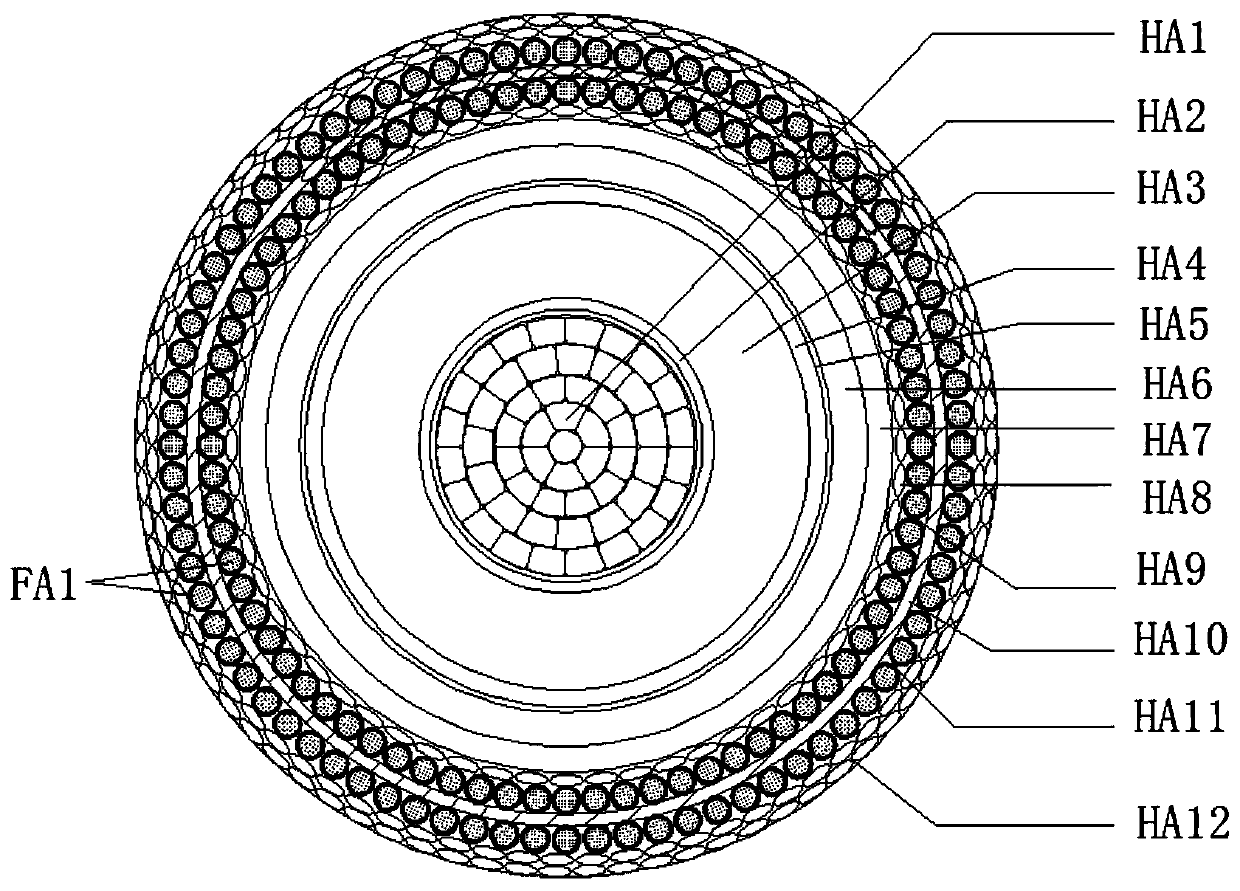

[0038] see image 3 As shown, this embodiment provides a single-core non-metallic armored cable HA, which includes water-blocking conductor HA1, conductor shielding layer HA2, conductor insulating layer HA3, insulating shielding layer HA4, water-blocking buffer layer HA5, metal Shielding layer HA6, inner sheath HA7, inner lining layer HA8, first armor layer HA9, cladding layer HA10, second armor layer HA11 and outer layer HA12.

