Feedback torque adjustment and metal plate bending system

A torque adjustment and sheet metal technology, which is applied in the field of sheet metal processing, can solve the problems of low sheet metal processing quality, poor effect, and long processing cycle, so as to avoid deflection or empty folding, save subsequent processing, and improve The effect of processing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

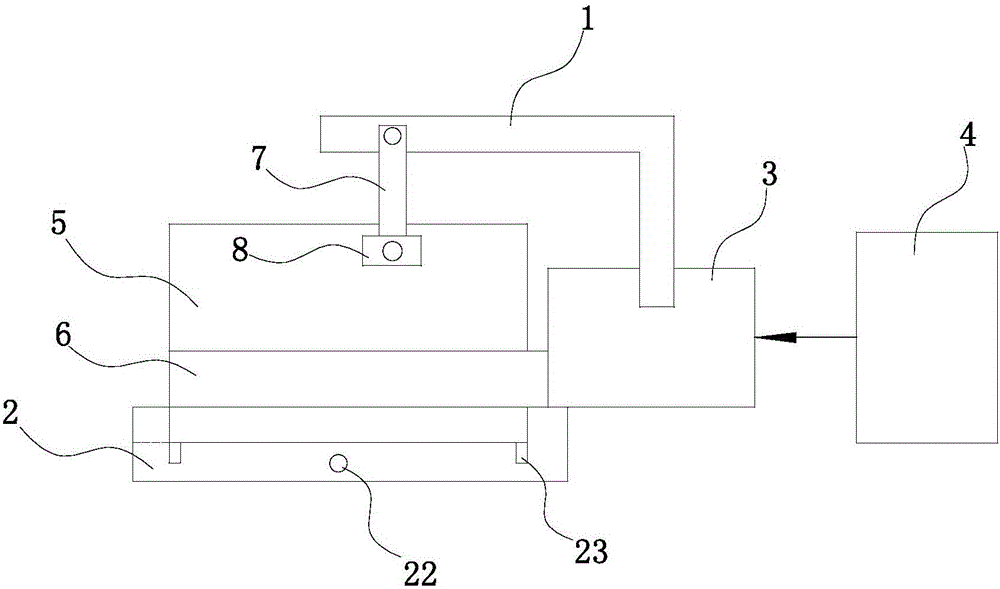

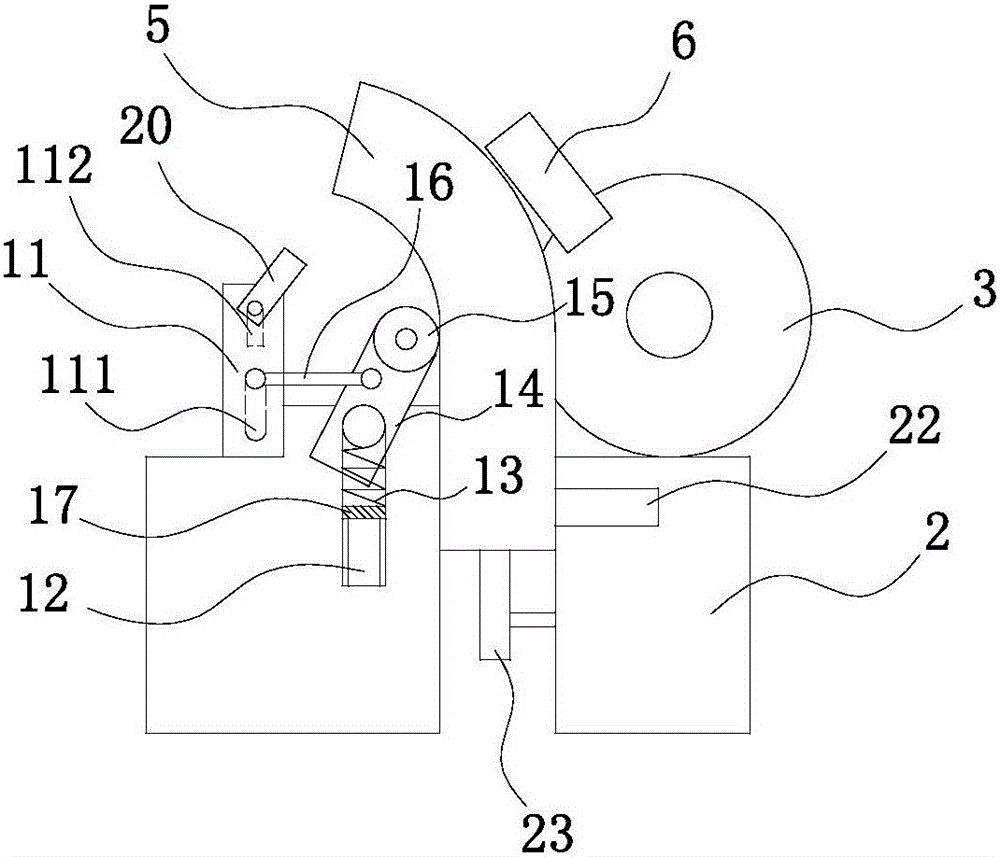

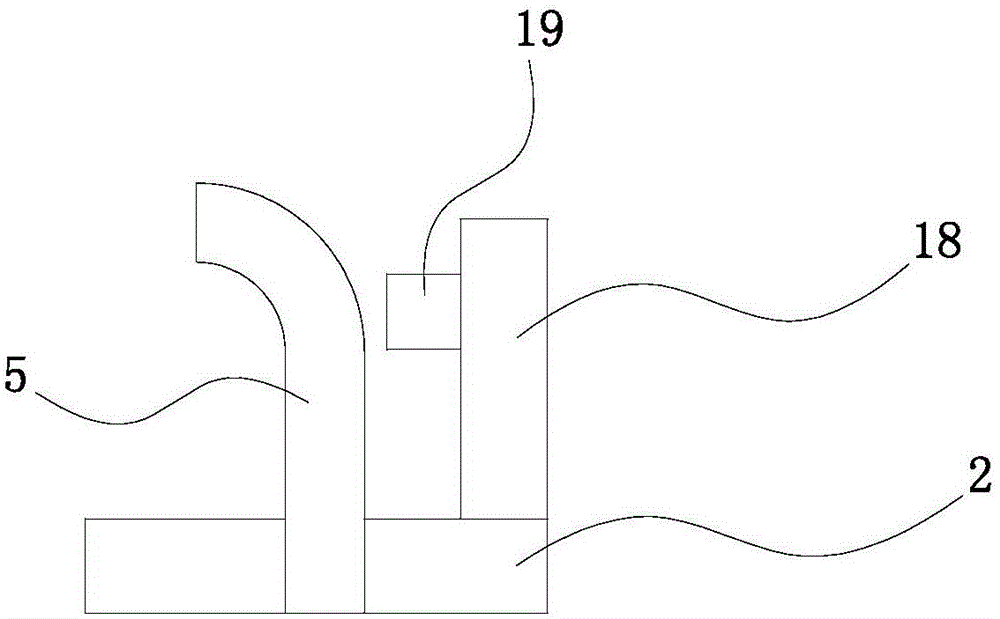

[0017] Such as Figure 1 to Figure 4 As shown, the sheet metal feedback torque adjustment bending system of this embodiment includes a drive motor 3 installed on the frame 1, a clamping and fixing seat 2 and a host 4 that controls the drive motor 3, and the motor shaft of the drive motor 3 Install the bending shaft 6, clamp the workpiece 5 on the fixed seat 2;

[0018] It also includes an ultrasonic thickness detector 8 installed on the frame 1 by means of a first bracket 7, a first pressure sensor 12 and a roller 15 installed on the clamping and fixing seat 2, a detection feedback device and a controller connected to the host 4 10. The roller 15 is located on the bending side of the workpiece 5, and the first pressure sensor 12 is installed in the installation groove 21 of the clamping seat 2, and the pressure plate 17 located at the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com