[0039] The water-blocking conductor HA1 is formed by layering and twisting multiple aluminum wire materials, and each layer is filled with seawater-proof water-blocking glue. The shape of the monofilament is trapezoidal, and the resistivity is not greater than 0.028264Ω·mm at 20°C 2 / m. The conductor structure type is a type wire conductor, and the conductor cross section is 1600mm 2 . Water-blocking conductor HA1 is extruded with conductor shield HA2, conductor shield HA2 is extruded with XLPE insulation HA3, insulation is extruded with insulatio...

Embodiment 2

[0043] see Figure 4 As shown, this embodiment provides a single-core optoelectronic composite non-metallic armored cable HB, which includes water-blocking conductor HB1, conductor shielding layer HB2, conductor insulating layer HB3, insulating shielding layer HB4, and water-blocking buffer layer HB5 from inside to outside. , Metal shielding layer HB6, inner sheath HB7, optical unit HB8, first armor layer HB9, cladding layer HB10, second armor layer HB11 and outer layer HB12.

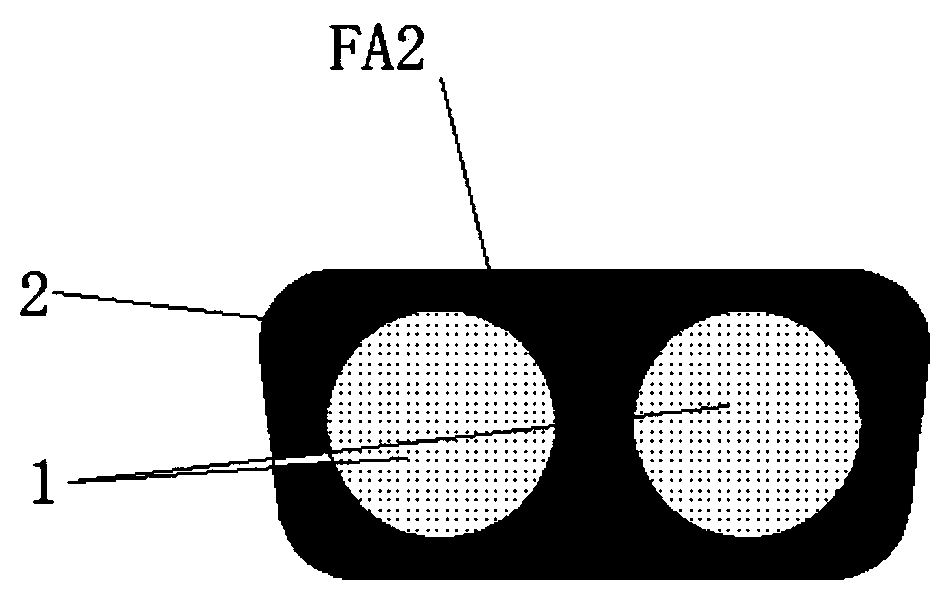

[0044] Among them, compared with Example 1, this structure removes the inner liner, and the diameter of the non-metallic armored element FA1 in the first armored layer HB9 is 6.0mm, and two light beams with a diameter of 5mm are placed symmetrically in the armored layer. For unit HB8, the armor layer of non-metallic armor element FA1 can protect the optical cable.

Embodiment 3

[0046] see Figure 5 As shown, this embodiment provides a hybrid armored cable HC, which includes water-blocking conductor HC1, conductor shielding layer HC2, conductor insulating layer HC3, insulating shielding layer HC4, water-blocking buffer layer HC5, and metal shielding layer HC6 from inside to outside. , Inner sheath HC7, inner lining layer HC8, first armor layer HC9, cladding layer HC10, second armor layer HC11 and outer layer HC12. Among them, except the first armor layer HC9 is made of multiple armored copper wires TA twisted, the diameter is 6.0mm, and the resistivity at 20°C is not greater than 0.01777Ω·mm 2 / m, the rest of the structure and materials are the same as in Example 1. The first armor layer HC9 is made of multiple armored copper wires TA twisted. The main function is to increase the carrying capacity and short-circuit current of the submarine cable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com